Chain sheet structure

A technology of chain pieces and joints, applied in the direction of chain links, etc., can solve the problems of stress concentration, poor effect, chain rotation obstruction, etc., to achieve the effect of dispersing stress, increasing stability and smoothness, and avoiding vibration and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

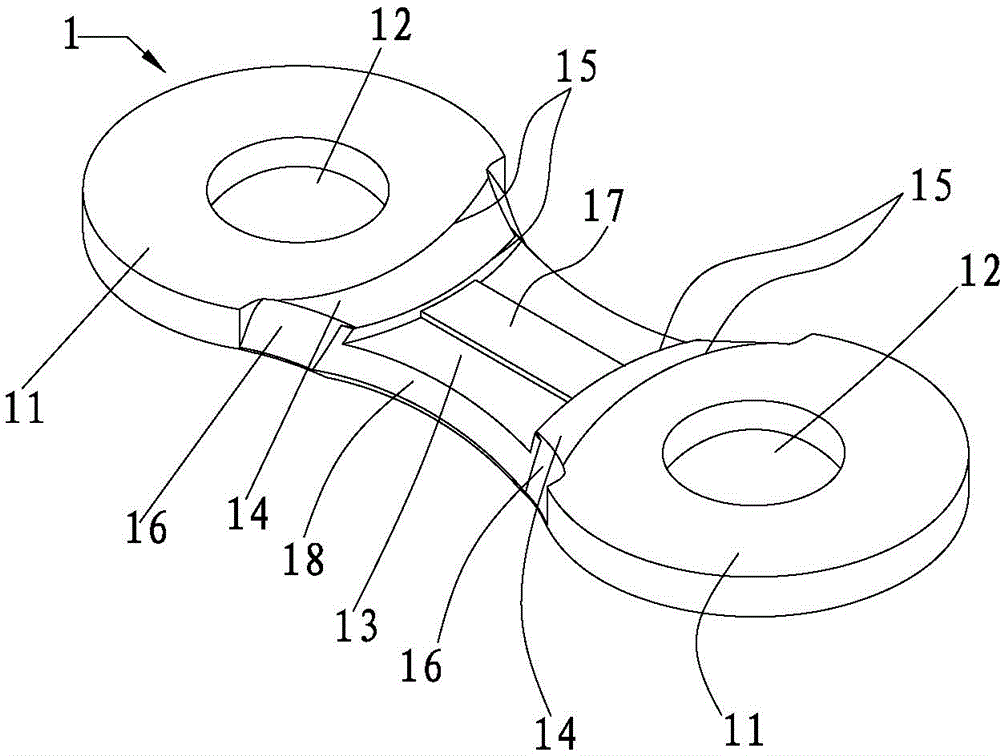

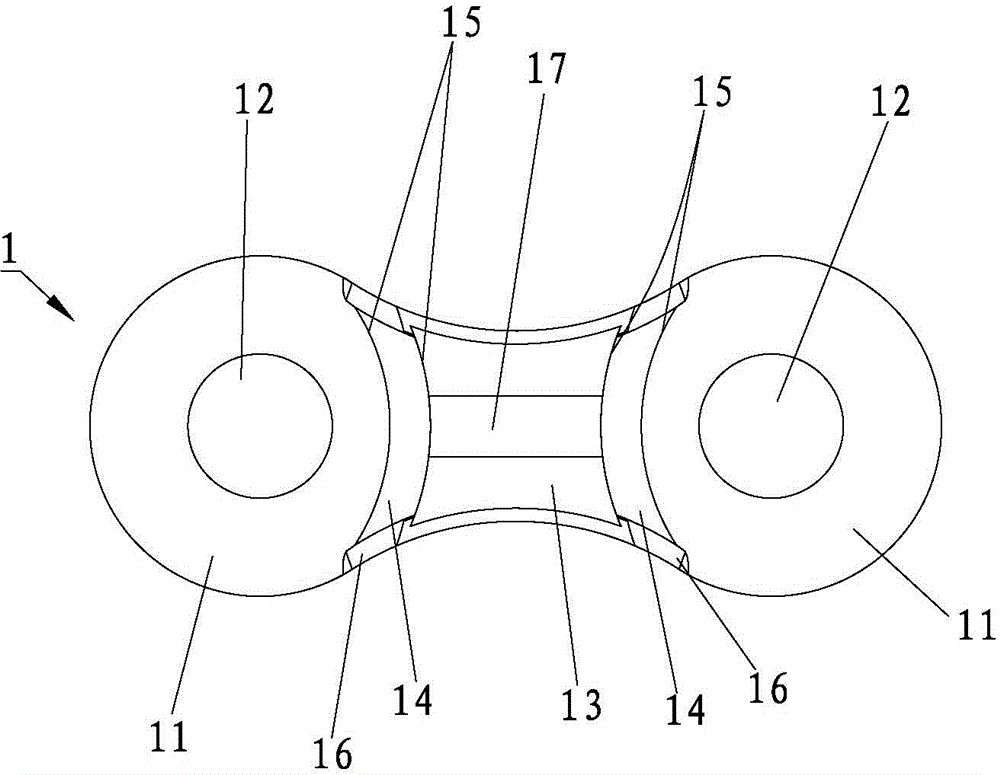

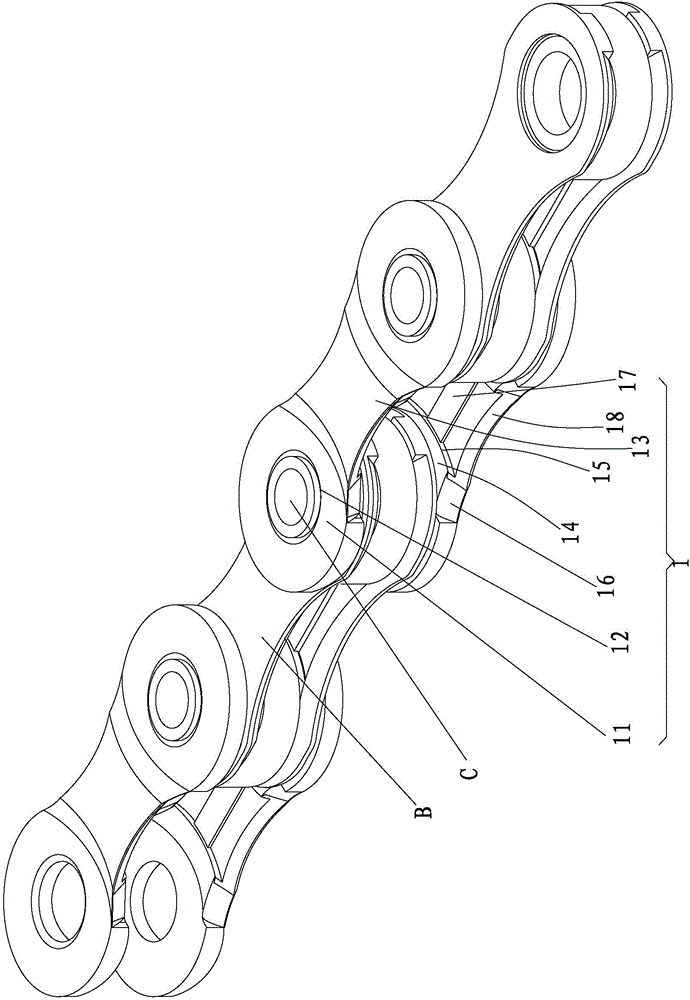

[0053] see figure 1 As shown, the embodiment of the present invention is provided with a chain piece body 1, and the two ends of the chain piece body 1 are provided with opposite arc-shaped joints 11, and the joint portion 11 is provided with a penetrating shaft hole 12, and the two On the inner side between the joints 11, there is a waist 13 that protrudes toward the outer side, is concave and thinner, and the joints between the waist 13 and the two joints 11 are respectively provided with a connecting surface 14 in the shape of a circular arc. The connection surface 14 can be an inclined surface or a plane. In this embodiment, it is described as an inclined surface. The connection surface 14 is gradually inclined from the joint portion 11 towards the waist portion 13. Using the inner and outer edges of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com