High-speed ejection device for steel ball

A technology of ejection device and steel ball, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of uncontrollable steel ball launch speed and simple structure, and achieve high reliability, convenient operation and overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

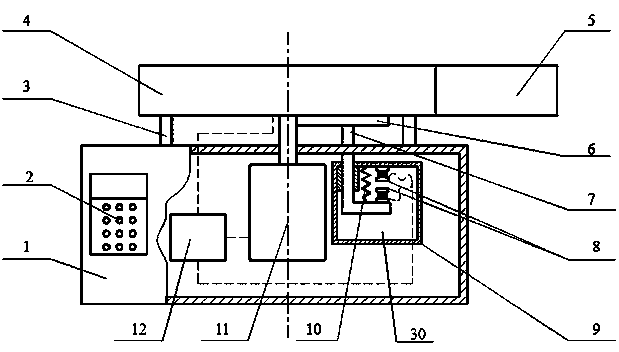

[0020] see Figure 1 to Figure 3 , this embodiment is basically the same as Embodiment 1, and the special feature is: the baffle push-pull device (30) includes two electromagnets (8), springs (10), push-pull rods (7) and push-pull device housings ( 9), the push-pull rod (7) passes through the guide groove in the push-pull device housing (9), and can move up and down along the guide groove. The electromagnet (8) is fixed on the top inside the push-pull device housing (9), and the electromagnet 2 (8) is fixed on the push-pull rod (7), and has an up-and-down position relationship with the electromagnet (8), and the two ends of the spring (10) are respectively connected with the top of the push-pull rod (7) and the push-pull device housing (9) , when the two electromagnets (8) are not energized, the spring (10) pulls the push-pull rod (7) up, and when the two electromagnets (8) are energized, the push-pull rod will be pushed up under the repulsion of the electromagnetic force (7)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com