Patents

Literature

412results about How to "Precise speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

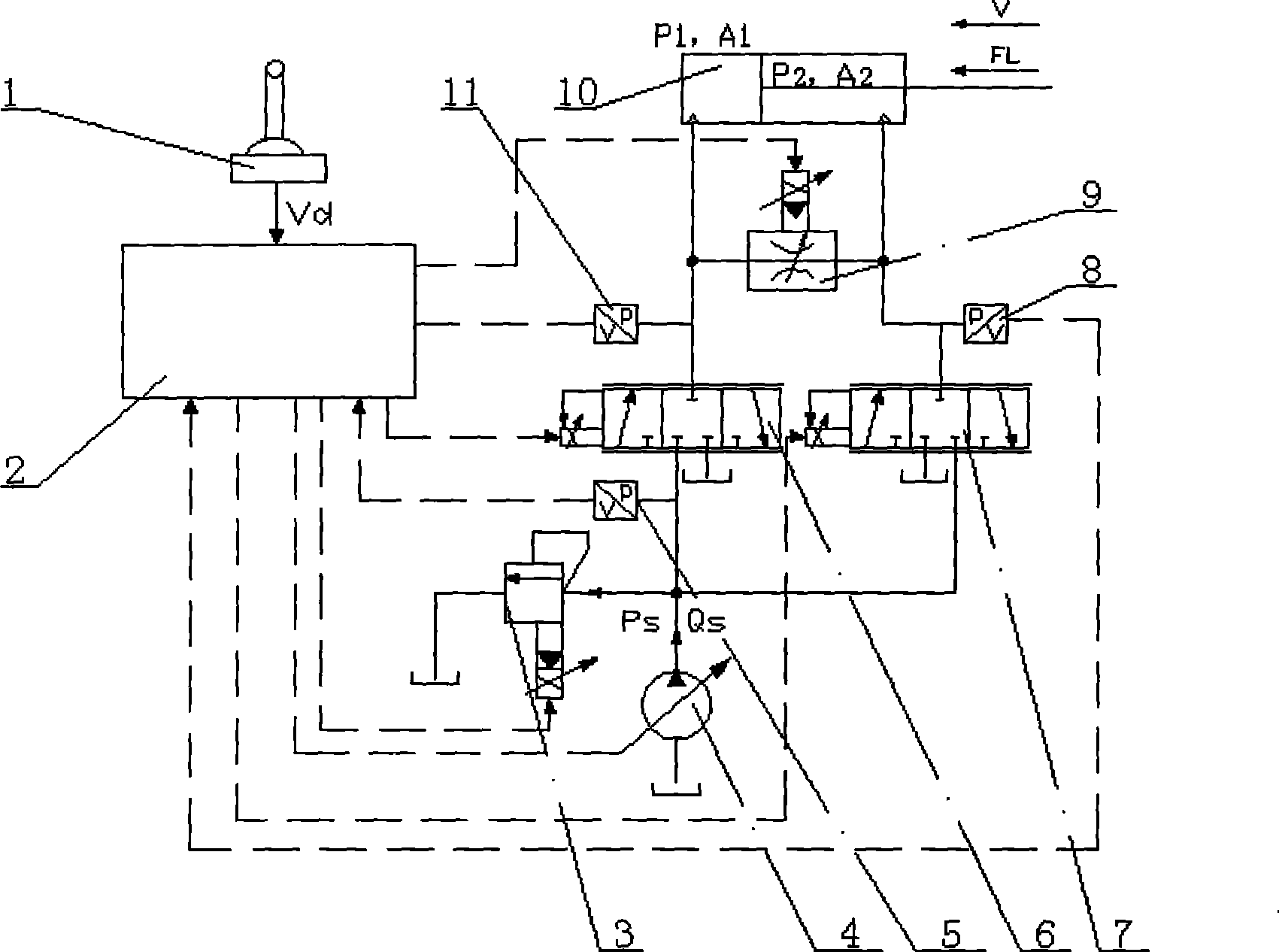

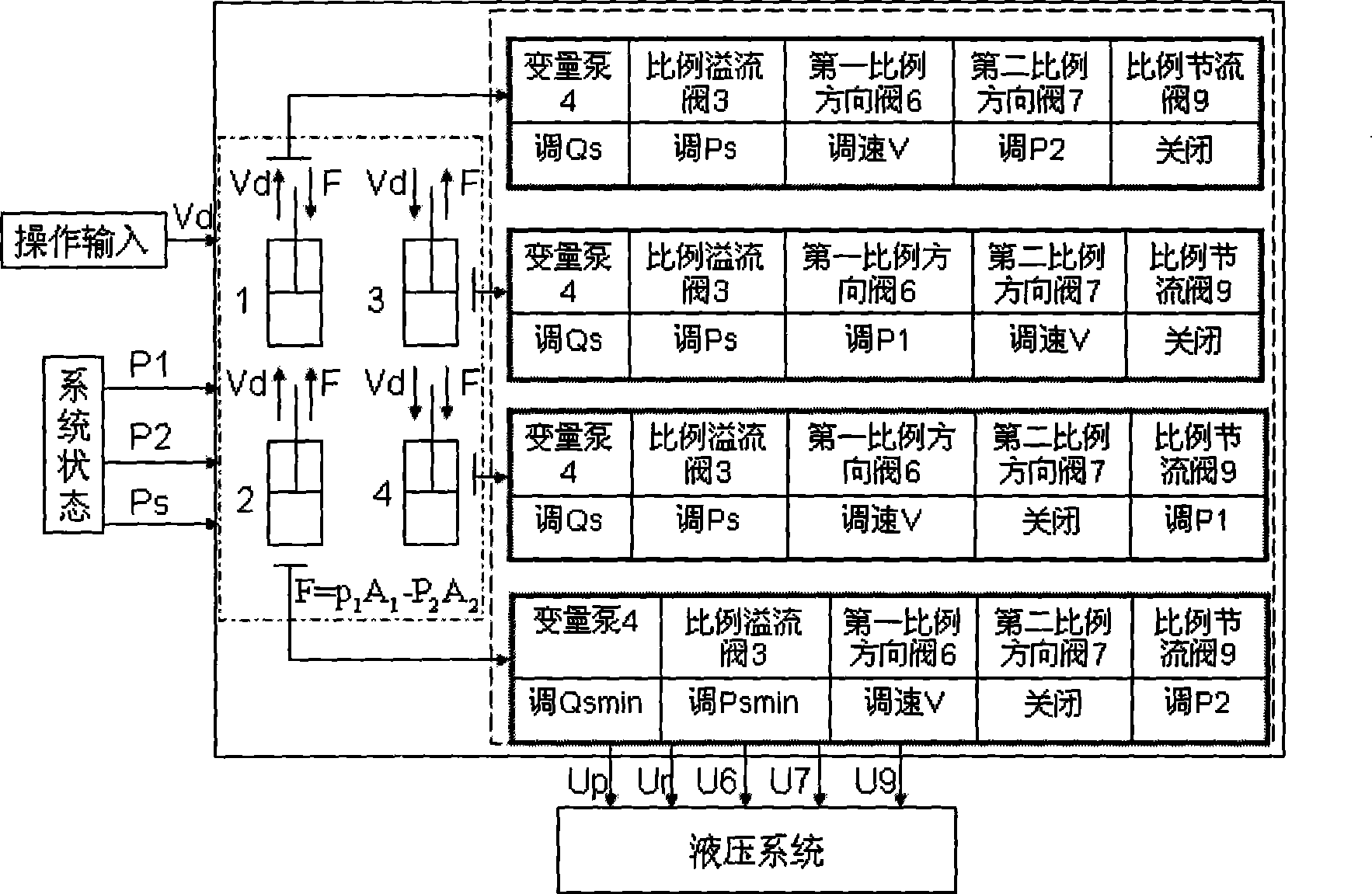

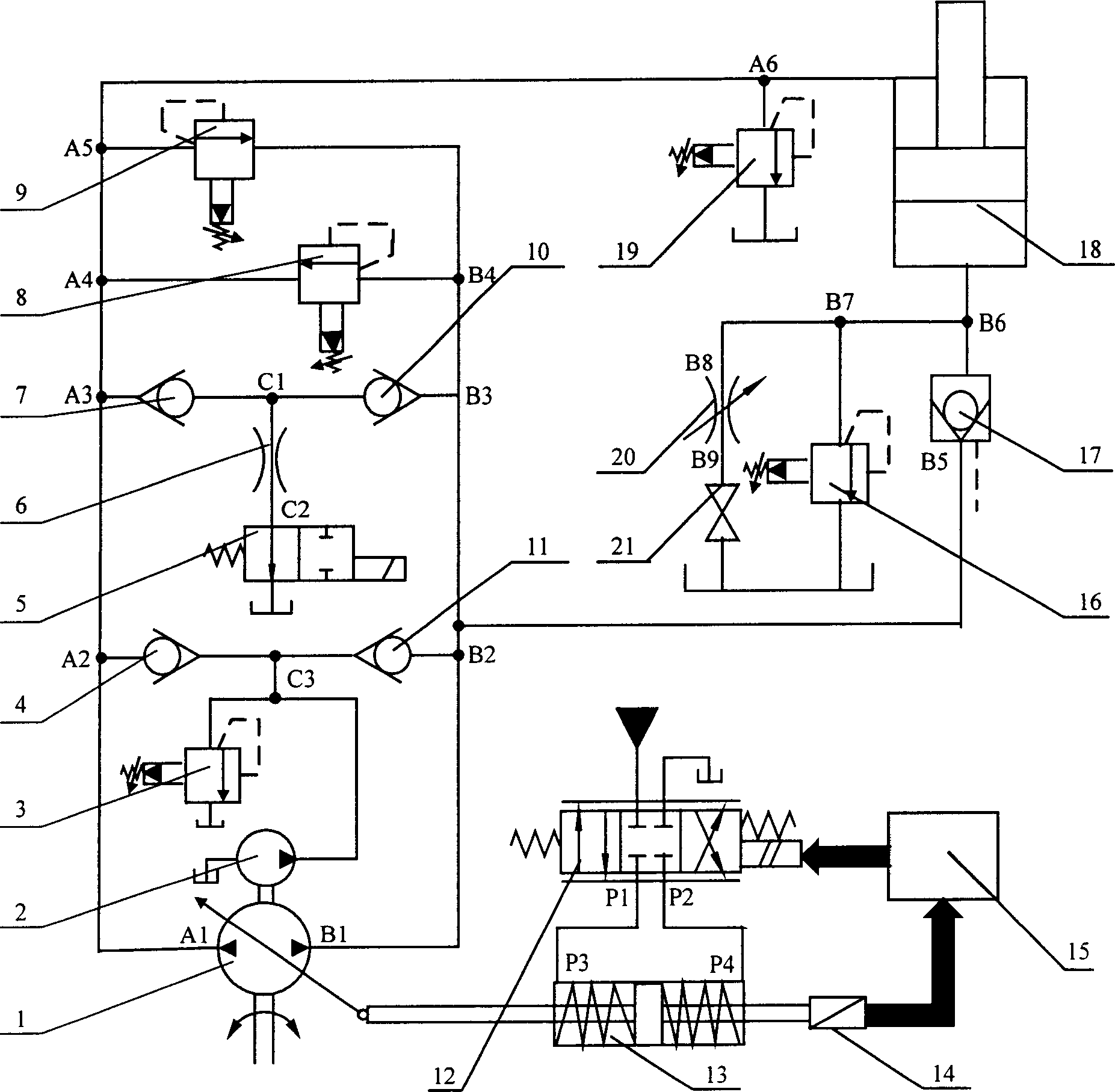

Independent electrohydraulic load sensitive energy regeneration hydraulic system of engineering machinery load port

InactiveCN101413522AAchieve regenerationReduce lossFluid-pressure actuator componentsLoad sensingElectrical connection

The invention discloses an independent electrohydraulic load sensing energy regeneration hydraulic system of an actuator port of an engineering machine. An oil outlet of a variable pump is connected with an oil inlet of a proportional relief valve, a first pressure sensor, an oil inlet of a first proportional directional valve, and an oil inlet of a second proportional directional valve respectively. An oil outlet of the first proportional directional valve is connected with a second pressure sensor, the oil inlet of a proportional throttle valve and a rodless cavity of a hydraulic cylinder respectively. An oil outlet of the second proportional directional valve is connected with an oil outlet of the proportional throttle valve, a third pressure sensor and a rod cavity of the hydraulic cylinder. A Controller is in electrical connection with a control handle, the variable pump, the proportional relief valve, two proportional directional valves, the proportional throttle valve and three pressure sensors. The system adopts the pressure sensors to detect working conditions, selects control policies according to the working conditions, reduces energy loss in flow restriction and realizes overload energy regeneration under the control of an actuator. Speed and energy-conservation control is realized through the combination of pump control and valve control.

Owner:ZHEJIANG UNIV

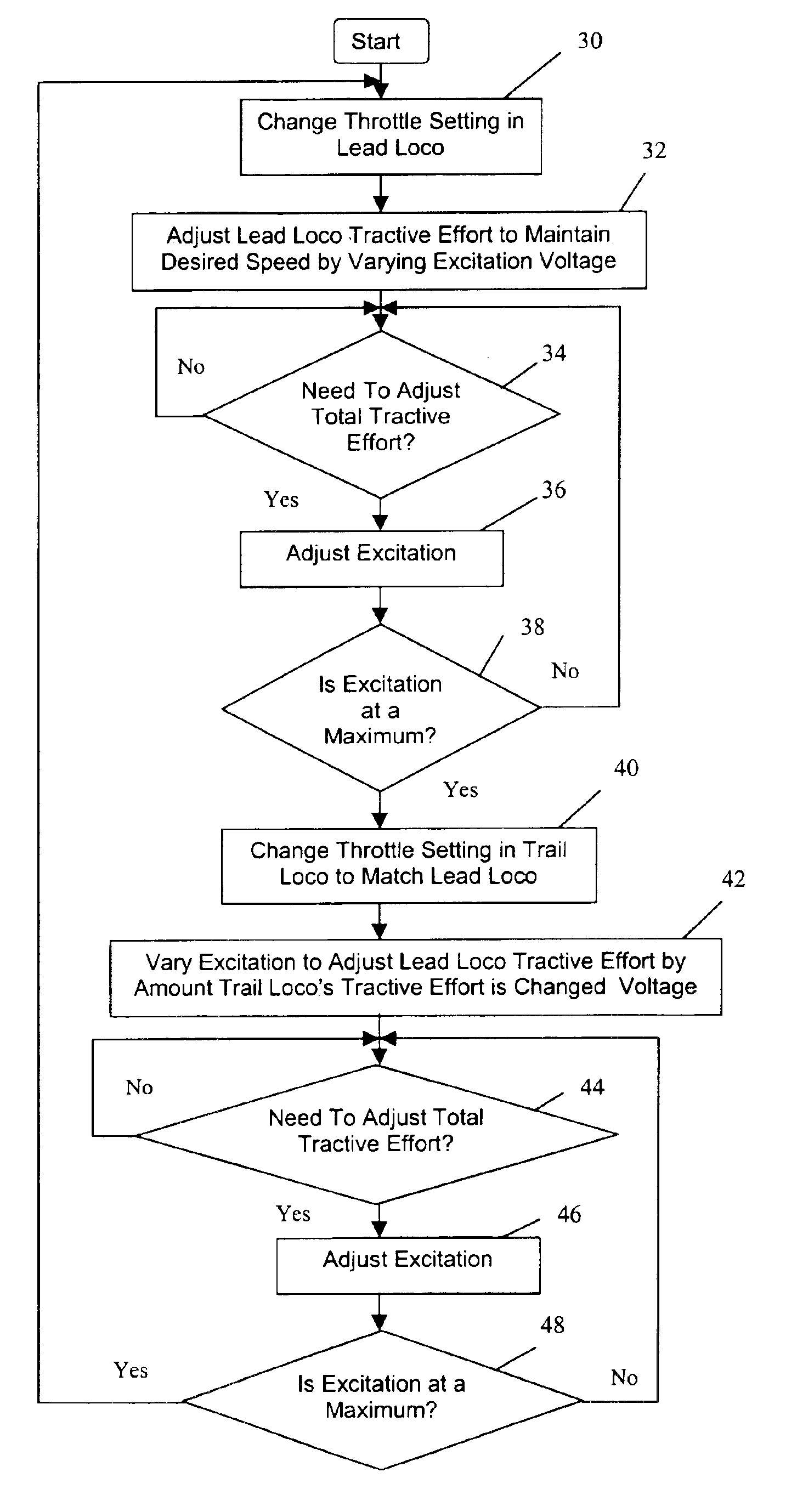

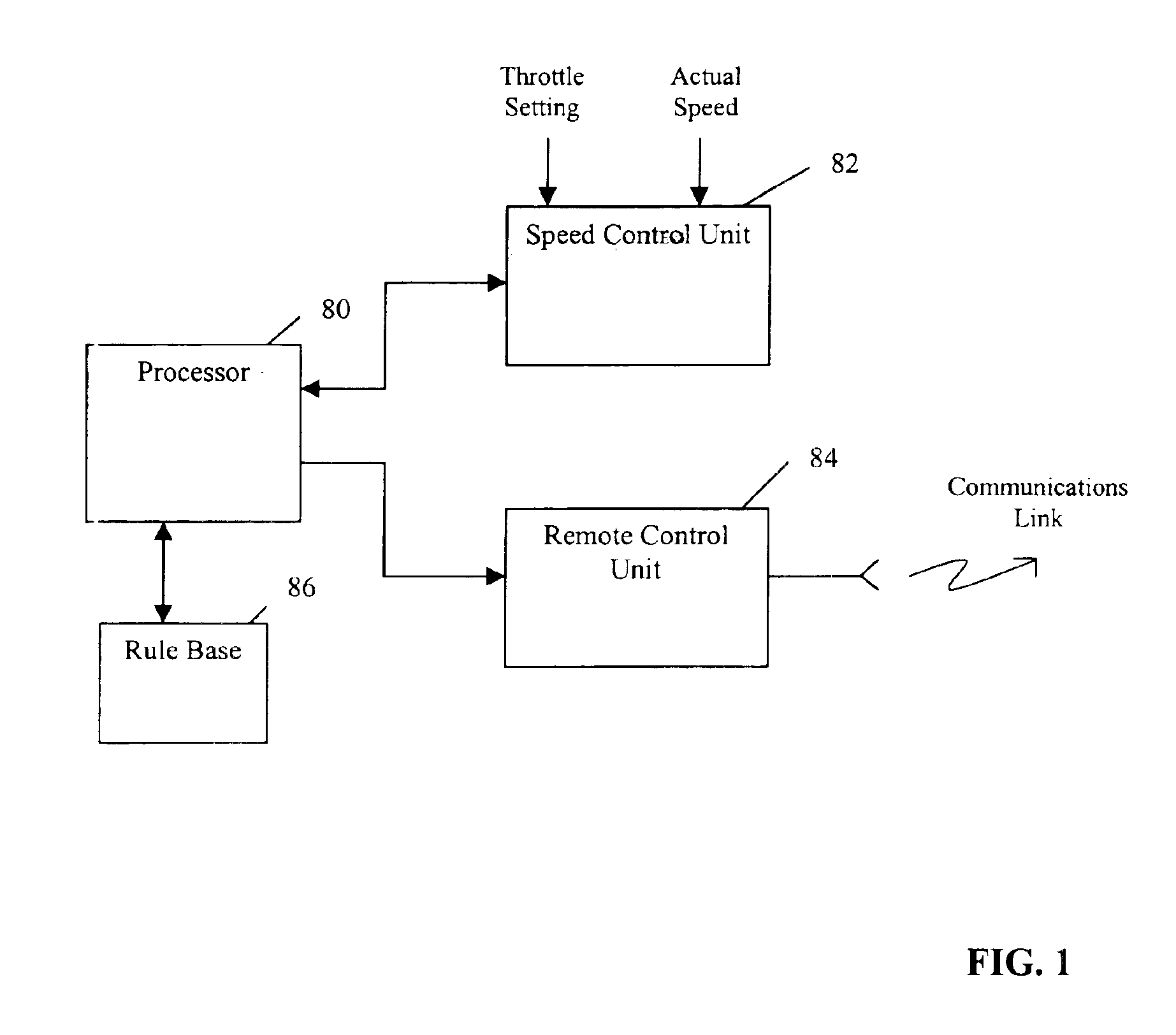

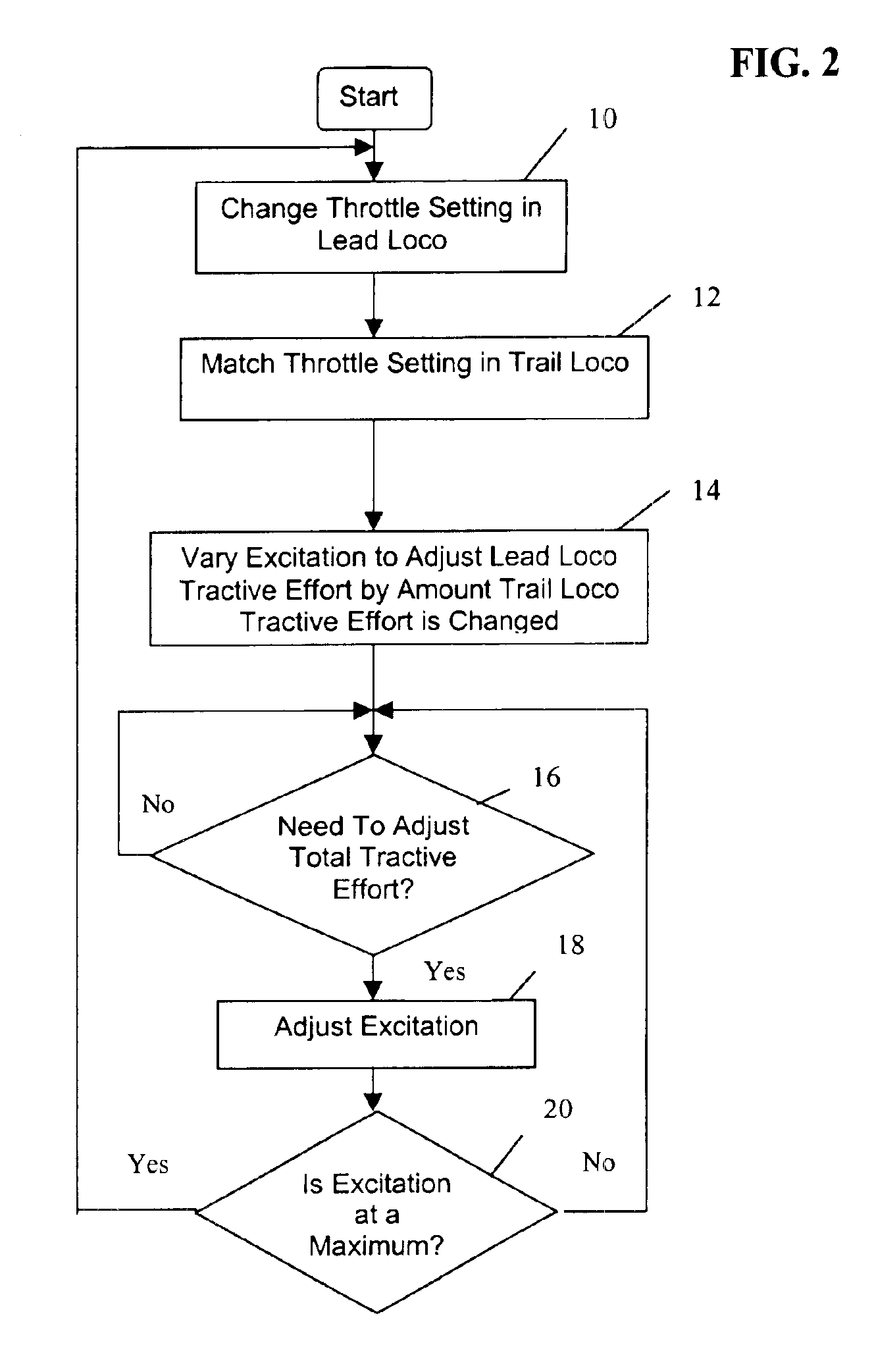

Slow speed consist control by independently controlling each locomotive

InactiveUS6937925B2Precise speed controlImproved slow speed controlAnalogue computers for trafficSpeed/accelaration controlLow speedRemote control

A method for controlling locomotive consists at slow speeds by independently controlling each locomotive is provided. The method comprises controlling the throttle settings and main generator excitation of a control locomotive, independently controlling, from the control locomotive, the throttle setting of each of the controlled locomotives, and compensating for a combined consist tractive effort change induced by a change in the throttle setting of each of the controlled locomotives by adjusting the main generator excitation of at least one of the locomotives to maintain a preset consist speed. The method further includes changing the throttle settings concurrently in the control and controlled locomotives, changing the throttle settings of the controlled locomotives only after the control locomotive reaches a maximum generator excitation, and changing the throttle settings according to a rule base. As a result, aspects of the invention enable slow speed control of locomotive consists comprising trail locomotives that may lack main generator excitation remote control, or Slow Speed, capability.

Owner:GENERAL ELECTRIC CO

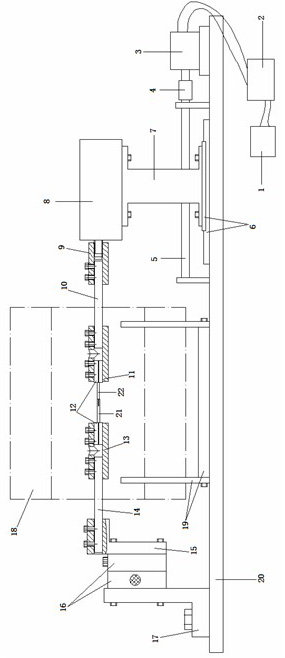

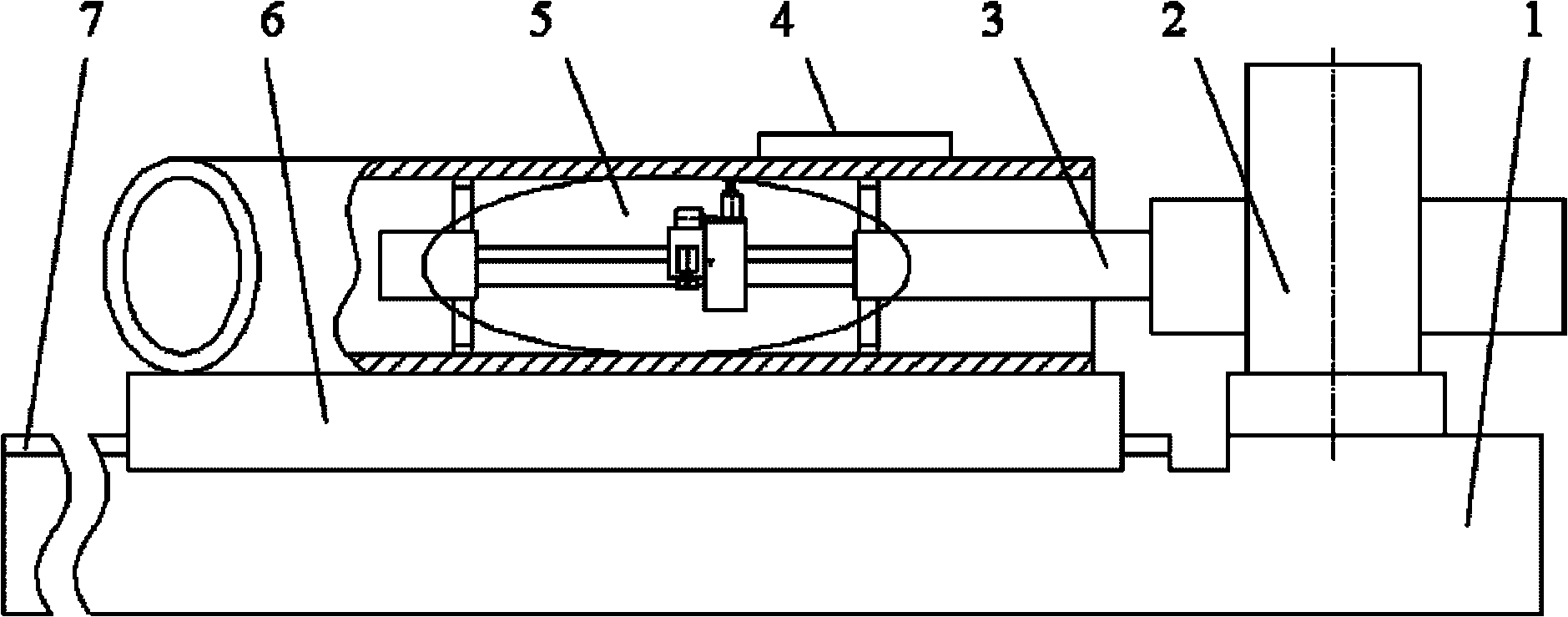

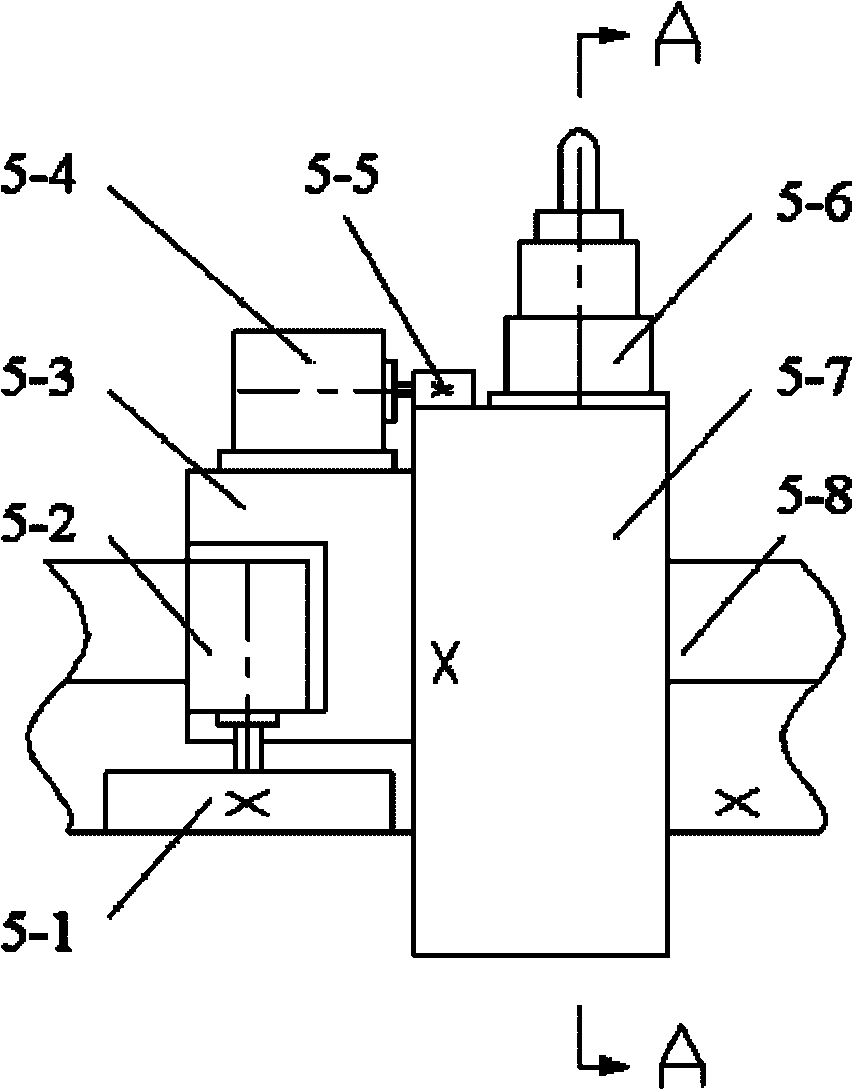

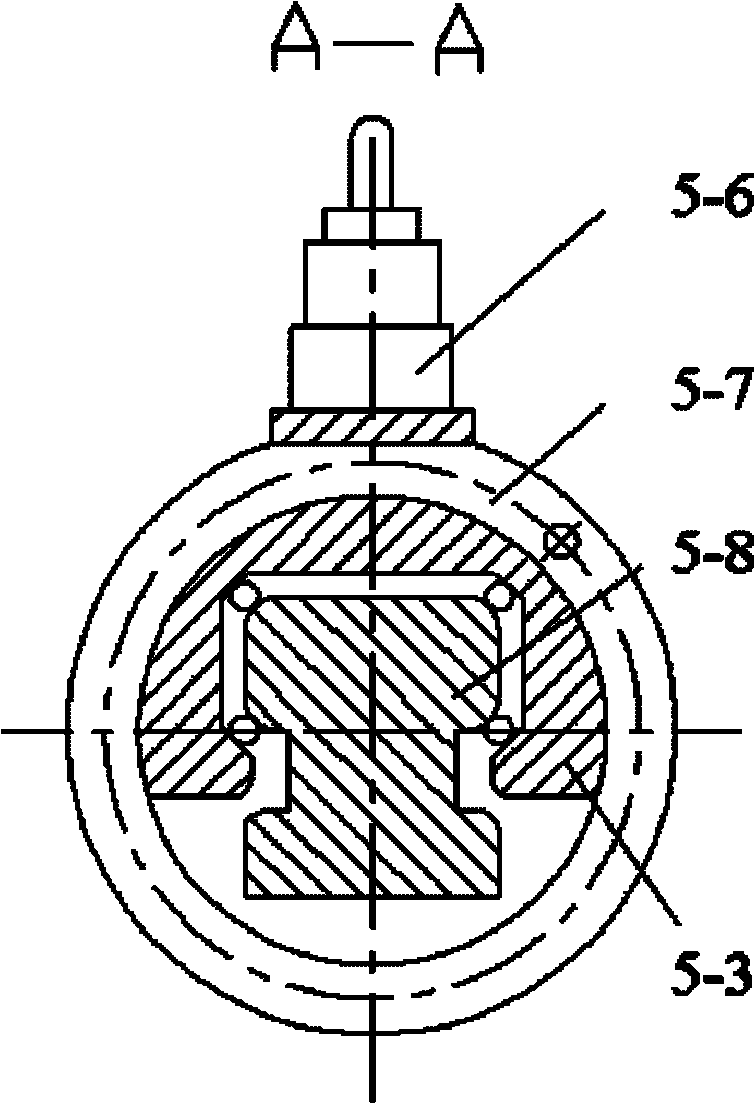

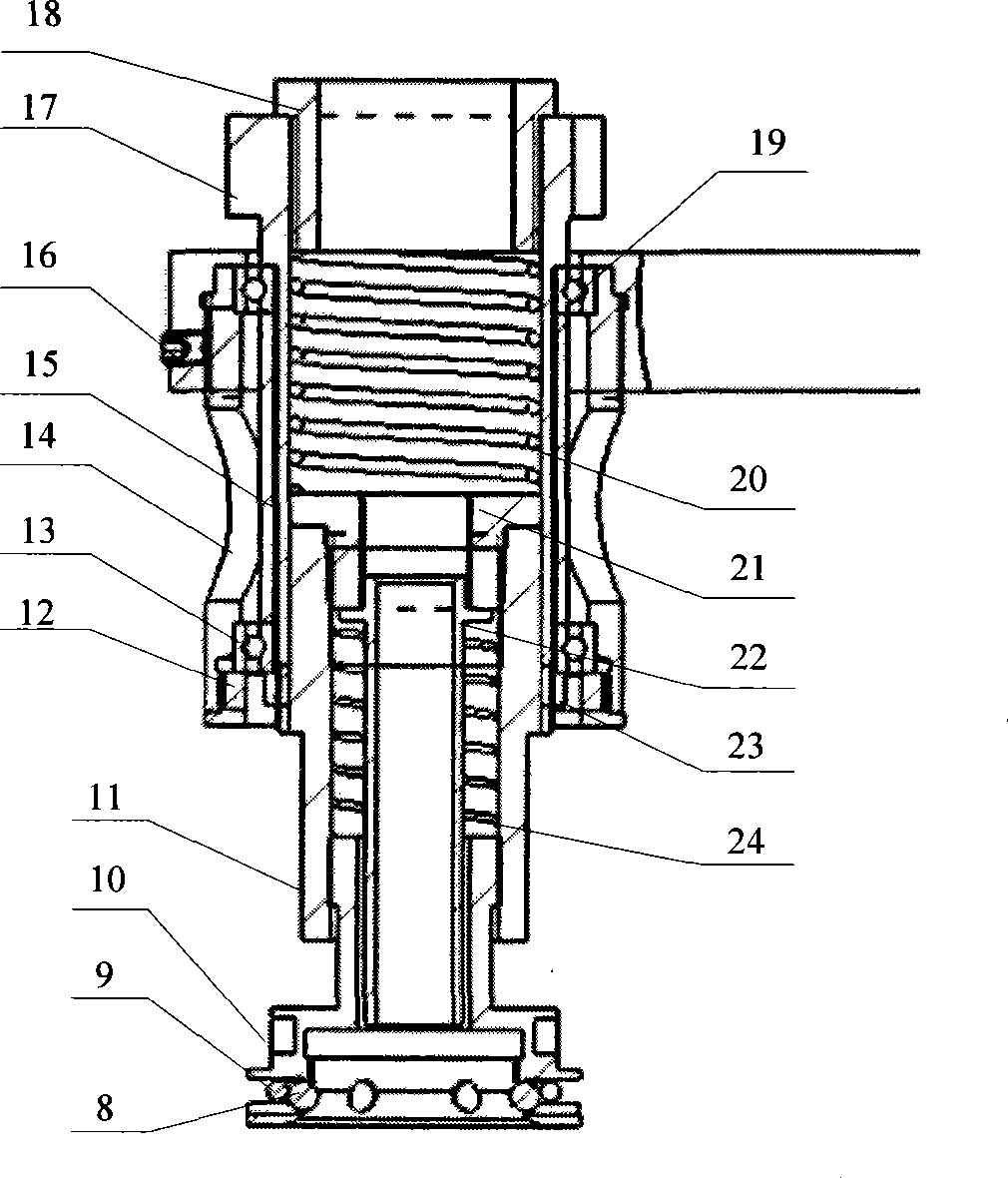

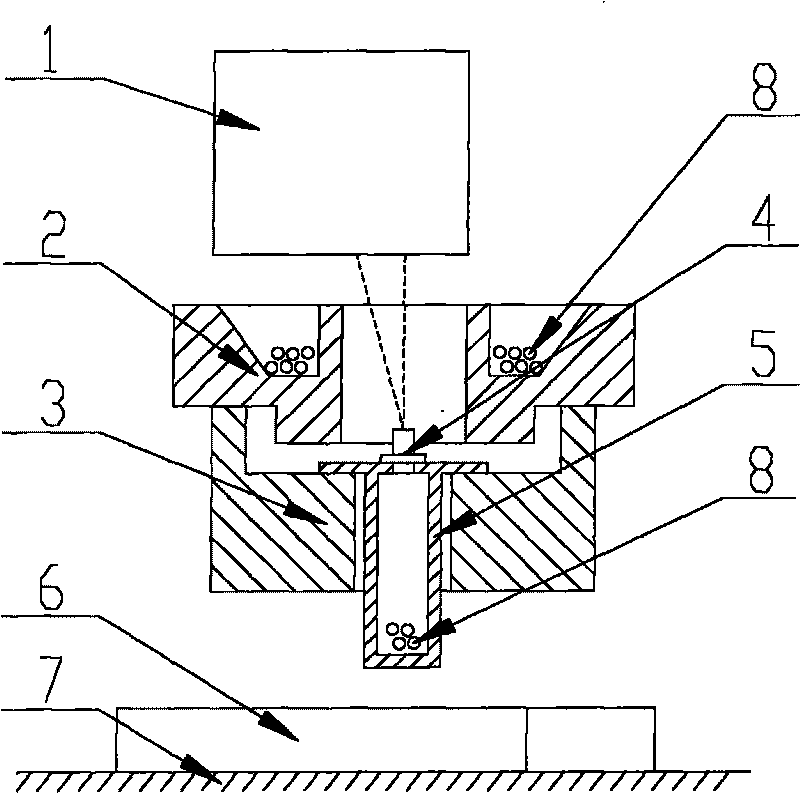

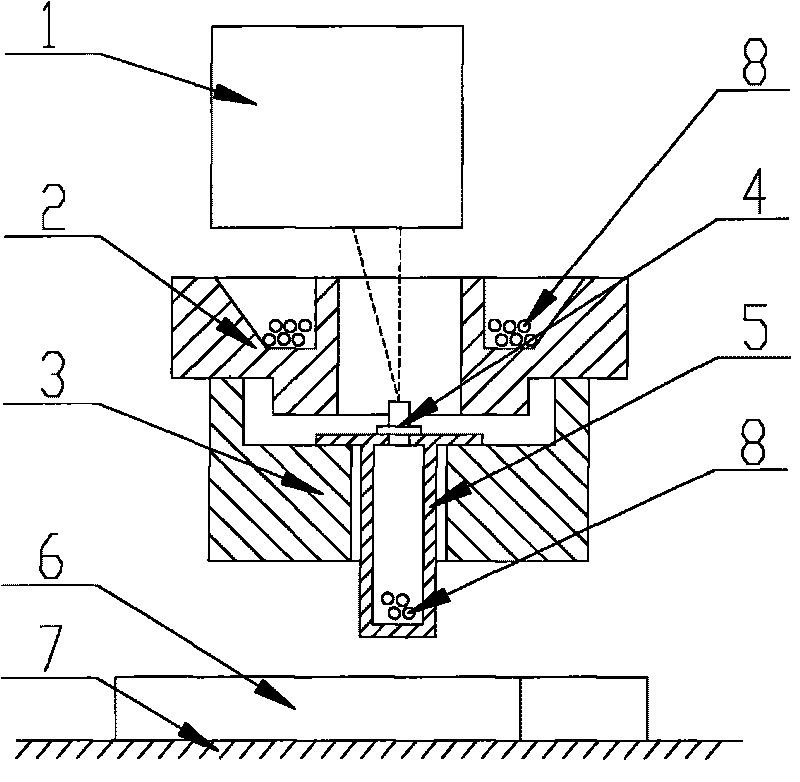

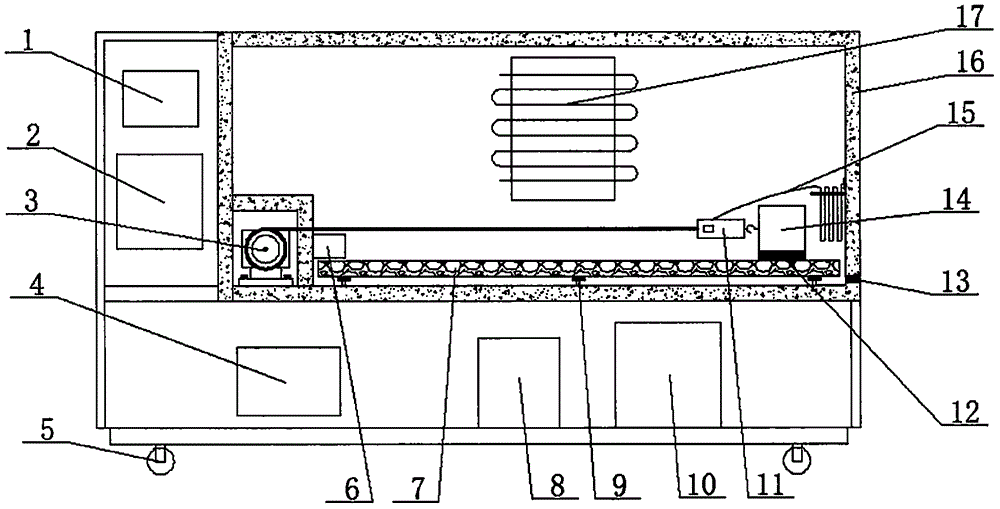

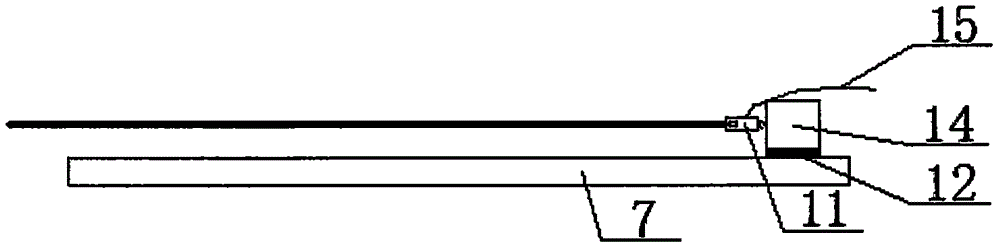

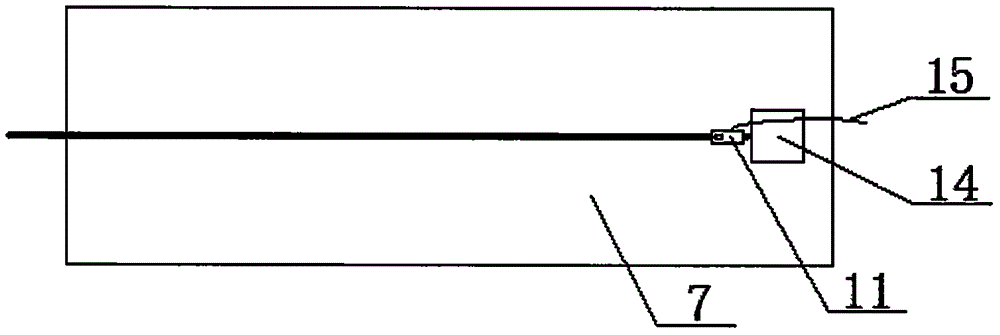

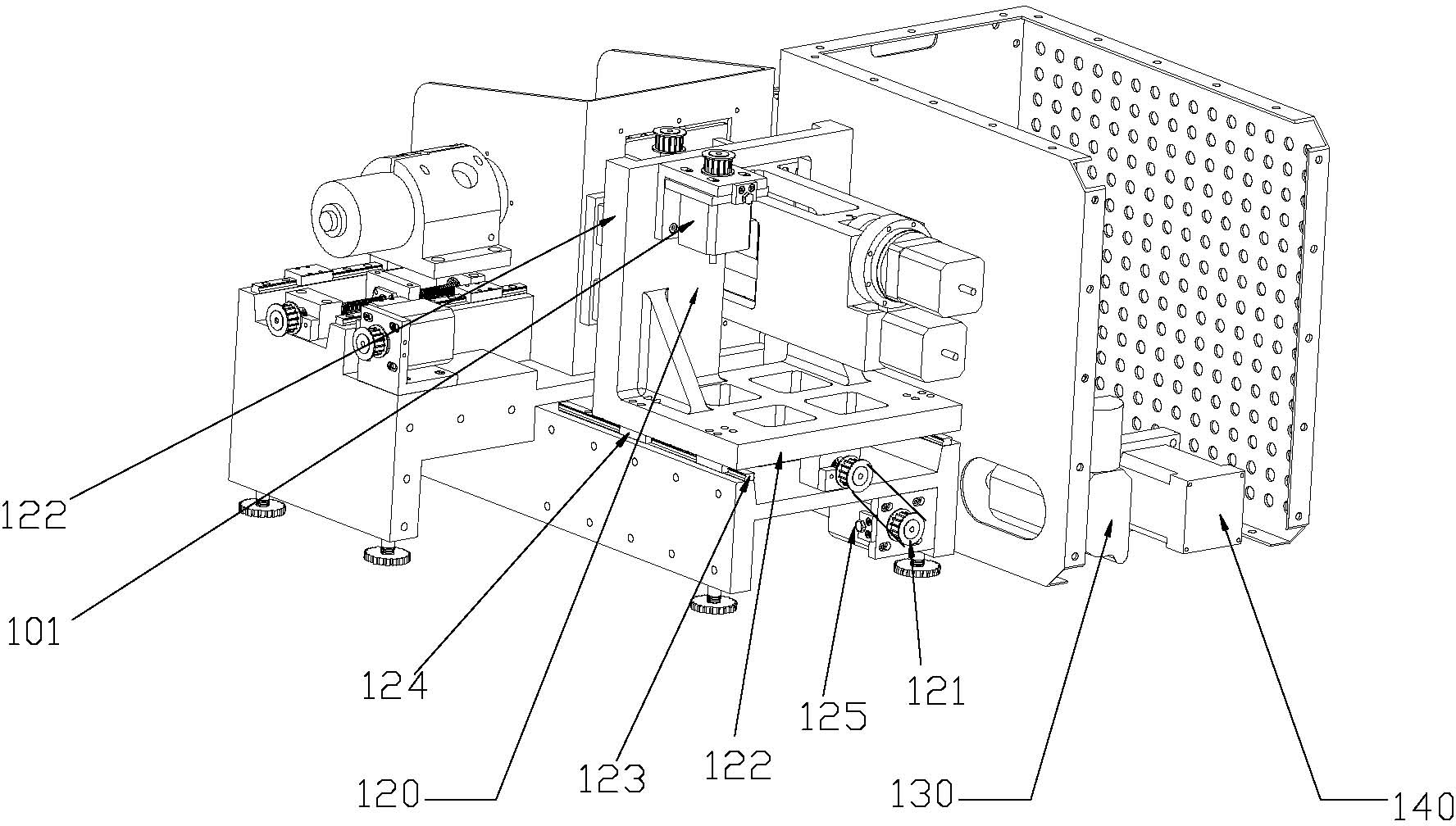

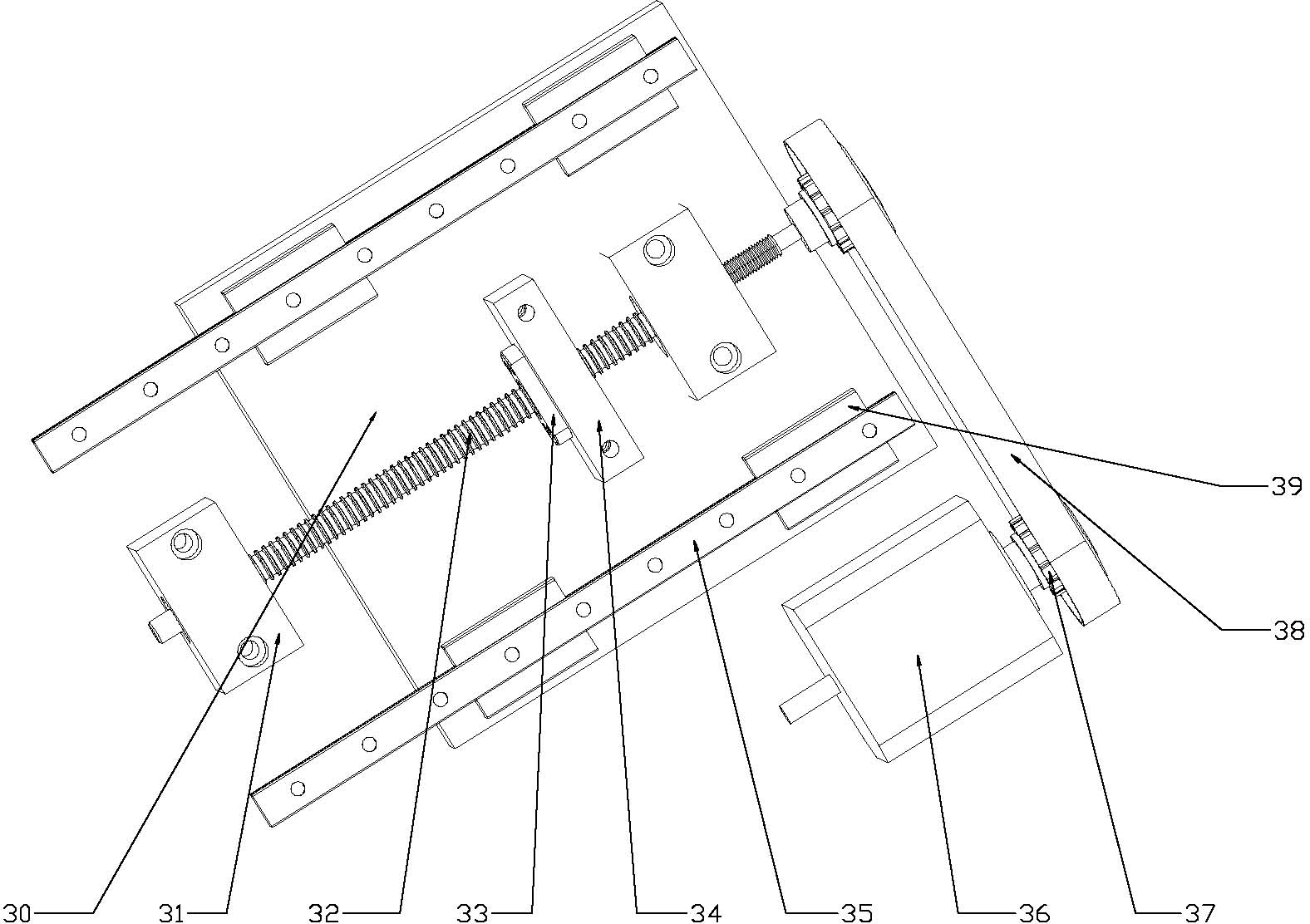

Device for testing insertion and withdrawal forces of contact elements of electric connectors in high temperature environments

InactiveCN102680152AControl test temperatureEasy to operateMachine part testingApparatus for force/torque/work measurementElectricityReciprocating motion

The invention discloses a device for testing insertion and withdrawal forces of contact elements of electric connectors in high temperature environments, which comprises a left mechanical clamping device, a right mechanical clamping device, a force testing device, a mechanical drive device, a driving device, an adjusting platform and an electromagnetic induction heating device, wherein the left mechanical clamping device is used for clamping a jacks and has a heat insulation function, the right mechanical clamping device is used for clamping inserting pins and has a heat insulation function, the force testing device is used for testing insertion and withdrawal forces of contact elements, the mechanical drive device is used for driving the force testing device to carry out a reciprocating motion, the driving device is used for driving the mechanical drive device, the adjusting platform is used for adjusting the alignment accuracy of a contact element, and the electromagnetic induction heating device is used for simulating the temperature of a working environment. A contact element is heated to a specified temperature by using the electromagnetic induction heating device; the driving device drives the right mechanical clamping device to move through the mechanical drive device so as to realize the insertion and withdrawal motions of the contact element; and then the force testing device acquires data. Through adopting a method for testing insertion and withdrawal forces of contact elements directly in high temperature environments, the device can truly respond to the operating situations of the contact element at high temperature, therefore, the device is suitable to be used in various electric connector factories and research institutions, and ensures the accuracy of measured data.

Owner:ZHEJIANG SCI-TECH UNIV

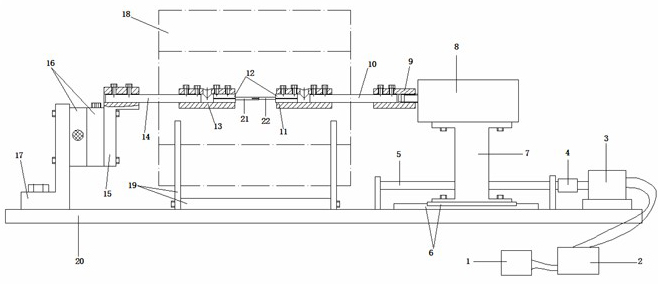

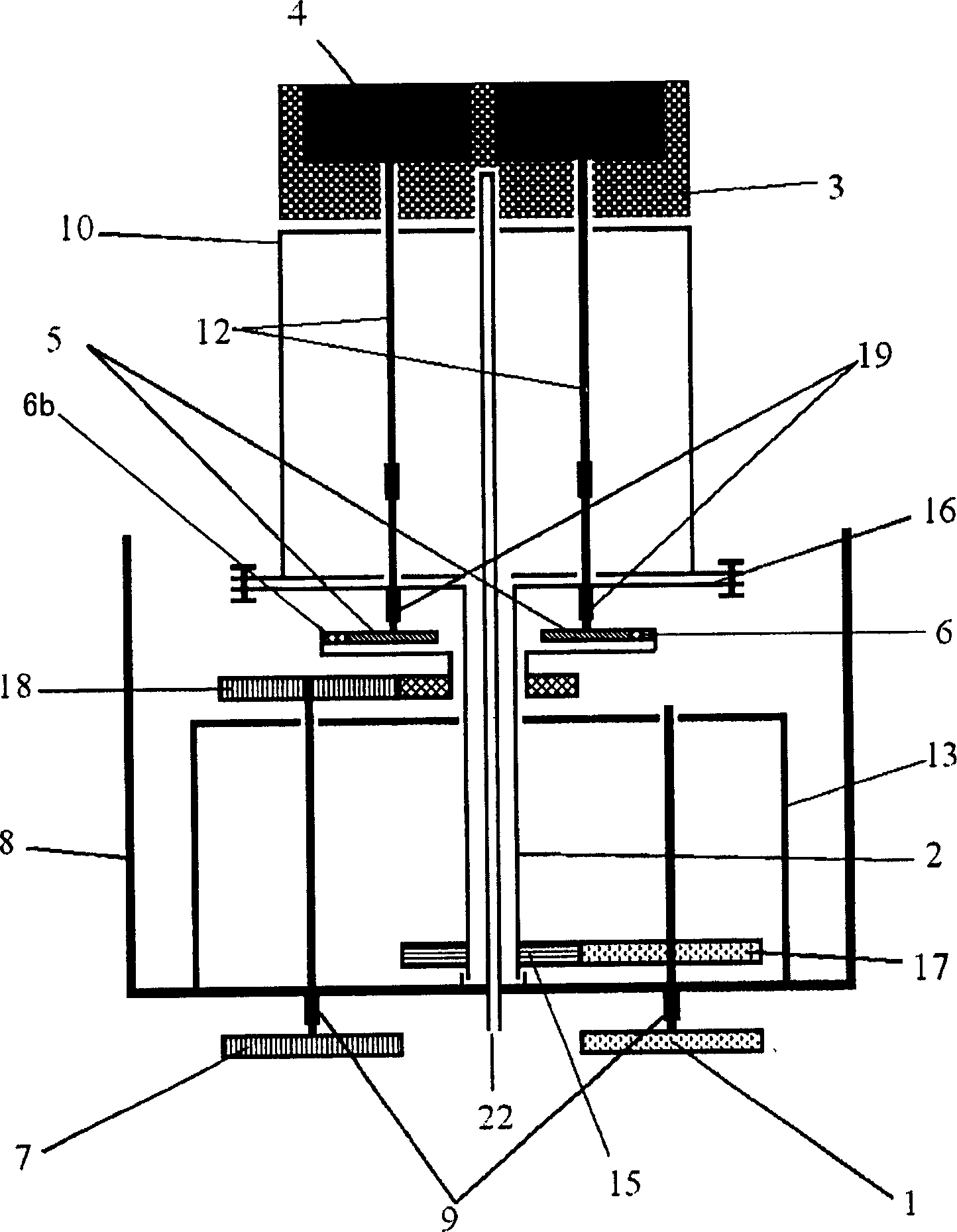

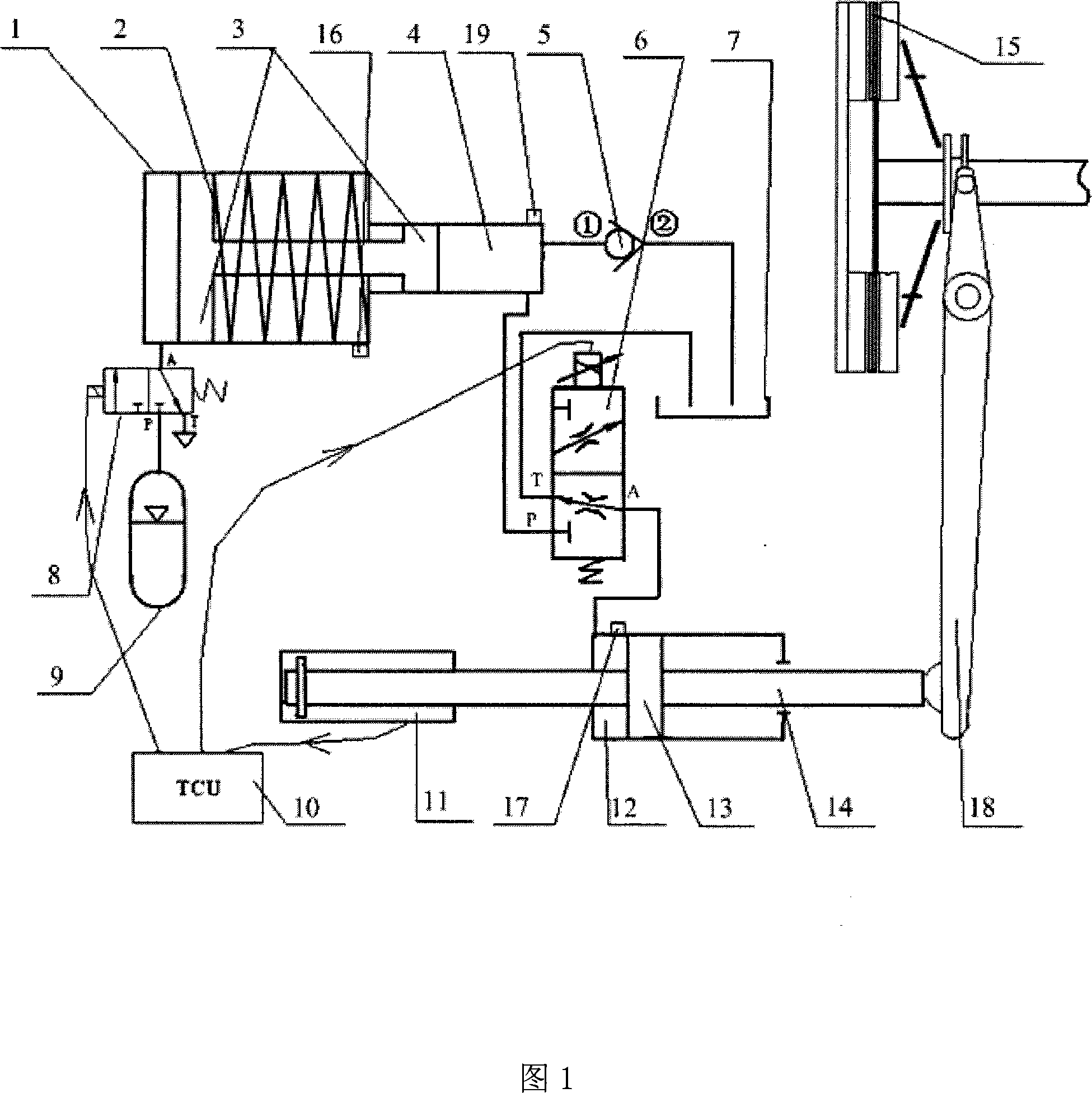

Asymmetric cylinder closed-loop speed system controlled by electro-hydraulic proportional pump

The invention relates to a control system of electric liquid ratio pump control asymmetry cylinder. Wherein, the oil gate A1 of electric liquid ratio pump (1) with closed-loop flux control system is connected to the single valve (4) oil gate A2, the single valve (7) oil gate A3, the overflow valve (8) oil gate A4, the overflow valve (9) oil gate A5, the flux division overflow valve (19) oil gate A6 and the asymmetry oil cylinder (18) rod chamber; the oil gate B1 of electric liquid ratio pump (1) is connected to the single valve (11) oil gate B2, the single valve (10) oil gate B3, the overflow valve (8) oil gate B4, the overflow valve (9) oil gate B4, and the liquid control single valve (17) oil gate B5; and the oil gate B6 of liquid control single valve (17) is connected to the non-rod chamber of asymmetry oil cylinder (18) and the maintenance-safety circuit. The oil feeding circuit, main pump zero flux unload circuit and pressure-limited circuit are arranged between the non-rod chamber and the rod chamber oil pip.

Owner:WUHAN UNIV OF SCI & TECH

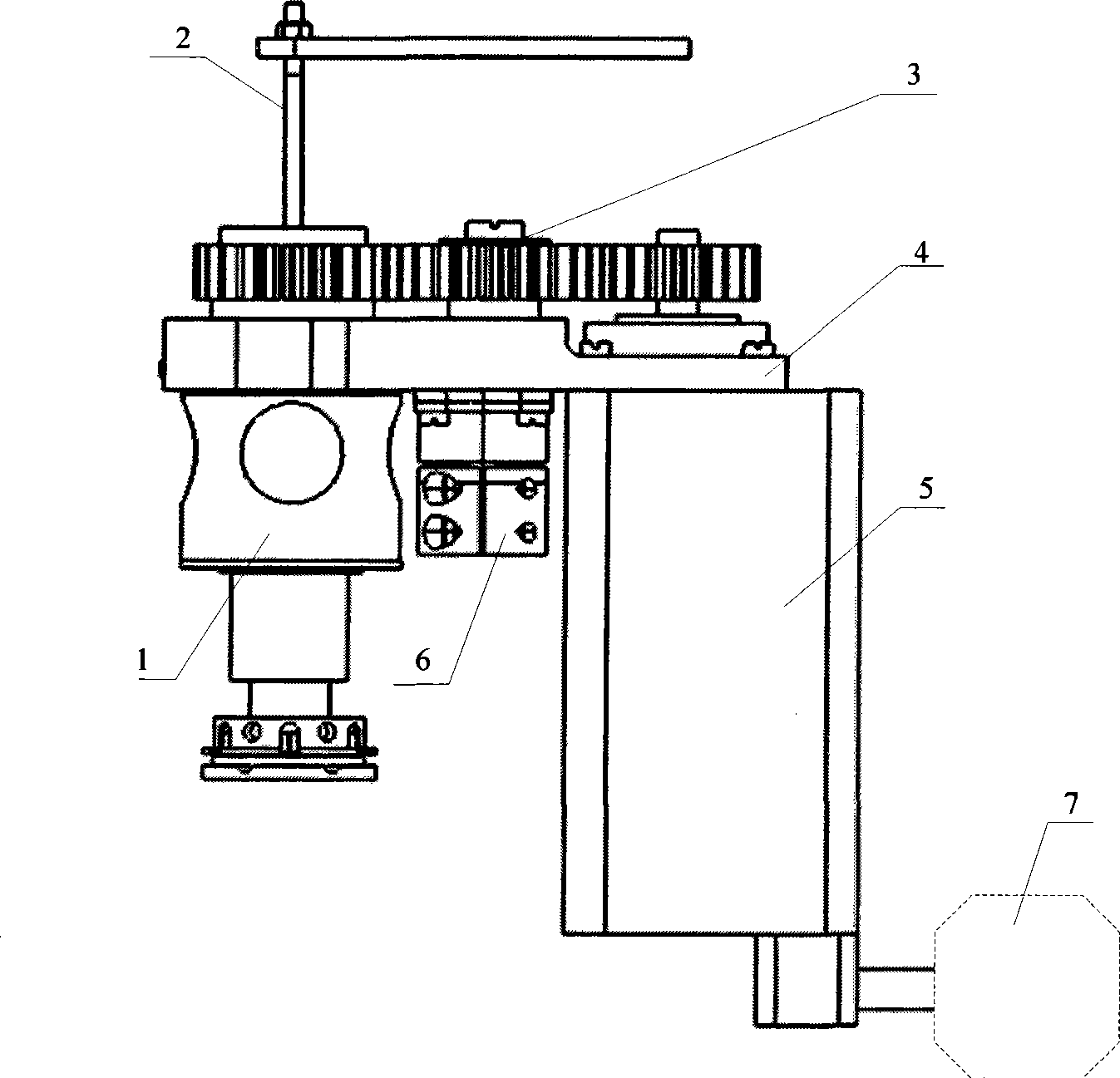

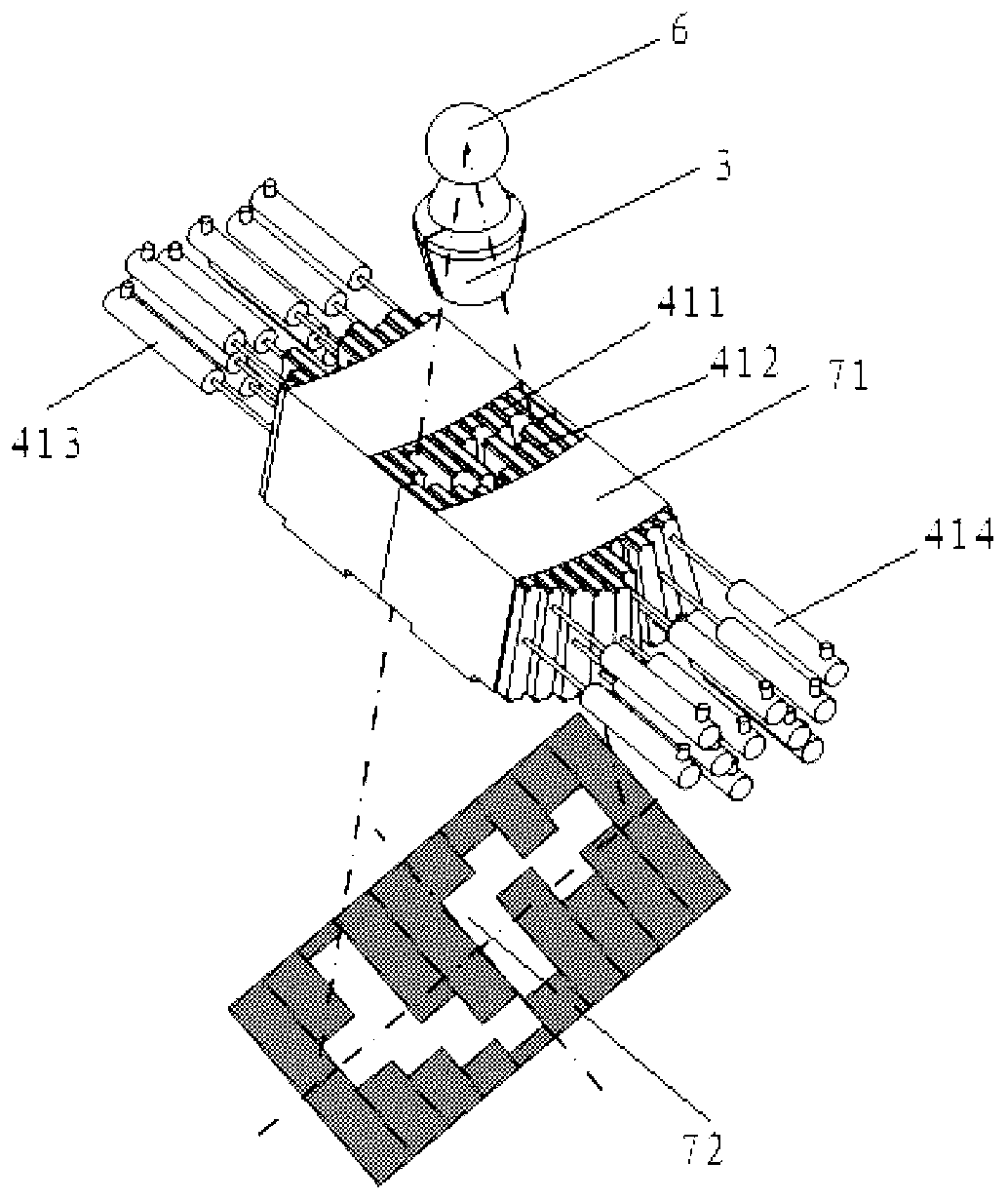

Equipment and method for milling inner surface of bent pipe

InactiveCN102205438AOvercome efficiencyOvercome precisionFeeding apparatusMilling equipment detailsEngineeringHeavy load

The invention belongs to the field of large-scale heavy load part processing and relates to equipment and a method for milling the inner surface of a bent pipe. The equipment comprises an equipment machine body, a vertical column, a supporting rod, a clamping device, a revolution milling device, a workbench and a guide rail. The machining of the inner surface of the arc line section of the bent pipe is realized in a mode of guide rail leading matched with gear transmission by matching the circular motion along the guide rail and the revolution motion around a slide block, and through the screw feed cutting motion along the bus of the bent pipe under the drive of a servo motor. The equipment can perform transmission stably and reliably; the mechanism has a simple design; the control mode is simple and direct; the cutting state is stable; the cutting impact load is small; and the surface quality, the efficiency and accuracy are high. The equipment and the method are suitable for processing the inner surfaces of the arc line sections of various large-and-medium-sized bent pipe parts.

Owner:DALIAN UNIV OF TECH

Servo bottle cap screwing mechanism

InactiveCN101386399APrevent crushingEffective screwingThreaded caps applicationPulp and paper industryServomotor

The invention relates to a servo bottle cap screwing mechanism in the technical field of packaging machinery, which comprises a cap screwing head, a waste cap withdrawing mechanism, an idler wheel mechanism, base blocks, a servomotor, a connecting support and a motor control system, wherein, the cap screwing head, the idler wheel mechanism, the servomotor and the connecting support are arranged on the base blocks, the motor control system controls the servomotor to rotate at certain rotating speed and torque, and the generated dynamic power is transferred to the cap screwing head by the idler wheel mechanism, so as to cause the cap screwing head to rotate along with the servomotor; the connecting support is connected with a lifting guide rod to drive the base blocks to raise and fall periodically, and the height of the waste cap withdrawing mechanism is unchanged, and the waste cap withdrawing mechanism is arranged at a cap screwing machine. Under the germfree condition, the entire bottle cap screwing mechanism is lubrication free, has no leakage, is convenient for frequent rinsing and disinfection; the cap screwing torque is controlled by computer, the cap screwing mechanism is driven by servomotor and has large adjustable range; and besides, the working torque, the cap screwing speed, and the like, of the single cap screwing mechanism can be displayed, and the cap screwing mechanism can automatically discharge waste or abnormal caps.

Owner:SHANGHAI JIAO TONG UNIV

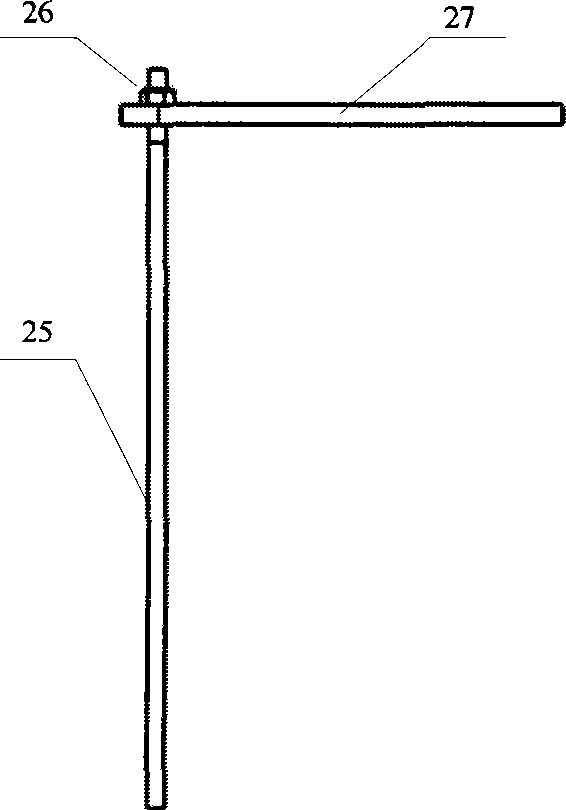

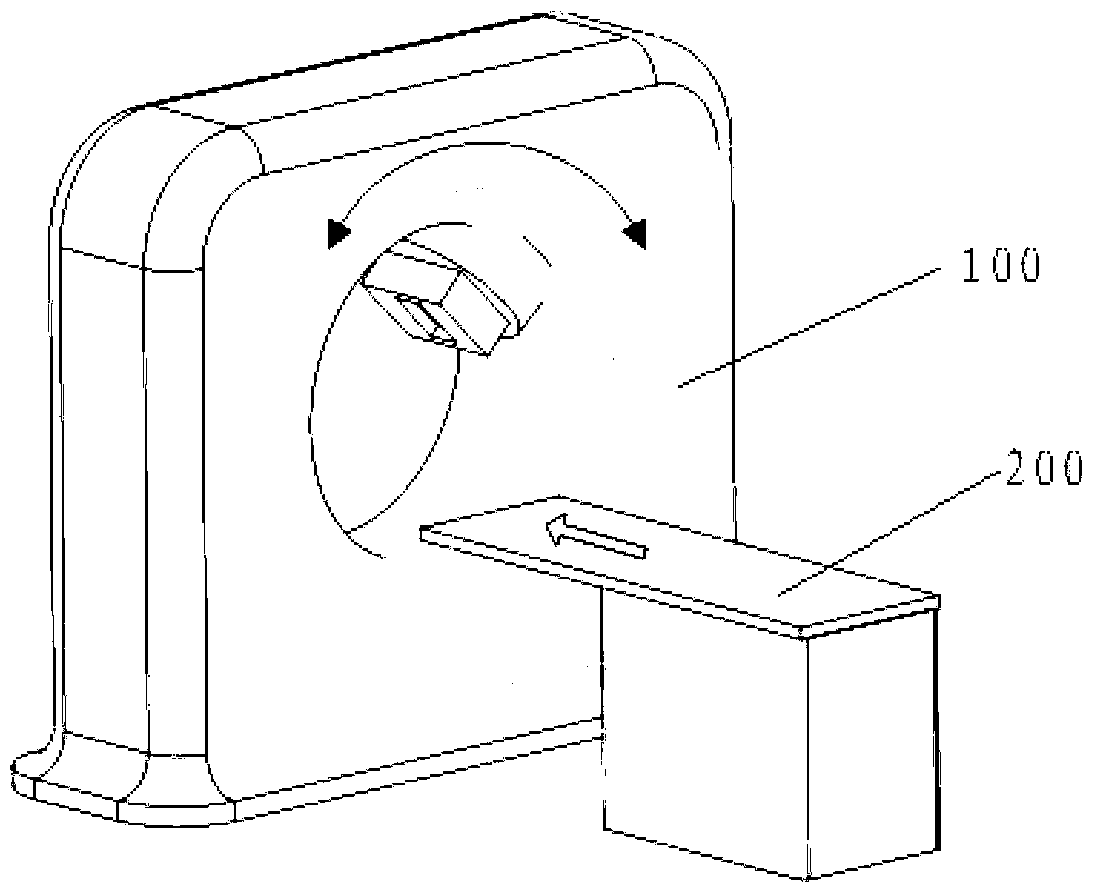

Radiotherapy equipment and radiotherapy system with radiotherapy equipment

InactiveCN103272338AImproved dose distribution capabilitiesMeet clinical needsX-ray/gamma-ray/particle-irradiation therapyMulti leaf collimatorEngineering

The invention discloses radiotherapy equipment and a radiotherapy system with the radiotherapy equipment. The radiotherapy equipment comprises a fixed cabinet, a rotary support, a main collimator, a radiation source and a multi-leaf collimator, wherein the rotary support is rotationally arranged on the fixed cabinet, and is provided with the radiation source, the main collimator is arranged on the radiation source, the multi-leaf collimator is mounted on the fixed cabinet and comprises multiple parallel leaf groups, each leaf group comprises a first leaf, a second leaf, a first linear motor and a second linear motor, the first and second leaves are oppositely arranged, the first linear motor is connected with the first leaf to drive the first leaf to move, and the second linear motor is connected with the second leaf to drive the second leaf to move. The radiotherapy equipment adopts the linear motors to drive the leaves to move, thus realizing the accurate control on the speed and position of the leaves and further improving the curing precision and efficiency.

Owner:TSINGHUA UNIV

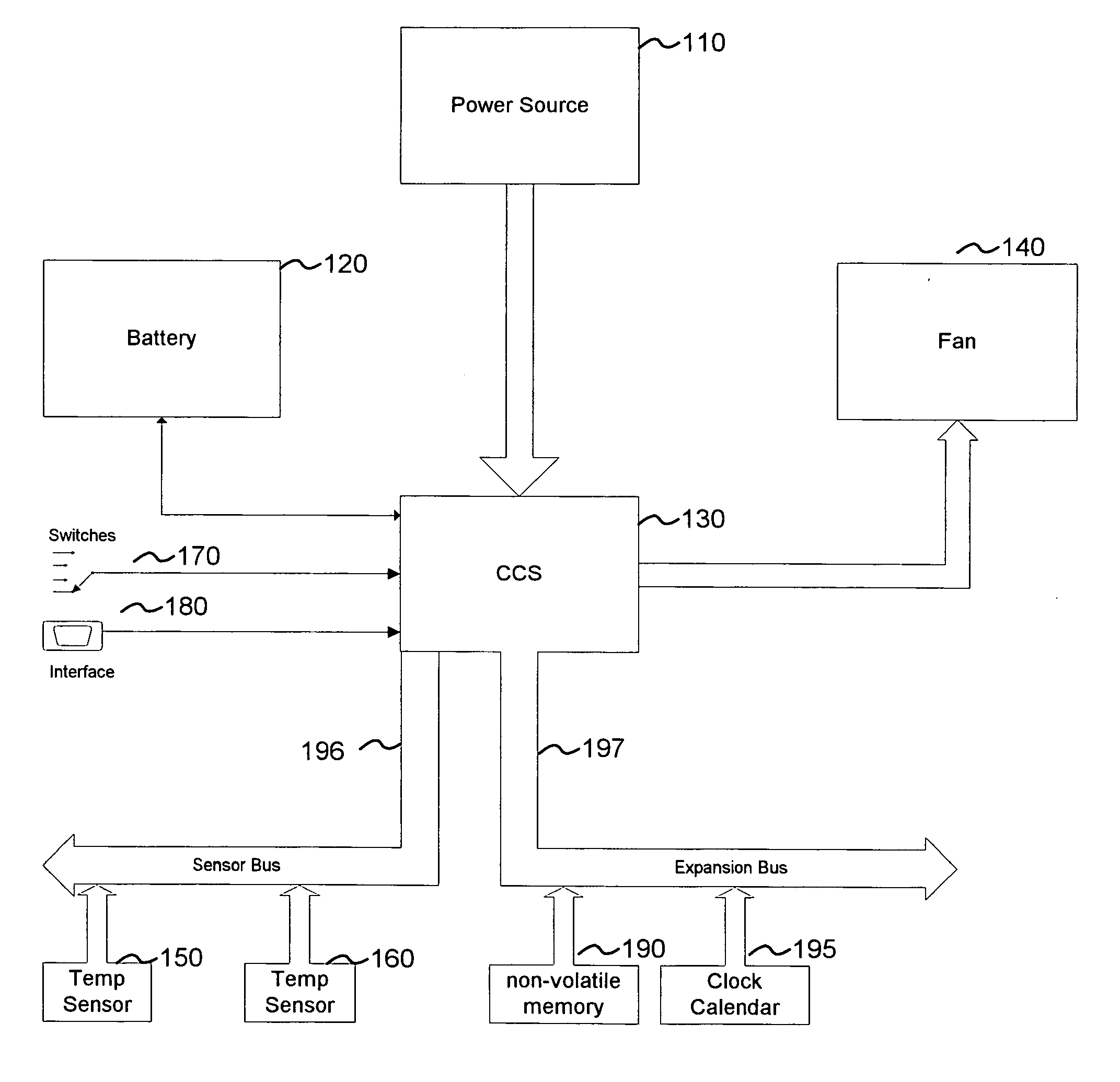

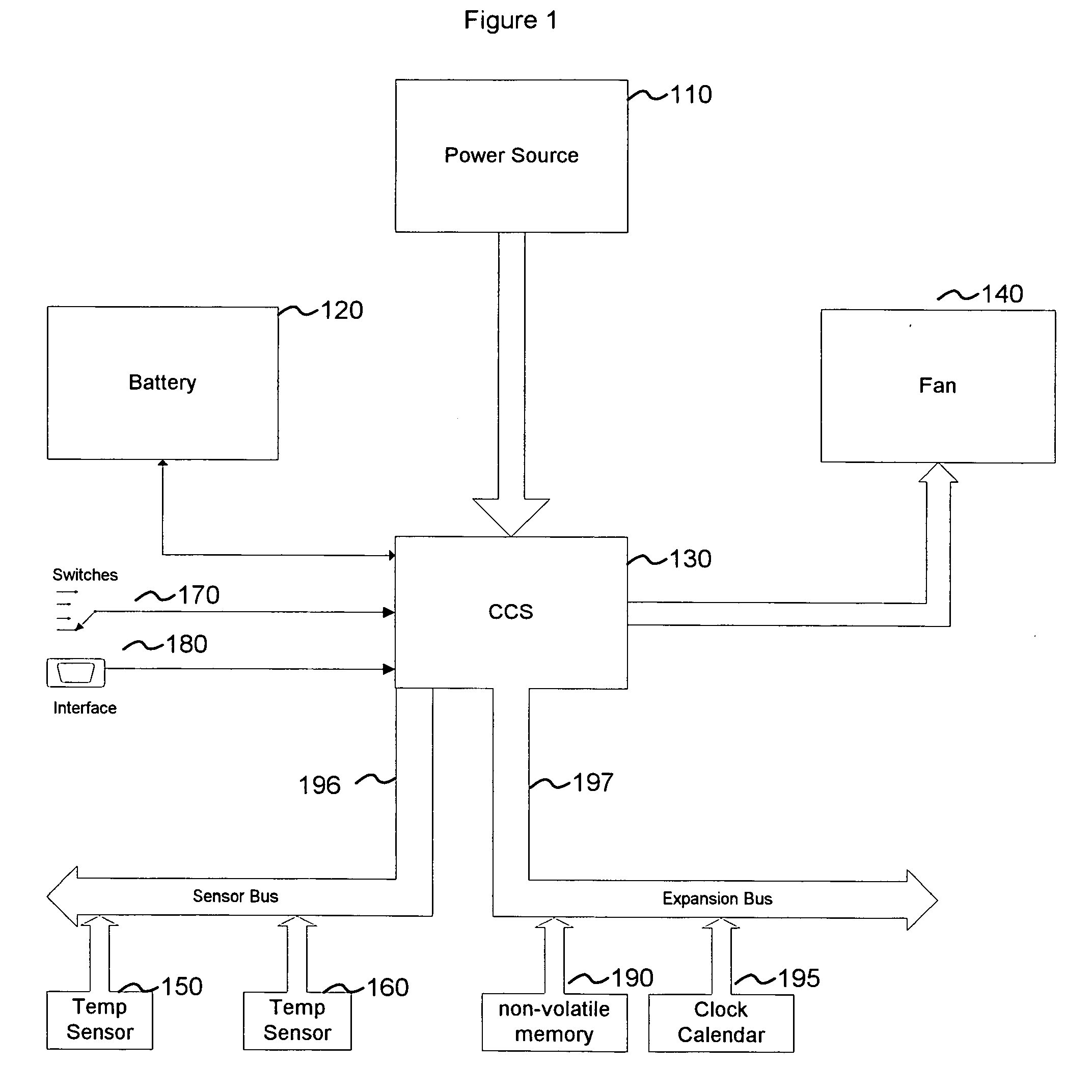

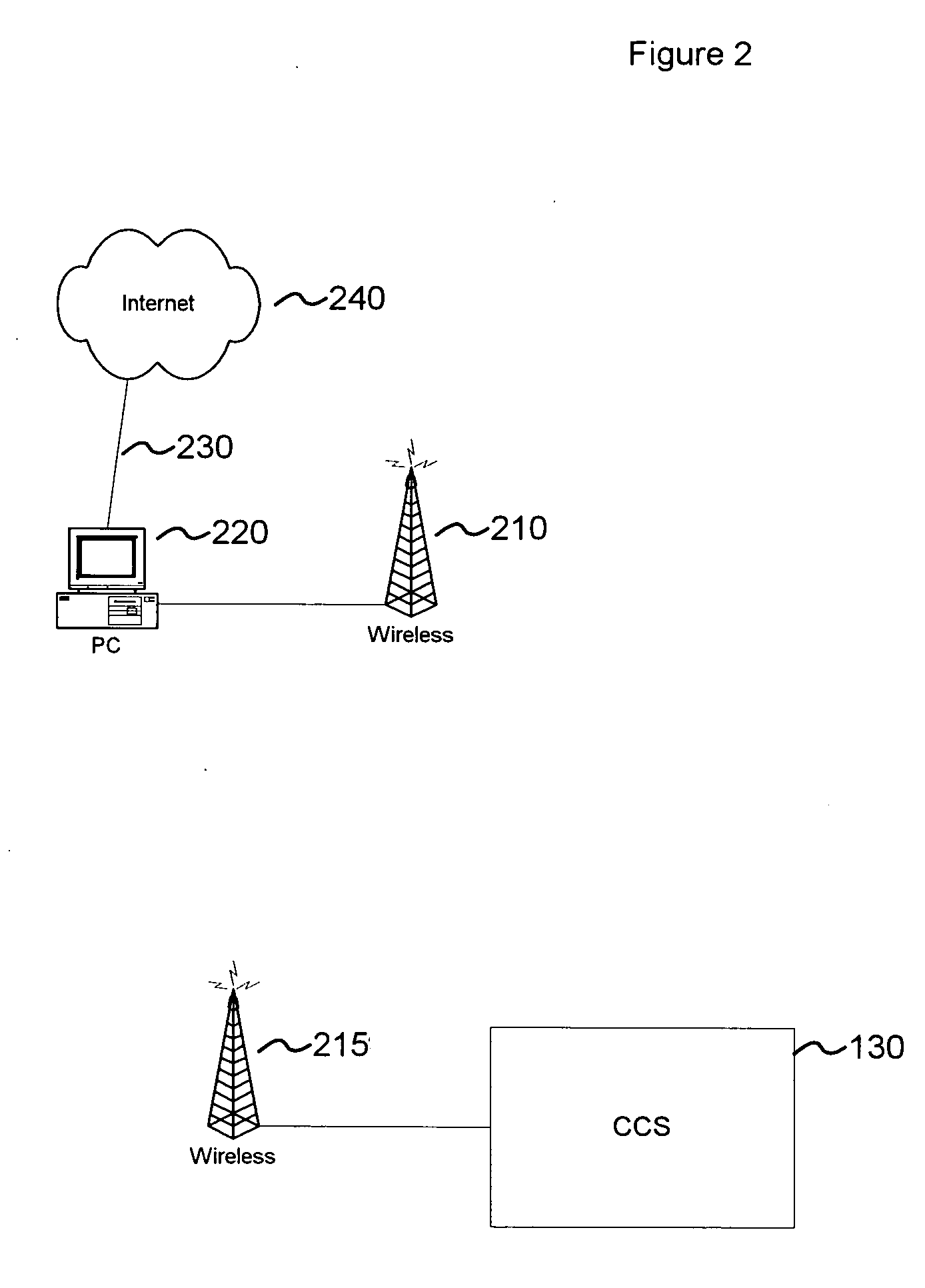

Air circulation control device

InactiveUS20060149422A1More airSolve low usageSampled-variable control systemsMechanical apparatusAir cycleElectrical battery

An improved air circulation control device for circulation fans, such as attic and greenhouse fans, to increase their efficiency. The current invention includes a self-contained system consisting of: a power delivery device, battery, temperature sensors, humidity sensors, fan system, and computational control system (CCS). The power delivery system (such as a solar collector device) produces electrical power. The invention uses this electrical power to charge the battery. The CCS monitors the temperature and humidity of the enclosed area and the charge status of the battery, and determines when to operate the fan and at what speed. The CCS also stores historical data, and in a further embodiment, can be tied into a weather predicting system to plan ahead for the collection and use of electrical energy in the system to evacuate warm air, or reverse the process to bring warm air from the outside into the enclosed area on a cold day.

Owner:DUNSTAN JAMES EDWARD +1

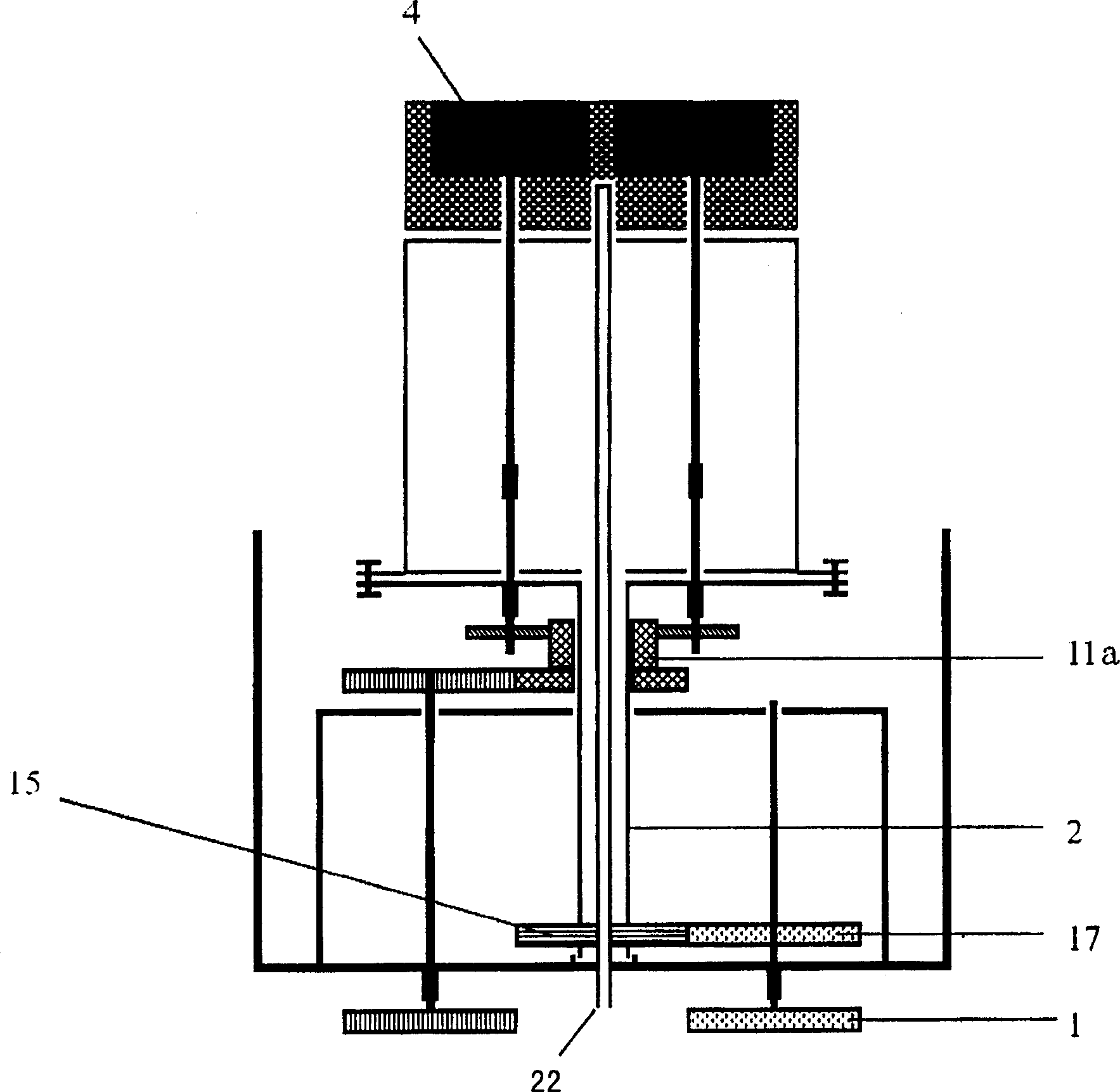

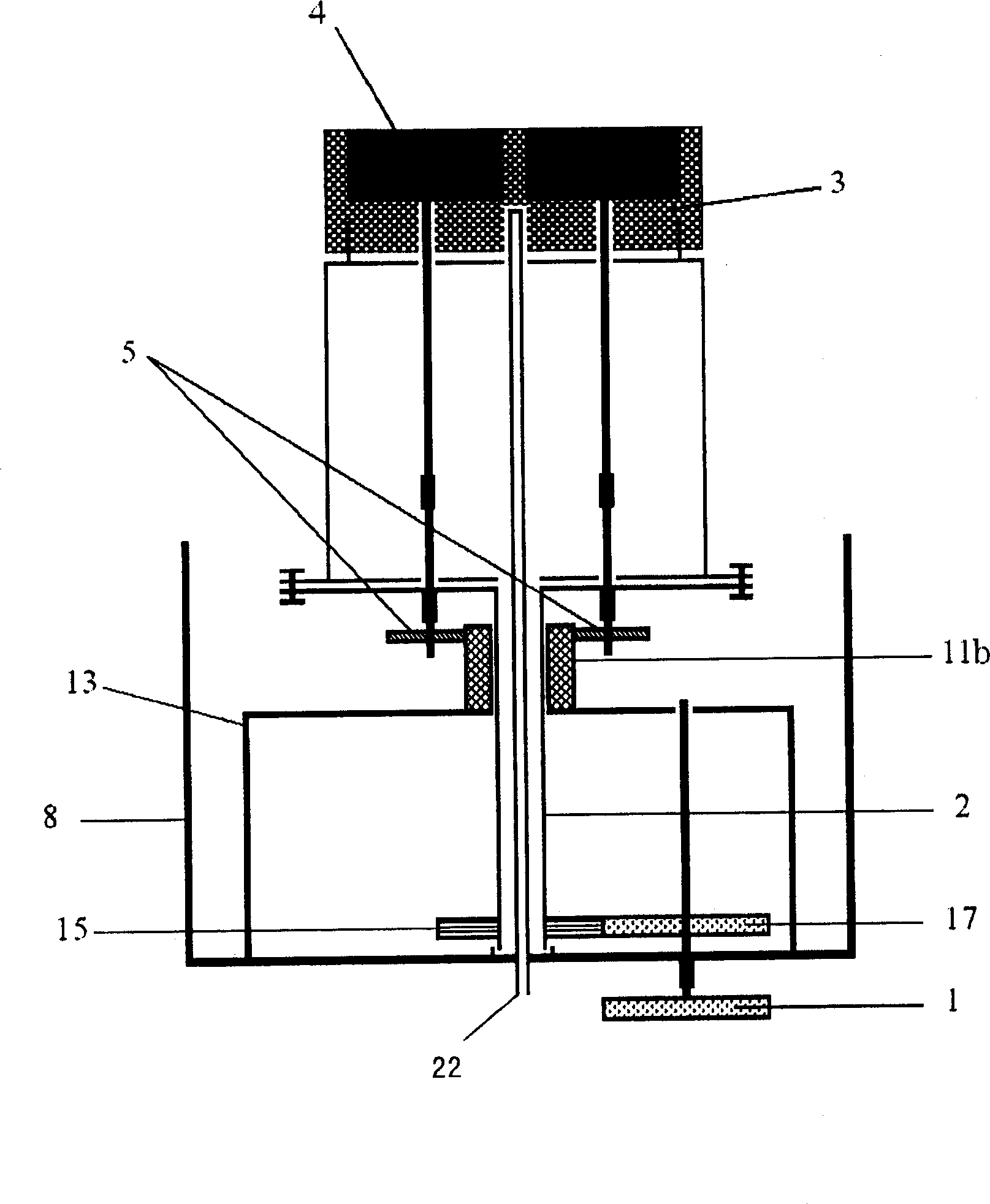

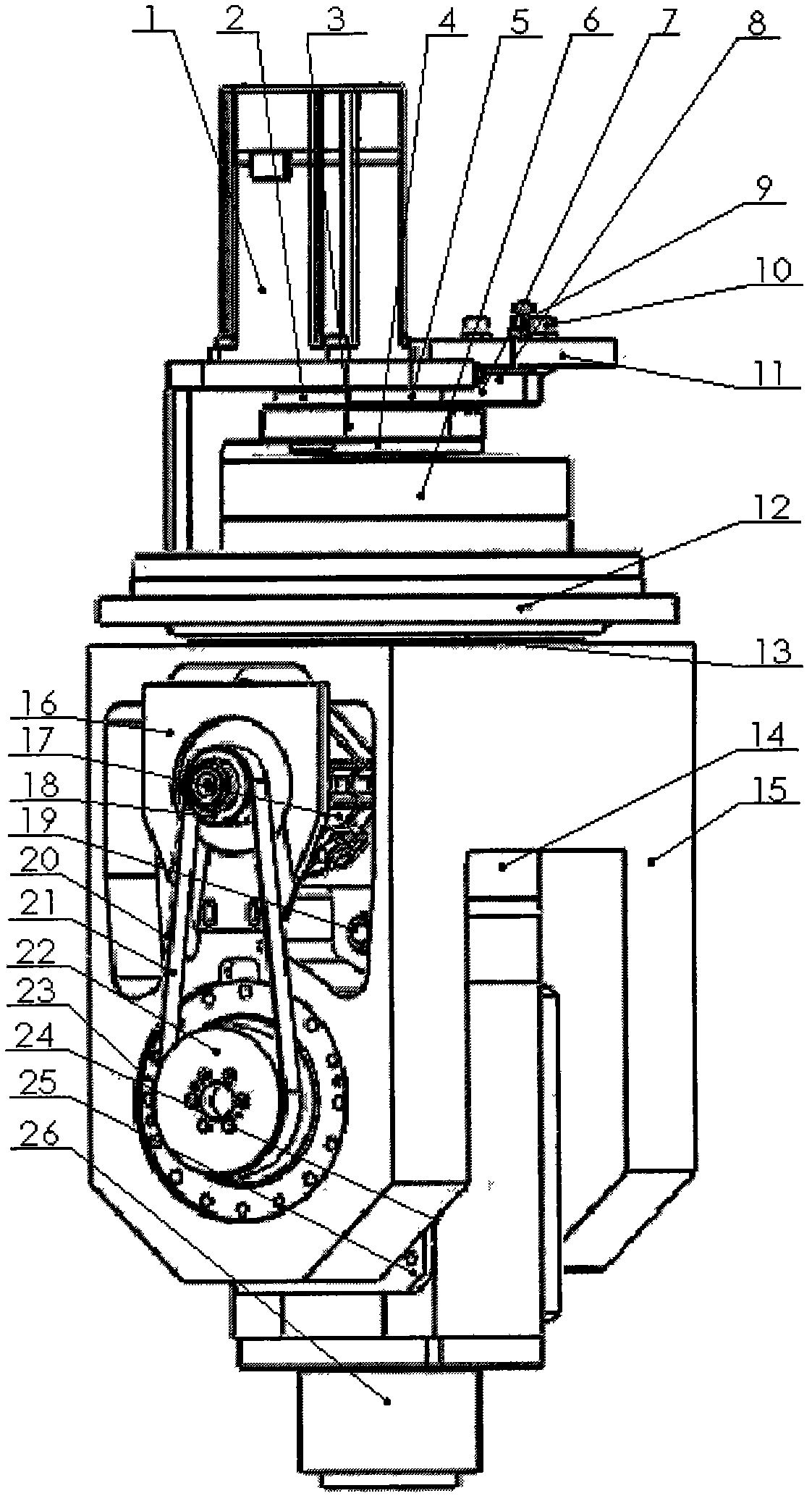

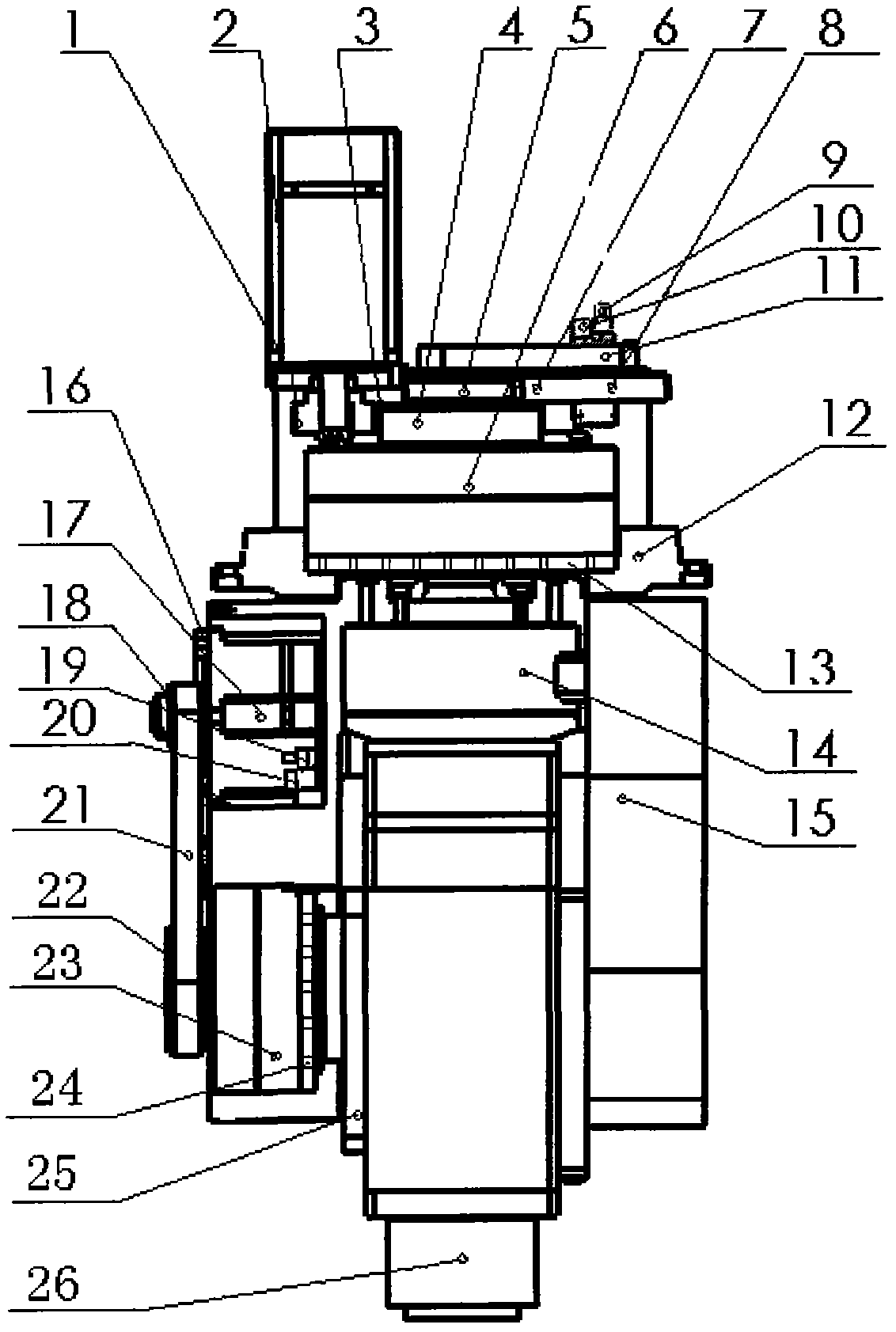

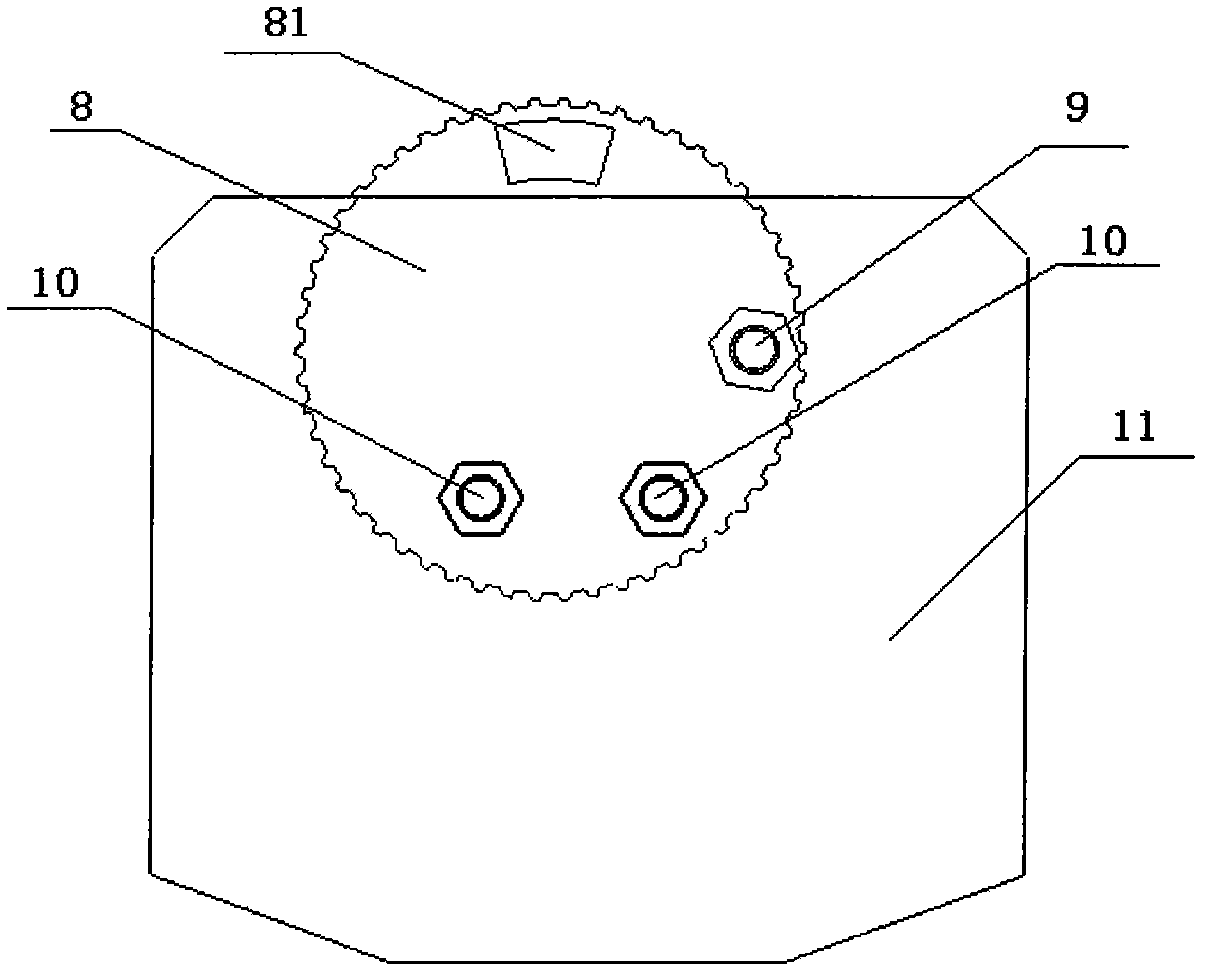

Revolution and rotation arrangement in reaction chamber of metallorganics chemical vapor deposition device

InactiveCN1865495ALower growth costsSave raw materialsChemical vapor deposition coatingGas phaseGraphite

The invention discloses a substrate base rotary structure in the metal organic chemical vapor deposition (MOCVD) equipment, which is characterized by the following: (1) the big graphite boat in the reacting chamber revolves one public fixing point; the small graphite boat rotates each center point; (2) the motor anchors substrate base (big graphite boat) to revolve; (3) the motor anchors the substrate base (small graphite boat) rotates; (4) the high-temperature region (substrate base) and low-temperature region (rotary dynamic structure) are separated by heat-durability material, which transmits the rotary dynamics.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

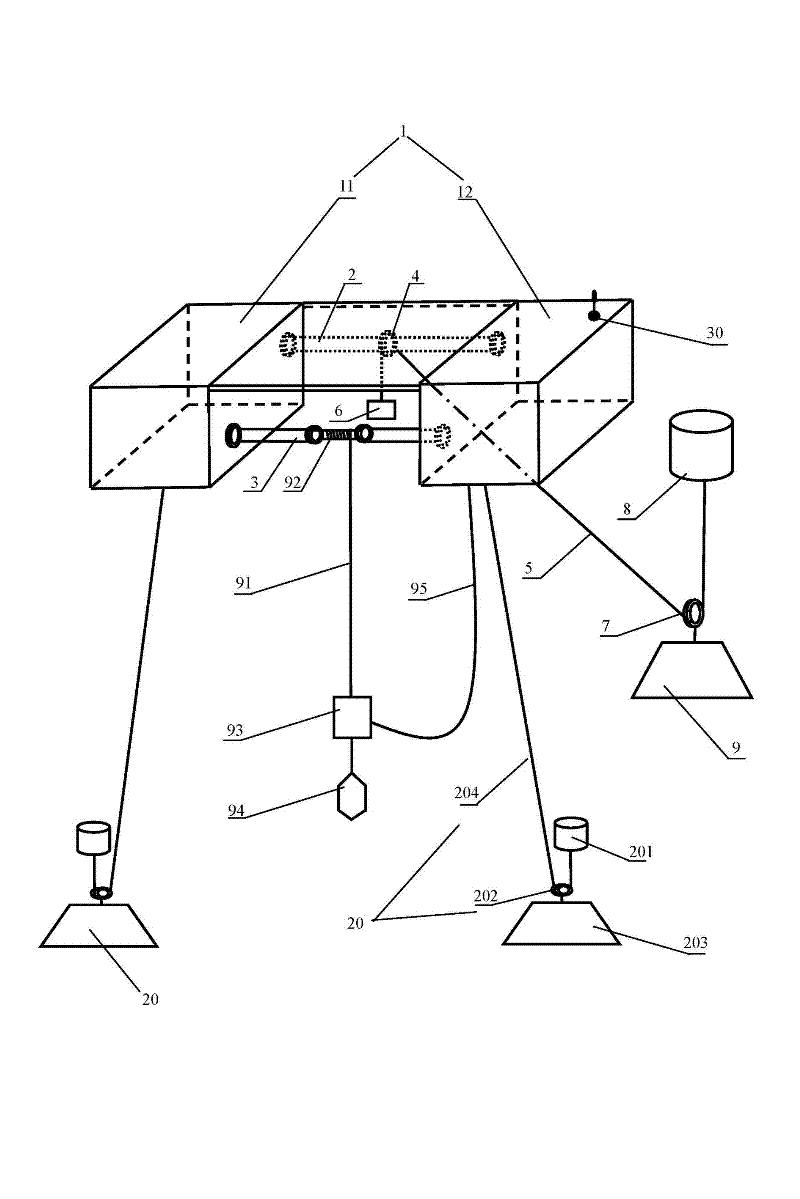

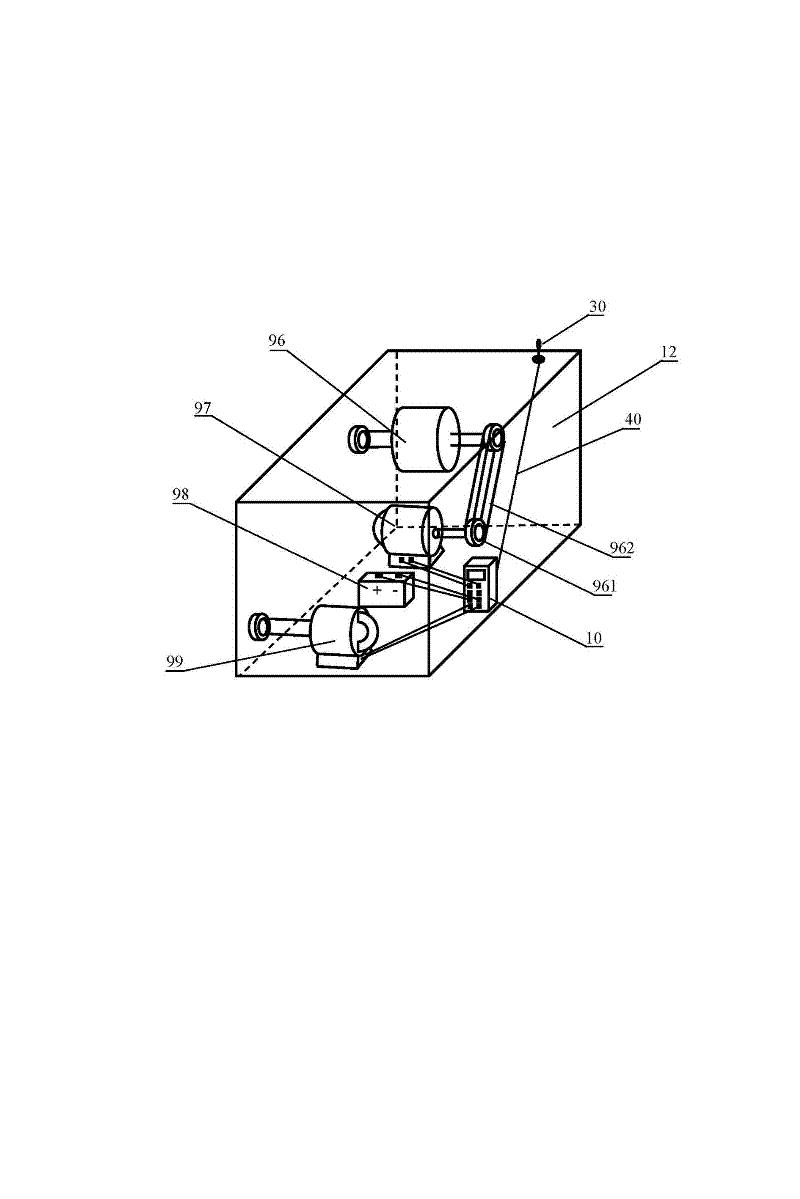

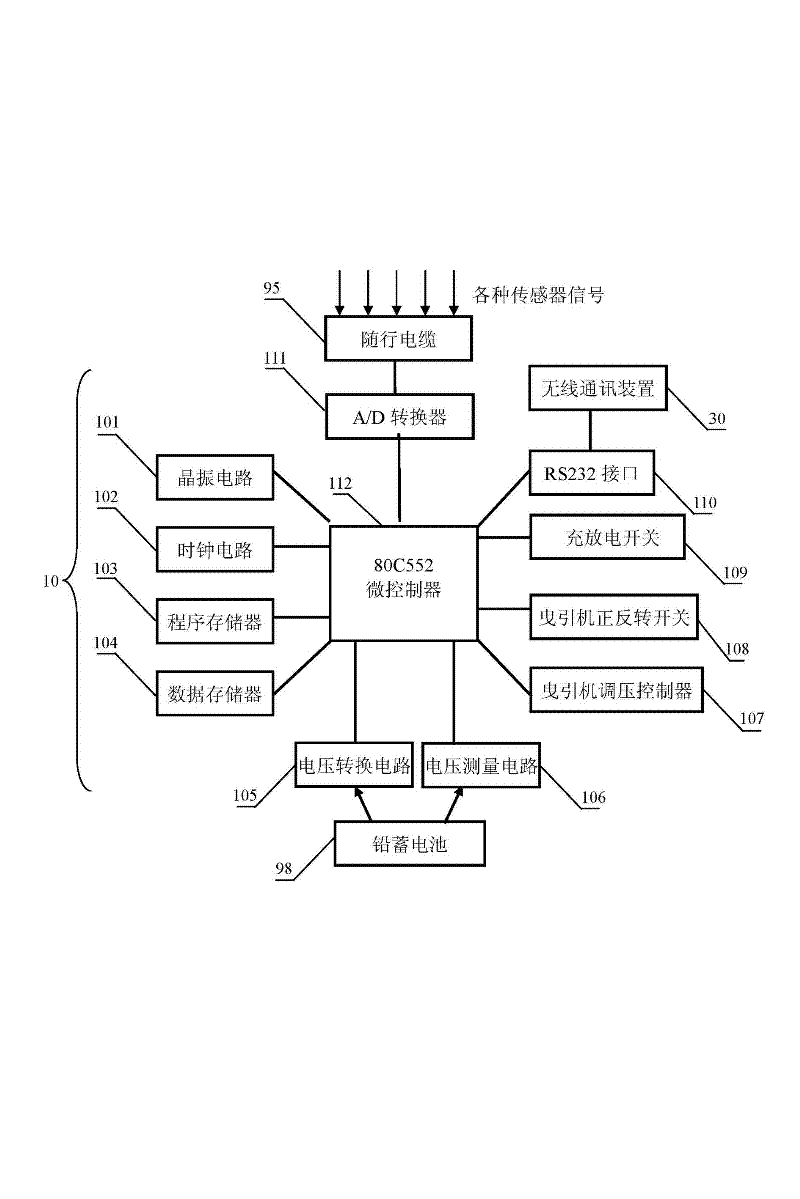

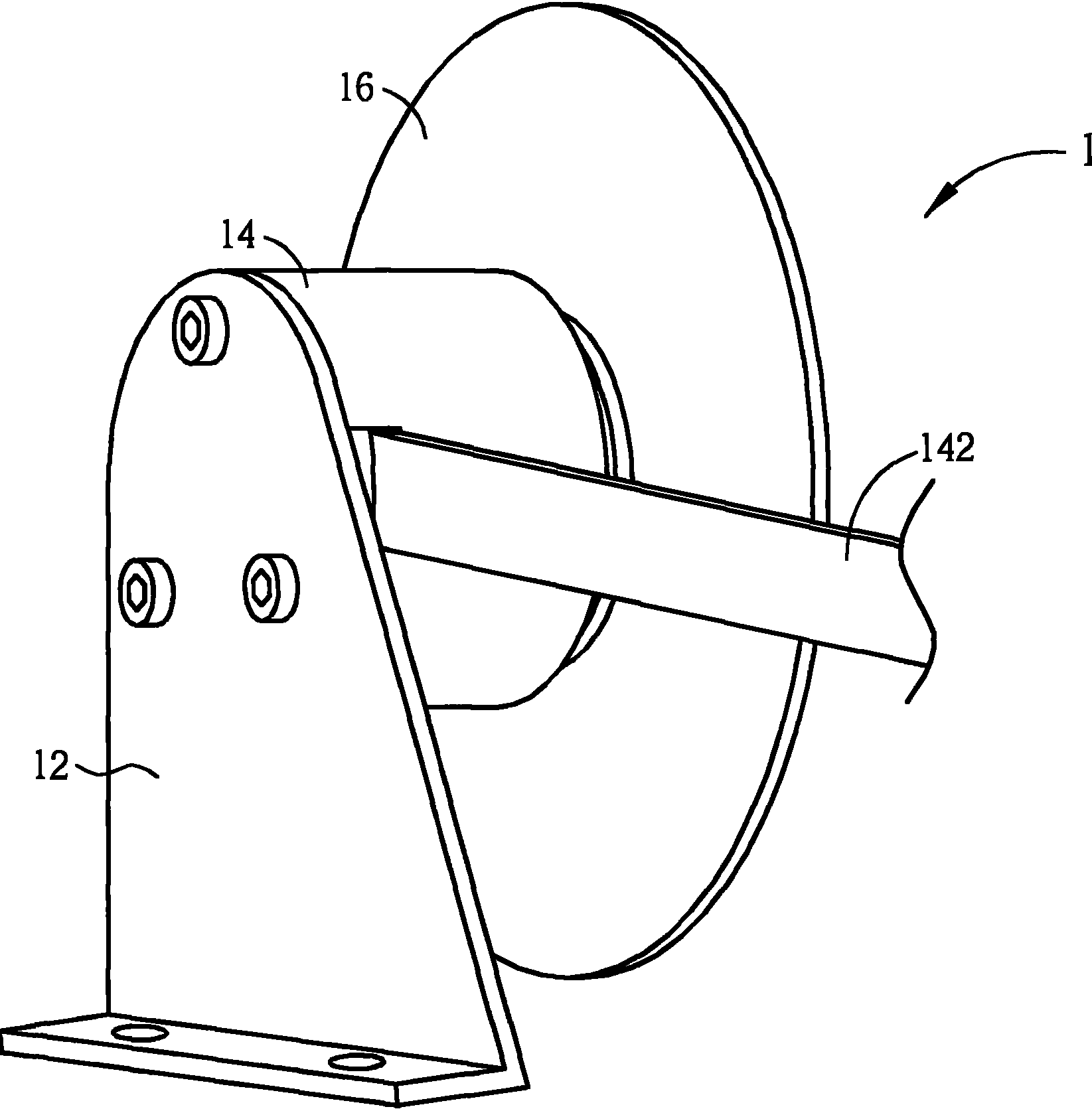

Traction type ocean environment automatic monitoring system driven by wave energy

InactiveCN102384015ARealize energy self-supplyStable long-term continuous operationBatteries circuit arrangementsWaterborne vesselsAutomatic controlEngineering

The invention discloses a traction type ocean environment automatic monitoring system driven by wave energy, which is composed of a sea surface cabin, an oscillation float, a measuring platform, a permanent magnet generator, a direct current tractor, a lead storage battery, an automatic control device, a wireless communication device and the like. The wave energy is converted into electric energyby utilizing the relative motion of the sea surface cabin and the oscillation float. Charging and discharging of the lead storage battery are completed under control of the automatic control device. The automatic control device gives orders to drive the direct current tractor to rotate positively or negatively so as to drive the measuring platform to float upwards and dive downwards circularly. The measuring platform can continuously measure ocean environment parameters during a moving process, and the wireless communication device is utilized for automatically uploading the measured data to a monitoring center on the bank. The traction type ocean environment automatic monitoring system can achieve self energy supplement, accurate control of speed and location of the measuring platform and uploading of the measured data of ocean environment parameters in real time, and has great advantages compared with a traditional ocean environment monitoring device.

Owner:JIMEI UNIV +1

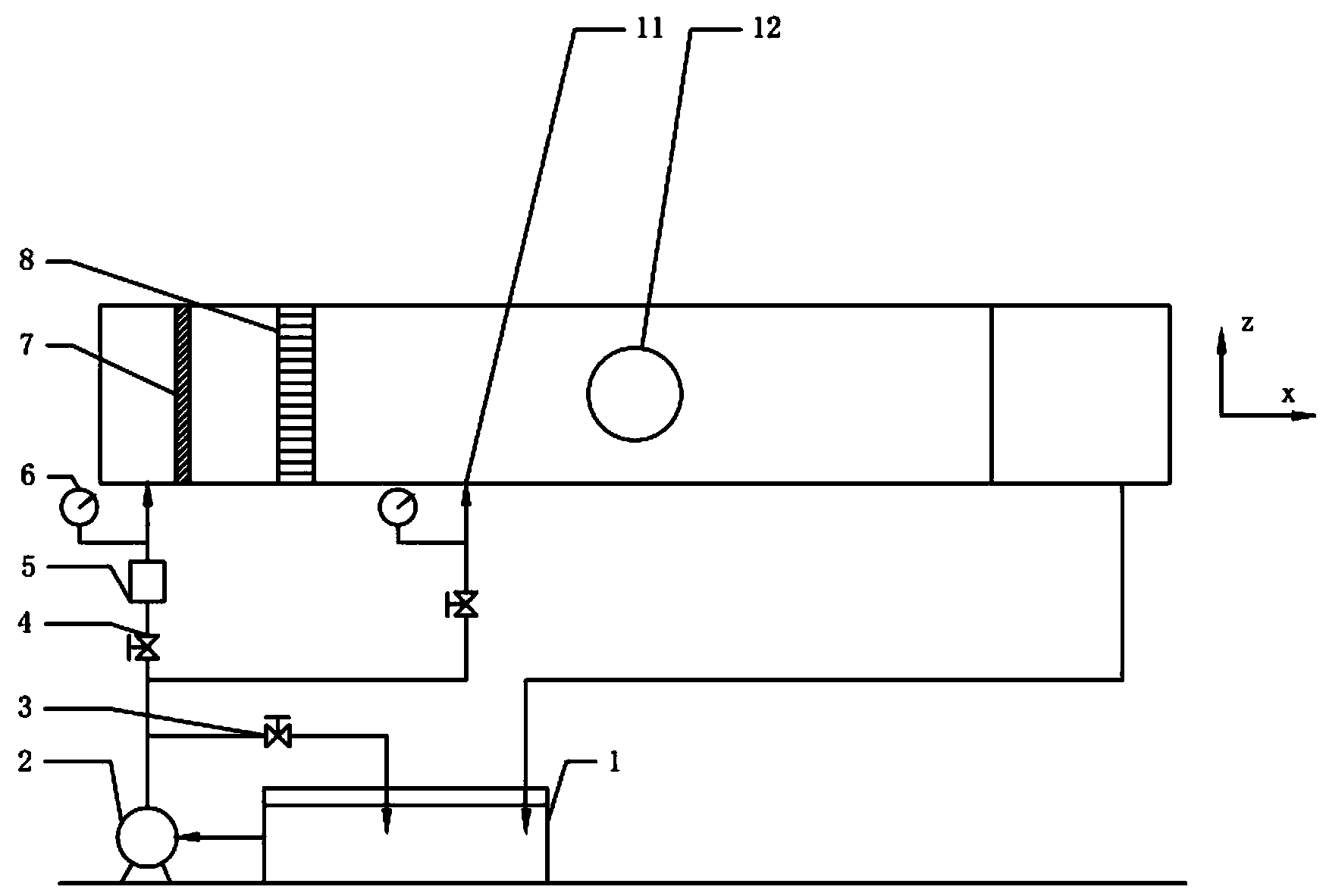

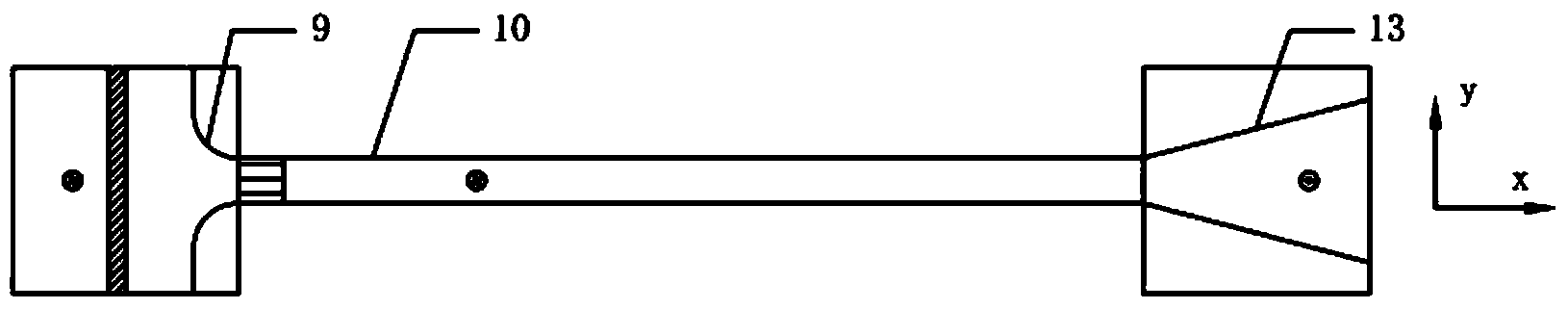

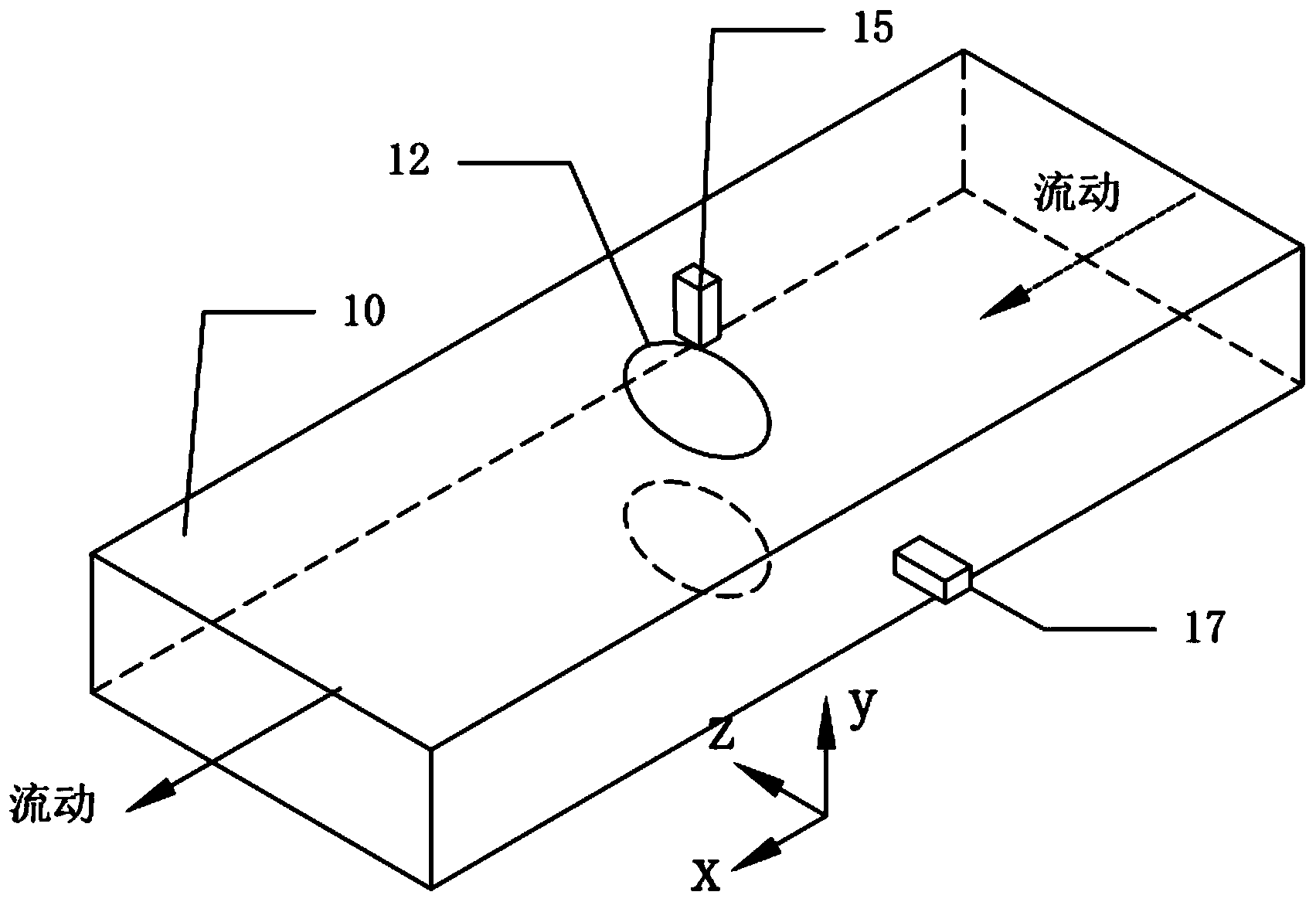

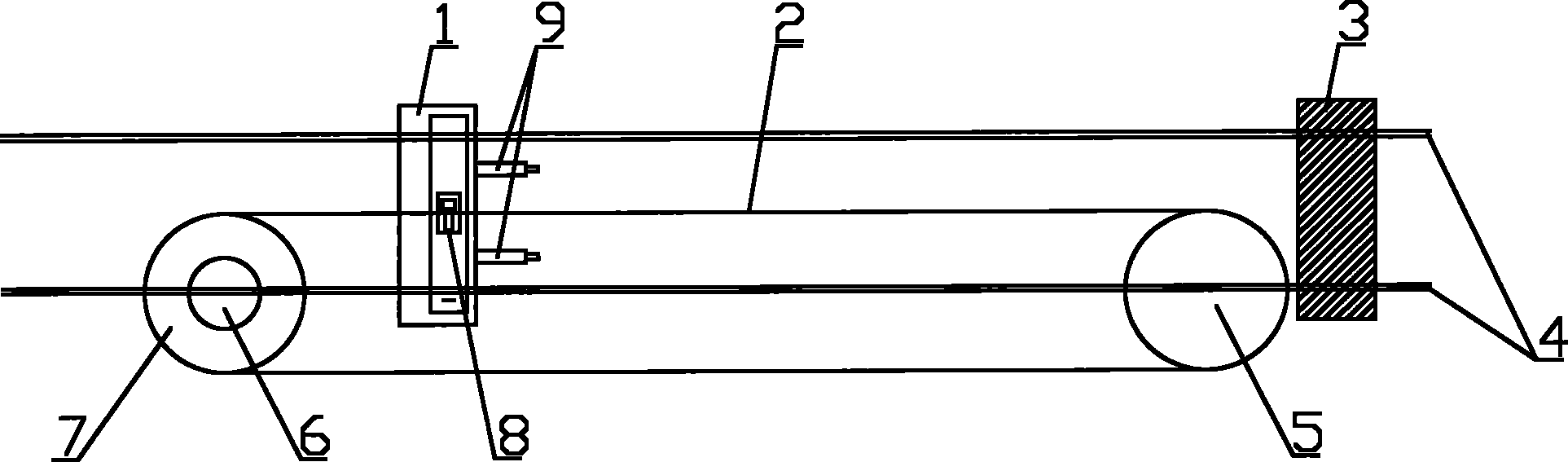

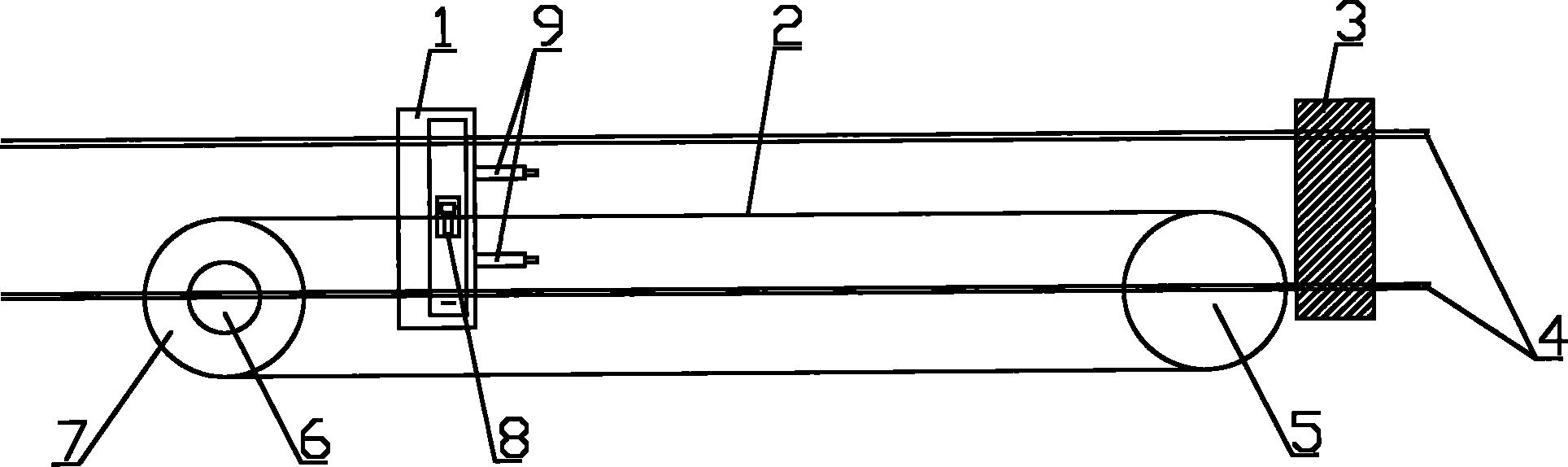

Device for testing jet flow drag reduction effect of two-dimensional plane

The invention aims at providing a device for testing the jet flow drag reduction effect of a two-dimensional plane. The device comprises a water tank, a water pump and a test section, wherein the test section comprises a two-dimensional channel, a two-dimensional channel inlet is arranged at one end of the two-dimensional channel, a two-dimensional channel outlet is arranged at the other end of the two-dimensional channel, the two-dimensional channel inlet is in a gradually reducing shape, the two-dimensional channel outlet is in a gradually expanding shape, a grid type rectifying section is arranged between the two-dimensional channel inlet and the two-dimensional channel, the water pump is communicated with the water tank, the water pump is communicated with the two-dimensional channel inlet through an inlet pipeline, the two-dimensional channel outlet is communicated with the water tank through an outlet pipeline, a speed regulator valve, an electromagnetic flow meter and a pressure meter are arranged on the inlet pipeline, the inlet pipeline is also communicated with a backflow pipeline on which an overflow valve is arranged, and the backflow pipeline is communicated with the water tank. The device has the advantages of low cost, compact structure, small size, convenience in daily maintenance and low noise. The device can be used for testing the drag reduction effect of jet flow surfaces and non-smooth surfaces and can also be used for conventional fluid dynamic tests.

Owner:HARBIN ENG UNIV

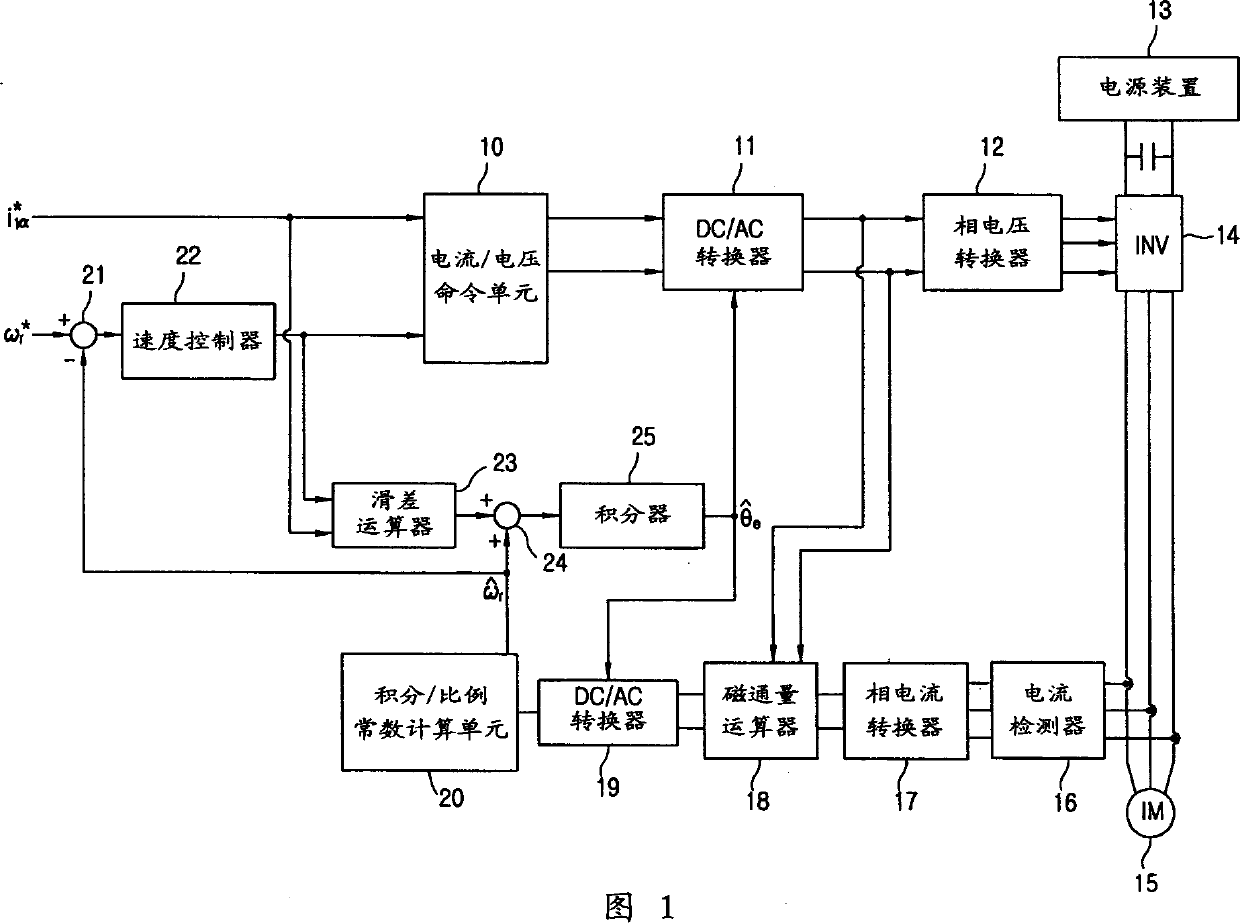

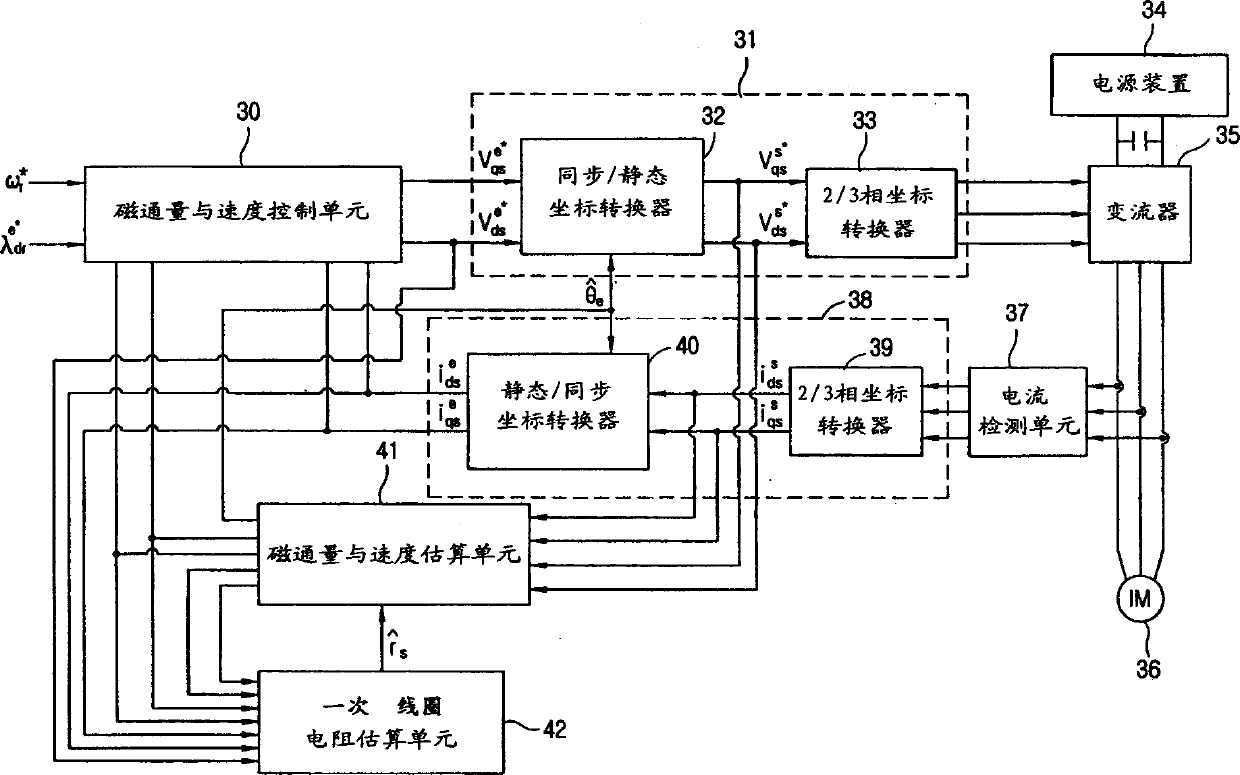

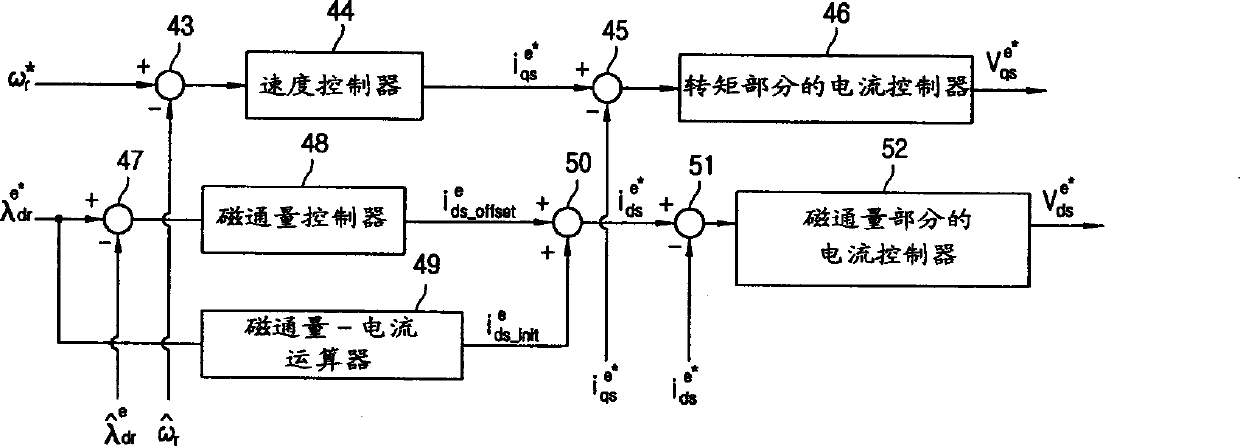

Vector control system without sensor for inductive motor and method

InactiveCN1339871AGuaranteed uptimePrecise speed controlElectronic commutation motor controlElectric motor controlElectrical resistance and conductancePhase currents

A sensorless vector control system of an induction motor includes: a magnetic flux and speed controlling unit for receiving a predetermined command value and generating two phase voltages of DC component; a first reference frame converting unit for converting the two phase voltages of DC component into three phase voltages of AC component; an inverter for receiving the three phase voltages of AC component and driving an induction motor; a current detecting unit for receiving the three phase power of AC component flowing between the inverter and the induction motor, and detecting and outputting three phase currents of AC component; a second reference frame converting unit for receiving the three phase currents of AC component, and converting and outputting two phase currents of DC component; a magnetic flux and speed estimating unit for receiving the two phase voltage of DC component and the two phase currents of DC component, estimating a magnetic flux and speed required for a vector control; and a primary resistance estimating unit for receiving the two phase voltages of DC component, the two phase currents of DC component and the magnetic flux and speed estimated values, estimating a primary resistance.

Owner:LG IND SYST CO LTD

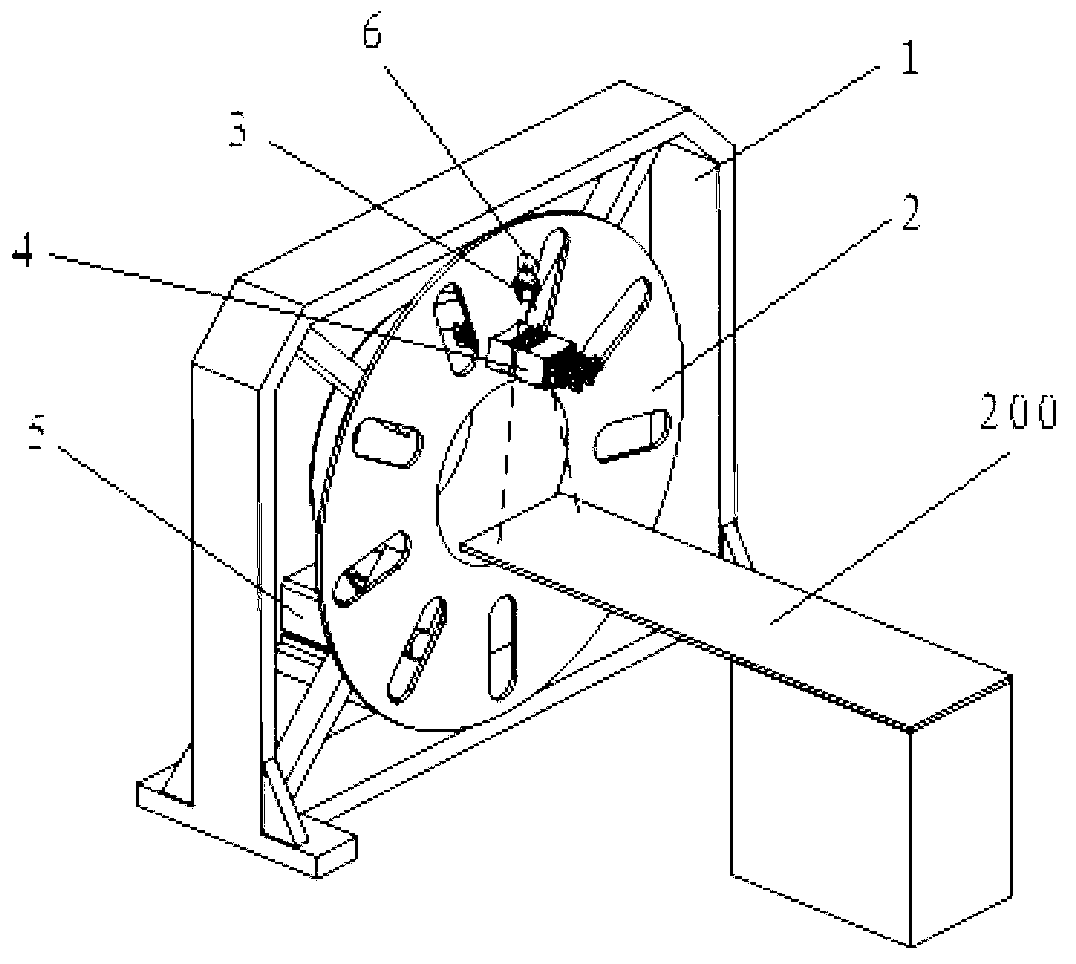

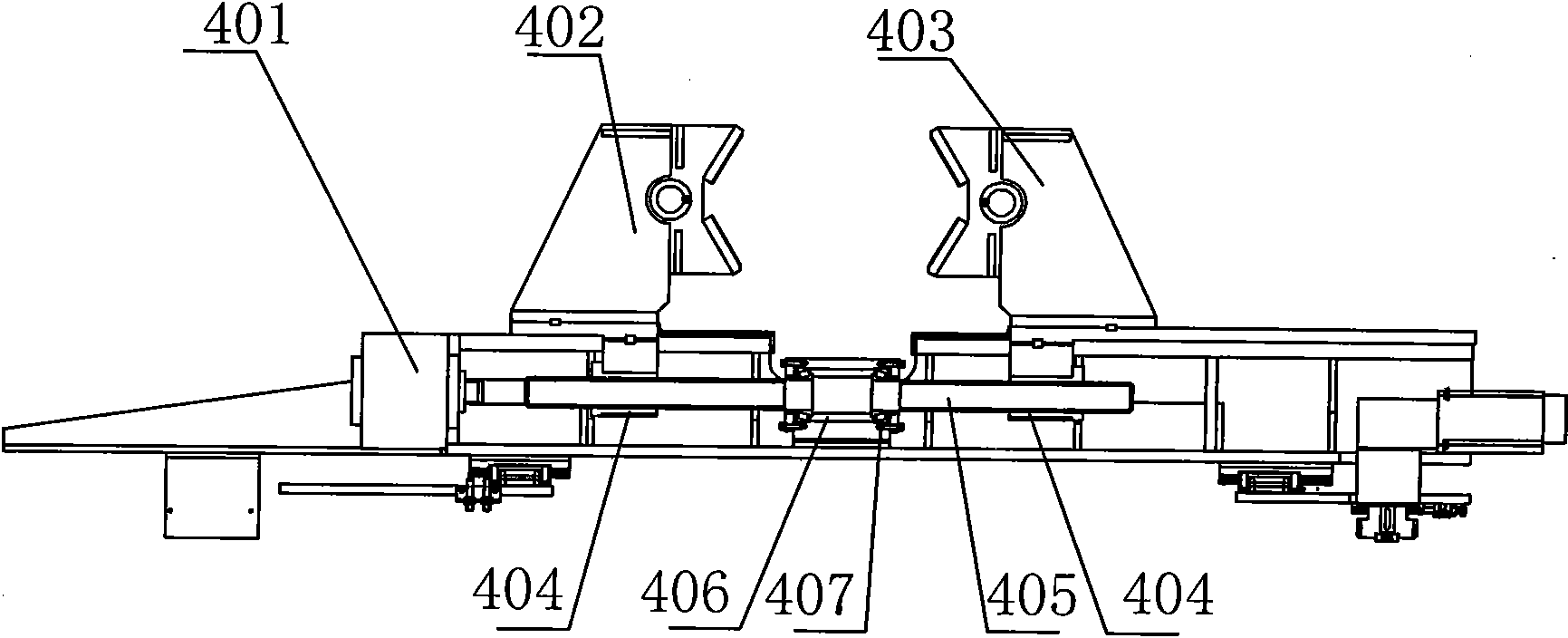

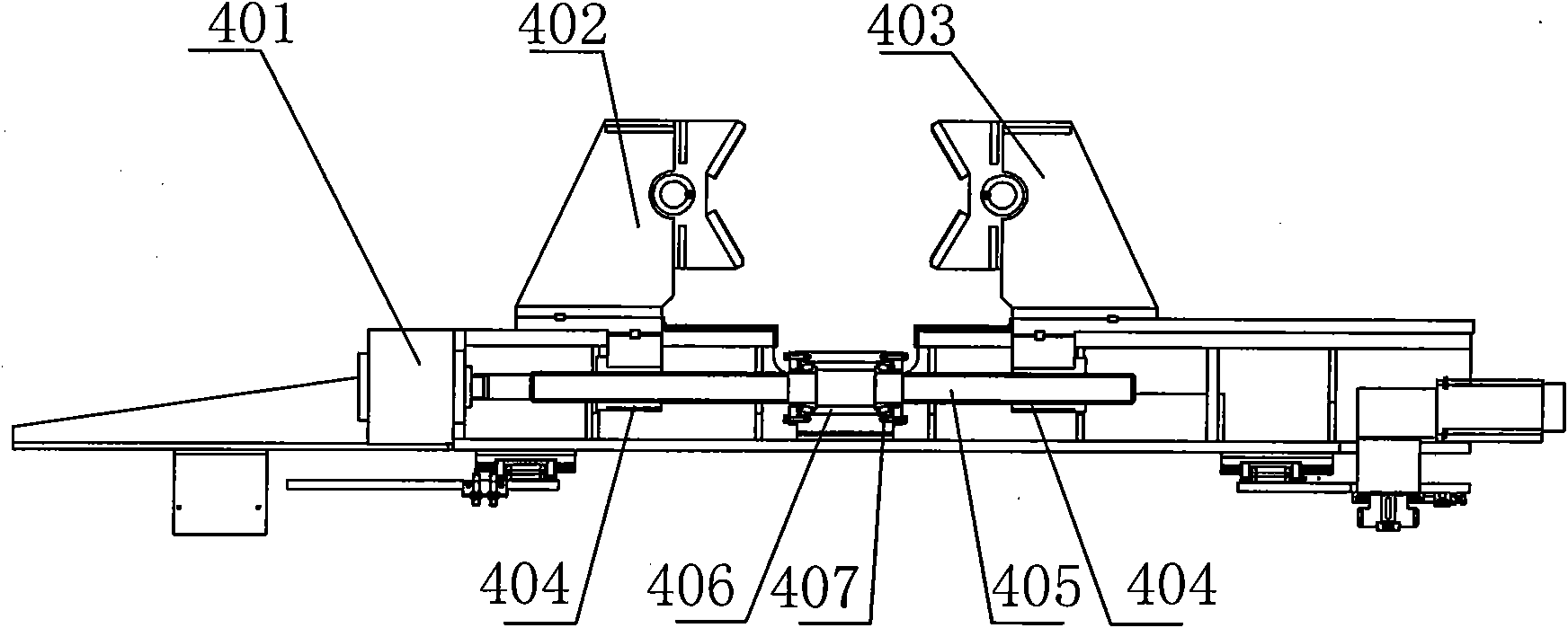

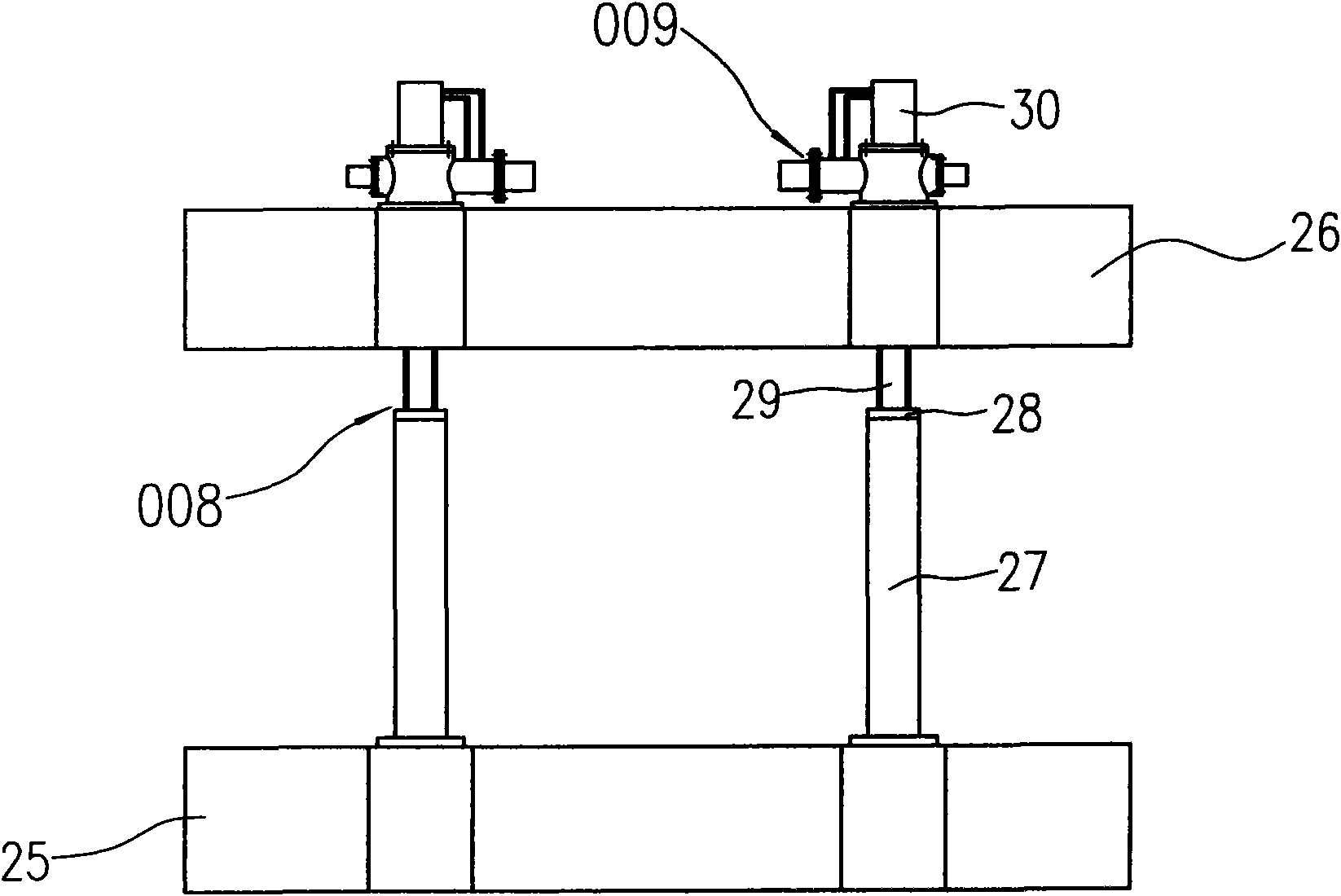

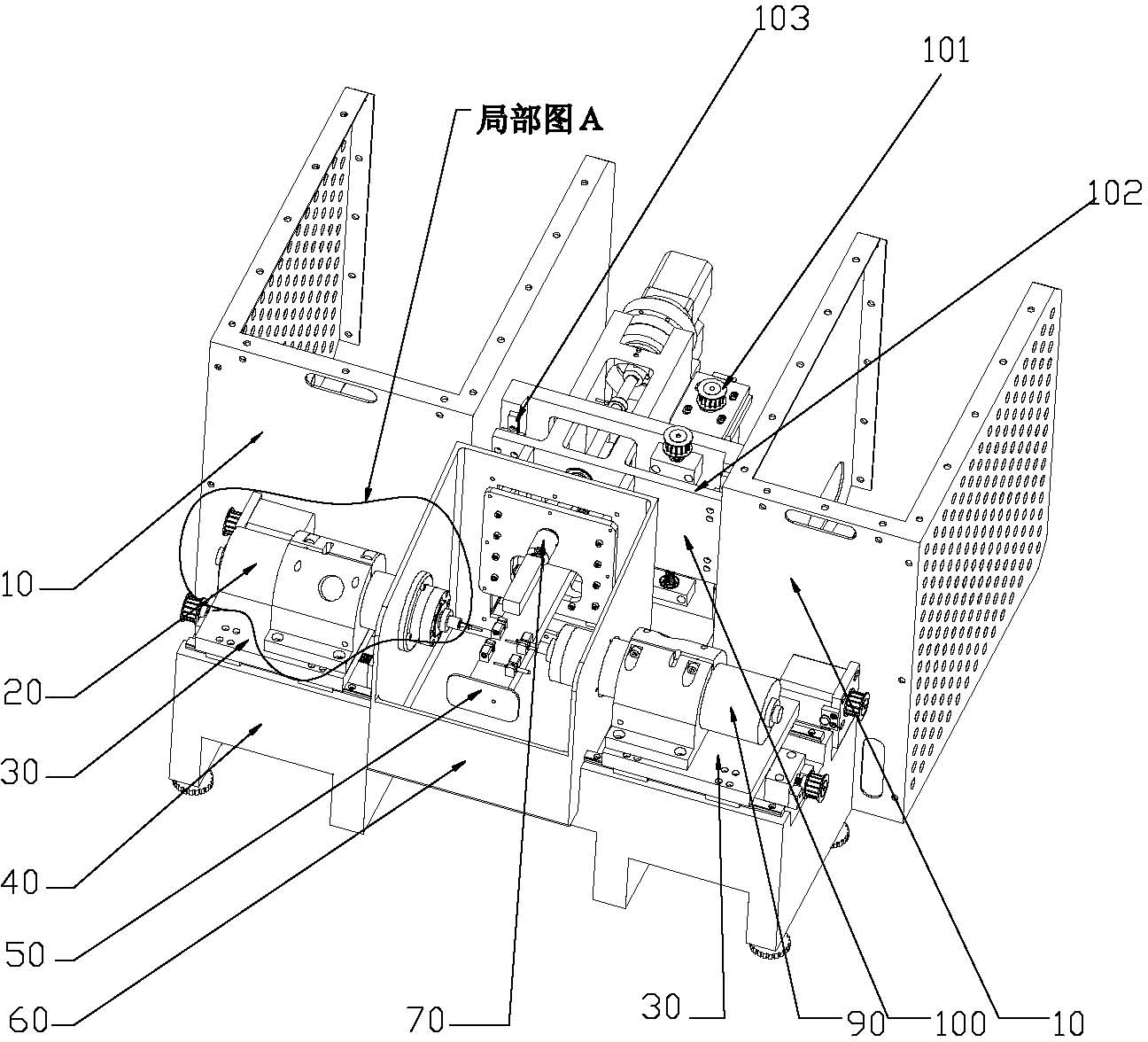

Centering clamping mechanism of CNC (Computerized Numerical Control) drilling machine of pipe fittings

InactiveCN101954600AEffective clampingAvoid shockPositioning apparatusBoring/drilling componentsHydraulic motorNumerical control

The invention relates to a centering clamping mechanism of a CNC (Computerized Numerical Control) drilling machine for pipe fittings, arranged on a drilling platform of the CNC drilling machine. The centering clamping mechanism of the CNC drilling machines for pipe fittings comprises two clamping blocks which are arranged at both sides of the circumference of a pipe fitting and can move along the horizontal diameter direction of the pipe fitting, nuts are arranged at the lower parts of the two clamping blocks and engaged with a positive and negative screw mandrel which has two sections of opposite threads and is supported by the middle of a supporting seat, the supporting seat is fixedly connected with the drilling platform, and a rotating motion driving mechanism is arranged at one end of the positive negative screw mandrel. According to the invention, the positive negative screw mandrel is driven to rotate by adopting a hydraulic motor, the clamping blocks at both sides are driven to simultaneously homodromously or oppositely move and rapidly finish the centering and clamping action to the symmetrical outer walls of a cylinder, a hydraulic motor controls and drives the centering and clamping action through a hydraulic station, the action and the speed can be accurately controlled through a CNC console and the automation requirement with high efficiency is accurately satisfied, and the pipe fitting can be slowly and effectively clamped hydraulically to prevent mechanical clamping from causing impact and damage to the pipe fitting.

Owner:WUXI HUALIAN PRECISION MACHINERY

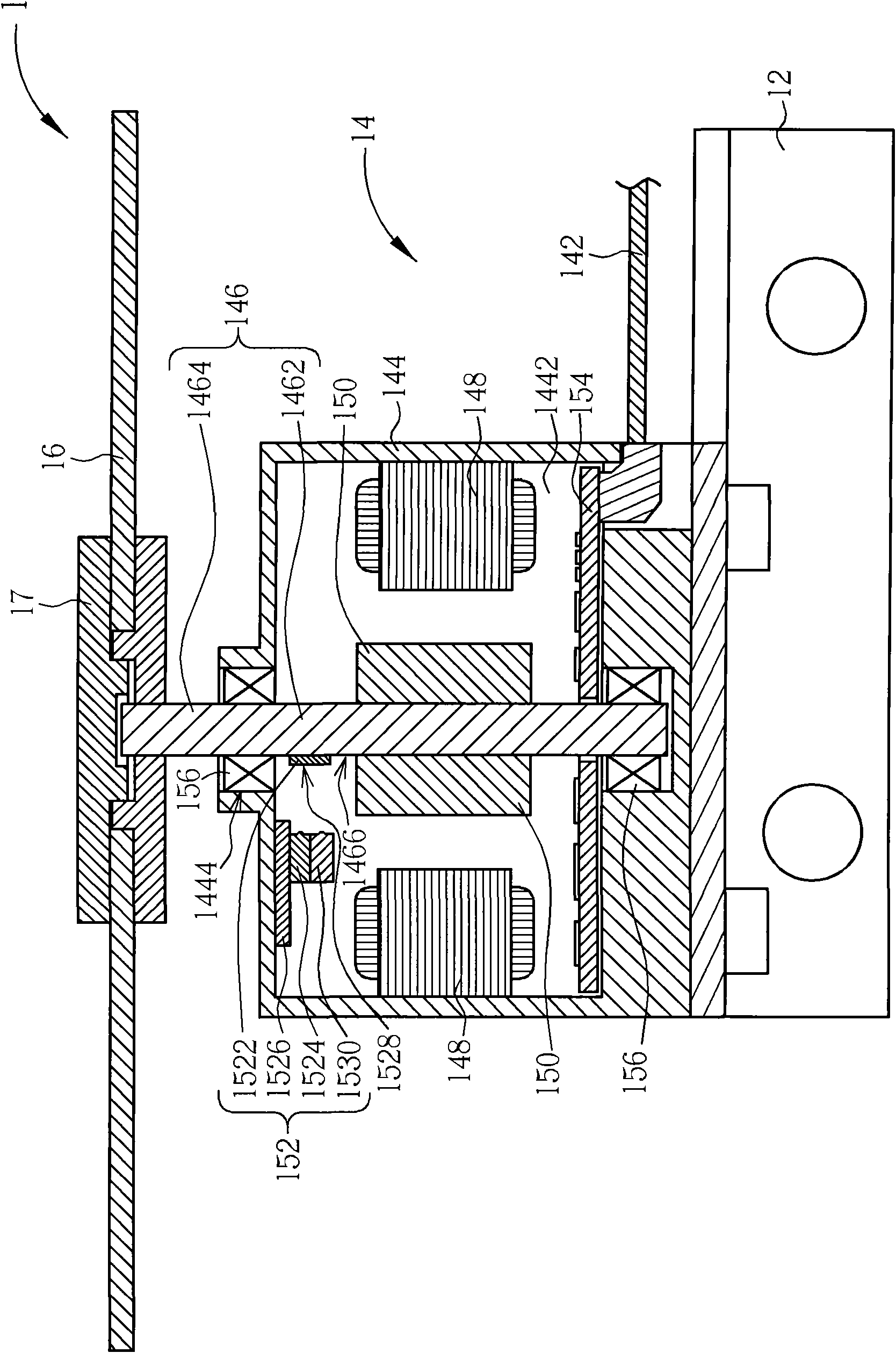

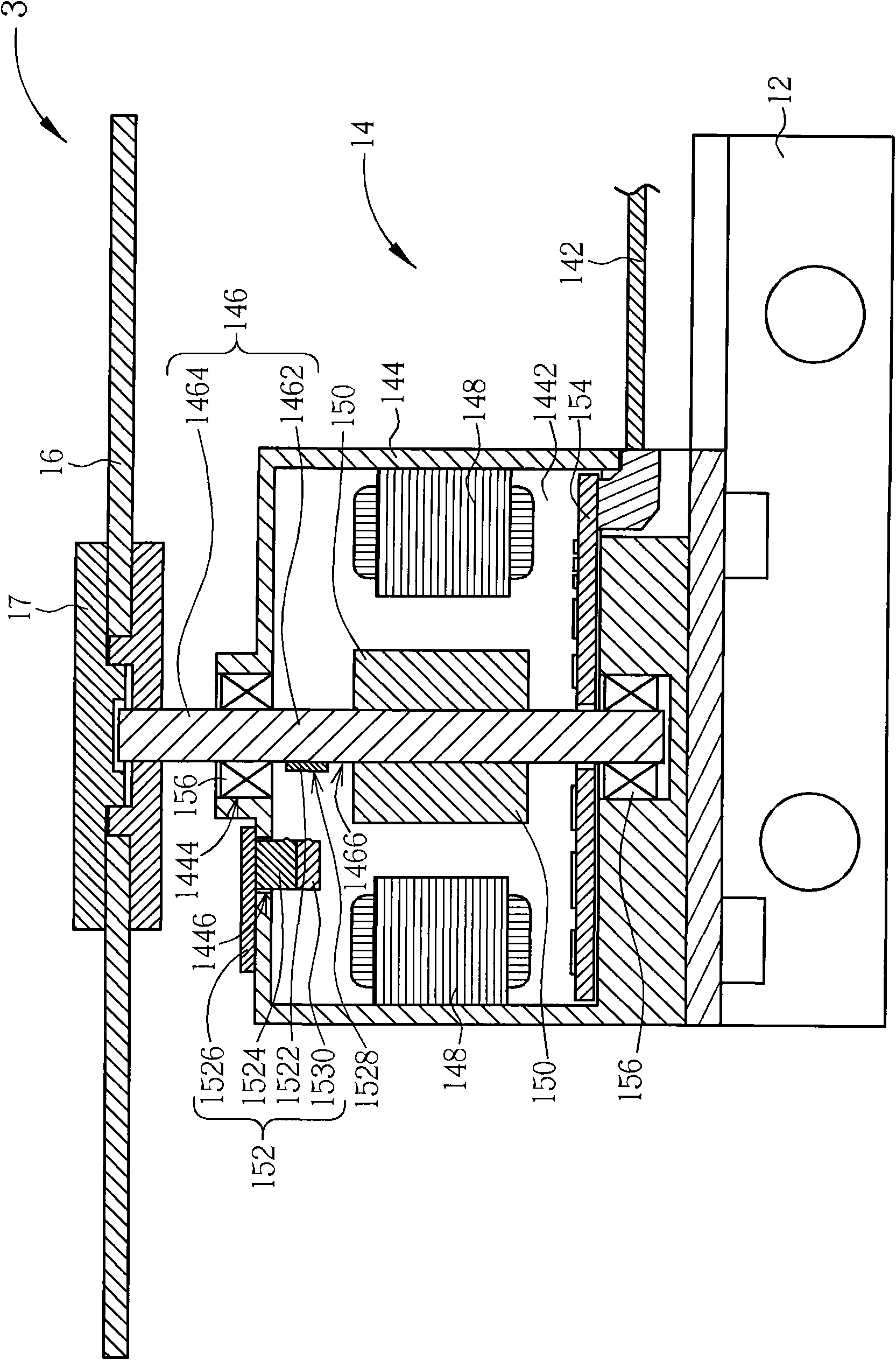

Servo hydraulic transmission mechanism

InactiveCN101839258AAvoid hidden dangers of mechanical failureVersatileServomotor componentsFiltration separationAutomatic controlControl function

Conventional pressure filters generally adopt hydraulic cylinder-driven opening / closing compression mechanisms, and have numerous disadvantages of unreliable multi-cylinder synchronous operation, bad control sensitivity and precision, and the like. The invention proposes an opening / closing compression mechanism driven by a hydraulic cylinder comprising a servo hydraulic valve or by a hydraulic motor in order to realize digital control over position, stroke, speed, pressure and other motion variables and adapt to the work characteristics and need of pressure filters better. The servo hydraulic valve has a hydraulic control valve controlled by a stepping motor, a position sensor and a pressure sensor, and is combined with the hydraulic cylinder or the hydraulic motor as a whole. The mechanism has the advantages of perfect control function, improved sensitivity, precision, work stability and reliability and use convenience. In addition, as a hydraulic system, a motion control system and an electric automatic control system are simplified and less in components, the servo hydraulic transmission mechanism is advanced, reasonable, economical and applicable.

Owner:宋家骏

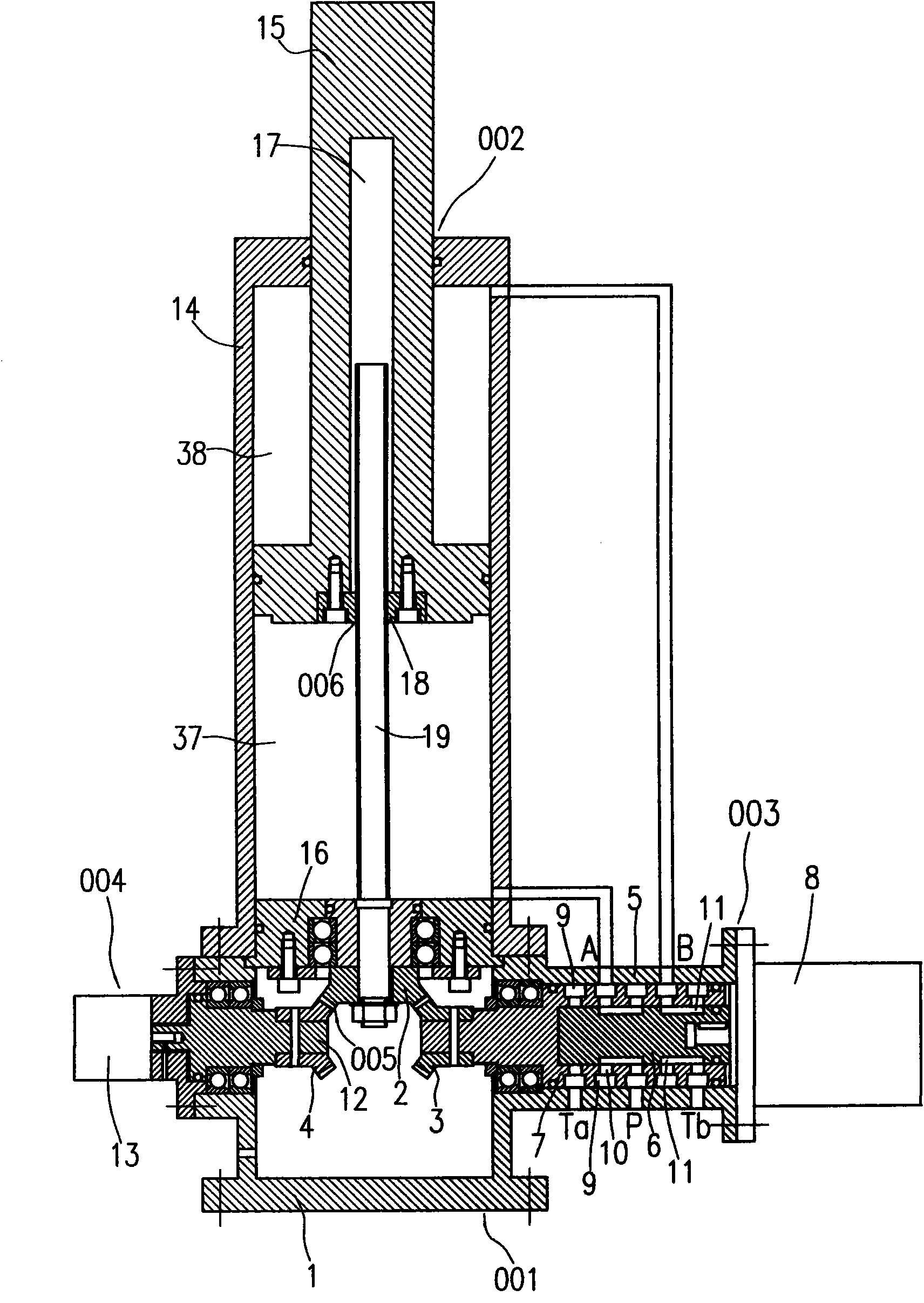

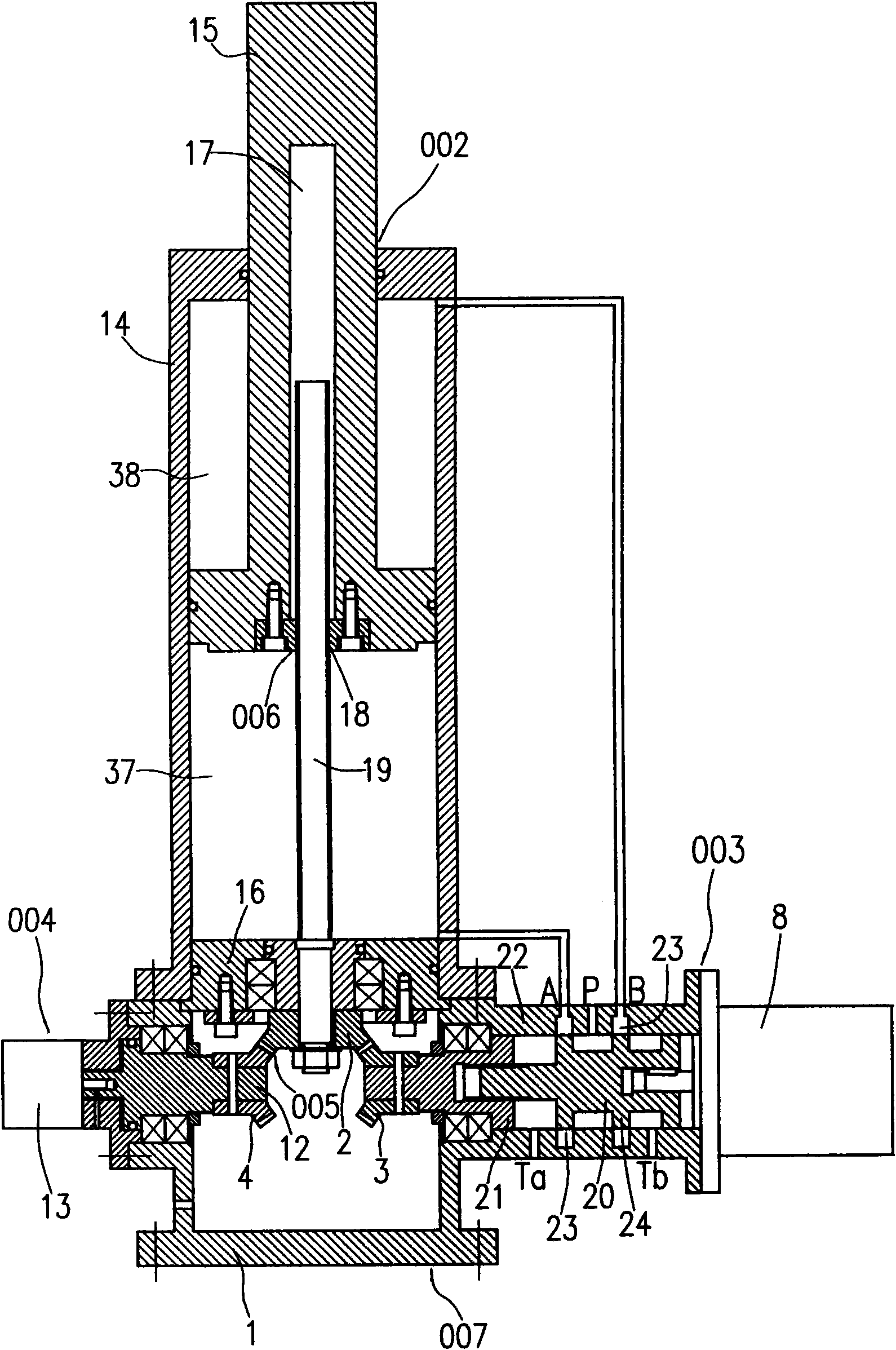

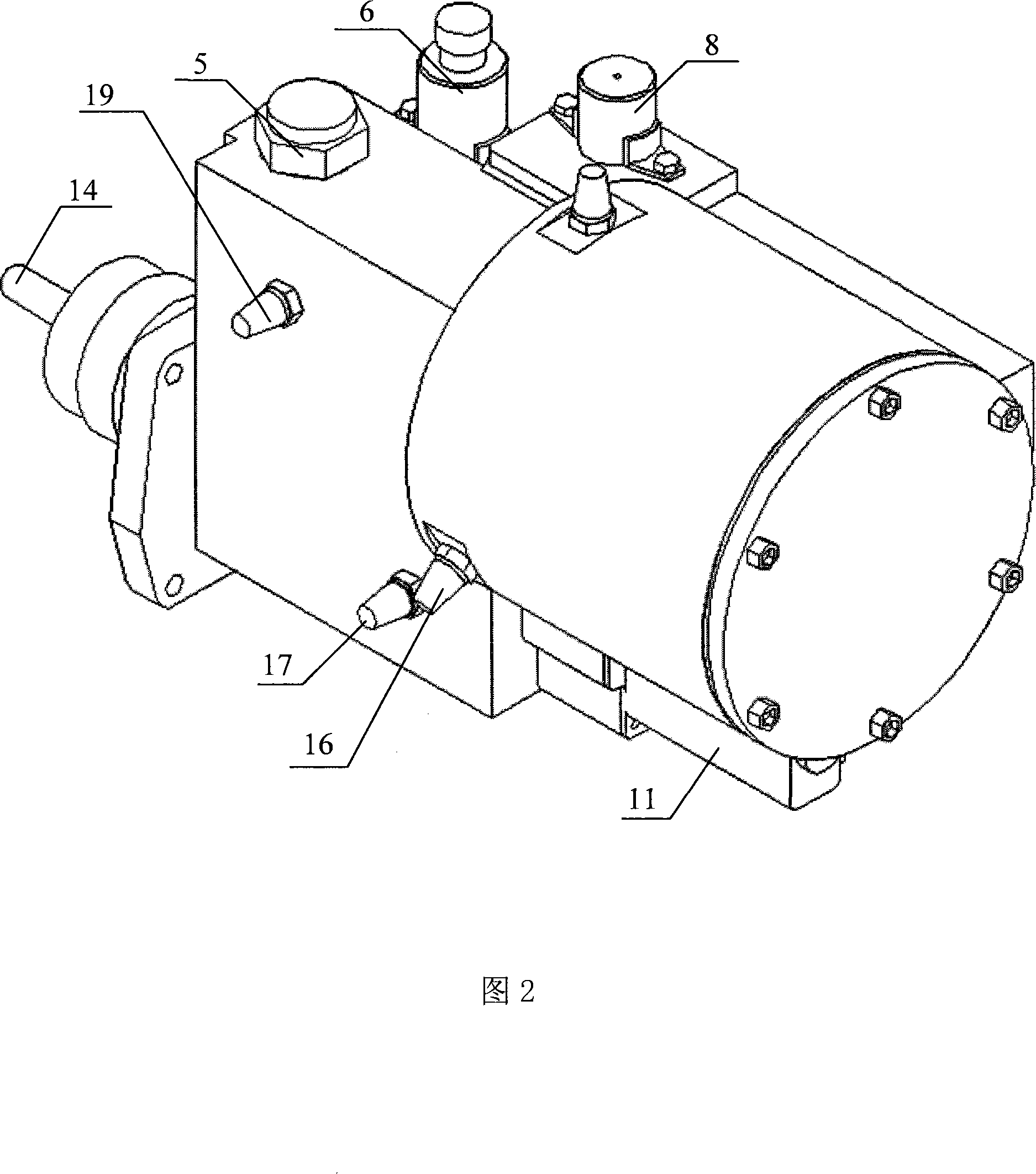

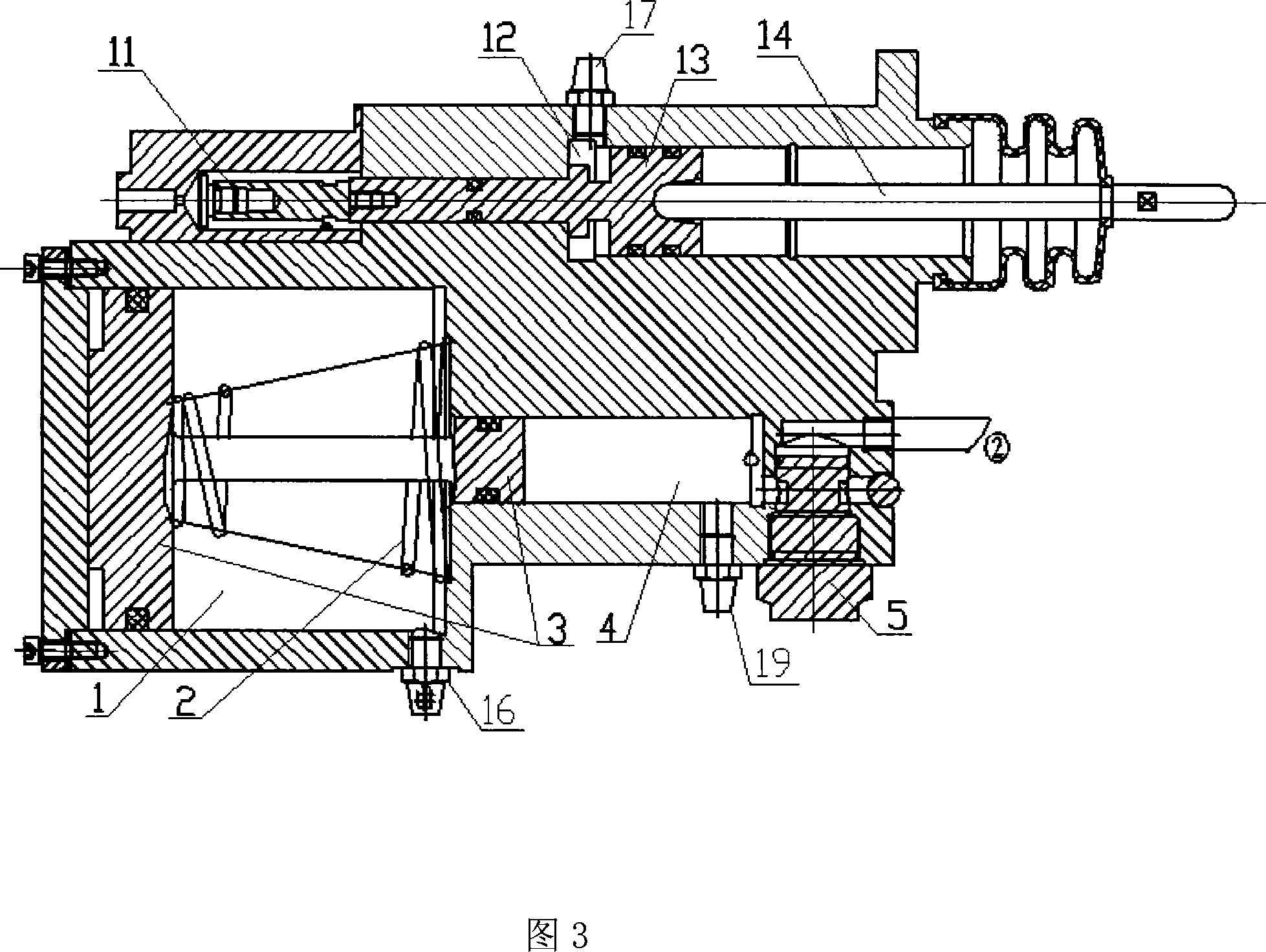

Pneumatic power fluid-control type clutch automatic control device

InactiveCN101158377AOvercome the influence of control accuracyQuick responseClutchesFluid controlAutomatic control

The invention discloses a pneumatic hydraulic control clutch automatic operation device applied to vehicles. The invention aims at overcoming the problems in the prior art of large volume, slow response, low control precision, etc. The device is provided with an automatic control system consisting of a hydraulic control circuit, an air pressure control circuit, a displacement sensor (11) and an electric control unit (10). Two interfaces at one end of the hydraulic control circuit are respectively connected with a through-hole pipeline on the cylinder bottom and the cylinder wall of a transition hydraulic cylinder (4); the interface at the other end is connected with a through-hole pipeline on the cylinder wall of an execution hydraulic cylinder (12). The air pressure control circuit is connected with a through-hole pipeline on the cylinder wall at the left end of a pneumatic cylinder (1). A core rod of a displacement sensor (11) is fixedly connected with a piston rod at the left end of a piston (13). Corresponding wiring ends of the electric control unit (10) are respectively connected with an electromagnet wiring end of a two-position three-way proportion flux valve (6), an electromagnet wiring end of a two-position three-way pneumatic valve (8) and a wiring end wires of the displacement sensor (11).

Owner:JILIN UNIV

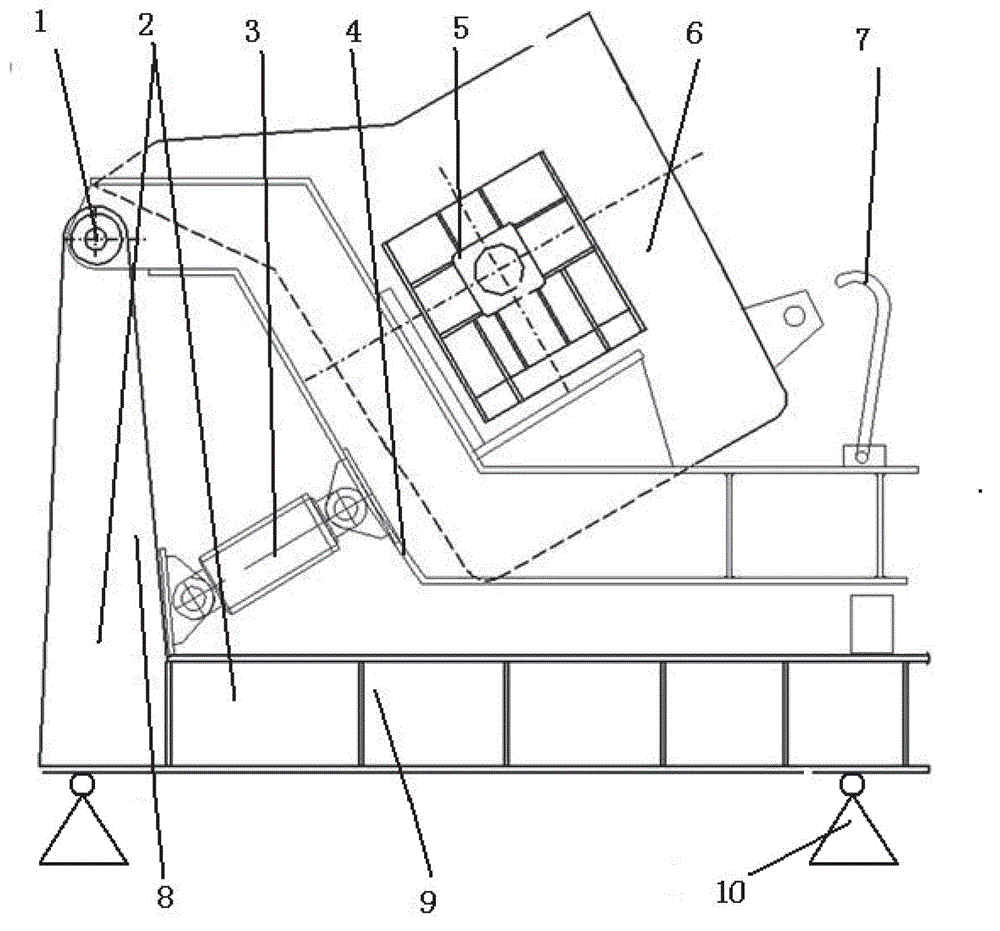

Hot-metal bottle tipping device with weighing

InactiveCN102909361ASmall drop in molten ironLess splashing of molten ironMelt-holding vesselsCasting parameters measurement/indication devicesEngineeringOperation safety

The invention relates to a hot-metal bottle tipping device with weighing, belonging to the technical field of casting. The hot-metal bottle tipping device with weighing comprises a tilting shaft (1), a fixed bracket (2), a tilting hydraulic cylinder (3), a tilting bracket (4), a safety hook (7) and a weighing pressure head (10), wherein the fixed bracket (2) is composed of a tilting shaft bracket (8) and a base (9) and is fixed on a ground foundation or a tipping work platform of a hot-metal bottle (6); the weighing pressure head (10) is positioned below the fixed bracket (2); the safety hook (7) is welded on the tilting bracket (4); and the tilting hydraulic cylinder (3) is arranged below the tilting bracket (4). The hot-metal bottle tipping device has the advantages of being capable of ensuring that an tipping angle of the hot-metal bottle can be more than 90 degrees and preventing the hot-metal bottle from slipping simultaneously, being safe and reliable to operate, and being capable of accurately controlling the casting speed and flow rate of molten iron so as to ensure that the little molten iron is spattered during casting, and the environmental pollution is little, and therefore, the device is suitable for casting work of pig casting machines in metallurgical production enterprises.

Owner:BEIJING SHOUGANG INT ENG TECH

Part collision tester of electric automobile

The invention discloses a part collision tester of an electric automobile, comprising a running track, one end of the running track is provided with a collision barrier, and the running track is used for an automobile model to slide. The automobile model realizes movement through a traction guiding mechanism comprising a driving wheel provided with a motor, a circulating chain and a driven wheel and is provided with an automatic quickening separating device for connecting with the circulating chain, the automatic quickening separating device comprises a cam mechanism, and the high point and the low point of the cam mechanism are connected with clamping fixtures; and the automobile model is also provided with a buffer device. The invention has the advantages of convenient and quick test, accurate speed control and short accelerating stroke and can replace a real automobile to test parts of the automobile so that the test cost is greatly reduced.

Owner:KUNSHAN INNOVATION TESTING INSTR CO LTD

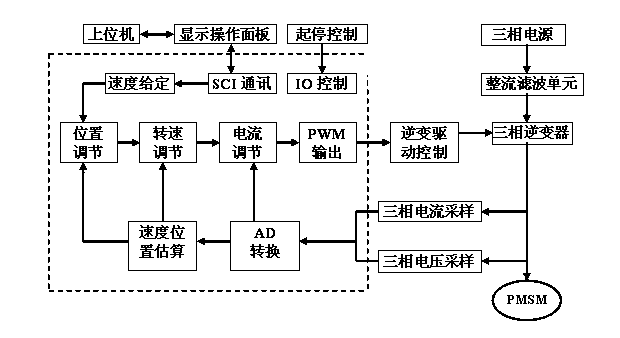

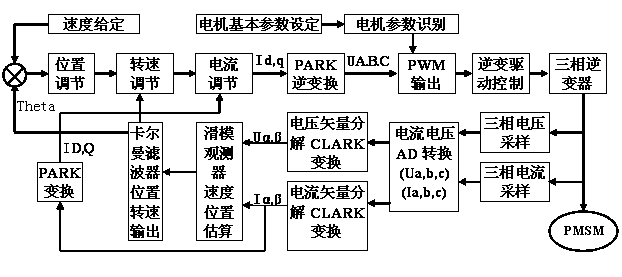

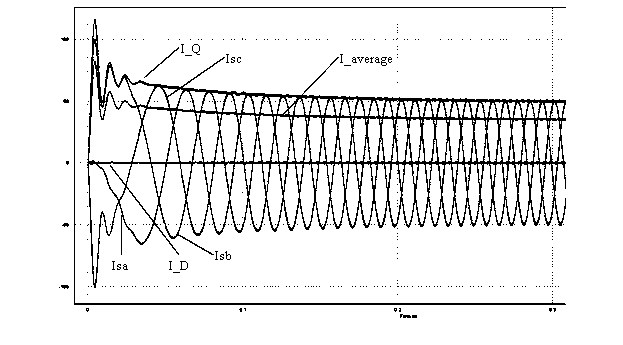

Control system of alternating current servo permanent magnet synchronous motor

InactiveCN103856132AAchieve speed andPrecise speed controlElectronic commutation motor controlVector control systemsControl systemPermanent magnet synchronous motor

The invention discloses a control system of an alternating current servo permanent magnet synchronous motor. The control system comprises a rectification filtering unit, a three-phase inverter, a core computing control unit, an inversion driving control circuit and a communication monitoring control part. The communication monitoring control part is composed of a display operation panel and a starting-stopping control part, the display operation panel is in signal connection with the core computing control unit, the starting-stopping control part is connected with one input end of the core computing control unit, one output end of the core computing control unit is connected with the input end of the inversion driving control circuit, the output end of the inversion driving control circuit is connected with one input end of the three-phase inverter, a three-phase power source is connected with the other input end of the three-phase inverter through the rectification filtering unit, the output end of the three-phase inverter is respectively connected with the input end of a data collecting circuit and the input end of the alternating current servo permanent magnet synchronous motor, and the output end of the data collecting circuit is connected with the other input end of the core computing control unit.

Owner:XINXIANG XIAFENG ELECTRIC LTC

Device and method for measuring hardness of cigarettes and filter sticks

ActiveCN101696921AGuaranteed accuracyImprove stabilityInvestigating material hardnessNational standardEngineering

The invention provides a device and a method for measuring hardness of cigarettes and filter sticks. The device comprises an air-floatation pressing mechanism, a laser displacement measuring head (1) and a control unit, wherein the laser displacement measuring head (1) is positioned above the air-floatation pressing mechanism and is used for measuring respective position values in a prepressing state and a total pressing state; the control unit controls the air-floatation pressing mechanism to execute prepressing or total pressing operation; and the air-floatation pressing mechanism comprises a pressing weight (2), an air-floatation shaft supporting plate (3) and a prepressing weight (5), wherein the center of the pressing weight (2) is provided with a first through hole for laser to pass; the center of the air-floatation shaft supporting plate (3) is provided with a second through hole used for accommodating the prepressing weight (5), and the air-floatation shaft supporting plate (3) is supported under the pressing weight (2) to make the pressing weight (2) keep a preset distance from the prepressing weight (5); and the prepressing weight (5) is separably arranged in the second through hole, and the top of the prepressing weight (5) is fixed with a plug (4) of the laser displacement measuring head (1). The device and the method adopt gravity supported by air floatation for vertical pressing, and the pressing speed, pressing force and pressing time can be accurately controlled according to user requirements in a national standard range.

Owner:BEIJING OMERICA TECH

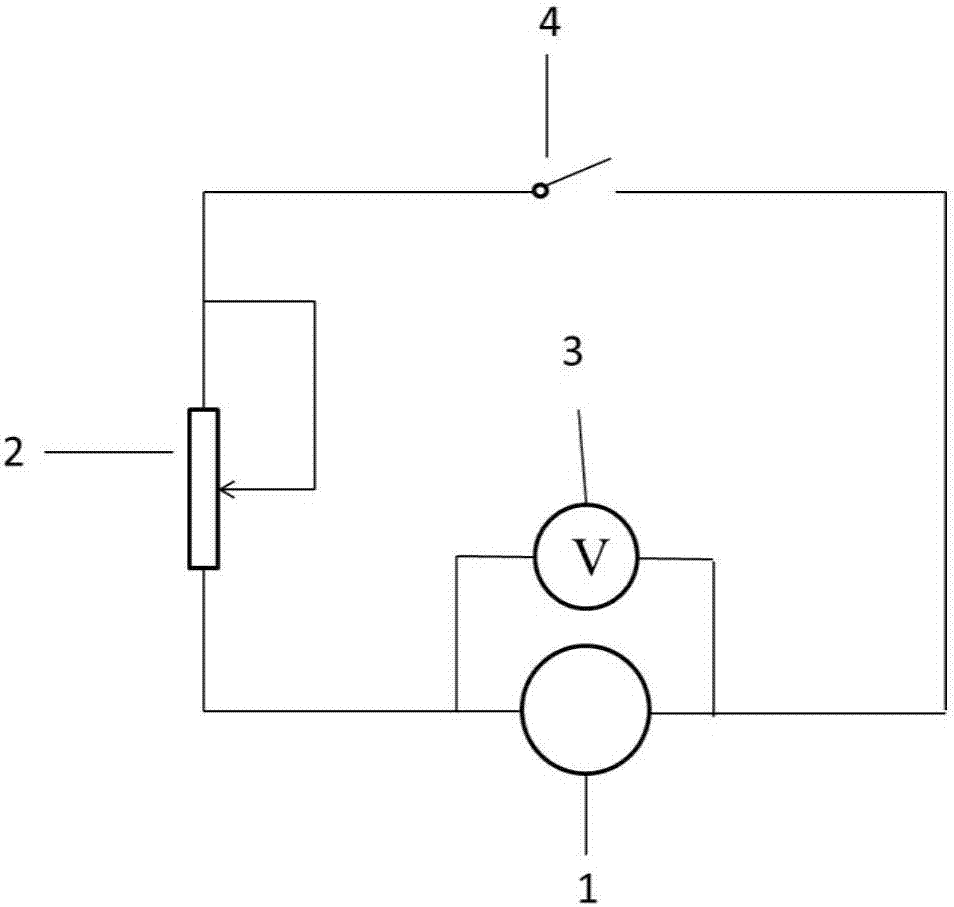

Method for pre-lithiation of cathode pole piece of lithium ion battery

InactiveCN107464919AAvoid consumptionAvoid platingCell electrodesSecondary cells charging/dischargingPolymer electrolytesEngineering

The invention discloses a method for pre-lithiation of a cathode pole piece of a lithium ion battery. The method comprises the step of forming an external short-circuited circuit between the anode and the cathode of a button battery. According to the invention, a solid polymer electrolyte film is formed on a cathode surface in advance in the manner of pre-lithiation, so that the lithium ion consumed in the process of firstly charging the whole battery can be avoided and the first coulombic efficiency of the battery is increased.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Color wheel motor, color wheel module and projection device

ActiveCN102096165AReduce detection impactReduce or block heat dissipation pathwaysProjectorsStructural associationEngineeringColor wheel

The invention discloses a color wheel motor, a color wheel module thereof and a projection device. The motor comprises a shell, a rotor rotation shaft and a position detection module. The shell comprises a sealed containing space and a through hole communicated to the containing space. The rotor rotation shaft comprises a first part arranged in the containing space and a second part protruded to the shell from the through hole. The second part can be provided with the color wheel fixedly. The position detection module comprises a detection material arranged on the first part and a detection element which is arranged on the shell and is capable of detecting the detection material, and the position detection module is used for detecting the rotation position of the rotor rotation shaft. Therefore, the color wheel motor, the color wheel module thereof and the projection device provided by the invention have the advantages that the detection environment with less dust can be provided to the detection module by means of the dust-proof design of shell of the motor, and the influences of dust and particles and the like to the detection can be inhibited effectively.

Owner:BENQ INTELLIGENT TECH SHANGHAICO LTD +1

Intelligent electric rail car traffic network system

ActiveCN101332820APrecise speed controlAvoid traffic accidentsRailway componentsRailway stationTraffic networkTraffic congestion

An intelligent electric rail vehicle traffic network system comprises a control center, a platform and an electric rail vehicle, and works out real time passenger flow transportation data by the operation sub-system of the control center arranged in the control center and forecasts the vehicle flow information of next time, thus being capable of better arranging the vehicle transportation work even if being capable of issuing an emergency traffic leading direction under a situation of traffic jam, besides, the electric rail vehicle and other vehicle meeting processing sub-systems can also carry out detection on the meeting intersection of the electric rail vehicle, thus completely avoiding a meeting accident from happening and greatly improving the running safety. Besides, the carriage of the electric rail vehicle is in a three-layer design without runways; each layer is not communicated either, thus having a high space utilization rate without waste, thereby greatly increasing the load of the passengers; besides, each row of seats of each layer at the two sides of the electric rail vehicle is correspondingly provided with a door; therefore, the passengers can easily get on and off the vehicle without a crowding situation. Besides, the platform consists of a left platform and a right platform, the passengers of each layer get on and off the vehicle according to the same direction that is preset, the order is improved greatly as well; besides, the platform of each layer is provided with a display screen which is used for displaying the number, the empty seats of the carriage and the positions of the empty seats of the electric trail vehicle entering the station, and the like, the passengers can select the seats according to demands and stand on the corresponding platform for waiting, thus being very convenient.

Owner:陈笠

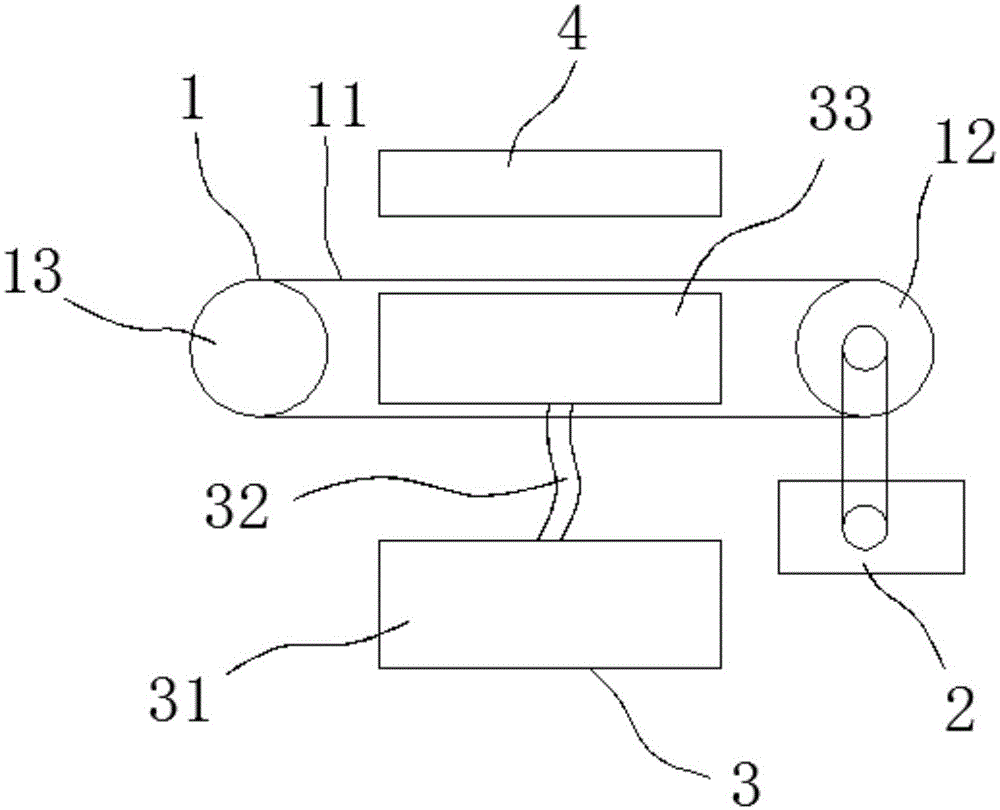

Paper feeding device capable of conducting two-way paper flattening

InactiveCN105059988ANot easy to warpImprove printing qualityWebs handlingDrive wheelPulp and paper industry

The invention relates to a paper feeding device capable of conducting two-way paper flattening. The paper feeding device comprises a paper transmission device, a drive device, a negative pressure device and an air blowing device. The paper transmission device comprises a conveyor belt, a first drive wheel and a second drive wheel. The conveyor belt surrounds the first drive wheel and the second drive wheel. The first drive wheel and the second drive wheel drive the conveyor belt to rotate. The drive device is arranged on one side of the first drive wheel. An output shaft of the drive device is linked with the first drive wheel. The negative pressure device comprises a negative pressure draught fan, a negative pressure pipeline and a negative pressure port. The suction opening of the negative pressure draught fan is communicated with one end of the negative pressure pipeline. The other end of the negative pressure pipeline is communicated with the negative pressure port. The negative pressure port is fixedly arranged on the inner side of the conveyor belt. The opening of the negative pressure port is upwards. A plurality of vent holes are formed in the conveyor belt. The air blowing device is arranged above the conveyor belt. The air blowing opening of the air blowing device is downwards. As paper is flattened through air blowing and negative pressure, the paper can be laid on the conveyor belt more flatly, and the printing quality can be improved.

Owner:桂林威迈壁纸有限公司

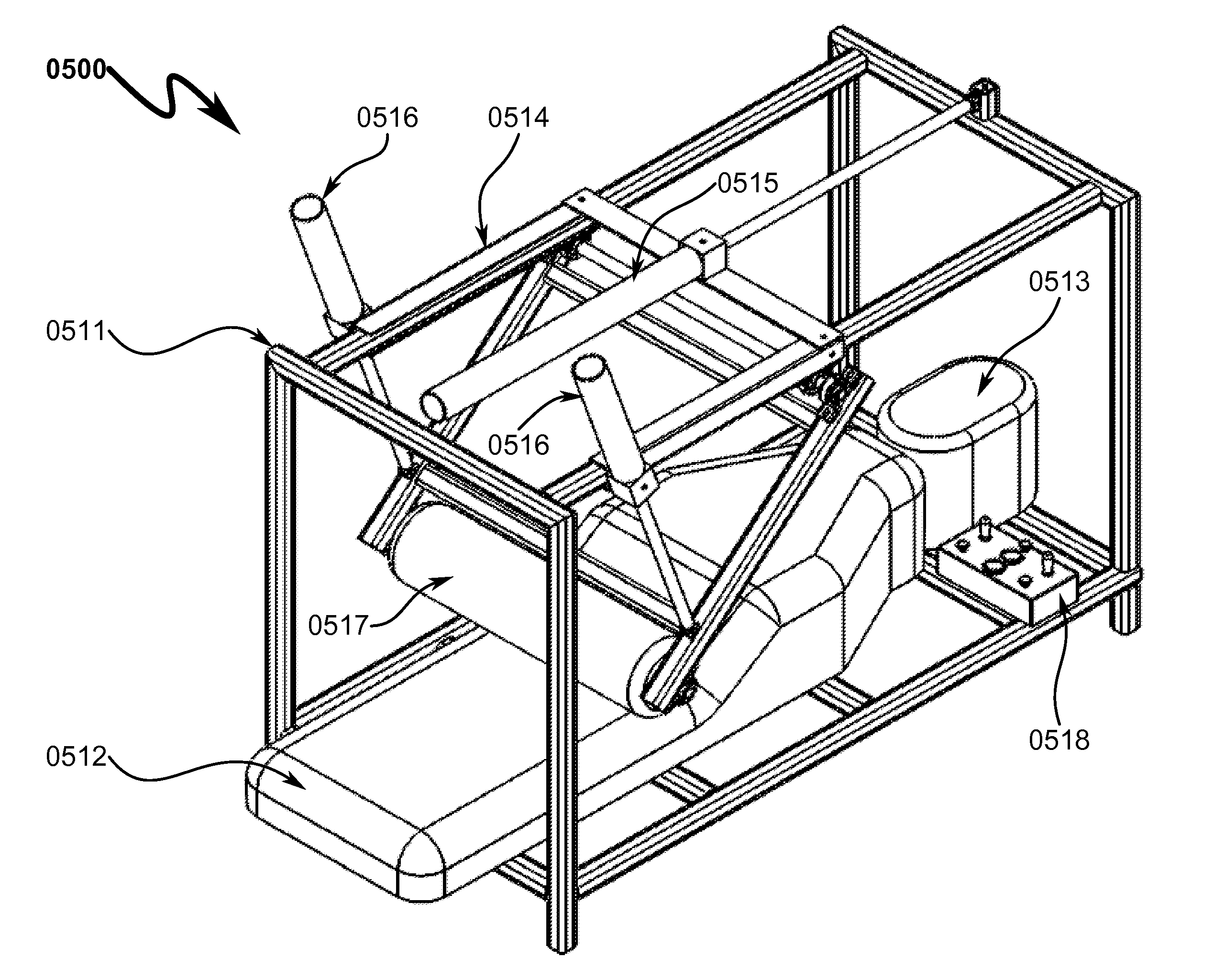

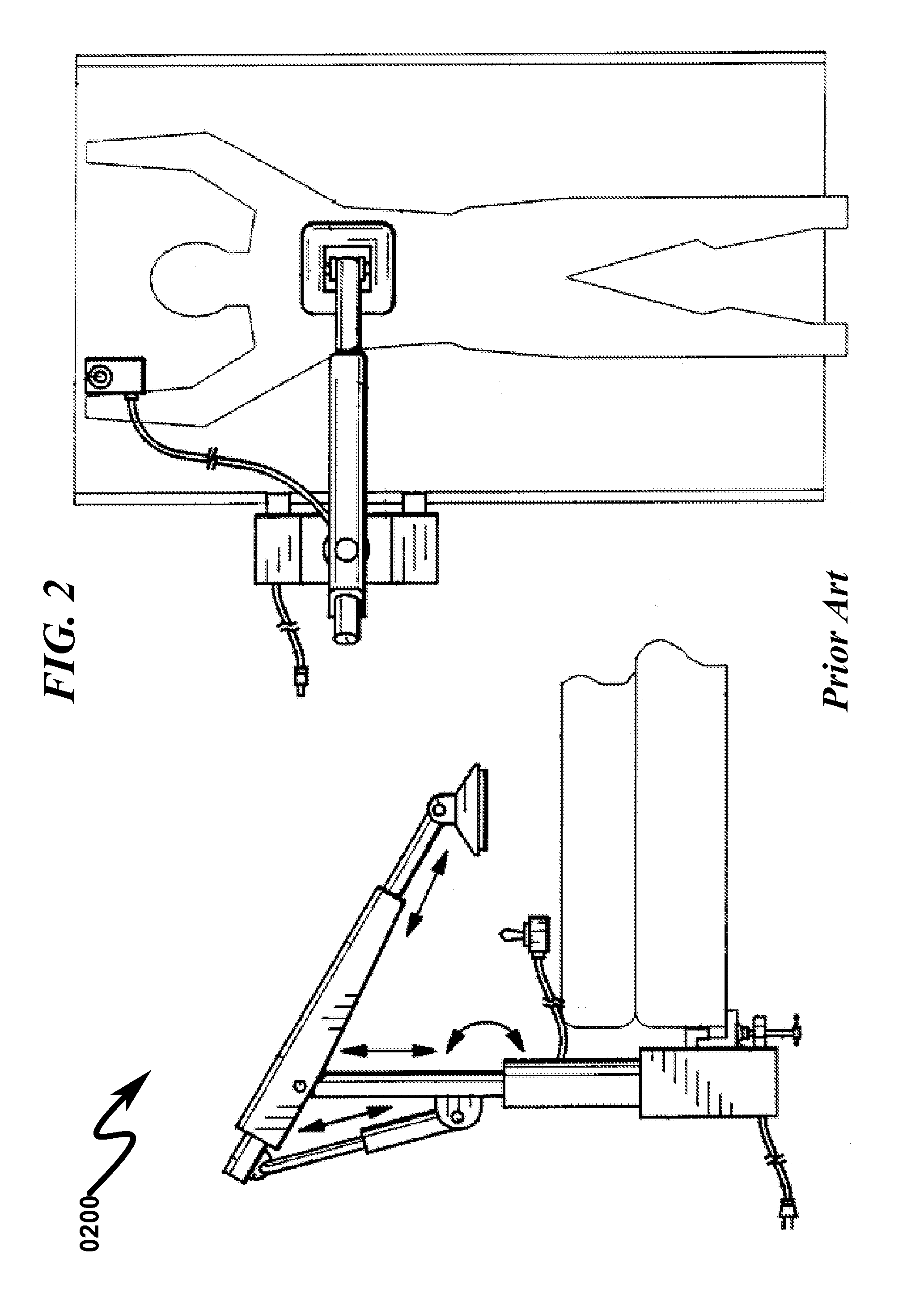

Massage Table System and Method

InactiveUS20150305967A1Precise horizontal placement speed controlPrecise speed controlRoller massageBody contactMassage

A massage table system / method allowing self-application of adjustable compression and stretching is disclosed. The system incorporates a frame support structure (FSS) horizontally supporting a patient support table (PST) and patient face cradle (PFC) permitting a massage patient to receive adjustable massage from a body contact assembly (BCA) positioned using a horizontal slide assembly (HSA) under pneumatic control of a horizontal cylinder assembly (HCA). The patient is massaged via a patient massage roller (PMR) radially articulated by the BCA in response to pneumatic pressure applied by a vertical cylinder assembly (VCA) while the BCA is positioned longitudinally over the patient by the HSA. A control interface box (CIB) provides adjustment of HSA travel speed, position, and applied pressure to the PMR by the VCA. Computer controls within the CIB may permit automated patient massage procedures by pre-programmed / memorized operation of pneumatic valves controlling the HSA and BCA.

Owner:ONEAL COLBY HARPER

Testing device and testing method for measuring road surface friction attenuation rate of snow-melting agent under low-temperature environment

ActiveCN105823725AThe test results are meaningfulSignificance of test resultsUsing mechanical meansMaterial analysisUltrasound attenuationSnow melting

The invention provides a testing device and testing method for measuring the road surface friction attenuation rate of a snow-melting agent under the low-temperature environment .The testing device is composed of a testing box and a road surface friction coefficient measuring device .The road surface friction attenuation rate of the snow-melting agent under the low-temperature environment is measured by building a road surface testing table and controlling the temperature in the testing box .The testing device is used in the testing method .The method includes the three steps of test preparation, measurement and result sorting .Testing results obtained through the testing device and the testing method are accurate, stable and reliable and can truly reflect changes of anti-slip performance of a road surface after the snow-melting agent is used, advantages are remarkable, and the preferential road snow-melting agent plays an important role in improving road driving safety and reducing traffic accidents.

Owner:SHANDONG JIAOTONG UNIV

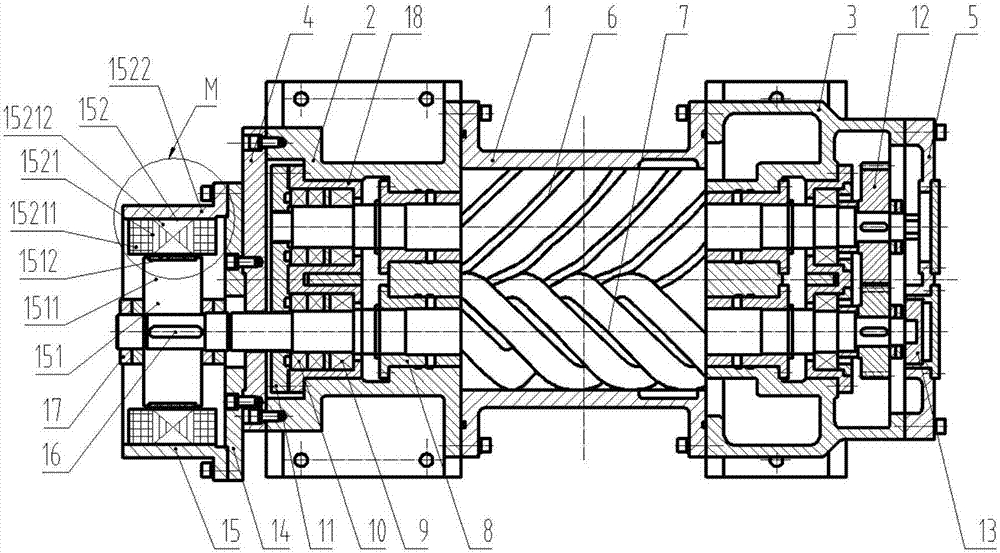

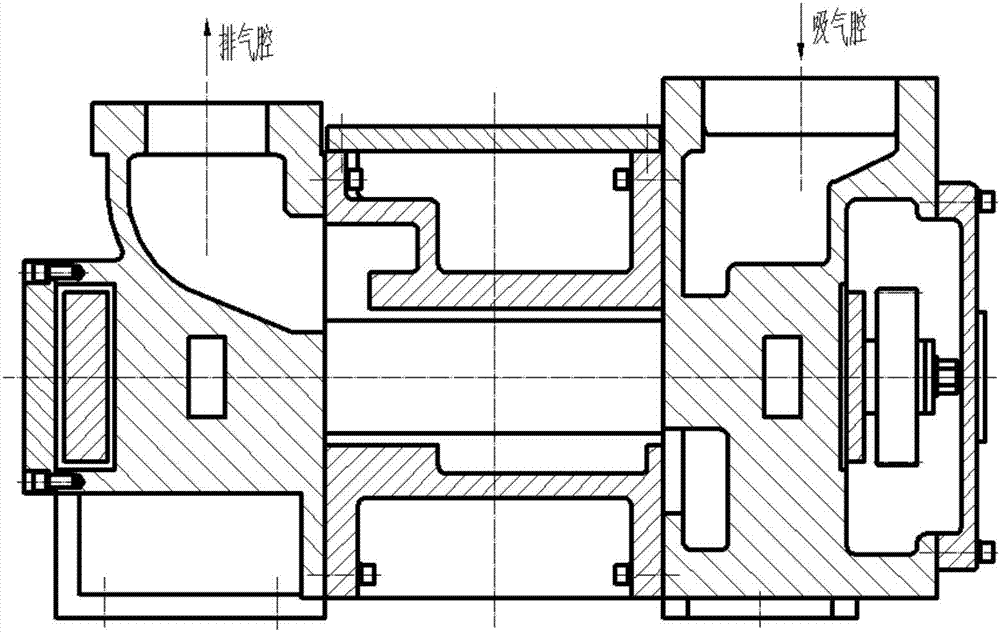

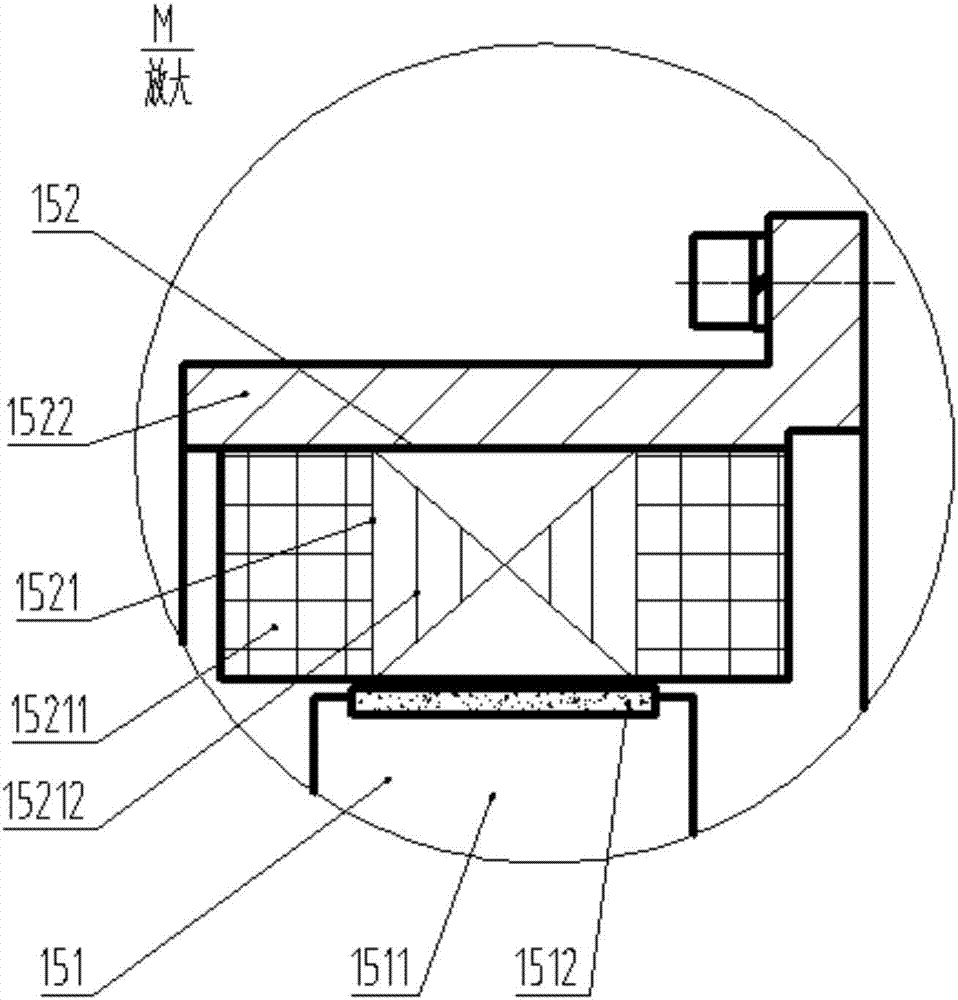

Screw compressor directly driven by frameless permanent magnet synchronous motor

InactiveCN106939888AImprove transmission efficiencySimple structureRotary/oscillating piston combinations for elastic fluidsPump componentsLow noiseThrust bearing

The invention discloses a screw compressor directly driven by a frameless permanent magnet synchronous motor. The suction end cover is installed on the suction end seat; the bearings include four upper and lower thrust bearings arranged in the exhaust end seat, two upper and lower radial bearings arranged in the exhaust end seat and suction There are two upper and lower radial bearings in the air end seat; there are bearing seats between the suction end seat and the exhaust end seat and the bearings; the female rotor and the male rotor are arranged in the body, and the female rotor and the male rotor are provided with A mechanical seal, a shaft end gland and a synchronous gear, balance discs, motor plates and a frameless permanent magnet synchronous motor are arranged at both ends of the male rotor, and the frameless permanent magnet synchronous motor includes a flywheel rotor and a stator assembly. The invention has the beneficial effects of simple structure, convenient maintenance, low noise, low energy consumption, time saving and high efficiency, high degree of automation and more precise control precision.

Owner:湖北富升科技有限公司

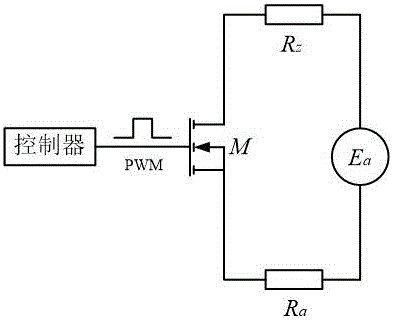

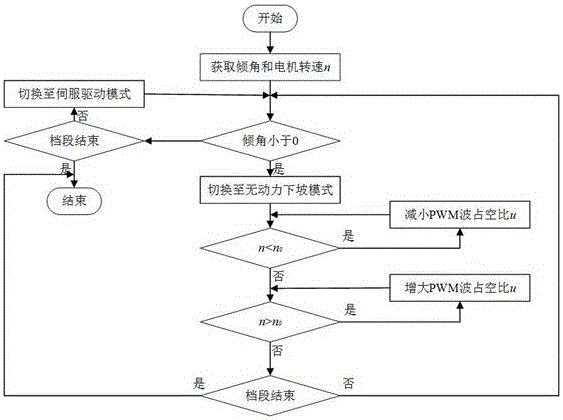

Control method for unpowered descending speed

InactiveCN106160620AAchieve speed controlPrecise speed controlAC motor accelaration/decelaration controlEngineeringControl theory

The invention discloses a control method for an unpowered descending speed of a patrol robot. According to the method, a pulse width modulation method is applied to dynamic braking and the unpowered descending speed of the patrol robot is controlled by changing the PWM wave duty cycle of the control circuit. According to the speed control method, the control on unpowered descending speed of robot can be accurately realized, the running safety of the robot in unpowered descending process can be ensured and basis is laid for the further implementation of a recycling method for unpowered energy.

Owner:WUHAN UNIV

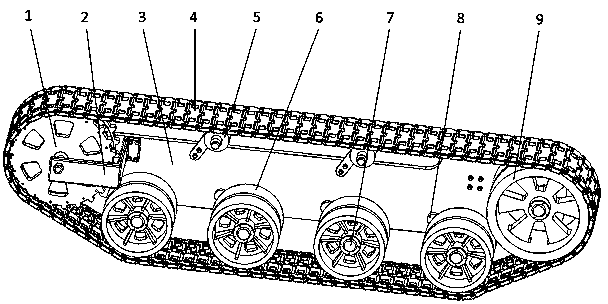

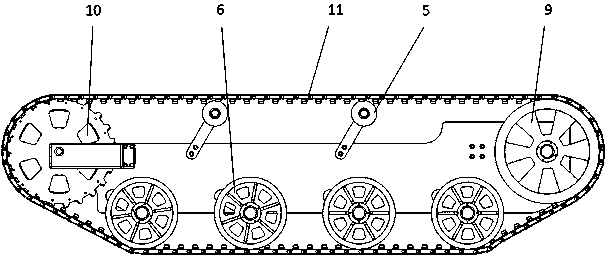

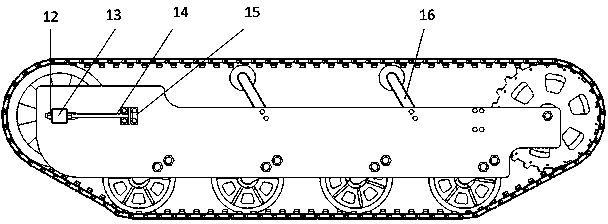

Caterpillar-type driving system of patrolling robot

InactiveCN103465977AHighlight substantiveSimple structureEndless track vehiclesDrive wheelEngineering

The invention relates to a caterpillar-type driving system of a patrolling robot. The caterpillar-type driving system comprises a driving wheel assembly, a driving wheel shaft fixed piece, a side frame, a caterpillar plate, drag chain wheels, thrust wheels, end covers, thrust wheel fixed pieces, a guide wheel, a caterpillar pin, a tensioning nut, a movable piece, a tensioning bolt, a tensioning fixed piece, drag chain wheel fixed pieces, a guide wheel supporting piece and a control part, wherein the driving wheel shaft fixed piece is fixedly arranged on the side frame by a bolt; a shaft of the driving wheel assembly is fixedly mounted at the front end of the side frame by the driving wheel shaft fixed piece; the driving wheel assembly is engaged with grooves at the two sides of a caterpillar chain; the two drag chain wheels are fixedly arranged on the side frame by the drag chain wheel fixed pieces; the four thrust wheels are fixedly arranged on the side frame by the thrust wheel fixed pieces; the guide wheel is connected with the movable piece by the guide wheel supporting piece; and the two end covers are respectively and fixedly arranged on each of the outer sides of the thrust wheels and the guide wheel. The invention designs an effective caterpillar driving system by utilizing a wheel hub motor; and the caterpillar-type driving system is simple in structure and convenient to operate and the speed control is more accurate.

Owner:SHANGHAI UNIV

Photoelectric feedback type carpentry milling head device with double swing angles

ActiveCN102019636AIncreased processing flexibilityImprove work efficiencyMulti-purpose machinesShip's carpenterEngineering

The invention provides a photoelectric feedback type carpentry milling head device with double swing angles. The photoelectric feedback type carpentry milling head device with the double swing angles comprises a supporting seat, a main shell, an electric spindle connecting plate, an electric spindle, a shaft C driving mechanism, a shaft A driving mechanism and two rotary photoelectric encoders, wherein the supporting seat is provided with the shaft C driving mechanism which comprises a servo motor and a transmission mechanism, and an output shaft of the shaft C driving mechanism is connected with the main shell; the main shell is provided with the shaft A driving mechanism which comprises a servo motor and a transmission mechanism, and an output shaft of the shaft A driving mechanism is connected with the electric spindle through the electric spindle connecting plate; the shaft C and shaft A driving mechanisms are provided with a travel switch respectively, a positioning block is arranged on a limit belt wheel which is connected to the output shafts of the driving mechanisms, and a corresponding limit switch is arranged on the supporting seat or the main shell; and grating discs in the rotary photoelectric encoders are arranged on the output shafts, and a photoelectric detector and a light source are arranged on the supporting seat or the main shell. The photoelectric feedback type carpentry milling head device with the double swing angles can realize polyhedron carving and milling processing during the processing of wood and artificial boards, and is suitable for carpentry high-accuracy and high-speed multi-axle numerically-controlled machine tool.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Micro double-spindle false tooth repair machine

ActiveCN102525677ASimplified volumeGuaranteed machining accuracyArtificial teethEngineeringMachining

The invention discloses a micro double-spindle false tooth repair machine. The false tooth repair machine comprises a base (40) and a first electric spindle system (20), a second electric spindle system (90), electric cabinets (10) and a workpiece rotating mechanism (70) which are arranged on the base (40). The false tooth repair machine is characterized in that: the first electric spindle system (20) and the second electric spindle system (90) are arranged coaxially, and cutters arranged on the first electric spindle system (20) and the second electric spindle system (90) and a workpiece arranged on the workpiece rotating mechanism (70) extend into a machining space (60) and are arranged vertically in a horizontal plane; the first electric spindle system (20) and the second electric spindle system (90) are arranged on respective X-axial feeding mechanisms (30); the workpiece rotating mechanism (70) is arranged on a Y-axis feeding mechanism (100), the Y-axis feeding mechanism (100) is arranged on a Z-axis feeding mechanism (120), and the Z-axis feeding mechanism (120) is arranged on the base (40); and a tool magazine system (50) is also arranged on the Y-axis feeding mechanism (100). The false tooth repair machine has the advantages of simple structure, small volume, high machining precision and convenience in operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com