Patents

Literature

76results about How to "Cause malfunction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

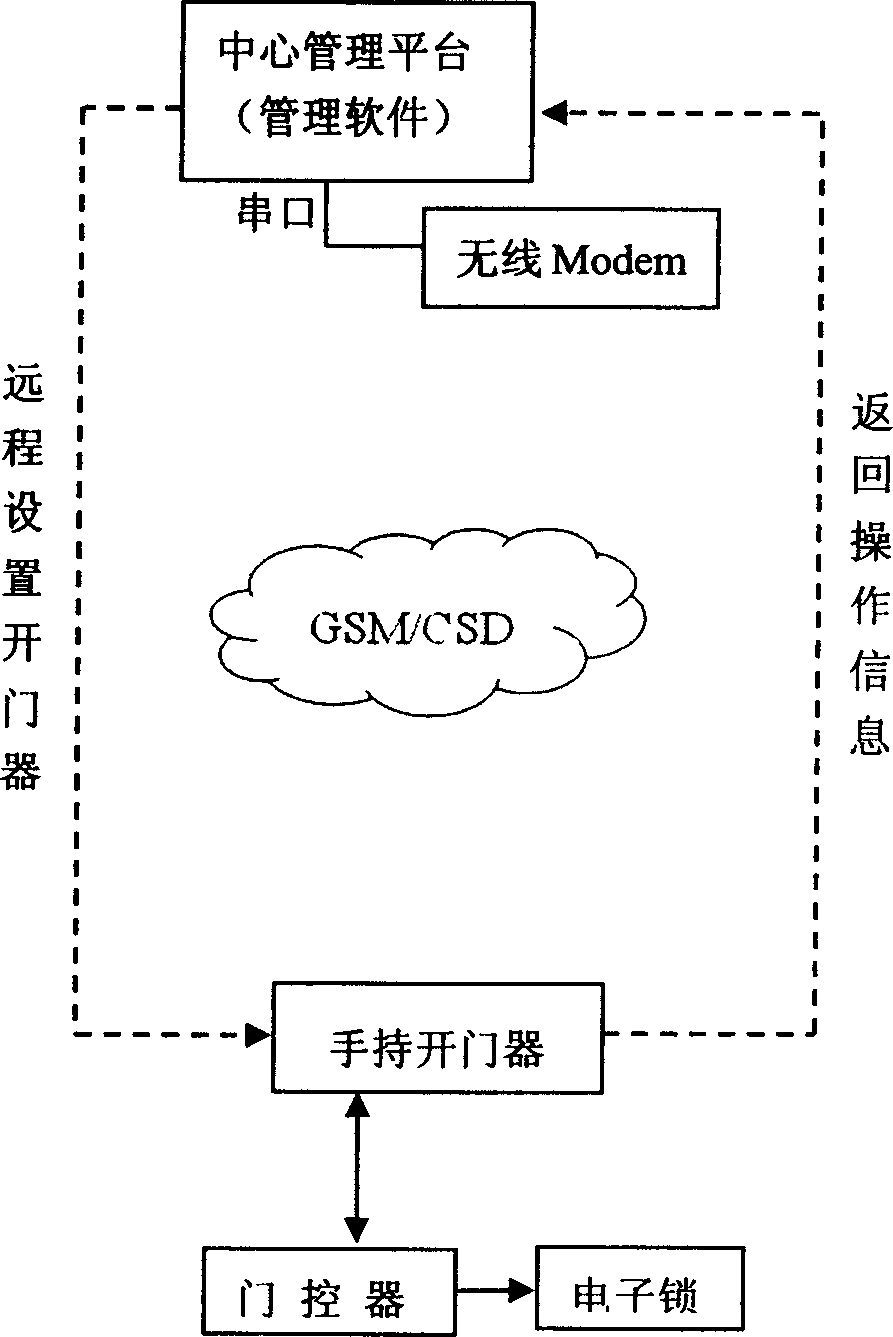

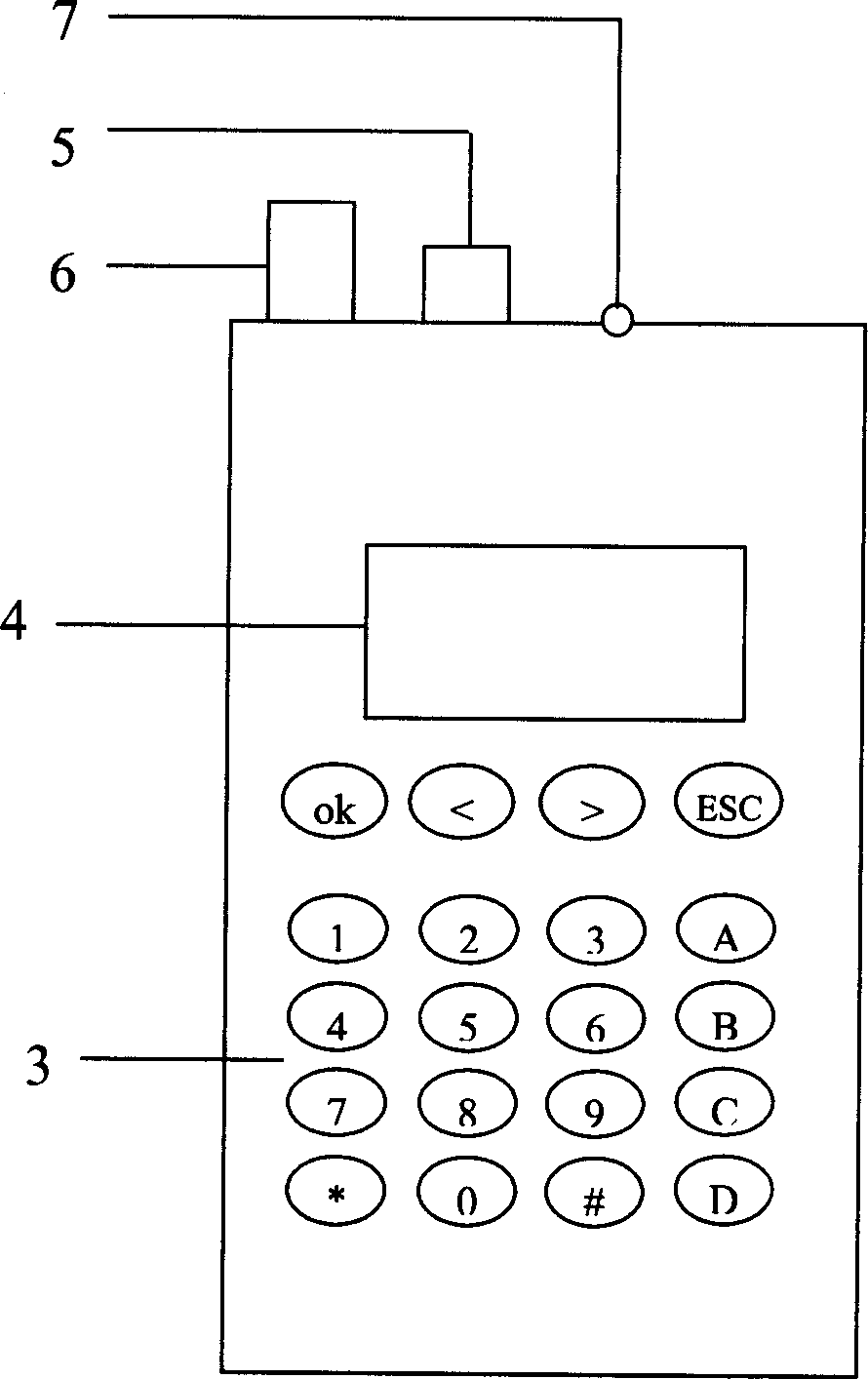

Radio communication Long-distance gate management system and apparatus

InactiveCN1741555AGet job location in real timeGet operation time in real timeTelephonic communicationIndividual entry/exit registersEngineeringCryptography protocols

A management system of radio communication gate inhibition comprises central managing platform including computer , radio remote management software and radio MODEN being connected to network through GSM net ; hand door opener including mobile phone SIM card to carry out communication with center in GSM mode ; gate controller including unique status code for executing command issued by hand door opener ; electronic lock being connected with gate controller by power for realizing unlock .

Owner:美迪特科技(沈阳)有限公司

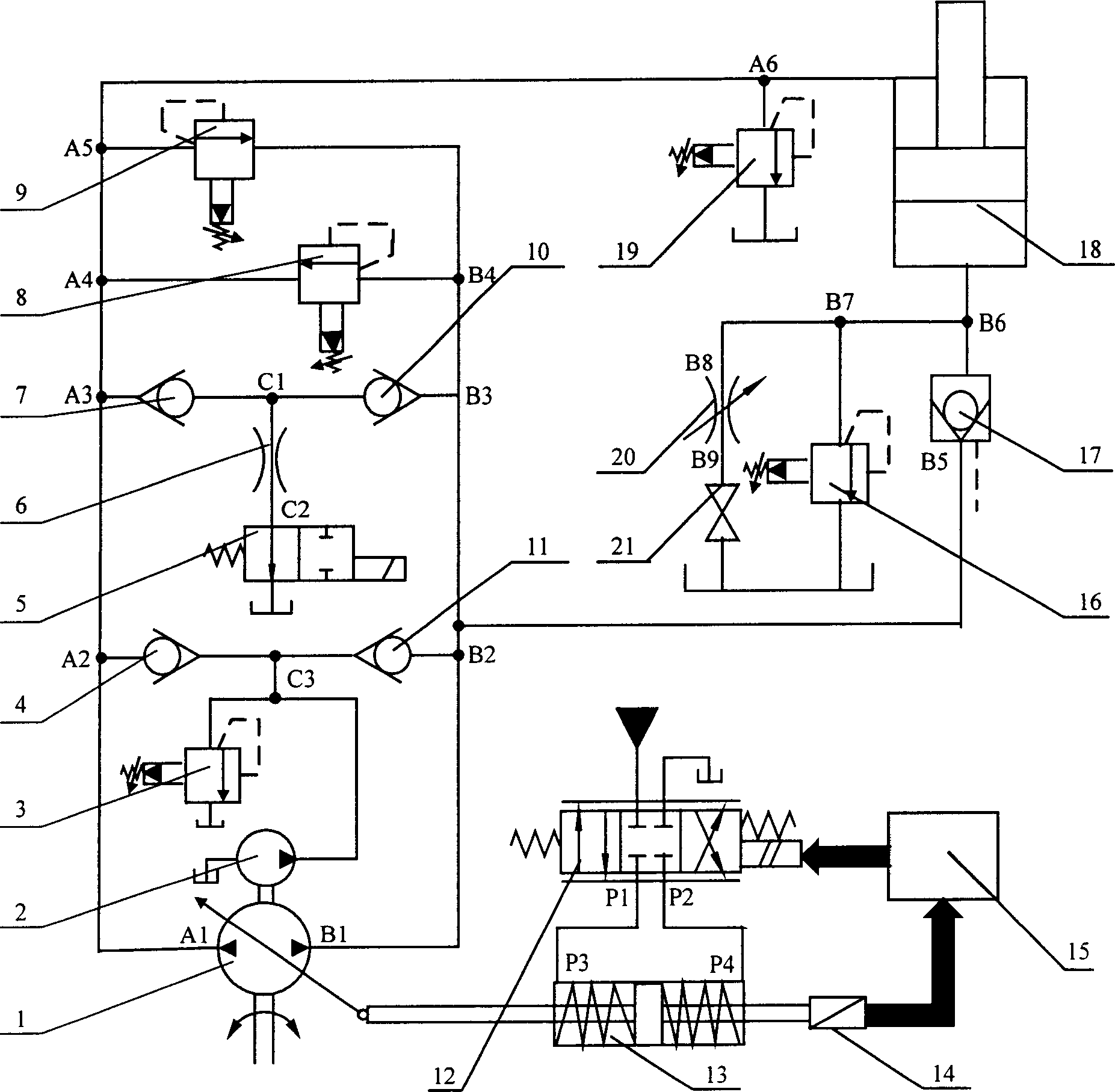

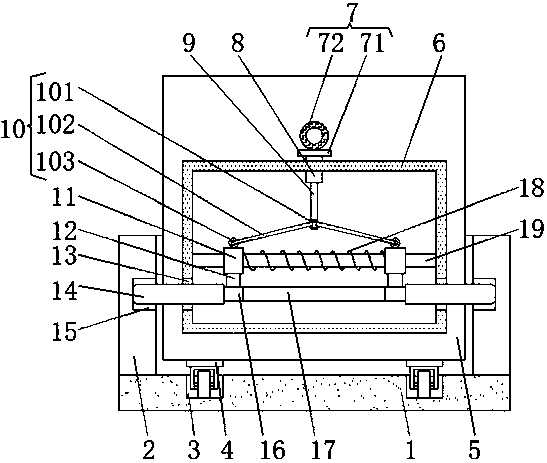

Asymmetric cylinder closed-loop speed system controlled by electro-hydraulic proportional pump

The invention relates to a control system of electric liquid ratio pump control asymmetry cylinder. Wherein, the oil gate A1 of electric liquid ratio pump (1) with closed-loop flux control system is connected to the single valve (4) oil gate A2, the single valve (7) oil gate A3, the overflow valve (8) oil gate A4, the overflow valve (9) oil gate A5, the flux division overflow valve (19) oil gate A6 and the asymmetry oil cylinder (18) rod chamber; the oil gate B1 of electric liquid ratio pump (1) is connected to the single valve (11) oil gate B2, the single valve (10) oil gate B3, the overflow valve (8) oil gate B4, the overflow valve (9) oil gate B4, and the liquid control single valve (17) oil gate B5; and the oil gate B6 of liquid control single valve (17) is connected to the non-rod chamber of asymmetry oil cylinder (18) and the maintenance-safety circuit. The oil feeding circuit, main pump zero flux unload circuit and pressure-limited circuit are arranged between the non-rod chamber and the rod chamber oil pip.

Owner:WUHAN UNIV OF SCI & TECH

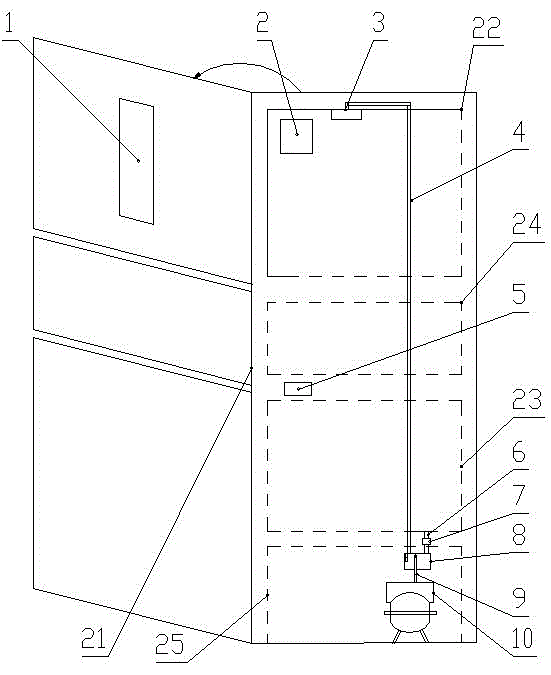

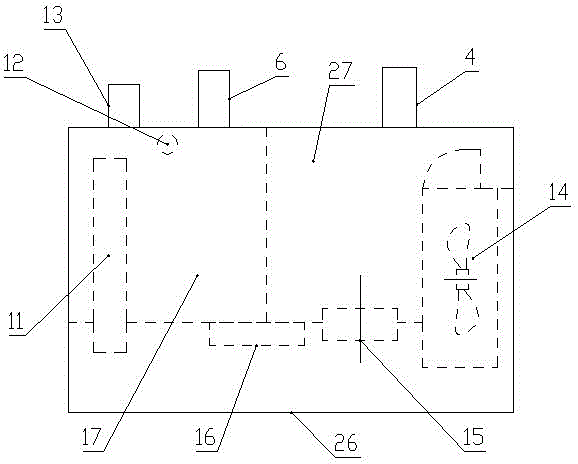

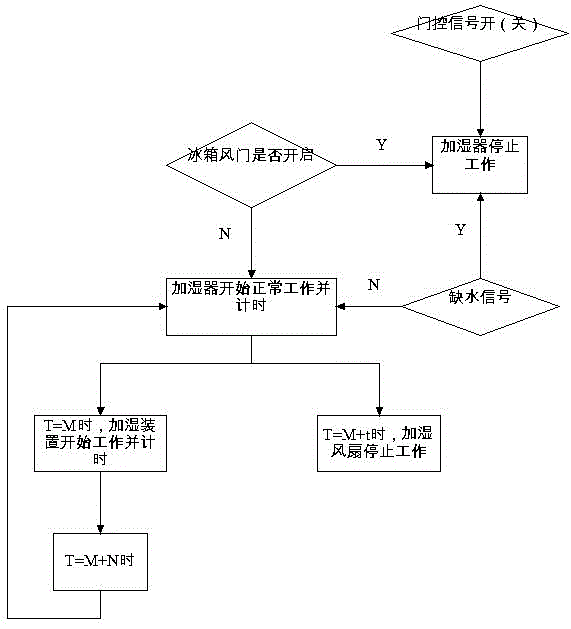

Refrigerator with refrigeration humidification device and refrigerating chamber humidification control method

ActiveCN104457097ASimple structureEasy to useLighting and heating apparatusDomestic refrigeratorsEvaporatorEngineering

The invention discloses a refrigerator with a refrigeration humidification device and a humidification control method of the refrigerator. A humidification device is arranged at the bottom of a refrigerator body; the humidification device comprises a shell; a water storage cavity, an atomization cavity, a humidification control plate, an ultrasonic atomization piece and a fan are arranged at intervals inside the shell; a manual water supply hole and a water inlet tube are arranged at the top of the water storage cavity at intervals; the upper opening of the water inlet tube is arranged inside a box body below an evaporator; a water shortage detector which extends into the water storage cavity is arranged on the shell; the water shortage detector is connected with an electric control device through a signal line; the ultrasonic atomization piece is arranged at the bottom of the atomization cavity; the bottom of the water storage cavity is communicated with the bottom of the atomization cavity; the fan for blowing mist to the refrigeration chamber is arranged inside the atomization cavity; a mist outlet tube is connected with the top of the atomization cavity; the other end of the mist outlet tube is communicated with the top of the refrigeration chamber upwards. By adopting the refrigeration humidification device, water can be both replenished manually and replenished by using defrosting water, the defrosting water can be automatically purified, and the humidity of the refrigeration chamber of the refrigerator is stably kept within a relatively high humidity range.

Owner:HENAN XINFEI ELECTRICAL EQUIP

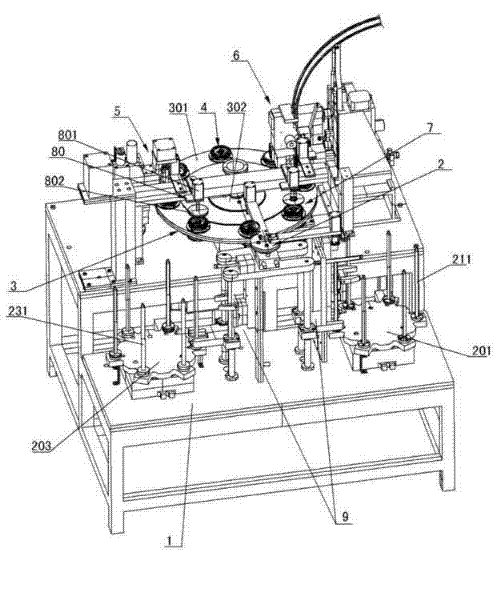

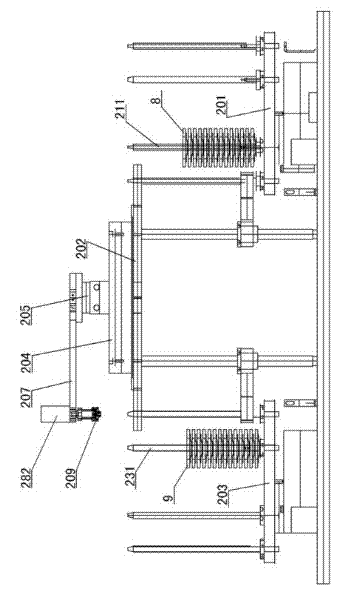

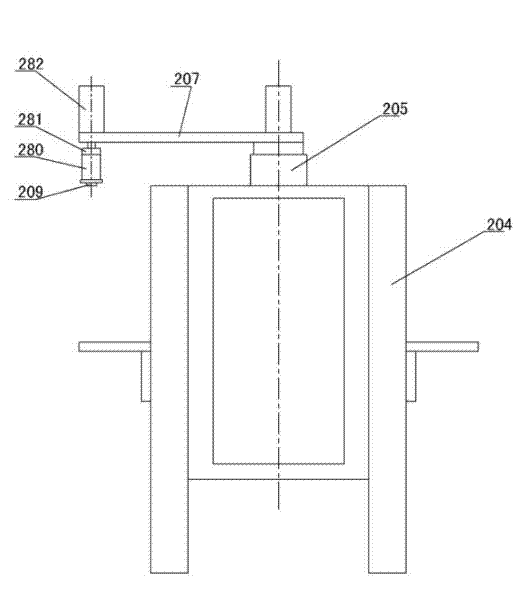

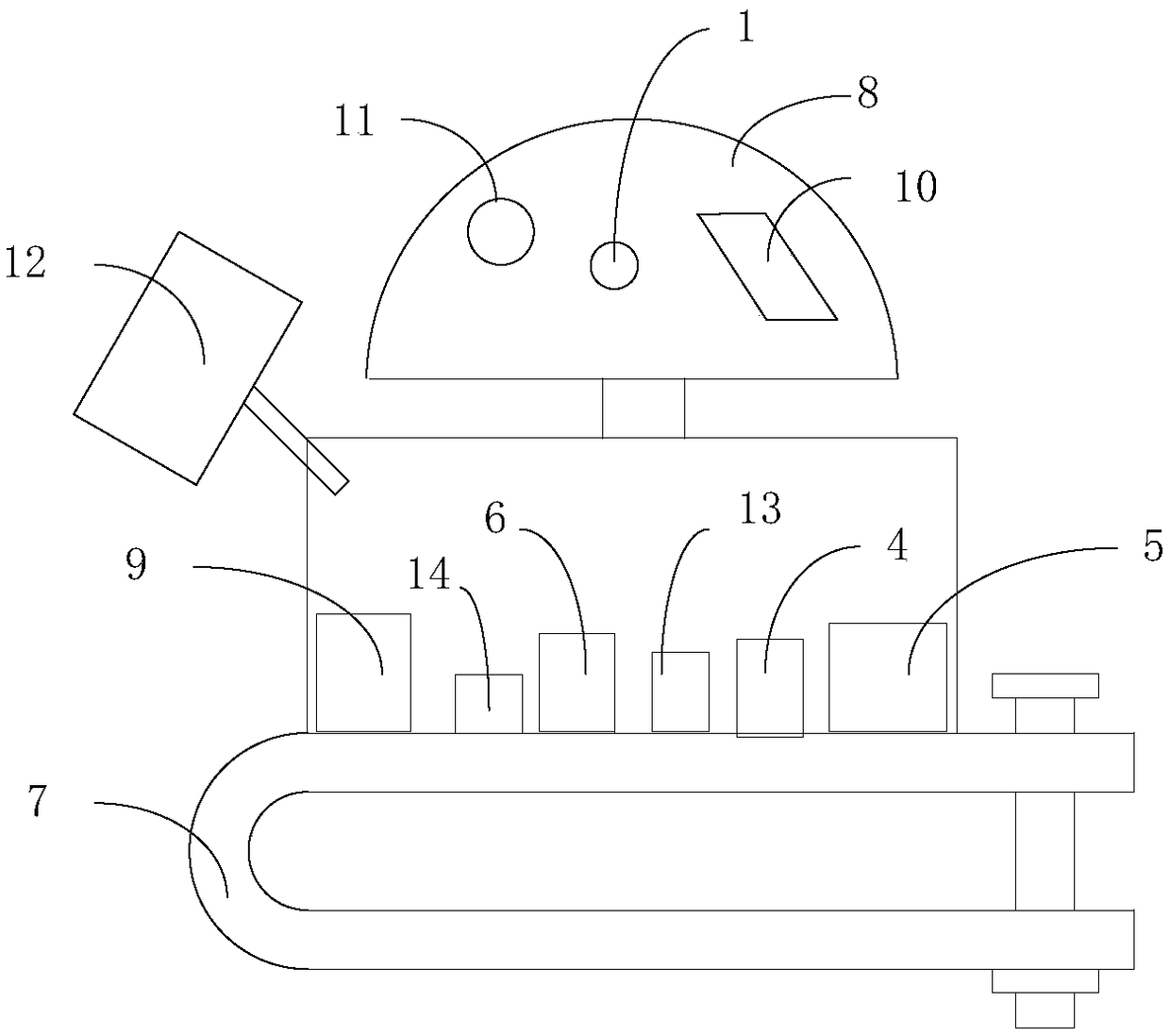

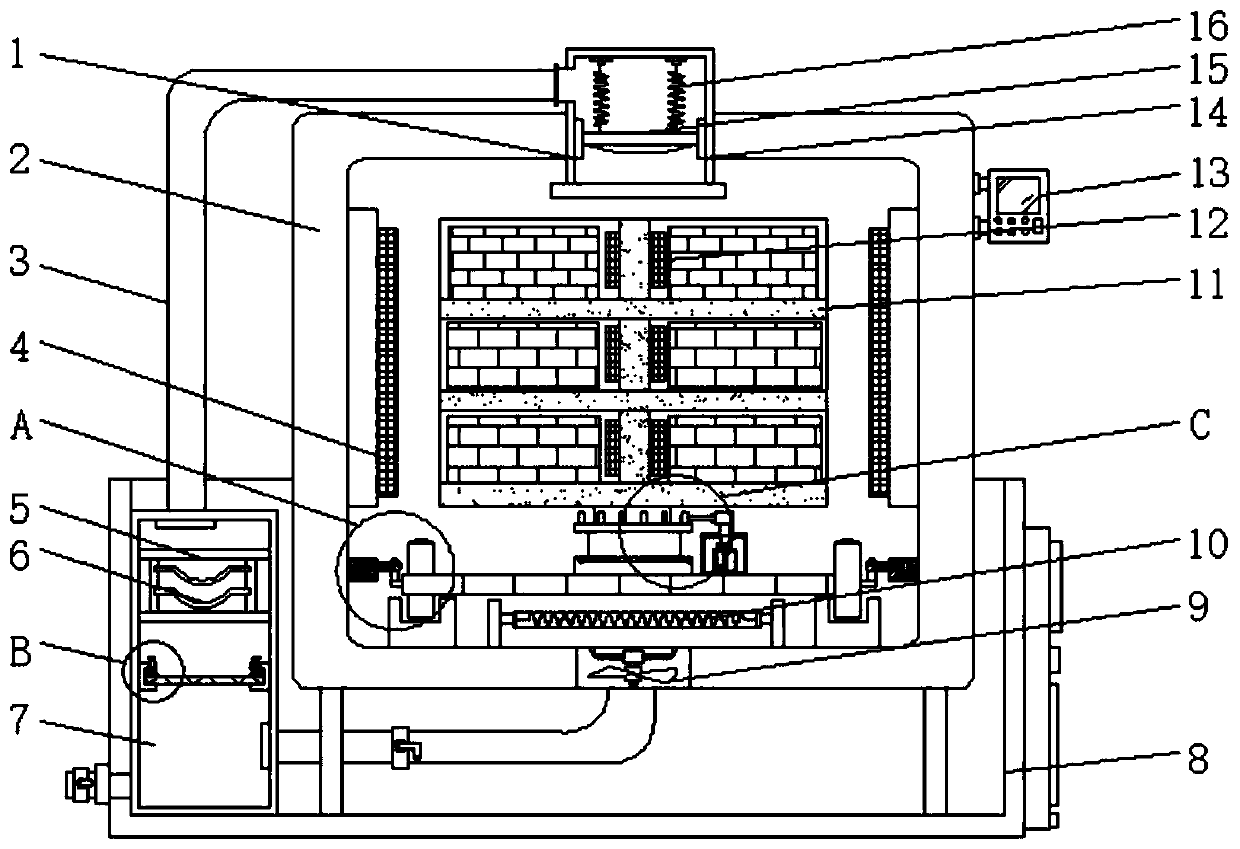

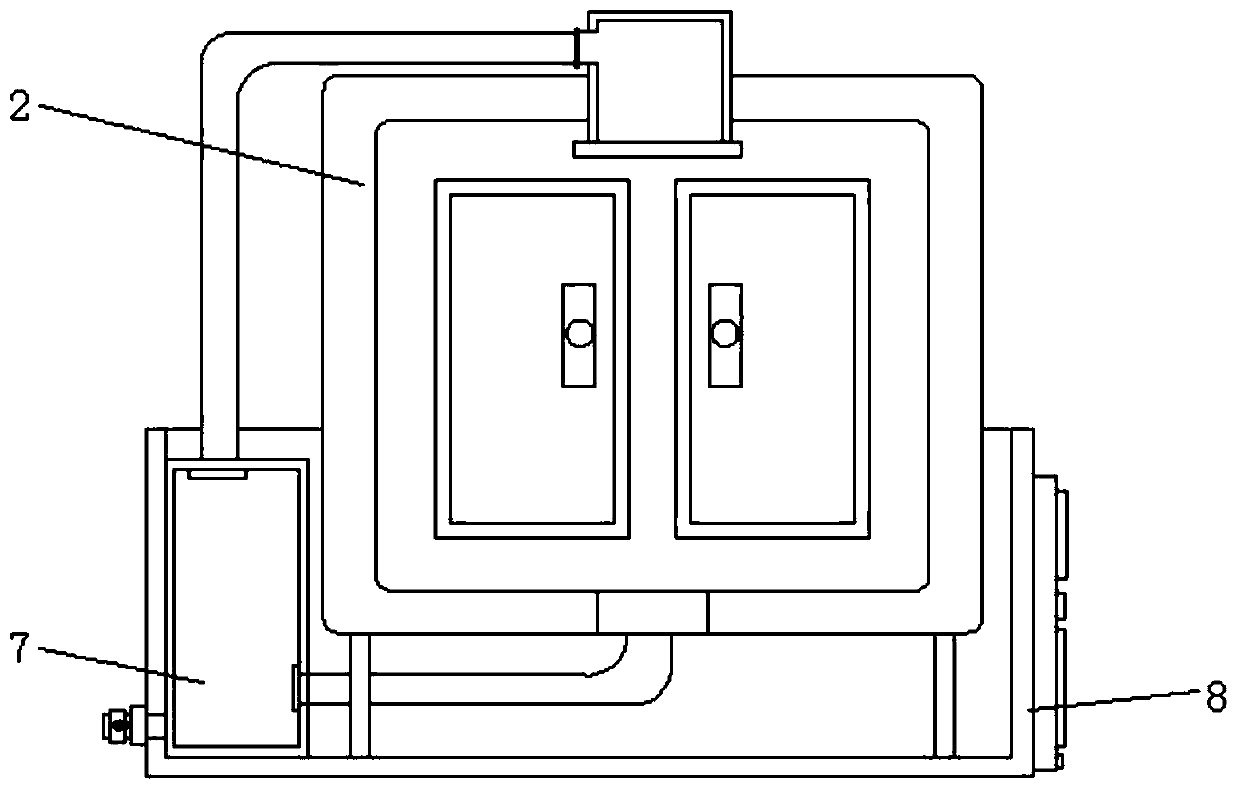

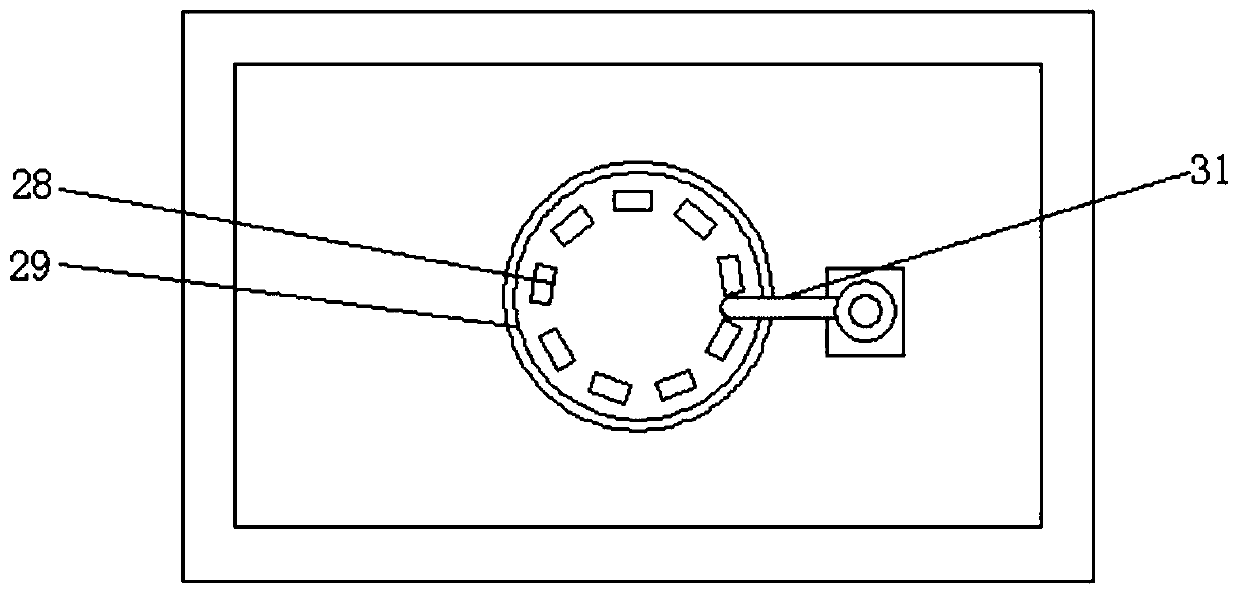

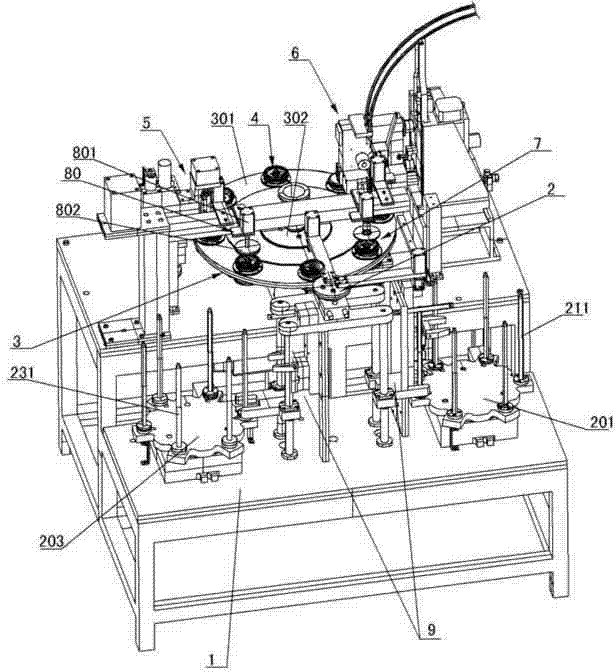

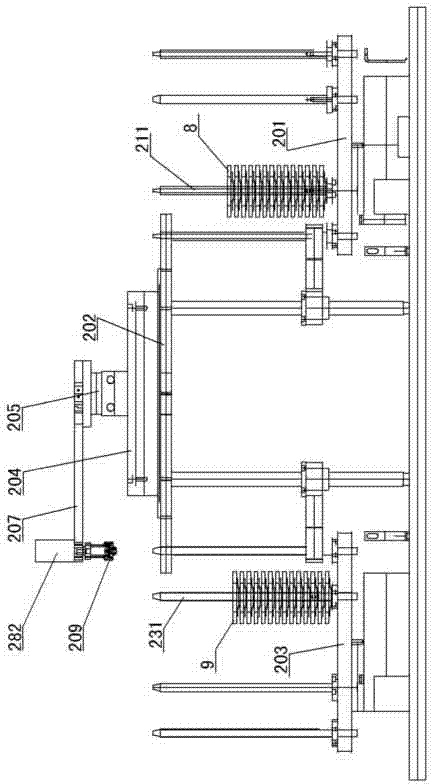

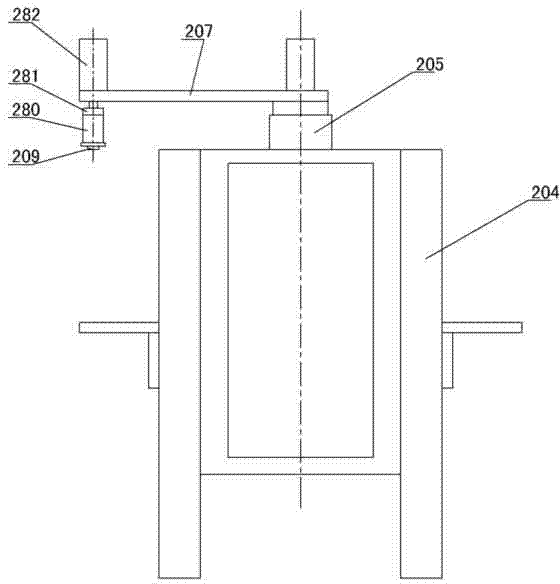

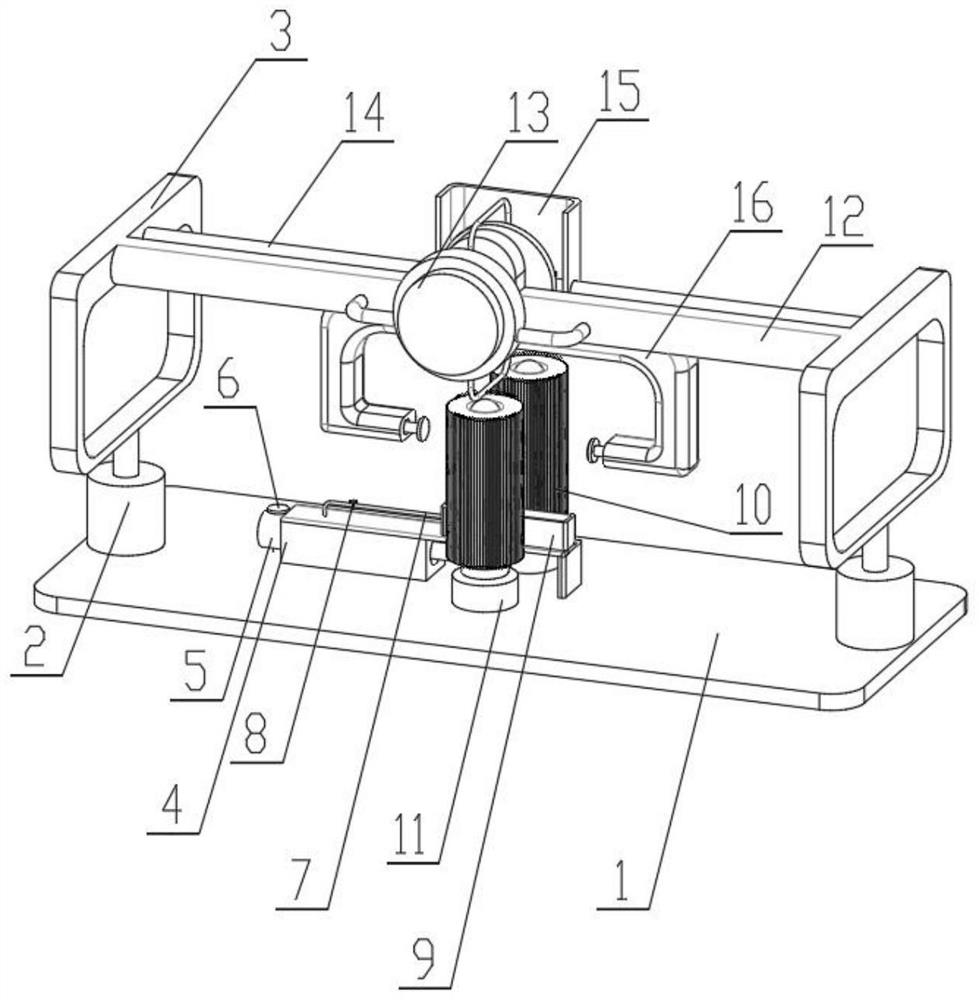

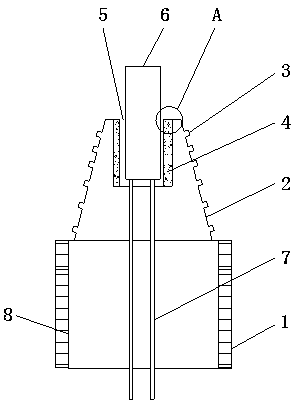

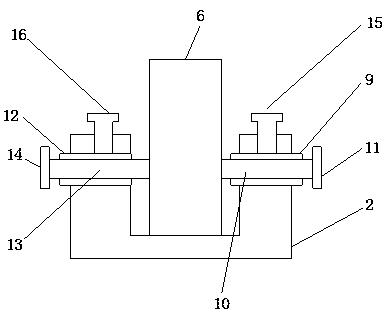

Full-automatic abrasive cloth flap disc machining equipment

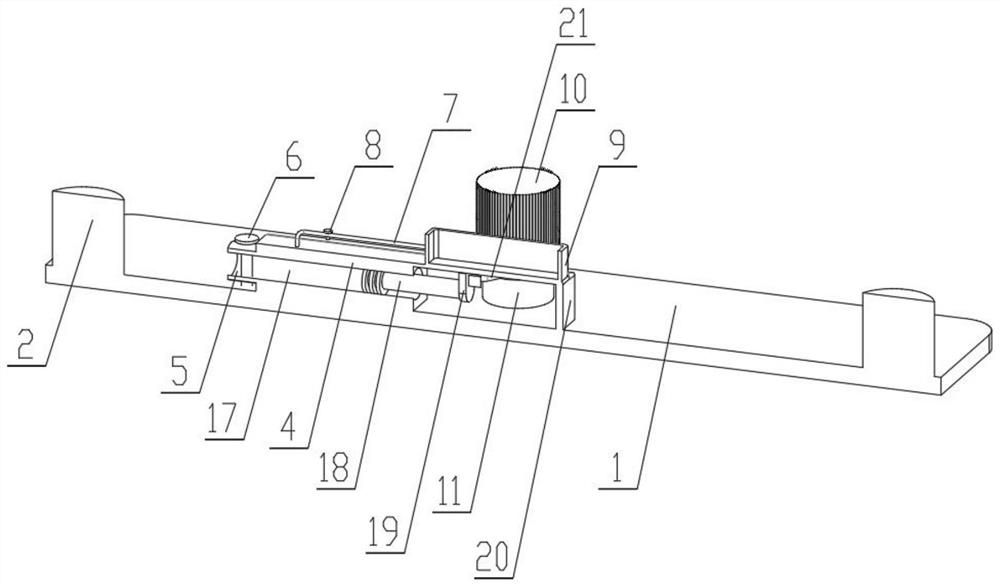

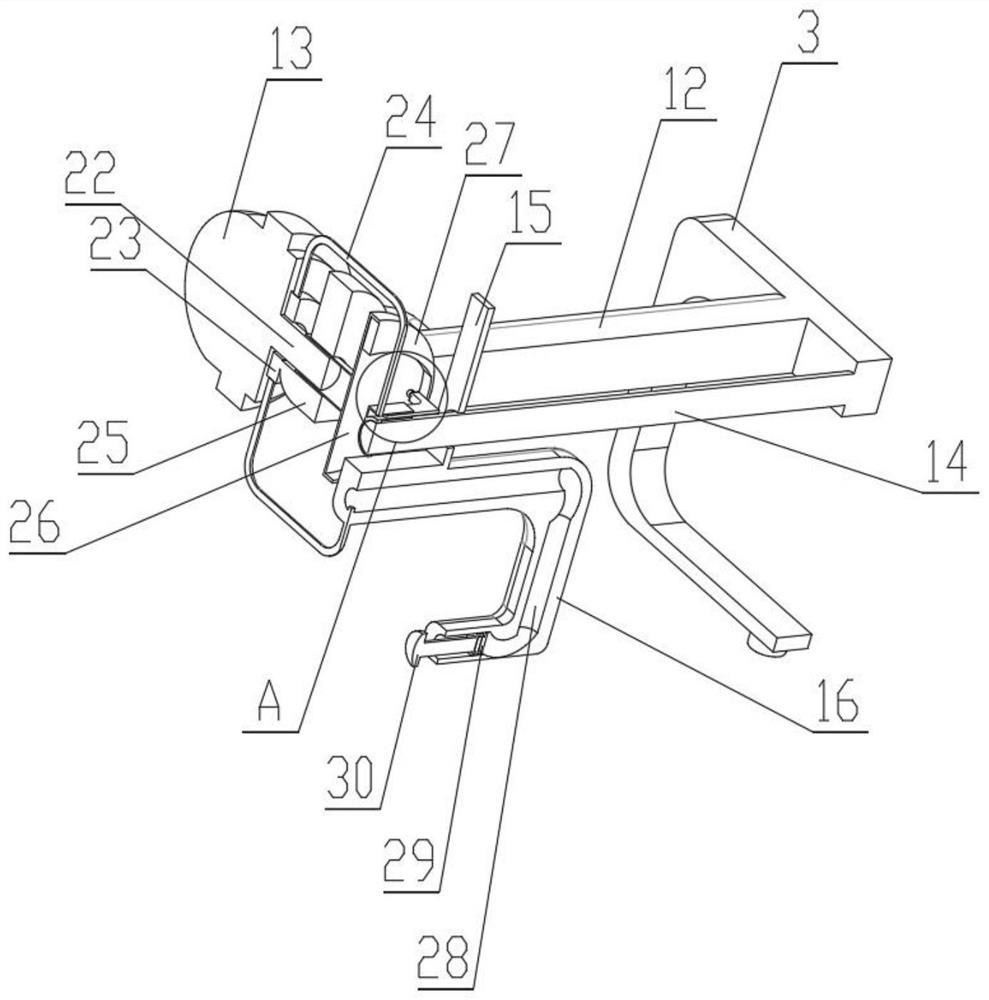

The invention discloses full-automatic abrasive cloth flap disc machining equipment, which comprises a frame; a feeding and discharging storage mechanism of a flap disc, a conveying rotary device, a flap disc autorotation mechanism, a glue dripping device, a slice mounting device and a reshaping mechanism are arranged on the frame; and when the machining equipment works, the flap disc is fetched and placed on the flap disc autorotation mechanism arranged on the conveying rotary device by the feeding mechanism of the flap disc, a small turntable and the flap disc are driven by a main turntableto rotate below the glue dripping device, the glue dripping device drips glue to the flap disc, then the main turntable continuously rotates to drive the flap disc coated with the glue to rotate below the slice mounting device, the slice mounting device slices an abrasive cloth tape, the slices are stuck to the flap disc coated with the glue, the main turntable continuously rotates to drive the flap disc stuck with abrasive cloth sheets to rotate below a reshaping device, the flap disc is reshaped by the reshaping device, finally, the main turntable drives the finished flap disc to rotate below the discharging storage mechanism, the finished disc is grabbed and discharged by the discharging storage mechanism, and machining of the whole process is finished.

Owner:台州市黄岩豪林抛光磨具有限公司

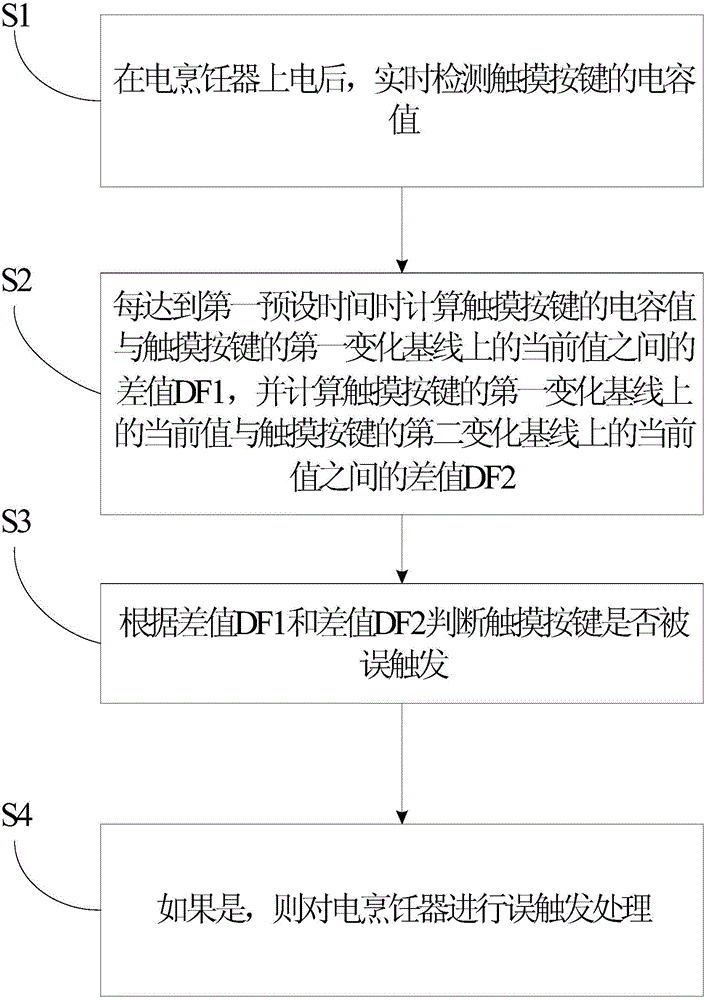

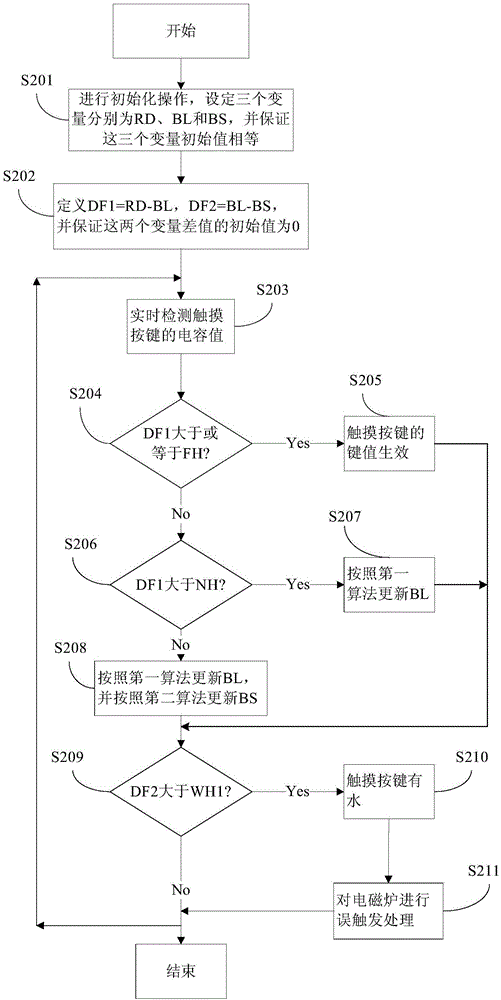

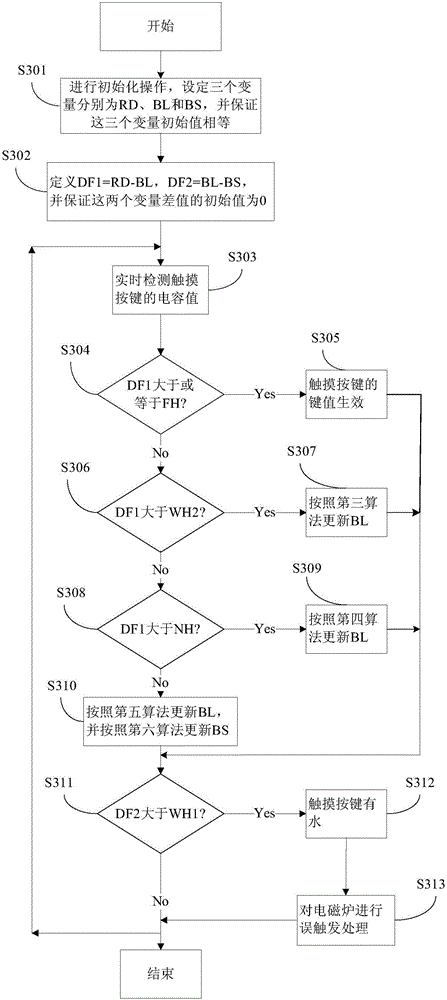

Electric cooker and method for controlling same

ActiveCN105361707AGuaranteed uptimePrevent changes in working statusCooking vesselsTouch panelCooker

The invention discloses a method for controlling an electric cooker. The electric cooker comprises a touch panel with touch keys. The method for controlling the electric cooker includes steps of detecting capacitance values of the touch keys in real time after the electric cooker is powered on; computing difference values DF1 between the capacitance values of the touch keys and current values of first variation base lines of the touch keys whenever first preset time is up, and computing difference values DF2 between the current values of the first variation base lines of the touch keys and current values of second variation base lines of the touch keys; judging whether the touch keys are falsely triggered or not according to the difference values DF1 and the difference values DF2; carrying out false trigger processing on the electric cooker if the touch keys are falsely triggered. Variation rates of the first variation base lines are higher than variation rates of the second variation base lines. The method for controlling the electric cooker has the advantages that faulty running of the electric cooker due to the fact that the touch keys are falsely triggered under inference of external factors can be prevented, and accordingly requirements of users can be met. The invention further discloses the electric cooker.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

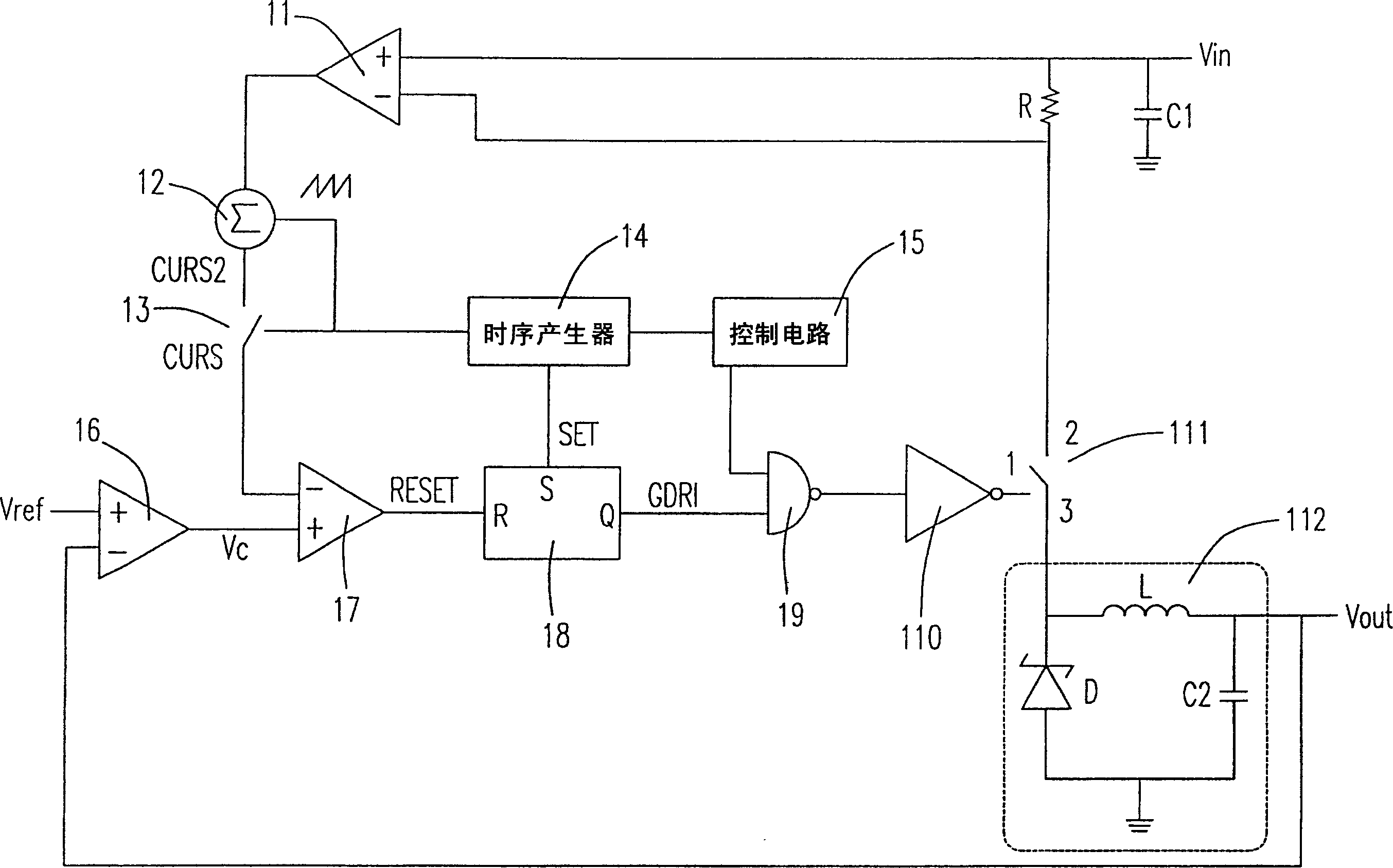

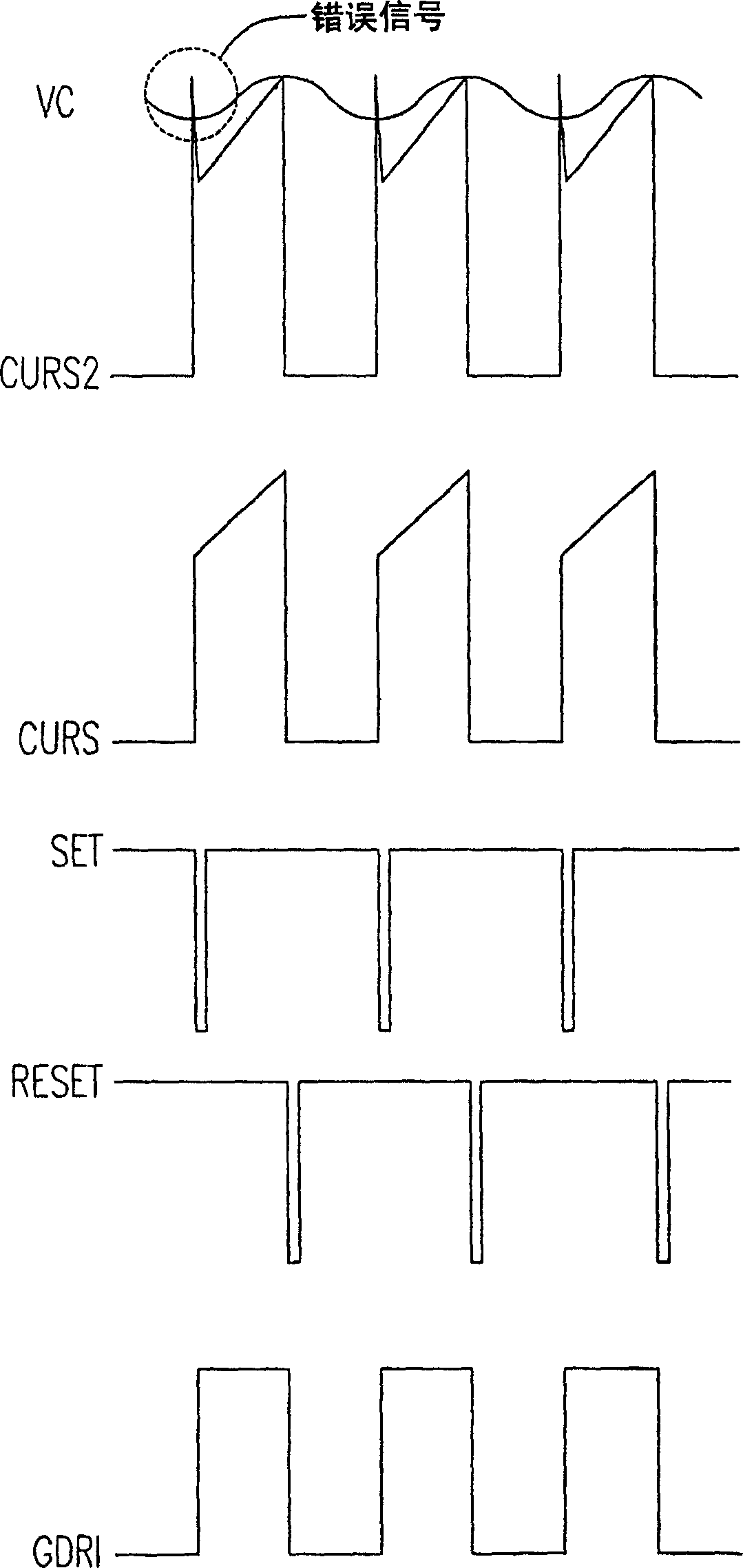

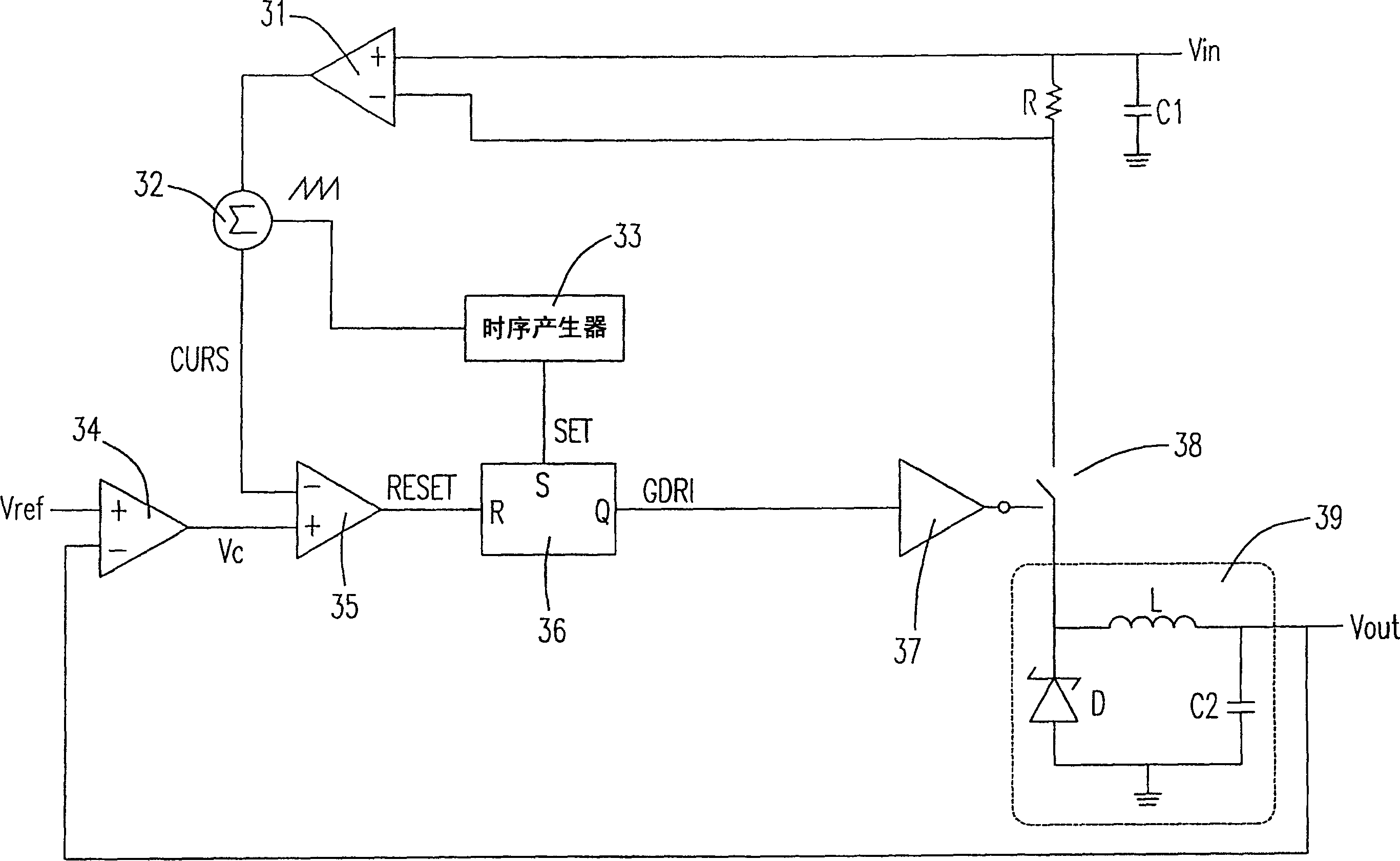

Controlling circuit, controlling method and sequence generator for dc-dc converter

InactiveCN1592056ACause malfunctionControl reachedApparatus without intermediate ac conversionElectric variable regulationStart timeControl manner

This invention provides a control circuit of a pulse width modulation DC to DC converter, a control mode and a time sequence generator which includes a current amplifier, a compensator, a comparator, a trigger, a time sequence generator connected to the said compensator and the trigger separately for generating modulation signals and set signals, among which, the set signal wave has a widened first low potential pulse at the heavy load state to make the reset signal unable to change to the trigger output signal when the set signal operates, and the wave of the set signal has another widened second low potential pulse when the wave form is at light load stale, so as to set the least starting time action and force the converter in a power-save mode, a driving circuit and a differential amplifier.

Owner:ANALOG INTEGRATIONS CORP

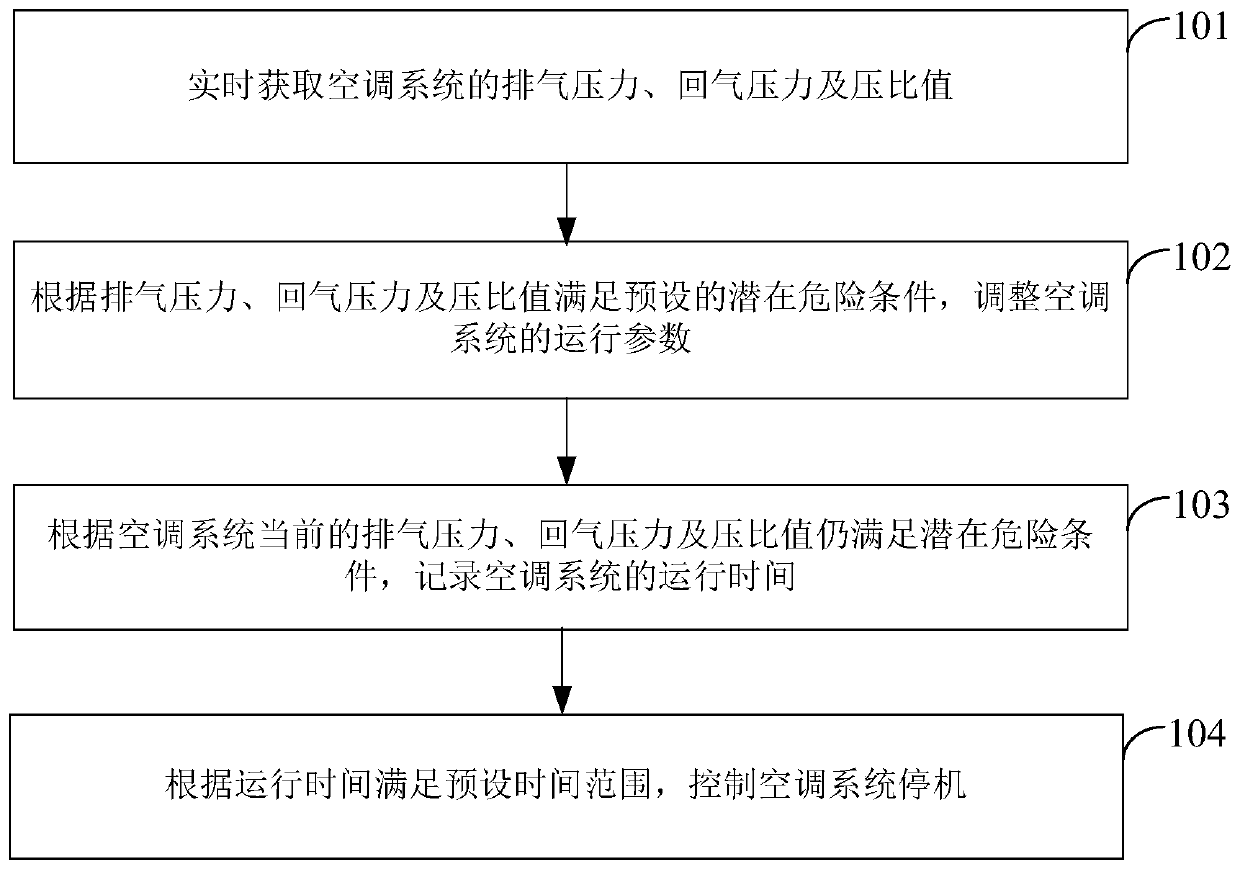

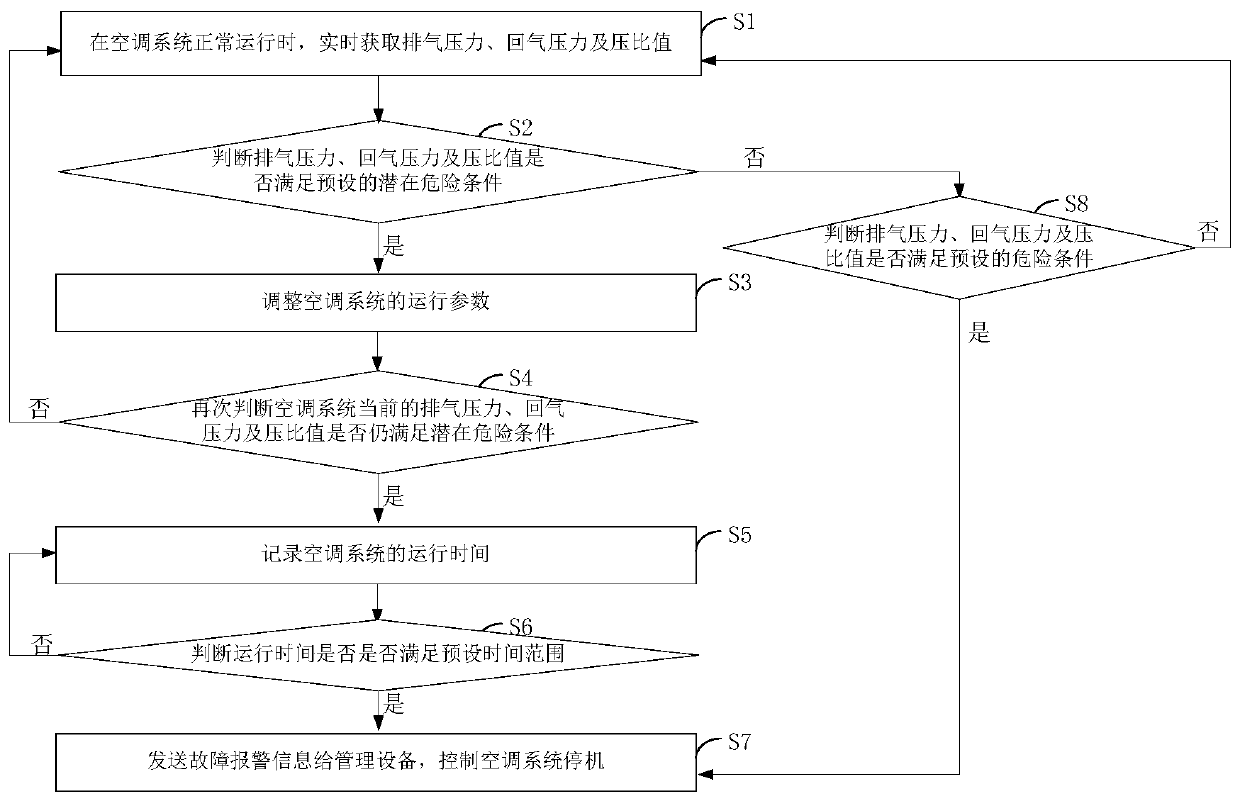

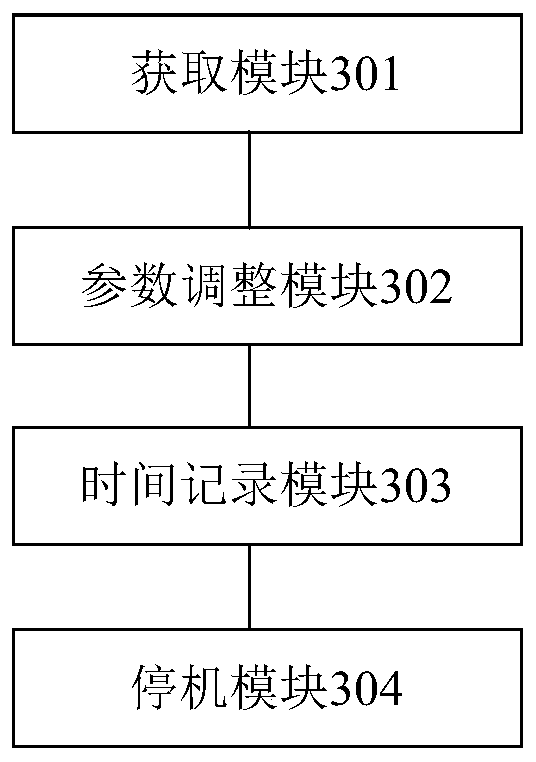

Air conditioning system control method and device, electronic equipment and storage medium

InactiveCN110925950AAvoid failureCause malfunctionMechanical apparatusSpace heating and ventilation safety systemsControl engineeringAir conditioning

The invention discloses air conditioning system control method and device, an electronic equipment and a storage medium. The air conditioning system control method comprises the following steps of obtaining an exhaust pressure, air return pressure and pressure ratio of an air conditioning system in real time; adjusting operation parameters of the air conditioning system according to potential dangerous conditions that the exhaust pressure, the air return pressure and the pressure ratio meet preset; recording the operation time of the air conditioning system according to the potential dangerousconditions that the exhaust pressure, the air return pressure and the pressure ratio are still meet the preset; and controlling the shutdown of the air conditioning system according to the conditionthat the operation time meets the preset time range. According to air conditioning system control method and device, the electronic equipment and the storage medium, the operation range of an air conditioner is judged, the operation parameters are adjusted when the fact that a potential safety risk exists is determined, if the potential safety risk still exists, the continuous operation time under the potential safety risk is recorded, and shutdown is carried out after the continuous operation time exceeds the preset time range, so that the real equipment failure caused by the potential safety risk is avoided, and when it is confirmed that the real safety risk exists in the system, and a machine is stopped immediately, so that the equipment damage caused by excessive exhaust pressure or air return pressure is avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Convenient-to-install computer case

InactiveCN108614622AEasy to installCause malfunctionDigital processing power distributionFixed frameComputer engineering

The invention discloses a convenient-to-install computer case. The convenient-to-install computer case comprises a back plane, wherein the upper surface of the back plane is fixedly connected with thelower surface of a fixed frame, two limiting slots are formed in the upper surface of the back plane, four rollers are arranged in the limiting slots in a sliding connection mode, and the four rollers are fixedly connected to the four corners of the lower surface of a computer case body respectively. According to the convenient-to-install computer case, through mutual cooperation of sliding bushes, a sliding rod, a spring, a connection device, clamping rods, clamping slots, through holes, the fixed frame and a traction device, when the computer case body is pushed into the limiting slots through the rollers, a worker loosens the traction device, the spring is released, the two sliding bushes are pushed to slide outwards, the sliding bushes drive the clamping rods to move into the clampingslots through sliding blocks, the clamping slots and the clamping rods are clamped, therefore, quick installation of the computer case body is realized, and the situation that a computer cannot worknormally because a plug gets loose or drops down when the case is touched accidentally is avoided.

Owner:龚艳霞

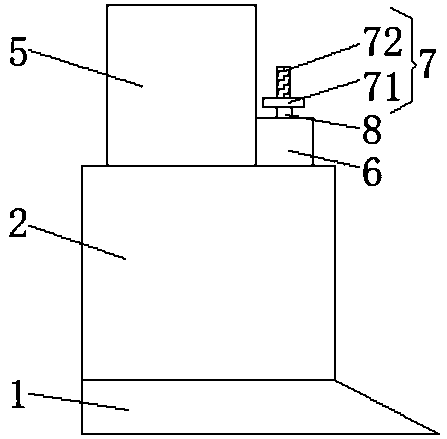

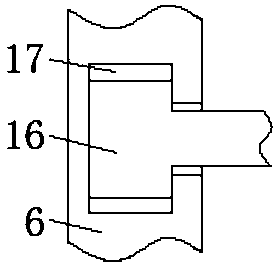

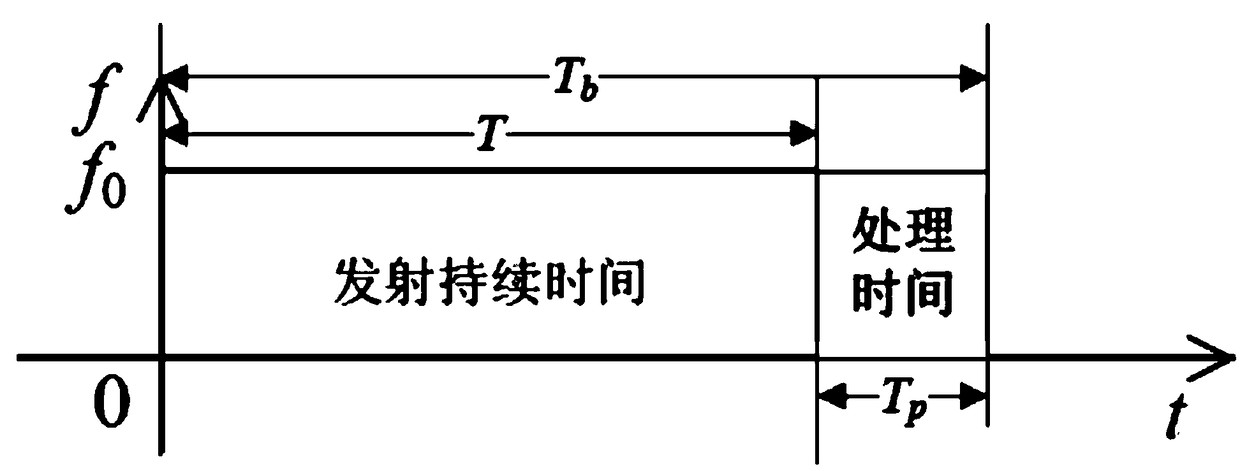

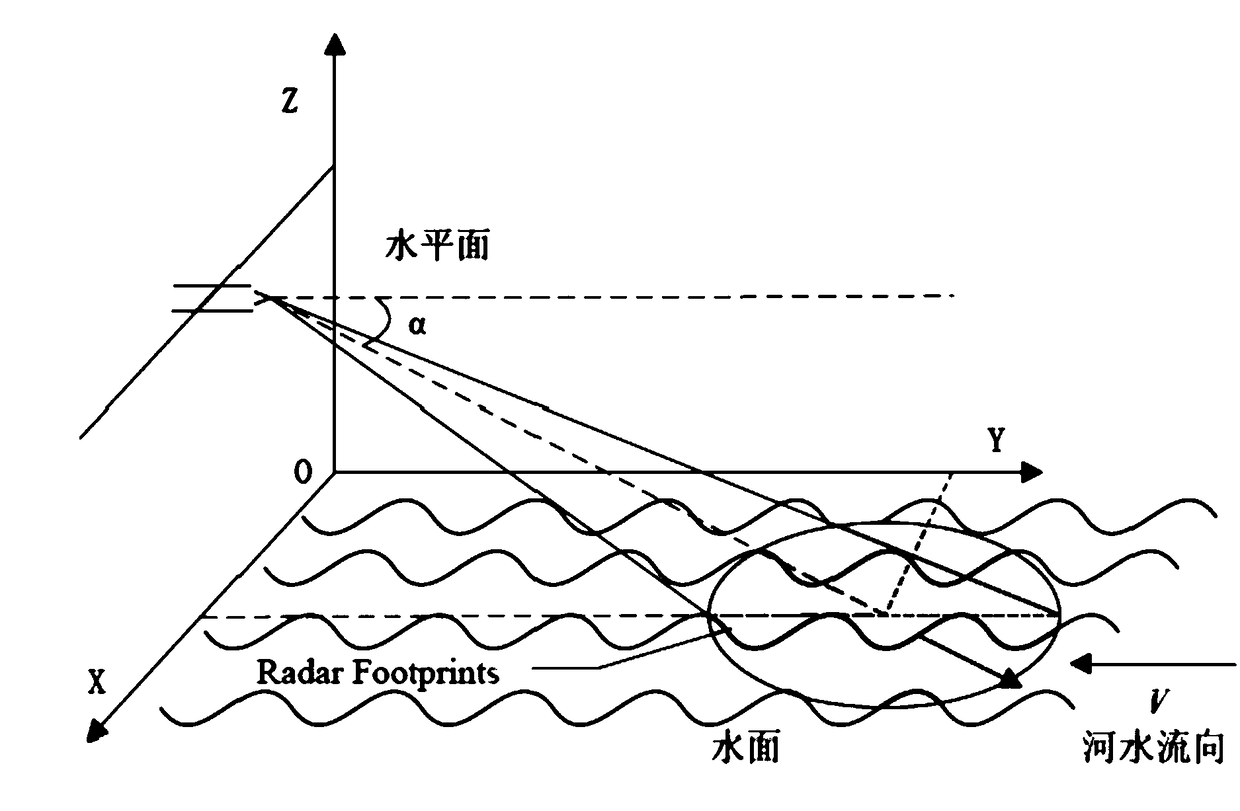

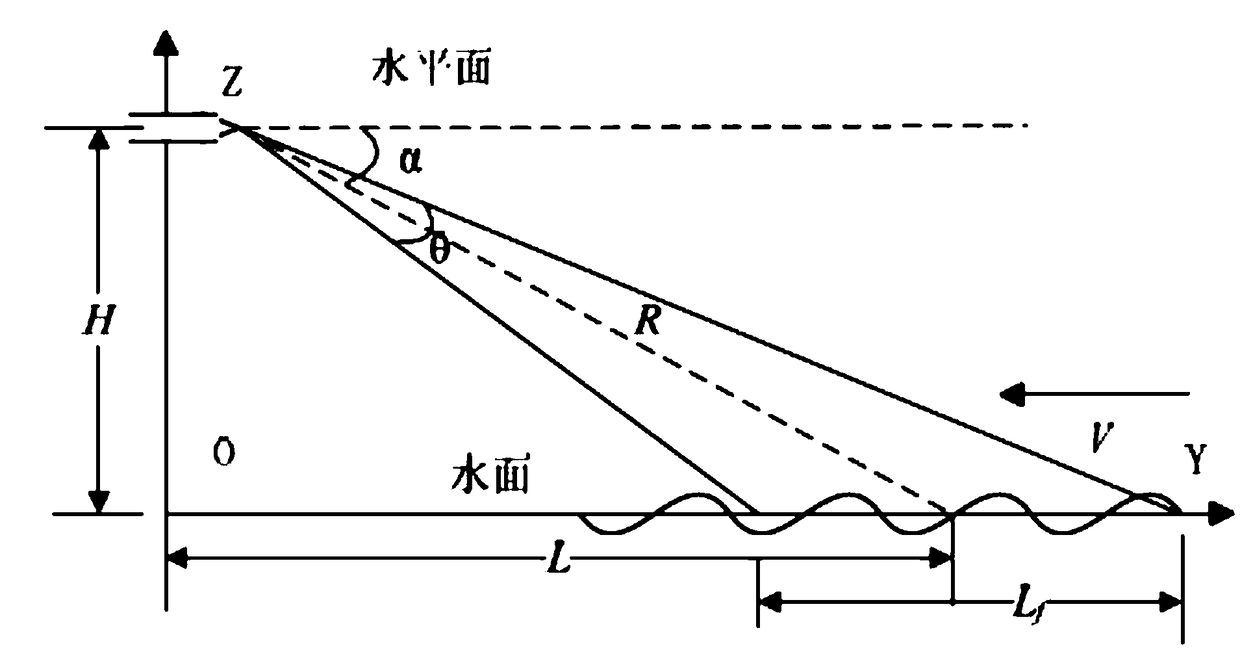

Radar current meter

InactiveCN109001723ACause malfunctionRadio wave reradiation/reflectionCurrent meterAudio power amplifier

The invention discloses a radar current meter, comprising a radar current meter system control unit, a transmitting signal generating unit and a radio frequency conditioning unit, the system control unit firstly transmits a radar signal to a river by virtue of a transmitting antenna, then an echo signal is returned to a receiving antenna after the transmitted radar signal passes through the river,the transmitted signal and a received signal are processed by virtue of a mixer, a bandpass amplifier and an ADC and are subjected to Doppler processing, then spectrum correction, parameter estimation and correction are performed, and finally data is packaged and sent to a hydrologic monitoring station. The radar current meter can be mounted on a water surface by adopting a non-contact measurement mode, no mechanical movement component exists, and a fault of a sensor can not be caused by sundries in water.

Owner:薛志勇

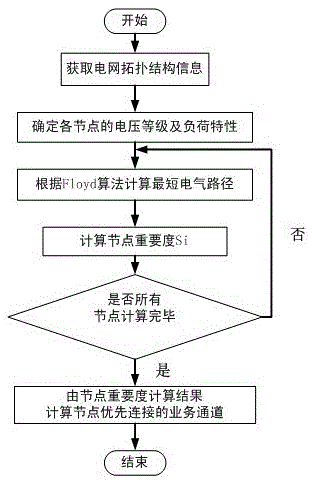

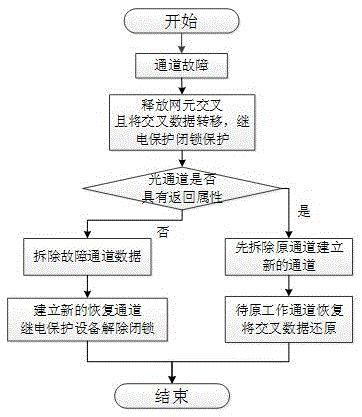

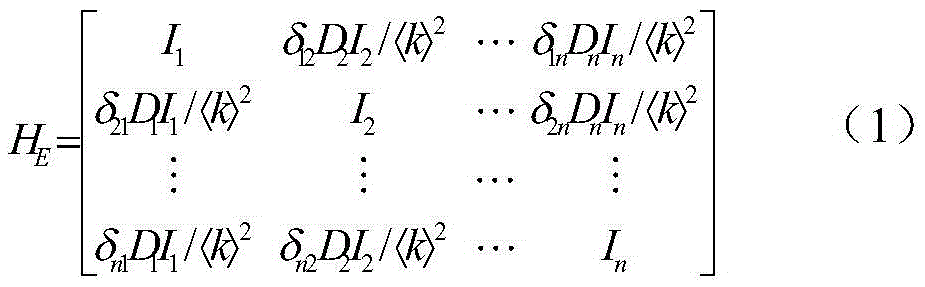

Intelligent recovery method for power control business

ActiveCN105530133AReduce computational workloadGuaranteed real-timeData switching networksRecovery methodPower grid

The invention relates to an intelligent recovery method for a power control business. According to an ASON based path calculation method, when a power grid control business has a fault, original business receiving and sending paths are removed first and then a list of optional nodes arranged in a descending order is formed according to the importance of each node obtained by calculation in a network; when a new route channel is established, a node arranged at the back is selected as a new business path channel to ensure an important site function in a power grid not to be influenced by rerouting; and meanwhile, business receiving and sending channels of a faulted channel are removed to ensure receiving and sending paths of the power grid control business to be always consistent. The method specially comprises two processes of business path selection and line fault recovery selection: 1) business path selection and 2) control business channel fault recovery. The invention proposes a novel routing method, so that the intelligent recovery of the power control business is realized and the time delays of the receiving and sending paths of the control business are ensured to be consistent.

Owner:WUHAN UNIV

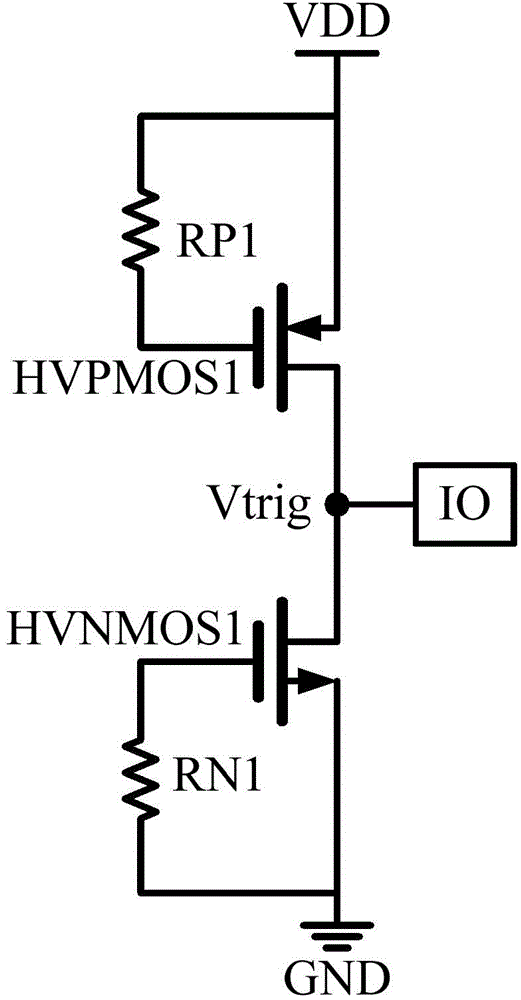

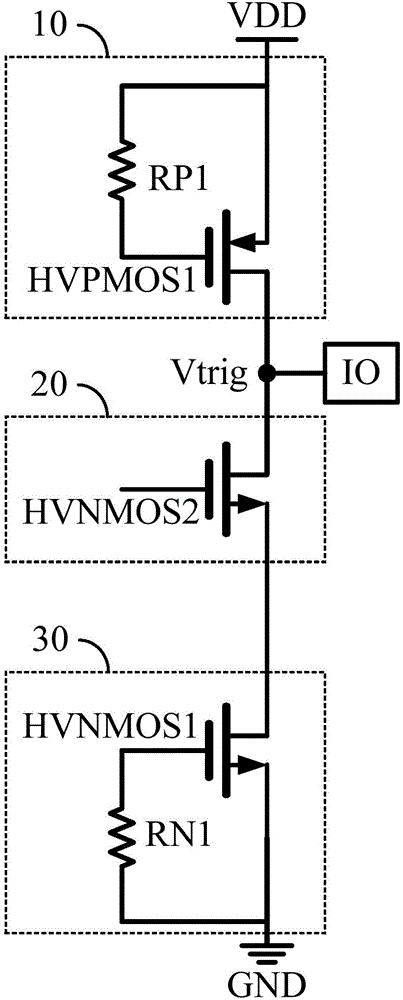

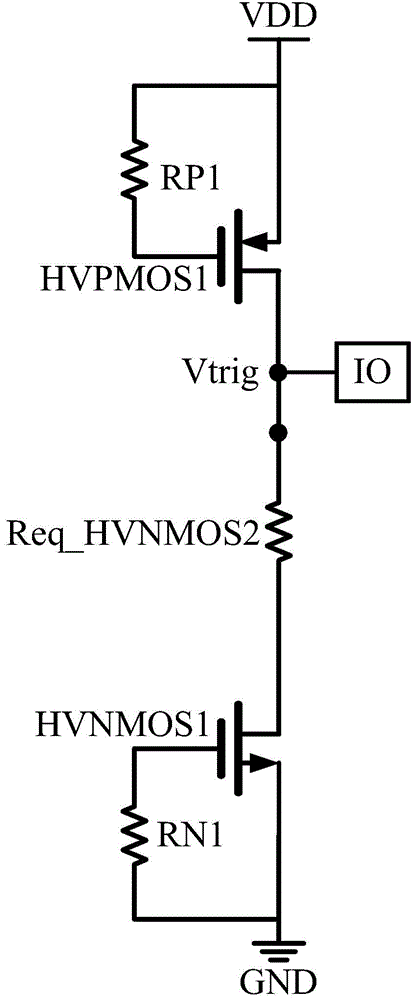

High-voltage ESD protective circuit

ActiveCN106033756ACause malfunctionIncrease the trigger voltageSolid-state devicesSemiconductor devicesGgNMOSHigh pressure

The invention provides a high-voltage ESD protective circuit which is used for discharging ESD current that flows from an IO PAD. The high-voltage ESD protective circuit at least comprises the components of a GDPMOS discharging unit which is arranged between a power supply and the IO PAD; an auxiliary discharging unit which is arranged between the IO PAD and ground and is connected with the GDPMOS discharging unit; and a GGNMOS discharging unit which is connected with the auxiliary discharging unit, wherein the auxiliary discharging unit is used for supplying an auxiliary discharging path of the GGNMOS discharging unit. The auxiliary discharging unit of the invention can supply the auxiliary discharging path of the GGNMOS discharging unit and improves ESD capability. By means of the stacked structure for aiming at high-voltage process, ESD capability of the circuit can be improved, and furthermore triggering voltage and noise resistance of the whole high-voltage ESD protective circuit can be improved, thereby preventing misoperation of the whole high-voltage ESD protective circuit caused by noise.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

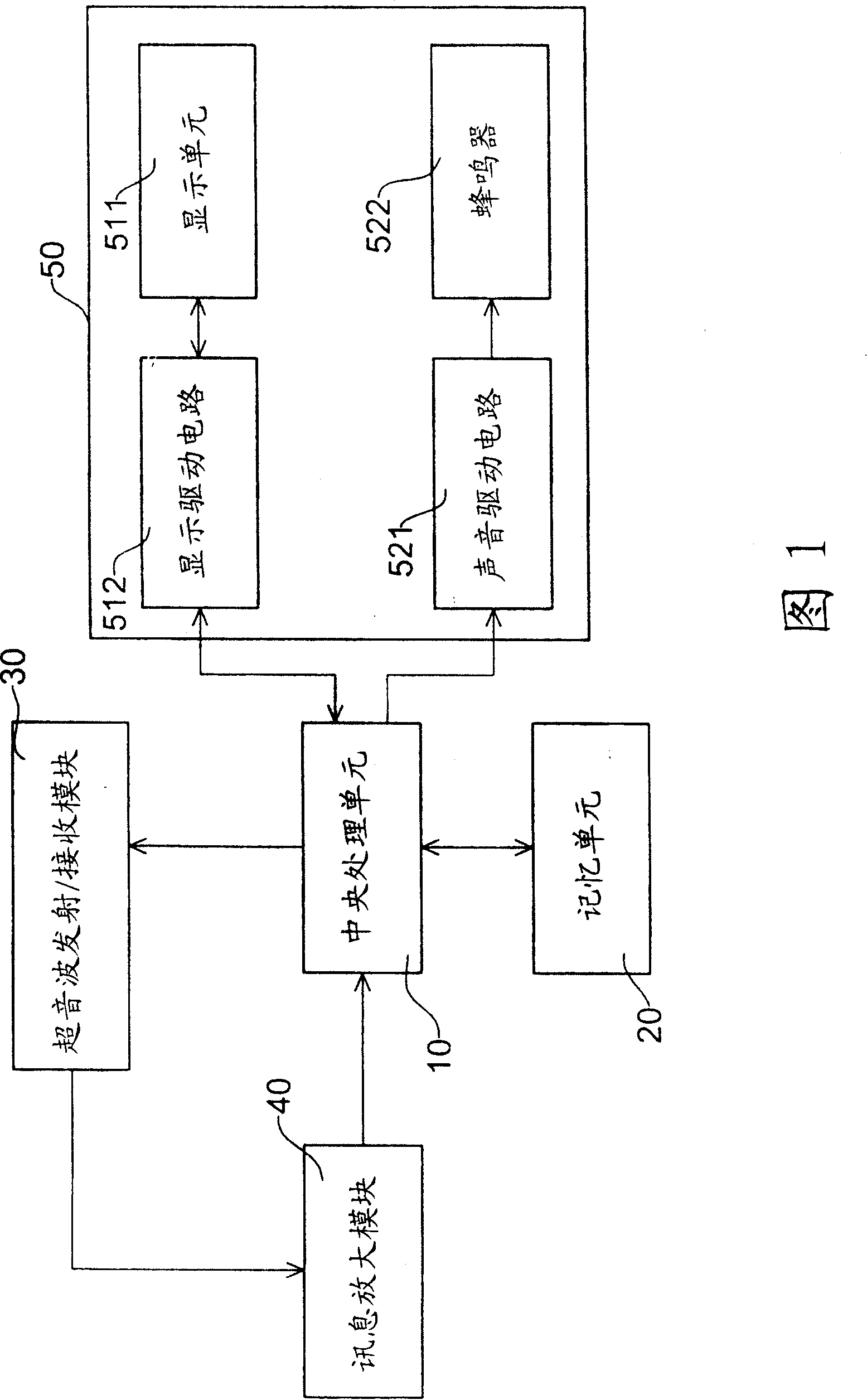

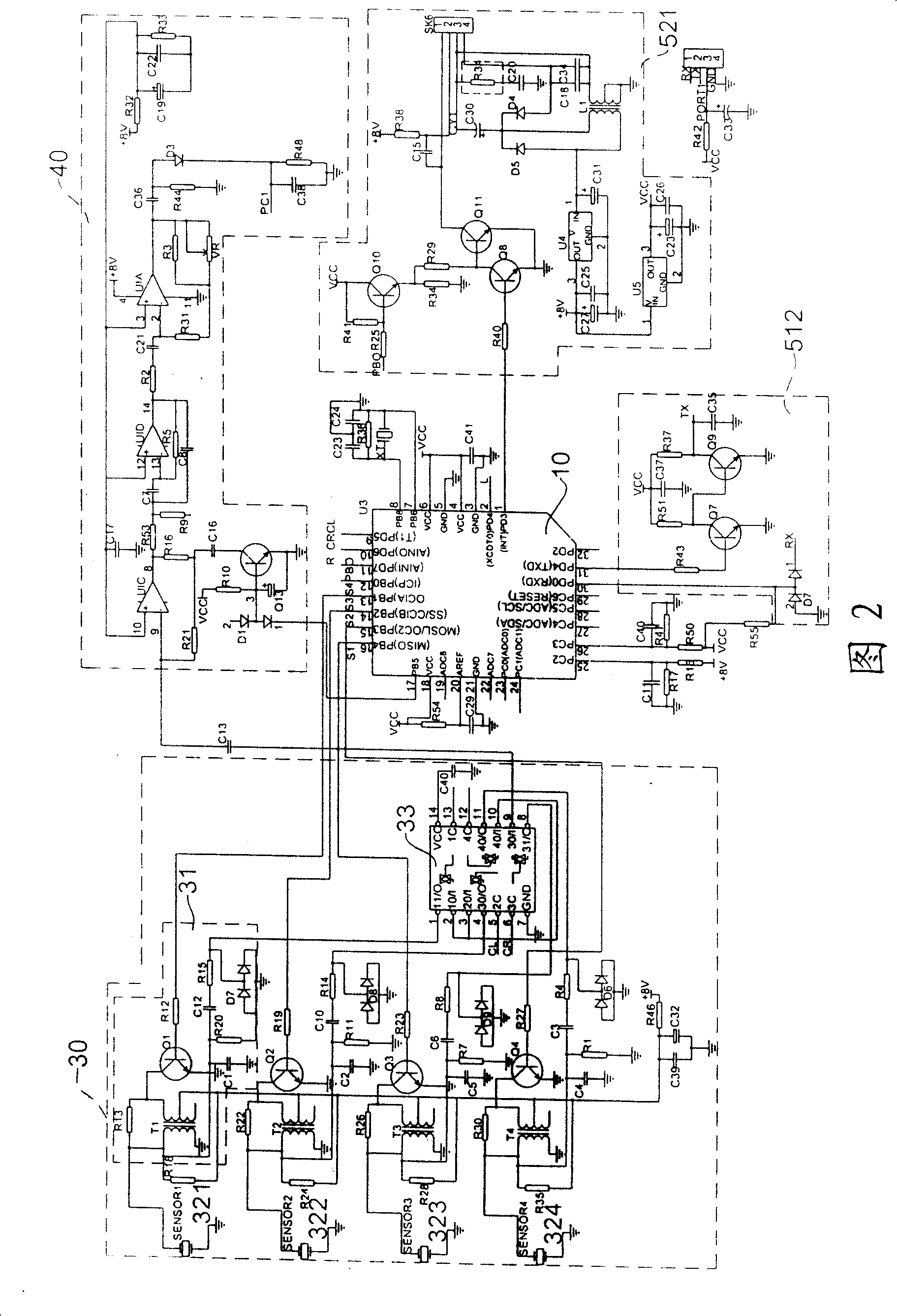

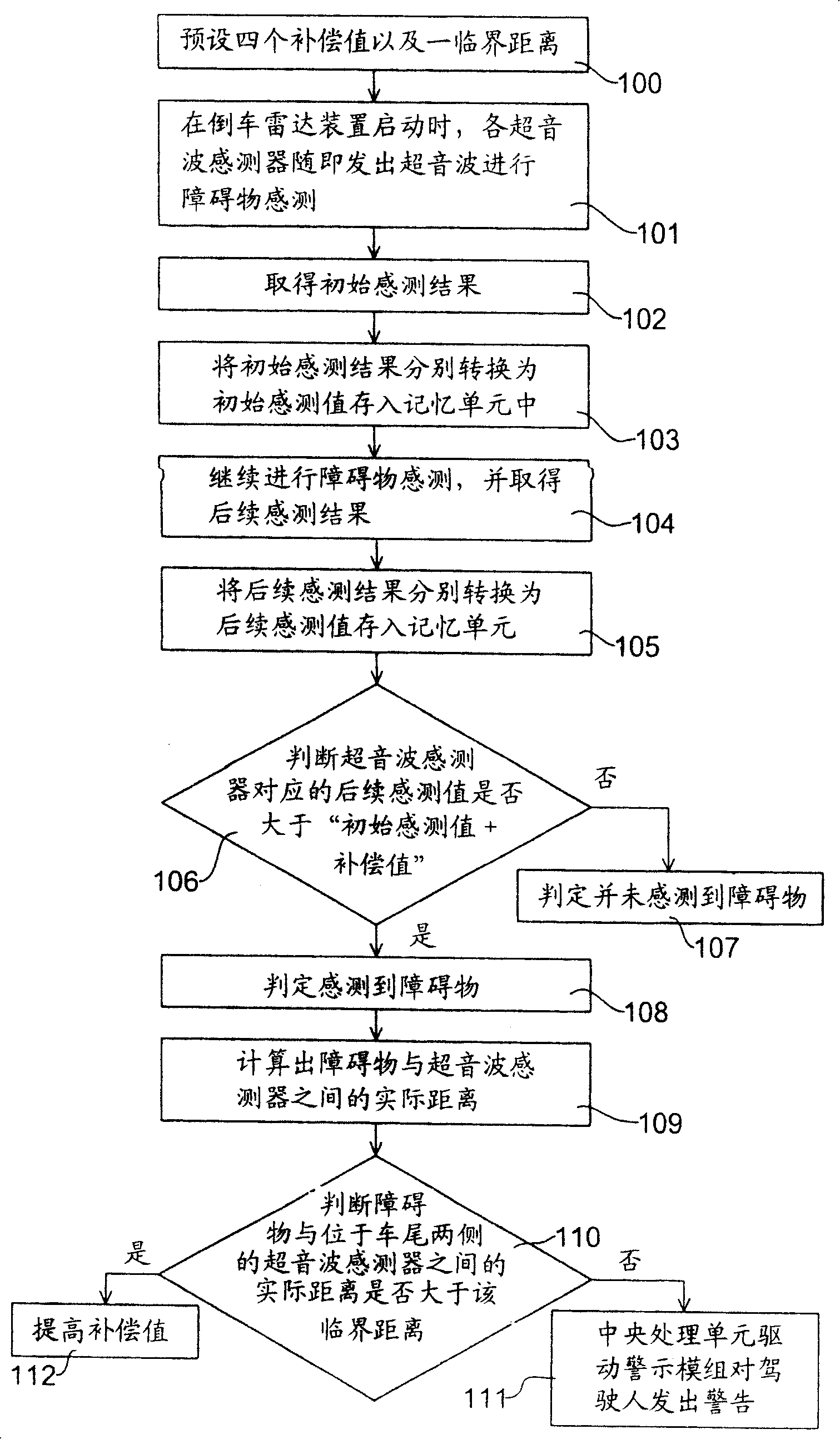

Backing radar installations automatically correcting sensory element scanning area and method thereof

The invention relates to a reverse radar apparatus which automatically revises the scanning area of a sensor and a method thereof. The apparatus of the invention mainly comprises a central processing unit, a memory unit, an ultrasound emission and receiving module, a signal amplifying module and a caution module, wherein, the central processing unit is provided with default compensation value and critical distance in advance. The surrounding status is firstly recorded as initial sensing value when the reverse radar apparatus is started, and then the initial sensing value is compared with subsequent sensing value recorded by sensing the surrounding status when in reversion, if the subsequent sensing value is more than the sum of the initial sensing value and the compensation value, whether the actual distance between the barrier and the ultrasound sensors arranged at both sides of the car rear is larger than the critical distance is judged, and if the actual distance is larger, the compensation value is increased, so the reversion radar can sense the existence of barriers when barriers are closer to the ultrasound sensor, thus reducing the sensitivity of ultra sensors arranged at both sides of the car rear, and achieving the goal of avoiding the misoperation of reverse radar.

Owner:COLIGEN CHINA

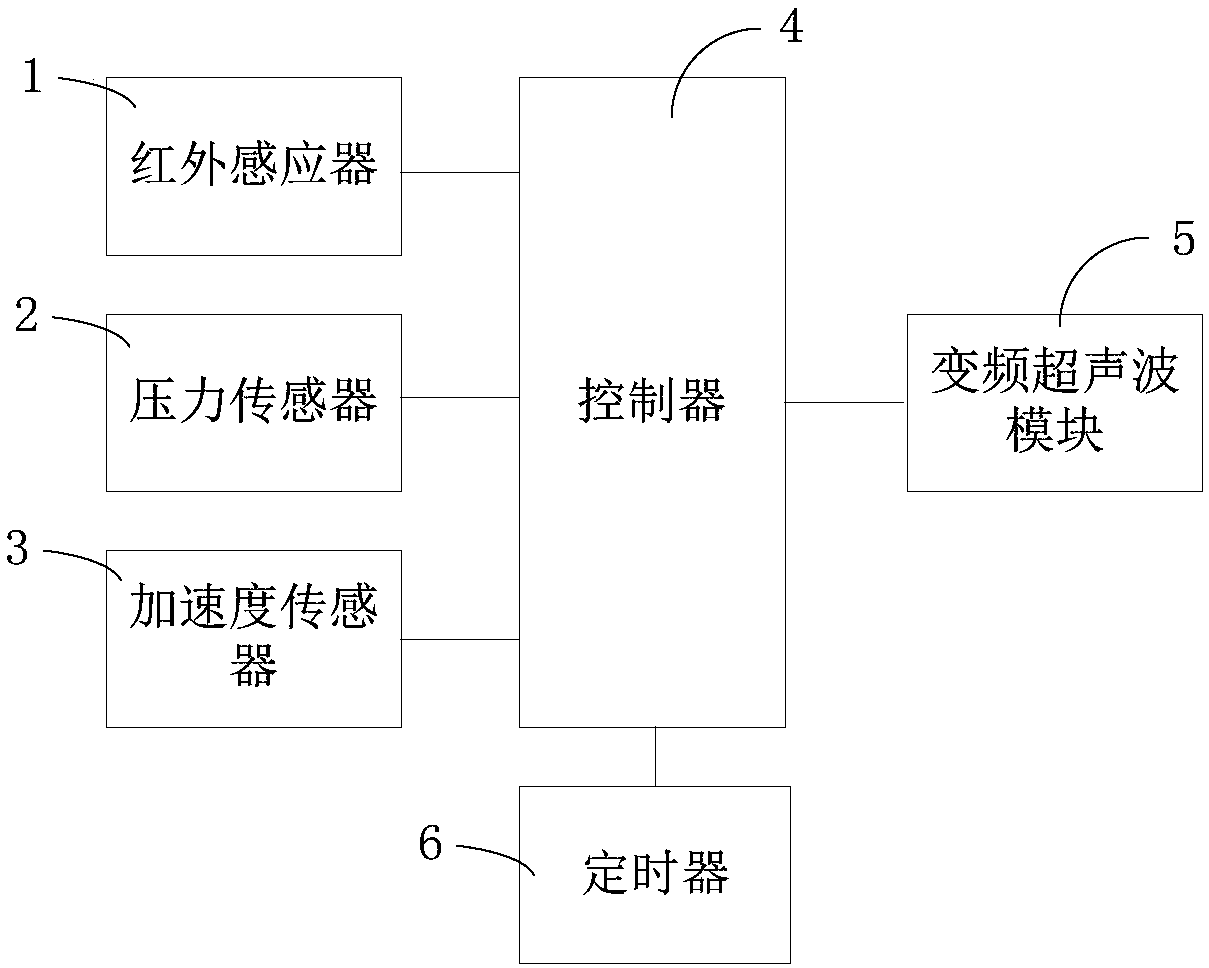

Infrared induction bird repellent

InactiveCN108739790AImprove bird repelling effectAvoid failureAnimal repellantsInfraredTransmission line

The invention provides an infrared induction bird repellent which includes infrared sensor, pressure sensor, acceleration sensor, controller, frequency conversion ultrasonic module and timer; the infrared sensor is connected with the controller to obtain the infrared sensing information of the bird approaching the bird repellent, the pressure sensor and the acceleration sensor are arranged on thetransmission line and used to respectively obtain the pressure information and acceleration information of the transmission line; the controller is connected with the frequency conversion ultrasonic module and is used to start the frequency conversion ultrasonic module according to the pressure information, acceleration information and infrared sensing information; the frequency conversion ultrasonic module is used to emit frequency conversion ultrasound to expel the birds; the timer is used to turn off the frequency conversion ultrasonic module after predetermined time. The embodiment of theinfrared induction bird repellent improves the bird-expelling effect by providing the infrared induction bird repellent, and avoids the substation equipment and transmission line malfunction caused bybird trouble.

Owner:STATE GRID CORP OF CHINA +1

Drying device for producing shale porous bricks

InactiveCN111156805AEvenly heatedIncrease flow rateDrying gas arrangementsDrying chambers/containersThermodynamicsBrick

The invention discloses a drying device for producing shale porous bricks, which comprises an exhaust groove, a drying chamber, an installation tank, a base and a placing frame, wherein the installation tank is arranged at the bottom end of one side of the interior of the base, the drying chamber penetrating through the top end of the base is arranged in the interior of the base on one side of theinstallation tank, a heating wire is arranged at the bottom end of the interior of the drying chamber, and sliding groove is arranged at the bottom end of the interior of the drying chamber on two sides of the heating wire; a first mounting plate is mounted in the sliding groove through rollers matched with the sliding groove, a mounting seat is arranged at the central position of the top end ofthe first mounting plate, the placing frame is arranged at the top end of the mounting seat, and a plurality of heating blocks are arranged on two sides of the placing frame. According to the invention, a driving motor drives a mounting shaft to rotate through the matching action of a cross rod and a convex block, so that the intermittent rotation of the mounting seat is realized, the shale porousbricks can be uniformly heated during drying, the air flow speed can be increased during the rotation process, and the heating efficiency is improved.

Owner:LINAN TONGXIN BUILDING MATERIAL CO LTD

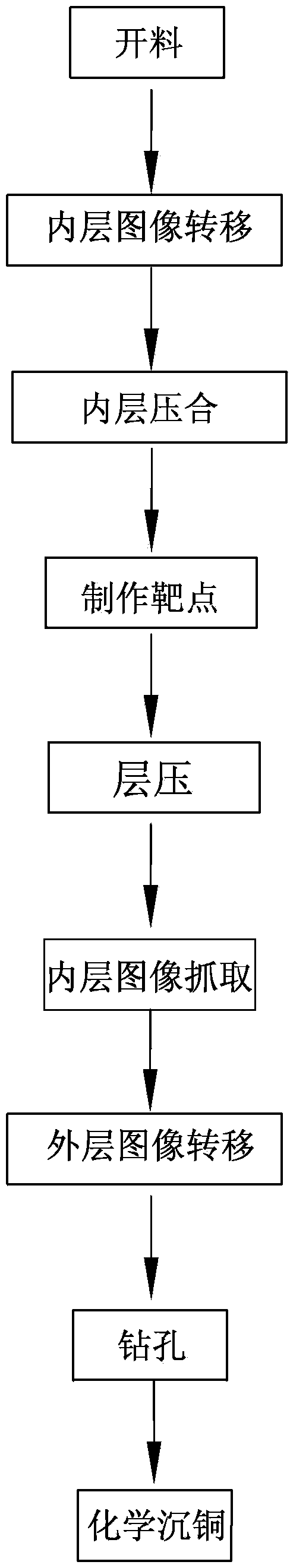

Manufacturing method of multi-layer PCB (printed circuit board)

ActiveCN103533783ACause malfunctionGuaranteed accuracyMultilayer circuit manufactureCopper foilCopper coil

A manufacturing method of a multi-layer PCB comprises the steps as follows: 1), board cutting is performed, so that a jointed board is formed; 2), an inner-layer image is transferred; 3), inner-layer press fit is performed; 4), a target point is manufactured: a part of an exposed inner-layer copper foil of an inner-layer circuit image is manufactured into a special image, so that the target point is manufactured; 5), lamination is performed; 6), the inner-layer image is captured: a CCD (charge coupled device) image sensor is used for capturing the target point on the inner-layer copper coil, and position information of the target point is stored in a computer; 7), an outer-layer image is transferred: the target point on the inner-layer copper foil is captured through the CCD image sensor and taken as a reference, and an outer-layer circuit image is formed; 8), drilling is performed; and 9), chemical copper deposition is performed, and the inner-layer circuit image and the outer-layer circuit image are conducted. The target point is manufactured on a part of the copper foil of the inner-layer circuit image, and when the outer-layer image is transferred, the target point on the inner-layer copper foil is taken as a reference, so that the accuracy of the outer-layer circuit image and the inner-layer circuit image is guaranteed.

Owner:东莞康源电子有限公司

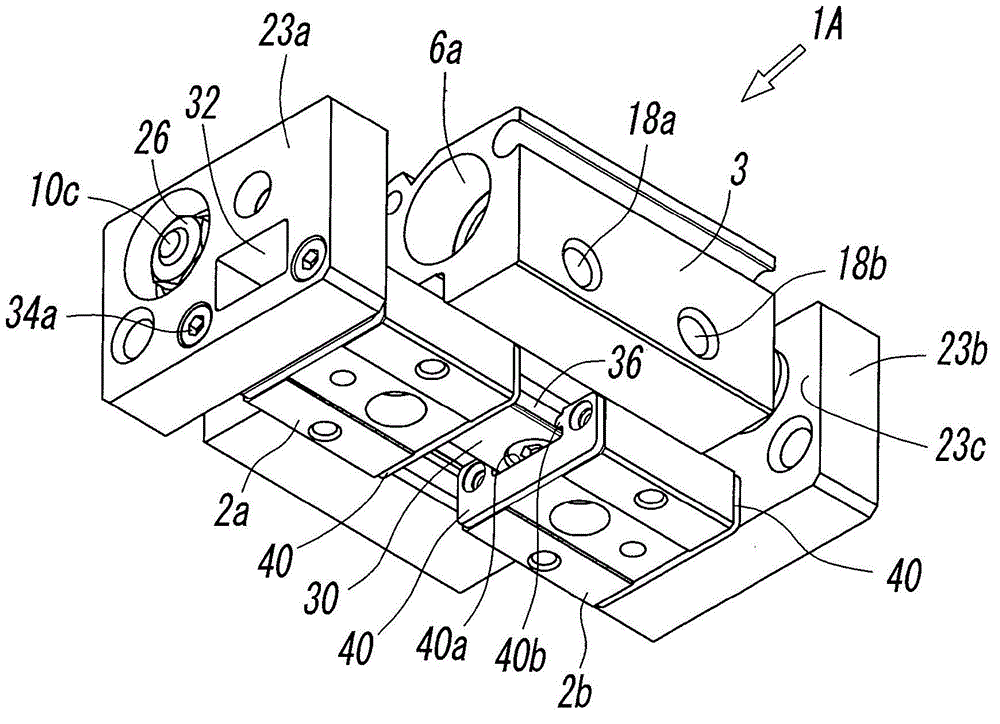

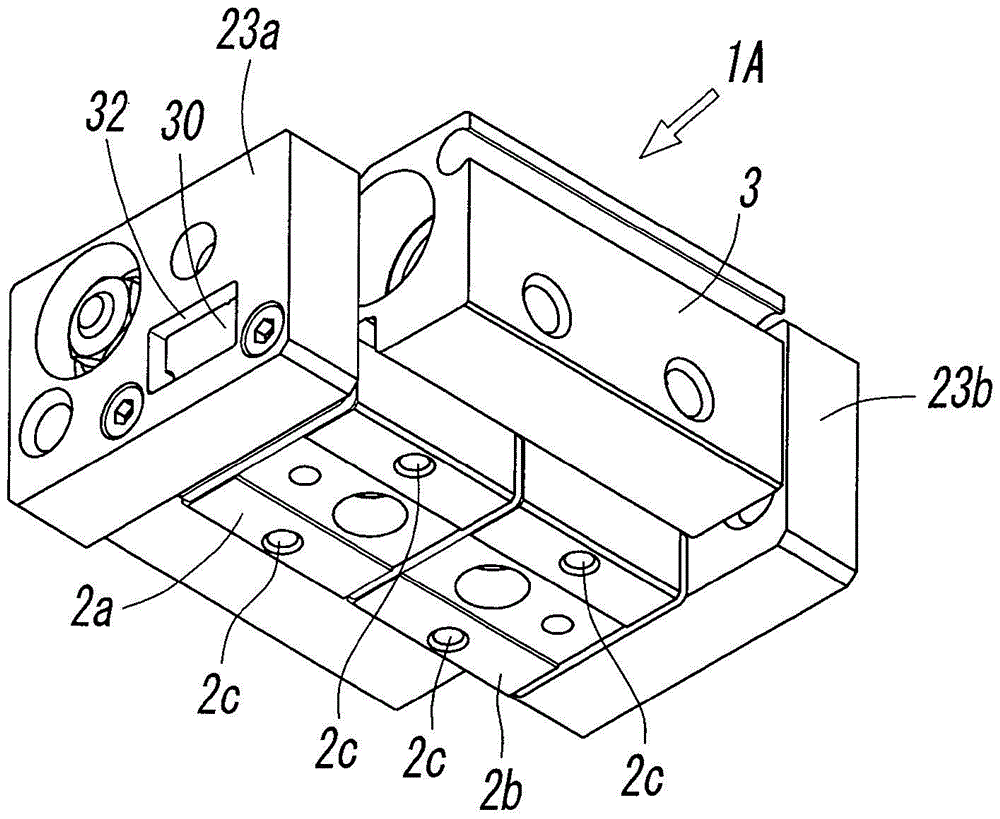

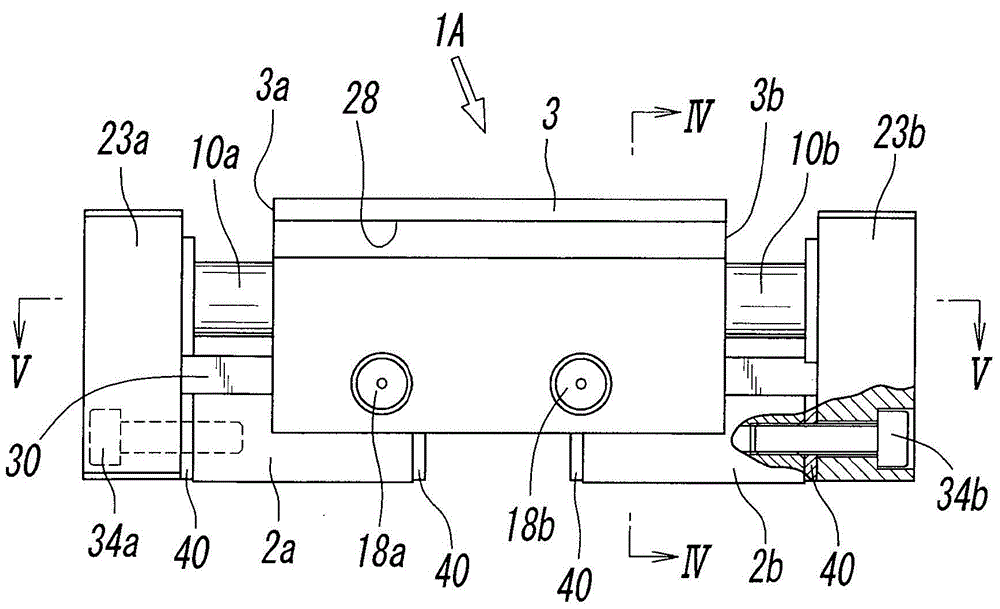

Opening and closing chuck

ActiveCN104816309ANo malfunctionNo malfunction due to dustSleeve/socket jointsGripping headsEngineeringManipulator

Owner:SMC CORP

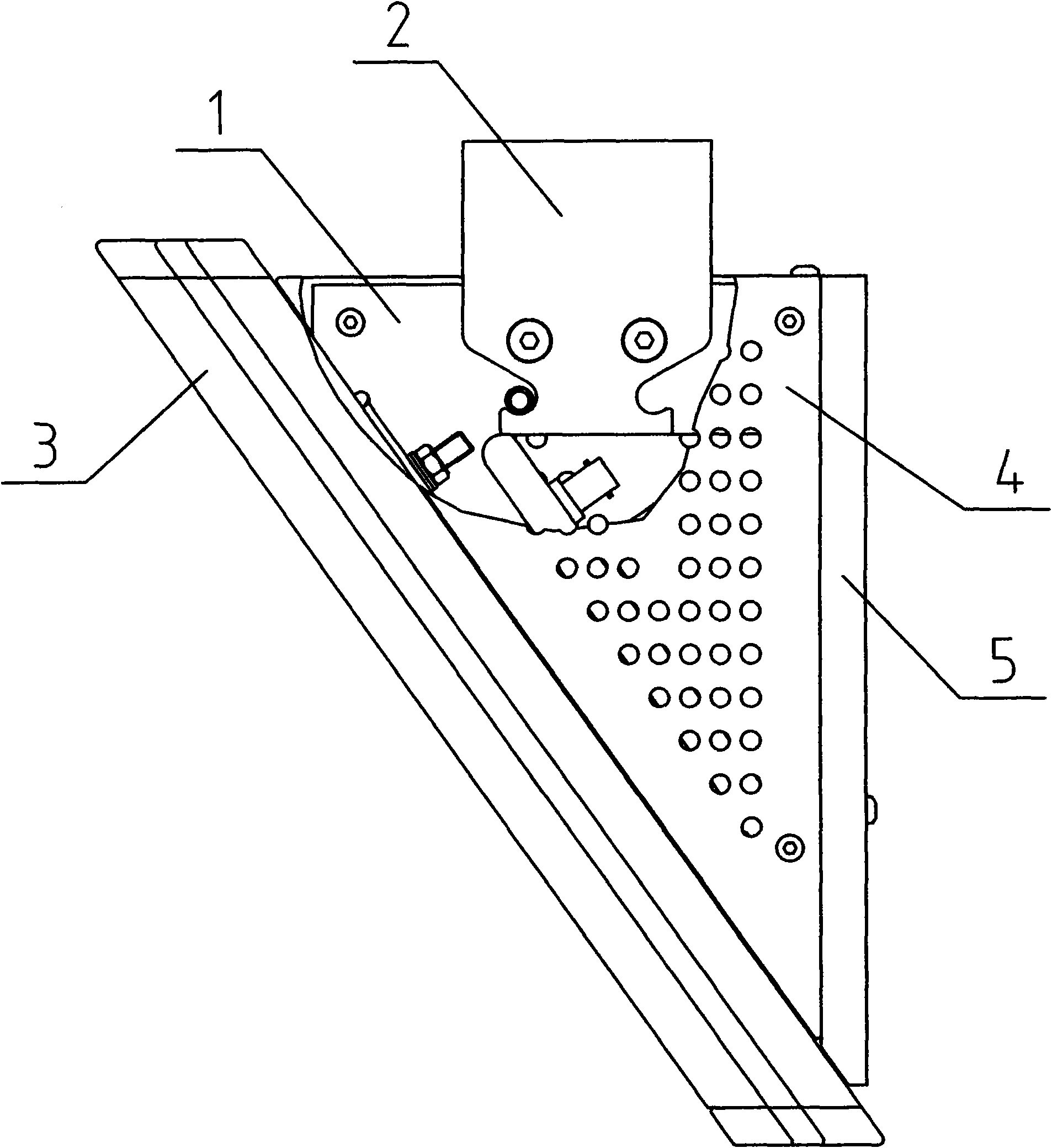

Railway vehicle vehicle-mounted TV

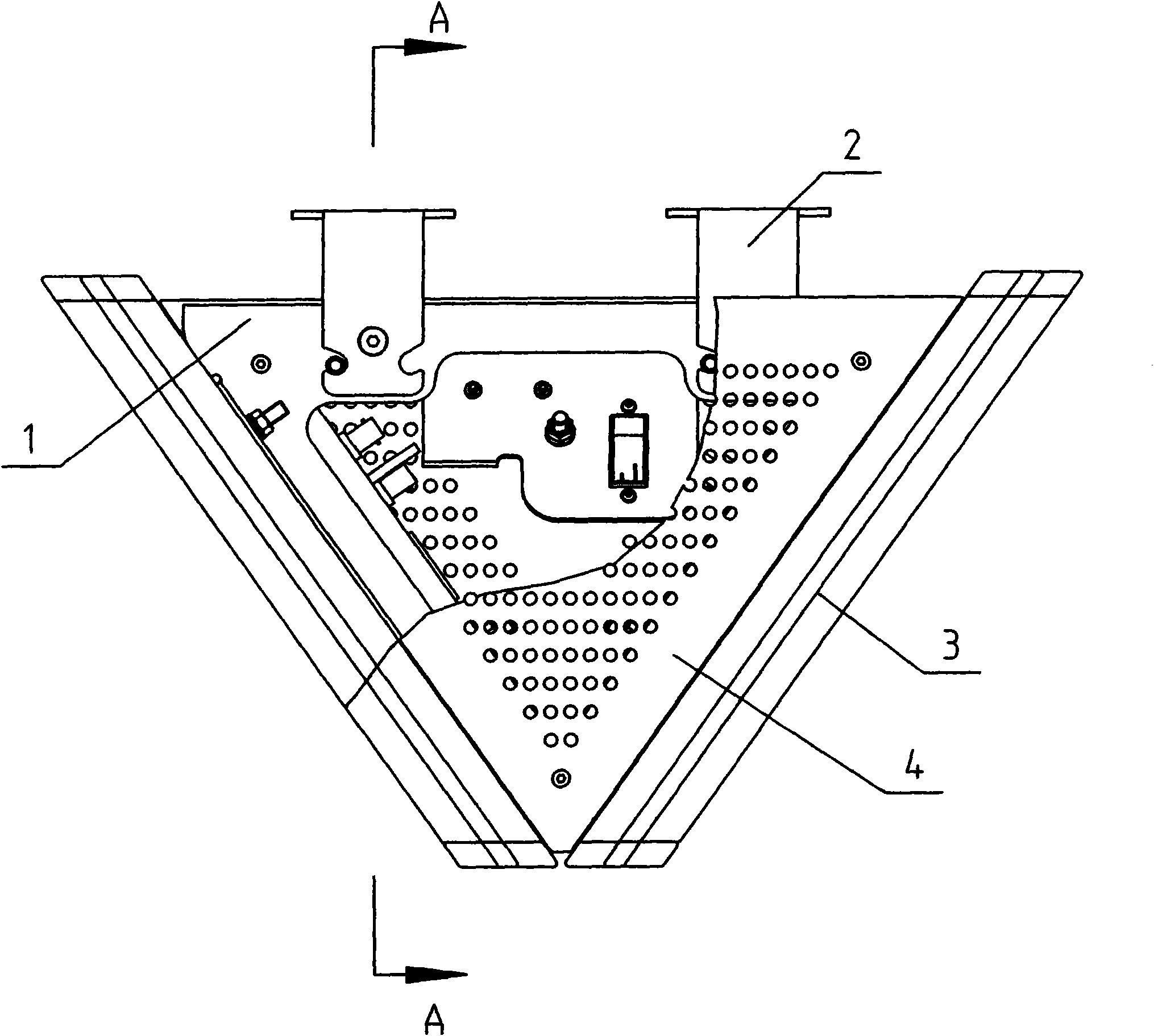

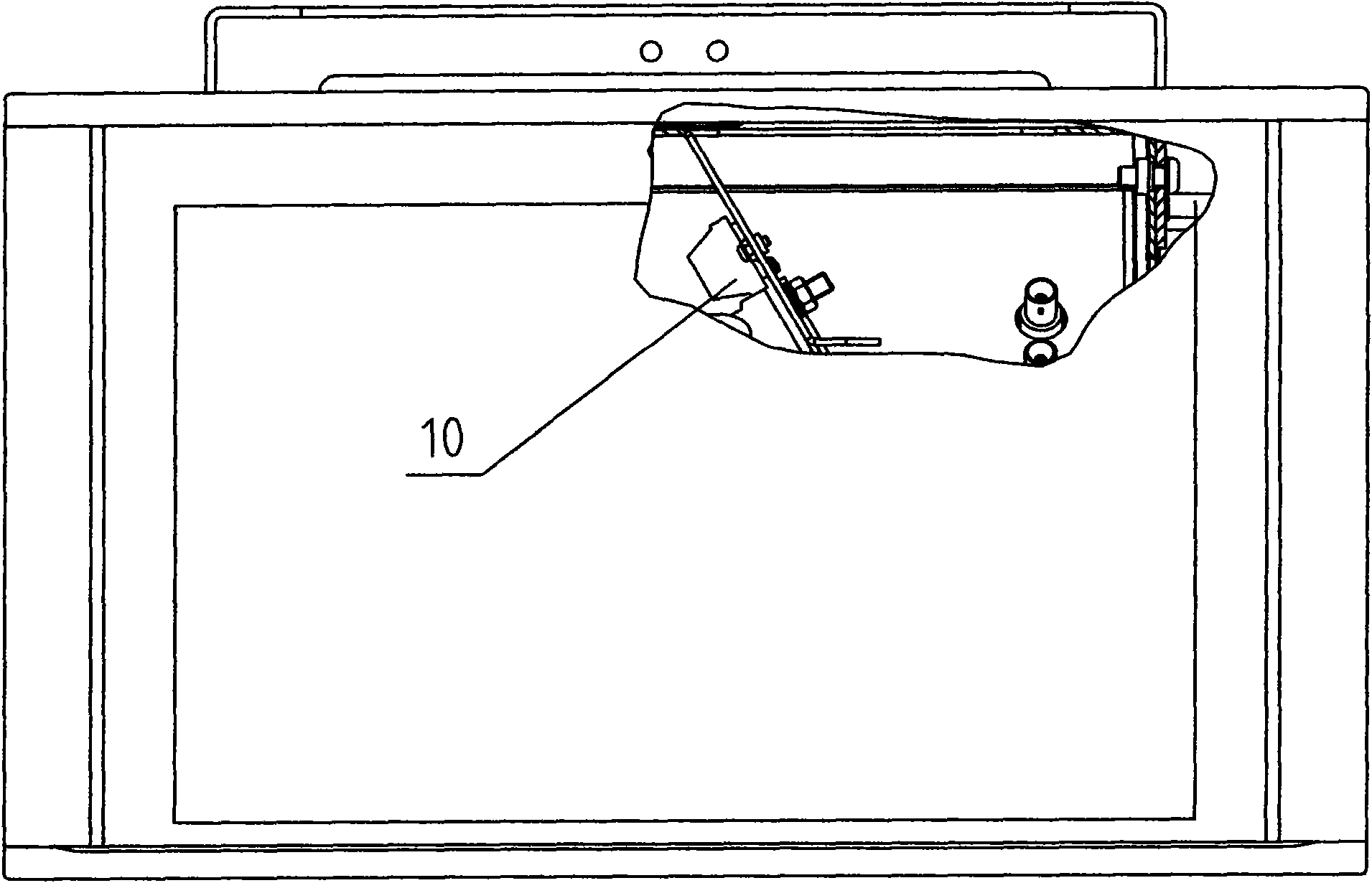

ActiveCN101860692ASatisfy viewing angleWon't hurtTelevision system detailsMachine supportsDisplay deviceTransducer

The invention relates to a railway vehicle vehicle-mounted TV which is arranged on a ceiling of a guest room. The vehicle-mounted TV comprises a video display, a triangular support bracket and a cover plate, wherein, the video display is assembled on the triangular support bracket; the cover plate is arranged at two sides of the video display; the video display is internally provided with an arrangement plate; one side of the arrangement plate is provided with a circuit board; the other side of the arrangement plate is provided with a display screen; the circuit board is provided with a power supply / signal input board, an LED control board and a backlight high pressure transducer. The railway vehicle vehicle-mounted TV of the invention has simple and reasonable structure and high reliability, and is beautiful and practical; the video display is arranged on the triangular support bracket, leads the display to be inclined downwards for a certain angle, thus satisfying watching view angle of passengers; and meanwhile the video displays can be interchanged compatibly. The railway vehicle vehicle-mounted TV of the invention uses metal shell, is sturdy and durable, has edge chamfers and smooth surface, ensures that passengers can not be hurt due to touch, is also provided with power supply protection and conversion circuits, and can not cause television fault due to the touch of passengers.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Full-automatic abrasive cloth flap disc machining equipment

The invention discloses full-automatic abrasive cloth flap disc machining equipment, which comprises a frame; a feeding and discharging storage mechanism of a flap disc, a conveying rotary device, a flap disc autorotation mechanism, a glue dripping device, a slice mounting device and a reshaping mechanism are arranged on the frame; and when the machining equipment works, the flap disc is fetched and placed on the flap disc autorotation mechanism arranged on the conveying rotary device by the feeding mechanism of the flap disc, a small turntable and the flap disc are driven by a main turntableto rotate below the glue dripping device, the glue dripping device drips glue to the flap disc, then the main turntable continuously rotates to drive the flap disc coated with the glue to rotate below the slice mounting device, the slice mounting device slices an abrasive cloth tape, the slices are stuck to the flap disc coated with the glue, the main turntable continuously rotates to drive the flap disc stuck with abrasive cloth sheets to rotate below a reshaping device, the flap disc is reshaped by the reshaping device, finally, the main turntable drives the finished flap disc to rotate below the discharging storage mechanism, the finished disc is grabbed and discharged by the discharging storage mechanism, and machining of the whole process is finished.

Owner:台州市黄岩豪林抛光磨具有限公司

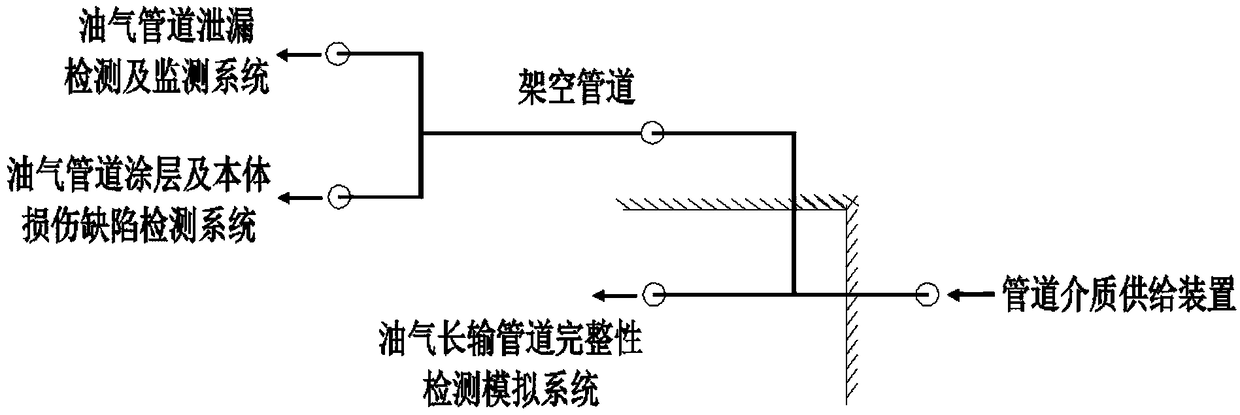

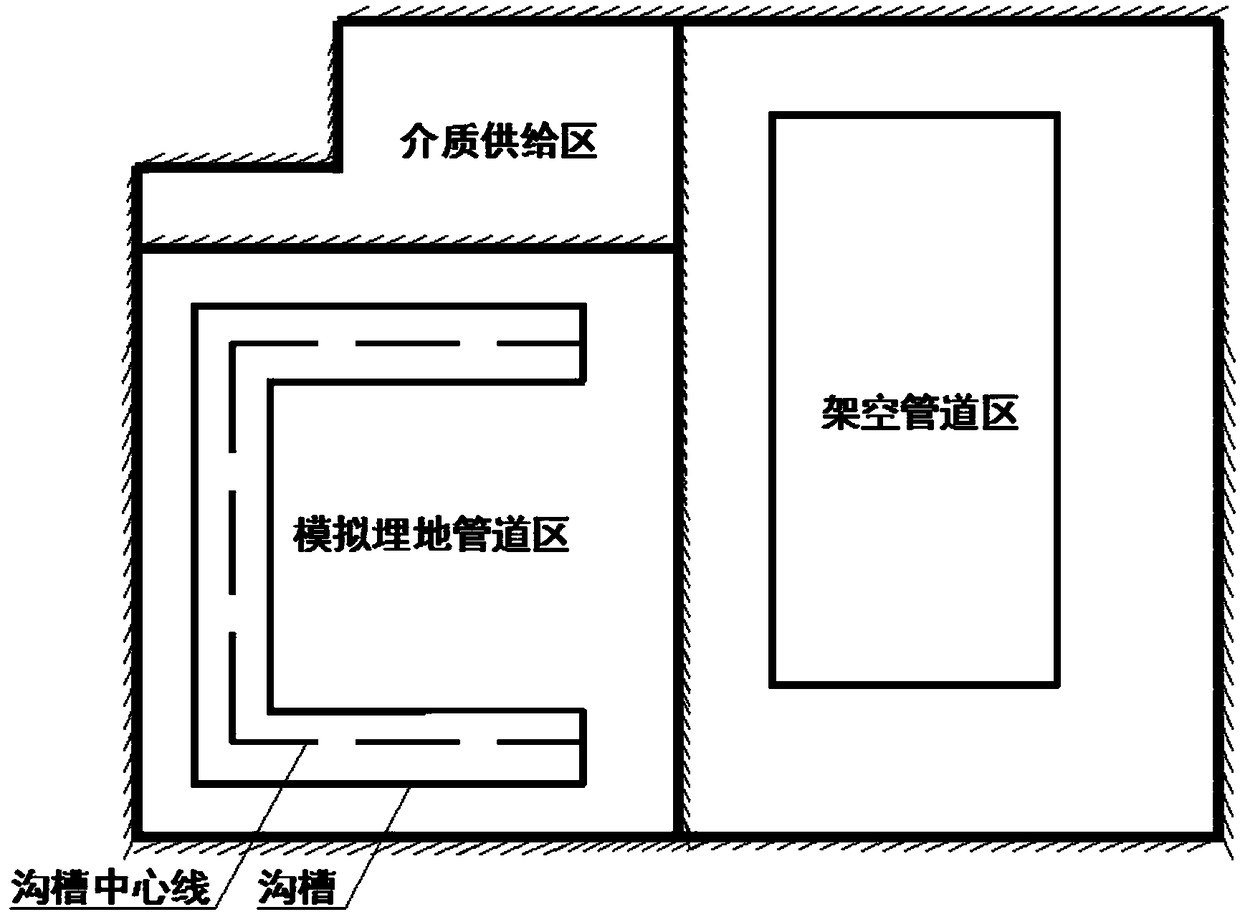

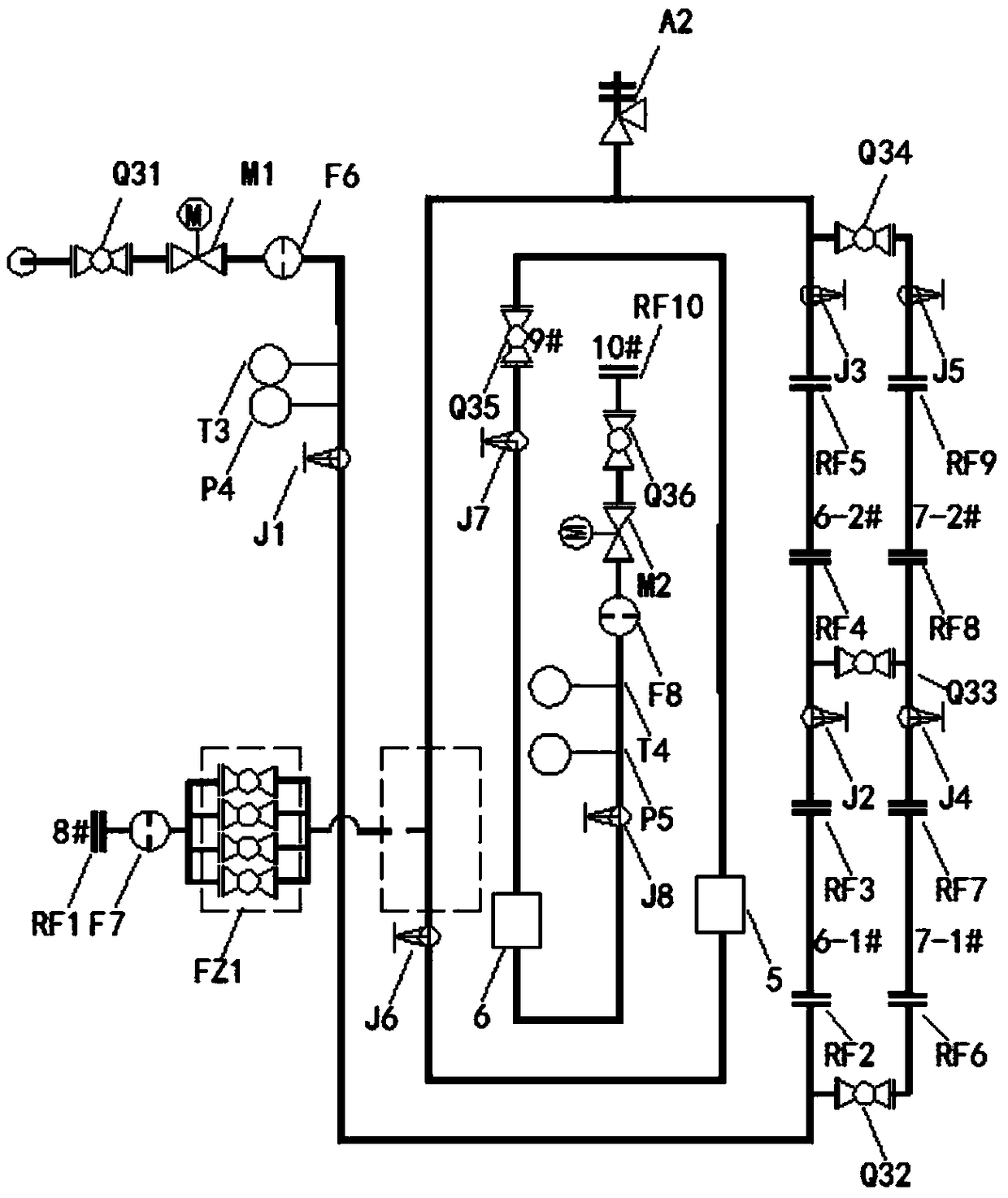

Three-dimensional multi-layer oil and gas pipeline safety detecting system

PendingCN108119762AAffect securityReflect the degree of influencePipeline systemsDimensional modelingOil and gas pipelines

The invention discloses a three-dimensional multi-layer oil and gas pipeline safety detecting system which is provided with a medium supply area, a simulated buried pipeline area and an overhead pipeline area. A pipeline medium supply device is installed in the medium supply area, and a lower layer simulated buried long-distance pipeline integrity detection simulation system is installed in a trench of the simulated buried pipeline area, and upper two layers of overhead pipeline simulation subsystems are installed in the overhead pipeline area. The three-dimensional multi-layer oil and gas pipeline safety detecting system has the advantages that corresponding scene simulation is performed against problems that may occur in oil and gas pipelines in different actual scenarios, and the simulation conditions are presented hierarchically; for the actual transportation environment of oil and gas pipelines, the pipeline environment exposed to the air is simulated by the overhead pipeline simulation subsystems respectively, the buried pipeline environment is simulated by the simulated buried long-distance pipeline integrity detection simulation system, and the two are tested in different regions; the simulation conditions and teaching effects are straightforward and simple, which helps students to visually observe and learn fault points and fault situations and is concise, efficient and attractive.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

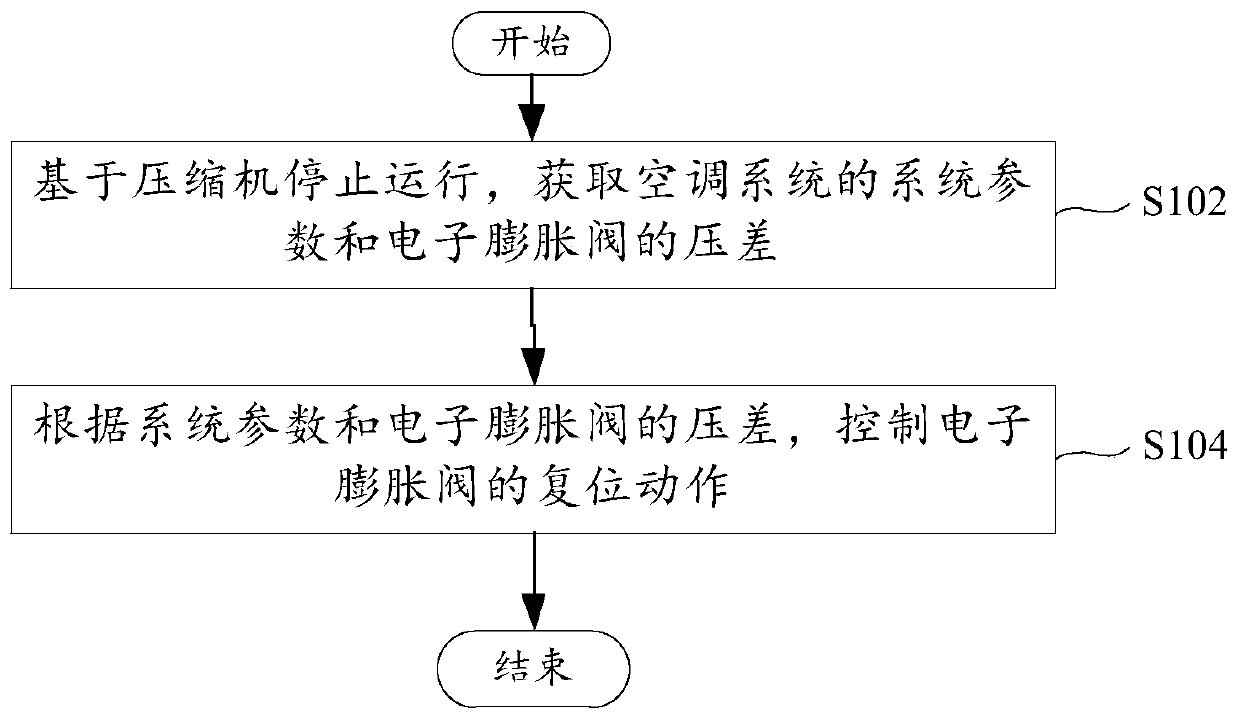

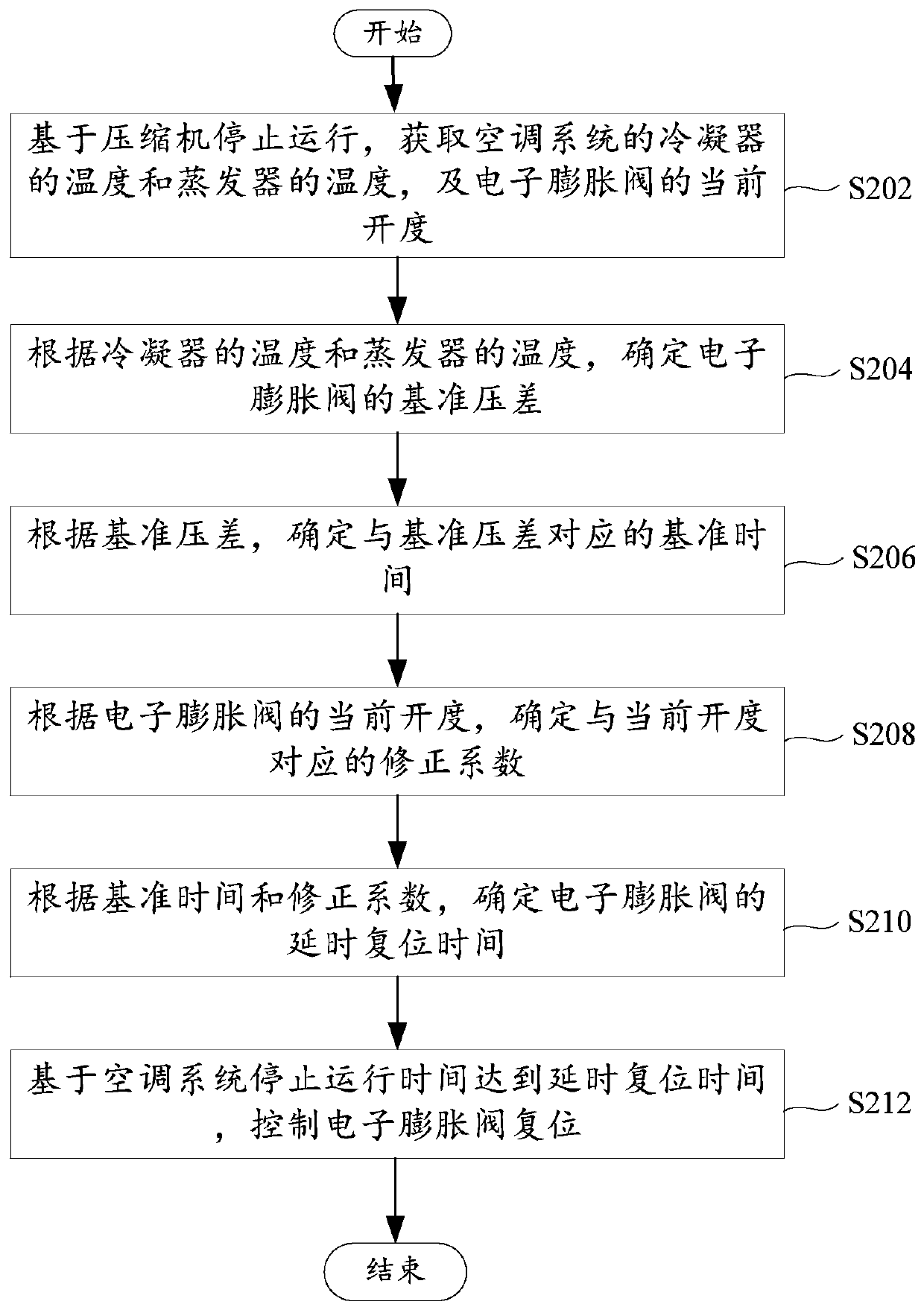

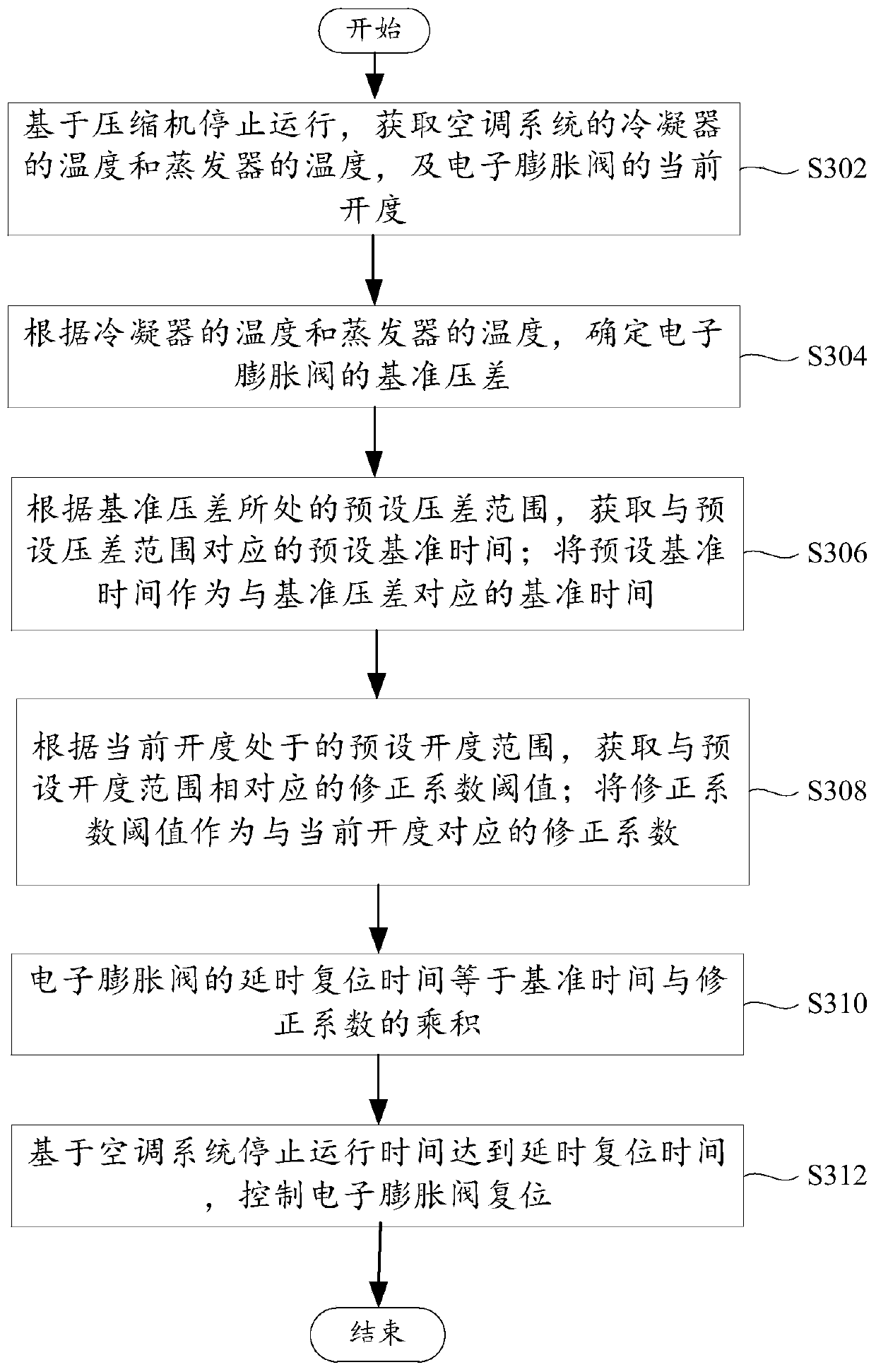

Control method of air-conditioning system, air-conditioning system and computer storage medium

ActiveCN111426009ACause malfunctionImprove stabilityMechanical apparatusSpace heating and ventilation safety systemsControl engineeringEngineering

The invention provides a control method of an air-conditioning system, the air-conditioning system and a computer storage medium. The air-conditioning system comprises a compressor and an electronic expansion valve; and the compressor communicates with the electronic expansion valve through a pipeline. The control method of the air-conditioning system comprises the following steps: acquiring a system parameter of the air-conditioning system and pressure difference of the electronic expansion valve on the basis that the compressor stops operating; and according to the system parameter and the pressure difference of the electronic expansion valve, controlling reset action of the electronic expansion valve. According to the control method of the air-conditioning system provided by the invention, the system parameter and the pressure difference of the electronic expansion valve are acquired, and the reset action of the electronic expansion valve is controlled according to the system parameter and the pressure difference of the electronic expansion valve, so that delay reset of the electronic expansion valve is realized and reset failure of the electronic expansion valve caused by thatthe pressure difference of the valve body before and after exceeds the maximum action pressure difference is avoided, thereby improving the stability of the air-conditioning system.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

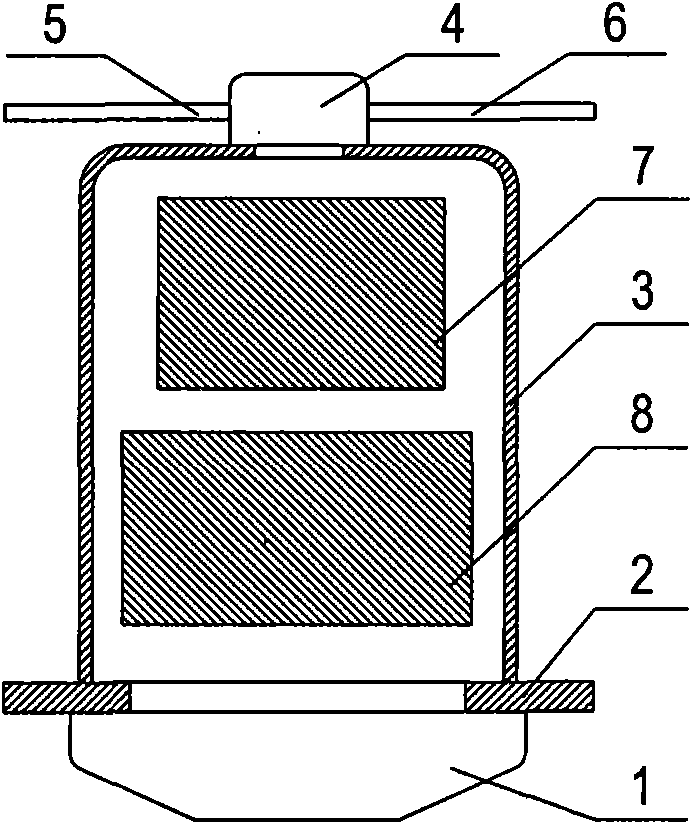

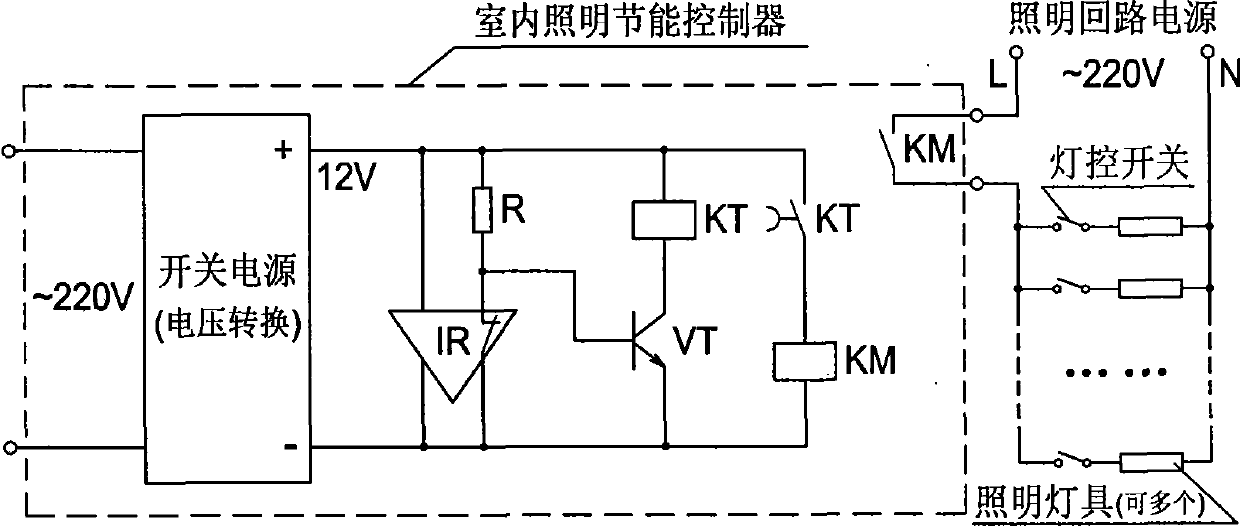

Indoor illumination energy-saving controller

InactiveCN101772241ASave electricityCause malfunctionElectric light circuit arrangementEnergy saving control techniquesMicrowaveControl circuit

The invention discloses an indoor illumination energy-saving controller, and relates to an energy-saving controller for indoor illumination. The controller comprises a dual-technology detector (microwave-passive infrared dual-technology detector), a switching power supply, a control circuit board, and a contactor controlling the on / off of an illumination power supply, wherein the control circuit board is provided with a delay circuit and an on / off circuit of the illumination power supply; the dual-technology detector, the contactor controlling the on / off of the illumination power supply, and the switching power supply are all connected to the delay circuit. The indoor illumination energy-saving controller can be used for controlling the indoor illumination power supply to be on when people exist indoors or to be delayed to be off when no people exists indoors, so that electric energy can be greatly saved.

Owner:中国建筑东北设计研究院有限公司

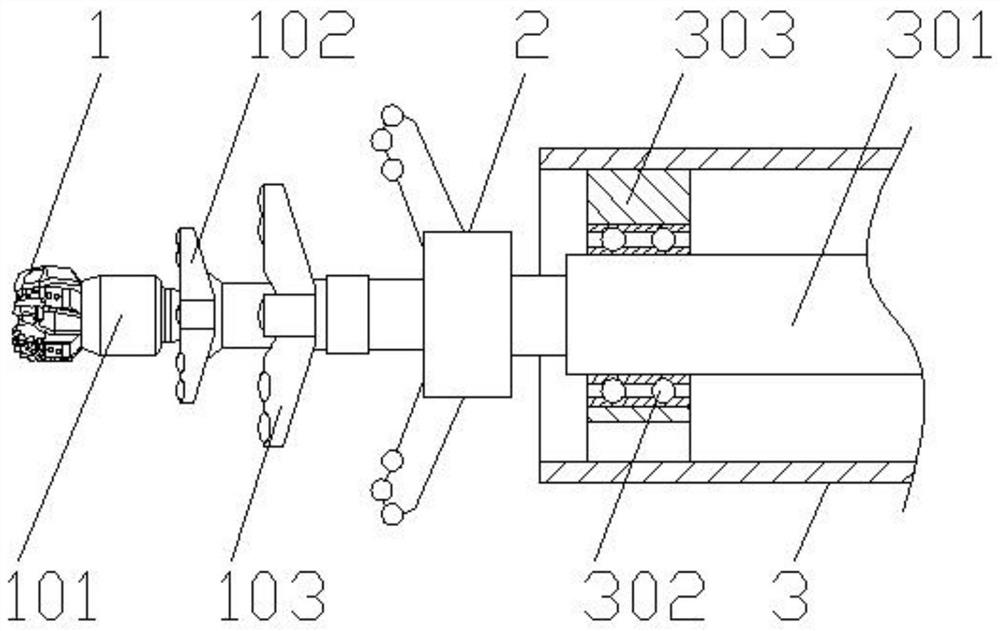

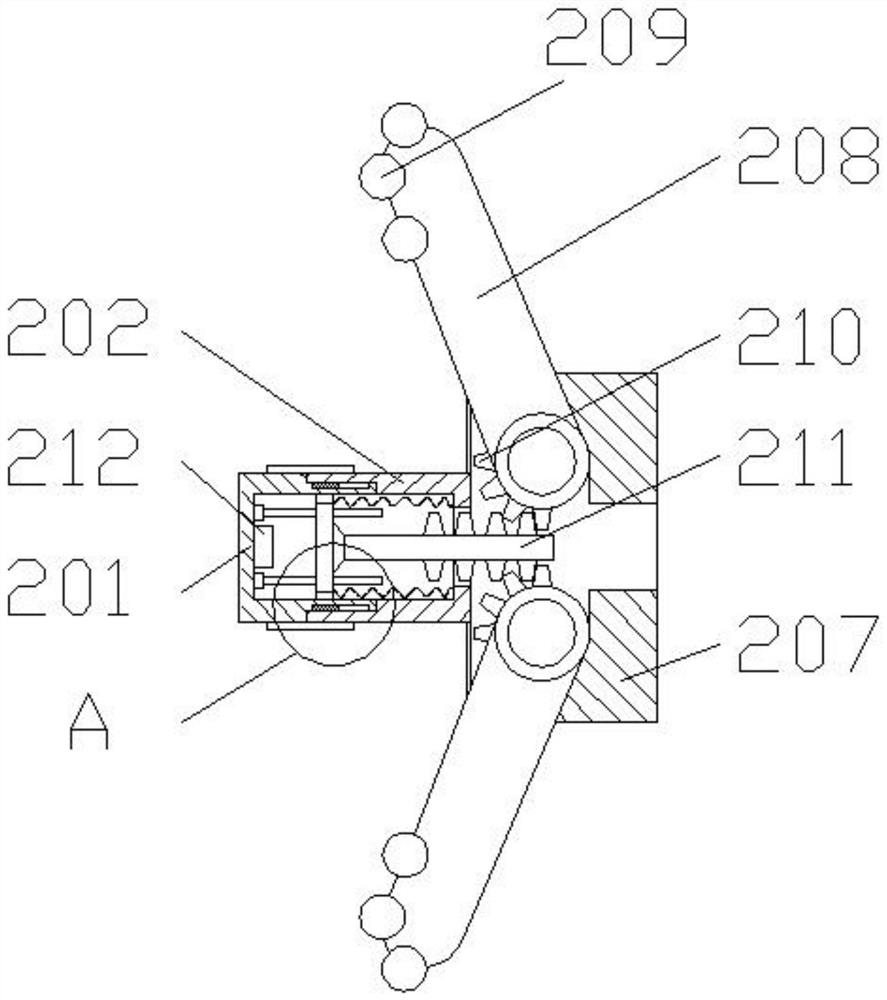

Soft coal seam one-time hole forming while-drilling casing device

PendingCN113530448AReduce exposure timeReduce disturbanceDrill bitsGas removalCoal briquetteButt joint

The invention relates to a soft coal seam one-time hole forming while-drilling casing device. The soft coal seam one-time hole forming while-drilling casing device comprises a multi-stage reamer bit, wherein a blade contraction mechanism is arranged on the right surface of the multi-stage reamer bit, a rotary casing dragging mechanism is arranged on the right surface of the blade contraction mechanism, and the blade contraction mechanism comprises a first butt joint sleeve. According to the soft coal seam one-time hole forming while-drilling casing device, the multi-stage reamer bit and the blade contraction mechanism are arranged, the multi-stage reamer bit can achieve the effect that multiple times of reaming can be completed through one bit and one-time drilling, disturbance to the hole wall is reduced, the hole exposure time is greatly shortened, and therefore the hole collapse probability is greatly reduced; if hole wall collapse occurs in the drilling process, a casing following the bit can support collapsed crushed coal outside the casing, and drilling accidents such as drilling tool falling and breaking, drill jamming and drill burying cannot be caused; and the casing can be pulled back and forth to crush coal briquettes, the crushed coal briquettes are discharged out of holes through drilling fluid, and local hole collapse can be treated.

Owner:陕西东田能源科技有限公司

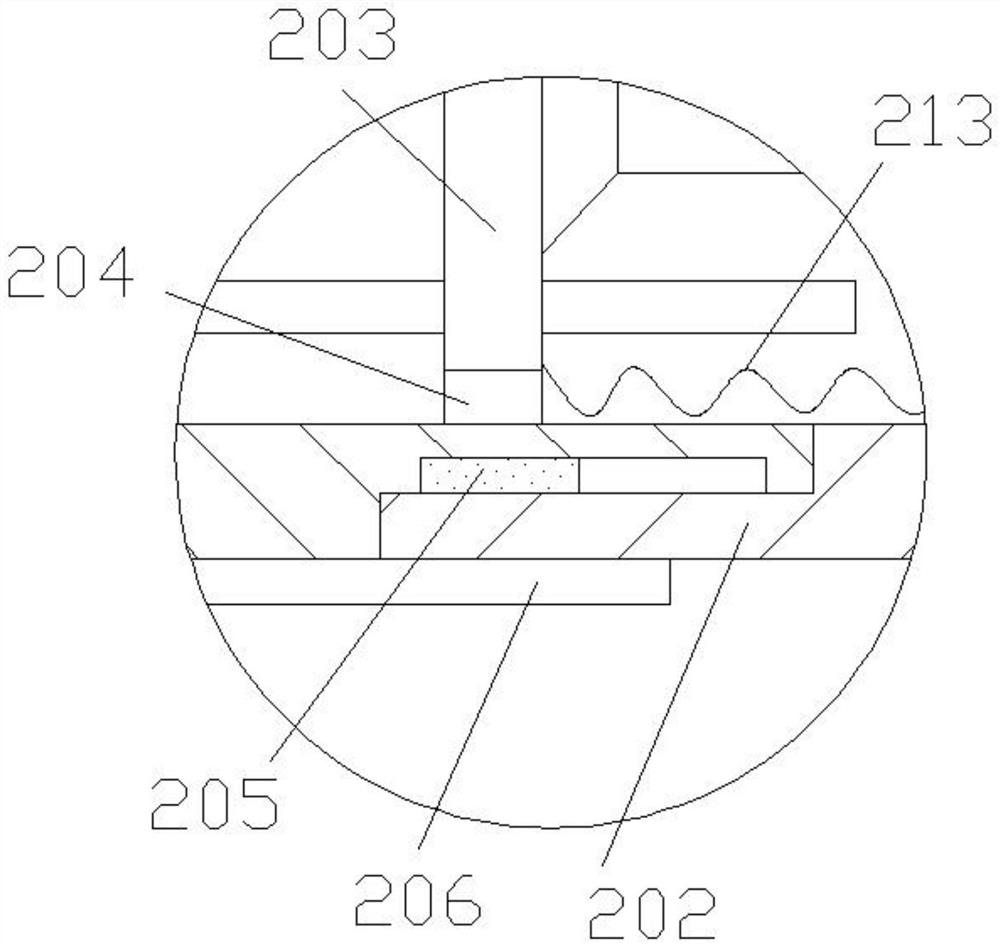

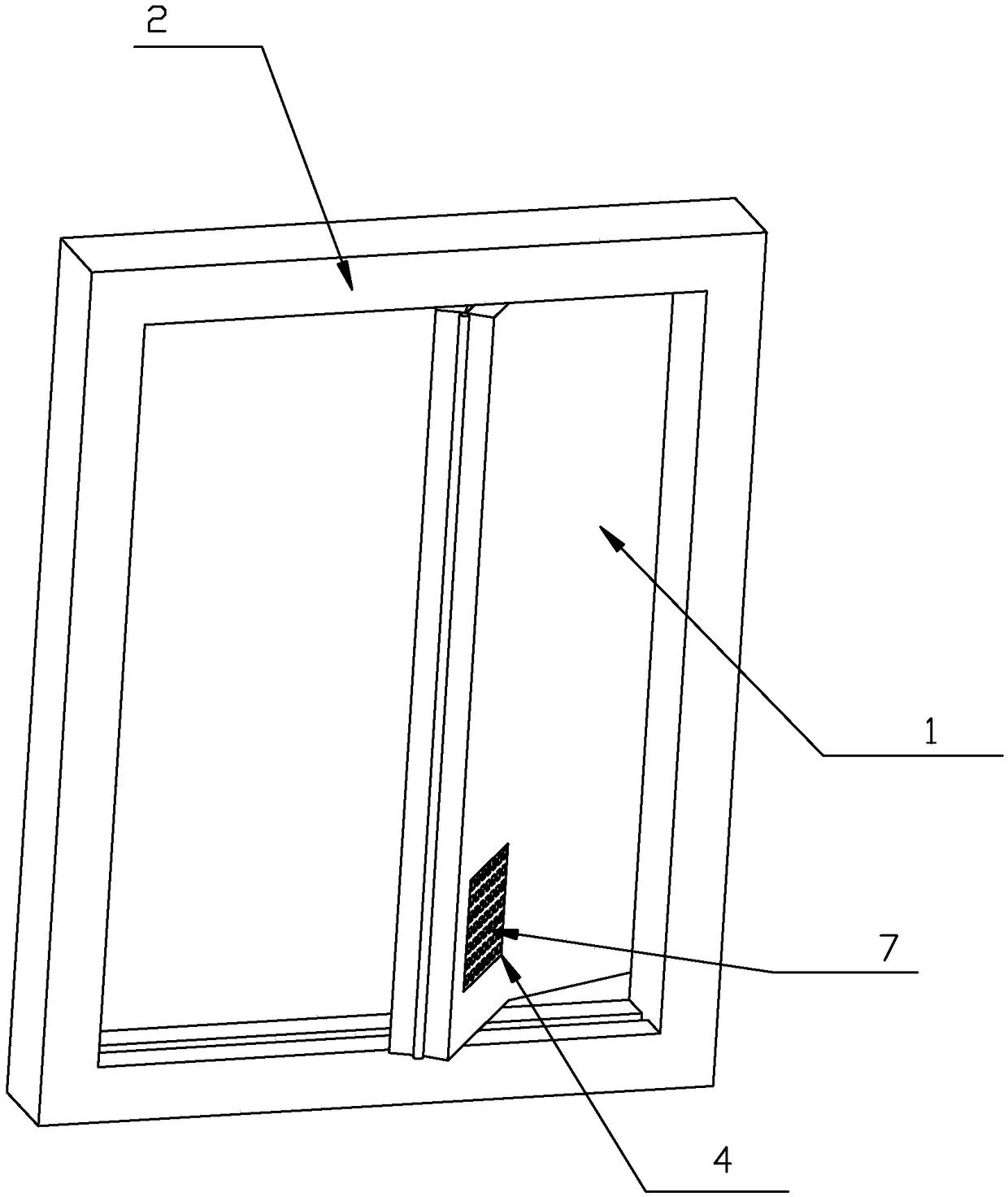

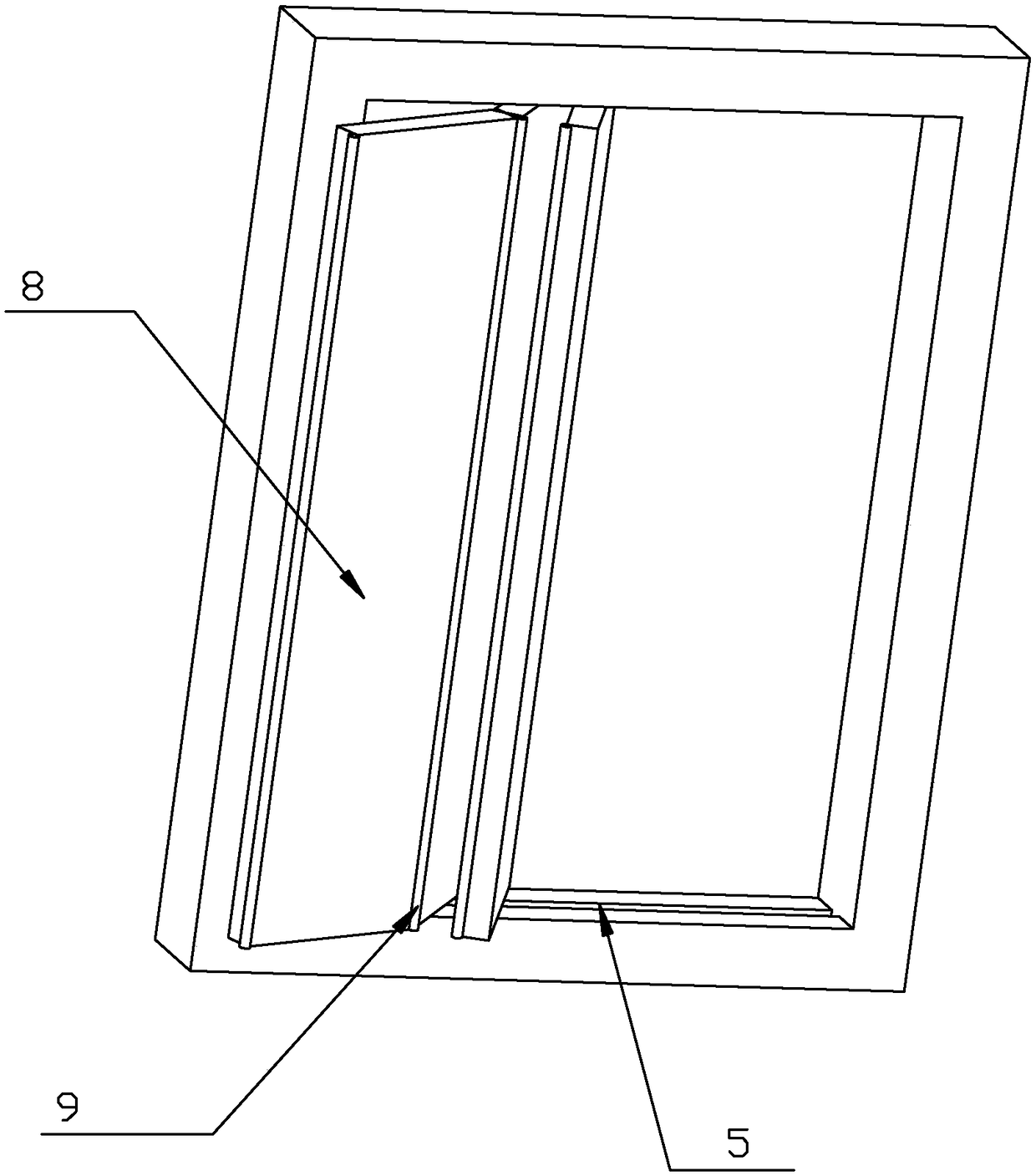

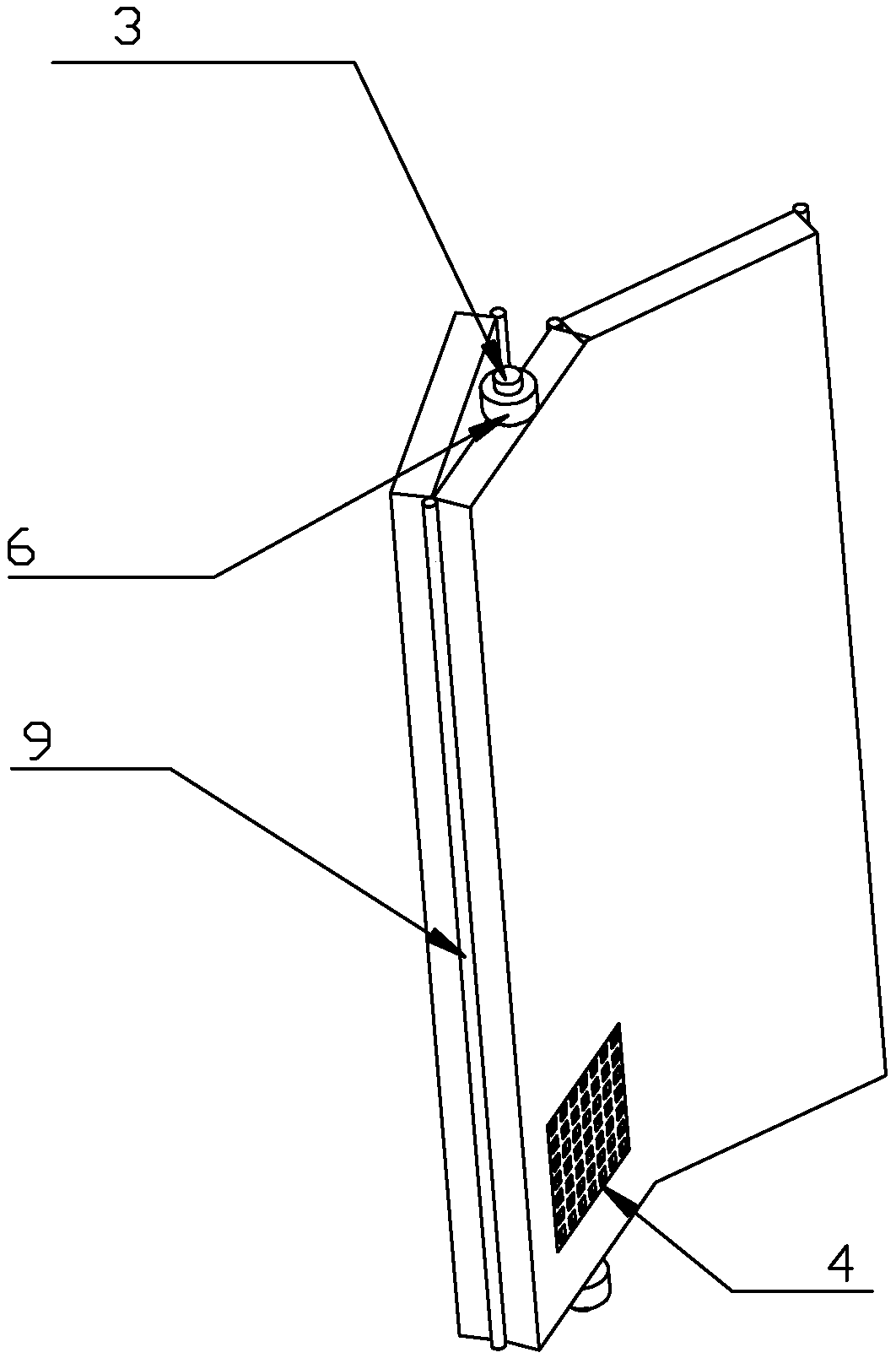

Folding rotary sliding door with indoor dehumidification function

InactiveCN109356488AIncrease flexibilityImprove practicalityLighting and heating apparatusSpace heating and ventilation detailsEngineeringMoisture sensor

The invention relates to a folding rotary sliding door with indoor dehumidification function. A door body comprises a sliding device and a dehumidification device embedded in the door body, the sliding device comprises pulleys and rotating units, and each rotating unit comprises an upper rotating block and a lower rotating block. When a door is opened, the door body can rotate through the rotatingunits and can be displaced to one side of a door frame through the pulleys; and when the door is closed, the door body can be displaced to the center of the door frame through the pulleys and can rotate through the rotating units to close the door. A dehumidification grid is arranged between the dehumidification device and the surface of the door body; the dehumidification device comprises a humidity sensor and a dehumidification unit, wherein the dehumidification unit comprises a CPU control module, a dehumidification module and a power supply module, and a working humidity value is arrangedin the CPU control module; and the humidity sensor can monitor the current humidity value in real time, and when the current humidity value is not less than the working humidity value, the CPU control module drives the dehumidification module to work. According to the folding rotary sliding door with the indoor dehumidification function, the indoor occupied space is effectively reduced.

Owner:WENZHOU POLYTECHNIC

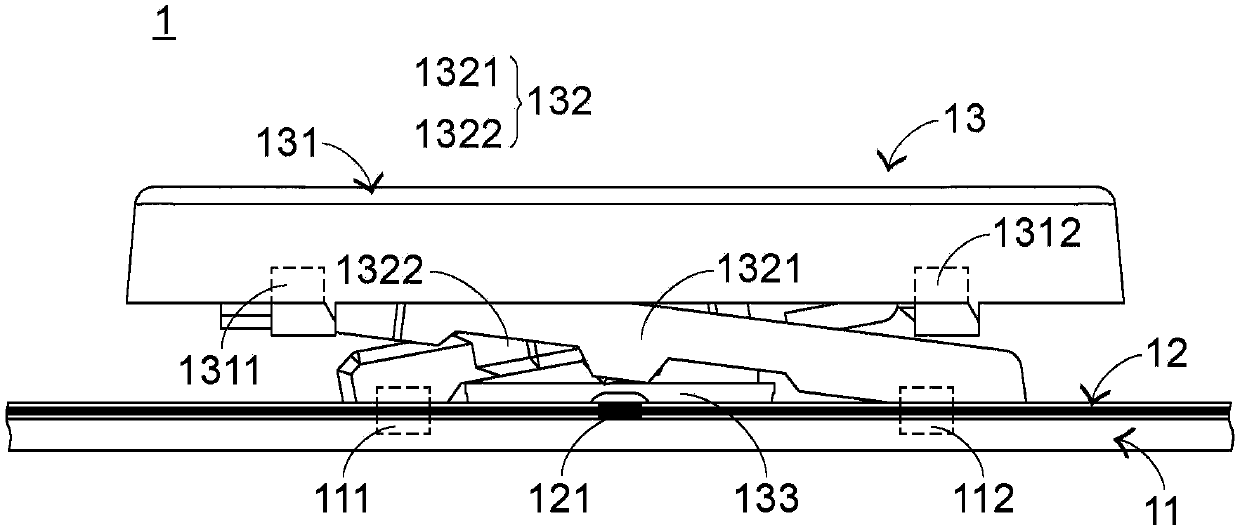

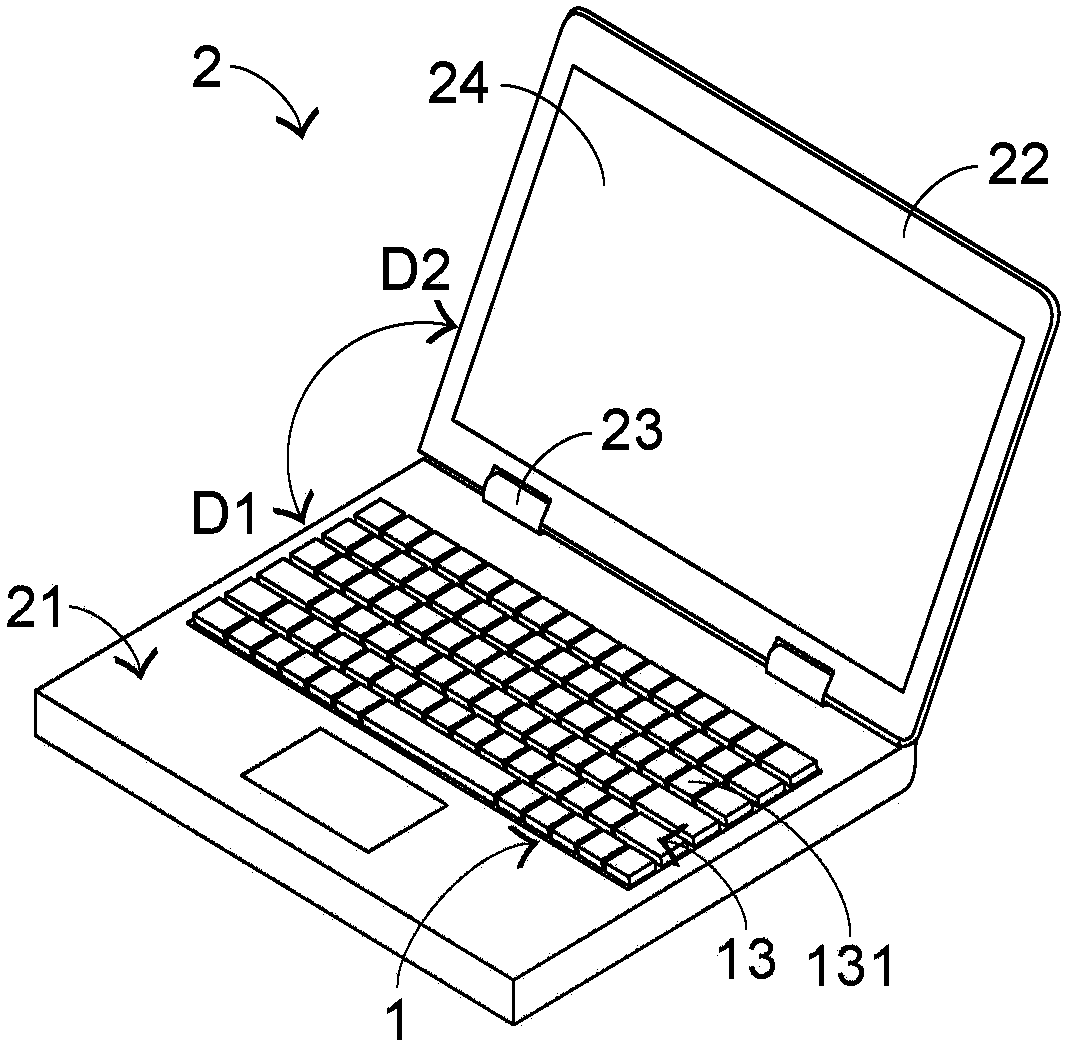

Keyboard and laptop computer employing same

InactiveCN107564753AAvoid misleadingAvoid accidental touchInput/output for user-computer interactionElectric switchesLaptopElectrical and Electronics engineering

The invention provides a keyboard and a laptop computer employing the same. The keyboard is disposed in the laptop computer, and comprises a film circuit board, a key frame, keys, a connecting rod connected to the key frame, and a fixed plate located below the key frame. When the connecting rod pivots relative to the key frame and drives the key frame to operate, a limiting convex part of the keyframe moves along a limiting guide part of the fixed plate, so as to enable the key frame to be limited and move in a first axial direction. Moreover, the key caps of the keys are restrained from being pressed when the key frame moves to a position which is equal to the key caps in height.

Owner:PRIMAX ELECTRONICS LTD

Double-side-face grinding machine suitable for hardware fitting grinding

InactiveCN114406838AImprove efficiencyAvoid Ineffective GrindingEdge grinding machinesGrinding carriagesElectric machinerySelf adaptive

The double-side-face grinding machine comprises a supporting base, two air cylinders, a supporting frame, a grinding column, a grinding motor, a supporting strip, a fixing clamp, a self-adaption reciprocating distance adjusting mechanism and a dust removal mechanism, and the two air cylinders are installed on the upper surfaces of the two ends of the upper surface of the supporting base correspondingly; the number of the supporting frames is two. According to the double-side-face grinding machine suitable for hardware fitting grinding, double-side-face grinding can be conducted on hardware fittings, the grinding reciprocating distance can be adjusted in a self-adaptive mode in the hardware fitting clamping process, then the invalid grinding process can be avoided, and therefore the grinding efficiency can be improved; and in addition, the grinding machine can also collect metal chippings generated by grinding the hardware fittings, so that the situation that the metal chippings are inhaled by workers to affect health is avoided, and the situation that the metal chippings enter the grinding machine to cause faults of the grinding machine is avoided.

Owner:盐城星禾子科技有限公司

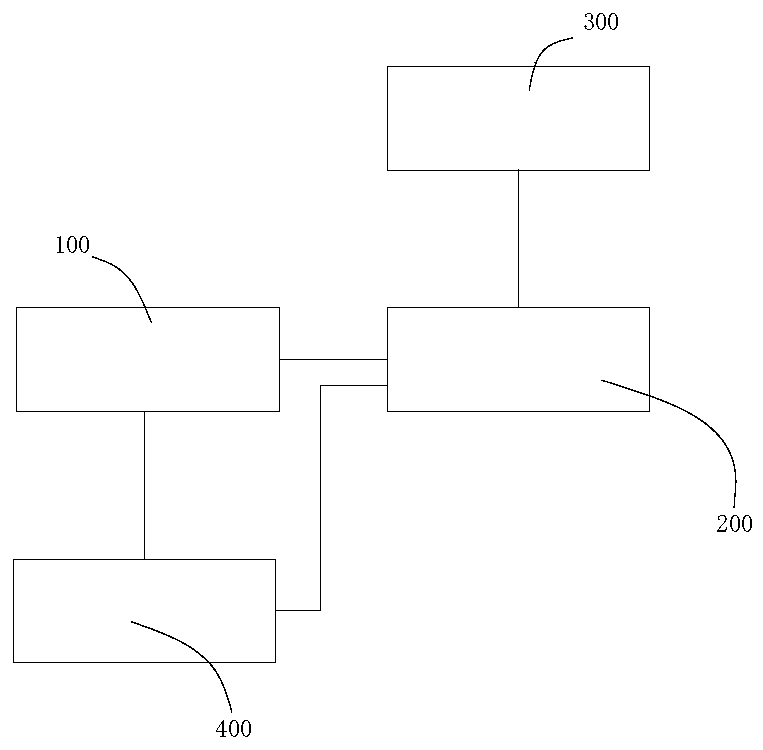

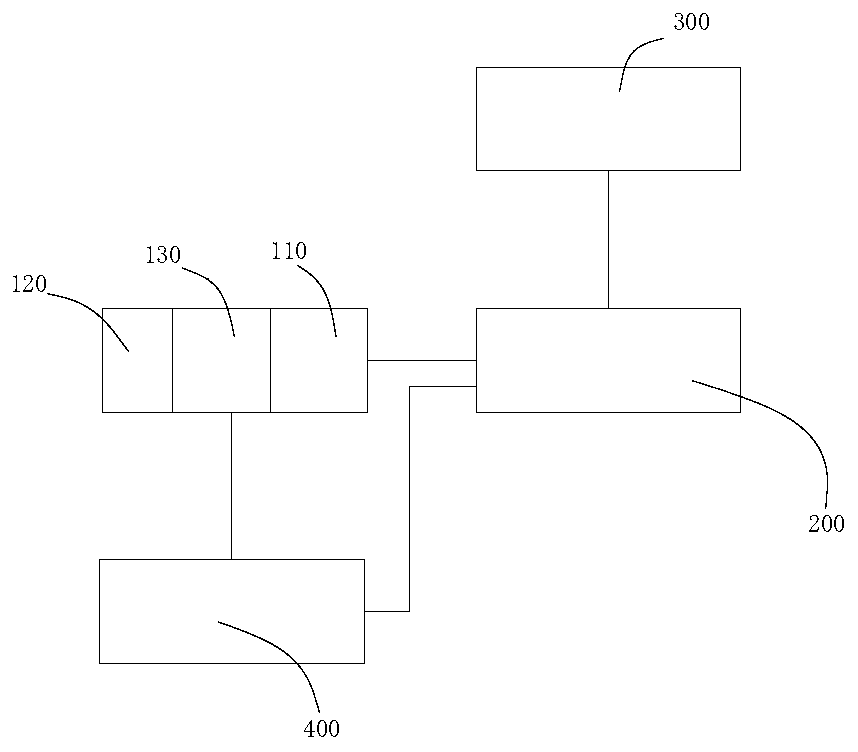

Aircraft oil-electricity hybrid energy supply system, aircraft and control method thereof

PendingCN109693796AStrong battery lifeStable and reliable flightEfficient propulsion technologiesPower plant typeElectric aircraftMechanical energy

The invention provides an aircraft oil-electricity hybrid energy supply system, an aircraft and a control method thereof. The energy supply system comprises an engine system, an engine controller, a power system and a fuel system; the engine system comprises an engine and a generator; the fuel system is connected with the engine through an oil way; the power output end of the engine is in drivingconnection with the generator; the generator is connected with the engine controller, and the engine controller is in control connection with the power system. Chemical energy generated in the fuel combustion process is converted into mechanical energy of the engine; the engine transmits mechanical energy to the generator to move, the generator converts the mechanical energy into electric energy,and the engine controller distributes the electric energy to the power system after rectifying the electric energy; compared with a pure electric aircraft, the cruising ability of the hybrid system ishigher, the engine does not directly drive the power system to work, and the aircraft is more stable and reliable in the flying process.

Owner:成都纵横大鹏无人机科技有限公司

Diode seat convenient for heat dissipation

InactiveCN108493171AImprove cooling effectEasy to installSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The invention discloses a diode seat convenient for heat dissipation. The diode seat comprises a base body, wherein an upper shell is fixed on the upper surface of the base body, a plurality of vent holes are formed in the surfaces of two sides of the upper shell, a diode is clamped in a groove formed in the top end of the upper shell, a conductor pipe connected to the tail end of the diode penetrates through the whole base body, and heat dissipation pieces are arranged on the left and right sides in the groove; and a first metal transverse rod is arranged in the first through hole formed in the surface of the right end of the upper shell, a first metal vertical rod is fixedly connected to the right end of the first metal transverse rod, a second metal transverse rod is arranged in a second through hole formed in the surface of the left side of the upper shell. By arranging the vent holes, the heat dissipation pieces, the first through hole, the first metal transverse rod, the first metal vertical rod, the second through hole, the second metal transverse rod, a second metal vertical rod, a first fastening bolt and a second fastening bolt, the problems that the heat dissipation function is poor, the fixation manner is not tight enough, and the diode is easily shaken to result in economic loss are solved.

Owner:MAANSHAN ZHONGJIE ELECTRONICS TECH

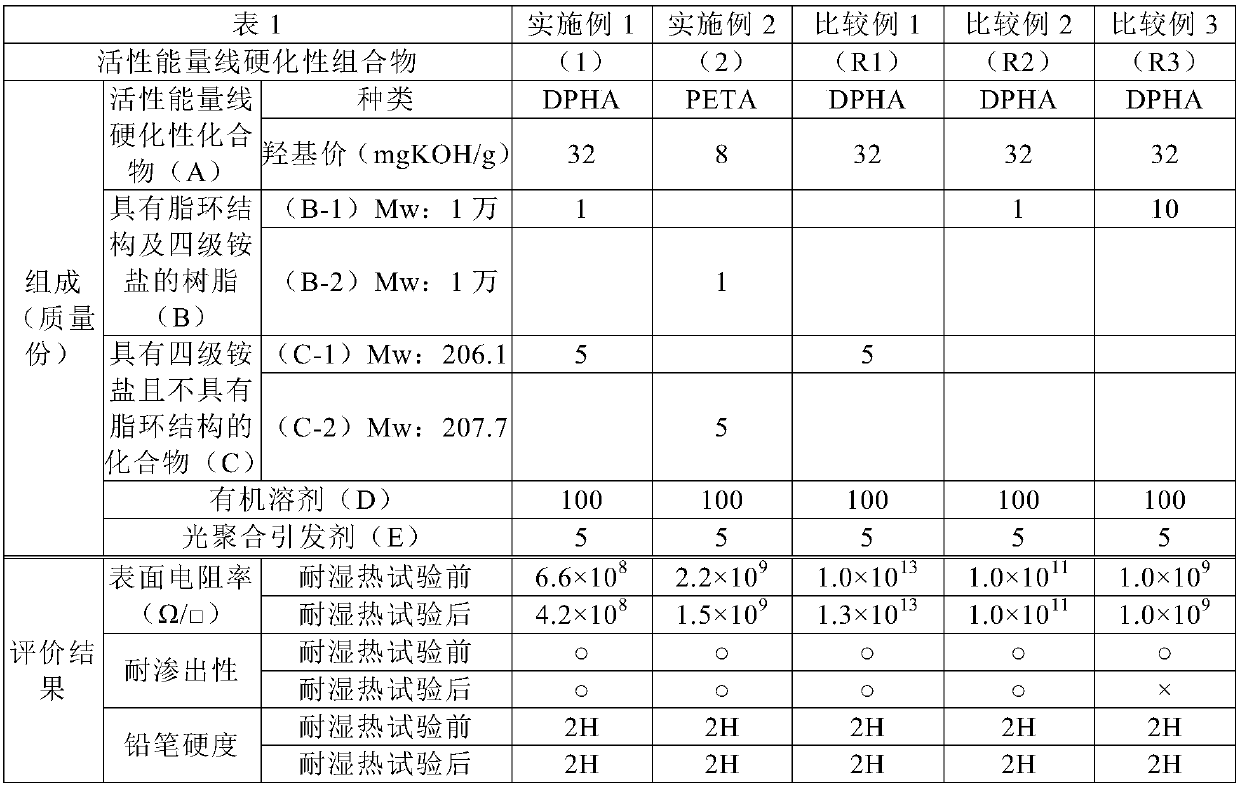

Active energy ray curable composition, and cured product and film using same

PendingCN109666361AGood antistaticPrevent adhesionElectrically-conductive paintsAmmoniumOrganic solvent

The invention provides an active energy ray curable composition, and a cured product and a film using the same. The active energy ray curable composition contains an active energy ray curable compound(A), a resin (B) having an alicyclic structure and a quaternary ammonium salt, a compound (C) having a quaternary ammonium salt and not having an alicyclic structure, and an organic solvent (D). Themass ratio [(B) / (C)] of the resin (B) to the compound (C) is preferably in the range of 5 / 95 to 40 / 60. The total blending amount of the resin (B) and the compound (C) is preferably in the range of 1 part by mass to 10 parts by mass with respect to 100 parts by mass of the active energy ray curable compound (A). The subject of the present invention is to provide an active energy ray curable composition capable of forming a hard coat layer having both excellent antistatic properties and excellent penetration resistance; and a film using the active energy ray curable composition.

Owner:DIC CORP

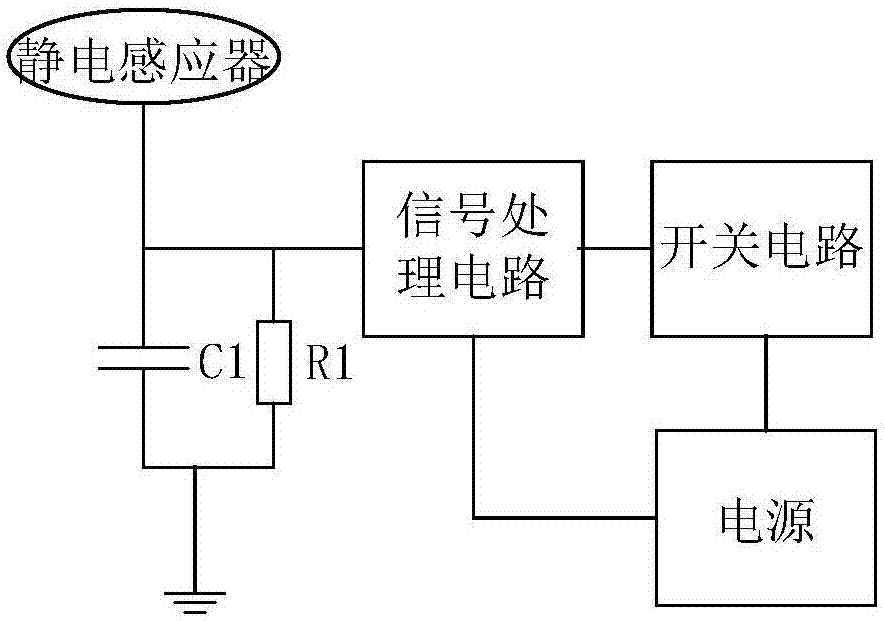

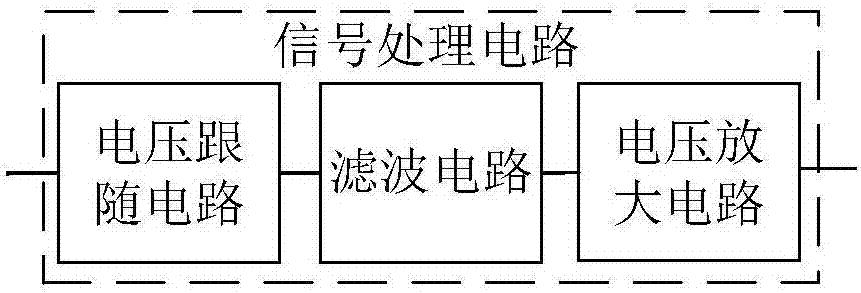

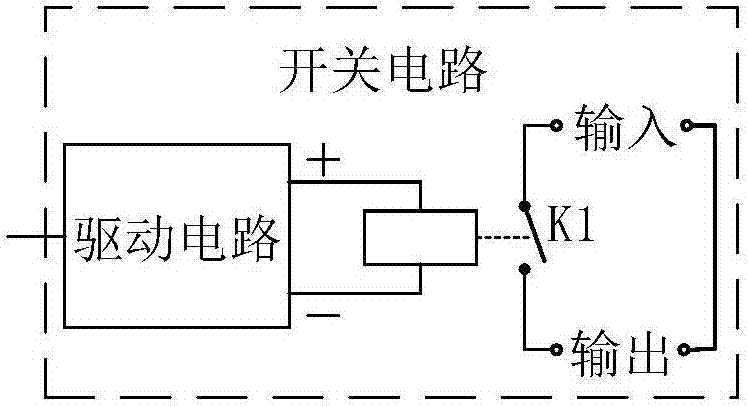

Electrostatic induction switch

PendingCN107046419ANot easy to interfereLow costElectronic switchingCapacitanceSignal processing circuits

The invention relates to an electrostatic induction switch, comprising an electrostatic inductor, a capacitor, a signal processing circuit, a switch circuit and a power supply; the electrostatic inductor is respectively connected with one end of the capacitor and the input end of the signal processing circuit, the other end of the capacitor is grounded, and the output of the signal processing circuit The terminal is connected to the input terminal of the switch circuit; the electrostatic sensor induces static electricity when the electrostatic body enters the sensing range, the capacitor stores the static electricity and generates a voltage signal, the signal processing circuit preprocesses the voltage signal, and the switch circuit realizes communication according to the preprocessed voltage signal off, the power supply supplies power to the signal processing circuit and the switching circuit. The invention is based on the principle of electrostatic induction, can control the on-off of the circuit according to the static electricity, does not need to make a sound, is not easily disturbed by the external environment, and has the characteristics of energy saving, small size, low cost and easy use.

Owner:王世朝

Hydropower station simulation test computer depth estimation method

InactiveCN108596463AImprove the effect of operation and maintenance skills trainingImprove the quality of standardized operationsResourcesElectrical appliancesEstimation methodsSimulation

The invention discloses a hydropower station simulation test computer depth estimation method. The method is characterized by comprising a rapid standard answer making technology design step and a computer depth estimation design step. According to the method, automatic estimation is taken as an aim, so that the labor intensity of instructors is greatly reduced. The method is independent of hydropower station simulation training systems, has certain universality, and can be seamlessly combined with the hydropower station simulation training systems, so that huge problems in current simulationtraining can be solved through less work and fewer charges, the effect of training hydropower station operation and maintenance skills by training departments is improved, standard operation quality of operators and maintainers is improved, and effective guarantee is provided for safe operation of electric power.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com