Full-automatic abrasive cloth flap disc machining equipment

A technology for abrasive cloth discs and processing equipment, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as high defective rate, low production efficiency, and unstable quality of finished abrasive cloth discs, and achieve The effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

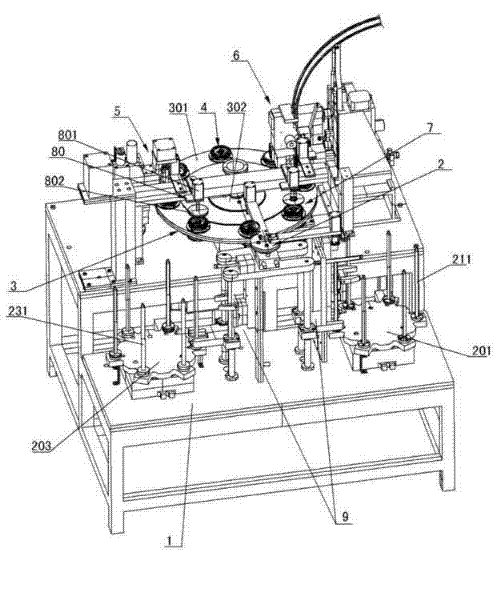

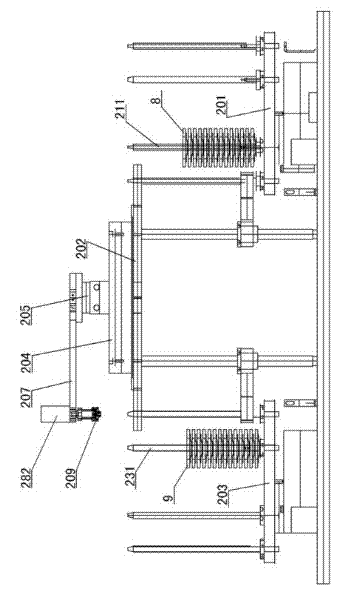

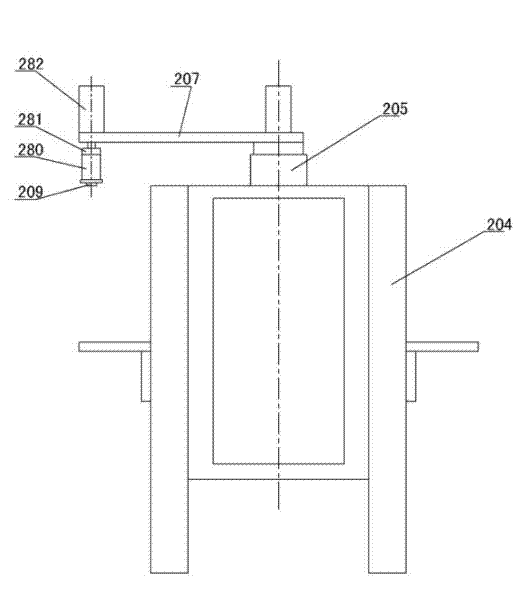

[0019] The present invention relates to a kind of fully automatic emery cloth disc processing equipment, such as Figure 1-Figure 12As shown, it is characterized in that it includes a frame 1, a tray-feeding and sending-out storage mechanism 2 is installed on the frame, a conveying rotation device 3, a leaf tray rotation mechanism 4, a glue dispensing device 5, a slicing and patching device 6 and a shaping mechanism 7. The leaf tray feeding and sending storage mechanism 2 includes a leaf tray storage tray 201 and a finished product storage tray 203, a leaf tray storage rod 211 is installed on the leaf tray storage tray 201, and a leaf tray 8 is placed on the leaf tray storage rod, and the finished product Finished product storage rod 231 is arranged on the storage tray 203, and finished product tray 9 is placed on the finished product storage lever 231, and the tray storage tray 201 and the finished product storage tray 203 are installed between the tray storage tray 201 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com