Asymmetric cylinder closed-loop speed system controlled by electro-hydraulic proportional pump

An electro-hydraulic proportional, asymmetric cylinder technology, used in fluid pressure actuation devices, servo motors, mechanical equipment, etc., can solve heat generation, and can only be applied to low-power and low-voltage fields, hydraulic system flow control systems Complicated, the system is not easy to heat up, etc., to achieve the effect of good energy saving, simplified hydraulic system, and fewer fault points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

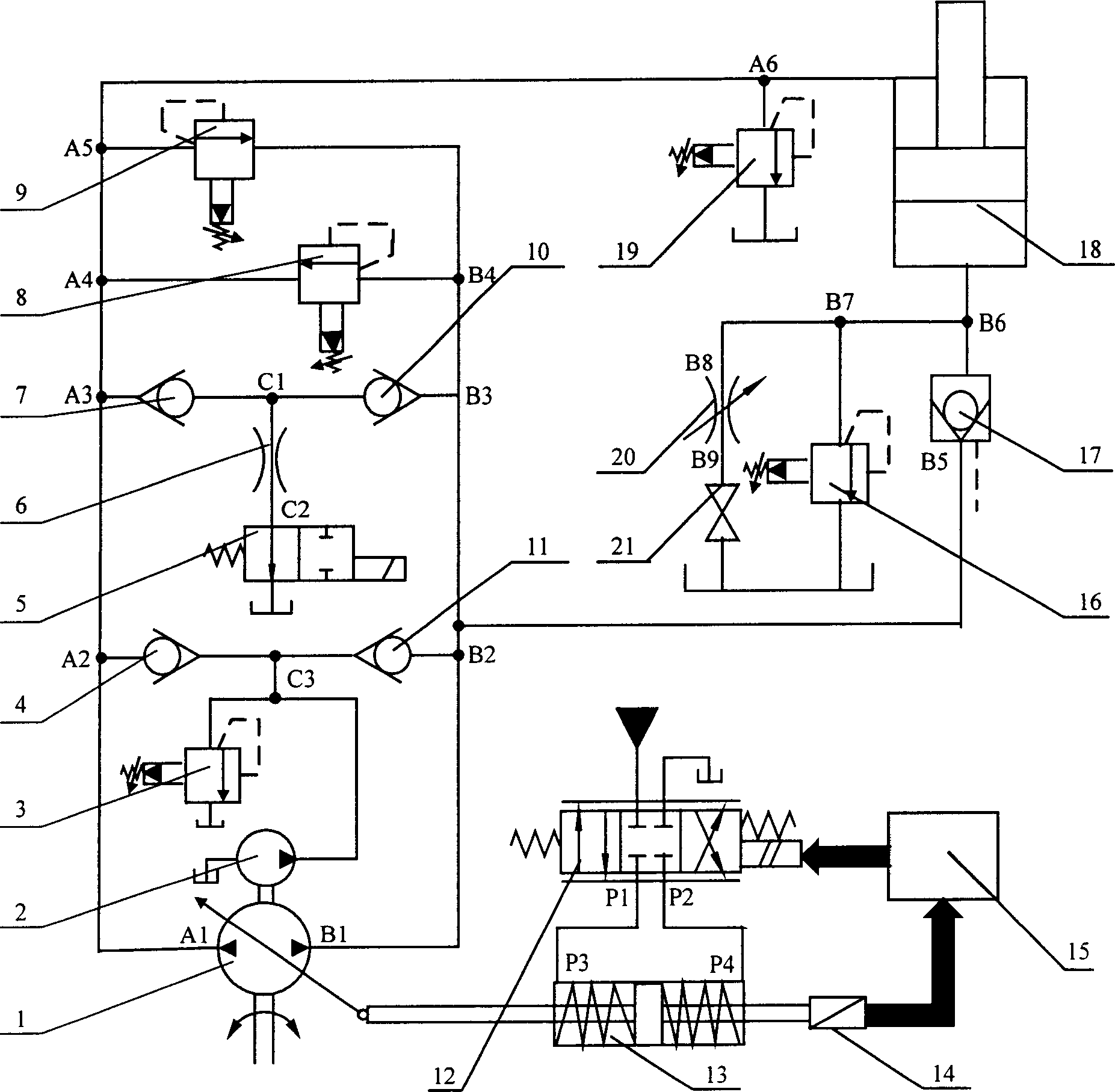

[0017] figure 1 It is a schematic diagram of a speed control system of the present invention. The system consists of a closed-loop flow control system, an oil supply circuit, a zero-flow unloading circuit for the main pump, a pressure limiting circuit, a flow diversion overflow valve[19], an inspection and safety circuit, and a hydraulic control check valve[17]. The oil cylinder [18] is composed; the left oil port A1 of the electro-hydraulic proportional pump [1] in the closed-loop flow control system is respectively connected with the oil port A2 of the check valve [4], the oil port A3 of the check valve [7], the overflow The oil port A4 of the flow valve [8], the oil port A5 of the overflow valve [9], the oil port A6 of the overflow valve [19], and the rod chamber of the asymmetric oil cylinder [18] are connected. In the closed-loop flow control system, The oil port B1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com