A current sharing method for a charger

A technology of chargers and current parameters, applied in current collectors, electric vehicles, electrical components, etc., can solve the problems of unbalanced output current of the chopper, thermal stress of the chopper, damage to the power device of the chopper, etc. The flow effect is stable and reliable, the flow sharing control is simple, and the calculation amount is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

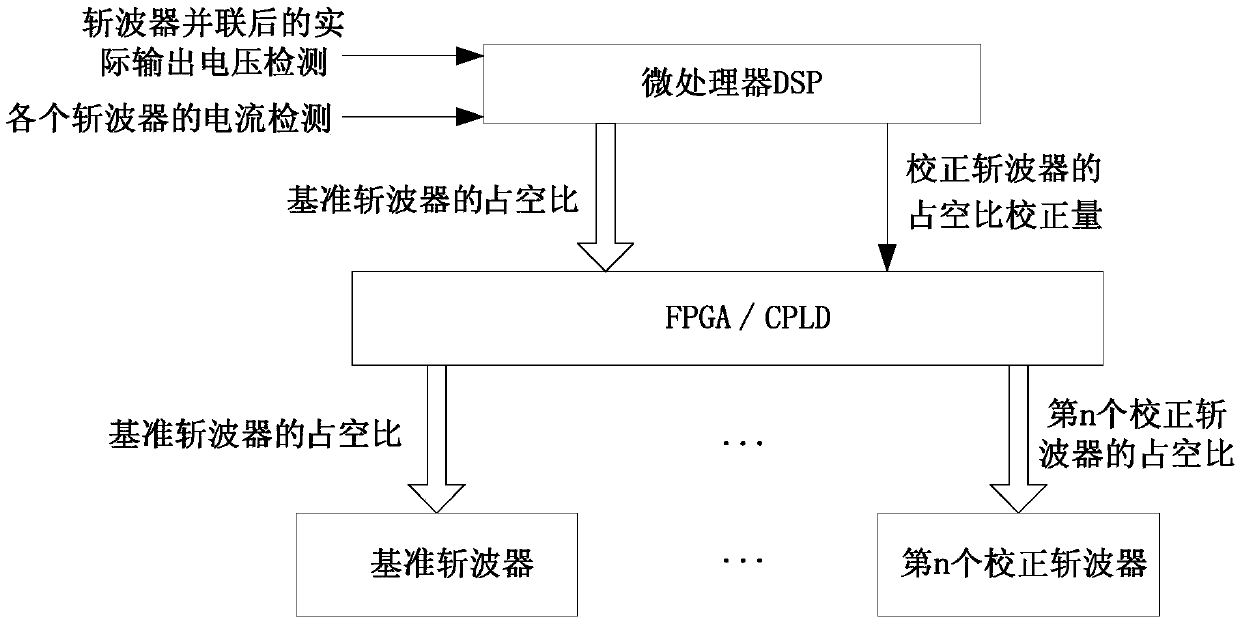

[0022] Such as figure 1 As shown, this example provides a current sharing method for a charger, including: a microprocessor DSP, an FPGA module, and at least two choppers, the choppers are connected in parallel, and the microprocessor DSP respectively detects all the choppers The actual output voltage of the choppers connected in parallel and the output current of each chopper; wherein, the microprocessor DSP drives a chopper through a PWM port, and the chopper driven by the microprocessor DSP is the reference chopper; the remaining choppers are driven by the FPGA module, and the chopper driven by the FPGA module is a correction chopper; after the microprocessor DSP collects the total actual output voltage of all choppers connected in parallel , compare the actual output voltage with the preset charging voltage value, adjust the duty cycle of the reference chopper until the actual output voltage matches the preset charging voltage value, and obtain that the reference chopper ...

Embodiment 2

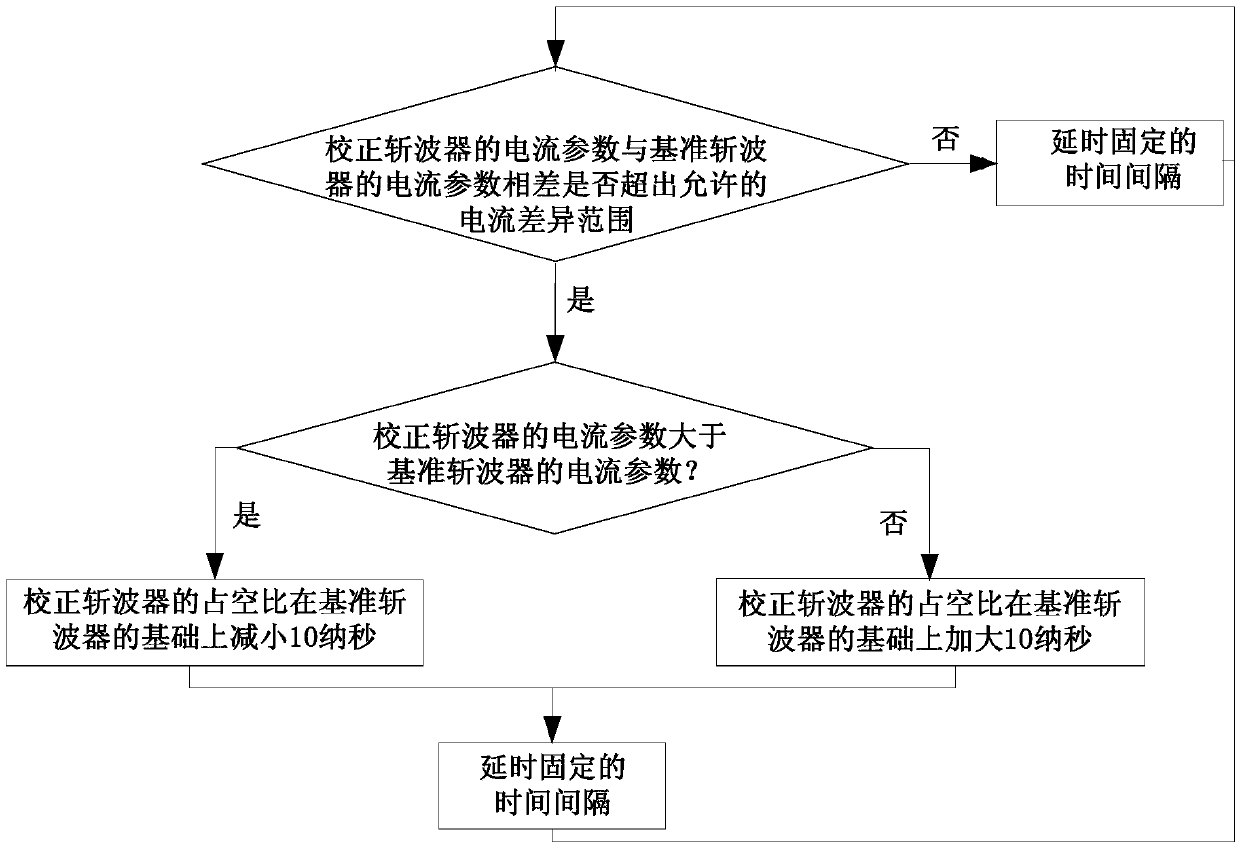

[0031] On the basis of Example 1, this example compares the current parameters of the reference chopper and the current parameters of the corrected chopper. When the current error between the two is greater than the allowable current difference, if the current parameter of the corrected chopper Greater than the current parameter of the reference chopper, then the duty ratio of the correction chopper is reduced according to the set duty ratio adjustment amount; if the current parameter of the correction chopper is less than the current parameter of the reference chopper , then the duty ratio of the correction chopper is increased according to the set duty ratio adjustment amount; after a fixed time interval, return to the current parameter of the reference chopper and the current parameter of the correction chopper Compare and loop accordingly. The workflow diagram of this example is as follows figure 2 As shown, when the current error between the two is less than the allowab...

Embodiment 3

[0039] On the basis of Embodiment 1 or Embodiment 2, in this example, a UPS takes power from the bus through the BUCK circuit and charges the battery. Since the UPS is a system with N wires, the chargers are divided into two groups, the positive group charger and the negative group charger. Both the positive group charger and the negative group charger have two chargers composed of BUCK circuits, named respectively A positive group charger, a second positive group charger, a first negative group charger and a second negative group charger, when the charger is running, the PWM ports of the first positive group charger and the first negative group charger drive After being calculated by the microprocessor DSP, it is sent through a PWM port of the microprocessor DSP, and the PWM port drive of the second positive group charger and the second negative group charger is carried out by the correction method described in embodiment 1 or embodiment 2 Correction, the correction value is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com