Three-dimensional multi-layer oil and gas pipeline safety detecting system

A technology for oil and gas pipelines and safety detection, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of high teaching cost, complex structure, and unsatisfactory pipeline accident simulation detection effect, to achieve rich content, Enhance the effect of experimentation and teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

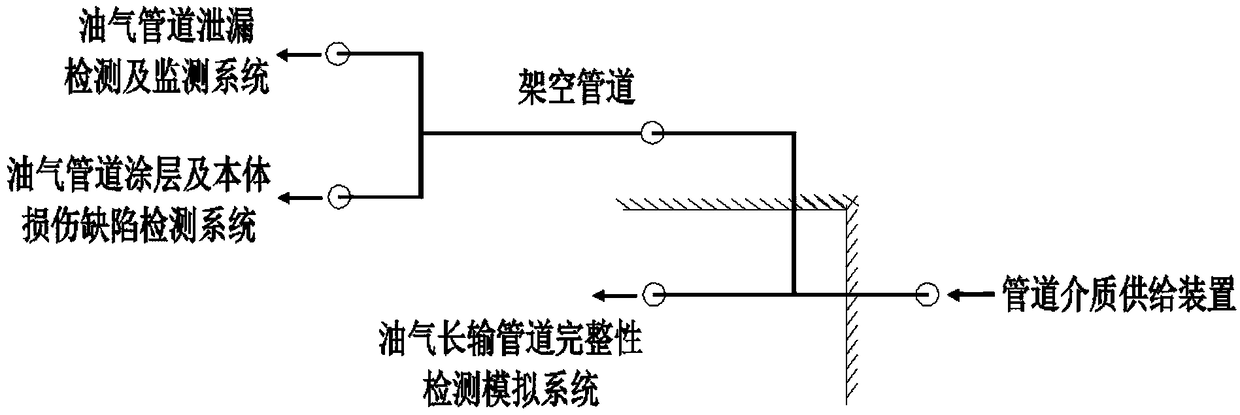

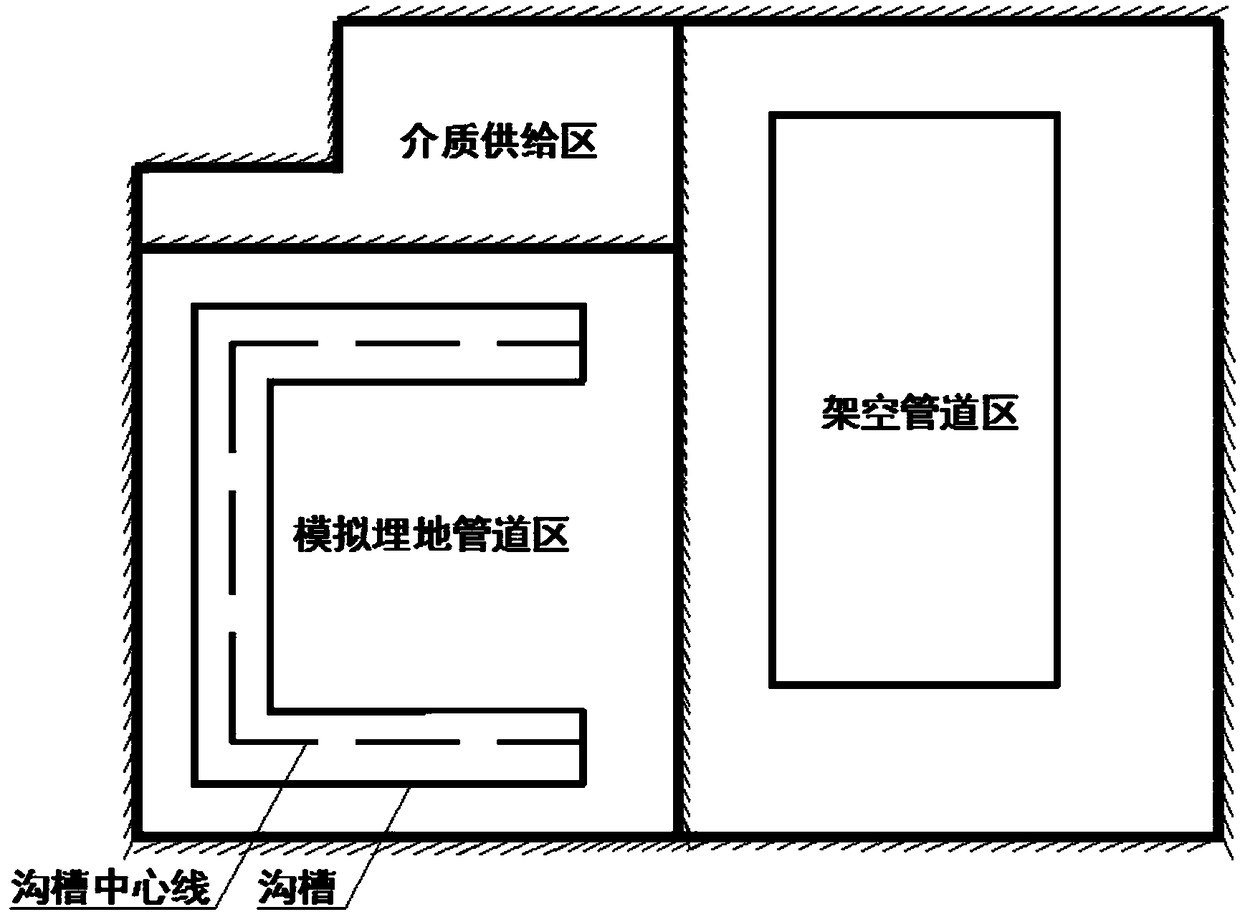

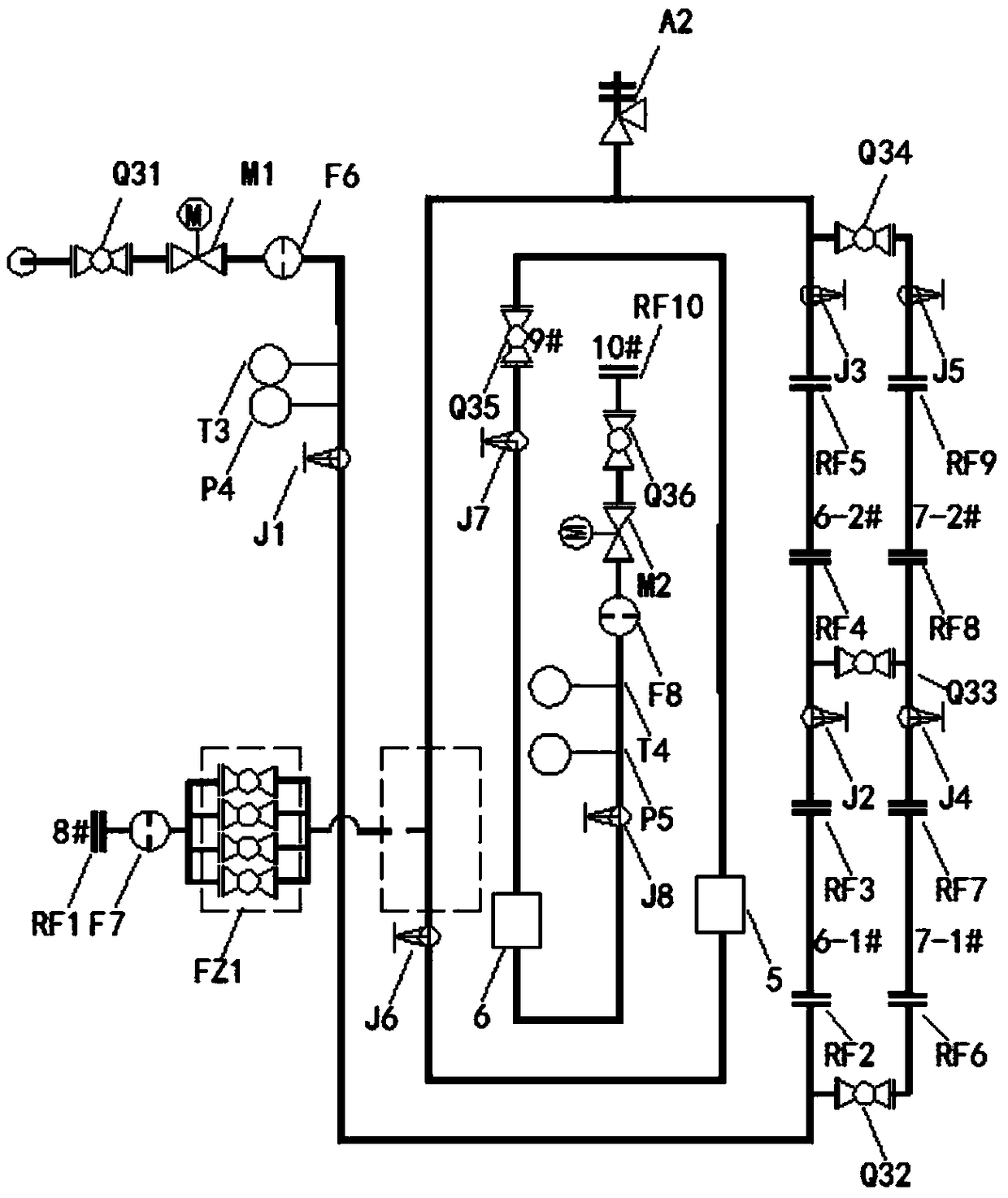

[0086] Such as figure 1 As shown, a three-dimensional multi-level oil and gas pipeline safety detection system includes a pipeline medium supply device and an oil and gas pipeline safety detection simulation system with three layers of upper, middle and lower layers;

[0087] Among them, the upper two layers of the oil and gas pipeline safety detection simulation system are overhead pipeline simulation subsystems, which are respectively the upper oil and gas pipeline leakage detection and monitoring system, the middle layer pipeline coating and the main body damage defect detection system, and the oil and gas pipeline The lower layer of the safety detection simulation system is the integrity detection simulation system of the simulated buried long-distance pipeline;

[0088] The three-layer simulation subsystems of the oil and gas pipeline safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com