Battery top cover assembly structure and battery top cover assembly method

An assembly structure and top cover technology, which is applied in the direction of battery cover/end cover, structural parts, battery pack components, etc., can solve the problems of limited overcurrent capacity of the pole, reduced safety performance of the battery cell, and small cross section of the pole, etc. , to achieve the effect of improving safety and stability, simplifying production process and increasing welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

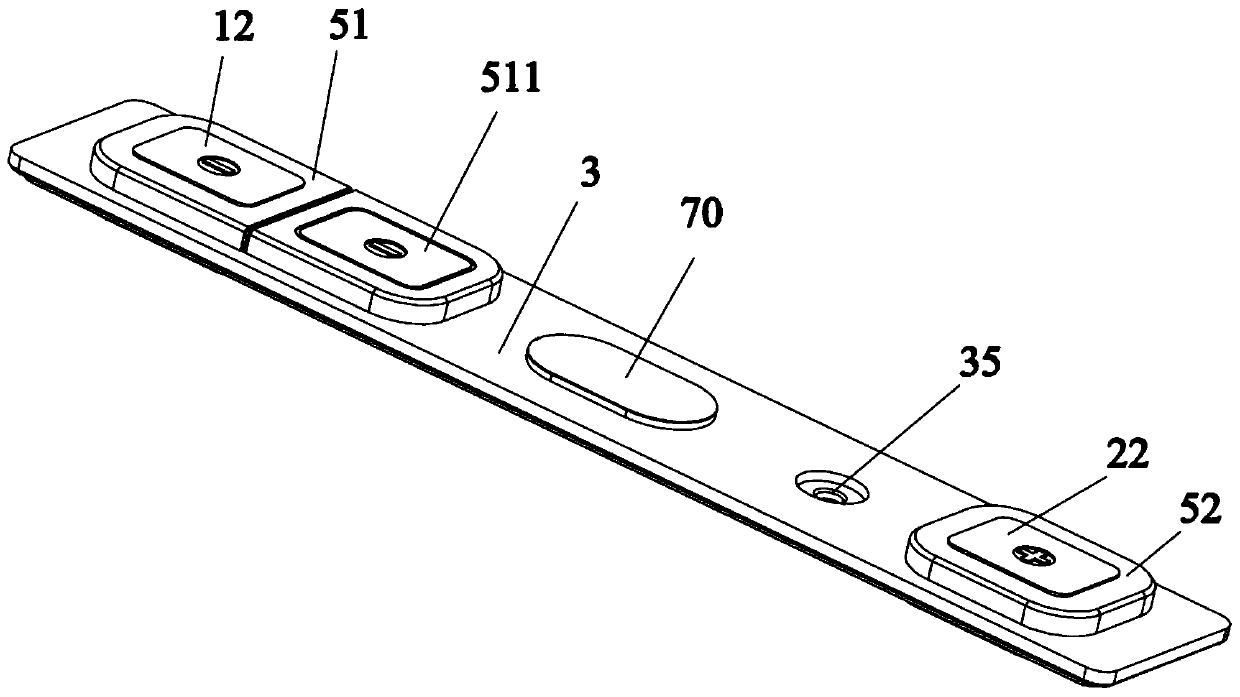

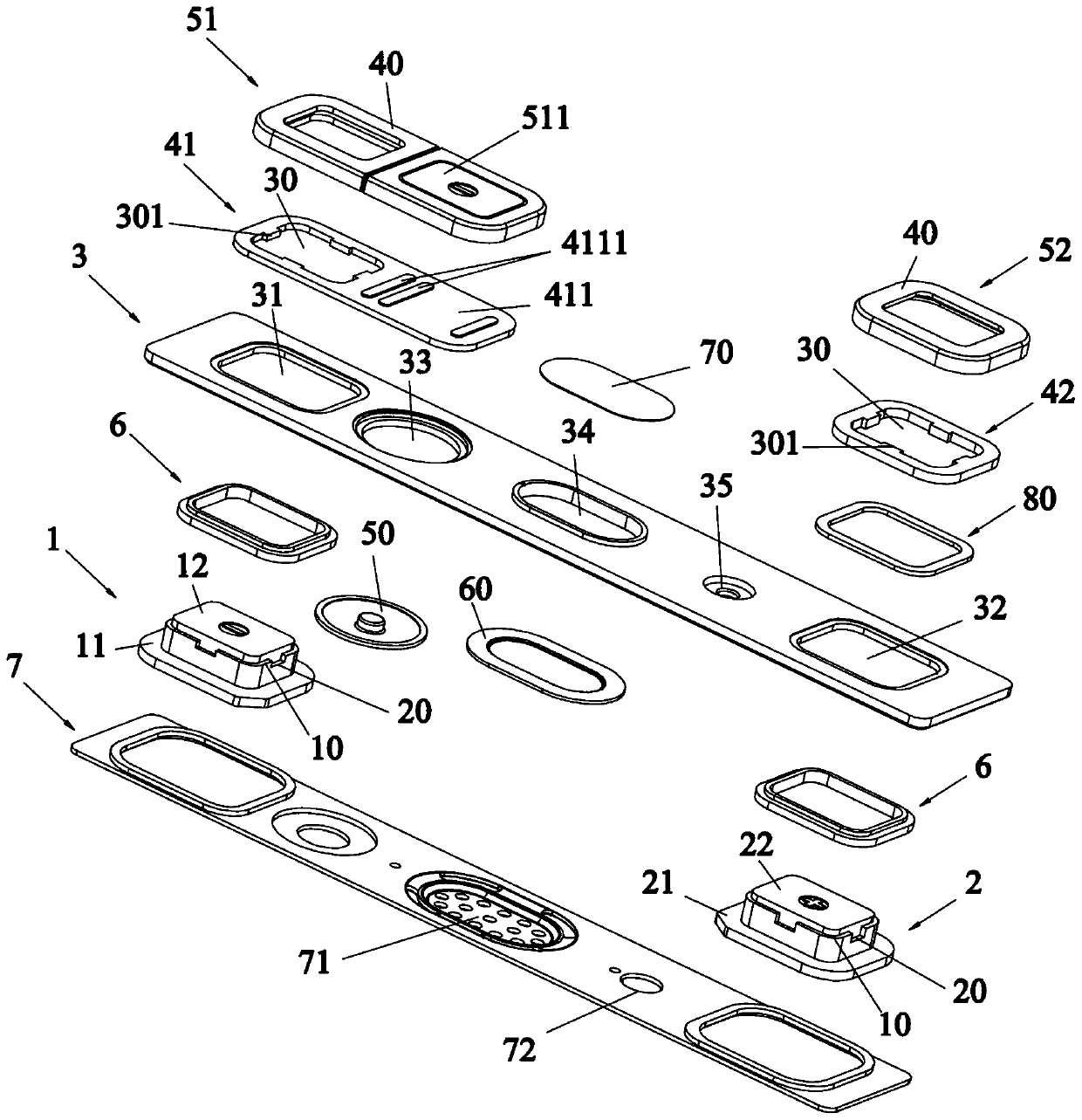

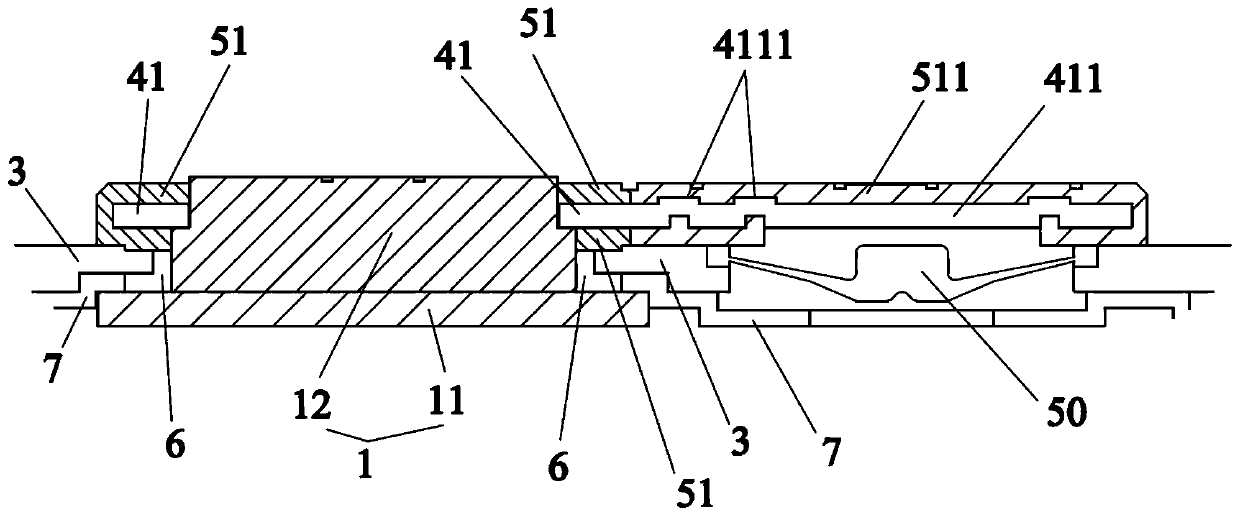

[0031] like Figure 1~4 As shown, a battery top cover assembly structure includes a first pole 1, a second pole 2 and a top cover sheet 3, the first pole 1 is installed with a first welding ring 41, and the second pole 2 is installed with a first Two welding rings 42, the top of the first pole 1 is covered with a first plastic part 51 that matches the first welding ring 41, and the top of the second pole 2 is covered with a second plastic that matches the second welding ring 42 The member 52, the first pole 1 and the second pole 2 respectively pass through the sealing ring 6 and are installed on the top cover sheet 3. Since the pole structure and manufacturing process of the power battery directly affect the performance of the lithium-ion battery cell and even the entire battery, in order to cooperate with the rubber-covered structure of the top cover and the pole of the present invention, the pole needs to form a structure that matches the plastic parts. It is used to fasten...

Embodiment 2

[0041] like Figure 1~4 As shown, a battery top cover assembly method, including:

[0042] Fix the first pole 1 to the top cover sheet 3 through the sealing ring 6, and fix the second pole 2 to the top cover sheet 3 through the sealing ring 6;

[0043] Put the welding hole 30 of the first welding ring 41 on the first cylinder 12, ensure that the protrusion 301 on the inner wall of the welding hole 30 is fixed in the positioning groove 20, and then perform laser welding, so that the first welding ring 41 is welded to the first pole 1, and then the first plastic part 51 is glued on the top of the first welding ring 41 and the first pole 1, and the second pole 2 and the second welding ring 42 are glued, so that the first pole 1 and the top Insulated connection between the covers 3;

[0044] Put the welding hole 30 of the second welding ring 42 on the second cylinder 22, ensure that the protrusion 301 on the inner wall of the welding hole 30 is fixed in the positioning groove 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com