Device for testing jet flow drag reduction effect of two-dimensional plane

A two-dimensional plane, testing device technology, applied in measurement devices, fluid dynamics testing, testing of machine/structural components, etc., can solve the problems of difficult daily maintenance, high cost, consumption of turbulent kinetic energy, etc. The effect of compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

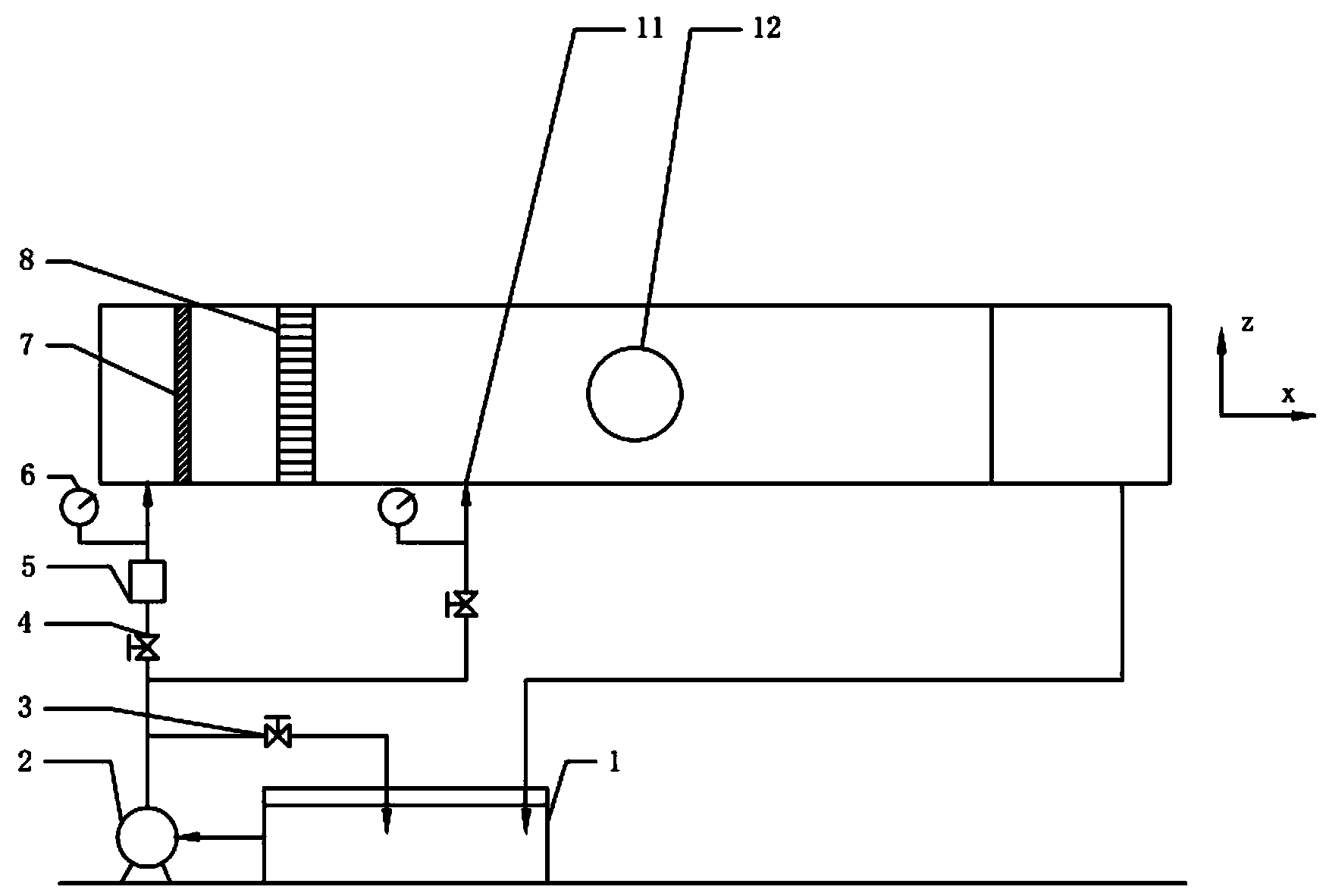

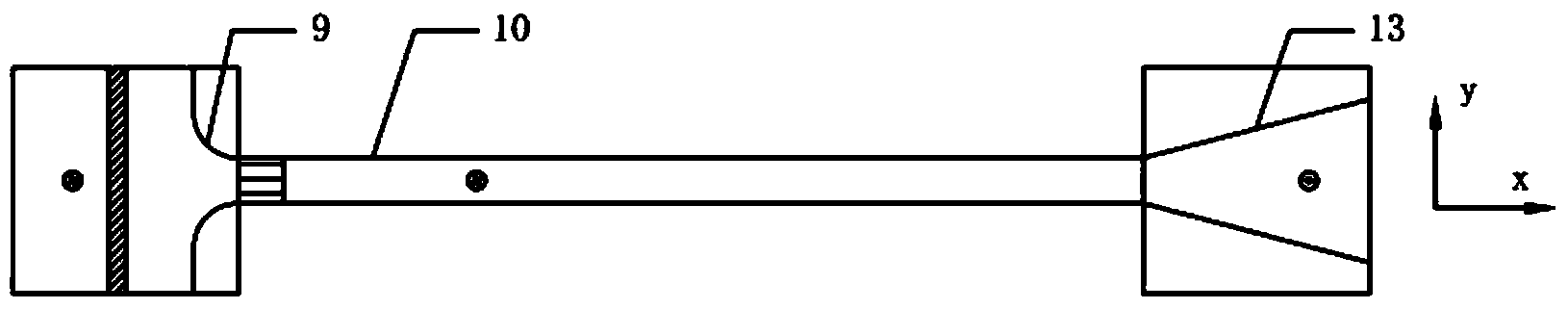

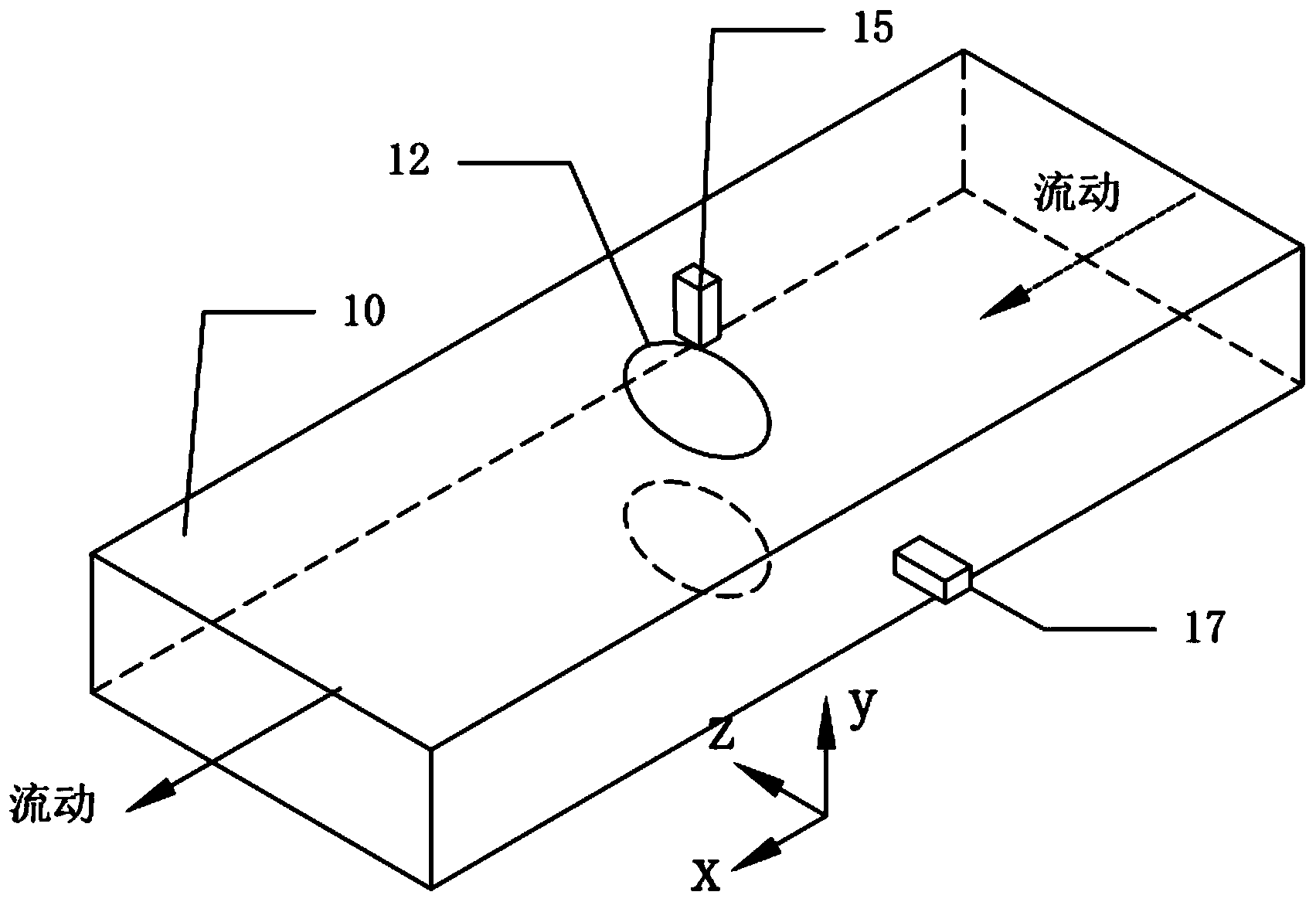

[0016] 1-2, the present invention consists of three parts: mainstream circulation pipeline, jet fluid circulation pipeline and PIV system. The mainstream circulation pipeline includes a water tank 1, a centrifugal pump 2, an overflow valve 3, a speed control valve 4, an electromagnetic flowmeter 5, a pressure gauge 6, a filter screen 7, a grid rectification section 8, two-dimensional channel inlet 9, two Dimensional channel 10, the outlet 13 of the two-dimensional channel and necessary loop connectors. The width of the two-dimensional channel is more than 10 times the height, which ensures that the flow at the center plane of the span width is a two-dimensional flow. The channel is made of 20mm thick transparent plexiglass to facilitate visual observation of the flow.

[0017] The jet pipeline includes a water tank 1, a centrifugal pump 2, an overflow valve 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com