Vector control system without sensor for inductive motor and method

An induction motor, vector control technology, applied in vector control systems, motor control, motor generator control and other directions, can solve the problems of difficult to obtain constants, unusable, difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

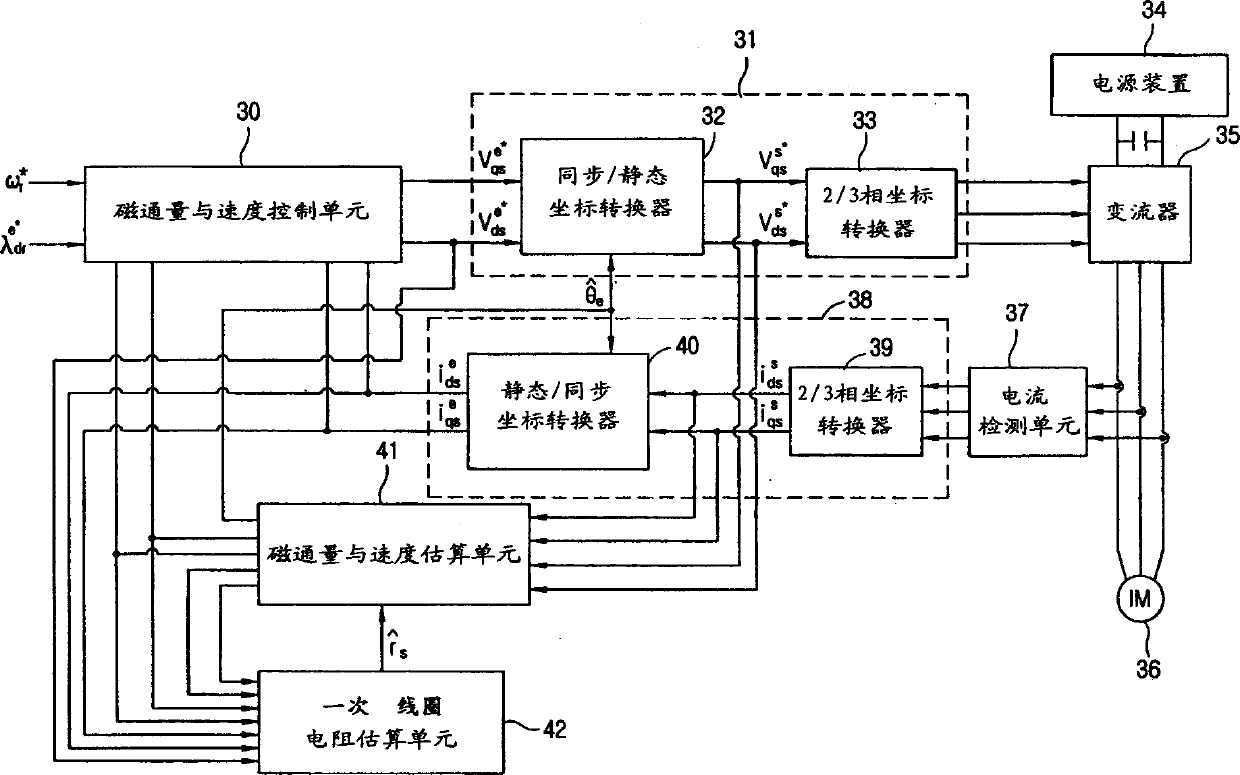

[0040] figure 2 is a schematic block diagram showing the structure of an induction motor sensorless vector control system according to a preferred embodiment of the present invention.

[0041] Such as figure 2 As shown, a sensorless vector control system for an induction motor, which is powered by a power supply device 34 to drive the induction motor, the system includes: a magnetic flux and speed control unit 30, which is used to receive a predetermined command value and generate a two-phase voltage of a DC component; The first frame of reference conversion unit 31 is used to convert the two-phase voltage of the DC component into the three-phase voltage of the AC component; the converter 35 is used to receive the three-phase voltage of the AC component and drive the induction motor; the current detector 37, It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com