Control method for unpowered descending speed

A speed control and power technology, which is applied in the field of unpowered downhill speed control of inspection robots, can solve problems such as the working state of the drive system, and achieve the effects of accurate speed control, convenient practicality, and simple speed control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

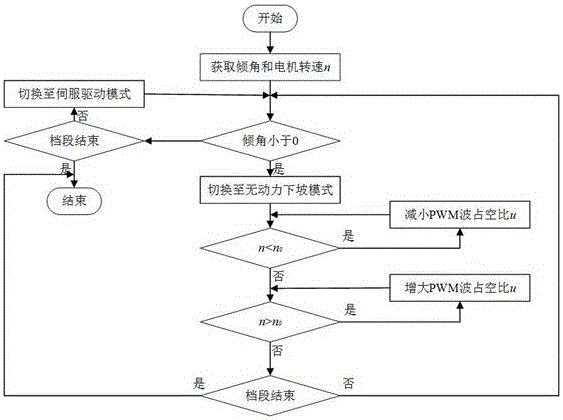

[0021] The speed control method will be introduced in more detail below in conjunction with the schematic diagram.

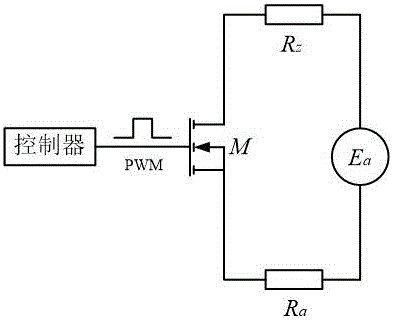

[0022] as attached figure 1 shown. According to the pulse width modulation method, by changing the duty ratio of the PWM wave of the control circuit, the on-off control of the switching device (such as MOS transistor) of the inverter circuit can be realized, thereby realizing the output voltage of the inverter circuit ( That is, the control of the armature induced electromotive force in the circuit.

[0023] attached to figure 1 Using Ohm's law for the loop in

[0024] u a =I a (R a +R z ) (1)

[0025] Among them, u is the duty cycle of PWM wave, E a is the induced electromotive force of the armature, I a is the armature current, R a is the armature resistance, R z is the energy consumption resistance;

[0026] Calculated from the electromagnetic torque formula

[0027] T=K t I a (2)

[0028] Among them, T is the electromagnetic torque, K t is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com