Air inlet automatic control engine

An engine and controller technology, applied in electrical control, engine control, combustion engine and other directions, can solve problems such as low engine efficiency and pollution, and achieve the effects of over thermal efficiency, low fuel consumption, and good ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

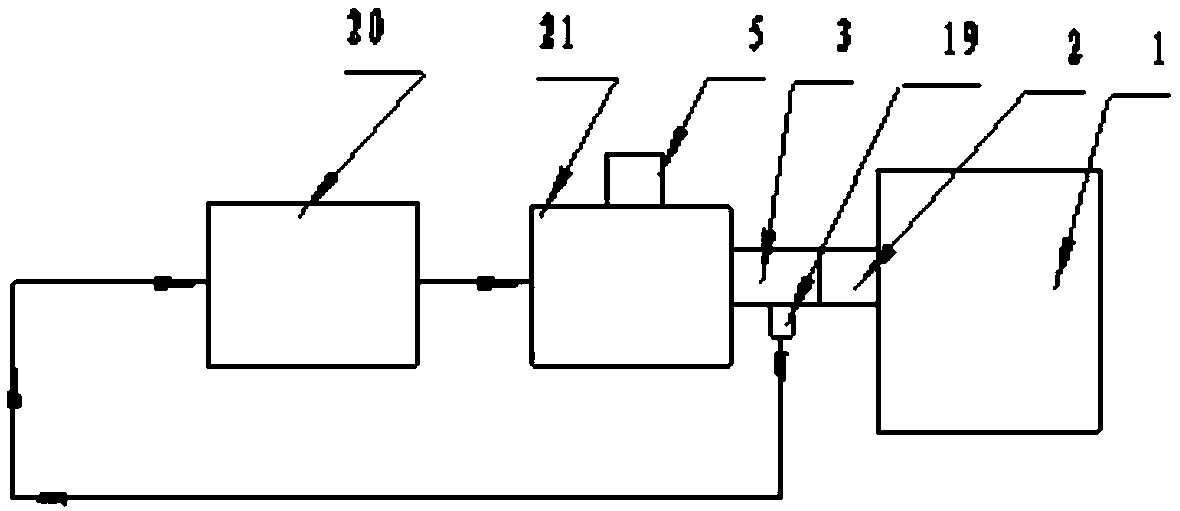

[0074] Such as figure 1 The schematic diagram of the engine automatic control air intake system is shown, the engine automatic control air intake system 4 is connected with the air intake port 2 of the engine body 1 to the automatic control air intake system air outlet 3, forming an air intake automatic control engine. Engines include: piston engines, rotary engines, jet engines, turbojet engines, turbofan engines, gas turbines. The automatic control air intake system is composed of: the sensor set on the engine air inlet 2 is connected to the input end of the controller, and the actuator is connected to the output end of the controller. Perform comparison, analysis, diagnosis, and calculation to draw correct conclusions, and then send control instructions to the output terminal to control the actuator to make correct adjustments to ensure that the system control parameters are within a reasonable range. The control parameters include: intake pressure, temperature, flow, Air ...

Embodiment 2

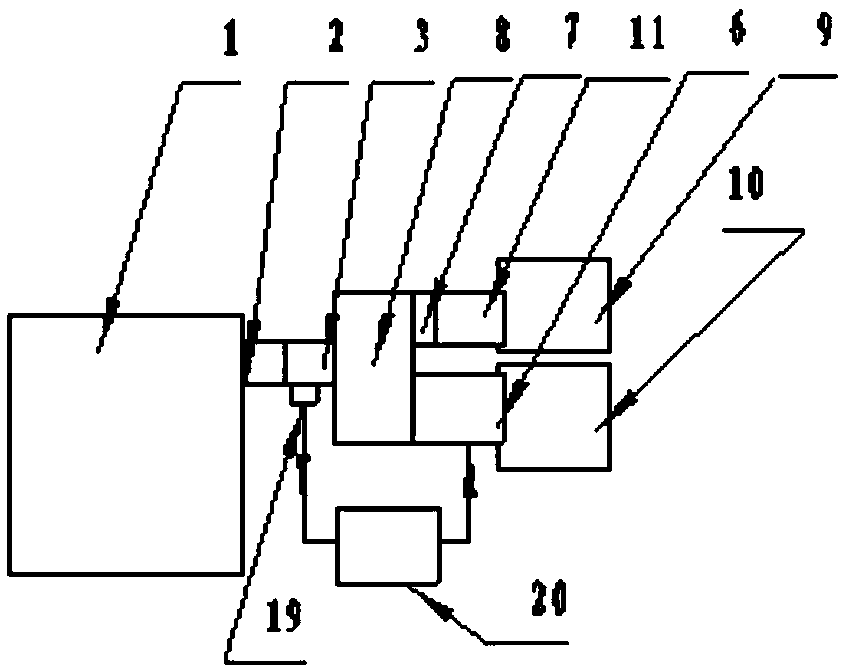

[0079] Such as figure 2 The shown schematic diagram of the air intake automatic control engine in which the air supercharger 6 is connected in parallel with the natural intake air is based on the embodiment 1, and the natural intake system is added.

[0080] The outlet of the air supercharger 6 is connected to the outlet of the natural intake system through the connection cavity, the air supercharger 6 is connected to the output end of the central controller, and the sensor arranged on the engine air inlet 2 is connected to the input end of the controller. The sensor detects the signal of the engine air inlet and outputs it to the controller, and the controller outputs instructions to control the speed of the air supercharger 6 and the output flow of air.

[0081] The parallel natural air intake system can effectively make up for the defect of insufficient air intake of the air supercharger when the engine rotates at a high speed. The air outlet 3 of the natural air intake s...

Embodiment 3

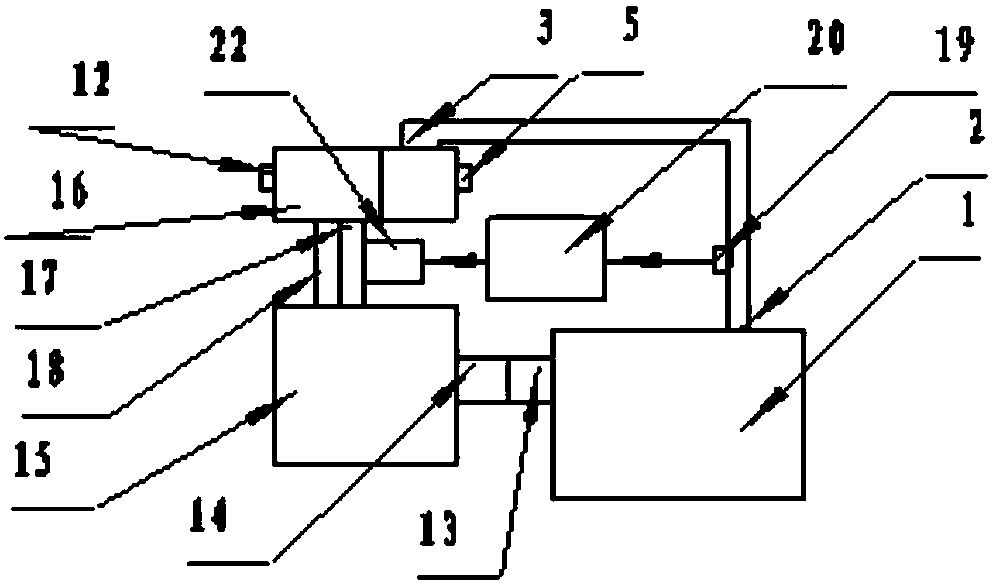

[0084] Such as image 3 Schematic diagram of the structure of the engine with automatic intake control of the dual air-driven turbocharger shown. The exhaust pipe of the engine passes through the heat exchanger to drive the turbocharger, and at the same time, the waste heat of the engine is transferred to the heat exchanger to be converted into steam. The steam and the output end of the exhaust gas of the engine are connected to the input end of the turbocharger, and the steam and the exhaust gas jointly drive the turbocharger.

[0085] It also includes: the heat exchanger is arranged on the turbocharger. In this way, the heat of the turbocharger can be absorbed to lower its temperature, and the hidden danger of high temperature and flammability can be eliminated. Steam and exhaust jointly drive the turbocharger, which can also make up for its low speed and low efficiency.

[0086] The sensor arranged on the engine air inlet 2 is connected to the input terminal of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com