Control system of alternating current servo permanent magnet synchronous motor

A permanent magnet synchronous motor and AC servo technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems of inability to adapt, inconvenient installation and debugging, etc., achieve safe and reliable performance, and overcome the influence of environmental conditions , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

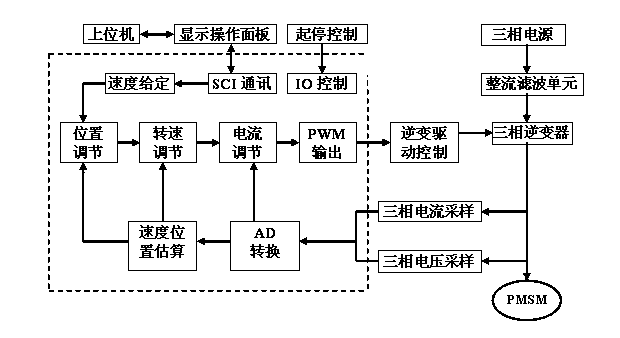

[0016] The present invention is described in further detail in conjunction with accompanying drawing, as figure 1 As shown in the figure, the rectification and filtering unit rectifies the three-phase alternating current into direct current through the full bridge. Four electrolytic capacitors are used between the positive and negative poles, two in parallel and two in series. The positive and negative poles of each capacitor are connected in parallel with a power resistor to maintain mutual Charge and discharge balance, effectively reducing the ripple of the DC bus.

[0017] The interior of the dotted line box is divided into a core operation control unit. This part is mainly for centralized operation and processing of digital and analog signals collected from various channels. The main chip adopts a 32-bit DSP data signal processor of TI Company, and the processing signals include external input and output switches. Control start and stop; input analog quantities such as fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com