Color wheel motor, color wheel module and projection device

A color wheel and motor technology, which is applied in the field of color wheel motors, color wheel modules, and projection devices, can solve problems such as increased heat dissipation burden, heat dissipation problems that cannot effectively prevent dust deposition, and reduced detection reliability, etc., to achieve extended and effective Operating life or maintenance cycle, taking into account the effects of dust prevention and heat dissipation, and solving the effect of poor dust prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

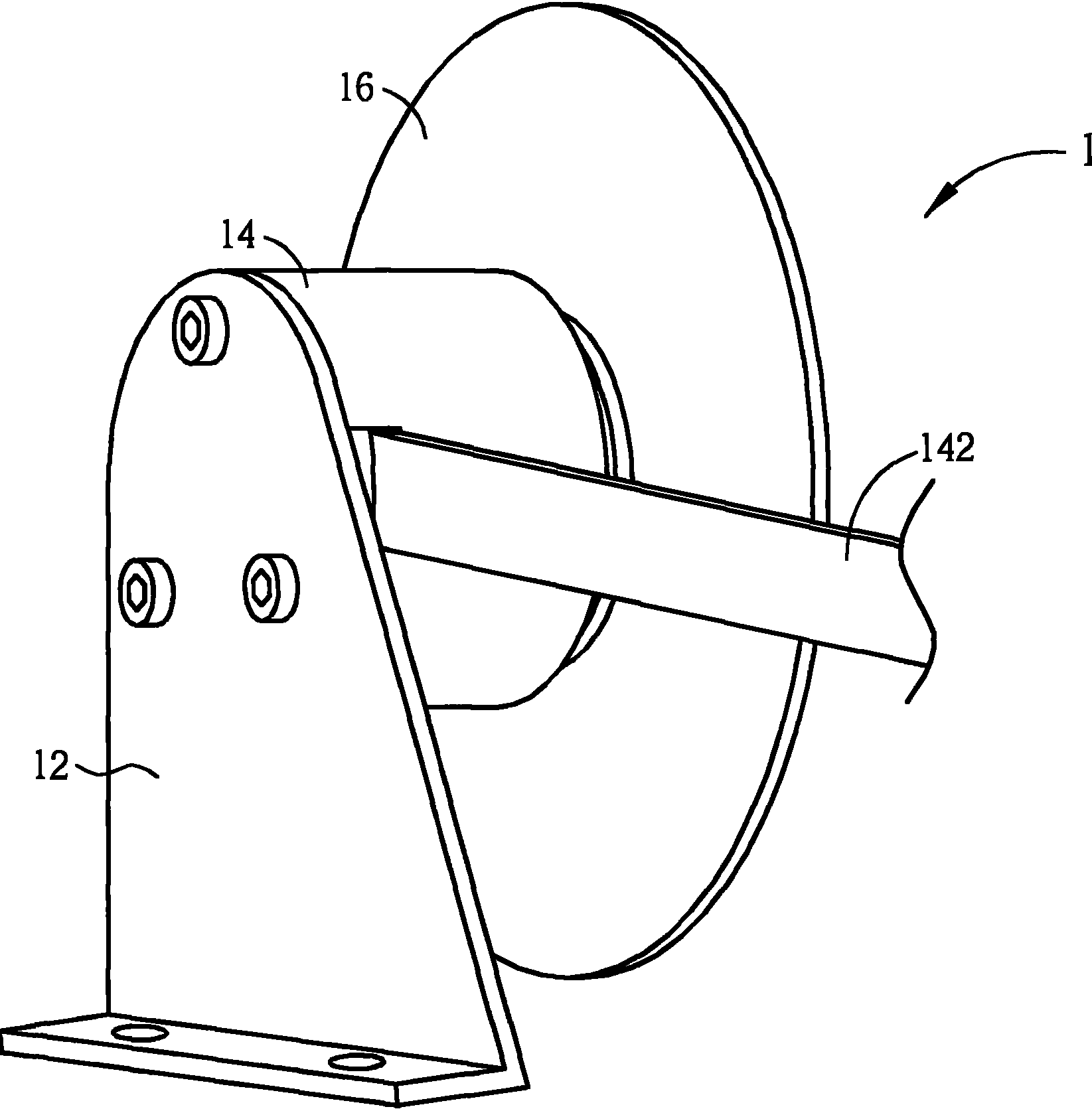

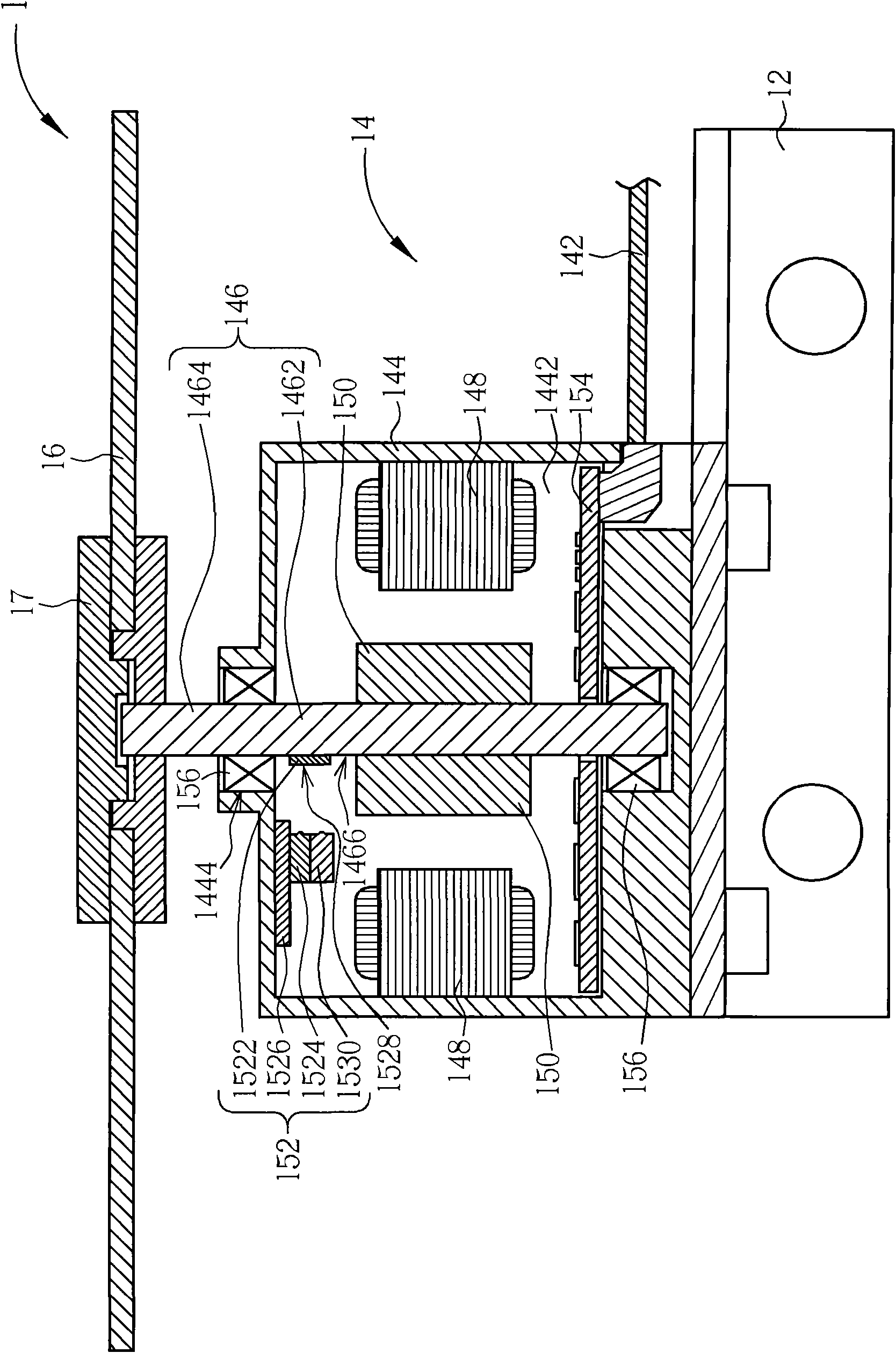

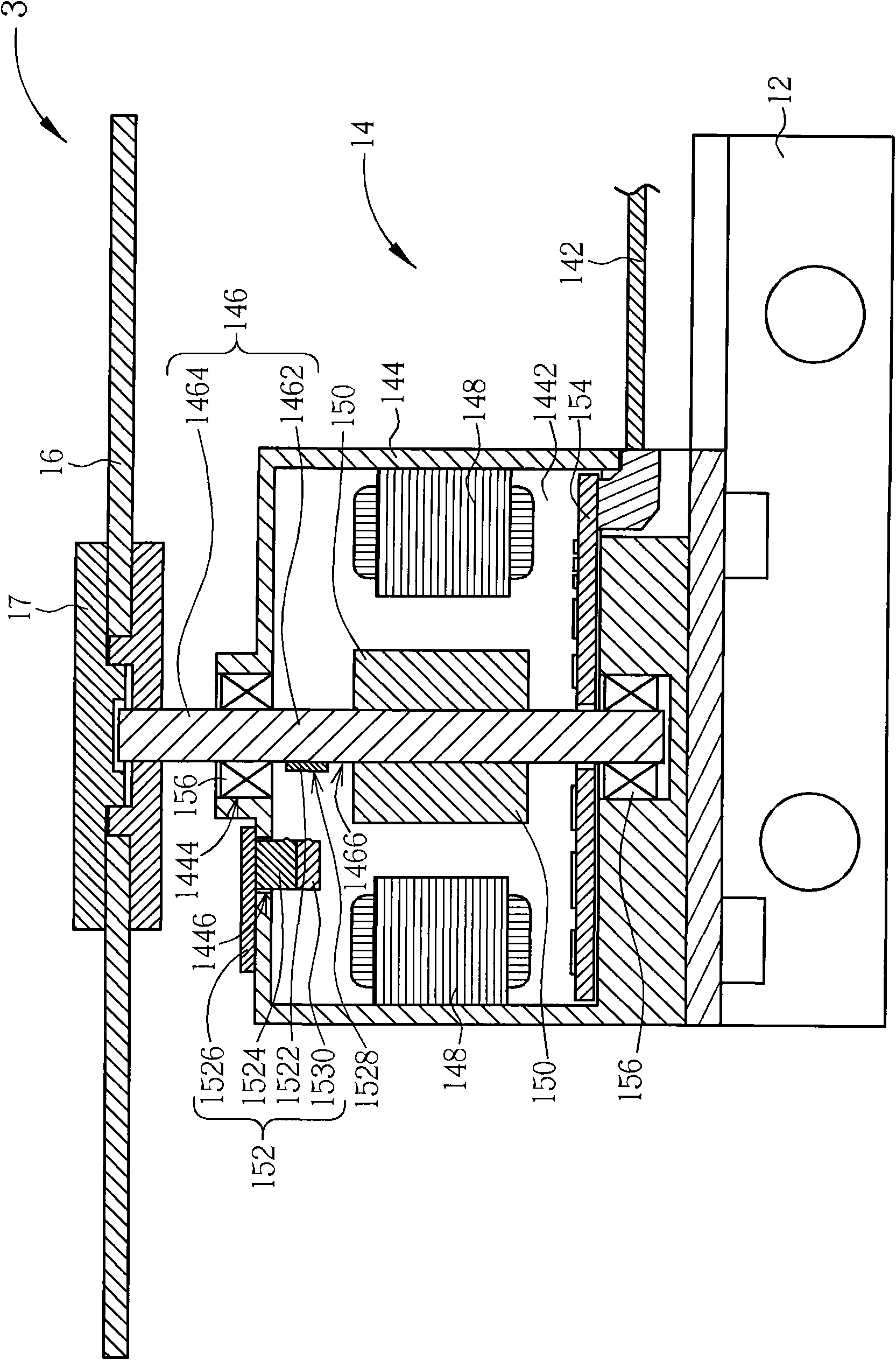

[0025] see figure 1 and figure 2 , figure 1 It is a schematic diagram of a color wheel module 1 according to a preferred embodiment of the present invention, figure 2 for figure 1 Sectional view of the color wheel module 1. The color wheel module 1 includes a fixing base 12 , a motor 14 and a color wheel 16 . The motor 14 is fixed on the fixing base 12 and electrically connected to a row of wires 142 to realize the control of the motor 14 . The color wheel 16 is mounted on the motor 14 and synchronized with the color wheel 16 by controlling the rotation state of the motor 14 . The color wheel module 1 is fixed on other structures, such as inside the casing of the projector, by the fixing seat 12 .

[0026] Further, the motor 14 includes a casing 144 , a rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com