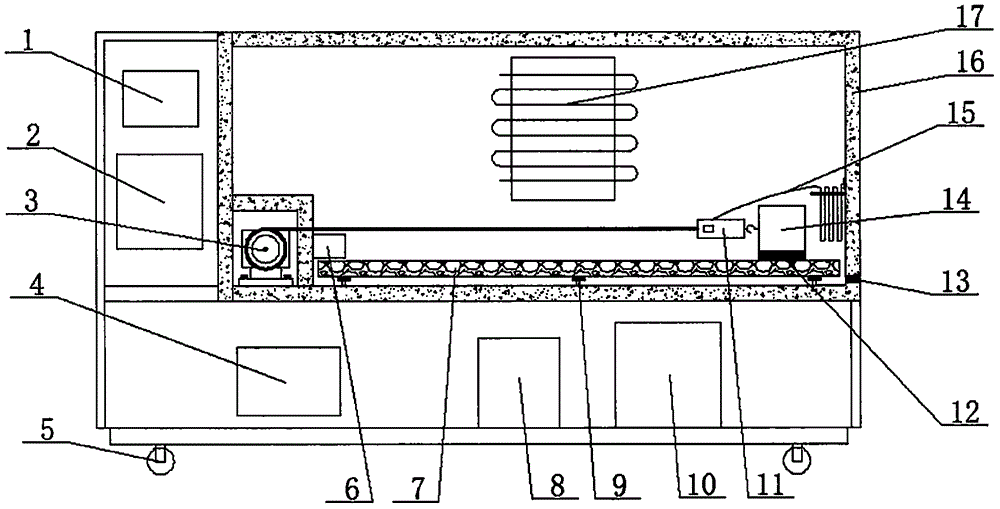

Testing device and testing method for measuring road surface friction attenuation rate of snow-melting agent under low-temperature environment

A low-temperature environment, road surface friction coefficient technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as unconsidered, difficult pressure calibration, device vibration, etc., to achieve precise control of speed and accuracy, friction coefficient measurement results accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In order to verify the reliability and beneficial effect of the test device and test method for the friction attenuation rate of snowmelting agent road surface under low temperature environment of the present invention, the present invention will be further described in detail below in conjunction with the examples, but the present invention is not limited to the following examples.

[0042] The specific test steps are as follows:

[0043] (1) Test preparation

[0044] ① Move the asphalt pavement test bench or cement pavement test bench to the test box, install and level it;

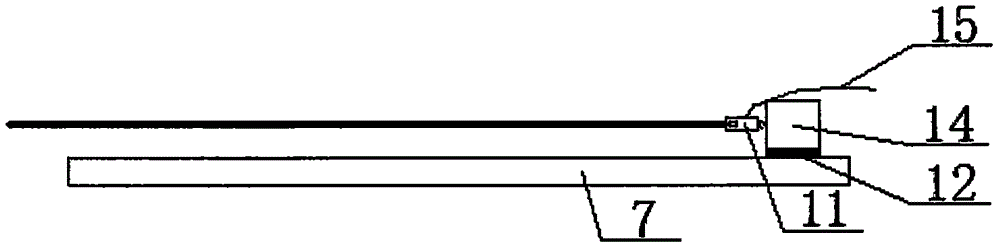

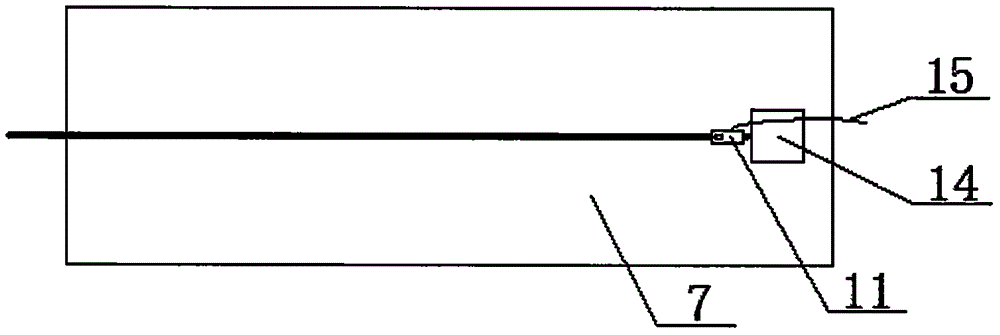

[0045] ②Place the slider in the middle position on the right side of the road test bench, and connect the tension gauge.

[0046] (2) Determination

[0047] ① Sprinkle 300ml of water on the road test bench, and scrape it flat with a rubber plate, so that the surface is evenly covered with a layer of water film;

[0048] ②Set the running speed to 4m / min, start the test and record the friction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com