Servo hydraulic transmission mechanism

A technology of servo hydraulic cylinders and hydraulic valves, which is applied to servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of complex structure, complicated interlocking devices, and high prices, so as to avoid hidden dangers of mechanical failure and meet Long travel, economical and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

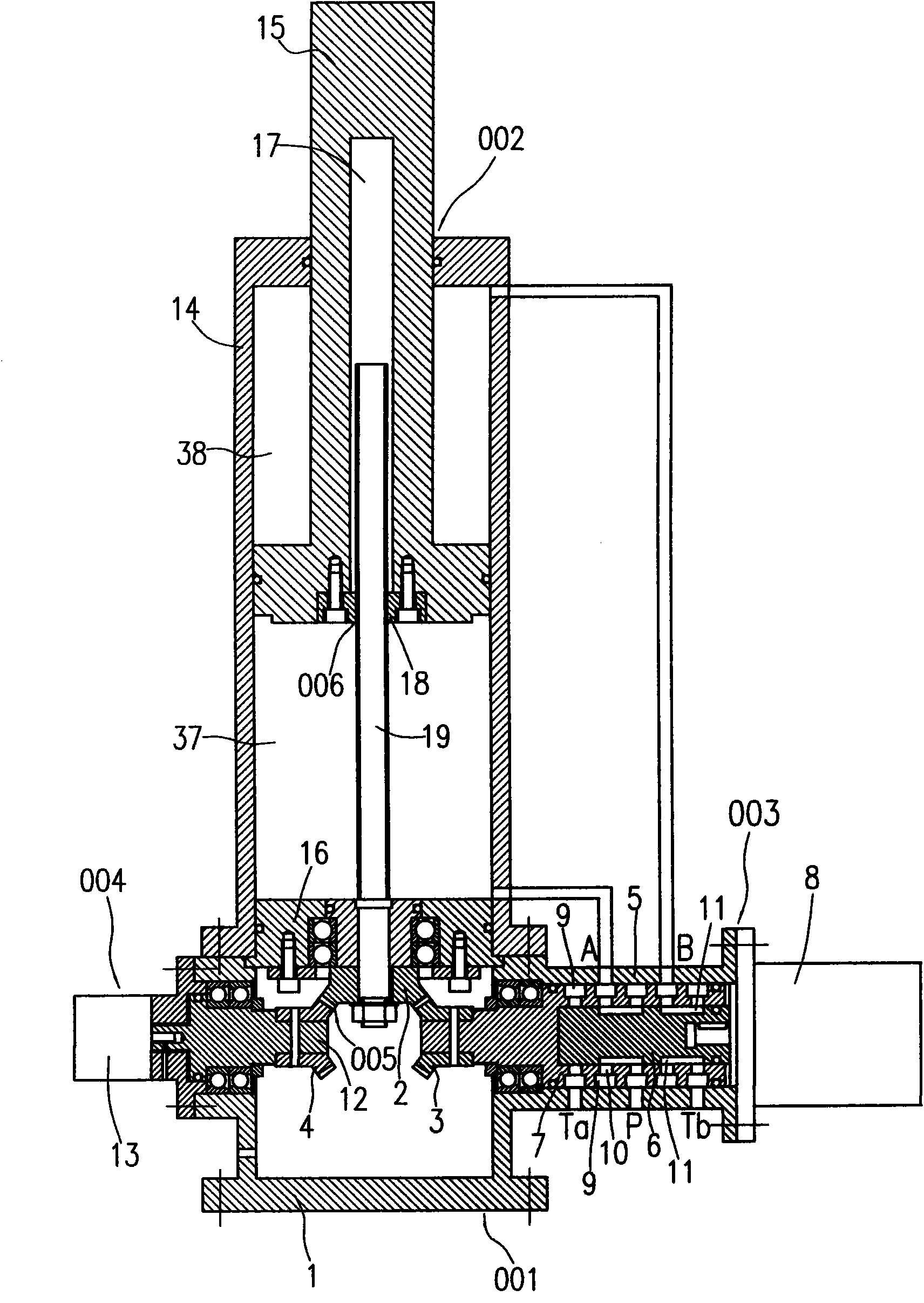

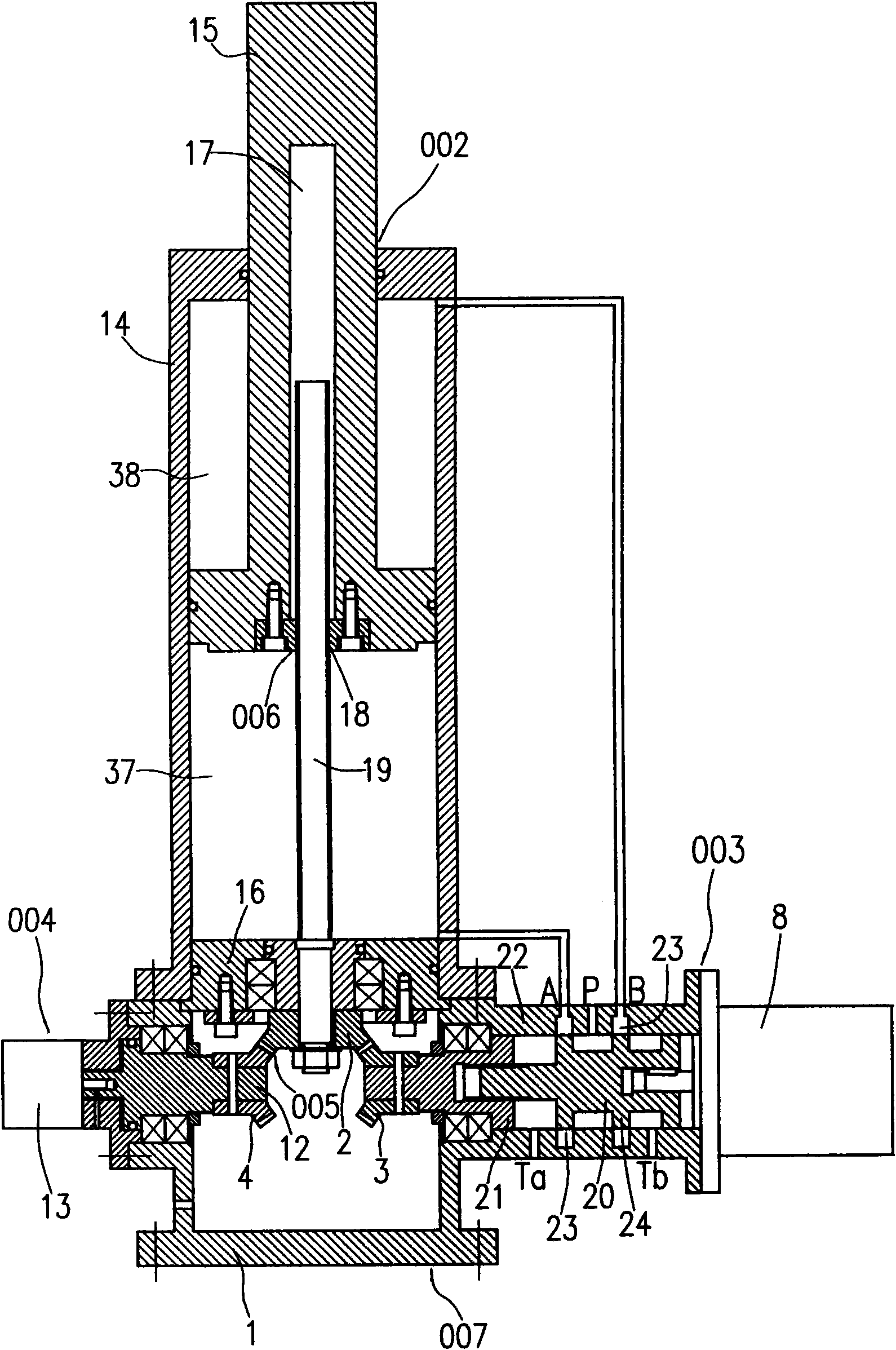

[0023] figure 1 It is a servo hydraulic cylinder including a servo hydraulic valve of the present invention. The servo hydraulic cylinder includes a servo hydraulic valve (001) and a hydraulic cylinder (002) integrated therewith. The servo hydraulic valve (001) includes a casing (1), a control valve (003), a sensor (004), and a gear pair (005). The gear pair (005) includes a driving gear (2), a driven gear A (3) and a driven gear B (4). The control valve (003) includes a valve casing (5), a valve core (6), a valve sleeve (7), and a stepping motor (8). One end of the valve sleeve (7) is fixedly connected with the driven gear A (3), and the valve core (6) is inserted into the inner hole of the valve sleeve (7). The valve casing (5) is a part of the casing (1), the stepper motor (8) is installed on the end face of the valve casing (5), and its output shaft is inserted into the valve core (6 ) in the inner hole at one end and connected with a key. The outer wall of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com