Centering clamping mechanism of CNC (Computerized Numerical Control) drilling machine of pipe fittings

A technology of CNC drilling machine and clamping mechanism, which is applied to the parts of boring machine/drilling machine, clamping, drilling/drilling equipment, etc. It can solve the problems of long clamping time, poor safety and low efficiency, and prevent impact The effects of damage and damage, meeting automation requirements, and efficient and accurate automation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

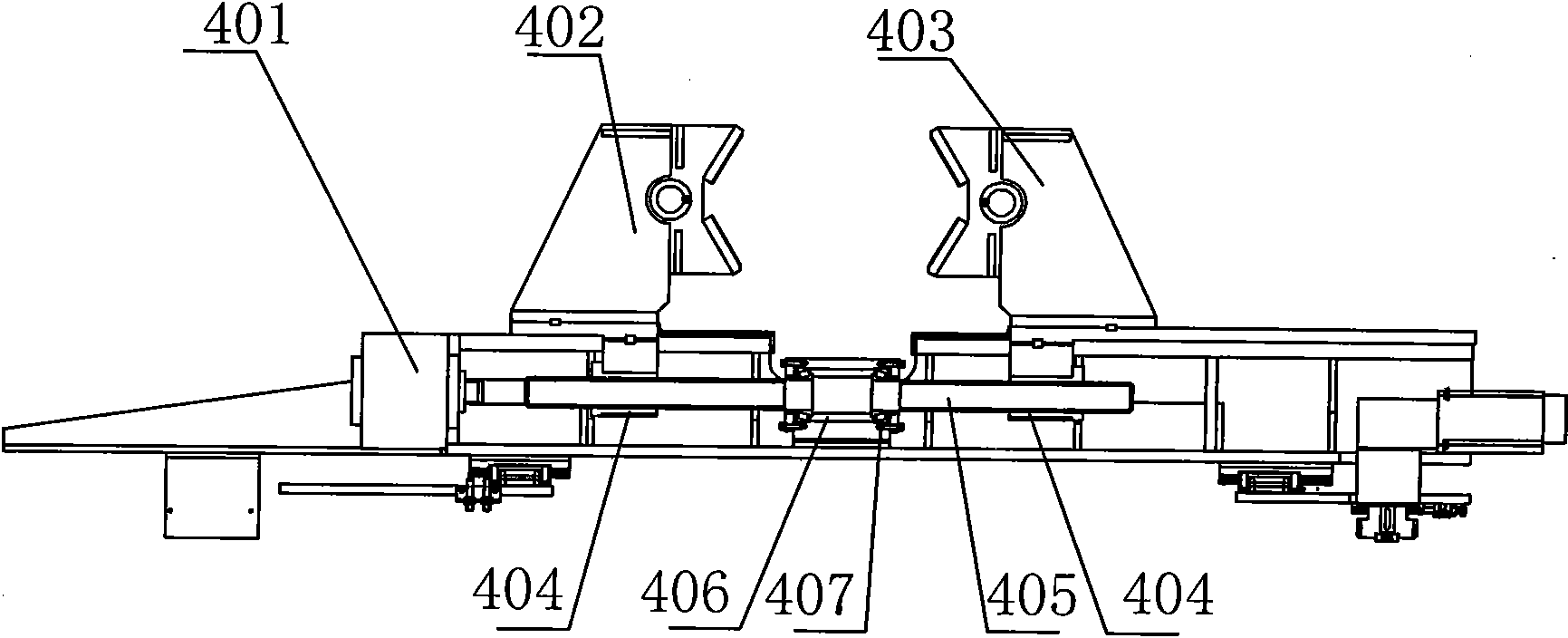

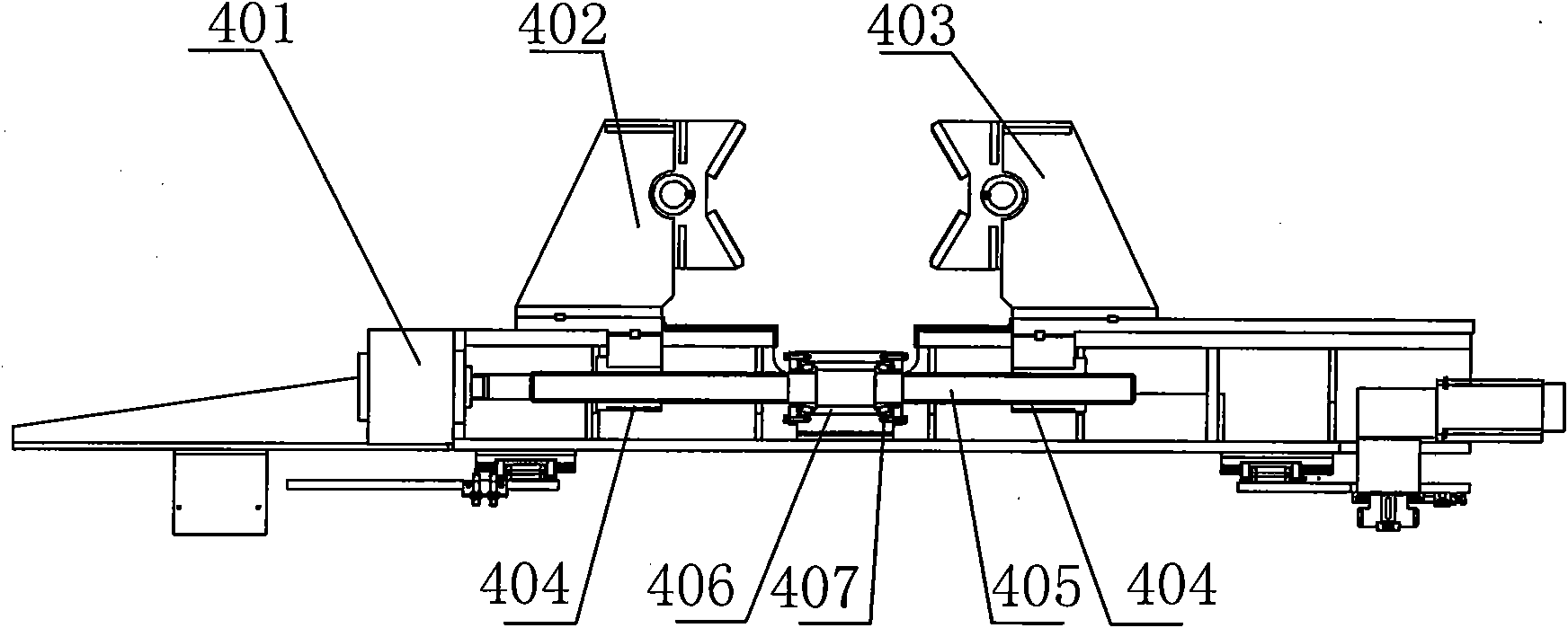

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, the bottom of the first clamping block 402 and the second clamping block 403 of the drilling platform is provided with a screw nut 404 which is engaged with a screw rod 405 . The middle part of the screw mandrel 405 is supported by the screw mandrel support seat 406 through the tapered roller bearing 407, the support seat 406 is fixed on the mobile drilling platform 4, and the screw mandrel 405 on both sides of the screw mandrel support seat 406 is positive and negative thread; The rod 405 is driven by the hydraulic motor 401 at the end, and the hydraulic motor 401 is controlled and driven by the hydraulic station, which is prior art; when the screw rod 405 rotates, the screw nuts 404 on both sides are driven to make the first clamping block 402 and The second clamping block 403 moves closer to the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com