Patents

Literature

94results about How to "Meet automation requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

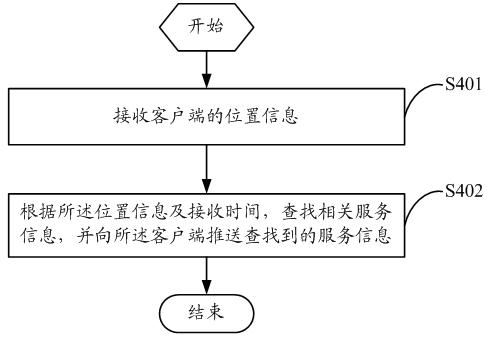

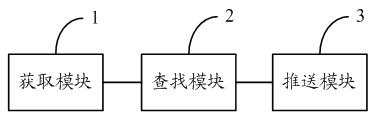

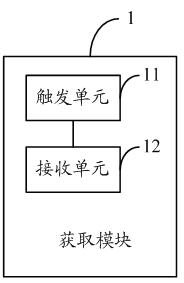

Method for providing service information and server

ActiveCN102098620AMeet automation requirementsMeeting Automation NeedsMessaging/mailboxes/announcementsLocation information based serviceService informationClient-side

The embodiment of the invention discloses a method for providing service information. The method comprises the following steps of: receiving position information of a client; and searching for relevant service information according to the position information and receiving time and transmitting searched service information to the client. The embodiment of the invention also discloses a server. By the method and the server, relevant service information can be searched for a user more automatically and intelligently according to the current position information and time of the user, so that the user can acquire needed service information in time.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

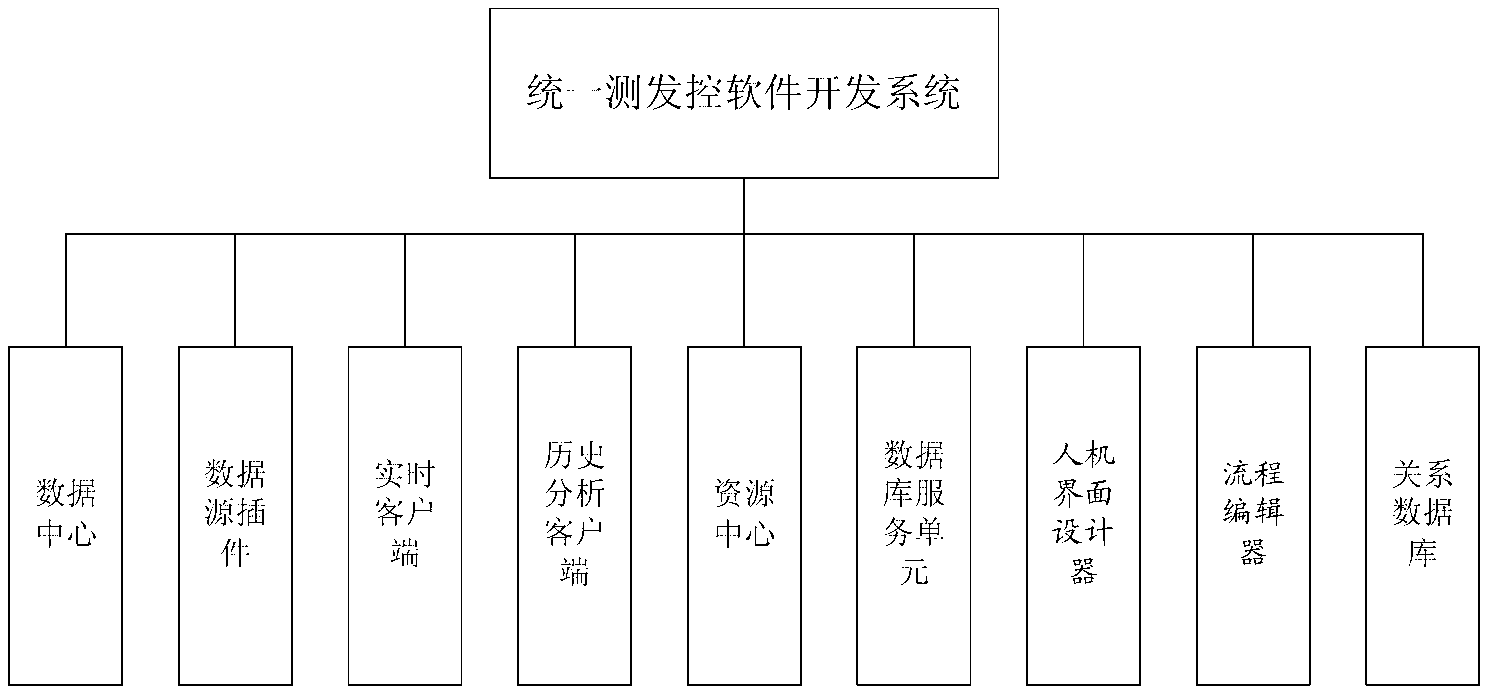

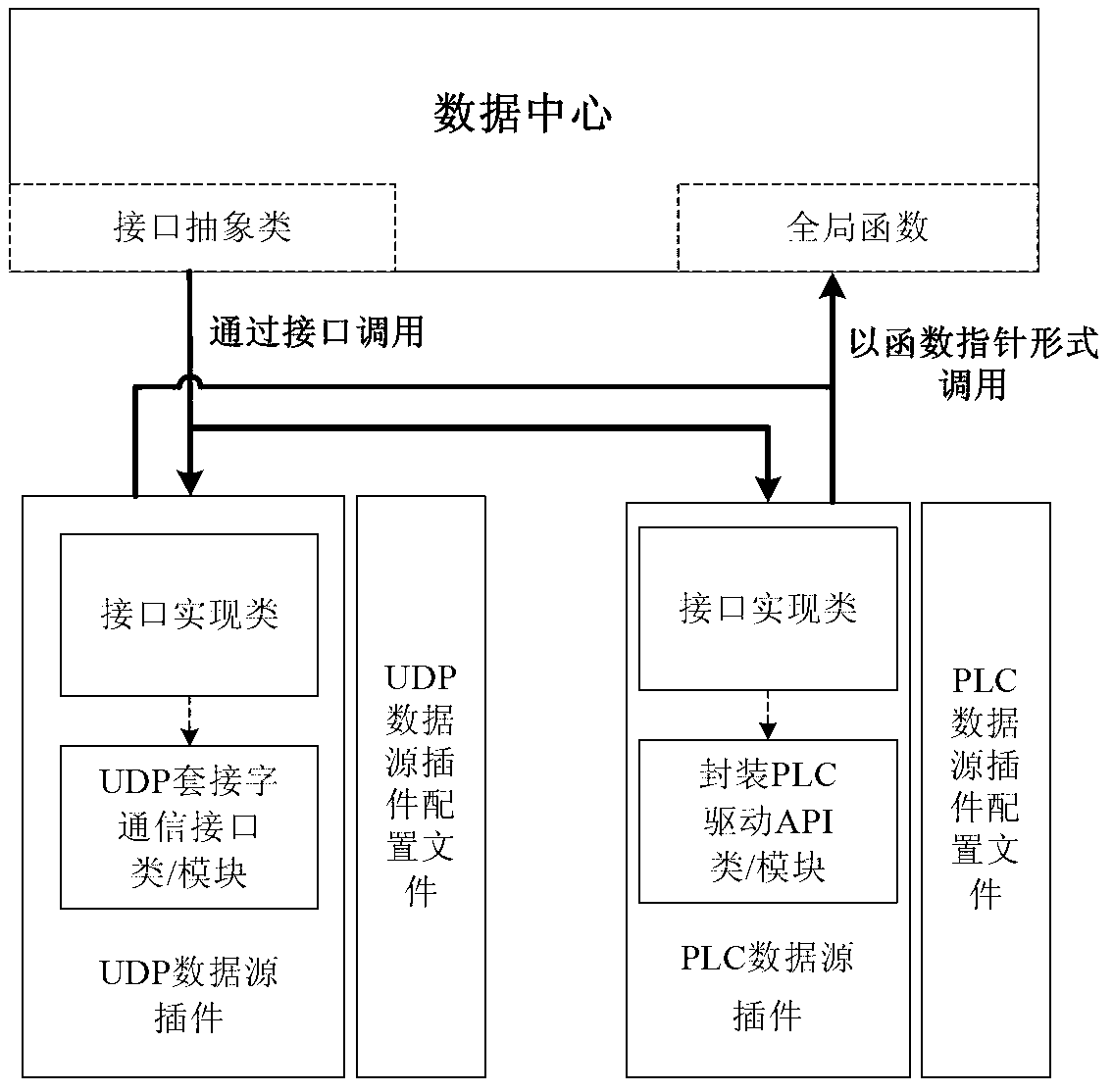

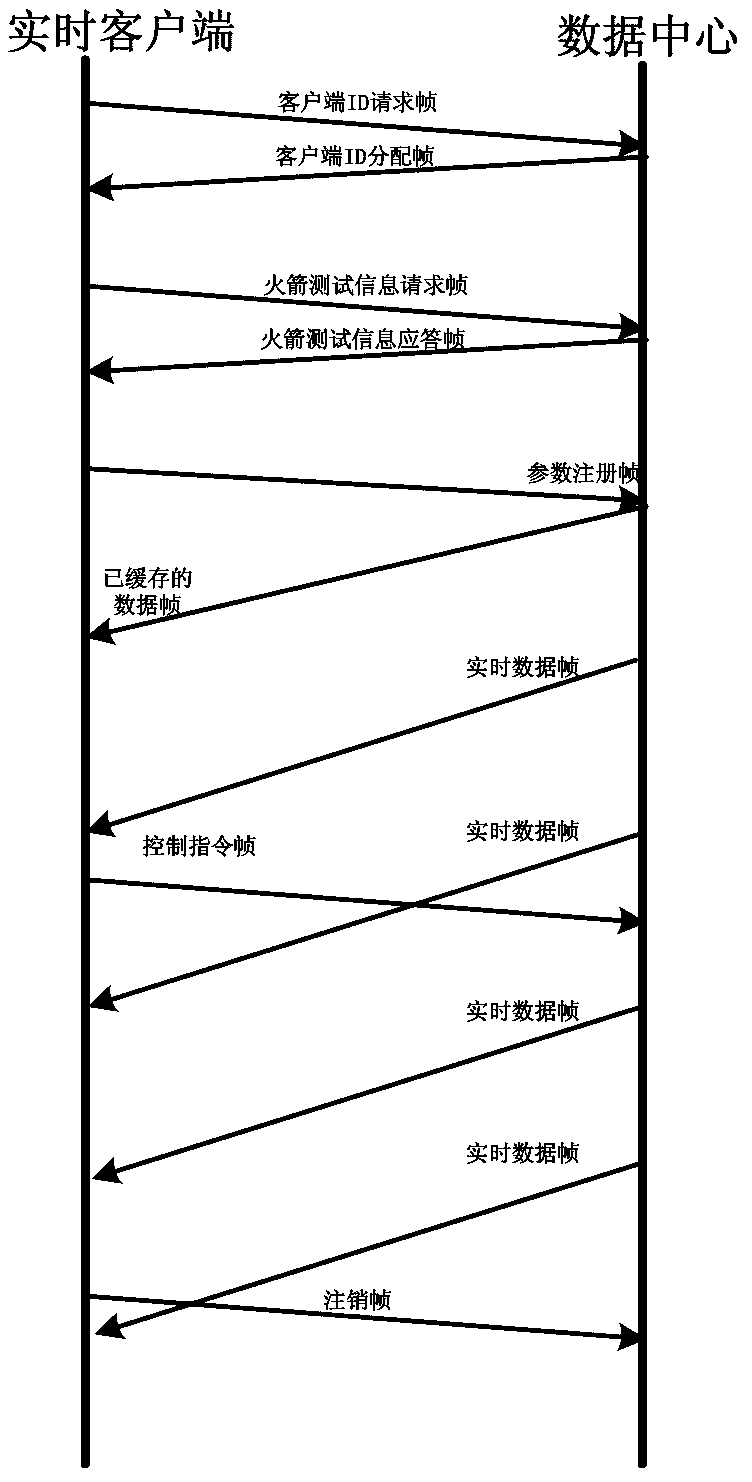

Unified measurement and development control software development system

ActiveCN103218225AEffective interactionImprove test efficiencySpecific program execution arrangementsSoftware developmentControl software

The invention discloses a unified measurement and development control software development system. The system is based on a plurality of components, and comprises four application components of a data center, a data source plug-in unit, a real-time client and a historical analysis client, two service components of a resource center and a database service unit, two tool components of a man-machine interface designer and a process editor, and a relational database. The system has strong structural universality and flexibility, various functional requirements of measurement and development applications are satisfied, unified effective application modes and development interfaces are provided for development personnel, and different components can be selected according to specific requirements to carry out configuration and customized development.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

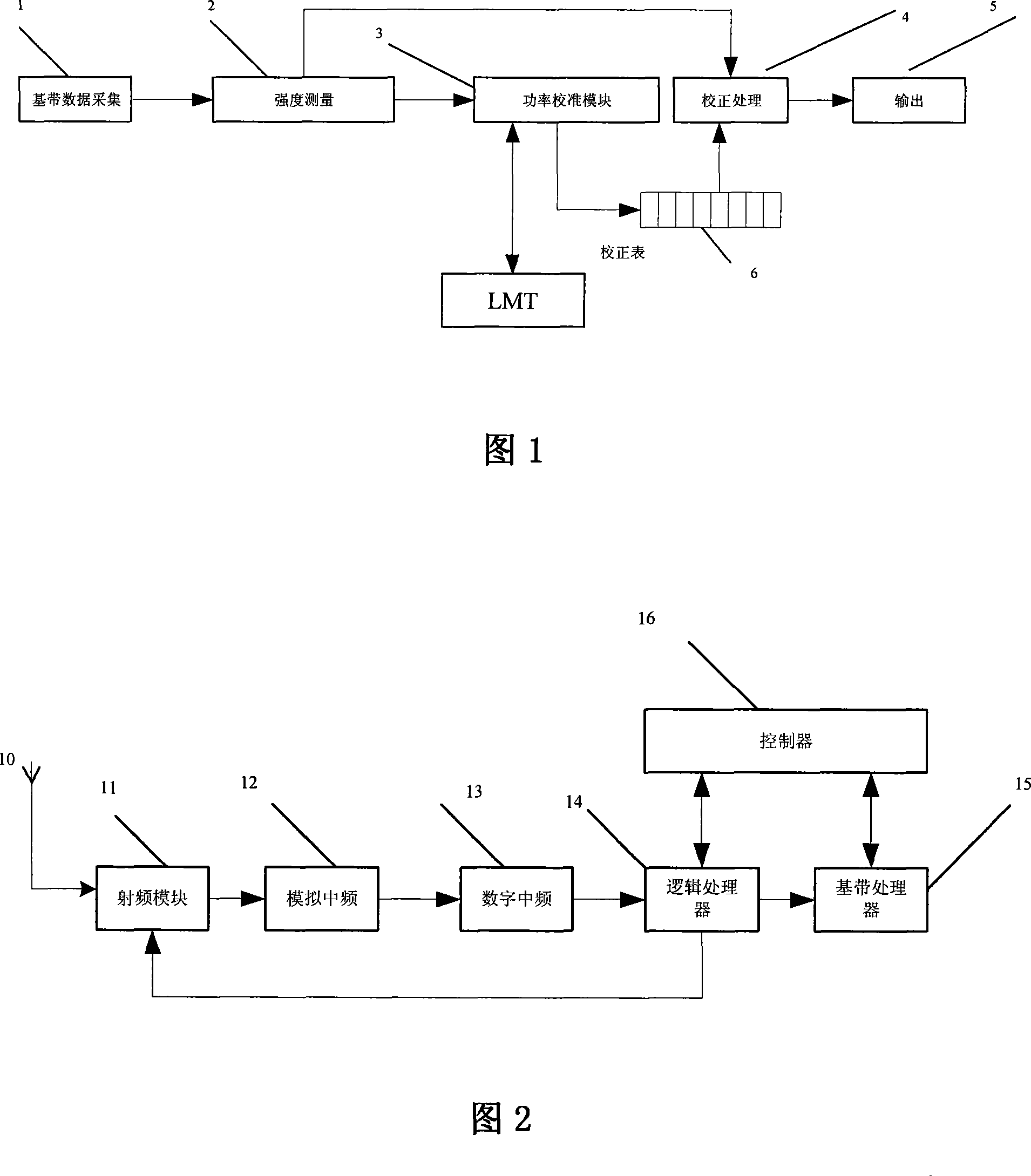

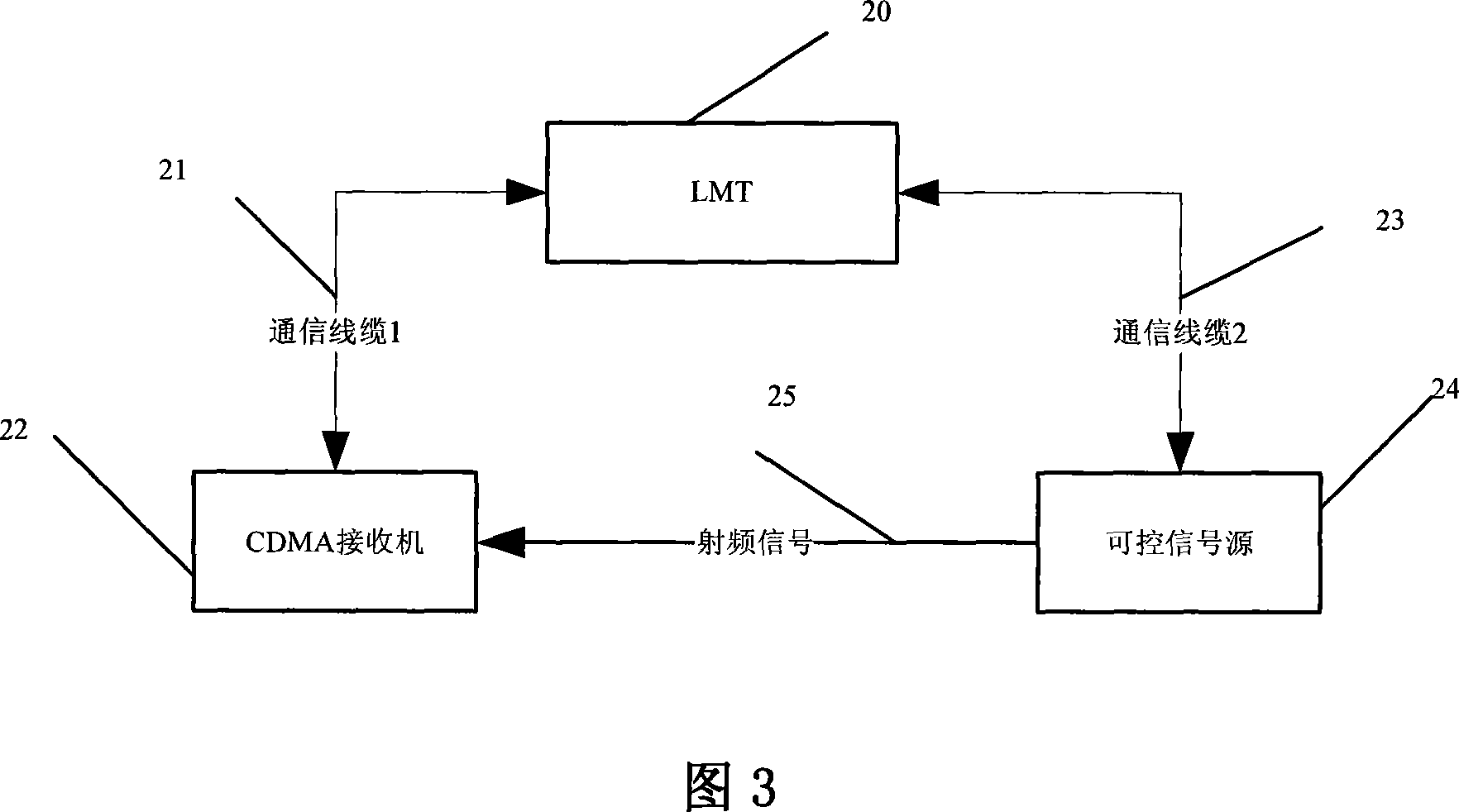

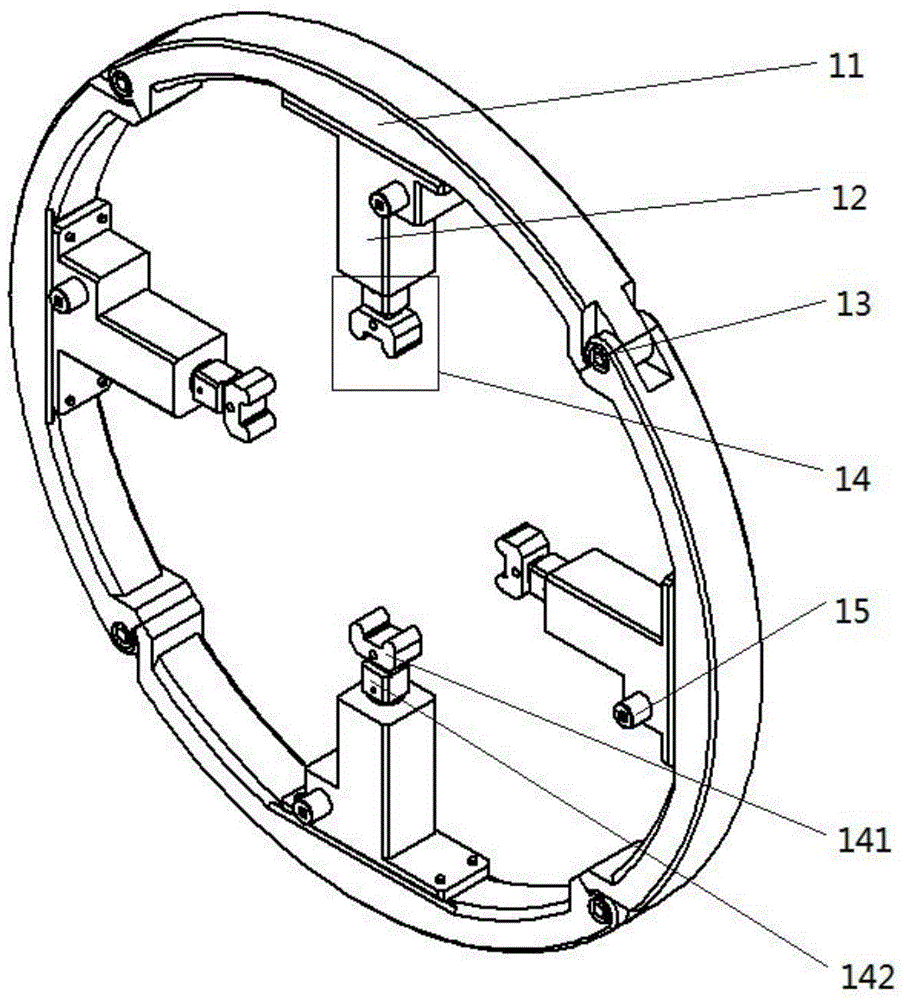

A power calibration and real time correction device for CDMA receiver and its implementation method

ActiveCN101188463AReduce consumptionHigh speedReceivers monitoringRadio/inductive link selection arrangementsCdma systemsNonlinear gain

The invention relates to a CDMA receiver power calibration and real-time correction device and the realization method thereof, and the method can be used for the power calibration and the real-time correction of terminal equipment such as the CDMA system, the base station facilities, and the road measurement meter. The method adopts a segment look-up table approach, and not only uses the fastness and simplicity of the look-up table approach but also combines segment treatment, thereby reducing the consumption of the storage room as much as possible. For linear gain section of a receiving link, i.e. the so-called big signal calibration, the look-up table approach is used directly; for non-linear gain section, i.e. small signal calibration, a noise compensation calibration method is adopted. The invention is used especially for the power calibration and the real-time correction of the massive equipment, and the power calibration method can meet the demand of automation and have the advantages of low cost, fast speed and high calibration precision.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

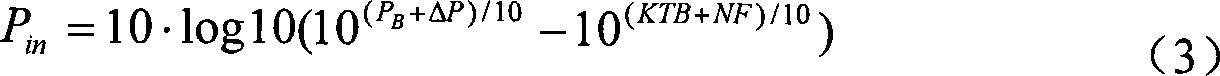

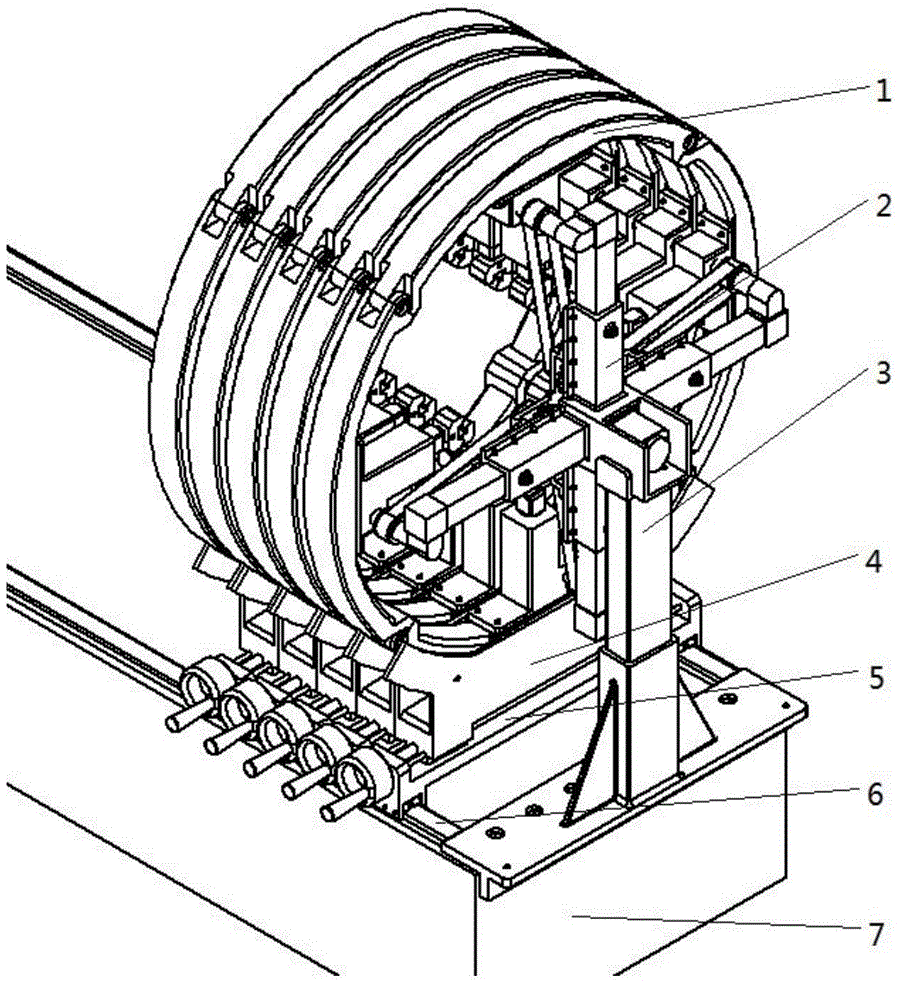

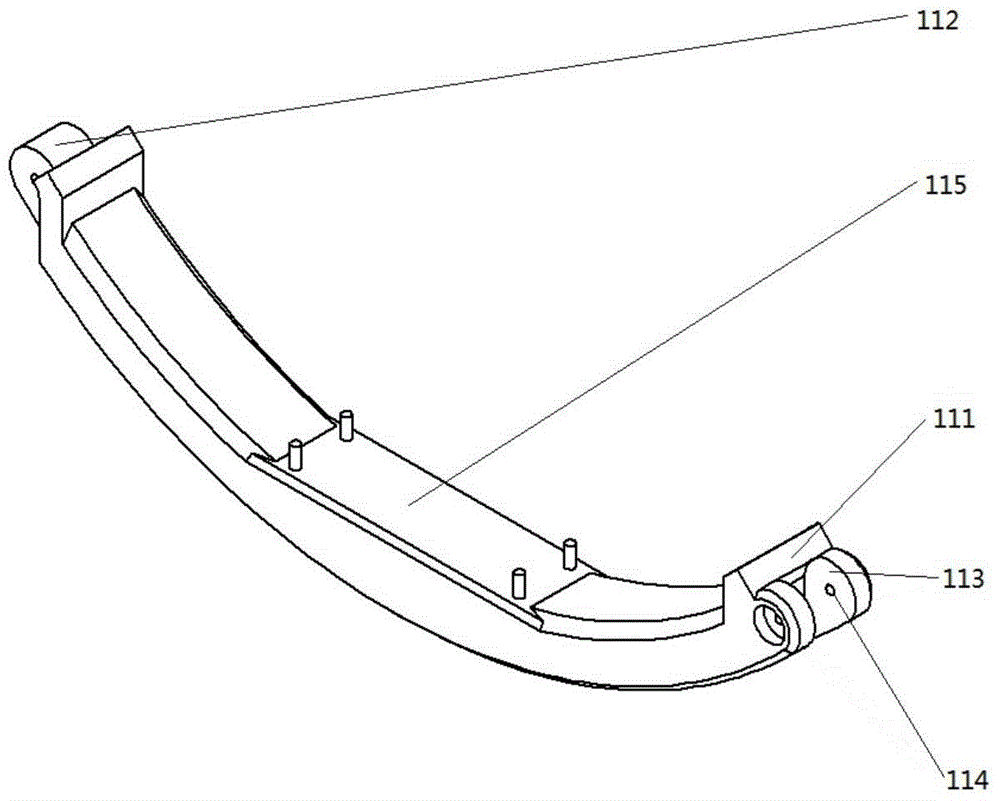

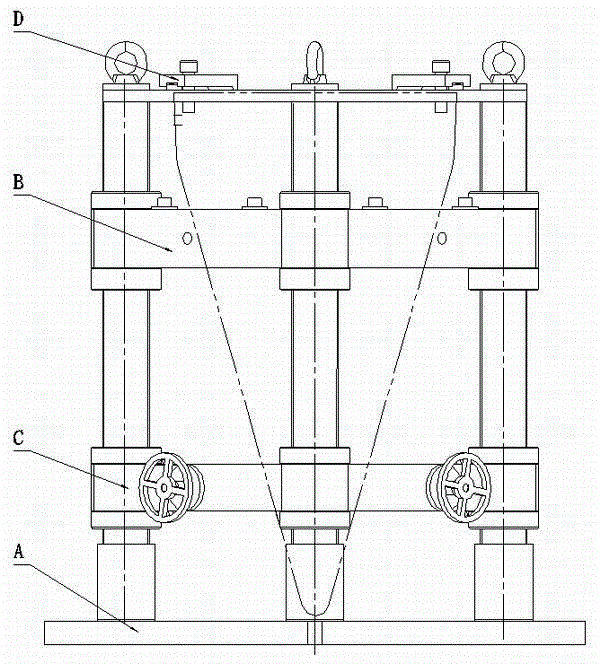

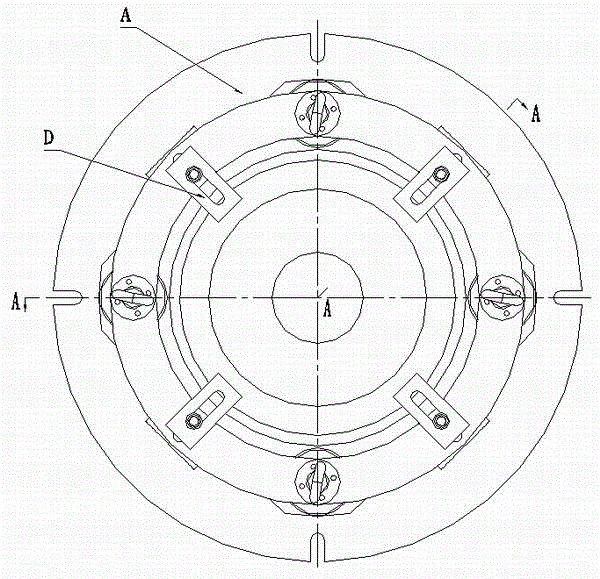

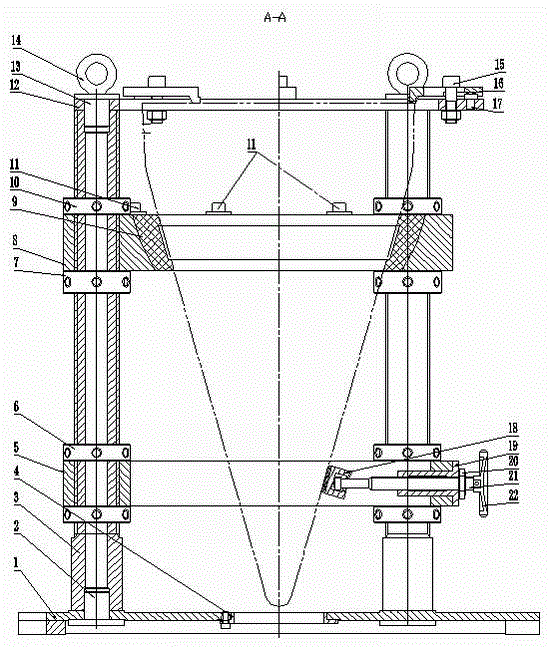

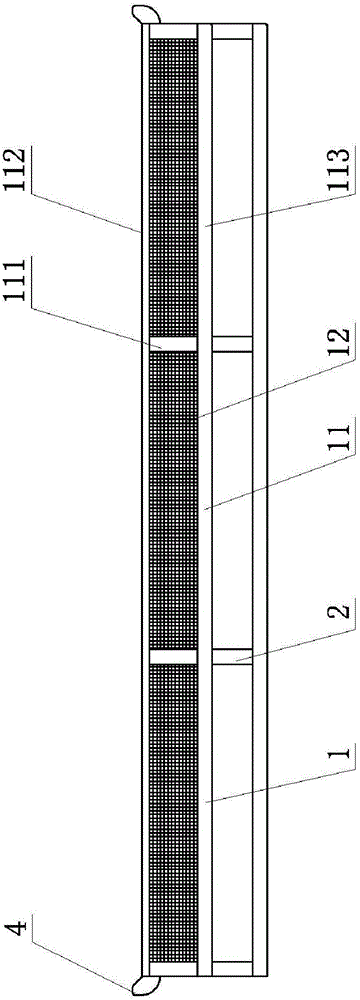

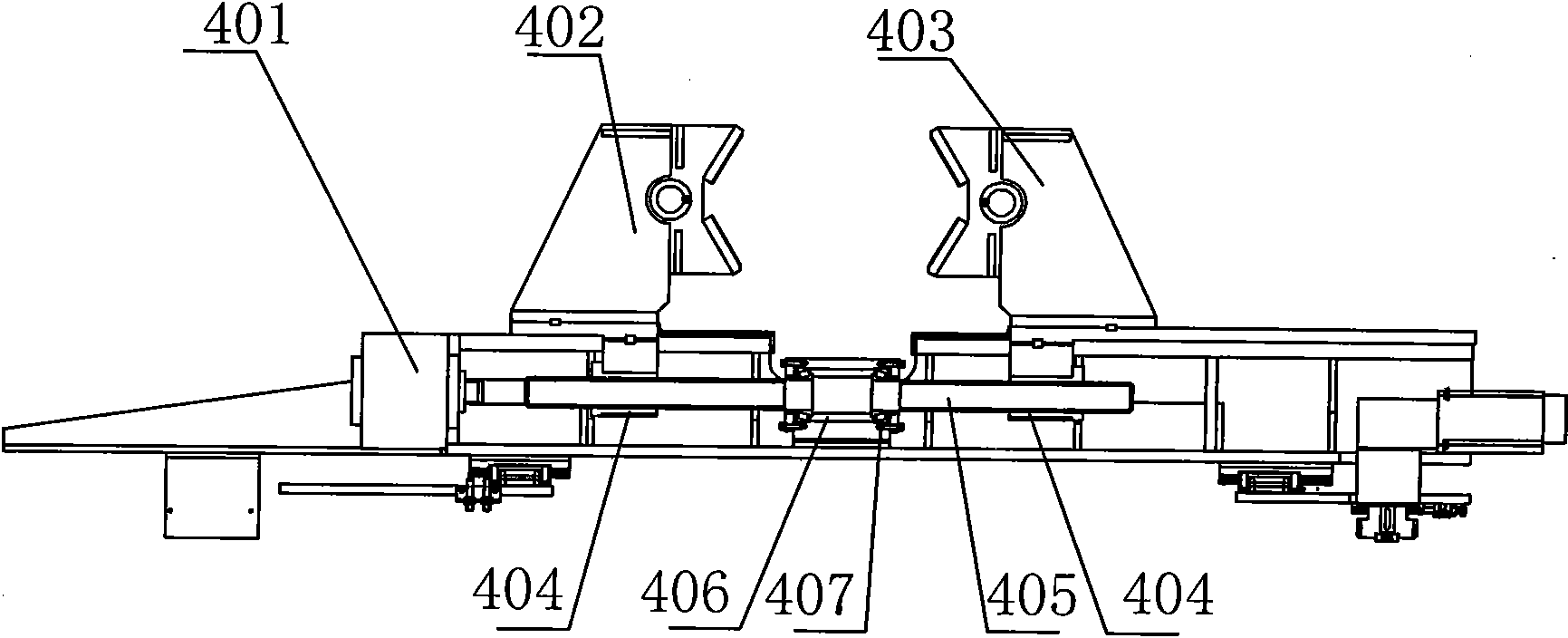

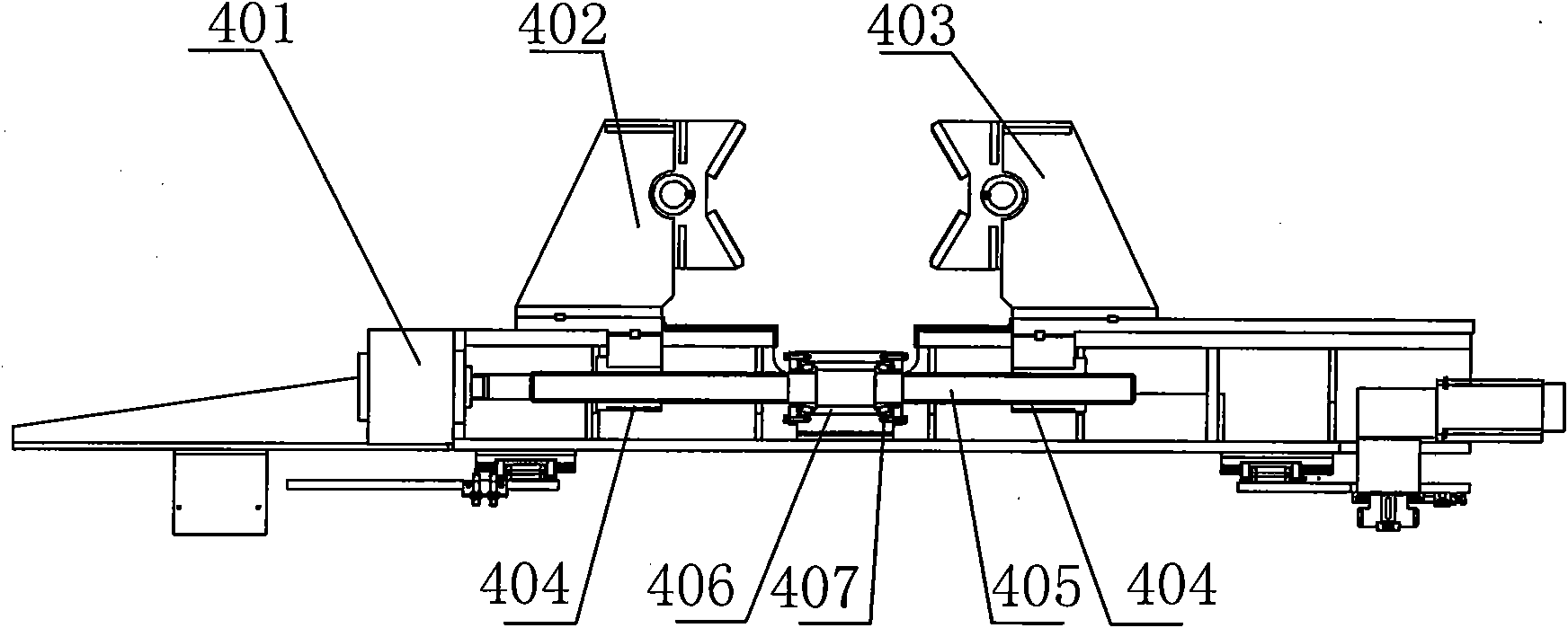

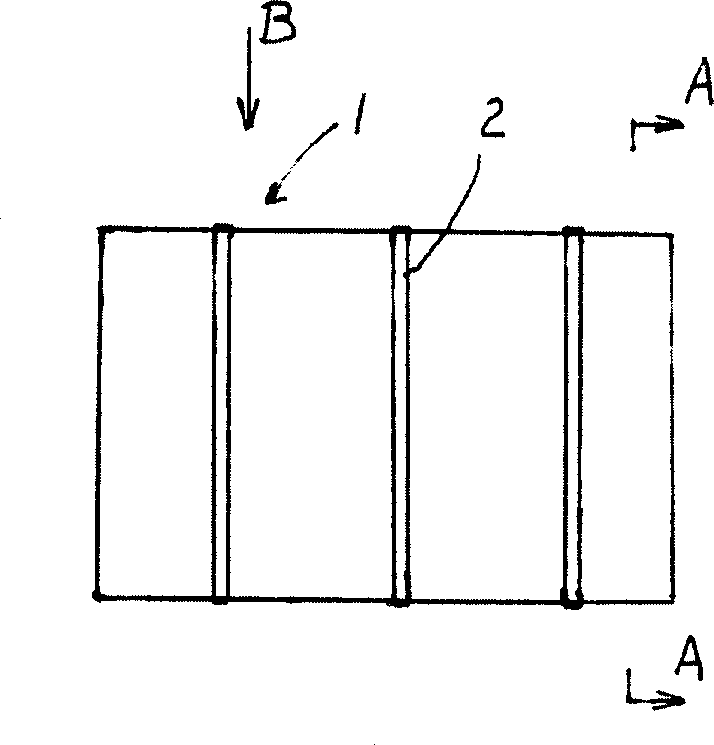

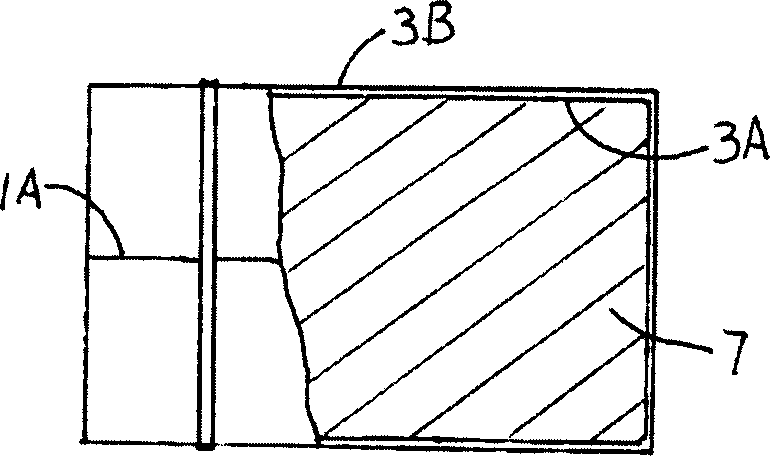

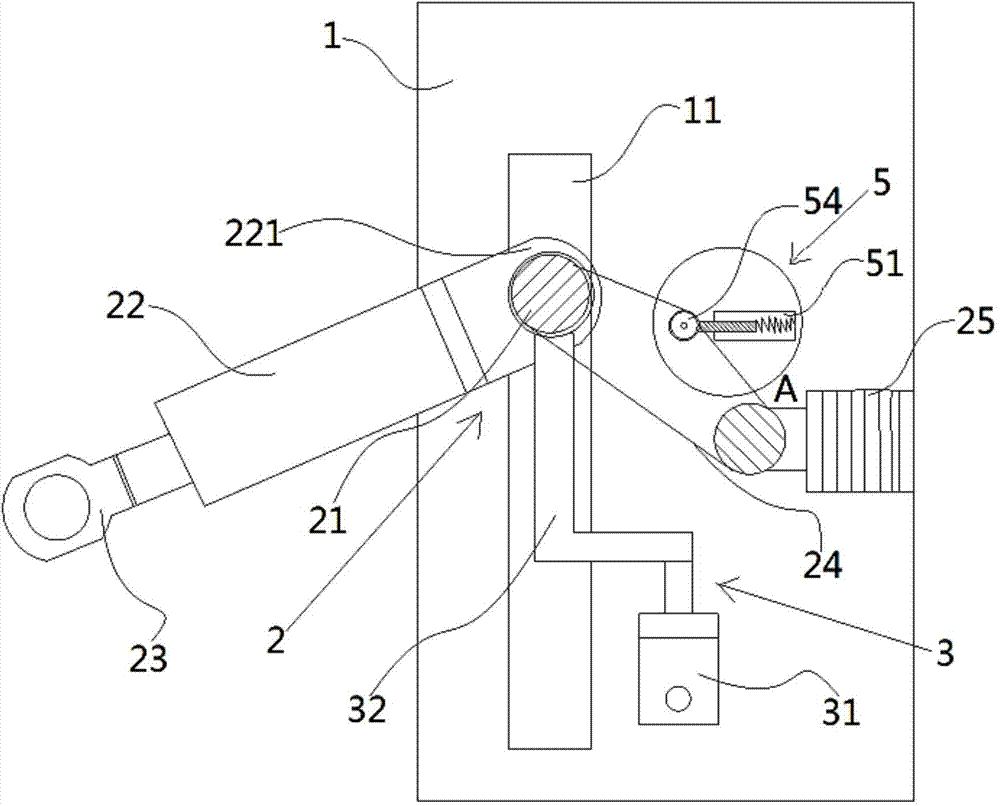

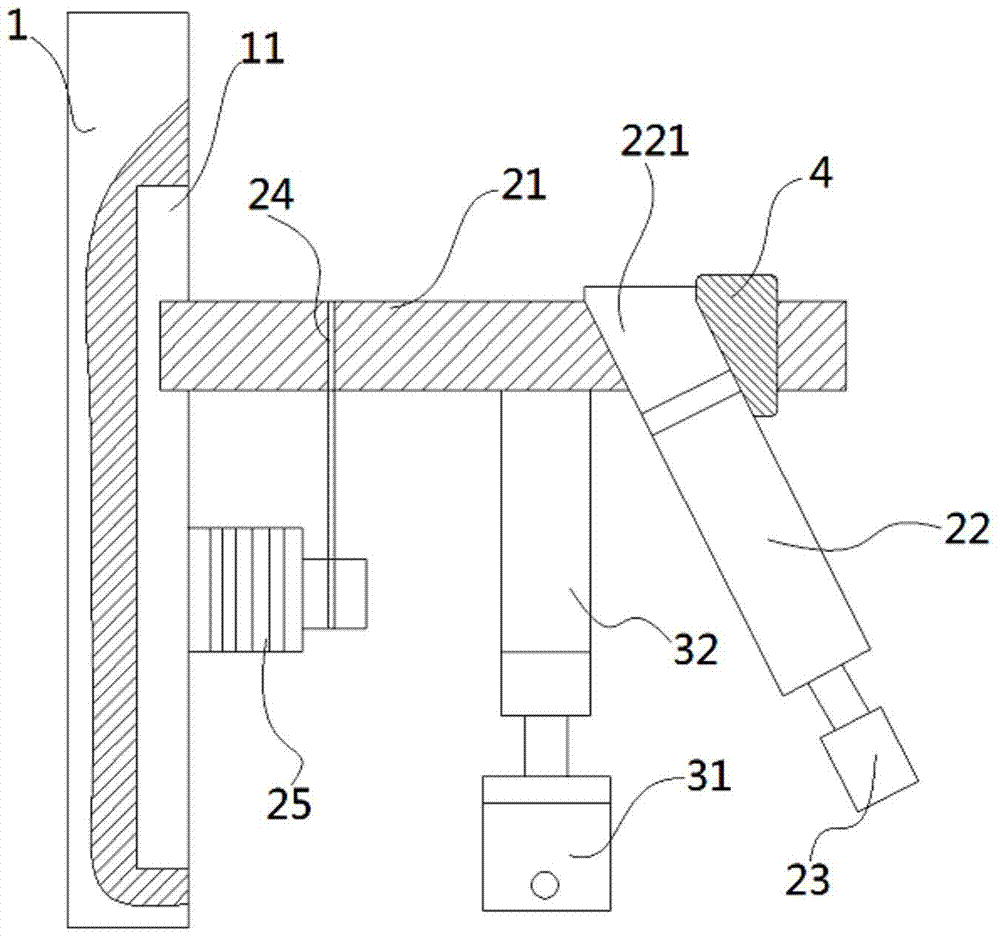

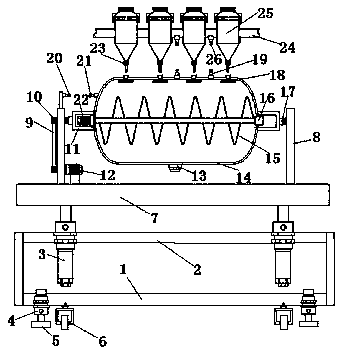

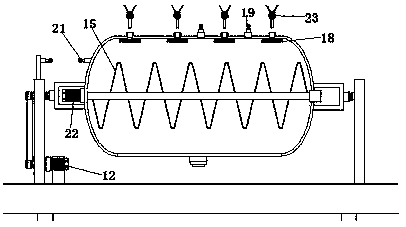

Flexible clamping device for cylindrical cabin butt assembly

The invention discloses a flexible clamping device for cylindrical cabin butt assembly. The flexile clamping device is used for solving the problem that an existing cylindrical cabin clamp is poor in adaptability and low in efficiency. The flexible clamping device comprises annular adjustable clamps, a clamp adjusting device, a clamp adjusting device support, a clamp support, a plurality of carriage sliding tables, guide rails and a base. The two parallel guide rails are fixed to the base. One end of the base is provided with the clamp adjusting device support. The clamp adjusting device support is provided with the clamp adjusting device. The carriage sliding tables are erected on the guide rails. The clamp support is arranged on the carriage sliding tables. The annular adjustable clamps are installed on the clamp support. The flexible clamping device has the beneficial effects of being good in adaptability, high in efficiency and high in clamping precision, and can be used for but assembly of cylindrical cabins of different radiuses and installation of accessory devices on the outer wall of the cabins.

Owner:XIDIAN UNIV

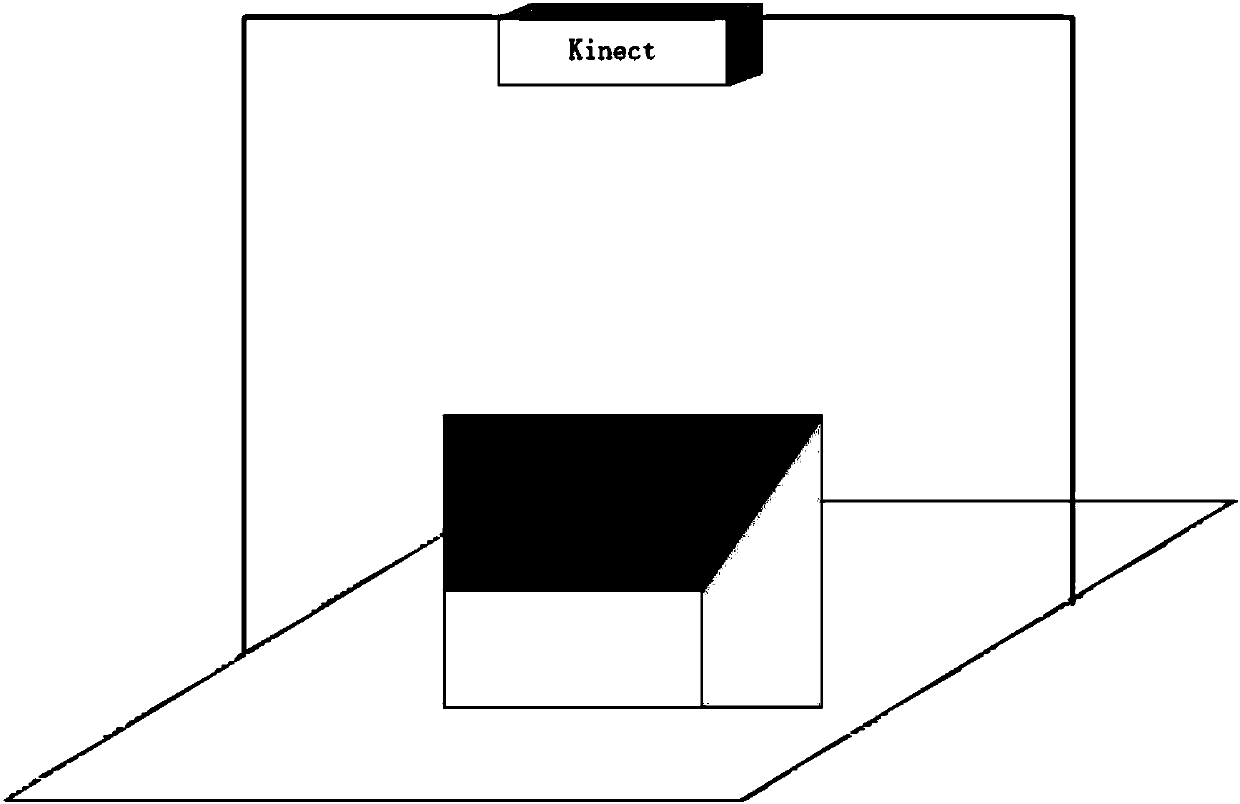

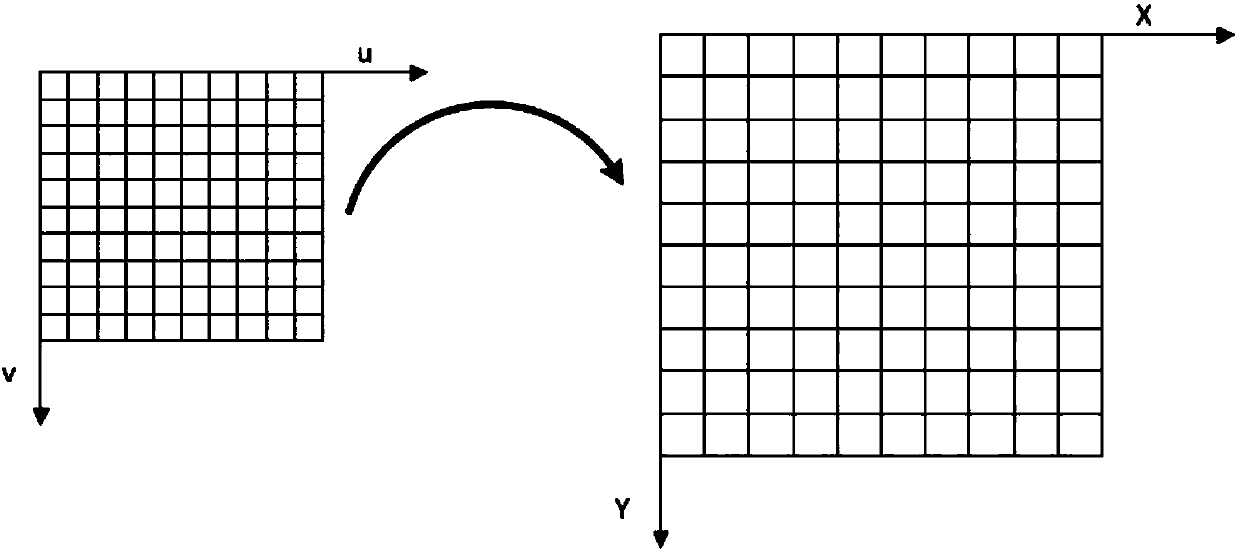

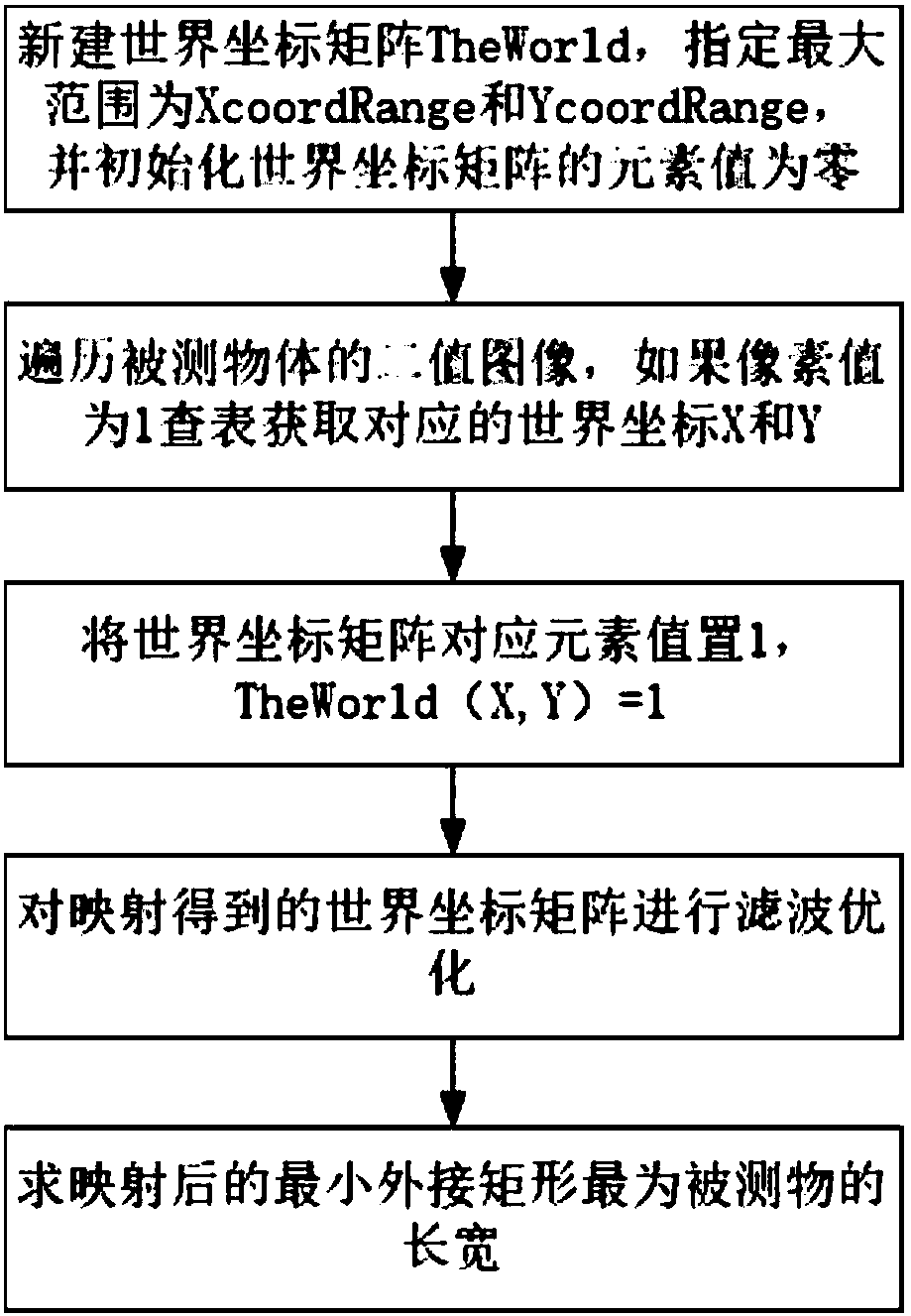

Object volume calculating method based on Kinect

ActiveCN107067431AImprove stabilityImprove reliabilityImage enhancementImage analysisColor imageDistance matrix

The invention discloses an object volume calculating method based on Kinect. The method comprises the steps of (1), acquiring a depth image and a color image by means of Kinect; (2), calibrating a color camera of the Kinect; (3), setting an ROI area of the depth image, performing image segmentation by means of a foreground color image which comprises a measured object and a background color image of a measurement platform that does not comprise the measured object, and obtaining a binary image of the measured object; (4), converting a background depth image ROI area to a background distance matrix, and performing preprocessing on the background distance matrix, filling in elements which are zero on the background distance matrix, and converting the foreground depth image ROI area to a foreground distance matrix; (5), obtaining a height matrix according to difference between the foreground distance matrix and the background distance matrix; and (6), calculating length, width, height and volume of the object. The object volume calculating method effectively settles problems of high labor intensity and long measurement time in traditional manual measurement, and is a noncontact measurement means. Damage of the measurement object is prevented. A requirement for automatic is satisfied and furthermore measurement precision is improved.

Owner:HOHAI UNIV CHANGZHOU

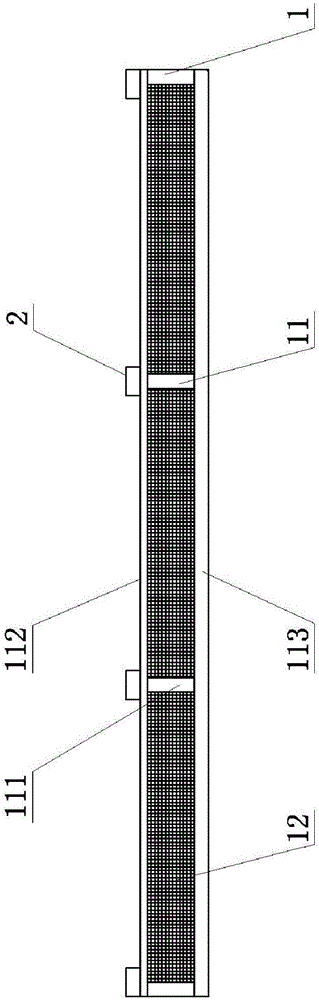

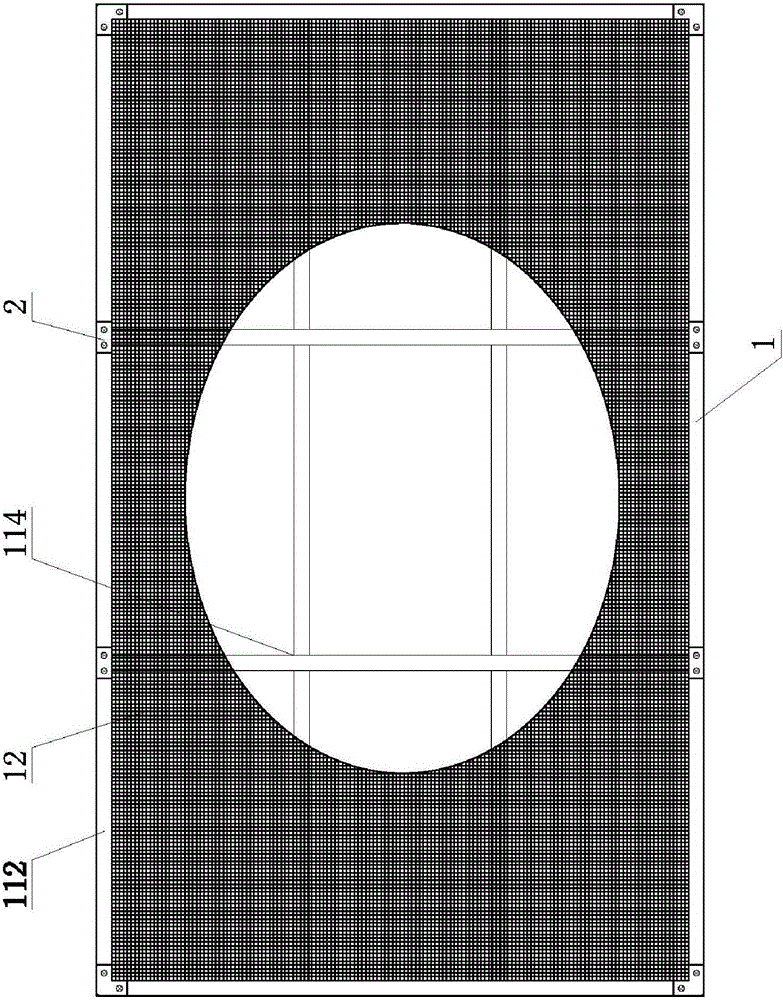

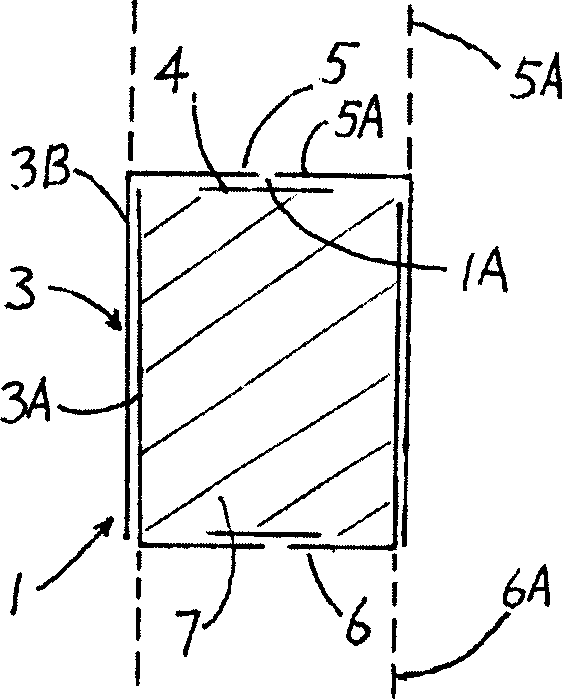

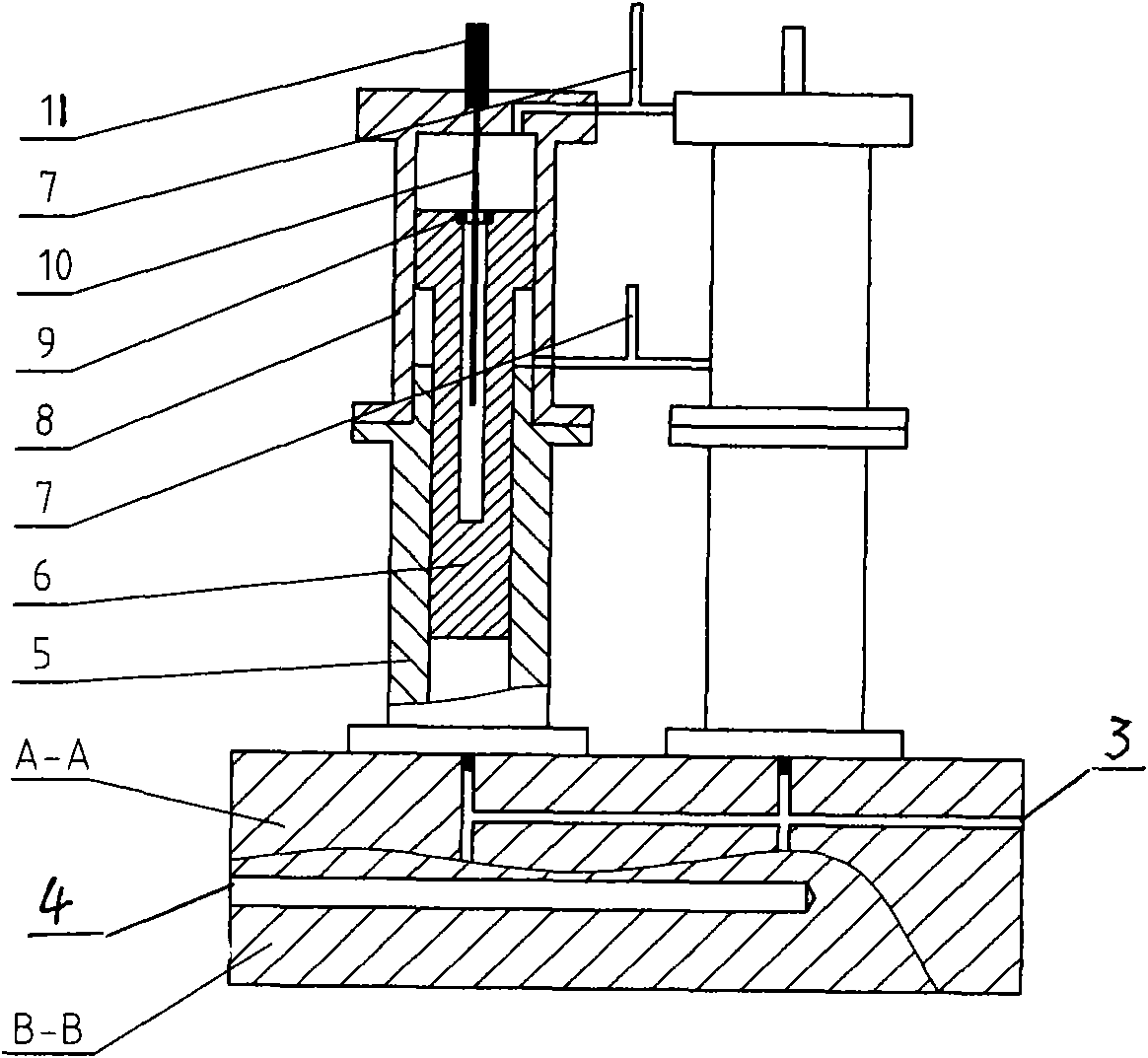

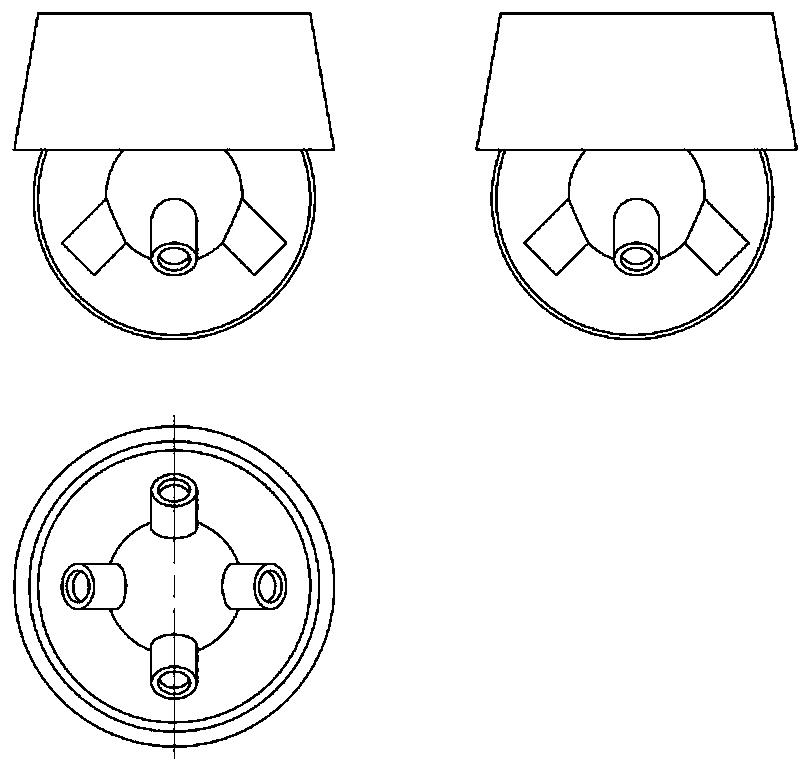

Conical radome machining and fixing fixture

InactiveCN104858685AMeet automation requirementsImprove processing efficiencyWork clamping meansPositioning apparatusNumerical controlEngineering

The invention provides a conical radome machining and fixing fixture, and belongs to the technical field of machine tool fixtures. The conical radome processing and fixing fixture comprises an overall support, a positioning device, a regulating device and a clamping mechanism; a disc base, a circular top plate and four pillar type columns are connected into a whole through the overall support by adopting positioning pins; the positioning device is arranged on the four pillar type columns in a sleeving mode by adopting an upper aluminum casting, and the center of the upper aluminum casting is provided with a nylon sleeve used for positioning a radome; the regulating device is arranged on the four pillar type columns in the sleeving mode by adopting a lower aluminum casting, and four spiral regulating mechanisms are evenly distributed on the lower aluminum casting; four pressing plates fixed by bolts are evenly distributed on the circular top plate of the clamping mechanism. The fixture can be suitable for regulating, positioning and clamping of radome parts of various different specifications for machining evenly distributed inner wall blind holes on a numerical control machine tool, meets the automation requirement of evenly distributed inner wall blind hole machining of the radome parts, and the machining efficiency is greatly improved.

Owner:久亿航宇科技(大连)有限公司

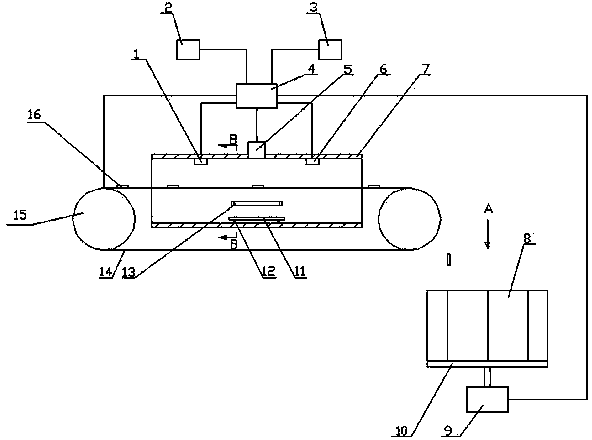

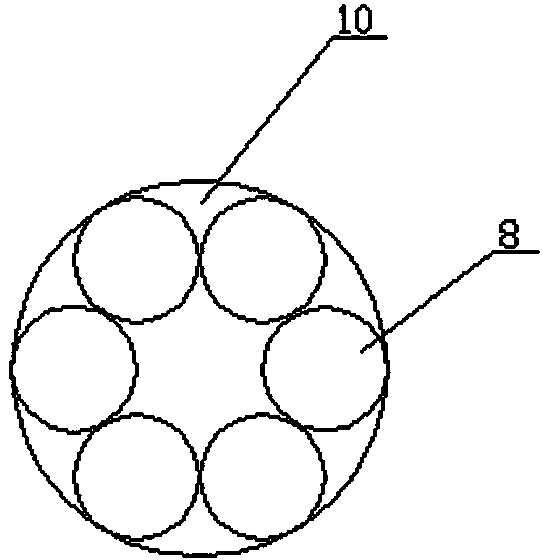

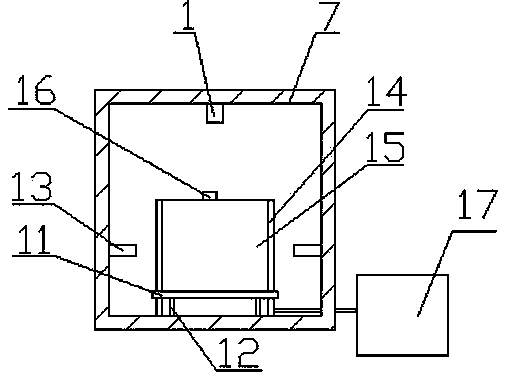

Fermentation tray for solid organic materials

InactiveCN105060965AShorten fermentation timeReduce secondary environmental pollutionClimate change adaptationOrganic fertiliser preparationOxygen deficitEngineering

The invention discloses a fermentation tray for solid organic materials. The fermentation tray comprises a fermentation tray body and layered supports, wherein the fermentation tray body comprises a bearing frame and a net disc mounted in the bearing frame, and the layered supports are mounted above or / and below the bearing frame of the fermentation tray body. The fermentation tray for the solid organic materials adopts a bearing frame and net disc combined structure, the fermentation time can be shortened greatly, bad smell caused by oxygen deficit can be avoided in an organic material fermentation process, secondary environmental pollution is reduced effectively, and good environmental protection property of fermentation is realized, so that the fermentation tray can better adapt to a tray type three-dimensional fermentation system.

Owner:GUANGXI LIYUANBAO SCI & TECH

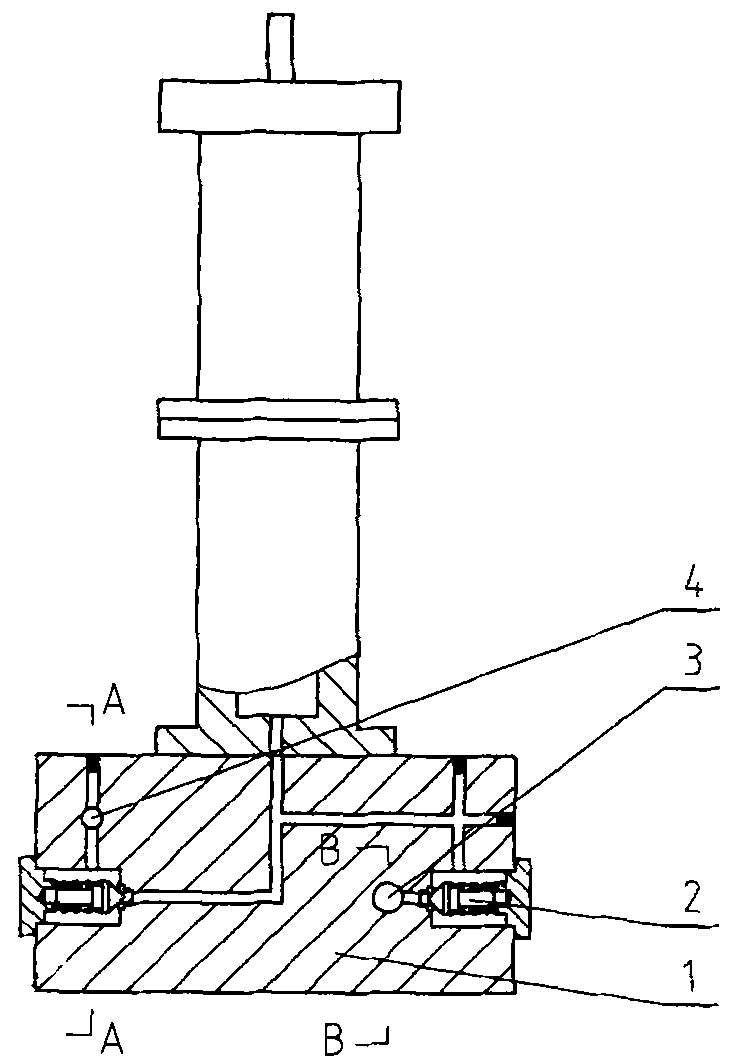

Centering clamping mechanism of CNC (Computerized Numerical Control) drilling machine of pipe fittings

InactiveCN101954600AEffective clampingAvoid shockPositioning apparatusBoring/drilling componentsHydraulic motorNumerical control

The invention relates to a centering clamping mechanism of a CNC (Computerized Numerical Control) drilling machine for pipe fittings, arranged on a drilling platform of the CNC drilling machine. The centering clamping mechanism of the CNC drilling machines for pipe fittings comprises two clamping blocks which are arranged at both sides of the circumference of a pipe fitting and can move along the horizontal diameter direction of the pipe fitting, nuts are arranged at the lower parts of the two clamping blocks and engaged with a positive and negative screw mandrel which has two sections of opposite threads and is supported by the middle of a supporting seat, the supporting seat is fixedly connected with the drilling platform, and a rotating motion driving mechanism is arranged at one end of the positive negative screw mandrel. According to the invention, the positive negative screw mandrel is driven to rotate by adopting a hydraulic motor, the clamping blocks at both sides are driven to simultaneously homodromously or oppositely move and rapidly finish the centering and clamping action to the symmetrical outer walls of a cylinder, a hydraulic motor controls and drives the centering and clamping action through a hydraulic station, the action and the speed can be accurately controlled through a CNC console and the automation requirement with high efficiency is accurately satisfied, and the pipe fitting can be slowly and effectively clamped hydraulically to prevent mechanical clamping from causing impact and damage to the pipe fitting.

Owner:WUXI HUALIAN PRECISION MACHINERY

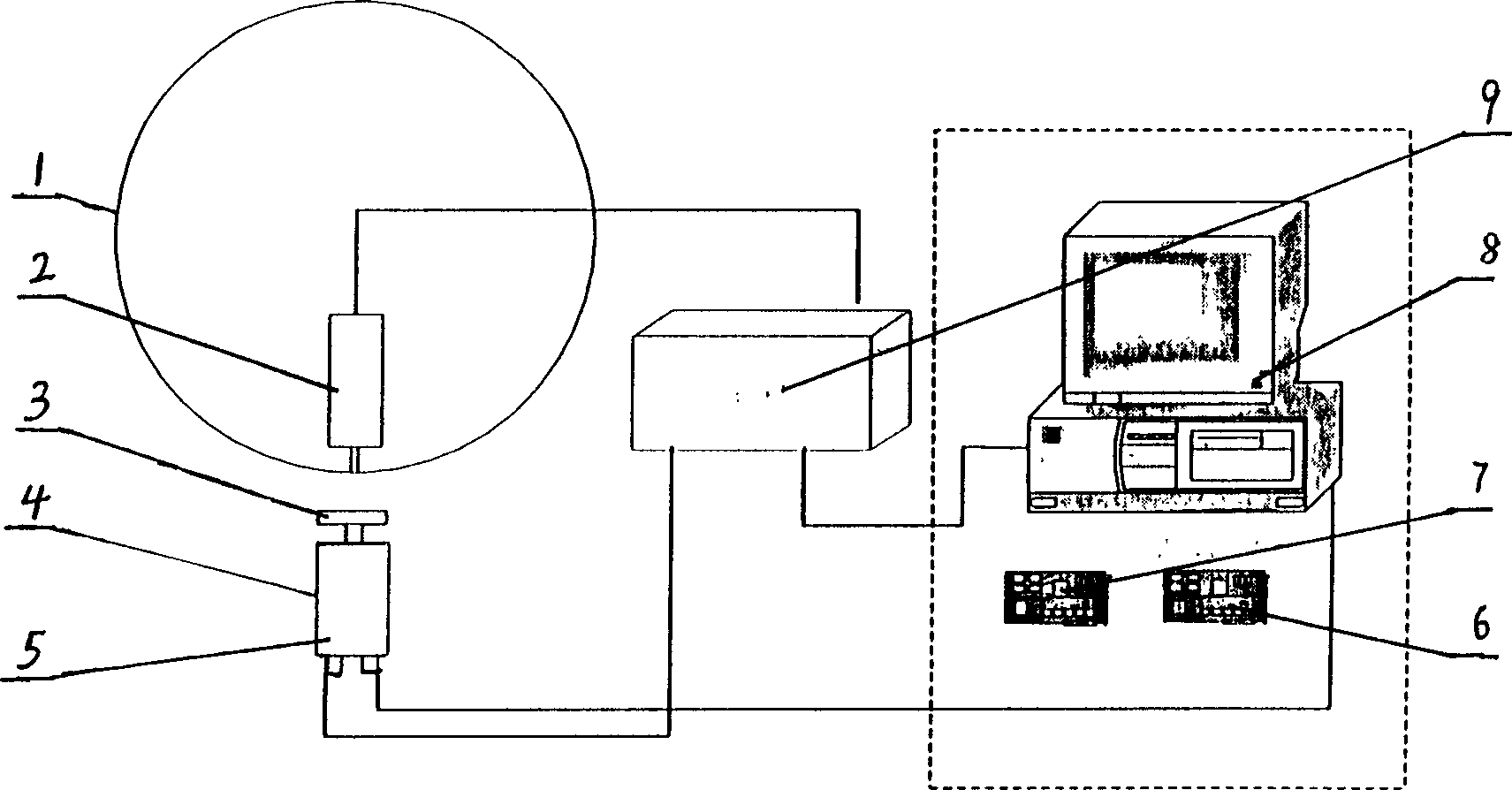

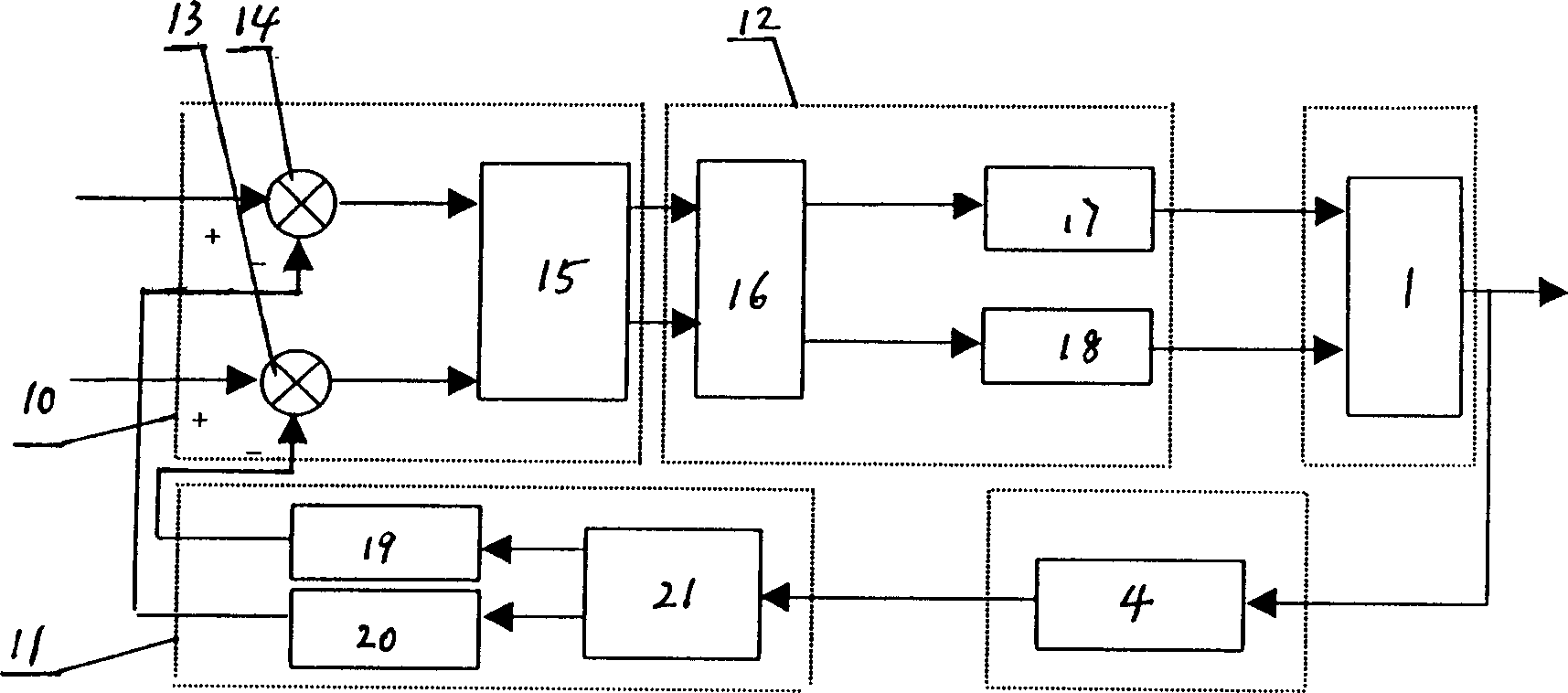

Intelligent control system for weld seam tracking and fusion penetration in spiral pipes

InactiveCN1546268AMeet automation requirementsComputer controlArc welding apparatusInformation processingNerve network

The invention discloses a kind of integrated intelligent control system for welding seam tracing and penetration in spiral tube, which includes spiral tube submerged arc welding machine, the character lies in: it also includes temperature field sensor, control box, and industrial control computer, there sets welding seam tracing and penetration integrated intelligent control model and interface driving circuit in the control box, there designs a temperature field welding seam and penetration characters identification information processing model in the industrial control computer. The invention only needs a sensor in order to extract the bias and penetration information of welding seam, which uses seam identification space frequency domain method to identify welding seam, uses penetration constant temperature line width method to identify the penetration degree. The invention also creates constant temperature line width which shows the penetration degree indirectly and reverse transmission nerve network for penetration degree. The invention realizes the automatic tracing of welding seam, completes the intelligent control for welding seam tracing and penetration.

Owner:NANCHANG UNIV

Cigarette box opening method and cigarette box envelope reclamation method

ActiveCN1789084AMeet the requirements of logistics automationMeet automation requirementsPackaging cigaretteEngineeringSmall footprint

Owner:CHINA TOBACCO SHANDONG IND

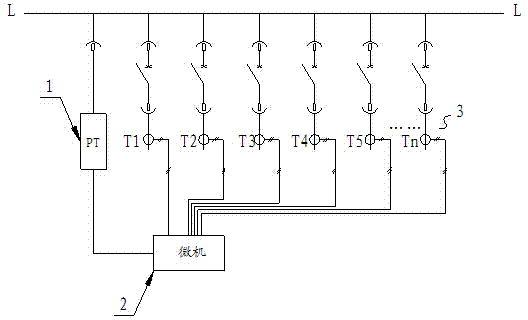

HHT (Hilbert-Huang transform)-based microcomputer small-current earth-fault line selection device

InactiveCN104515934AIncreased sensitivityImprove reliabilityFault locationMicrocomputerObservational error

The invention relates to an HHT (Hilbert-Huang transform)-based microcomputer small-current earth-fault line selection device which is serially connected with a voltage transformer and then connected to a busbar outgoing line. The line selection device comprises a microcomputer and a plurality of zero-sequence transformers, the microcomputer is provided with serial communication interfaces, the zero-sequence transformers are connected with the microcomputer through the serial communication interfaces, and the zero-sequence transformers are parallelly connected onto the microcomputer. A voltage transformer is in triangular connection with an opening of the microcomputer, the voltage transformer, the microcomputer and the zero-sequence transformers form a circuit connected onto the busbar outgoing line, and the microcomputer adopts HHT line selection. The HHT-based microcomputer small-current earth-fault line selection device has the advantages that by means of HHT for line judgment and selection, oblivion of fault features due to interference and measurement errors is avoided, and sensitivity and reliability in fault line selection are improved; in addition, owing to adoption of the microcomputer for treatment, low cost, easiness and effectiveness in implementation and realization of meeting the requirement on automatic utilization of a power distribution network are achieved.

Owner:ANHUI KAICHUAN POWER PROTECTION EQUIP

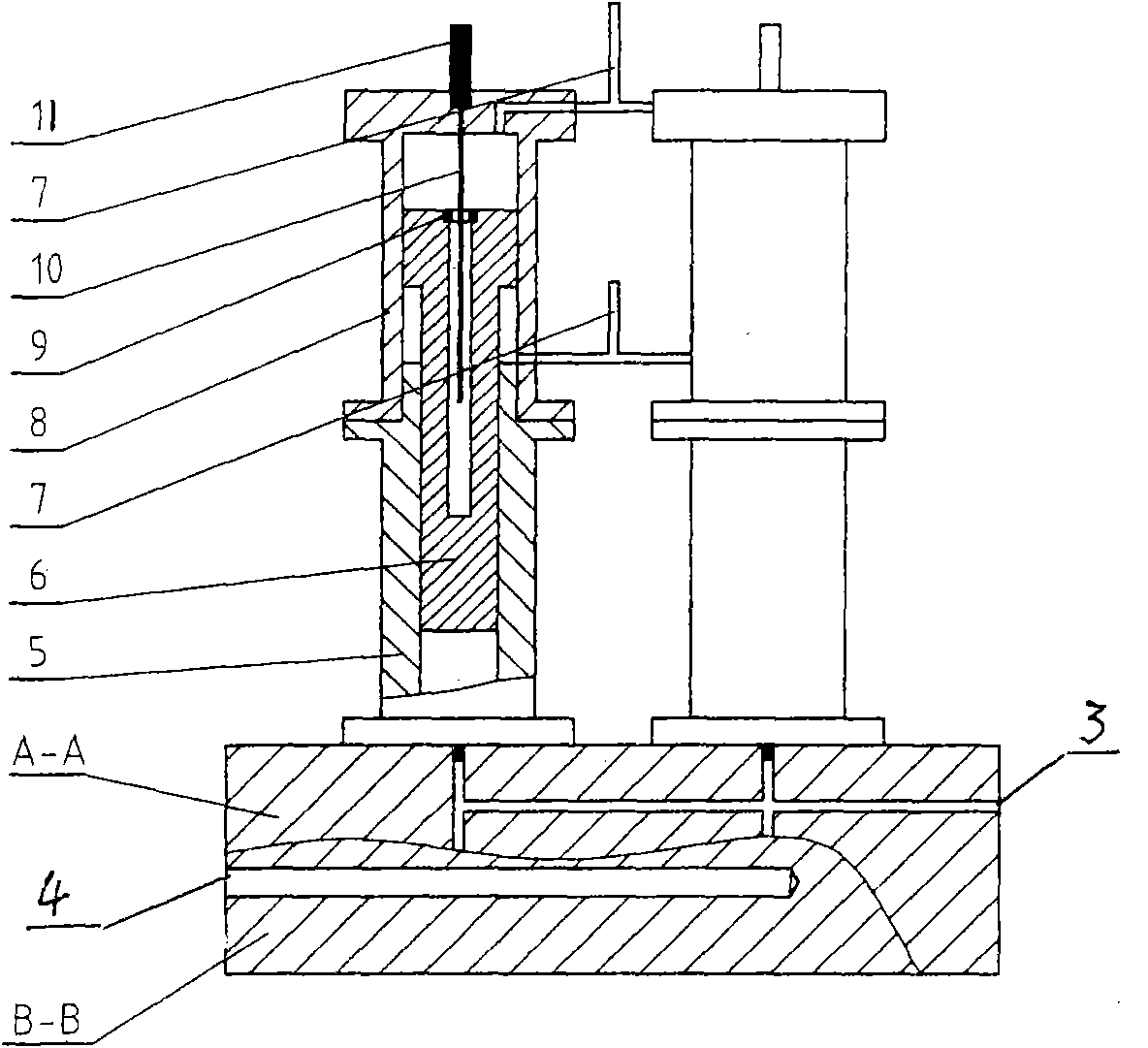

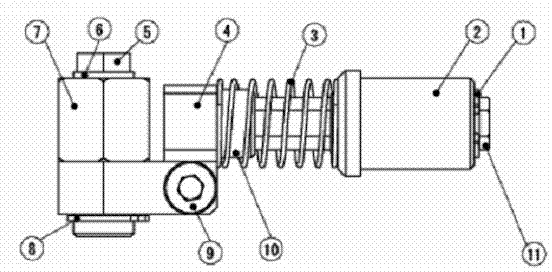

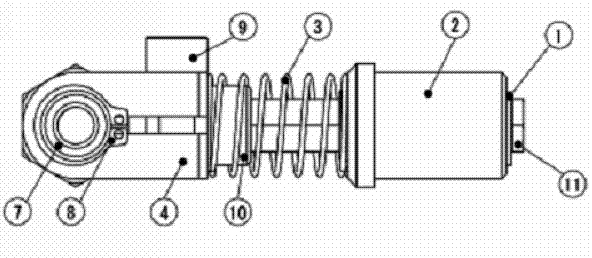

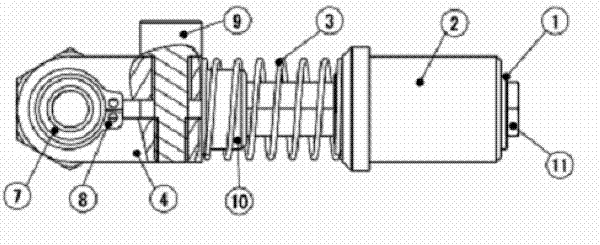

Supercharger with controllable hydraulic pressure and flow output

InactiveCN101994724AIncrease the diameterIncrease the itineraryFluid-pressure convertersEngineeringHigh pressure

The invention relates to a supercharger with controllable hydraulic pressure and flow output, wherein a twin-charger high-pressure fluid output structure is adopted, and the diameter and the stroke of a piston and a plunger of each charger are increased so as to meet a work pressure output requirement and simultaneously improve output flow, which is 10 times that of the traditional supercharger. A phase different between the operation cycles of the pistons of the two chargers is 180 degrees, the output high-pressure fluid enters a valve seat (1), and a waterway channel in the valve seat (1) is designed in a bridge type loop structure which ensures that the output high-pressure fluid is stable and balanced in flow. A displacement transducer control technology is introduced to meet an automation requirement of a water pressure test-tube engine test, and the work efficiency and the safety performance of a detection test on an oil transferring pipeline are greatly improved.

Owner:云南兴长江实业有限公司

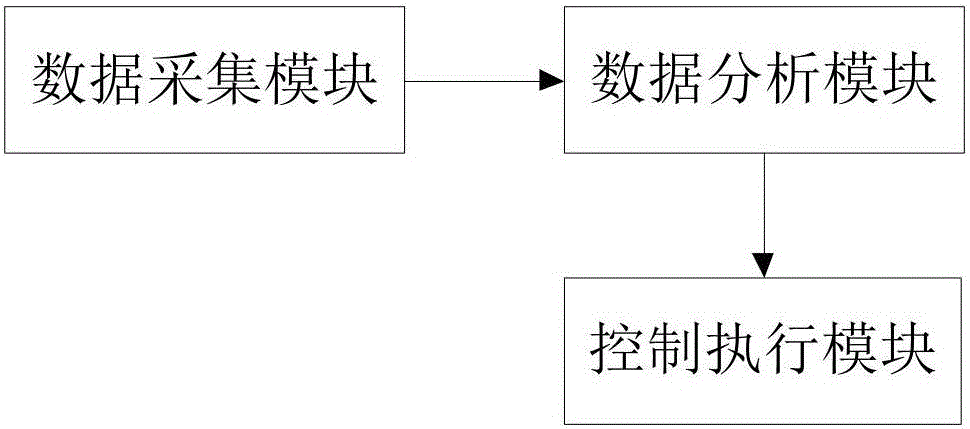

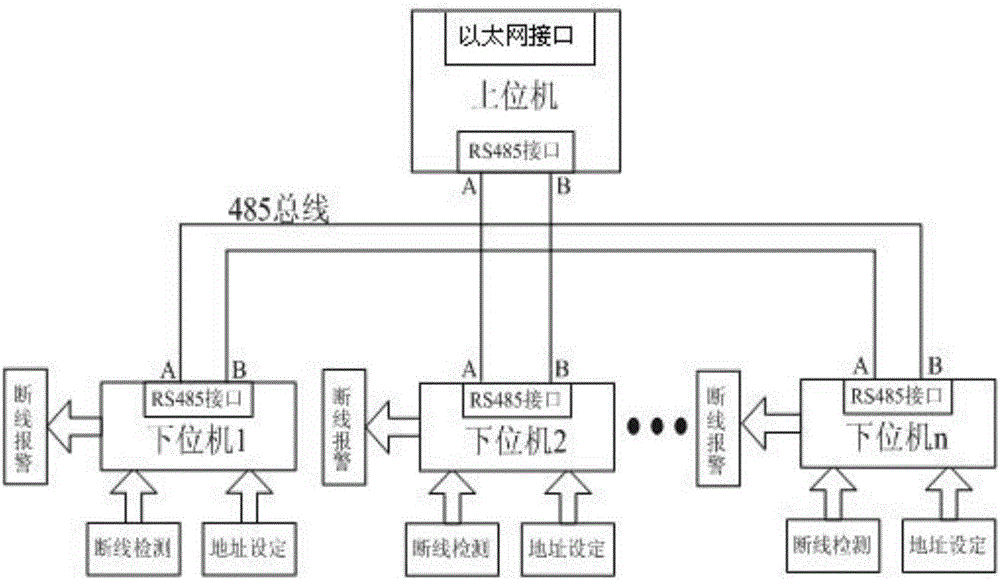

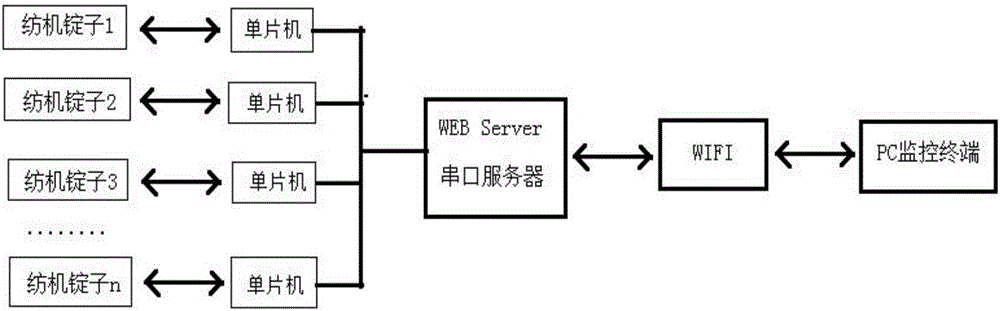

Two-for-one twister control system and method based on intelligent network

InactiveCN106567164AIncrease power consumptionOptimize slip ratioProgramme controlComputer controlInformatizationPower factor

The invention relates to a two-for-one twister control system and method based on an intelligent network. The two-for-one twister control system comprises a data acquisition module, a data analysis module, and a control and execution module, wherein the data acquisition module is used for real time conducting collection of operational parameters of each two-for-one twister, the data analysis module is used for analyzing and obtaining control strategies of the two-for-one twisters according to the operational parameters of each two-for-one twister, the control and execution module is used for executing control on the operational state of the two-for-one twisters according to the control strategy of the two-for-one twisters. Through the adoption of the control system and method, the operational parameters can be used for conducting real-time assessment on machine energy consumption and spindle control precision, optimization of indexes of spindle power dissipation and slip ratio and the like is achieved through adjustment of the rotate speed of a motor, so that service efficiency and product quality of the two-for-one twister are promoted; application of real-time monitoring technology of the networking two-for-one twisters can satisfy demands of textile enterprises for informatization and automation to a large extent; meanwhile, an adjustment range of the speed of a spindle is more wide, renovation of varieties is fast and convenient, changing of a belt pulley is unnecessary, potentialities of reactive power of the motor can be exploited to a large extent, a power factor is fully made use of and improved, and thus a purpose of electricity conservation is achieved.

Owner:SHAOXING UNIVERSITY

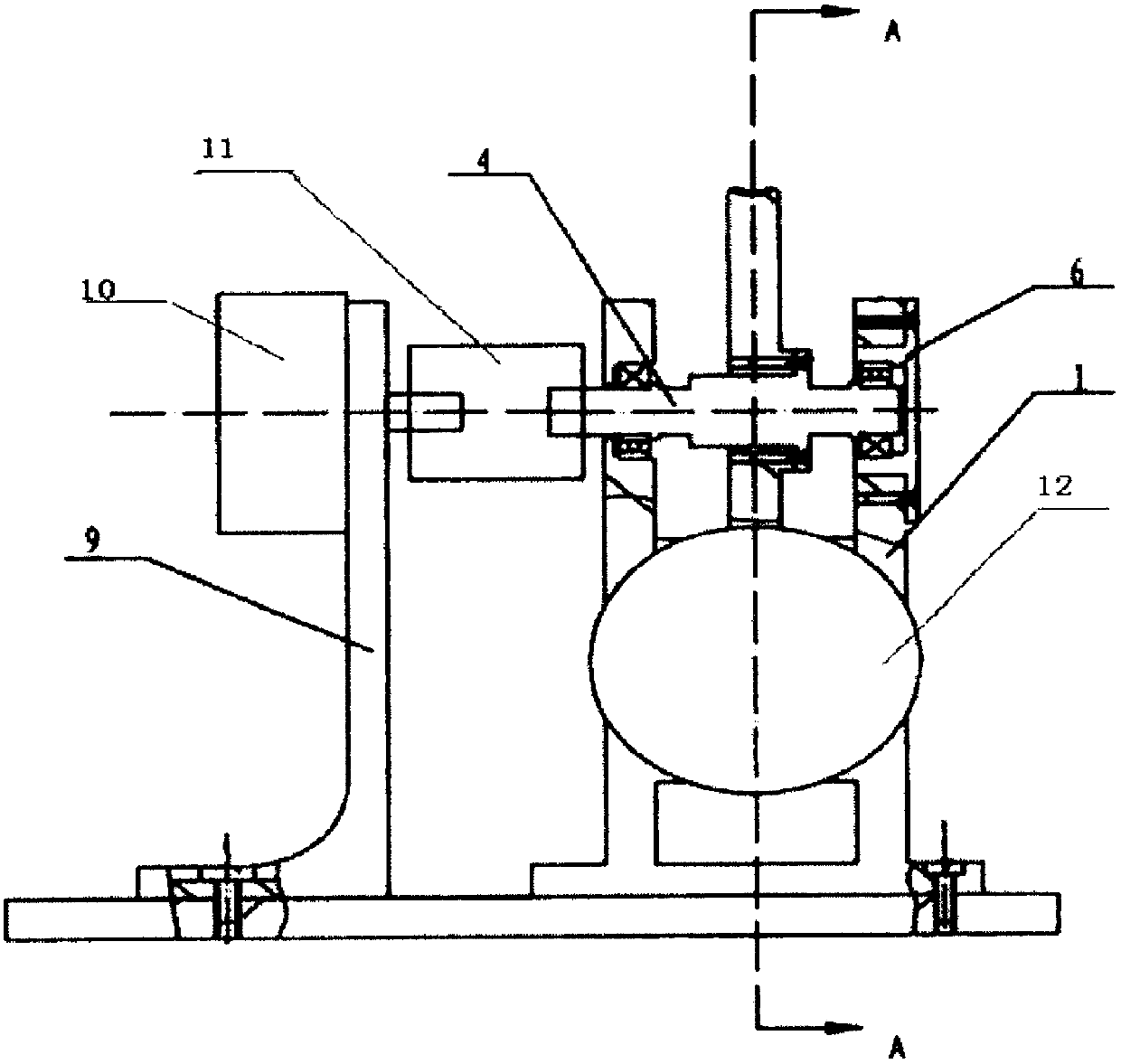

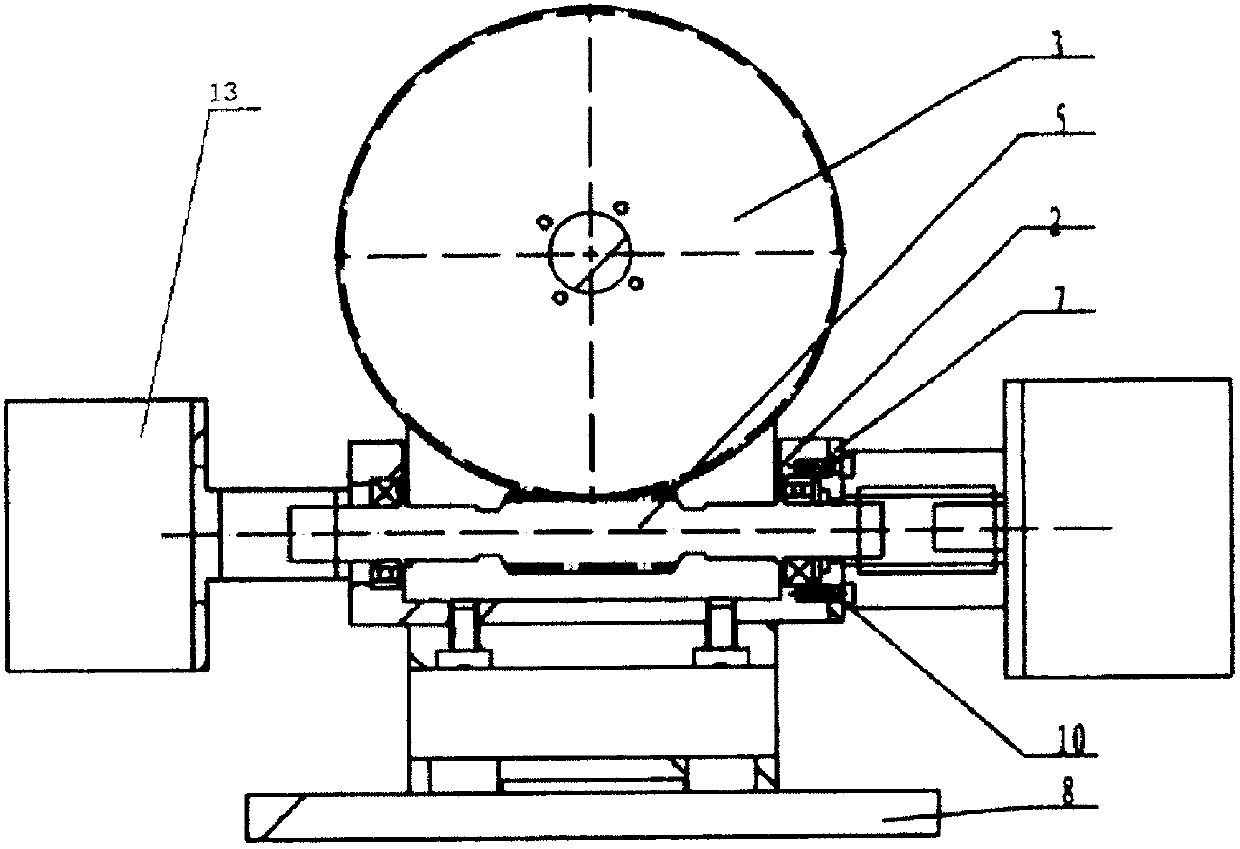

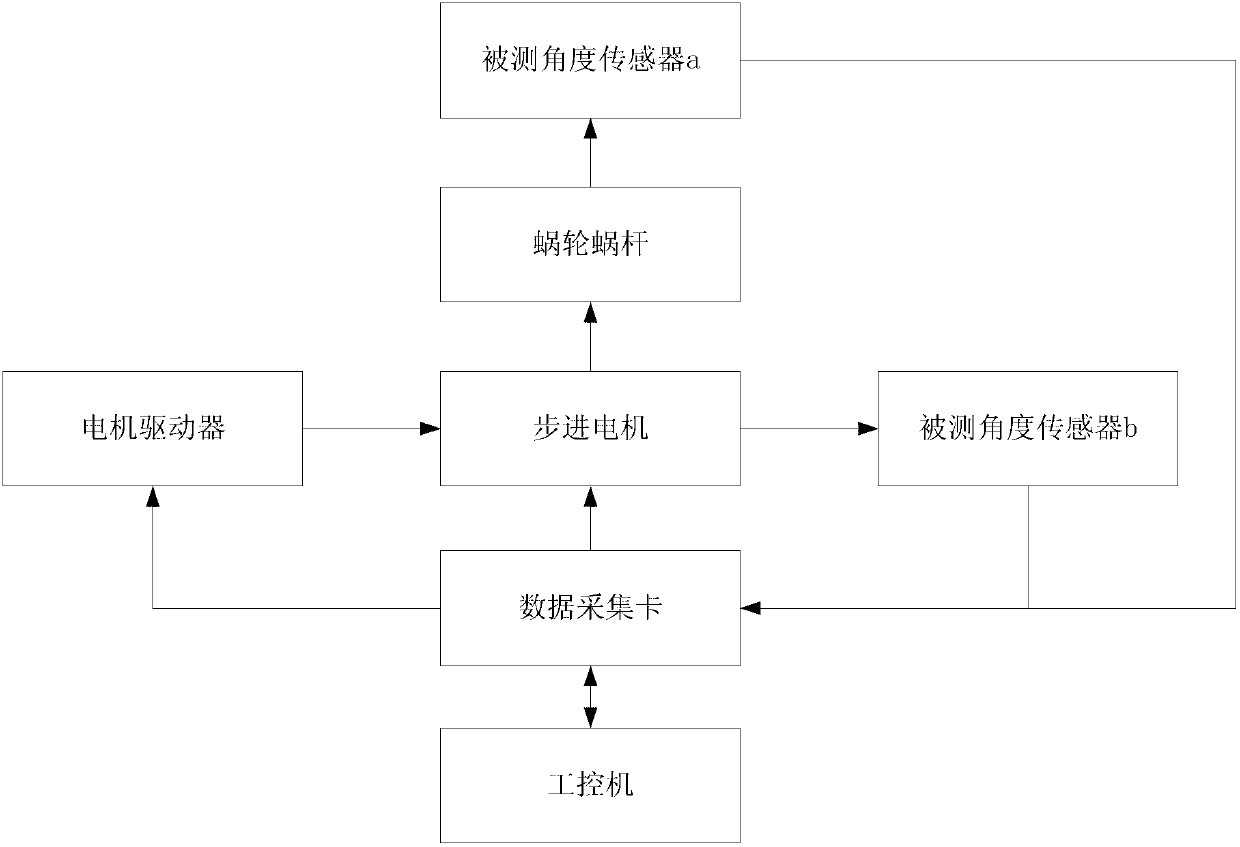

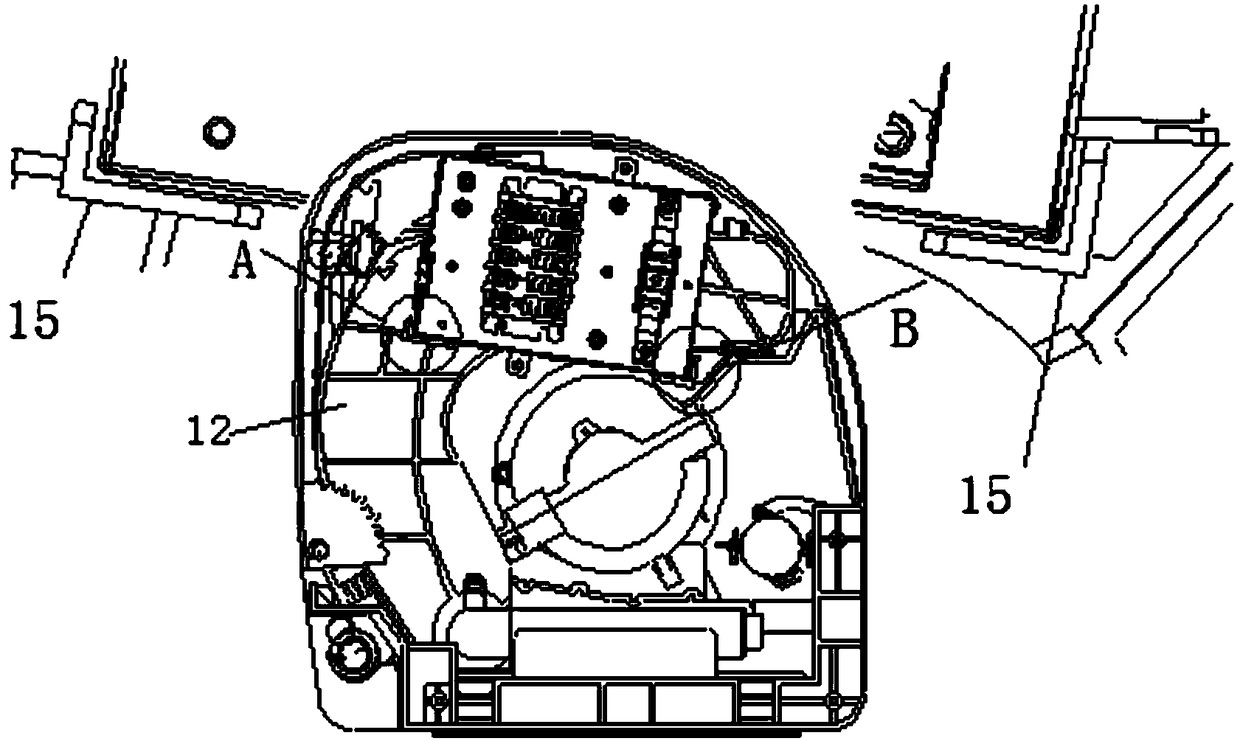

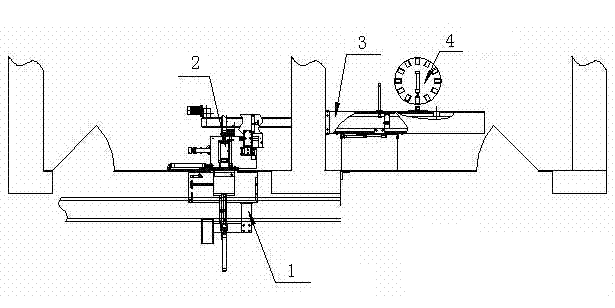

Method and device for multi-dimensional detection of angle sensor

ActiveCN102997887AMeet detectionMeet automation requirementsUsing optical meansCompassesPhysicsComputer control

The invention provides a method and device for multi-dimensional detection of an angle sensor. The method and device is used for performing high-accuracy static and dynamic accuracy detection on the angle sensor and can achieve accuracy detection of various angle sensors in a plurality of multi-axis planes. In the device, a closed-loop stepping motor is connected with one end of a worm B through a coupler, a detected angle sensor b is connected with the other end of the worm B through a coupler, a detected angle sensor a is connected with a revolving shaft through a coupler, the detected angle sensor a and the detected angle sensor b are both fixed outside a machine case through angle sensor installation bases, the revolving shaft is connected with a worm wheel A, the worm wheel A and the worm B are fixed inside the machine case through worm installation bases, the detected angle sensor a and the detected angle sensor b are both fixed outside a machine case through the angle sensor installation bases, a leveling structure is installed outside the machine case, and a computer controlling and processing unit is respectively connected with the closed-loop stepping motor, the detected angle sensor a and a detected angle sensor b through cables.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

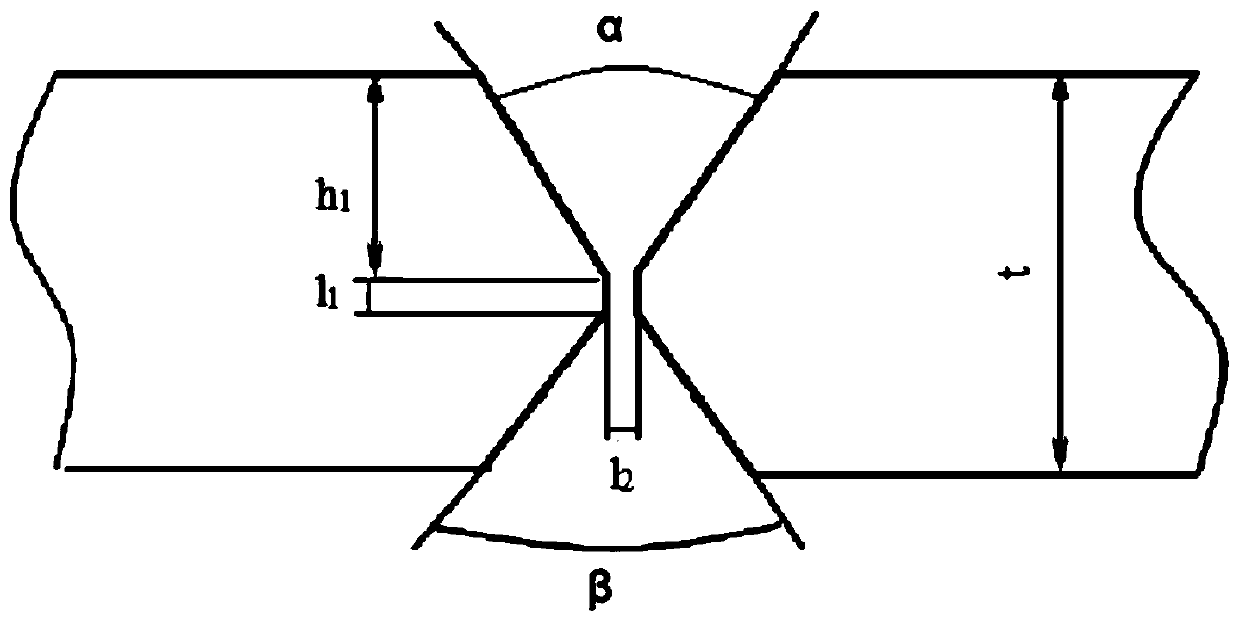

Marine high-strength steel plate double-wire submerged-arc welding process

InactiveCN109848526AImprove welding efficiencyHigh welding efficiencyArc welding apparatusSheet steelHigh strength steel

The invention discloses a marine high-strength steel plate double-wire submerged-arc welding process. An EH47 high-strength anti-cracking steel plate is selected, the thickness of the EH47 high-strength anti-cracking steel plate is 50-100 mm, a double-wire submerged-arc welding process with a front wire as a fine welding wire and a rear wire as a thick welding wire is adopted, and high-efficiencywelding of low heat input is realized. According to the marine high-strength steel plate double-wire submerged-arc welding process, the design requirements of the EH47 high-strength anti-crack steel plate welding joint high standard are met while the high efficiency of the double-wire submerged arc welding is guaranteed, so that the optimization of the welding quality and the efficiency is realized. The marine high-strength steel plate double-wire submerged-arc welding process is high in practicability, simple and convenient in welding operation, efficient and energy-saving, and is suitable for building and popularization and application of container ships.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

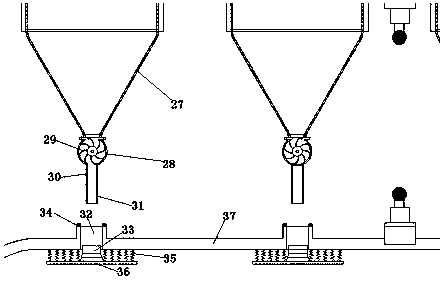

Screw sorting device

The invention relates to a screw sorting device which is characterized by comprising a pipeline, a belt type conveyer, a collecting mechanism, a touch screen and a controller, wherein a conveyer belt of the belt type conveyer penetrates into one end of the pipeline and then penetrates out of the other end of the pipeline; a first optoelectronic switch and a second optoelectronic switch are respectively arranged inside the rear and front ends of the pipeline; the first optoelectronic switch and the second optoelectronic switch are both mounted on the inner wall of the pipeline on two sides of the conveyer belt; a scale plate is arranged between a longitudinal middle lower wall of the pipeline and the conveyer belt; a space is formed between the scale plate and the conveyer belt; lighting sources are arranged on the walls, corresponding to the space, on two sides of the pipeline; a through hole is formed in the wall of the upper side of the pipeline; a camera is arranged inside the through hole; the camera is connected with the controller through a lead; the collecting mechanism is arranged below the front end of the conveyer belt. Due to the adoption of the screw sorting device, the time can be saved, the efficiency is improved, the fault rate is reduced, and the automation requirements on automatic assembling are met. The device is applicable to sorting of mingled screws with different lengths.

Owner:无锡微普动力科技有限公司

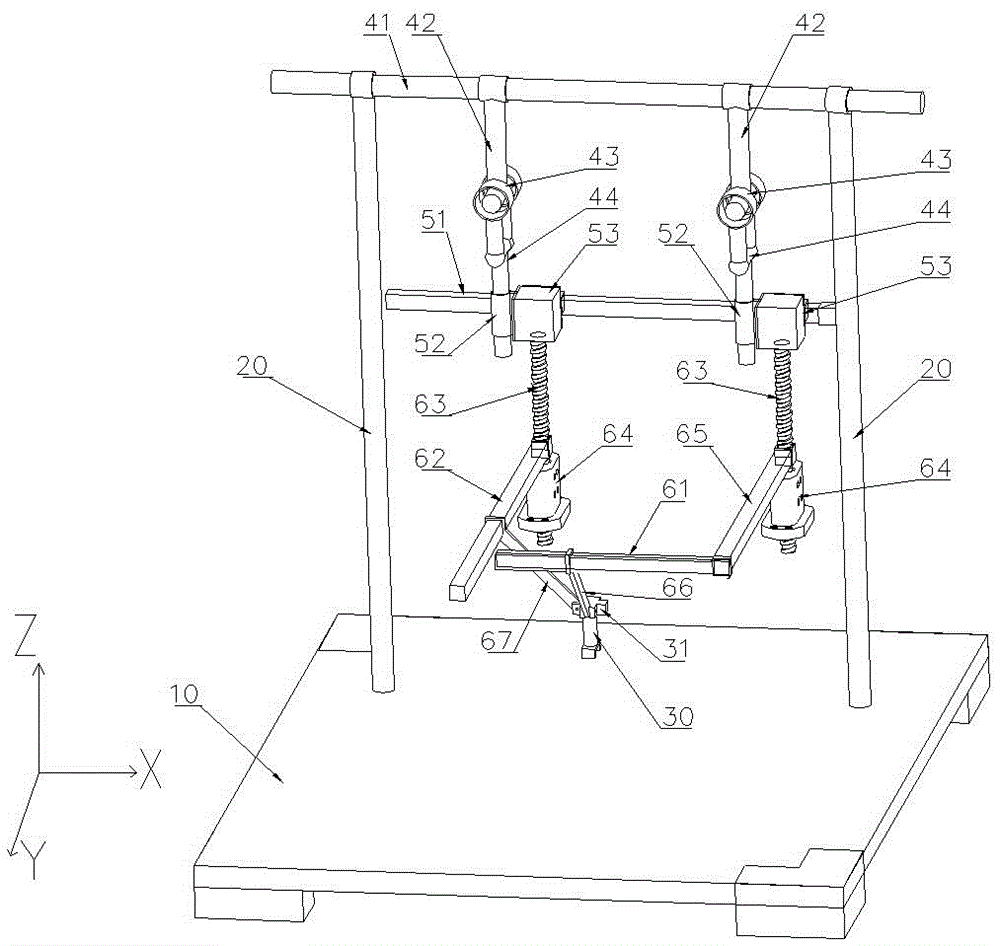

Series-parallel-based material sorting robot mechanism

InactiveCN105751206ARealize continuous grabbing and sorting operationsMeet automation requirementsProgramme-controlled manipulatorSortingThree degrees of freedomEngineering

The invention provides a series-parallel-based material sorting robot mechanism which can solve a problem that a conventional material sorting robot mechanism is unable to meet requirements of modern automated sorting work and comprises a base plate, brackets and a manipulator, wherein two brackets parallel to each other in a Z-axis direction are vertically fixed on the base plate; the series-parallel-based material sorting robot mechanism is characterized by further comprising a two-degree-of-freedom series mechanism and a three-degree-of-freedom parallel mechanism; the manipulator is mounted at the bottom end of the parallel mechanism; the parallel mechanism can drive the manipulator to achieve the linear movements in an X-axis direction, a Y-axis direction and the Z-axis direction; the series mechanism is rigidly connected with the parallel mechanism through a connecting structure; the series mechanism is mounted on the two brackets in a supporting manner; the series mechanism can drive the parallel mechanism and the manipulator mounted at the bottom end of the parallel mechanism to integrally rotate around the X-axis direction and the Y-axis direction.

Owner:JIANGNAN UNIV

Scraper adjusting device for circular screen printer

The invention discloses a scraper adjusting device for a circular screen printer. The scraper adjusting device comprises a base, a scraper pressure adjusting unit and a scraper height adjusting unit which are fixed on a frame of the circular screen printer, and a vertical rectangular limiting groove is formed in the base; the scraper pressure adjusting unit comprises a rotating shaft with one end hinged in the limiting groove, a connecting rod fixedly arranged at the other end of the rotating shaft and a scraper seat fixedly arranged at one end of the connecting rod, and one end of the connecting rod is fixed on the rotating shaft while the other end fixedly connected with the scraper seat; the rotating shaft is connected with the output shaft of a driving motor through a guiding belt; the scraper height adjusting unit comprises an air cylinder fixed on the base and a lifting rod fixedly connected on the piston shaft of the air cylinder, the other end of the lifting rod is provided with a ring, an annular groove corresponding to the ring is formed in the rotating shaft, and the ring sleeves the annular groove. Compared with the prior art, the scraper adjusting device has the advantage that the pressure and height of scrapers can be automatically adjusted.

Owner:TONGXIANG SIYUAN TEXTILE

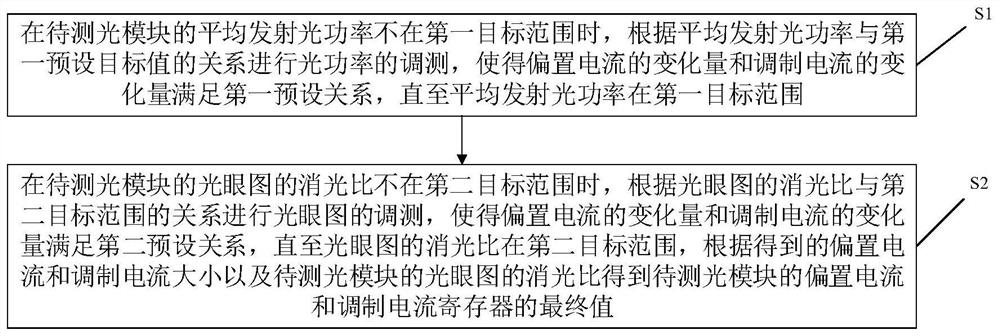

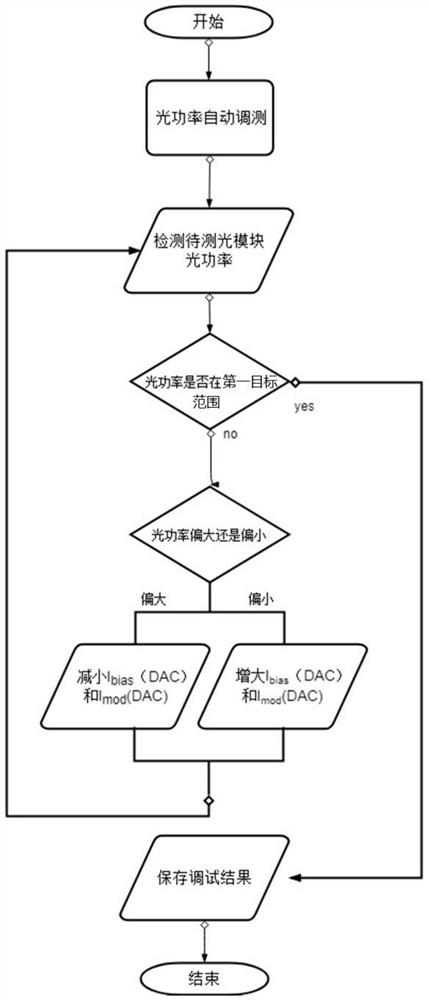

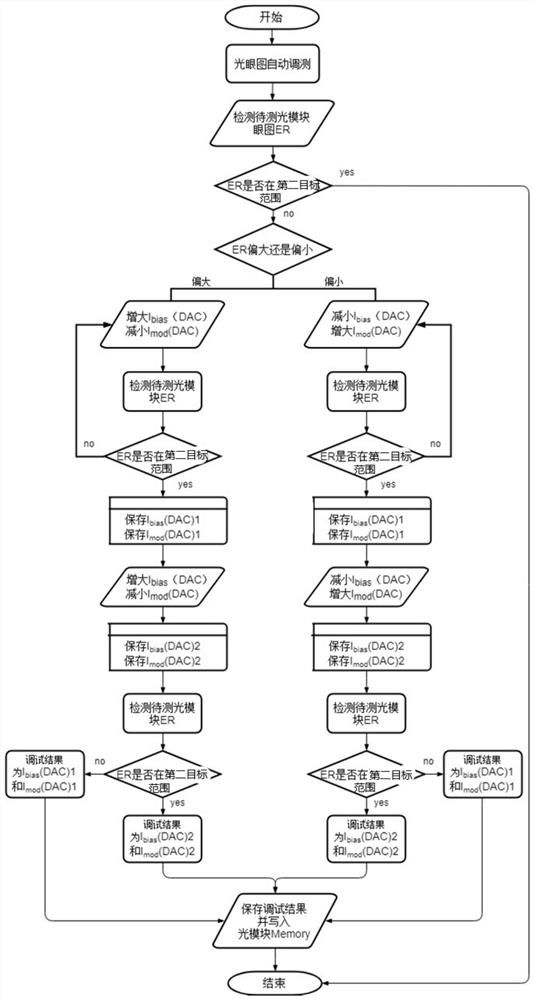

Automatic debugging and testing method and device for transmitting optical power and eye pattern of optical module

ActiveCN111934758AAutomatic commissioning with traces to followPerformanceElectromagnetic transmissionOptical ModuleOptical power

The invention discloses an automatic debugging and testing method and device for transmitting optical power and an eye pattern of an optical module and belongs to the field of optical modules. The method comprises the steps that when the average emission light power is not in a first target range, debugging and testing of the light power are carried out according to the relation between the average emission light power and the first target range, and therefore the variation of a bias current and the variation of a modulation current meet a first preset relation until the average emission lightpower is in the first target range; when the extinction ratio of the light eye pattern is not in the second target range, the optical eye pattern is debugged and tested according to the relationshipbetween the extinction ratio and the second target range, the variation of the bias current and the variation of the modulation current are enabled to meet a second preset relation until the extinction ratio is within a second target range, and the final values of the bias current and the modulation current of the to-be-tested optical module are obtained according to the magnitude of the obtainedbias current and modulation current and the extinction ratio. According to the method disclosed in the invention, optical power and extinction ratio parameters can be quickly adjusted to the target range without manual intervention.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

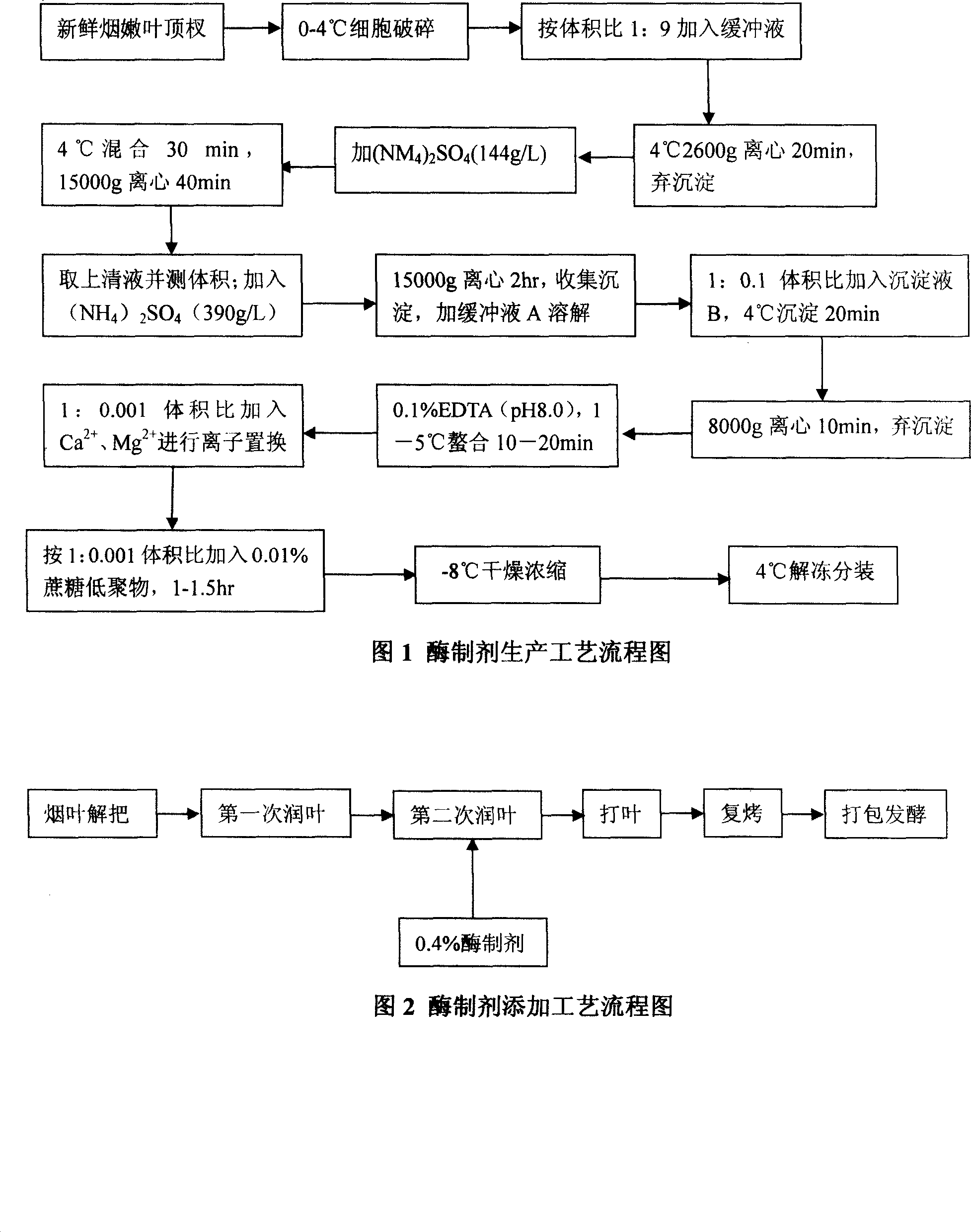

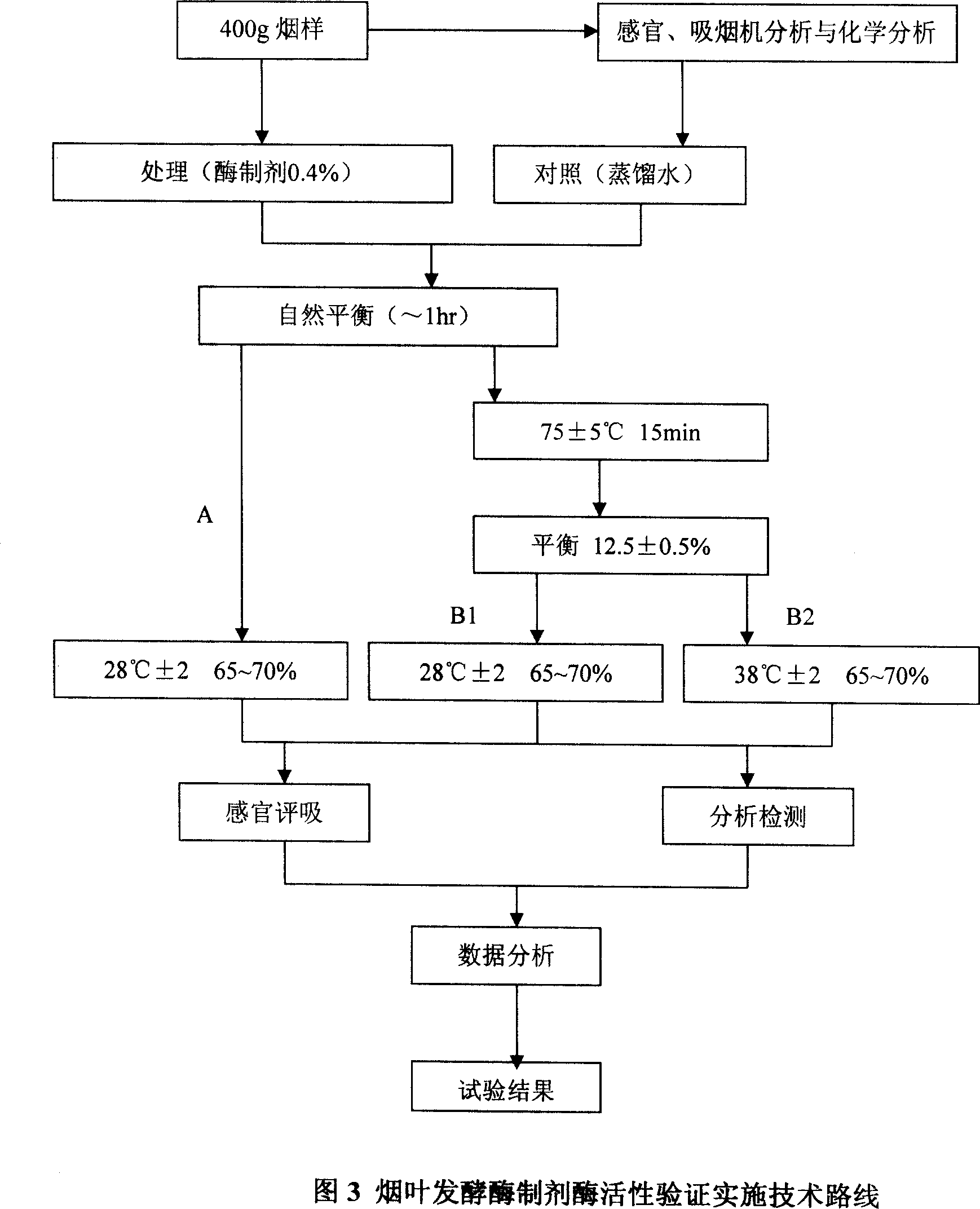

Method for producing tobacco leaf fermenting enzyme preparation

InactiveCN101144074AIt has the characteristics of high temperature resistance of rebaking lineHas high temperature propertiesTobacco treatmentEnzymesBiotechnologySaccharum

The present invention relates to a novel tobacco fermenting enzyme preparation production method. The purpose is to solve the technical problems that how improve the quality of the tobacco fermenting product is improved and how the reactivity protection of the tobacco fermenting enzyme preparation is realized in the natural fermenting field of tobacco. The enzyme preparation consists of a glucoseoxidase, a chlorophyl oxidase, a carotenoid oxidase, a protease, and a nicotine-degradation enzyme. Through the cell disruption of fresh leaves, (NH 4) 2 SO 4 is utilized to operate the second fractional precipitation to obtain crude enzyme fluid, an enzyme molecule adopts Ca 2 + and Mg 2 + to operate the metal ion exchange, to accomplish the molecule modification; a macro molecule combination modification is accomplished through adopting 0.01 percent of cane sugar low molecular polymer, thereby prolonging the half life period of theenzyme preparation and obviously improving the high temperature resistant ability. The experimental result employed by the enzyme preparation indicates that the nicotine is decreased by 9.3 percent, the total nitrogen is decreased by 5.7 percent, the protein is decreased by 7.1 percent; cigarette smoke condensates are decreased by 8.4 percent, the tar content is decreased by 5.1 percent, the cigarette smoke nicotine content is decreased by 28.0 percent, and the carbon monoxide is decreased by 1.6 percent. The enzyme preparation is employed when the tobacco leaf is wet for the second time before defolat and redrying.

Owner:云南万芳生物技术有限公司 +2

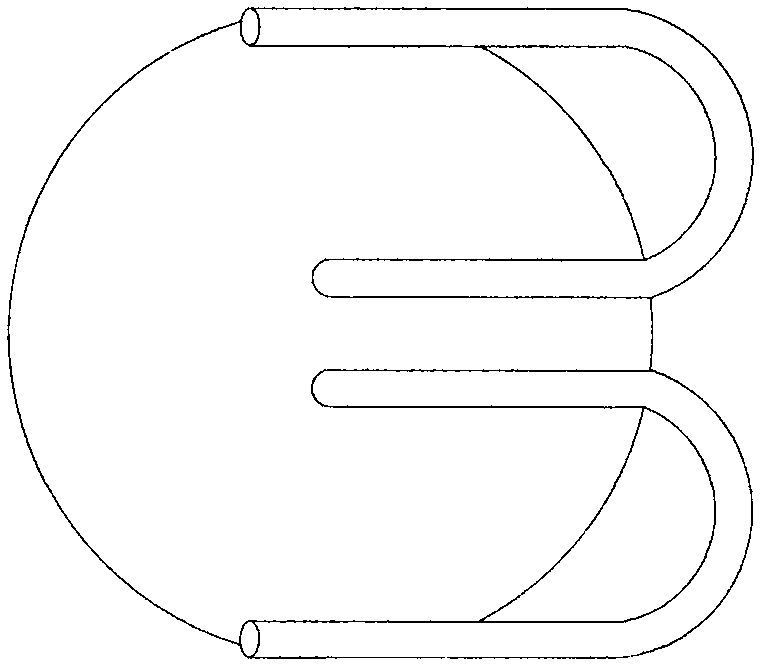

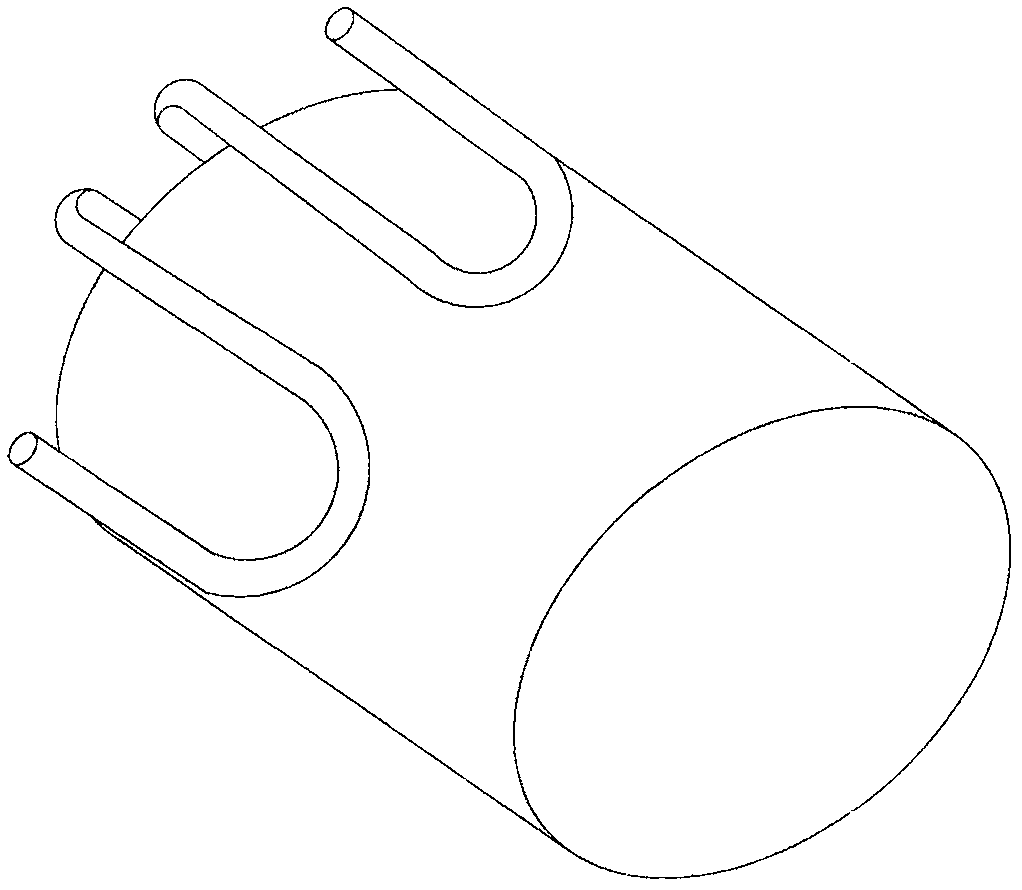

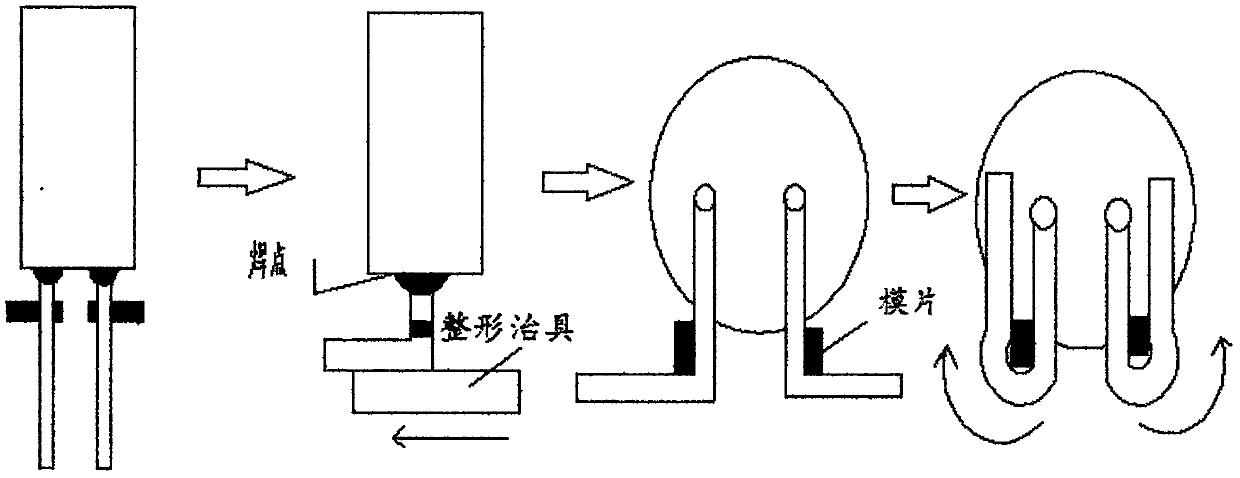

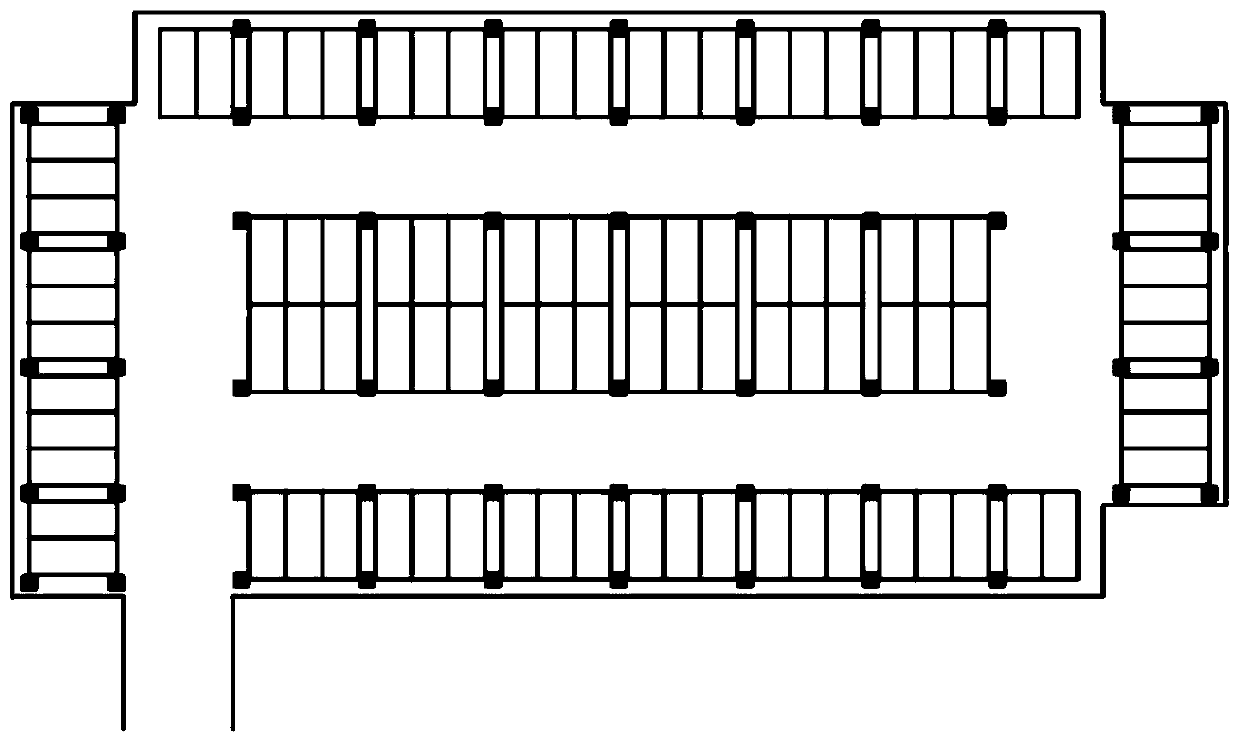

Fabrication method of I-shaped inductor capable of surface-mounting

InactiveCN108053989AIncrease productivityReduce manufacturing costEncapsulation/impregnationCoils manufactureSurface mountingCopper wire

The invention discloses a fabrication method of an I-shaped inductor capable of surface-mounting. The method comprises the following steps of S101, winding a magnetic core pin of the I-shaped inductor, burning a paint skin of a pin enameled copper wire, and immersing tin for 3-5 seconds; S102, encapsulating the I-shaped inductor welded with the tin; S103, performing pin shearing on the I-shaped inductor of which encapsulation is completed; S104, folding and straightening a pin of the I-shaped inductor of which the pin length is cut; and S105, pasting a die sheet with a thickness being 0.3-1 millimeter of a pin cushion onto two sides of the pin of the I-shaped inductor of which the pin is straightened, folding the straightened inductor pin towards an opposite direction by a clamp or by manual, and completing the surface-mounting formation process of the whole inductor. The inductor produced by the method is low in cost and simple and practical in structure, the contact surface of a bonding pad after a patch is processed is large, full-automatic production can be achieved, and the production efficiency and the additive value of a finished product are improved.

Owner:王强

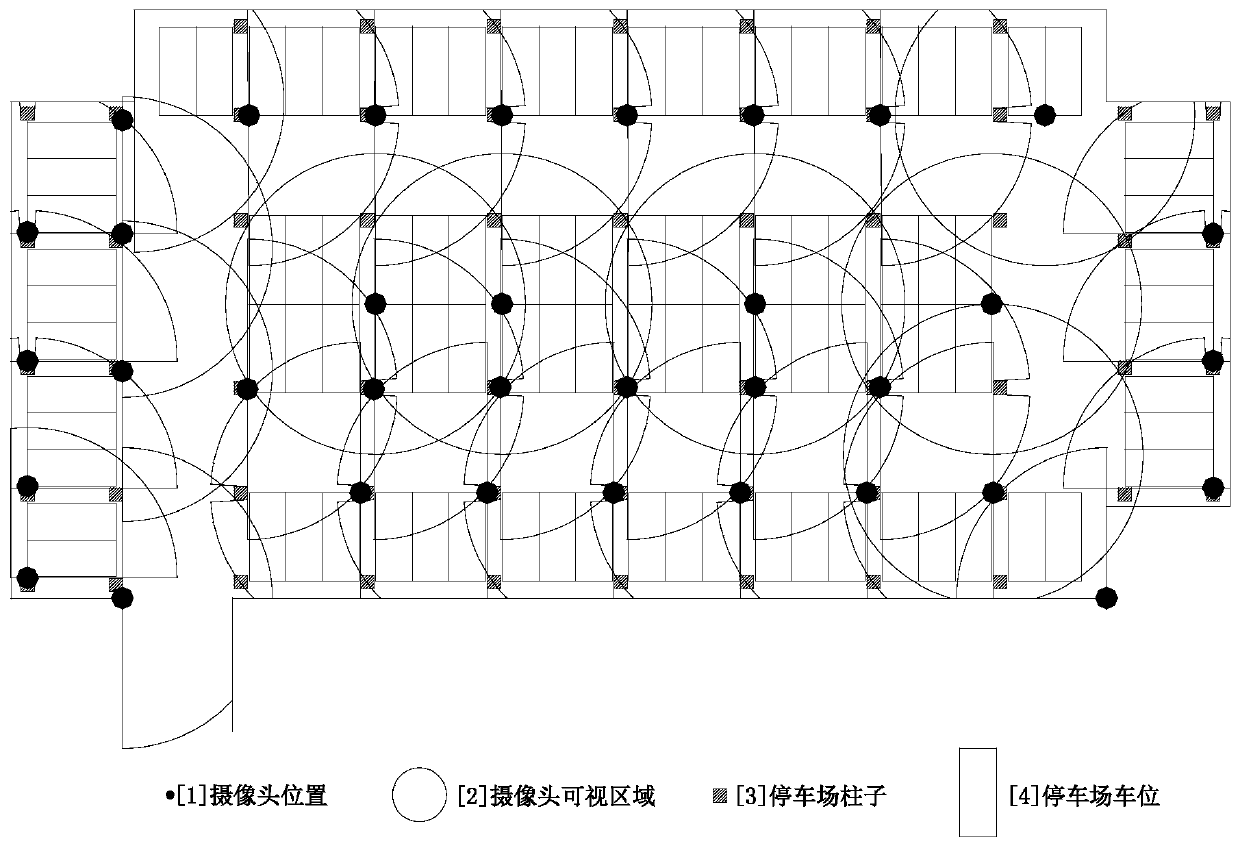

Unmanned parking system based on automatic valet parking technology

InactiveCN111415525ARealize automatic parkingRealize functionIndication of parksing free spacesForecastingIn vehicleControl system

The invention discloses an unmanned parking system based on an automatic valet parking technology. The system comprises a mobile terminal with a built-in APP, a vehicle-mounted camera, a master control system, a parking planning network system based on V2R and V2I technologies, and a parking lot monitoring assembly arranged in a parking lot. The parking lot monitoring assembly comprises a parkinglot camera and a sensor. The parking lot camera is used for collecting real-time condition information in the parking lot. The vehicle-mounted camera is used for collecting road condition informationin the driving process of a target vehicle. The sensor comprises a laser distance sensor used for collecting the distance between a target vehicle and an obstacle. The parking planning network systembased on the V2R and V2I technologies carries out path analysis and sends a path analysis result to the master control system, and the master control system calculates at least one vehicle parking / picking-up scheme and sends all planned schemes to an APP of a user mobile terminal for a user to select. Automatic parking and automatic vehicle taking of the vehicle are achieved.

Owner:SOUTH CHINA UNIV OF TECH

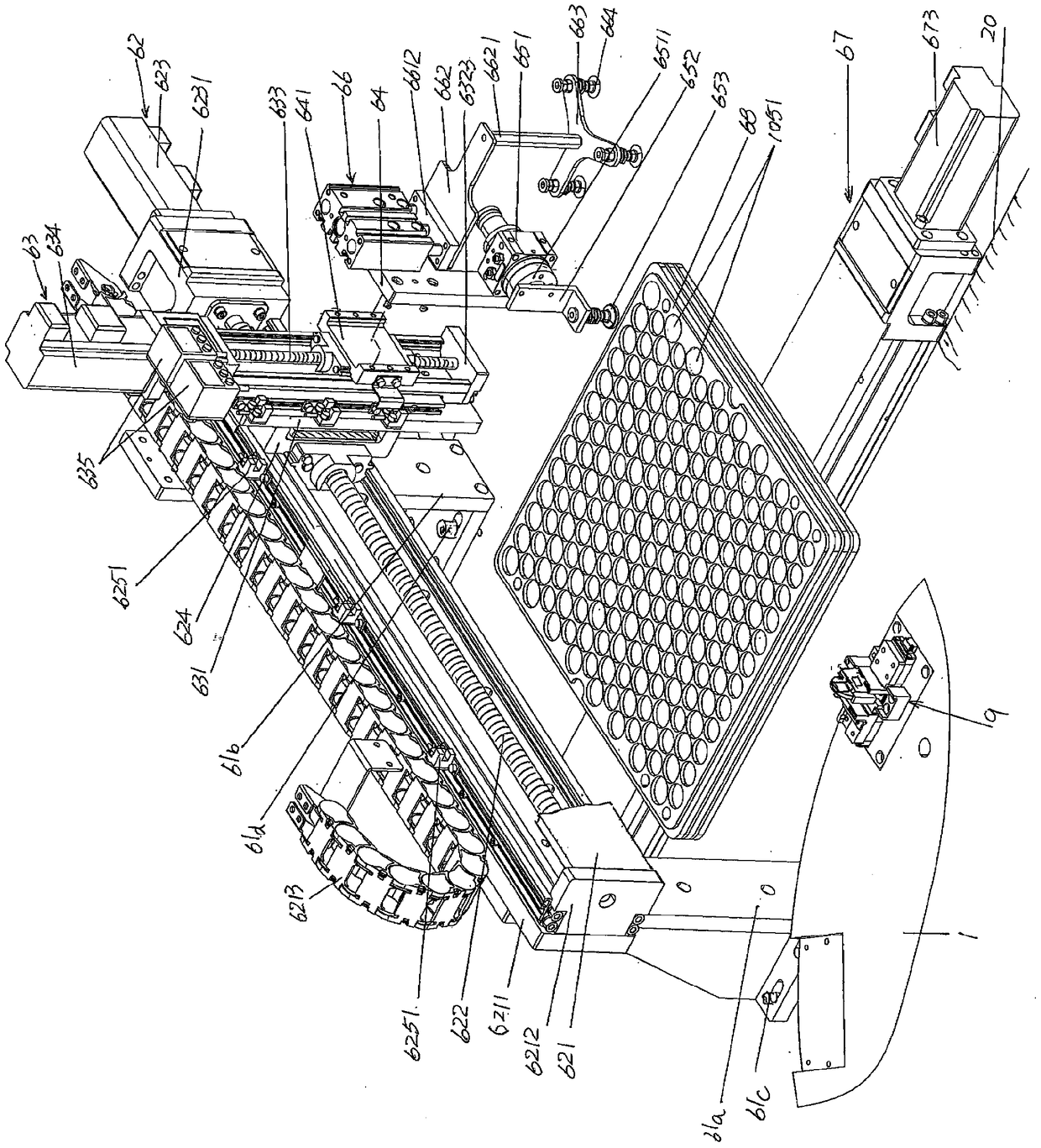

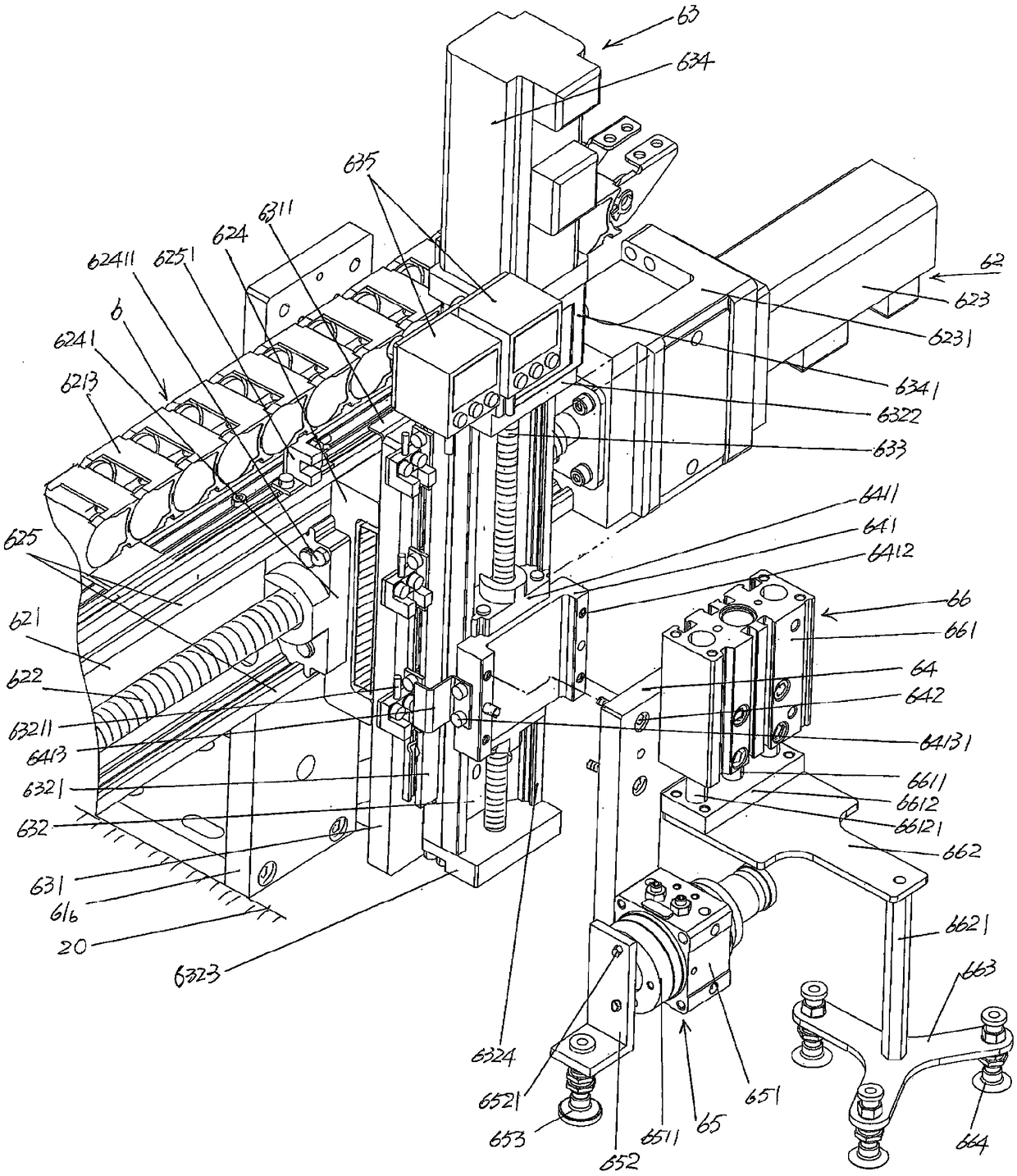

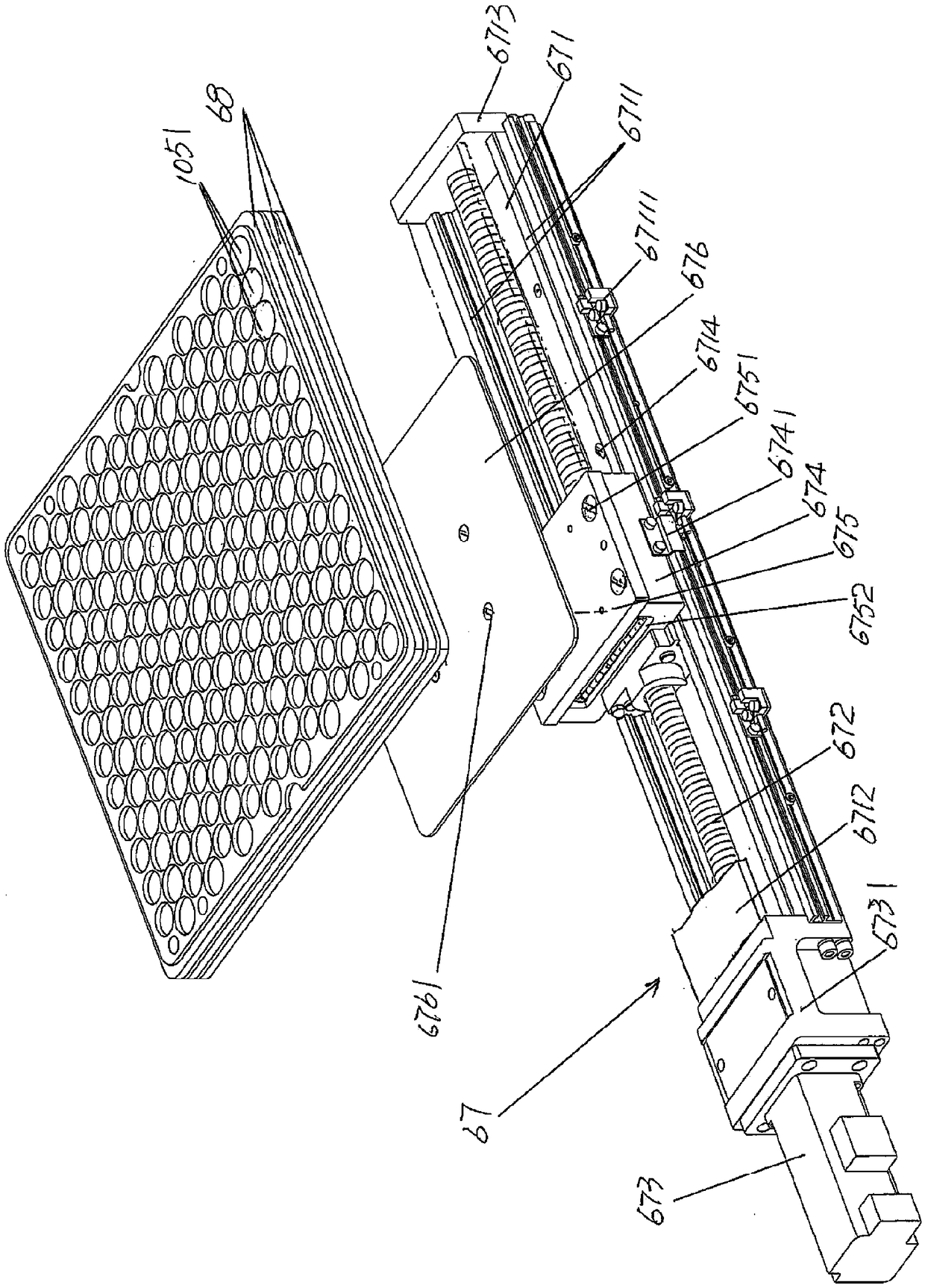

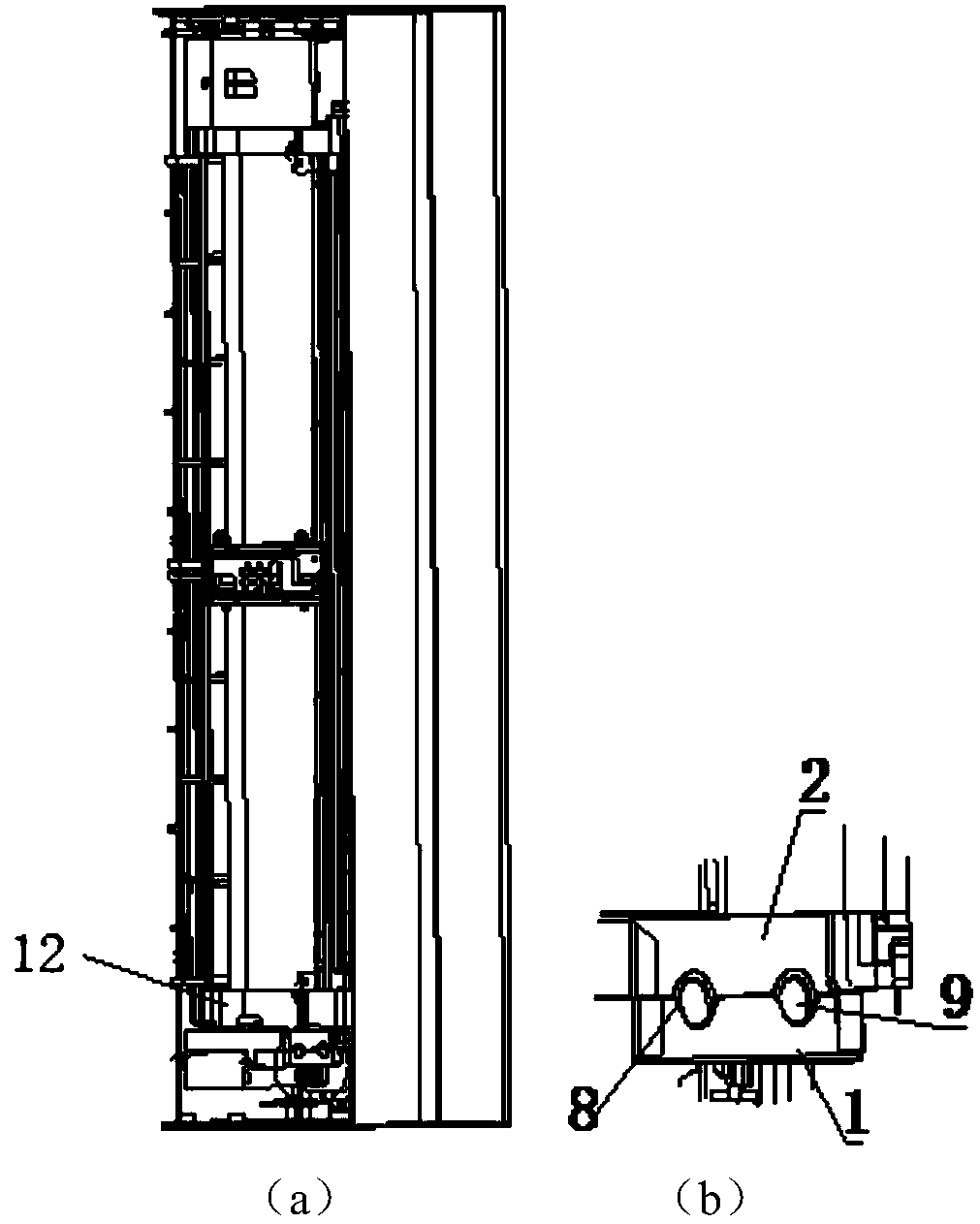

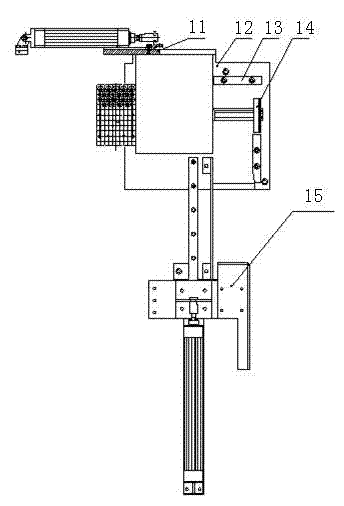

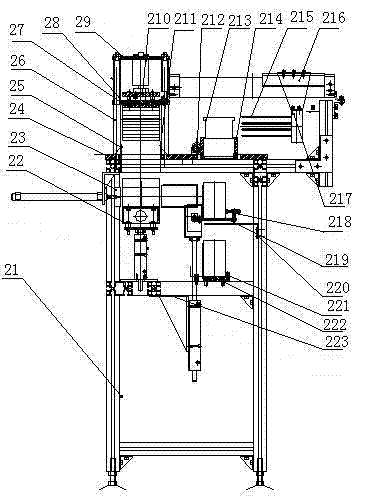

PTC automatic mounting device

PendingCN108817908AMeet automation requirementsReduce occupancyAssembly machinesMetal working apparatusEngineeringAutomation

A PTC automatic mounting device comprises a PTC mounting mechanism assembly, which comprises a PTC installation station first bracket, a PTC installation station second bracket, a horizontal displacement device, an up and down displacement device, a lifting platform, a PTC suction device, an empty PTC feeding tray removing device, a PTC feeding tray moving device and a PTC feeding tray, wherein the PTC installation station first bracket and the PTC installation station second bracket are fixed to a worktable, the horizontal displacement device is supported at the tops of the PTC installation station first bracket and the PTC installation station second bracket, the up and down displacement device is connected to the side, facing the PTC feeding tray, of the horizontal displacement device,the lifting platform is connected with the side, facing the PTC feeding tray, of the up and down displacement device, the PTC suction device and the empty PTC feeding tray removing device are arrangedon the side, facing the PTC feeding tray, of the lifting platform, the PTC feeding tray moving device is arranged on the worktable, and the PTC feeding tray is arranged on the PTC feeding tray movingdevice. The automation requirements are met, less space is occupied, and the movement is reliable.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

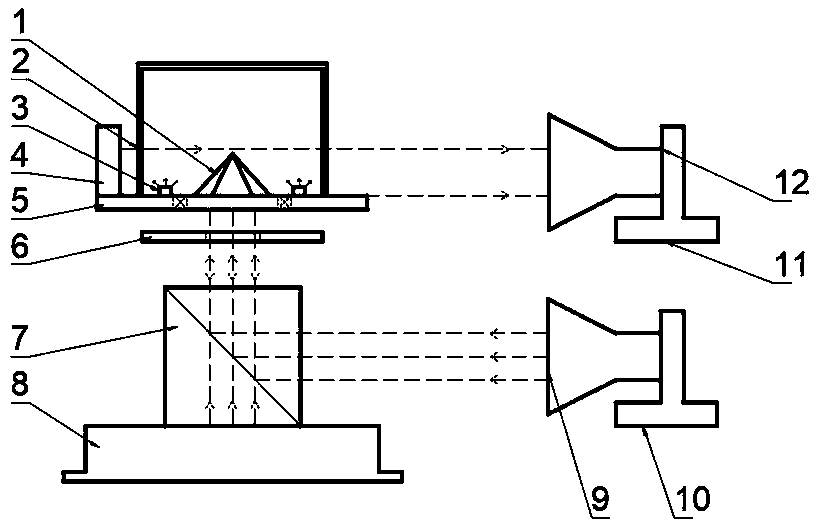

Novel gemstone imaging and characteristic recording method

PendingCN109444143AImplementation processMeet automation requirementsInvestigating jewelsCamera lensBeam splitter

The invention belongs to a method for identifying gemstones, in particular to a novel gemstone imaging and characteristic recording method. In the novel gemstone imaging and characteristic recording method, a gemstone, a first light source, an objective table, a diaphragm, a beam splitter prism, a second light source, a first imaging lens, a first lens moving table, a second lens moving table anda second imaging lens are used. During use, the gemstone is putted on the objective table, and the first light source and the second light source are opened for imaging; meanwhile, parasitic light iseliminated by the diaphragm; the first imaging lens and the second imaging lens are respectively adjusted by the first lens moving table and the second lens moving table; besides, coronal and lateralimages of the gemstone are acquired, and coronal and lateral characteristics of the gemstone are recorded and archived.

Owner:武汉恒宇科教仪器设备研发有限公司 +1

Angle-adjustable suction hardware tool

Disclosed is an angle-adjustable suction hardware tool, which is used for automatically sucking an injection mould product. A sucking disc is disposed on a sucking-disc mounting head. A holder is arranged on a manipulator clamp plate. A guide rod passing through a holder is connected to a rotary support, wherein the tail part of the guide rod is fixed by a snap ring and the guide rod has a hexagonal prism shape. A spring sleeves the guide rod, and two ends of the spring are separately connected to the holder and the rotary support. The rotary support is equipped with a limit bushing for fixating the radial position of the spring, is provided with a groove, and locks the sucking-disc mounting head through an inner-hexagon bolt. The sucking-disc mounting head is clamped on the rotary support through a snap ring, is connected to an end cap through a gasket, and has a threaded hole for linking to a gas path. According to the invention, the angle-adjustable suction hardware tool is small in size, light in weight, convenient for installing and adjusting in narrow and small space, and capable of adjusting an angle of the sucking disc for firmly sucking a product; and damage due to product rotation can be prevented, which results in a high quality rate of products.

Owner:STAR SEIKI XIANGYANG

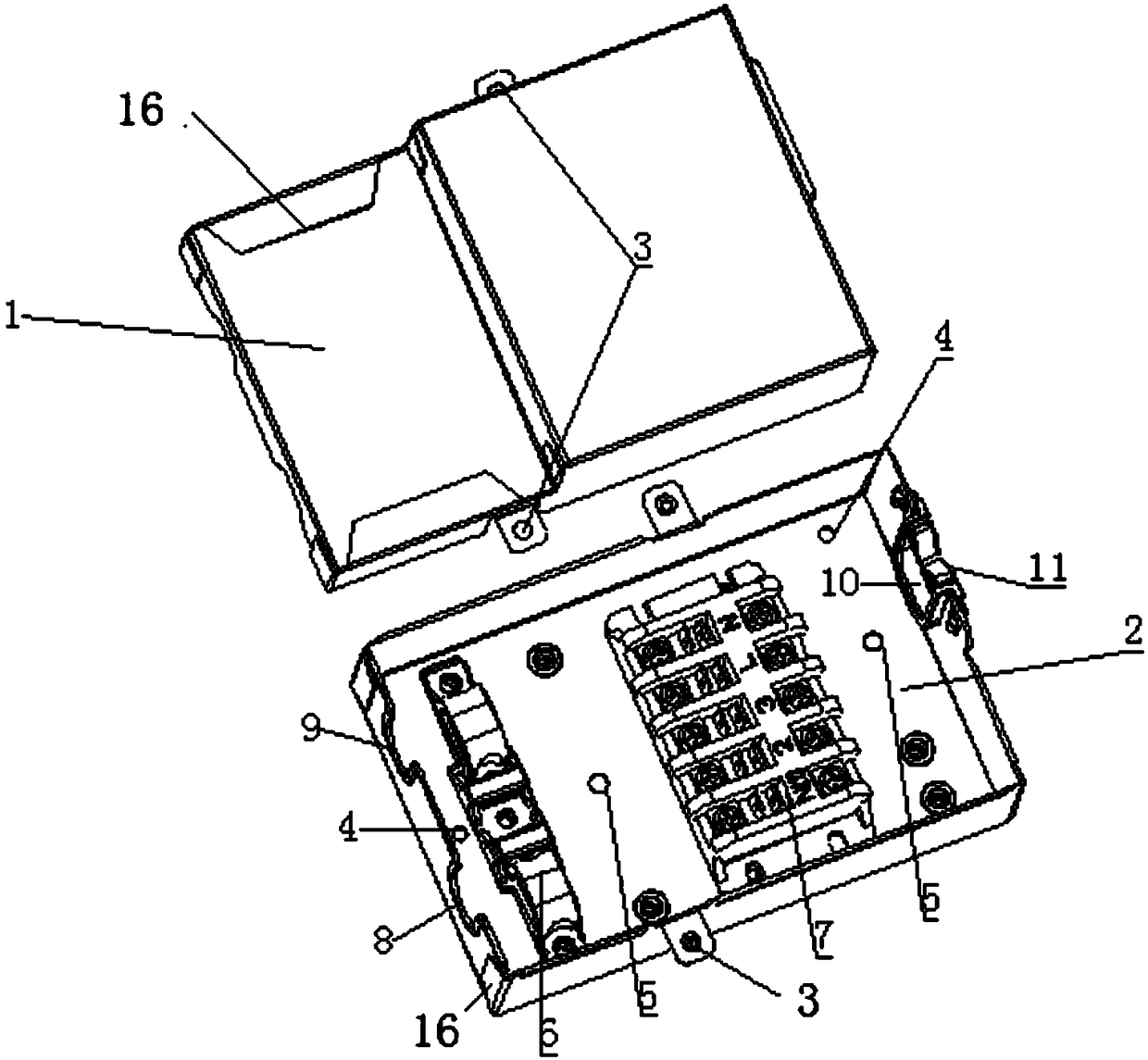

Novel junction box structure and air conditioner thereof

PendingCN108879530ARestricted degrees of freedomMeet automation requirementsElectrical apparatusEngineeringRefrigeration

The invention discloses a novel junction box structure and an air conditioner thereof, and belongs to the technical field of refrigeration and air conditioners. The junction box structure comprises ajunction box and a junction box matching device, wherein positioning holes and screw holes are formed in the junction box, the junction box matching device is located on the water pan of the air conditioner, and comprises positioning column, screw column and a baffle, the positioning columns and the screw columns are matched and mounted with the positioning holes and the screw holes respectively,and the baffle is used for supporting the junction box. According to the novel junction box structure and the air conditioner thereof, the invention is mainly used for mounting the connecting lines ofthe indoor and outdoor units and the power supply line of the indoor unit, and the junction box structure with self-posited design can liberate the hands of operators, meet automation requirements, improve production efficiency, and save cost.

Owner:GREE ELECTRIC APPLIANCES INC

Dispensing and mixing device for organic fertilizer manufacturing

PendingCN108970494AFully automatedRealize mass productionRotating receptacle mixersTransportation and packagingEngineeringOrganic fertilizer

The invention discloses a dispensing and mixing device for organic fertilizer manufacturing. When the dispensing is performed, a rotary dispensing driving assembly drives a feed port of a mixing tankto correspond to the position of a blanking cylinder, and then a lifting assembly drives the mixing tank to rise, so that the blanking cylinder extends into the mixing tank, and a blanking control assembly controls the blanking of each storage assembly; after the blanking is completed, the lifting assembly falls, an elastic cover assembly closes the feed port, and the rotary mixing driving assembly drives the mixing tank to rotate, thereby realizing the automatic dispensing and mixing of an organic fertilizer. The dispensing and mixing device for organic fertilizer manufacturing disclosed by the invention can well realize the automatic dispensing, and adopts a spiral stirring and rotating method when mixing at the same time, thereby greatly improving the efficiency of mixing and the uniformity of mixing; the mass production of organic fertilizer can be effectively realized, and the requirements of automation can be met.

Owner:ANHUI SCI & TECH UNIV

Method for operating pathological monitoring and diagnosis systems

InactiveCN106709237AMeet automation requirementsTelemedicineDiagnostic recording/measuringDiagnostic systemProcess information

The invention discloses a method for operating pathological monitoring and diagnosis systems. The method in various embodiments of the invention mainly includes acquiring and processing physiological parameter information of sick bodies and transmitting processed information to monitoring platform servers; automatically matching acquired physiological parameters with symptom data of the same types of historical sick bodies by the aid of the monitoring platform servers and issuing matching results to monitoring platforms; receiving the matching results by the aid of the monitoring platforms and adding artificial diagnosis records pertinently for the matching results for querying. The method has the advantage that the shortcoming of incapability of quickly and precisely diagnosing diseases and meeting requirements on automation in the prior art can be overcome.

Owner:北海中电高科孵化器有限公司

Automatic box retreating system of detonator

ActiveCN102515993AComplete human-computer isolationCompletely realize human-machine isolationDetonatorsDetonatorDetonation

The invention relates to an automatic box retreating system of a detonator, which belongs to the field of detonator propellant equipment of civil detonation devices and comprises a mould conveying device used for enabling a mould to automatically entering and leaving a process room and returning an empty mould to a conveying belt, a box retreating device used for achieving the effect that a pipe casing retreats from the mould and the pipe casing is automatically dropped, collected and molded, a conveying device used for enabling a finished box to reach the conveying device at the finished product collection position and an empty box feeding device used for enabling the empty box to reach the box retreating device through a belt conveyor. The mould conveying device is connected with the box retreating device which is connected with the empty box feeding device through the conveying the device. The automatic box retreating system of the detonator has the advantages of being capable of replacing manual workers to completely achieve the whole process of detonator box retreating procedures in basic detonator production, achieving complete man-machine separation, resolving safety hazards existing in the production process and having the advantages of being safe and reliable, reducing labor intensity and the like.

Owner:长春汇维科技股份有限公司 +1

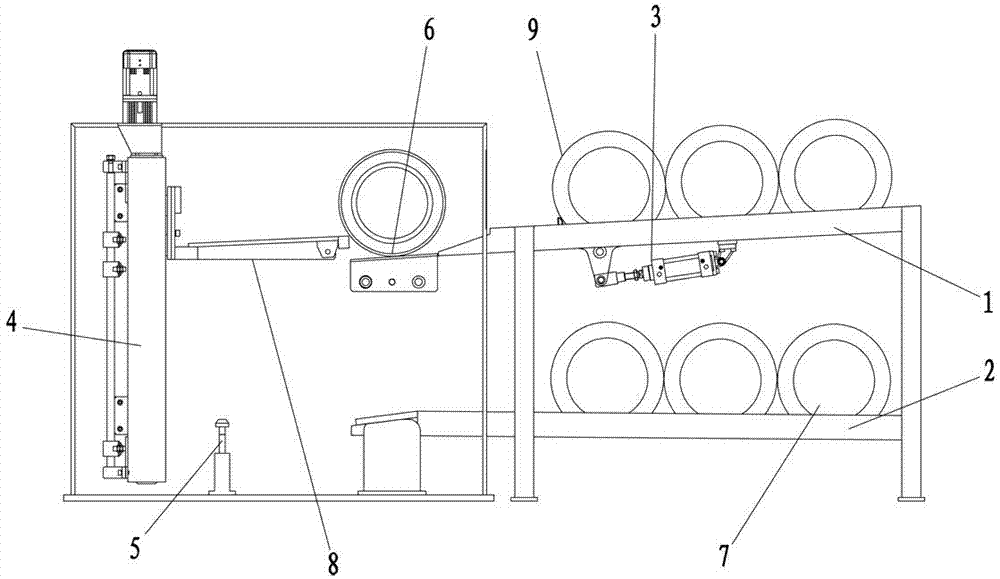

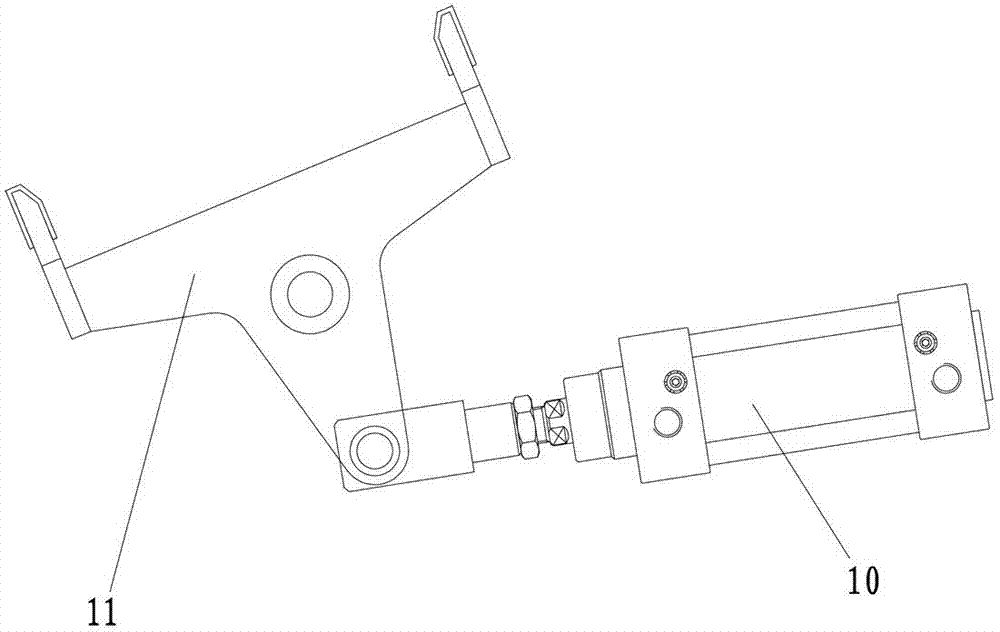

Automatic disc replacing device for wiredrawing machine

The invention discloses an automatic disc replacing device for a wiredrawing machine. The automatic disc replacing device comprises a disc-feeding guide rail with gradient, a disc-charging guide rail with the gradient, a disc stop mechanism, a linear motion mechanism and a disc ejecting mechanism, wherein the disc stop mechanism is used for controlling the feeding of the disc; the disc ejecting mechanism is used for promoting the discharging of the disc; the bottom of the disc-feeding guide rail is connected to a take-up reel work station; the linear motion mechanism is arranged between the take-up reel work station and the top of the disc-charging guide rail; the bottom of the disc-charging guide rail is connected to a take-up reel storage position; the disc stop mechanism is arranged on the disc-feeding guide rail; a support plate for supporting the take-up reel is arranged on the linear motion mechanism and can rotate upwards around the far end of the support plate; and the disc ejecting mechanism for ejecting the disc outwards is arranged under the near end of the support plate. The automatic disc replacing device has the beneficial effects that by using the structure, manual work is not involved in the disc replacement process of the wiredrawing machine, so that the disc can be replaced automatically, the automation degree of the wire drawing machine is improved, and the requirement of the modern production on the automation is met.

Owner:东莞市冠标电工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com