Method and device for multi-dimensional detection of angle sensor

An angle sensor and detection device technology, applied in measuring devices, surveying and navigation, and optical devices, can solve problems such as inability to perform dynamic precision detection, improve work efficiency and detection accuracy, improve detection accuracy, and reduce detection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

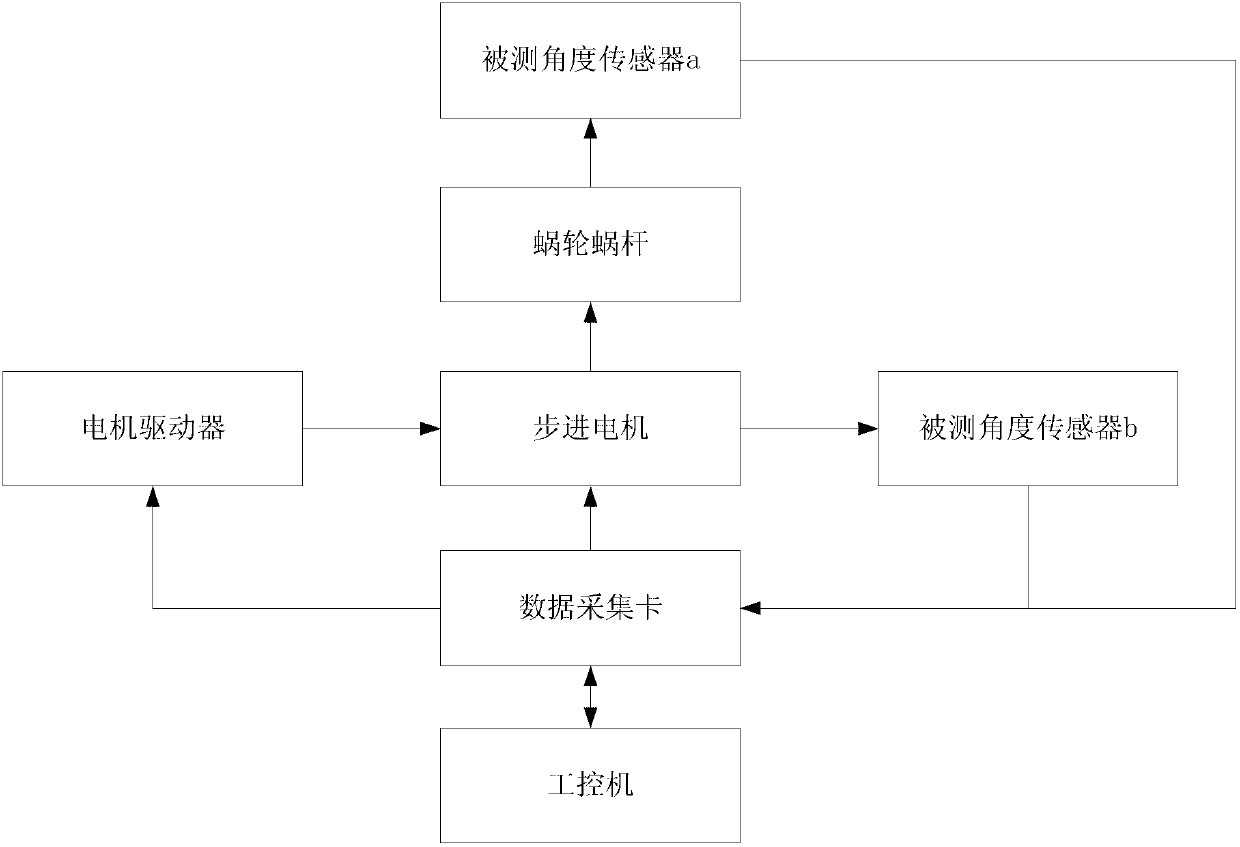

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is to perform static precision detection on the absolute angle sensor.

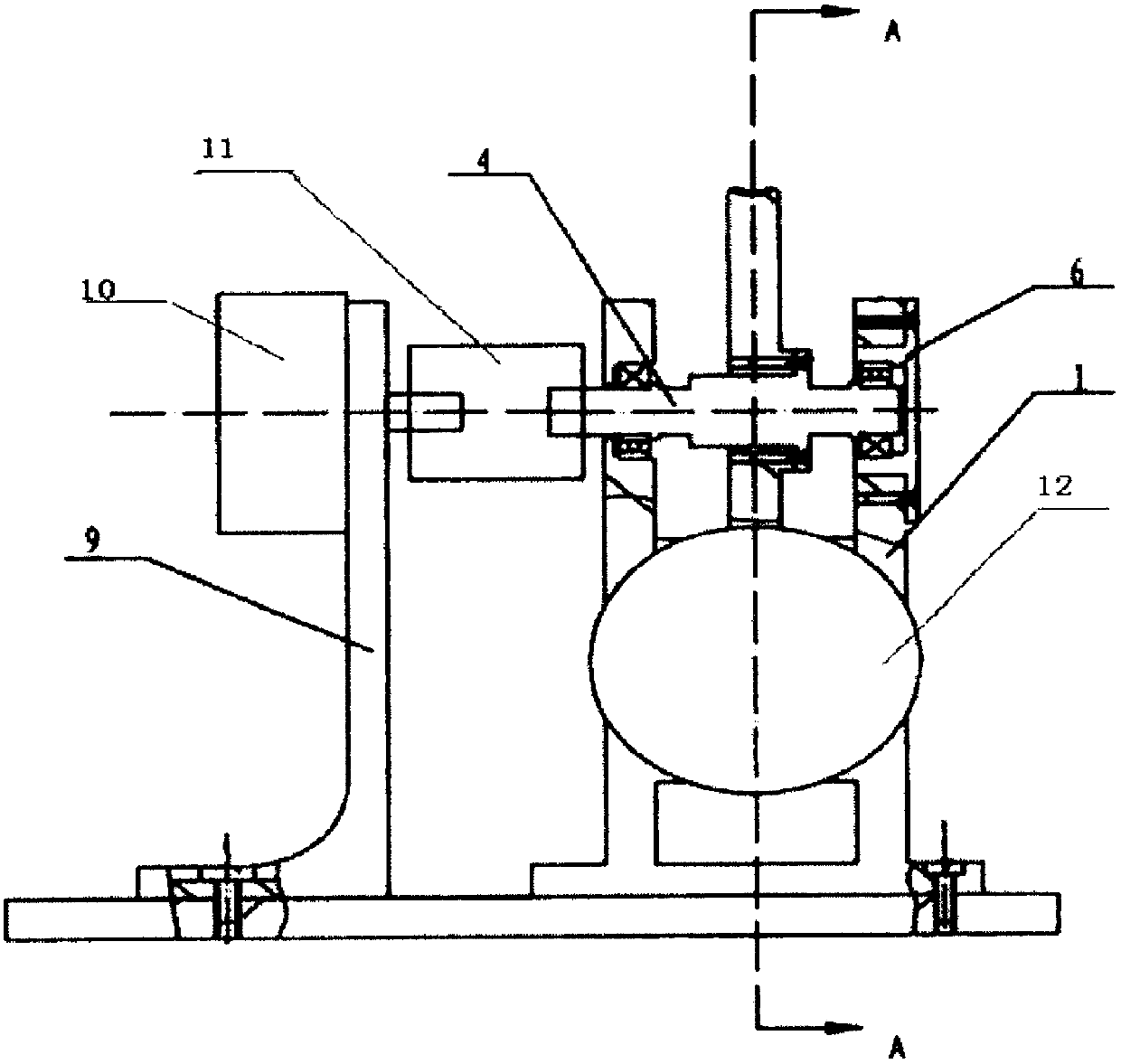

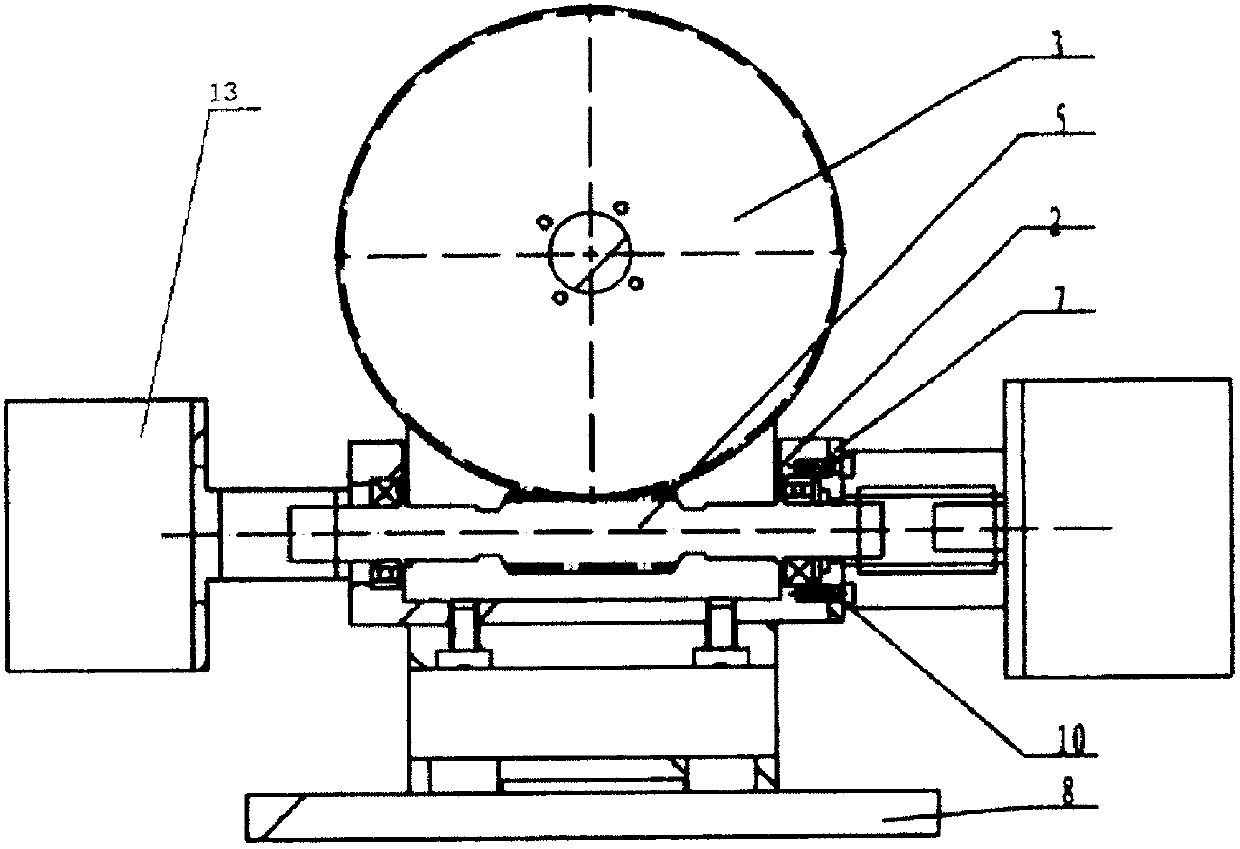

[0048] according to Figure 3 to Figure 6 Install the detection device in the connection mode shown, select the corresponding coupling and angle sensor mounting plate, and install the measured angle sensor on the corresponding mounting plate. Connect the appropriate data cables. Since the static accuracy test is performed in this example, it is necessary to connect the measured angle sensor to the output shaft decelerated by the worm gear. Since the absolute photoelectric encoder is selected for testing in this example, there is no requirement for the level or measurement method, so the detection device can be placed in any of the two placement methods, such as Figure 4 Placement as shown in , or flip the device 90 degrees along the A-A space.

[0049] Corresponding parameters are set on the industrial computer equipped with the special software of the present invention, such as...

Embodiment 2

[0057] This embodiment is to detect the dynamic accuracy of the planar electronic compass.

[0058] according to Figure 3 to Figure 6 Install the detection device in the connection mode shown, select the corresponding coupling and angle sensor mounting plate, and install the measured angle sensor on the corresponding mounting plate. Connect the appropriate data cables. Since the dynamic accuracy test is carried out in this example, and the electronic compass does not have high requirements for high-speed performance, the low-speed output shaft decelerated by the worm gear can be used for detection. Electronic compass accuracy detection needs to keep its level, so choose a horizontal detection plane (vertical output axis), such as Figure 4 For the installation method shown, use the leveling mechanism for leveling.

[0059] Corresponding parameters are set on the industrial computer equipped with the special software of the present invention, such as the type of the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com