Patents

Literature

67results about How to "Fast real-time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

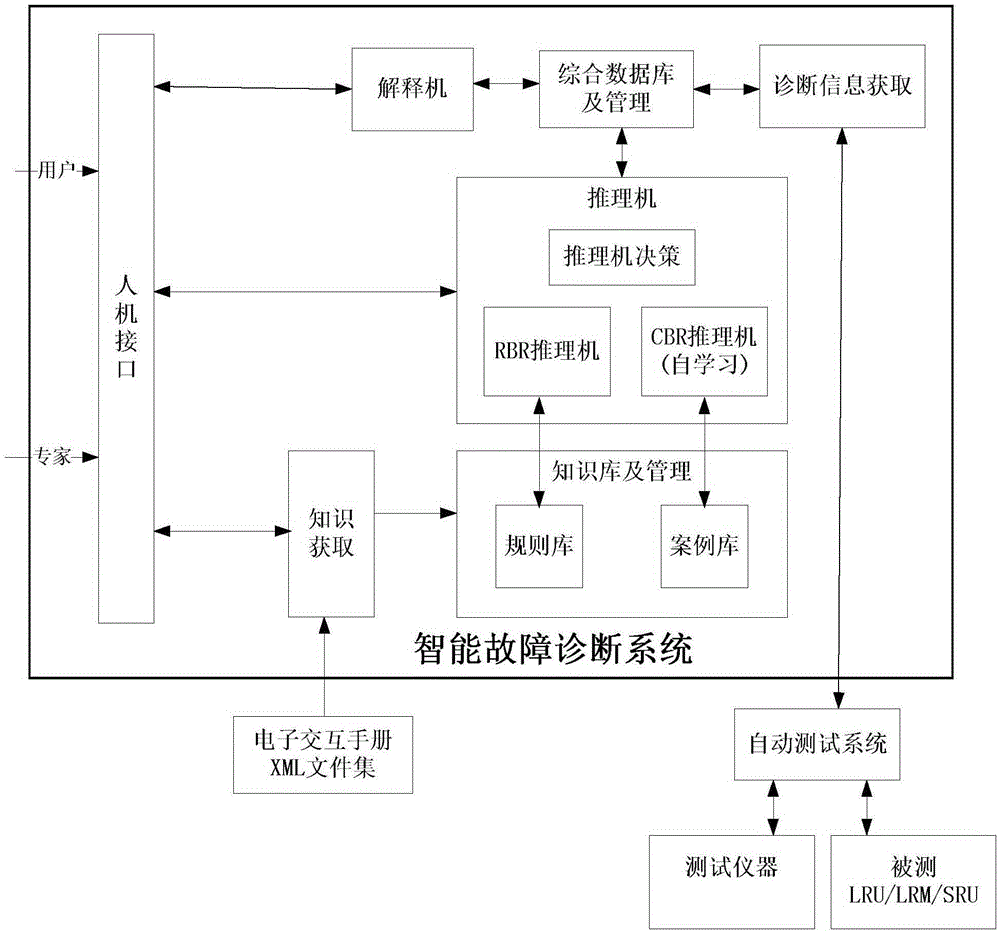

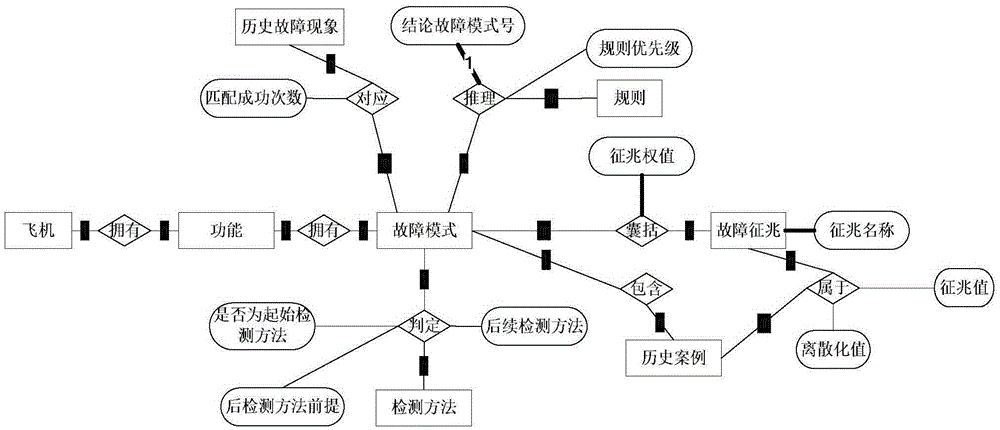

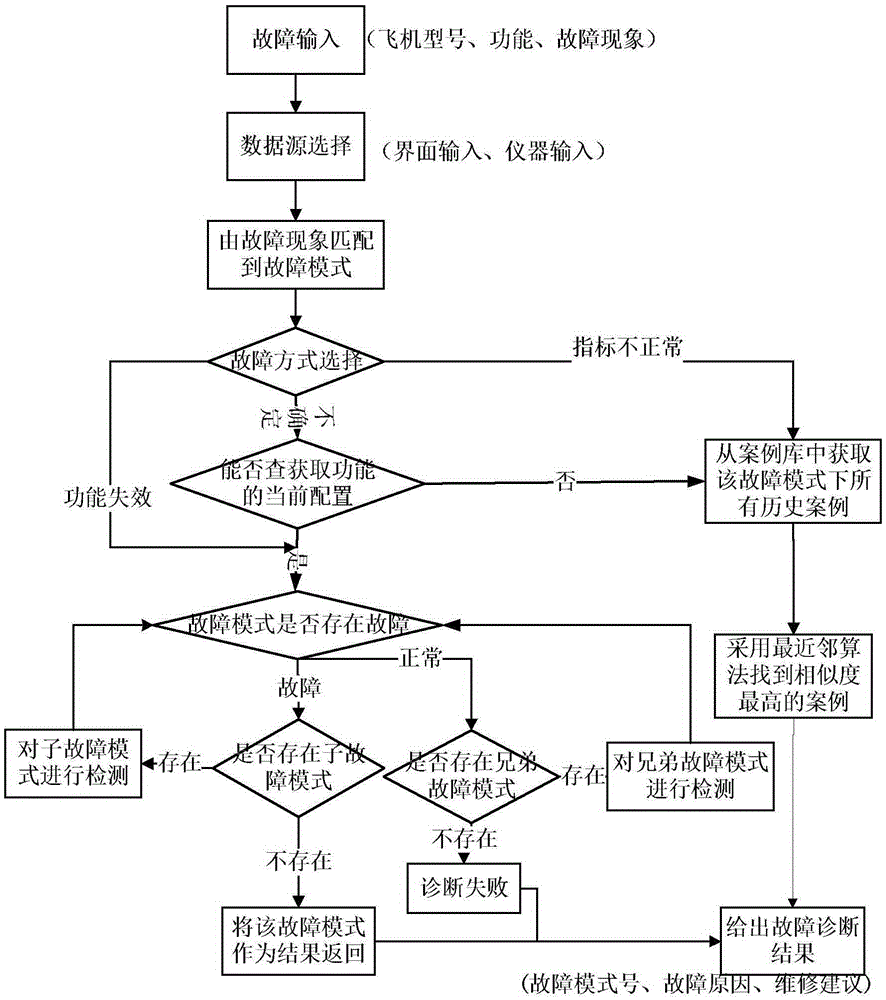

Intelligent fault diagnosis system for ICNI system

InactiveCN105302112AConvenient reasoningEasy to explainProgramme controlElectric testing/monitoringRelational databaseSql server

The invention discloses an intelligent fault diagnosis system for an ICNI system, which can improve the maintenance efficiency, carry out intelligent and automatic diagnosis and is applicable to the ICNI system. According to the technical scheme of the invention, a knowledge base and a management module thereof carry out standardization research and mathematical modeling based on a fault tree, an SQL Server database software framework is adopted, a relational database is used for building a logic relation among a fault phenomenon, a fault mode, a detection method, a historical case and a fault tree internal event to form the knowledge base; and a diagnosis information acquisition module interacts with an automatic testing system via Ethernet to acquire diagnosis data from the ICNI system and a testing instrument, a reasoning machine module adopts CBR and RBR hybrid diagnostic reasoning, after comprehensive judgment is carried out on the fault phenomenon inputted by the user, the field knowledge stored by the knowledge base and the diagnosis data from the automatic testing system, a reasoning method is automatically selected to carry out reasoning diagnosis on the fault, a reasoning process and a reasoning result are outputted to an explanation machine module, and a diagnosis report is generated.

Owner:10TH RES INST OF CETC

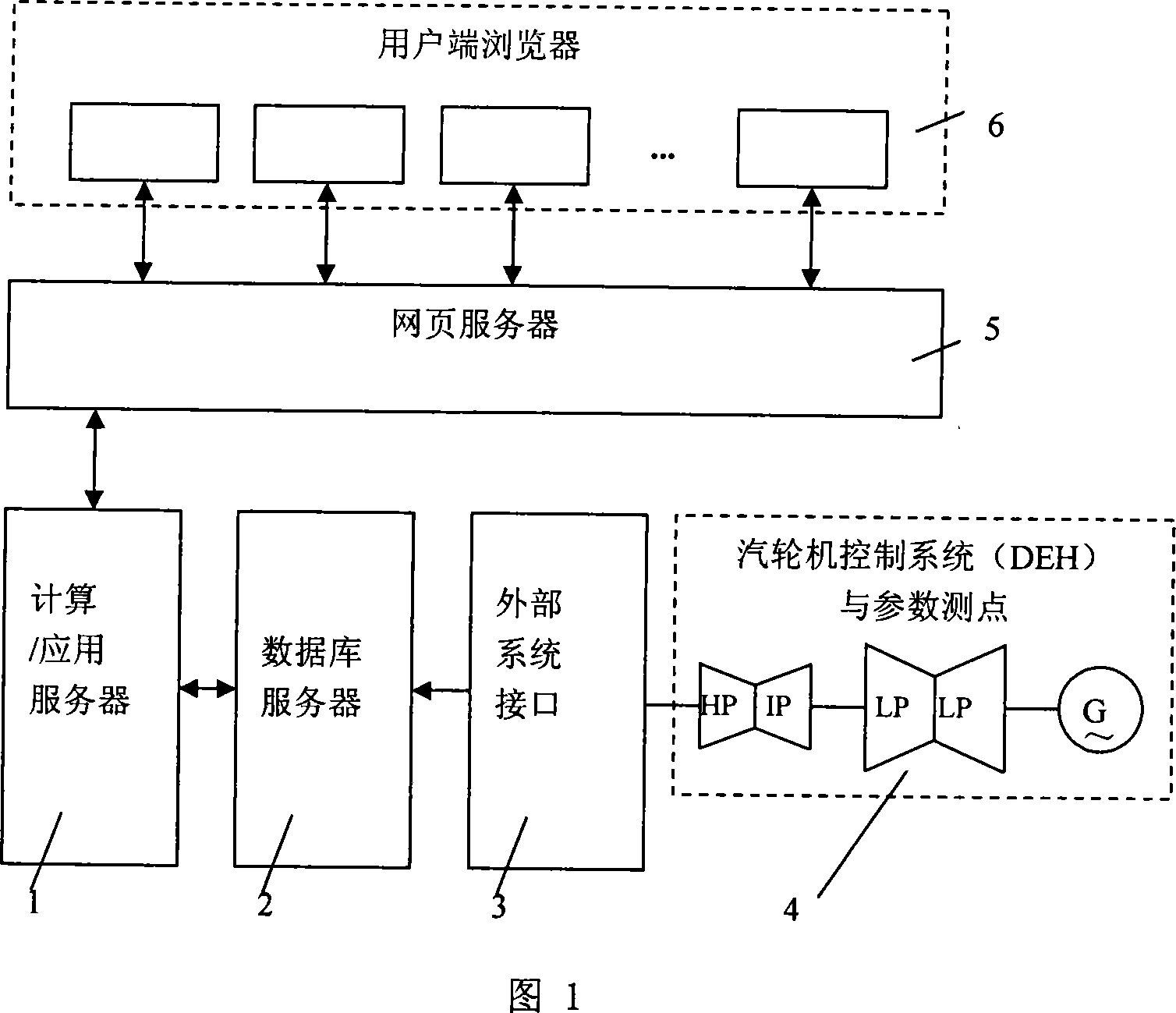

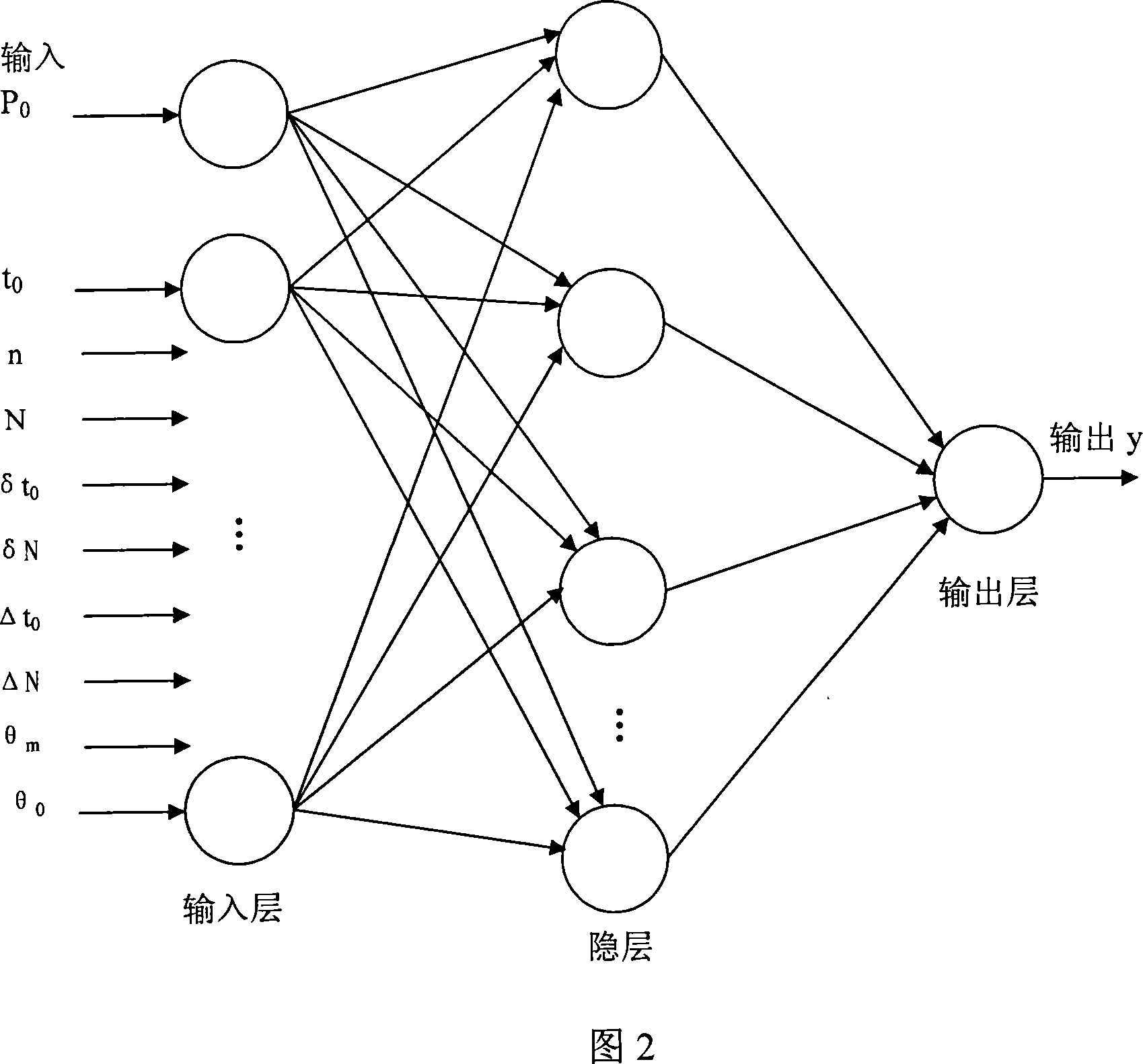

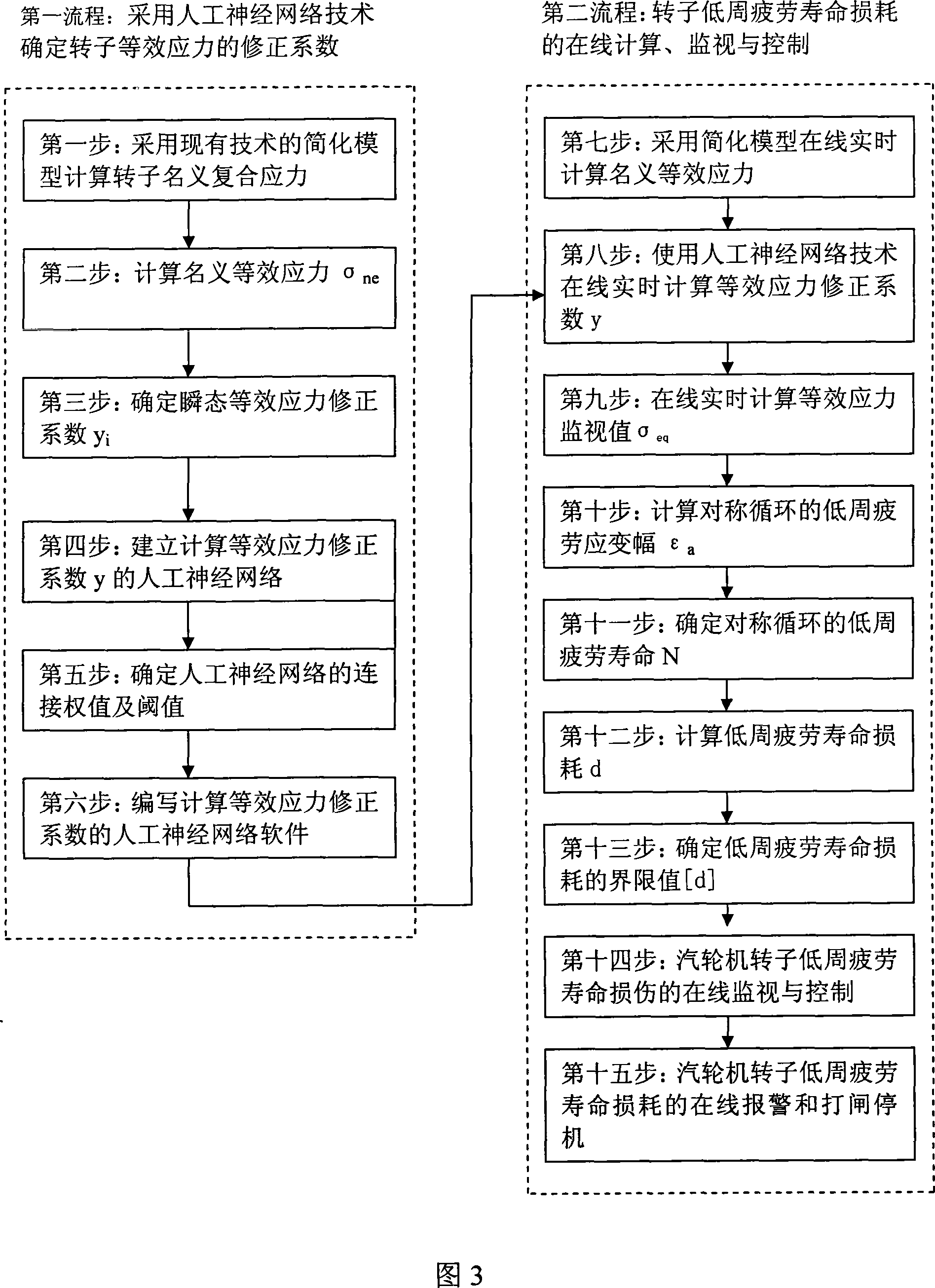

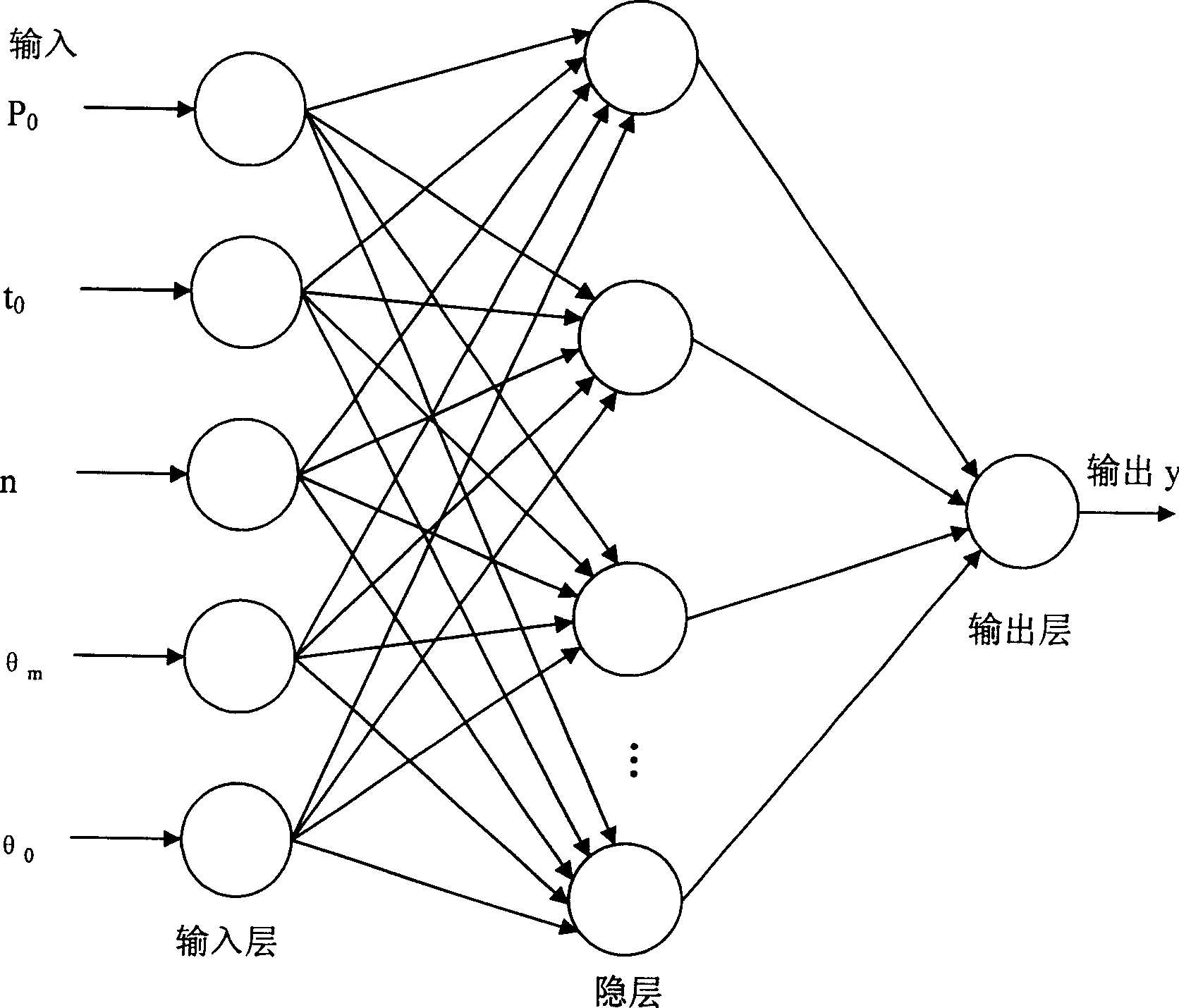

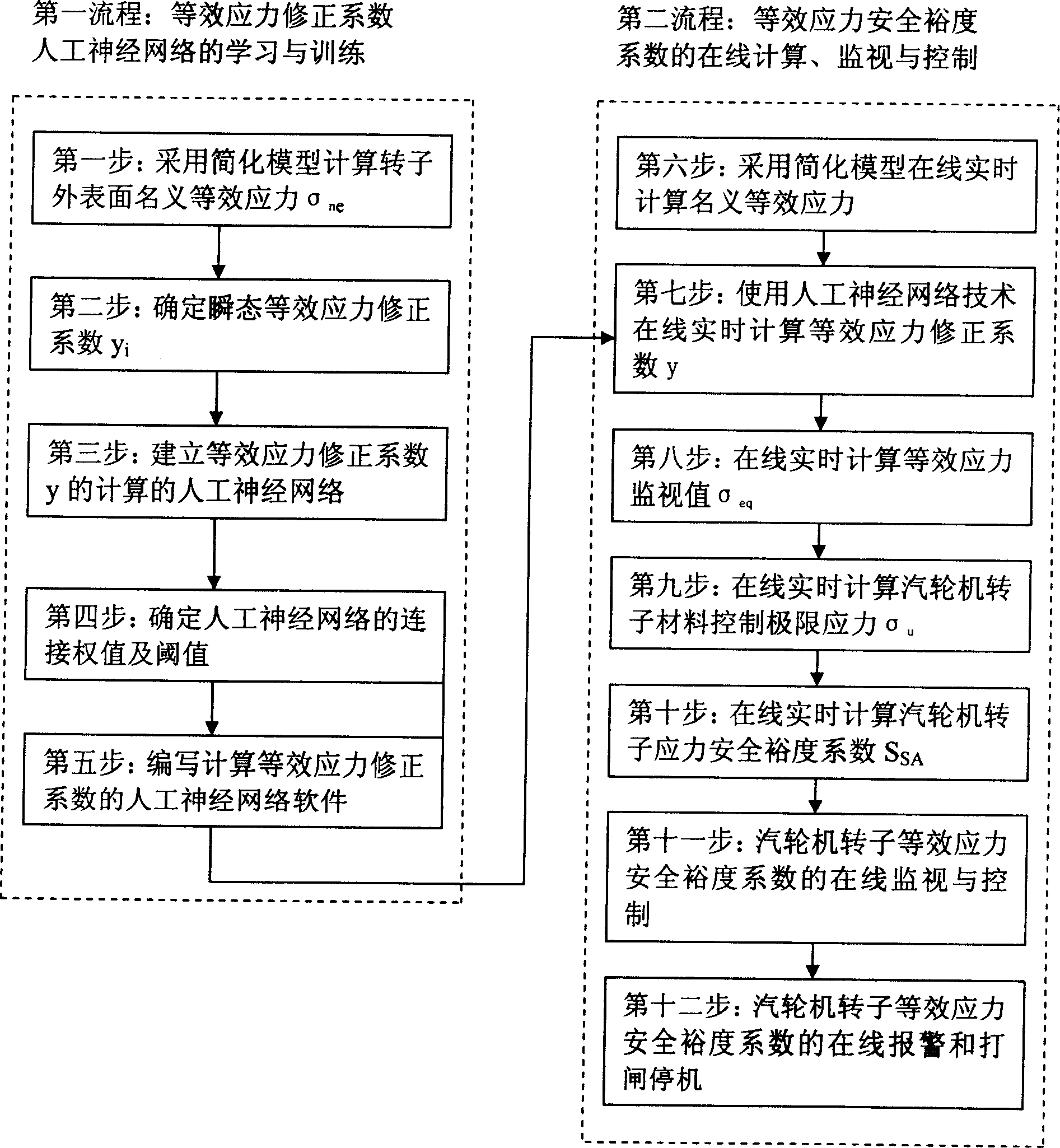

Method and system for on-line monitoring steam turbine roter low-cycle fatigue life consumption

ActiveCN101042059AReduced loss of low cycle fatigue lifeReduced cycle fatigue life lossMachines/enginesSafety/regulatory devicesNerve networkLow-cycle fatigue

It relates to a turbine rotor low cycle fatigue durability loss on line monitoring system, featuring in its computation, application server and software, database server, outside system interface, turbine control system DEH and parameter testing point, web server and user browser that connects with the computation and application server and each end item user browser respectively, with the computation and application server connecting with the data base server which connects with the turbine control system DEH and parameter testing point through the outside system interface. It is made of two processes, with the no.1 using artificial nerve network to determine turbine rotor equivalent stress coefficient, the no.2 process being on line computation, monitoring and control of the turbine rotor cycle fatigue loss. It realizes the working times of the turbine rotor of 10000 times.

Owner:SHANGHAI POWER EQUIP RES INST

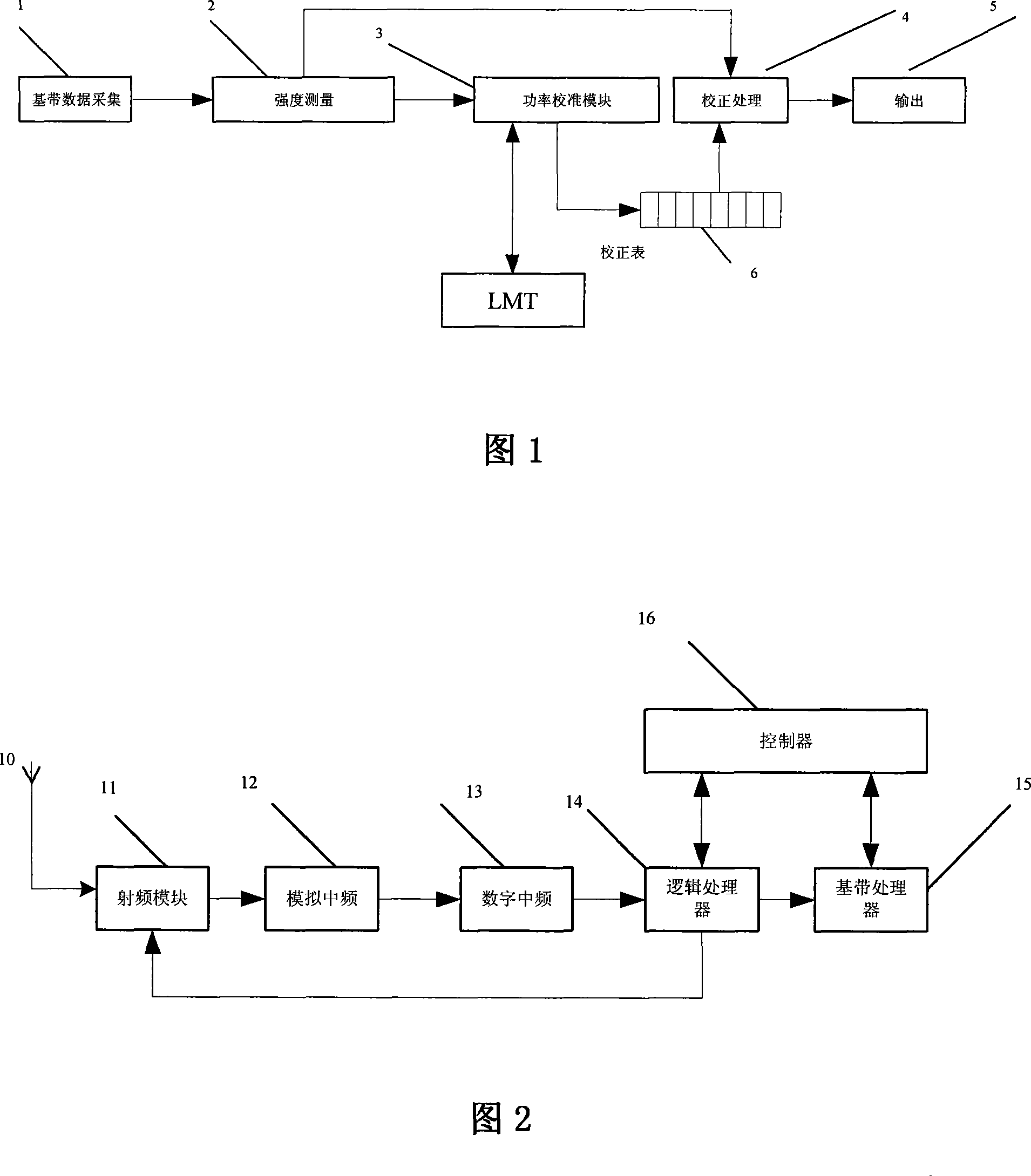

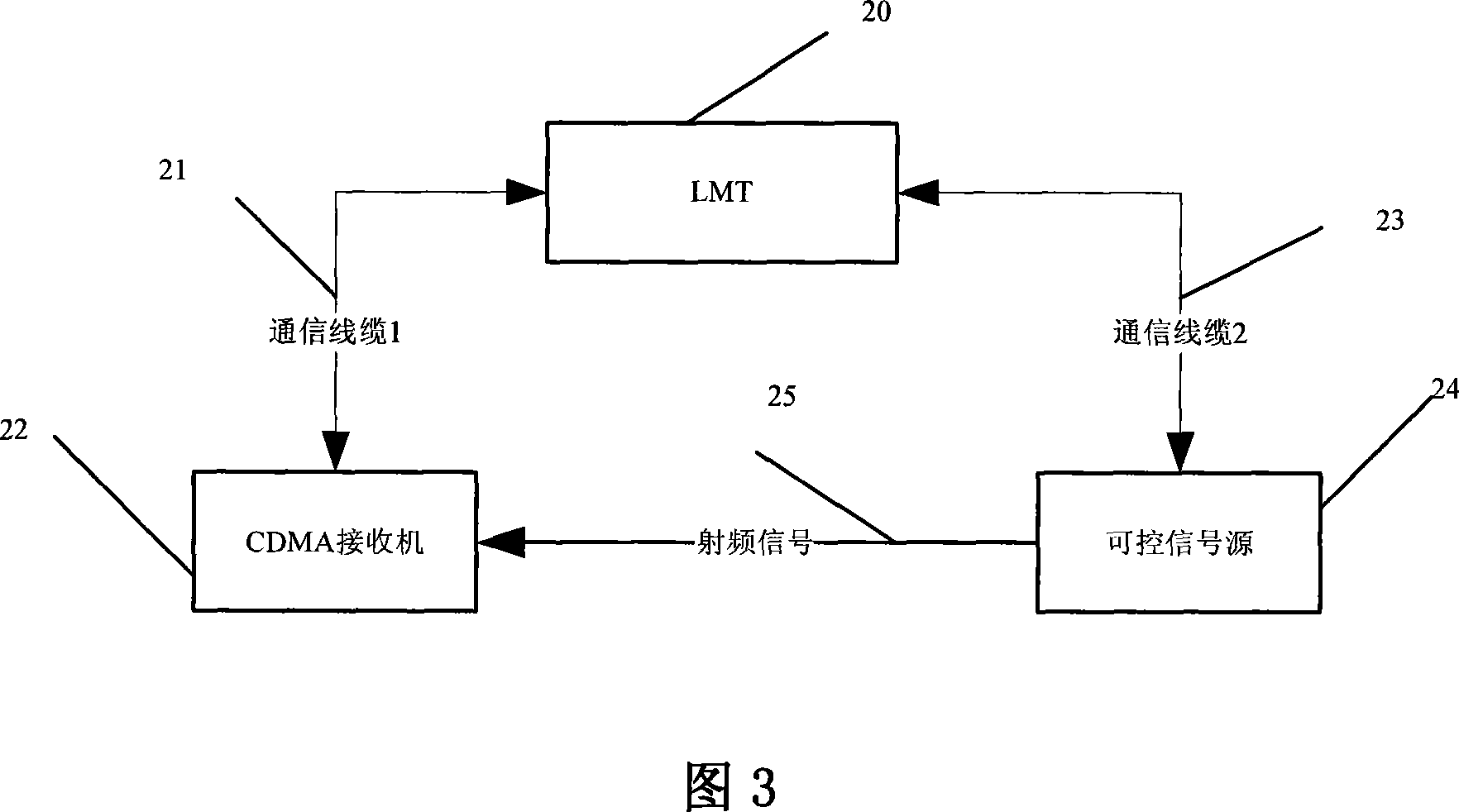

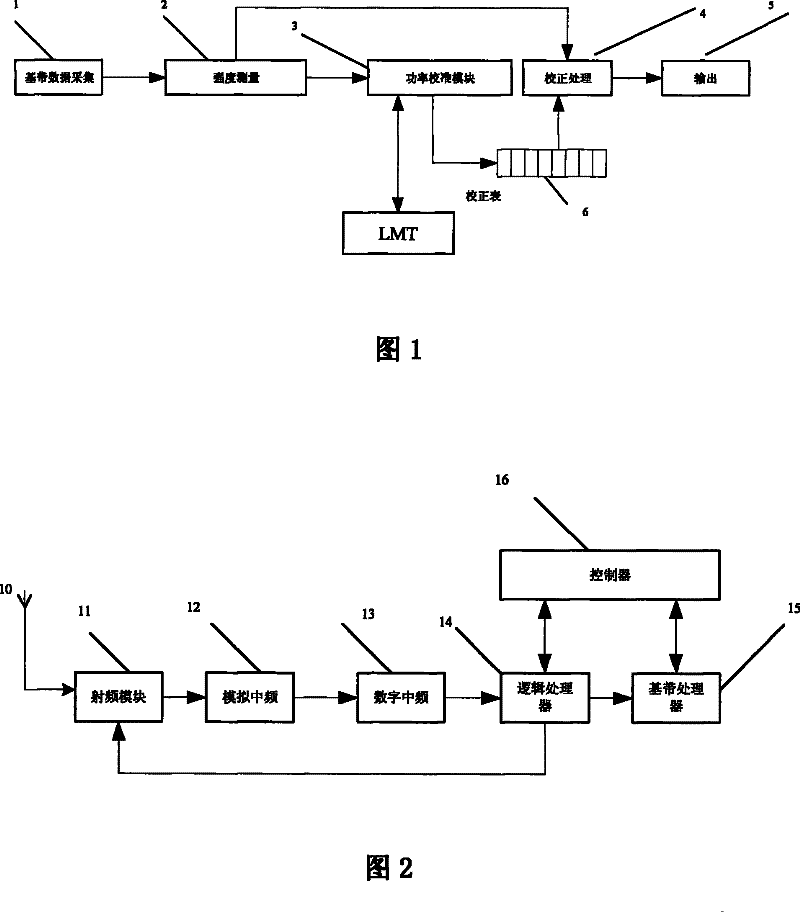

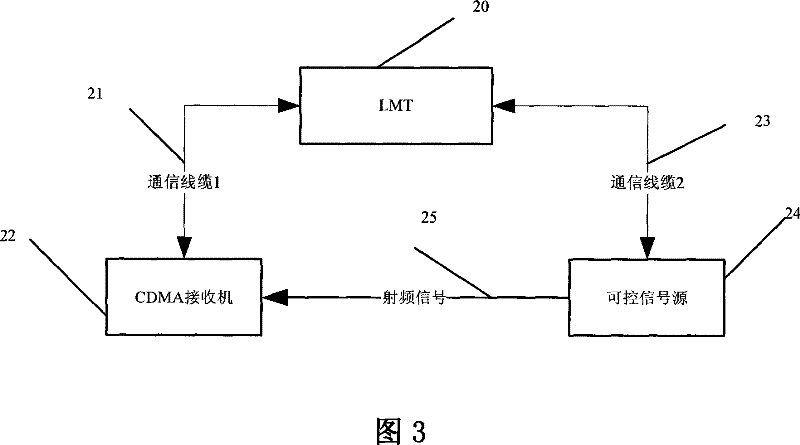

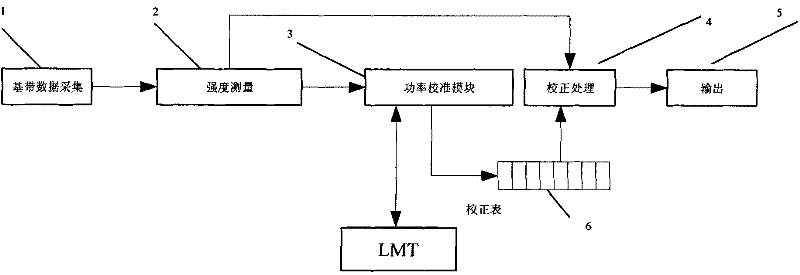

A power calibration and real time correction device for CDMA receiver and its implementation method

ActiveCN101188463AReduce consumptionHigh speedReceivers monitoringRadio/inductive link selection arrangementsCdma systemsNonlinear gain

The invention relates to a CDMA receiver power calibration and real-time correction device and the realization method thereof, and the method can be used for the power calibration and the real-time correction of terminal equipment such as the CDMA system, the base station facilities, and the road measurement meter. The method adopts a segment look-up table approach, and not only uses the fastness and simplicity of the look-up table approach but also combines segment treatment, thereby reducing the consumption of the storage room as much as possible. For linear gain section of a receiving link, i.e. the so-called big signal calibration, the look-up table approach is used directly; for non-linear gain section, i.e. small signal calibration, a noise compensation calibration method is adopted. The invention is used especially for the power calibration and the real-time correction of the massive equipment, and the power calibration method can meet the demand of automation and have the advantages of low cost, fast speed and high calibration precision.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

MRI and ultrasound guided treatment on a patient

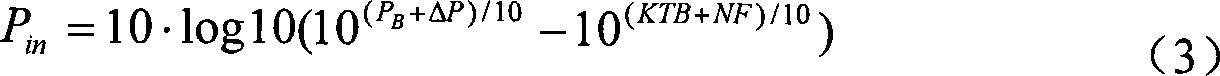

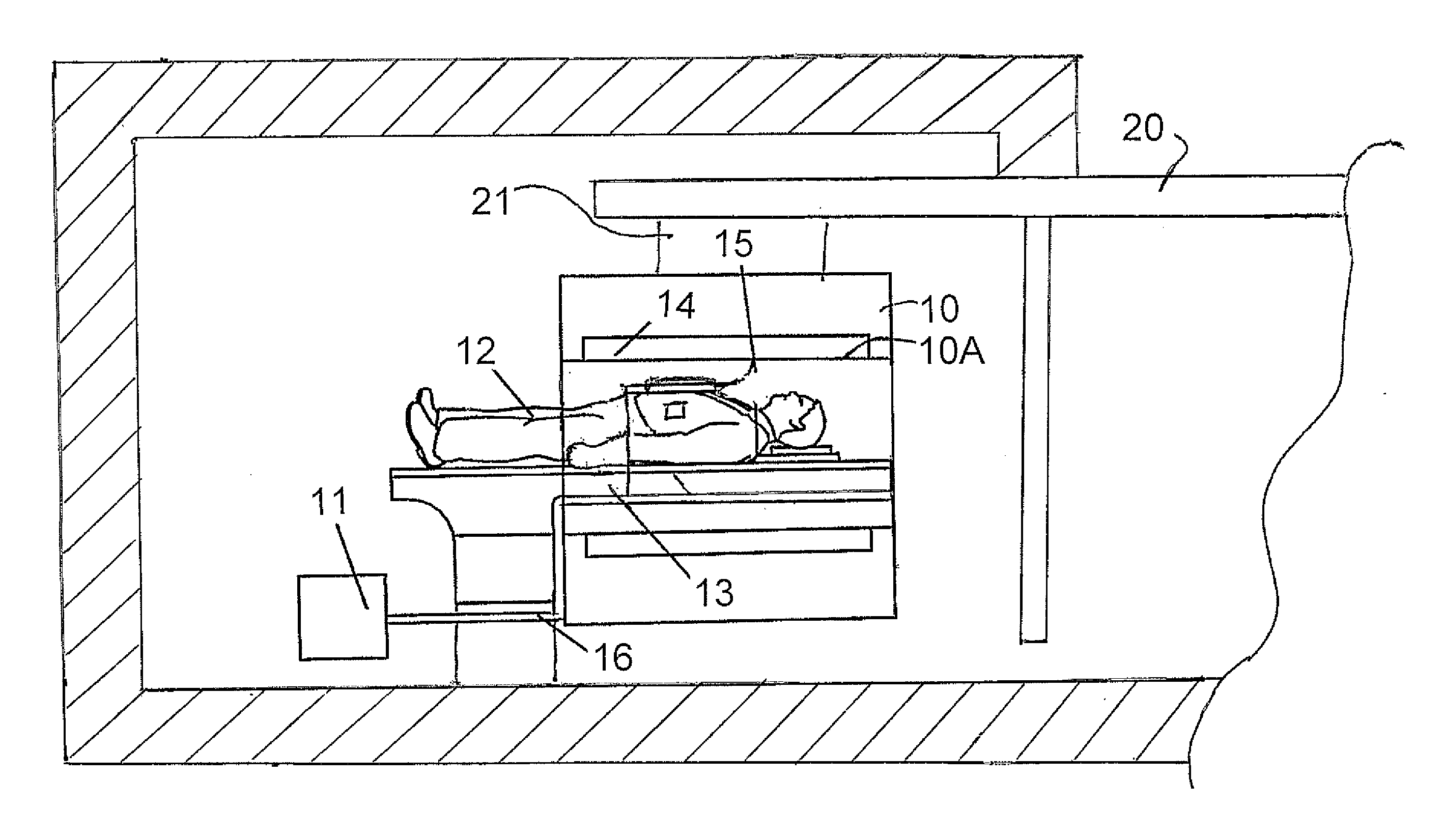

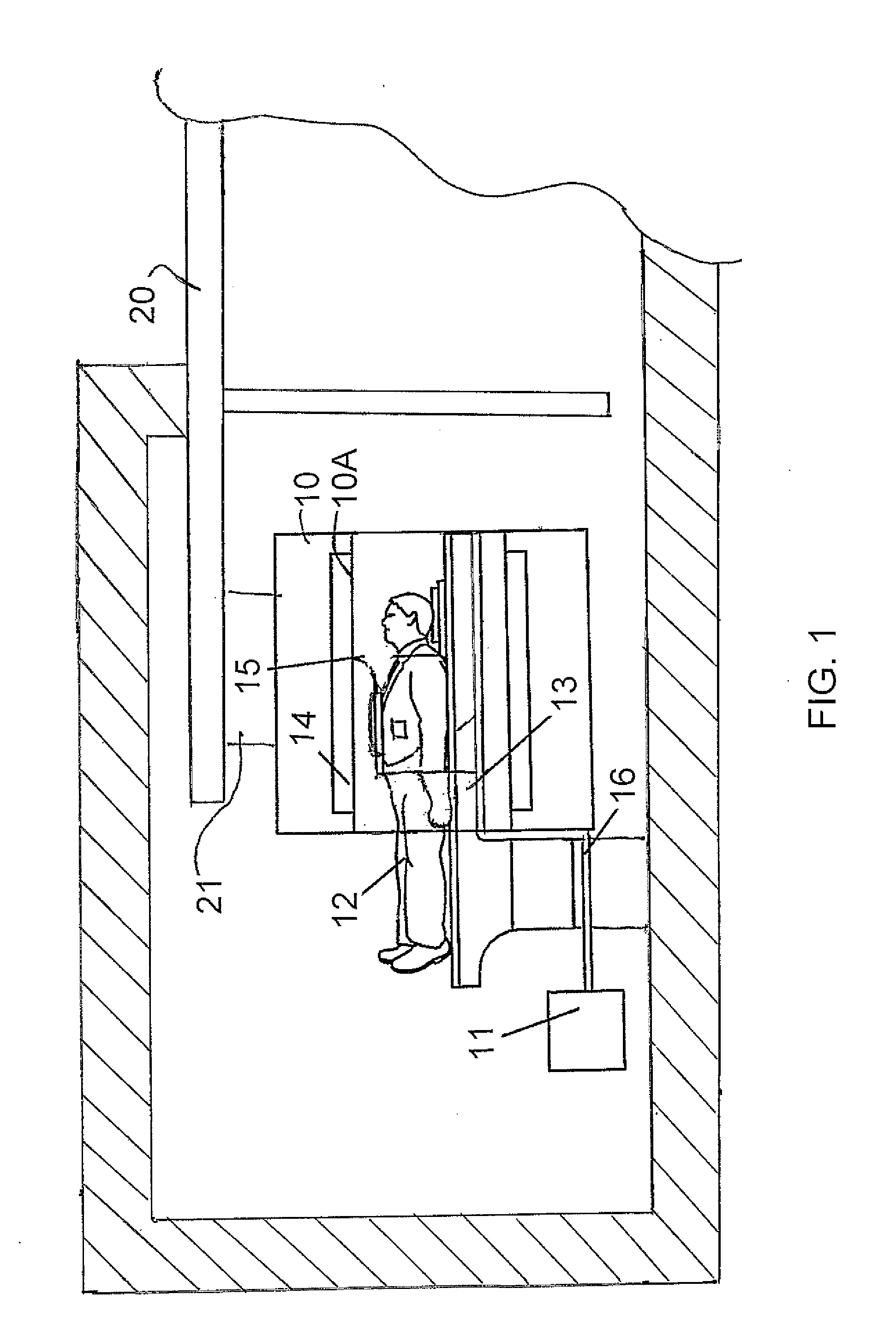

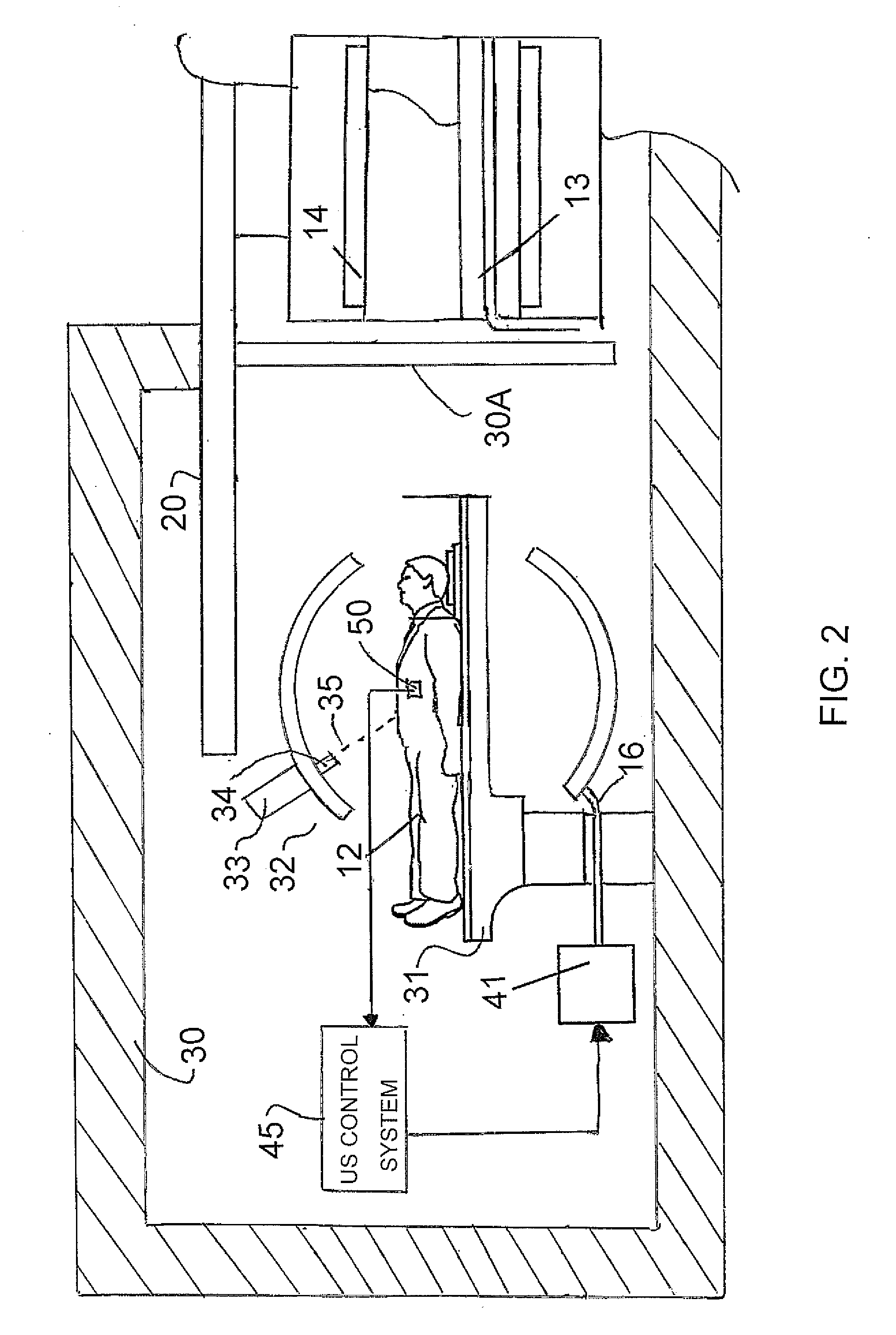

InactiveUS20110160566A1Fast real-timeThe process is simple and effectiveMagnetic measurementsOrgan movement/changes detectionBody regionBreathing

A method is provided for guiding a procedure on a region of interest in a body part of patient, where the body part moves within the patient by breathing, cardiac or other action. The procedure includes radiation therapy, or guidance of a probe for example for biopsy or brachytherapy. The method includes using an MRI system to obtain an MR image of the body part, during the procedure on the body part of the patient, obtaining real time ultrasound images of the body part of the patient as the body part moves within the body of the patient, registering the MR image of the body part with the ultrasound image of the body part so as to locate the region of interest in the ultrasound image of the body part and using the registered images to target the action to the region of interest as the body part moves.

Owner:IMRIS

Universal real-time multi-channel parallel timing measuring system

InactiveCN103616813ASuitable for carryingImprove real-time performanceElectric unknown time interval measurementExternal storageComputer software

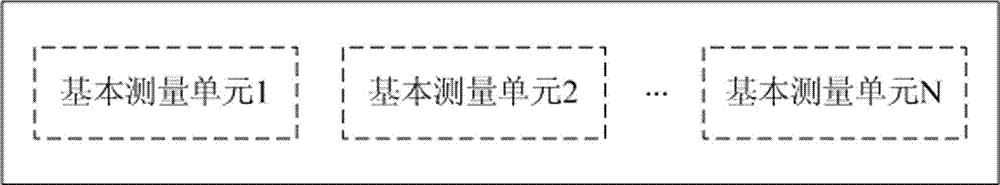

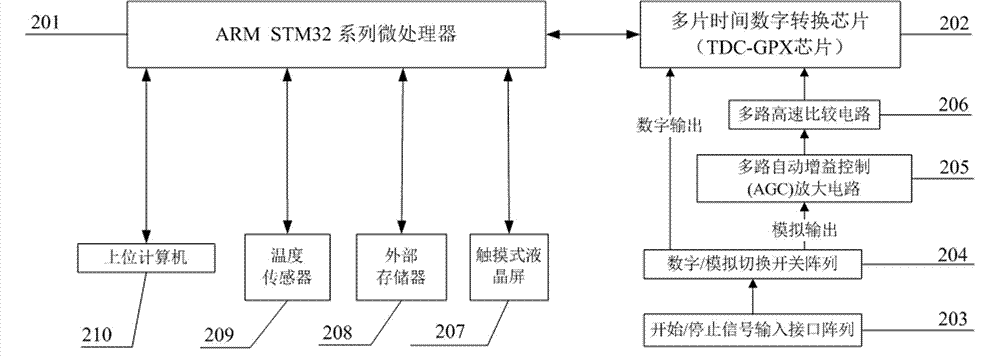

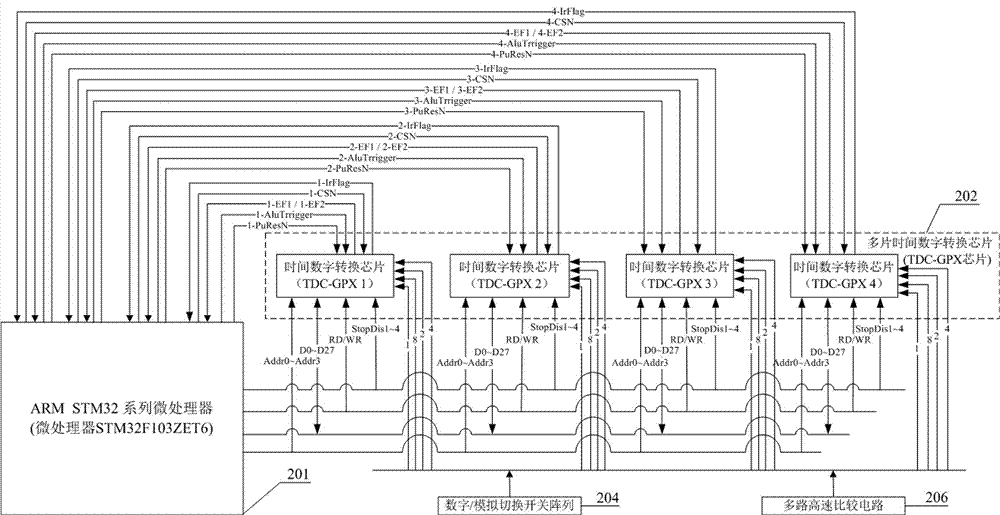

The invention discloses a universal real-time multi-channel parallel timing measuring system. The universal real-time multi-channel parallel timing measuring system comprises an ARMSTM32 series processor, a multi-disc TDC-GPX chip, a start / stop signal input interface array, a digital / simulation diverter switch array, a multi-channel AGC amplifying circuit, a multi-channel high-speed comparison circuit, a touch LCD, an external memory, a temperature sensor and an upper computer. According to the universal real-time multi-channel parallel timing measuring system, multi-channel simultaneous parallel timing is achieved, and the real-time performance is good; simulation, digital, single-ended and difference multiple types of signal input can be supported at the same time, and the applied range is wide; wire length compensation, channel consistency correction and temperature compensation of the multi-disc TDC-GPX chip and high precision are achieved; one microprocessor can control 1-4 TDC-GPX chips to form a basic measuring unit, multiple channels are needed, a plurality of basic measuring units are stacked for use, the structure is compact, and the expansibility is strong; by the aid of upper computer software based on a LabView, the development difficulty of graphical monitoring and displaying application programs is made to be simple.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

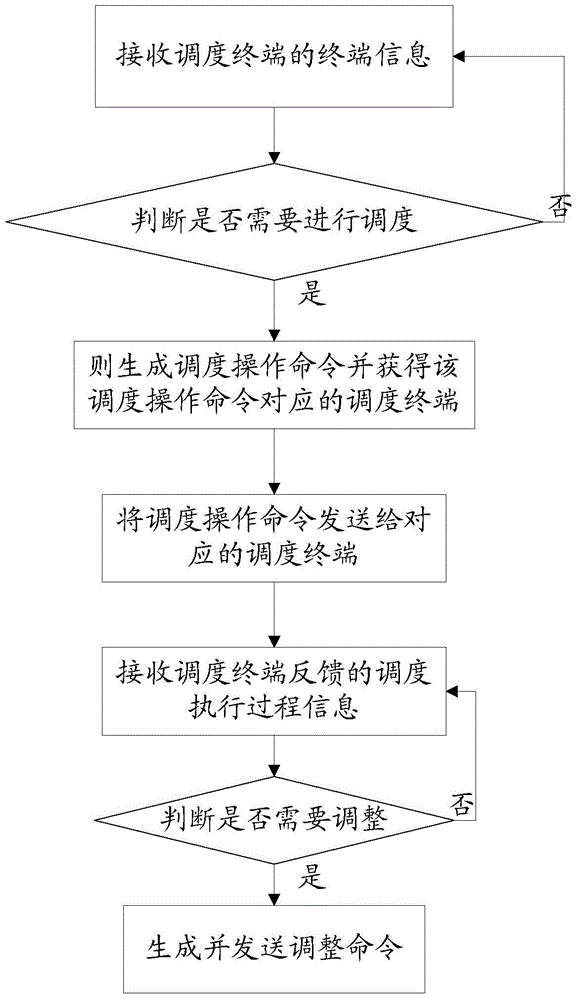

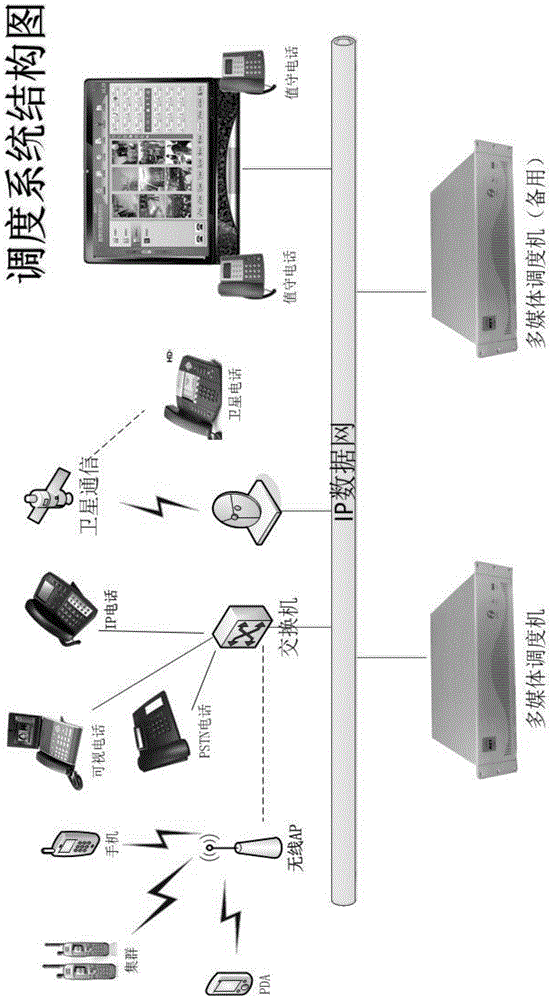

Scheduling terminal, scheduling console, scheduling method and communication scheduling command method

InactiveCN104410605ARealize triple playShorten the timeNetwork topologiesTransmissionVideo monitoringVoice communication

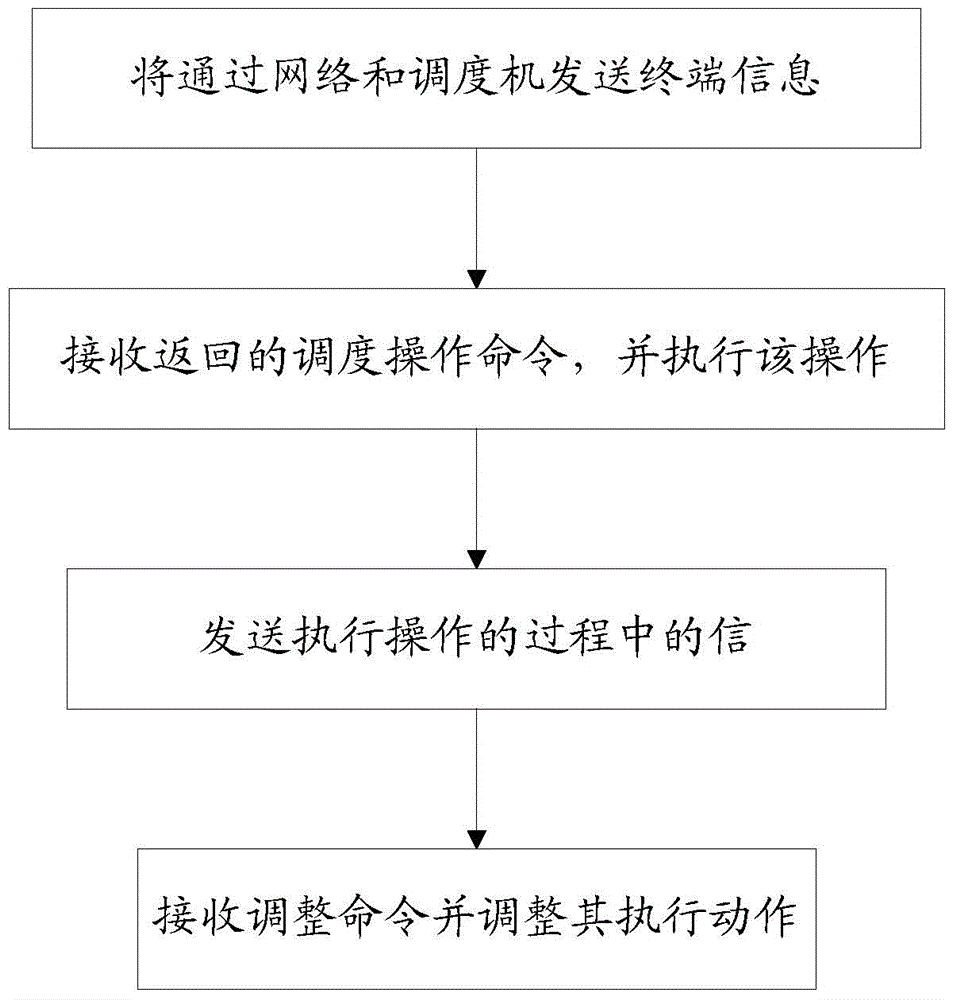

The invention provides a scheduling terminal and a scheduling console. The scheduling terminal comprises a sending unit, a performing unit, a feeding unit and an adjusting unit; the scheduling console comprises a receiving unit, an instruction generating unit, an instruction sending unit, an adjusting instruction sending unit and an emergency processing database unit. The invention further provides a communication scheduling command method and a system, a two-dimensional GIS is taken as auxiliary by the system, the system integrates with voice communication, video monitoring and video conferences to form a communication supporting platform for an integrated distribution network first-aid repair command system, voice, data and video functions are integrated into one body, scheduling command is carried out through multiple communication terminals in wired, wireless, video and voice modes, rapid circulation and timely monitoring on a business flow are realized, so fault first-aid repair scheduling is not limited by time and space.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

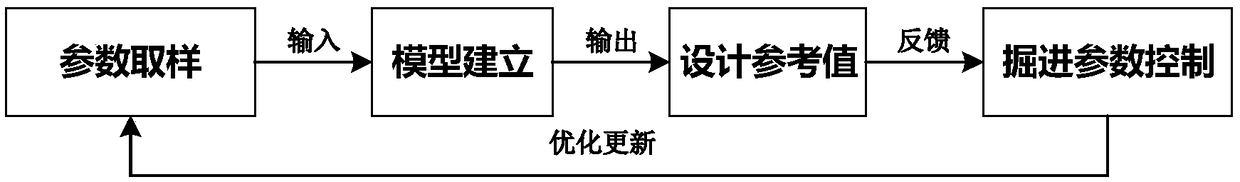

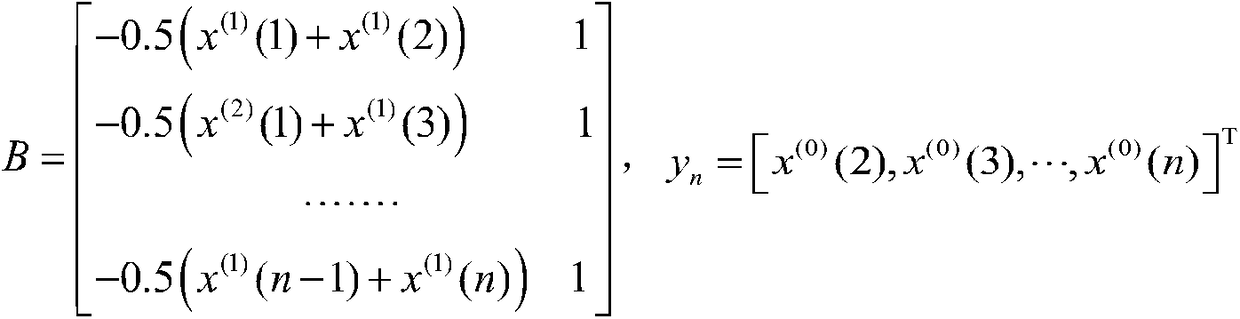

Shield driving parameter prediction method based on grey system model

InactiveCN108491590AControl tunneling parametersFast real-timeGeometric CADDesign optimisation/simulationAlgorithmOriginal data

The invention provides a shield driving parameter prediction method based on a grey system model. According to the method, tunneling parameters of continuous tunneling of a set quantity of rings by ashield tunneling machine are selected to serve as sampled data; the sampled data is converted into a generation sequence displaying a certain law, and a tunneling parameter grey prediction model basedon the grey system theory is established based on the generation sequence, wherein the sampled data is input into the tunneling parameter grey prediction model, and the tunneling parameter grey prediction model obtains tunneling parameter prediction values of subsequent tunneling segments through calculation; the tunneling parameter prediction values are fed back to a shield manipulator to guideshield tunneling machine tunneling parameter control; and tunneling parameter samples are updated in real time to realize dynamic circulation of tunneling parameter prediction. Through the method, byweakening the randomness of original data to highlight the inherent law of the original data, only a small amount of original data is needed; and meanwhile, the model is properly corrected through thedifference between a model fitting value and an actual value, prediction precision can be improved, and the prediction result is more approximate to practice.

Owner:BEIJING JIAOTONG UNIV +2

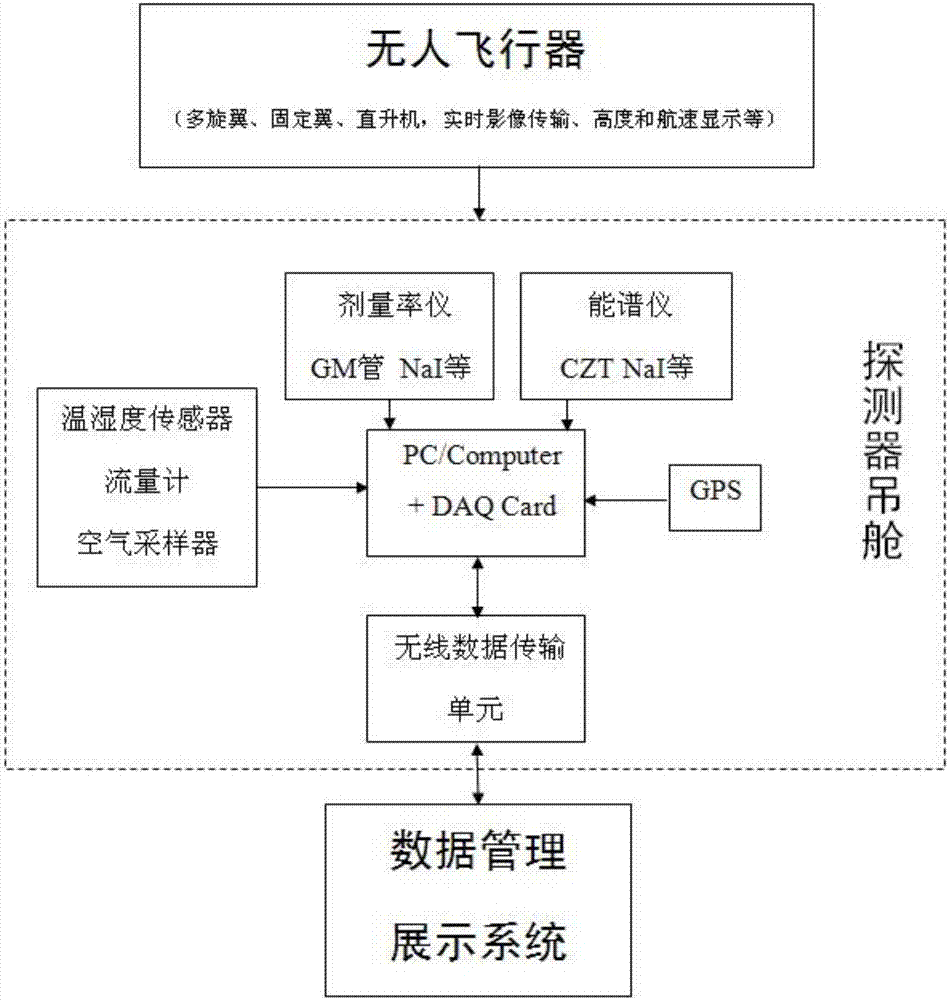

Unmanned aerial vehicle low altitude radiation monitoring system

InactiveCN107117312AReduce radiation doseFlexible and fast deploymentTransmission systemsRadiation measurementEmergency rescueDose rate

The invention belongs to the technical field of radiation monitoring, and relates to an unmanned aerial vehicle low altitude radiation monitoring system. The radiation monitoring system is mainly composed of three parts of an unmanned aerial vehicle system, a detector pod and a data managing and showing system. The unmanned aerial vehicle system comprises an unmanned aerial vehicle which is used for loading the detector pod. The detector pod comprises a radiation dose rate monitor measuring unit which is used for monitoring the level of the radiation dose rate on accident or incident scenes. The data managing and showing system is used for managing and showing the data monitoring of the detector pod. By utilization of the unmanned aerial vehicle low altitude radiation detection system, the radiation monitoring data and the radioactive contamination distribution situation of the accident (incident) scenes can be quickly obtained, technical supports are provided for emergency decisions and emergency rescues, and the dose of radiation affecting emergency workers can be obviously reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

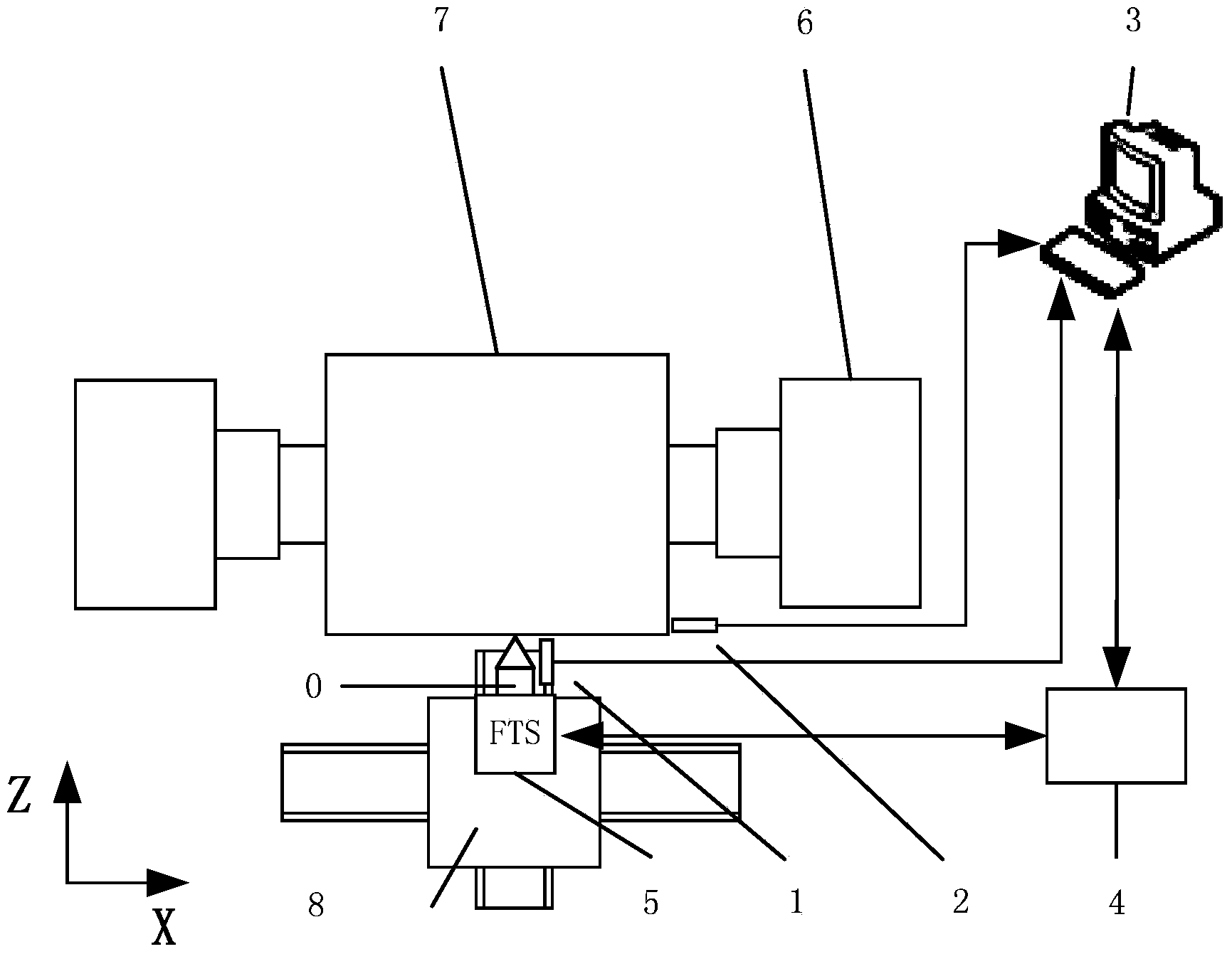

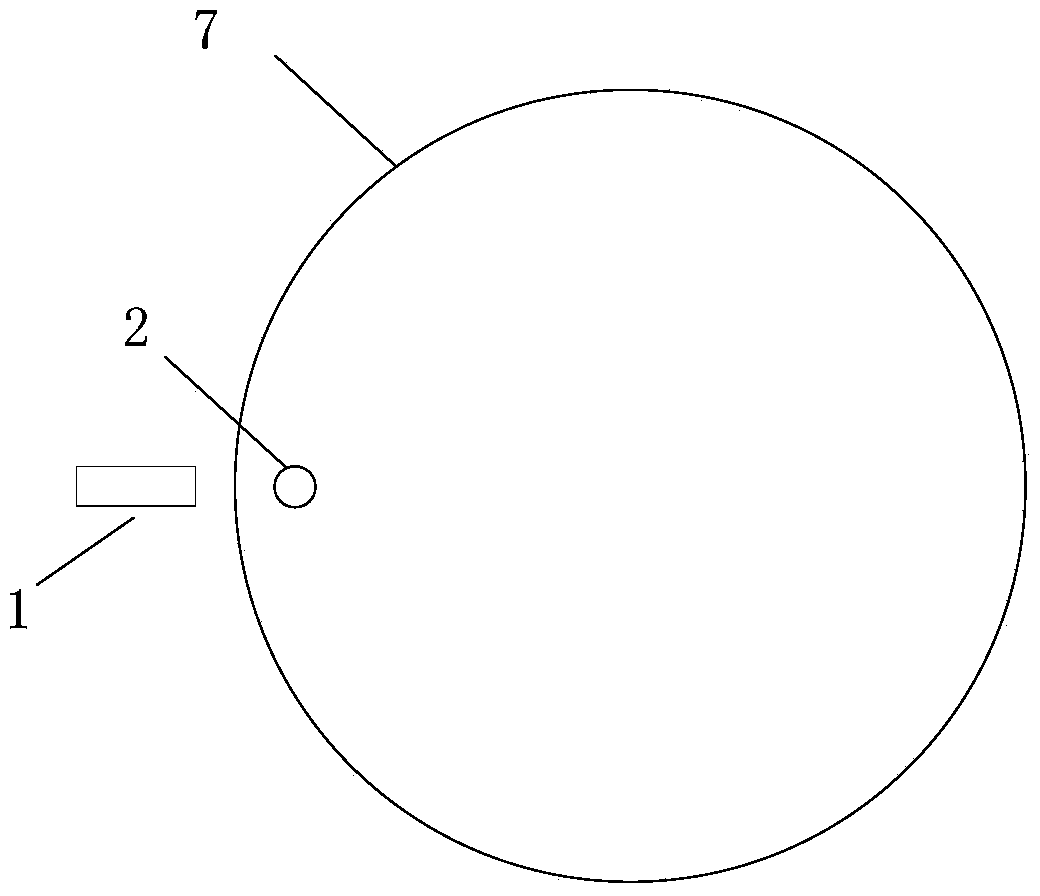

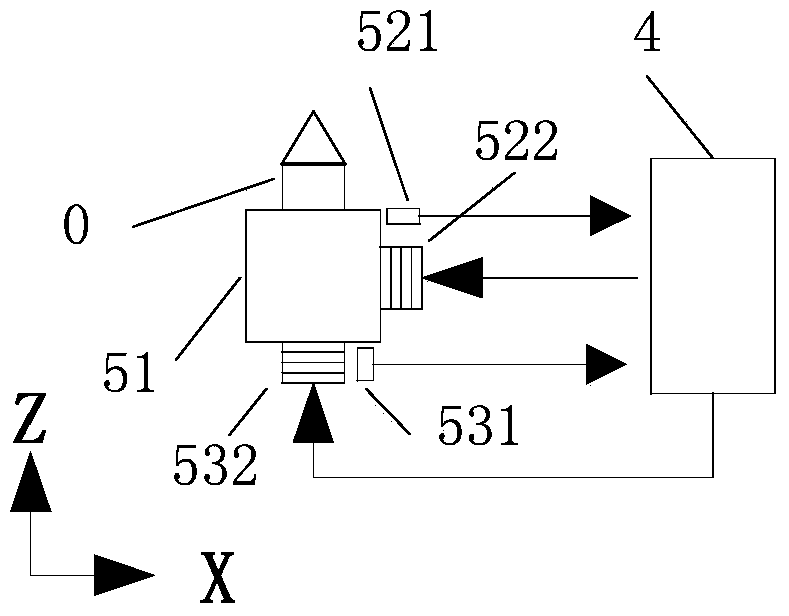

Device and method for compensating composition error of main shaft in real time

InactiveCN104070406AFast measurement and compensationImproving Error Compensation AccuracyMeasurement/indication equipmentsOther manufacturing equipments/toolsTwo degrees of freedomMachine tool

The invention discloses a device and a method for compensating a composition error of a main shaft in real time. The device comprises a radial capacitance displacement sensor, an axial capacitance displacement sensor, a control computer, a two-degree of freedom sharp knife servo controller and a two-degree of freedom sharp knife servo unit, wherein the output end of the radial capacitance displacement sensor is connected with the first input end of the control computer; the output end of the axial capacitance displacement sensor is connected with the second input end of the control computer; the two-degree of freedom sharp knife servo controller is respectively connected with the control computer and the two-degree of freedom sharp knife servo unit; the two-degree of freedom sharp knife servo unit is connected with a processing cuter; the radial capacitance displacement sensor is arranged at one side of the processing cutter, and the axial line thereof is vertically intersected with the axial line of a work-piece; the axial capacitance displacement sensor is arranged on one end face of the work-piece, and the axial line thereof is vertical to the end face of the work-piece. The device and the method for compensating the composition error of the main shaft in real time can perform on-line and real-time measurement and compensation on the composition error simply, rapidly and comprehensively, and can be widely applied to the field of precision machine tool machining.

Owner:GUANGDONG UNIV OF TECH

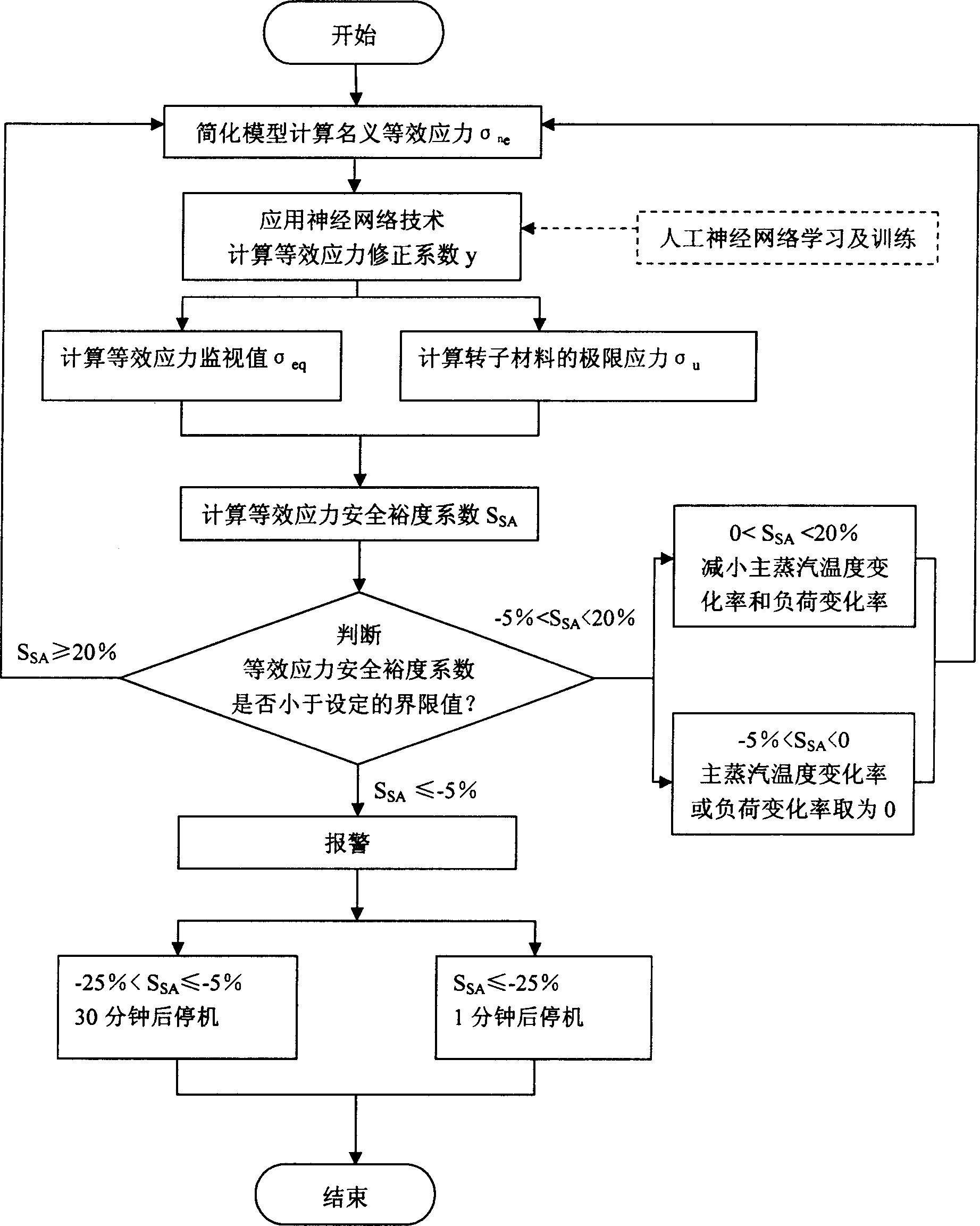

Online controlling method for steam turbine rotator equivalent stress safety margin coefficient

ActiveCN1908382AEffect stress safety margin factor monitoring and controlReduces low cycle fatigue life damageMachines/enginesSafety/regulatory devicesSafety marginEngineering

The invention relates to an online detecting method on the equivalent stress safe allowance factor of the rotor of turbine, wherein it is characterized in that: it uses artificial nerve network technique to realize the online real-time calculation and online real-time detection and control on said factor; if said factor is lower than preset value, it can control the temperature change rate of main steam, and the load change rate to improve the factor and prolong the service life. If the factor reaches the alarm value, it will alarm, and stop in preset time. The invention can realize quick and accurate online real-time calculation, detection and control.

Owner:SHANGHAI POWER EQUIP RES INST

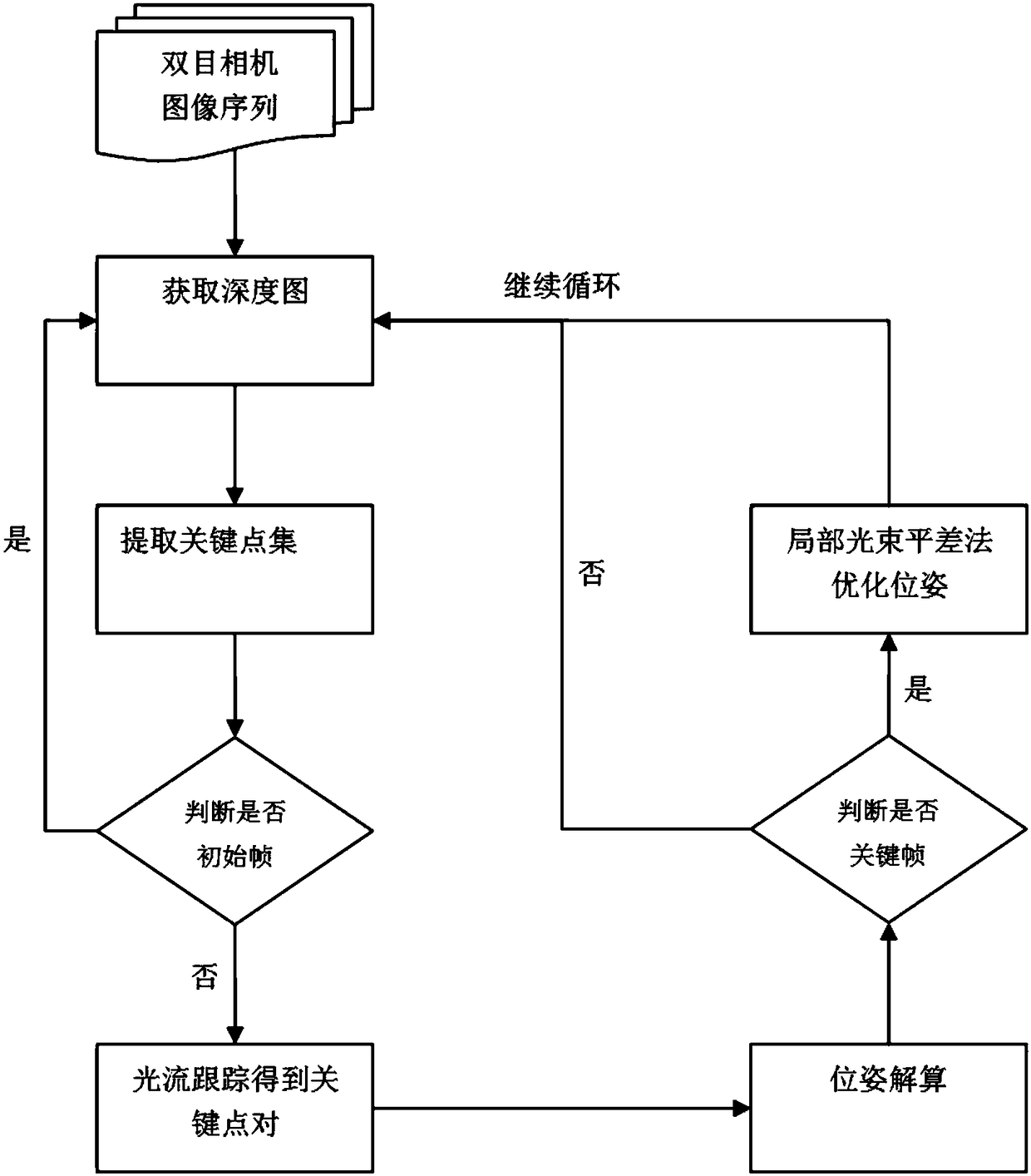

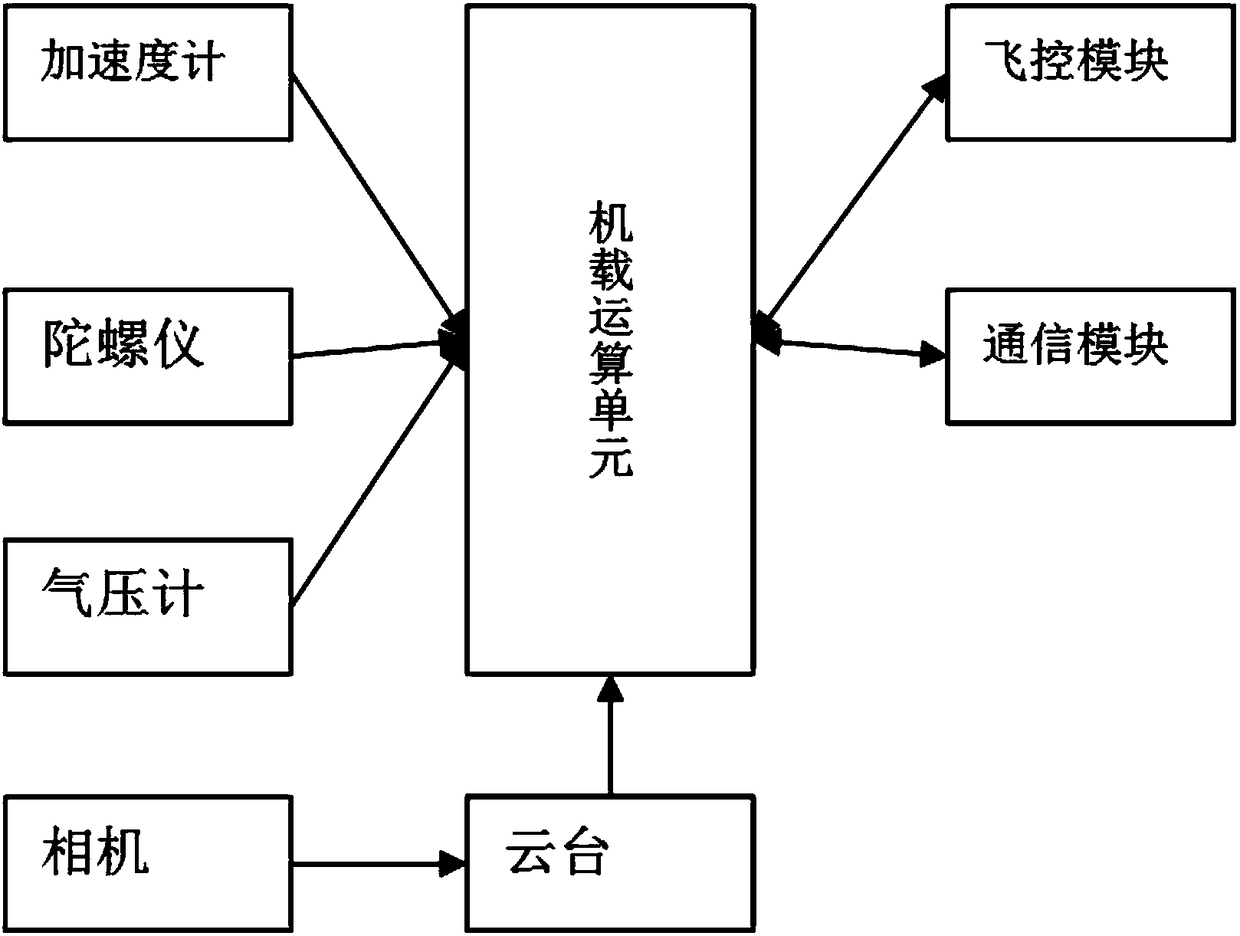

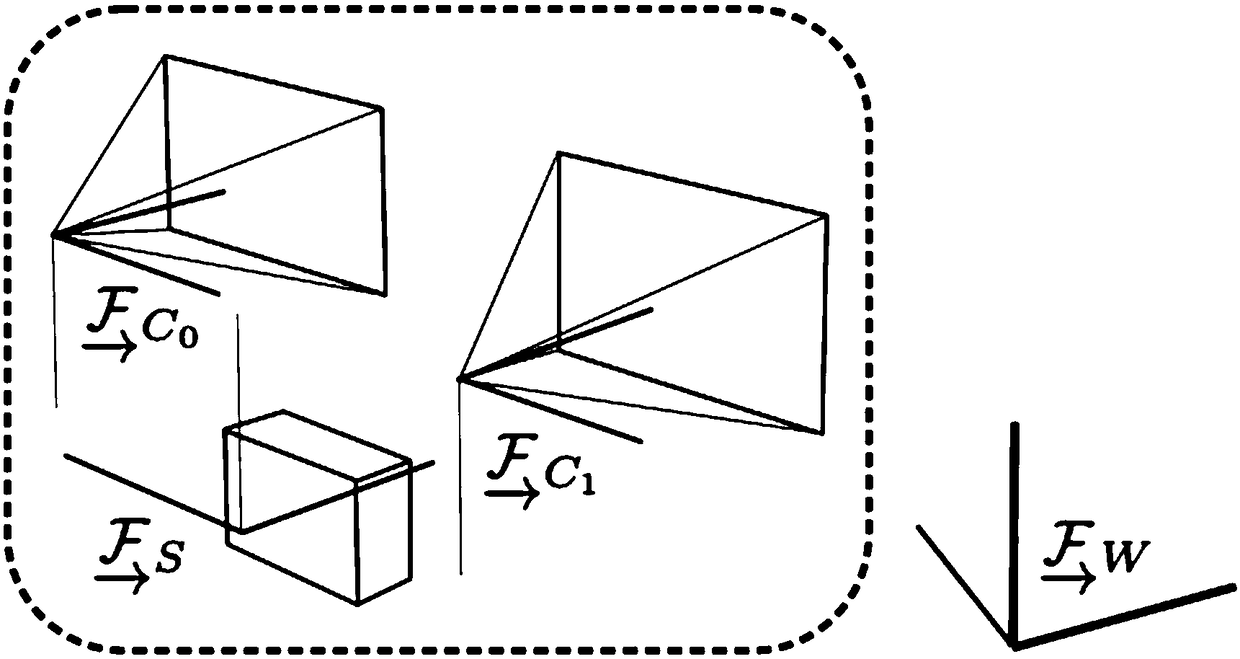

Binocular vision-based unmanned aerial vehicle positioning and navigating method

ActiveCN108520559AImprove the problem that the target depth cannot be accurately estimatedHigh precisionImage data processingControl systemUncrewed vehicle

The invention discloses a binocular vision-based unmanned aerial vehicle positioning and navigating method. The method comprises the steps that an image left-right view and a camera parameter can be obtained based on a binocular camera of an unmanned airborne control system, and obtain a corrected left-right view, and further obtain the depth information of the corresponding pixel; the key pointsof the left view are extracted to be filtered and screened; a matched key point set is found through optical flow tracking in the current frame, and a matched key point pair is obtained; a final poseresult is obtained according to the matched key point pair calculation cost function; finally, the input continuous image frames are screened to obtain a key image frame, and a combined cost functionis calculated for the key point set and the pose of the key image frame, and the cost function can be optimized and solved to obtain a updated pose. According to the method, the reliable depth data can be quickly obtained through the binocular camera; meanwhile, the matching relation is quickly calculated by utilizing the optical flow method; the real-time performance is high, the algorithm robustness is high, and the unmanned aerial vehicle positioning and navigation work can be completed under the indoor and outdoor large and medium scenes.

Owner:西安因诺航空科技有限公司

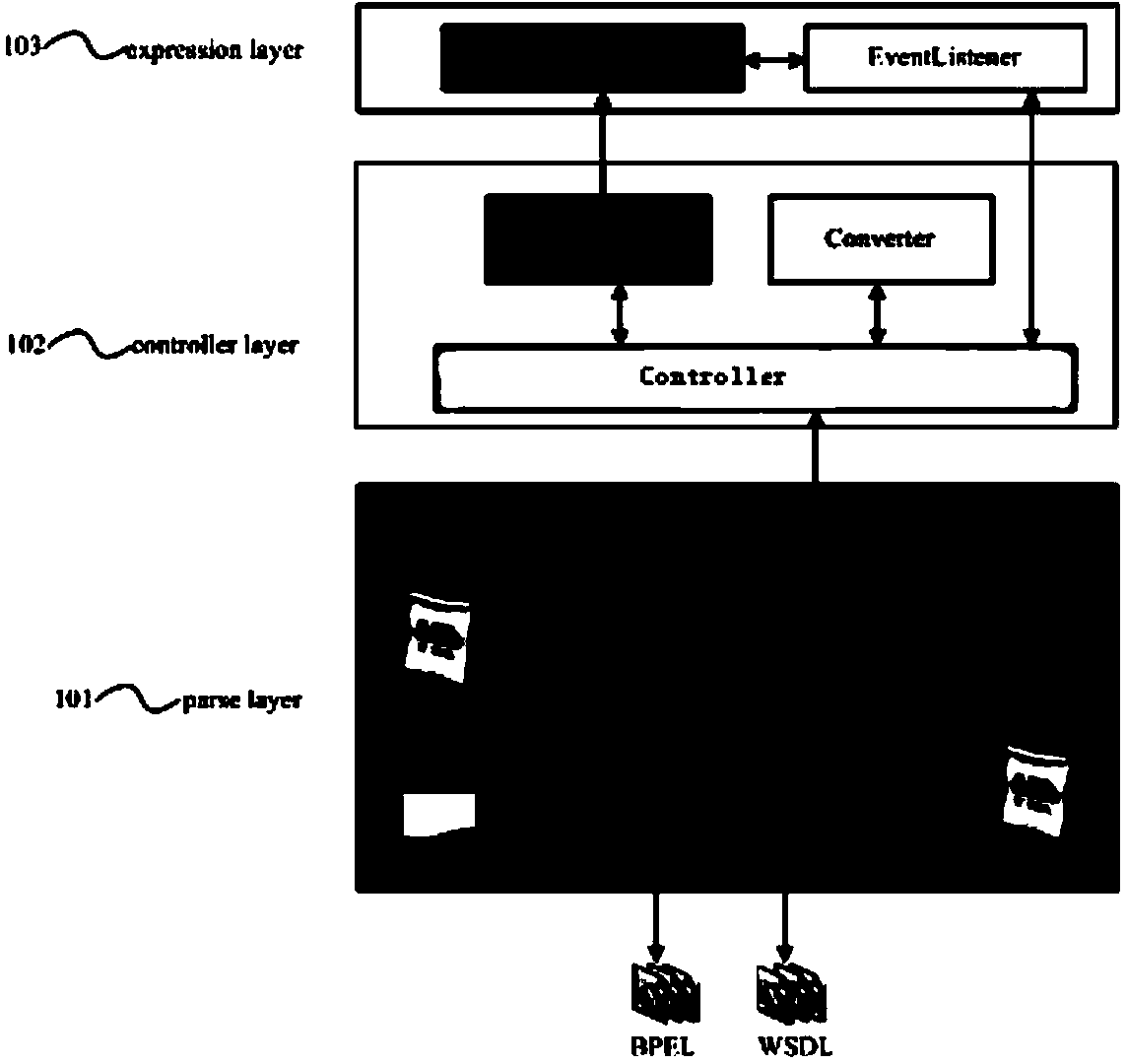

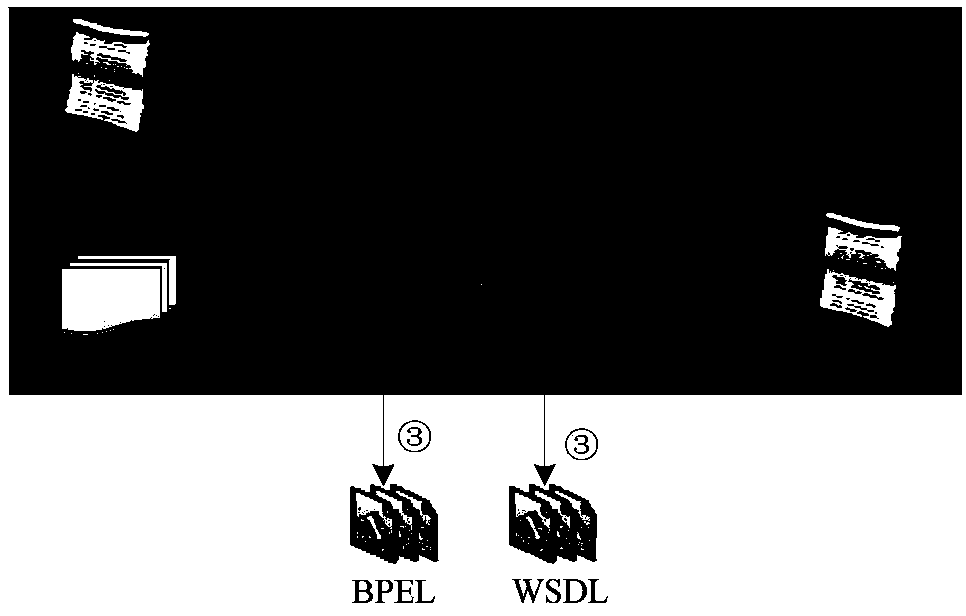

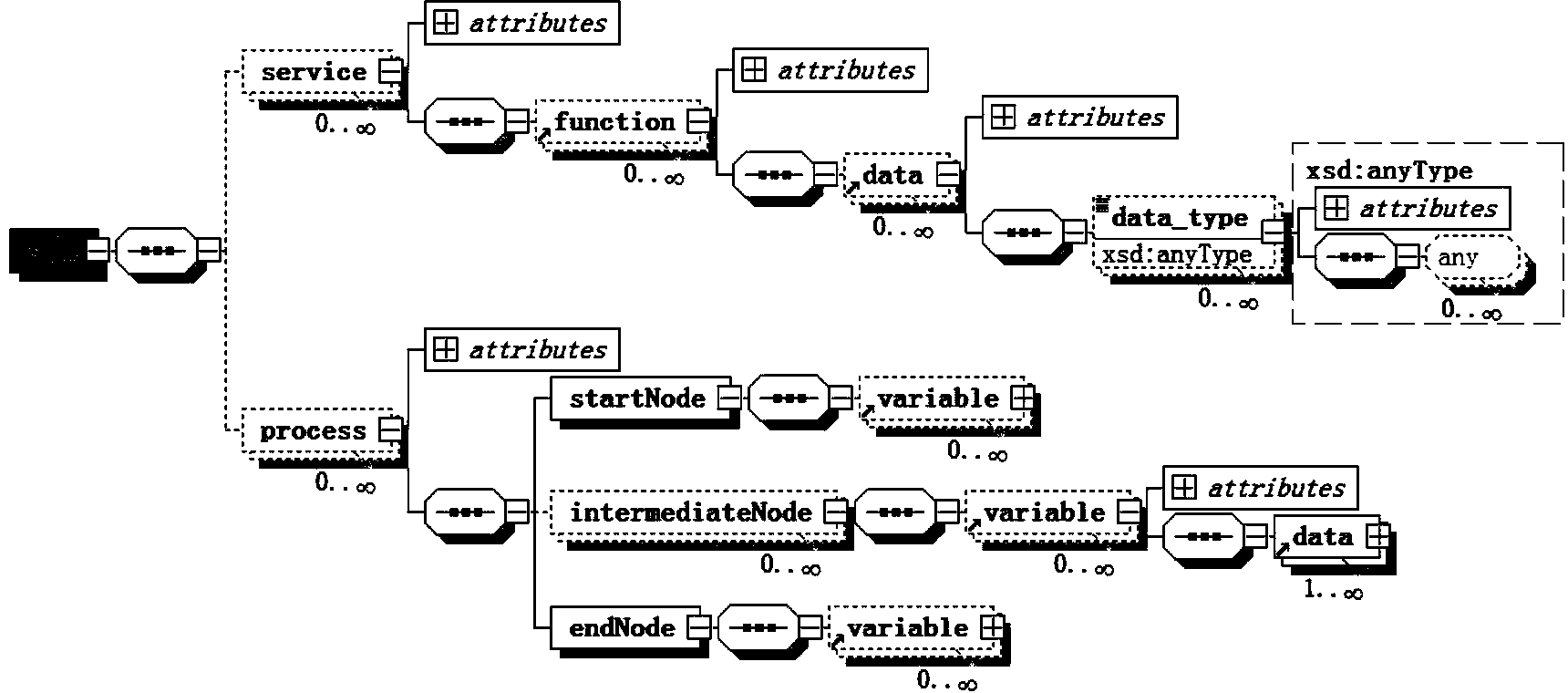

Web service data modeling and searching method based on SDD (service data description)

InactiveCN103390018AFast readFast real-timeSpecial data processing applicationsWeb serviceData description

The invention provides a web service data modeling and searching method based on SDD (service data description), which comprises the steps of I, establishing a web service data model based on the SDD, wherein the model is divided into a parse layer, a controller layer and an expression layer; and II, providing the web service data searching method described in the specification based on the model.

Owner:杭州医好网络科技有限公司

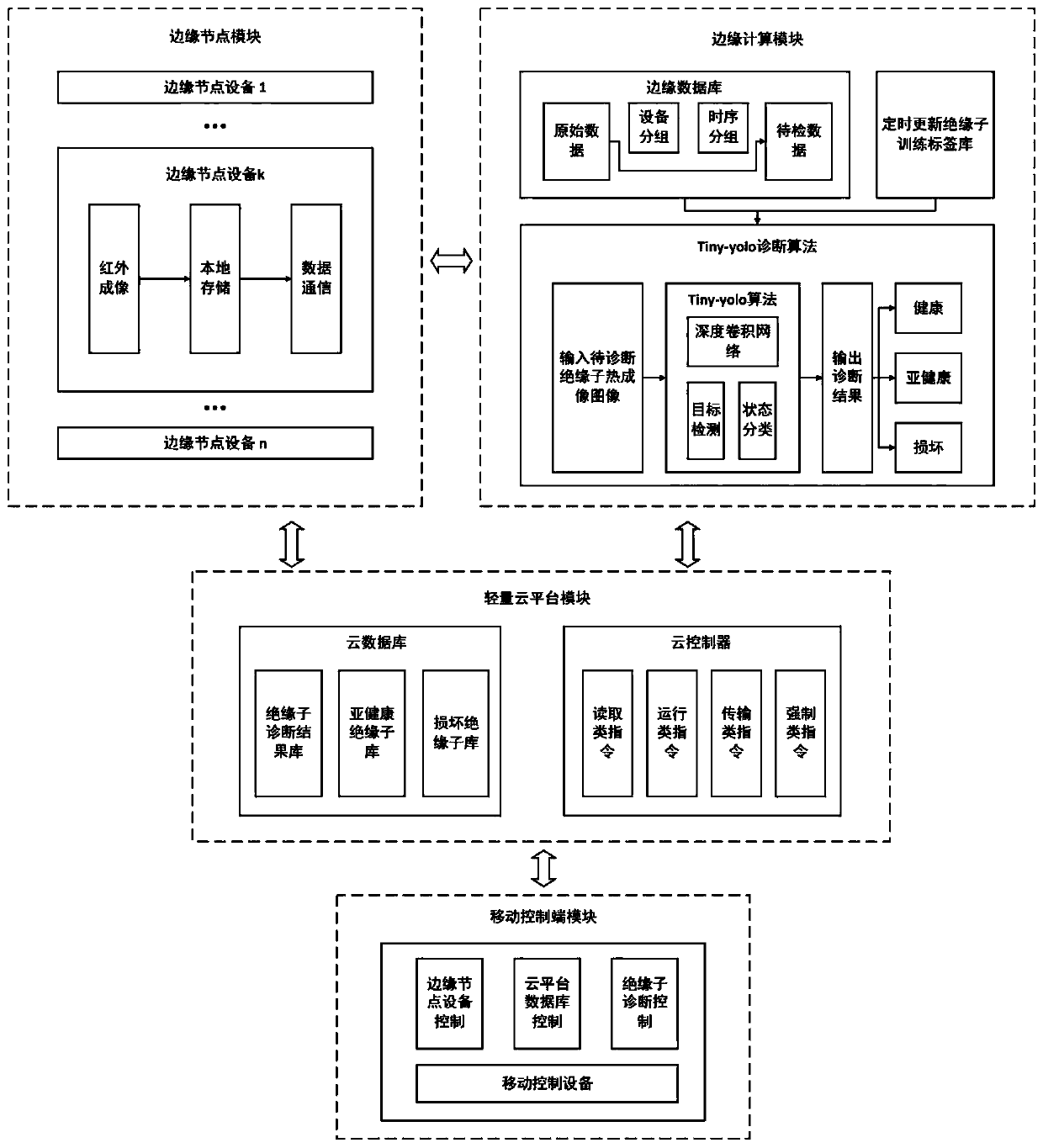

The invention discloses an insulator thermal imaging real-time diagnosis system based on edge calculation

ActiveCN109828845APay attention to sub-health statusReduce the burden onImage analysisResource allocationTime responseEdge computing

The invention discloses an insulator thermal imaging real-time diagnosis system based on edge calculation. The insulator thermal imaging real-time diagnosis system comprises an edge node module, an edge calculation module, a light-weight cloud platform module and a mobile control end module. The system is high in practicability, the edge node module provides a data source for the insulator diagnosis system, the edge calculation module provides a main data storage and calculation function, the light-weight cloud platform module provides a communication and storage function for the insulator diagnosis system, and the mobile control end module mainly performs control operation on each module. The system is high in innovativeness, the edge operation is applied to the field of insulator diagnosis for the first time, so that the burden of a cloud center is reduced, quick real-time response is realized, a thermal imaging picture is adopted as a diagnosis basis, the diagnosis scientificity isensured, an advanced deep learning algorithm is packaged, and the diagnosis accuracy is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

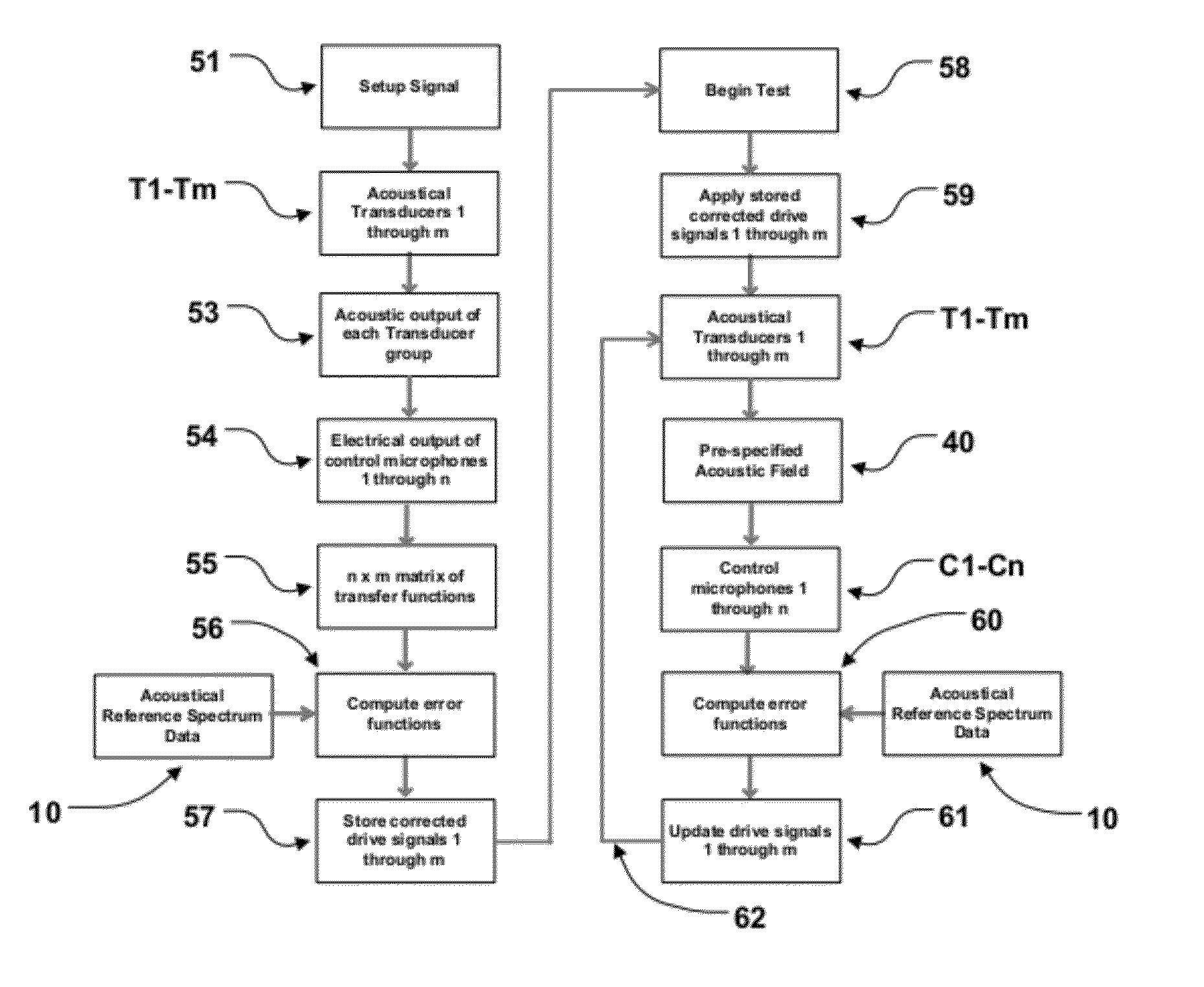

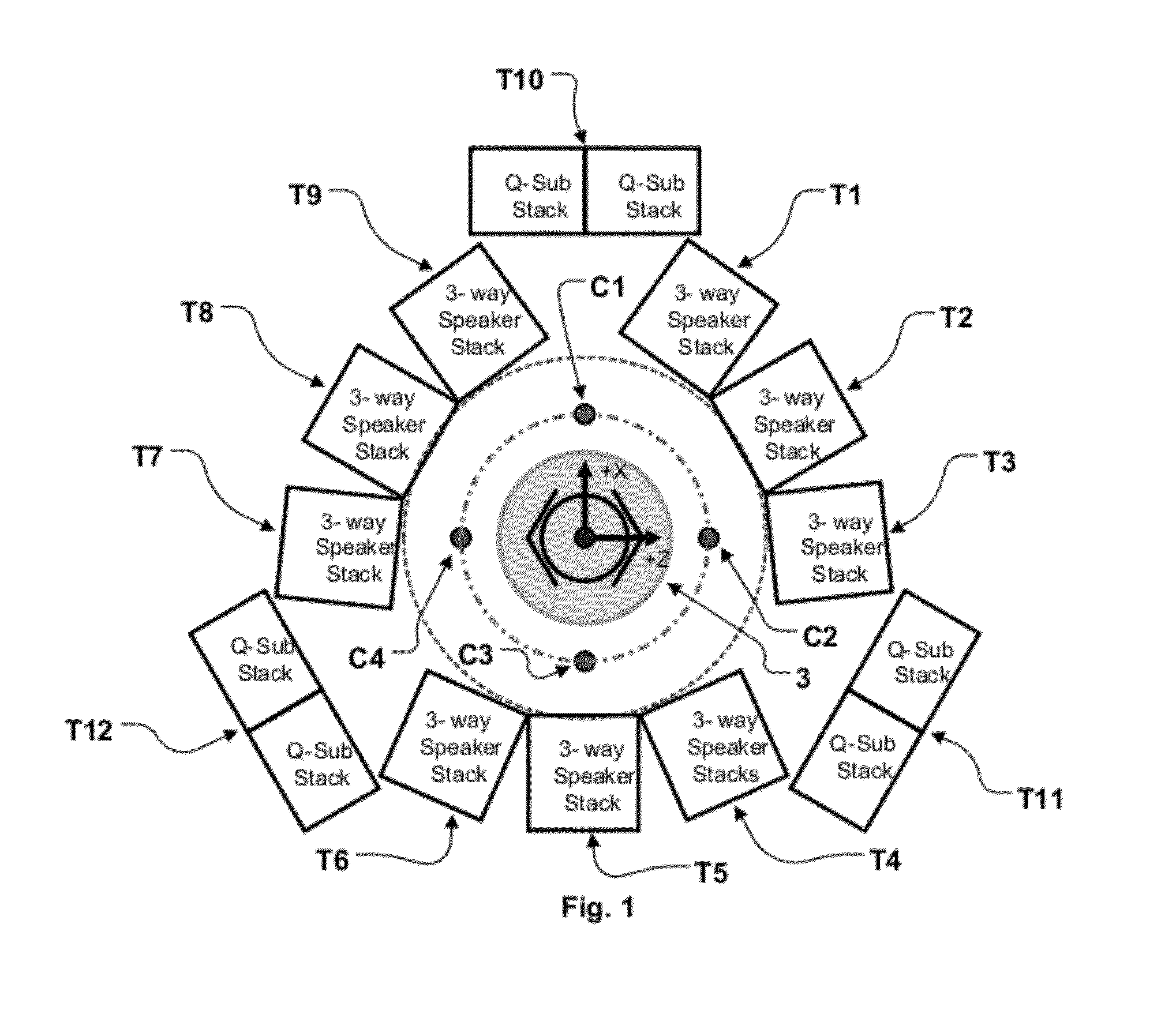

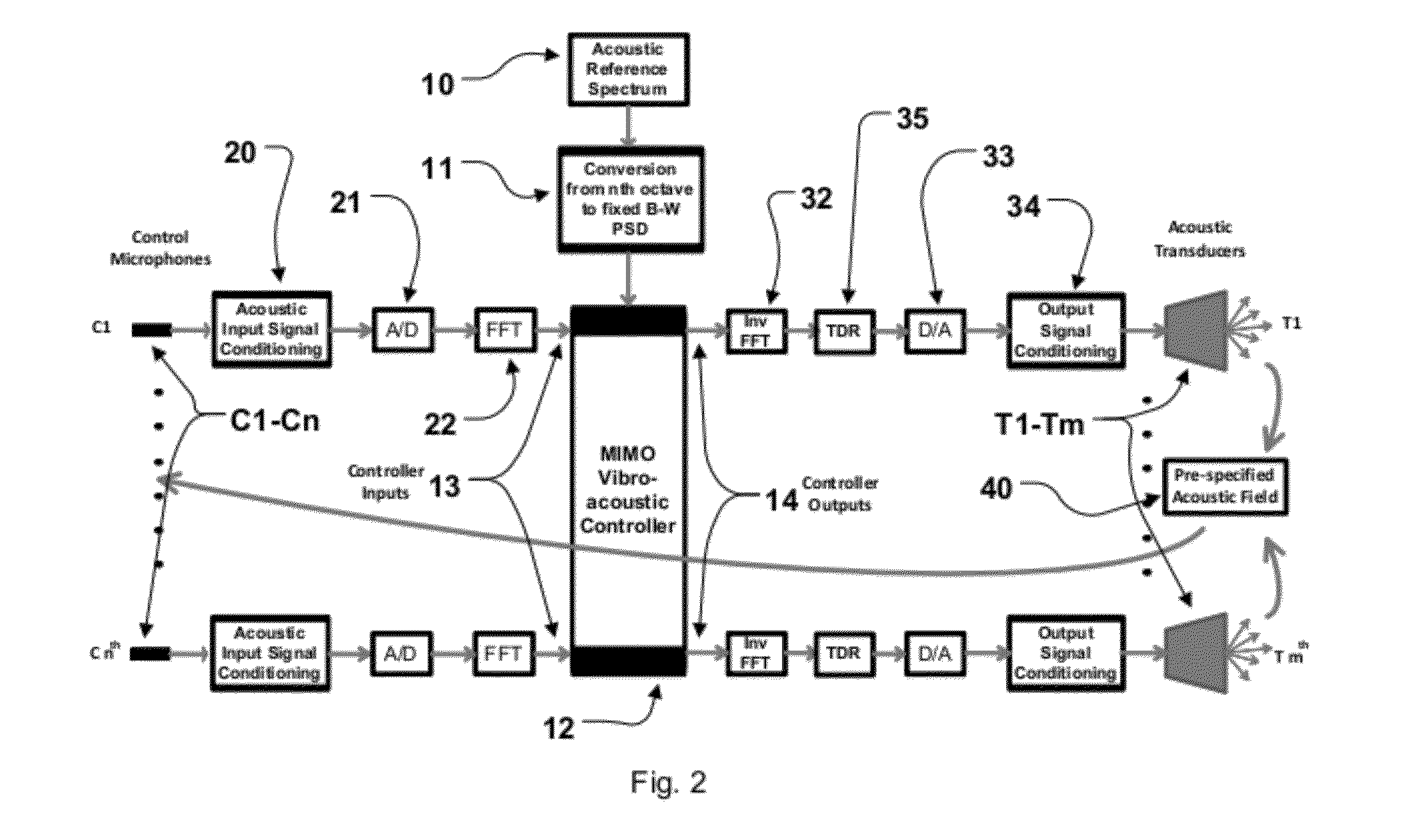

Direct field acoustic testing system, controls, and method

ActiveUS20120300580A1Faster real time updateIncrease speedAnalysing solids using sonic/ultrasonic/infrasonic wavesTransmission monitoringTransducerEngineering

A direct field acoustic testing system includes at least one control microphone, a controller operatively coupled to the control microphone such that the controller receives at least one input signal from the control microphone, and at least four acoustic transducer groups operatively coupled to the controller such that each transducer is separately controllable by the controller such that a separate output signal is received by each transducer from the controller. A setup signal is applied to each of the acoustical transducers. The acoustic output of each of the acoustical transducers is monitored using the at least one control microphone. Assumptions regarding the relationship between the acoustic fields measured by the control microphones are made to enable the controller to reduce the number of calculations needed to compute error functions and corrected drive signals to be applied to the acoustic transducer groups.

Owner:UNDERWOOD MARCOS

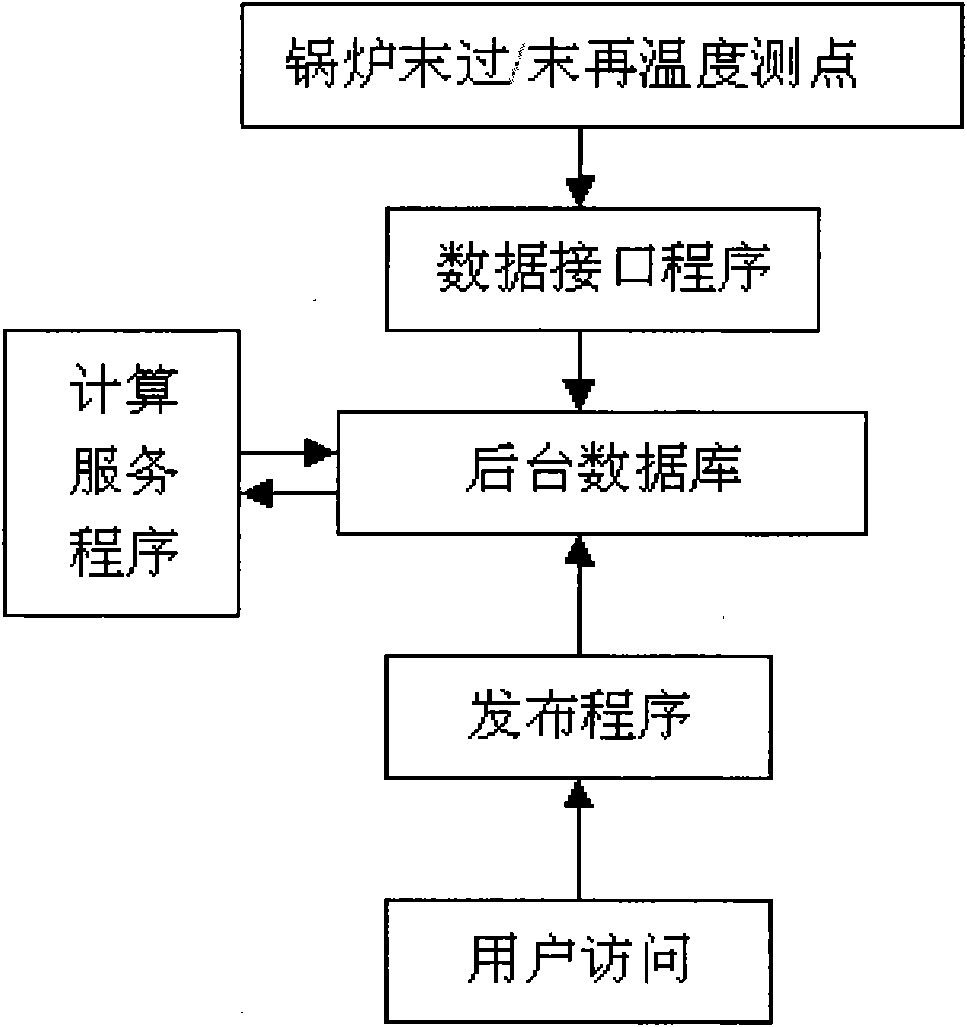

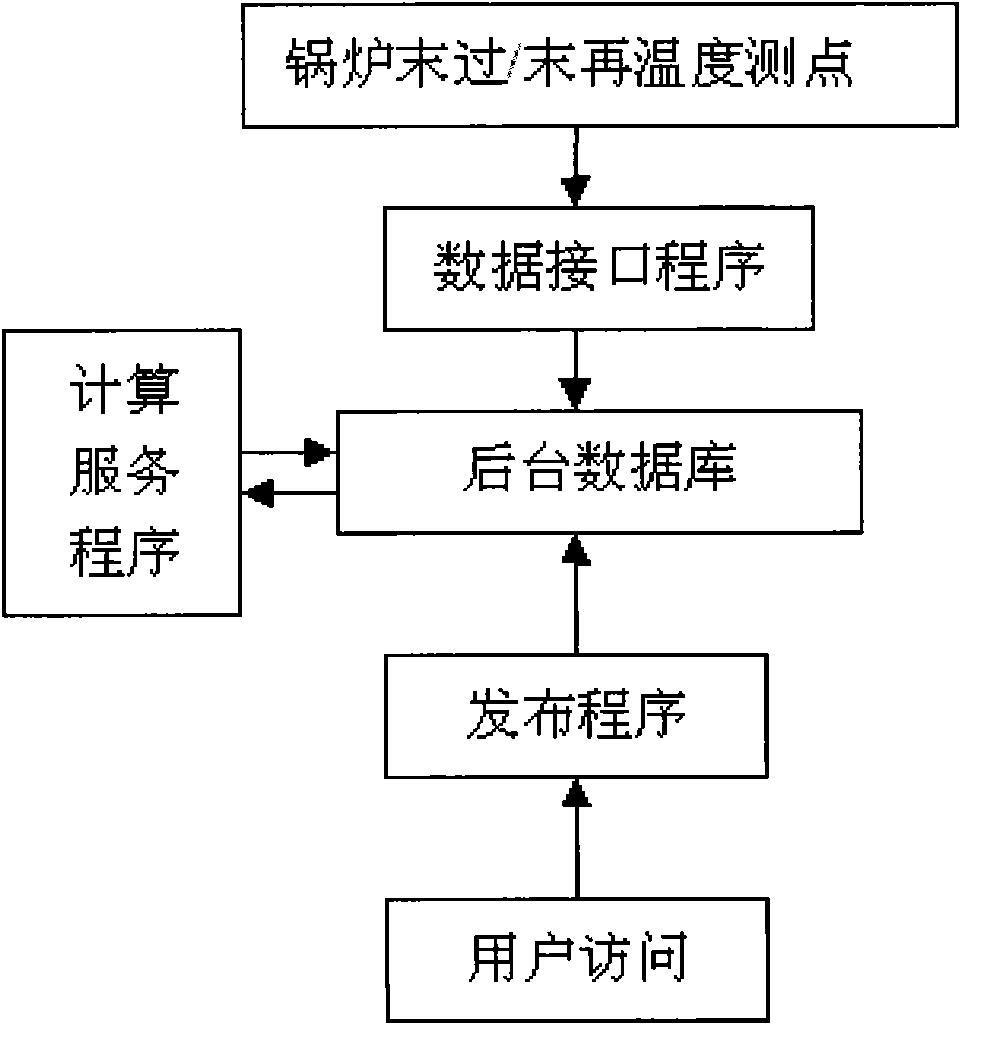

Method for online monitoring thermal deviations of final superheater and final reheater of boiler of power station

ActiveCN101832544AOnline Monitoring Monitoring and ControlRealize online real-time computingBoiler controlPower stationSuperheater

The invention provides a method for online monitoring thermal deviations of a final superheater and a final reheater of a boiler of a power station. The method comprises the following steps of: firstly, building an online monitoring device, then reading online detection data, calculating the thermal deviation of each screen and each tube according to the read online detection data, and storing and displaying the result. The invention has the advantages of realizing the fast online real-time calculation and the online monitoring and controlling of the thermal deviations of the final superheater and the final reheater of the boiler, realizing the safety operation of the final superheater and the final reheater of the boiler within the service period and prolonging the service life of the final superheater and the final reheater of the boiler.

Owner:SHANGHAI POWER EQUIP RES INST +1

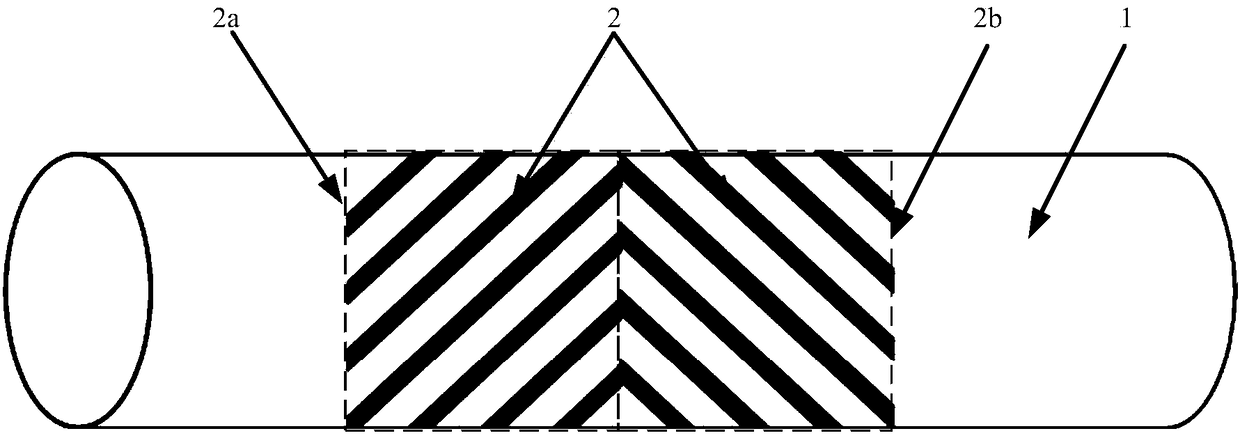

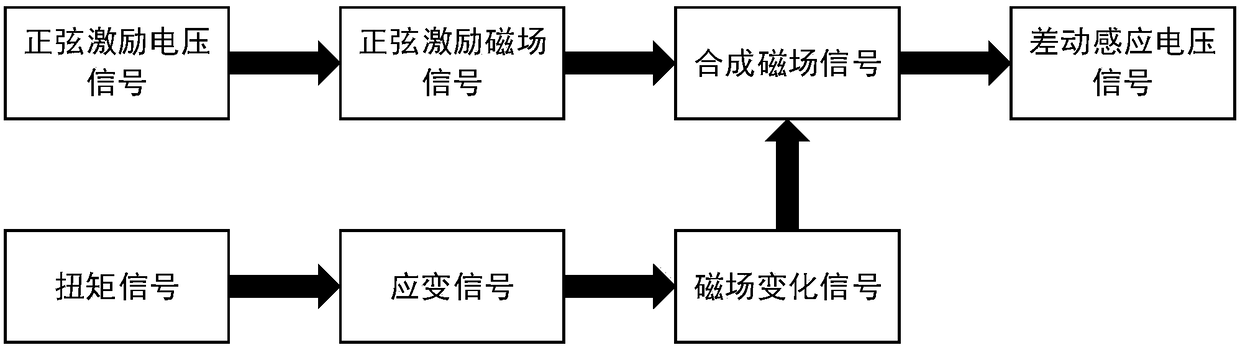

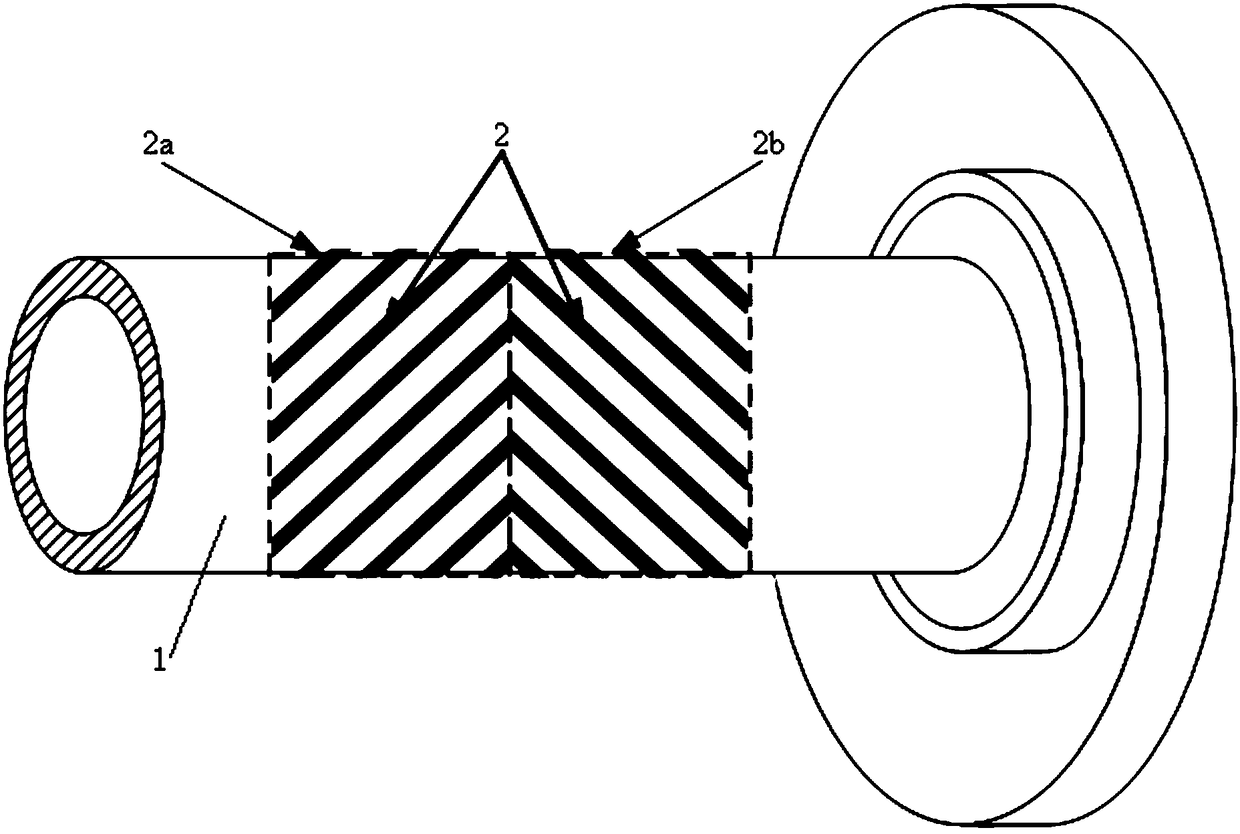

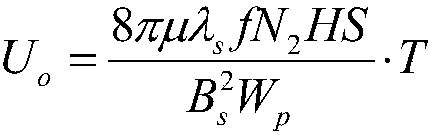

Non-contact torque measurement device based on counter-magnetostrictive effect

InactiveCN108562388ASimple measuring principleImprove accuracyWork measurementTorque measurementInverse magnetostrictive effectMeasurement device

The invention discloses a non-contact torque measurement device based on a counter-magnetostrictive effect and belongs to sensor measurement technologies. According to technical key points, a measuredrotating shaft is coated with giant magnetostrictive material coating strips, the giant magnetostrictive material coating strips are divided into positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips; the positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips obliquely coat the measured rotating shaft in an axial direction at equal intervals in a bilateral symmetry manner; left and right ends of the measured rotating shaft are respectively nested into inner holes of a left bearing and a right bearing; the left bearing and the right bearing are respectively nested into the left and right ends of a shaft sleeve; an exciting coil is assembled onto the inner wall of the shaft sleeve; a left measuring coil and a right measuring coil of the same specification are assembled in parallel on the inner walls of the exciting coil in the axial direction. According to the measurement device disclosed by the invention, the torque is dynamically measured in real time at high accuracy and high precision without being in contact with a transmission shaft or changing a stress state of the transmission shaft and under rotary and dynamic operating conditions.

Owner:HARBIN INST OF TECH

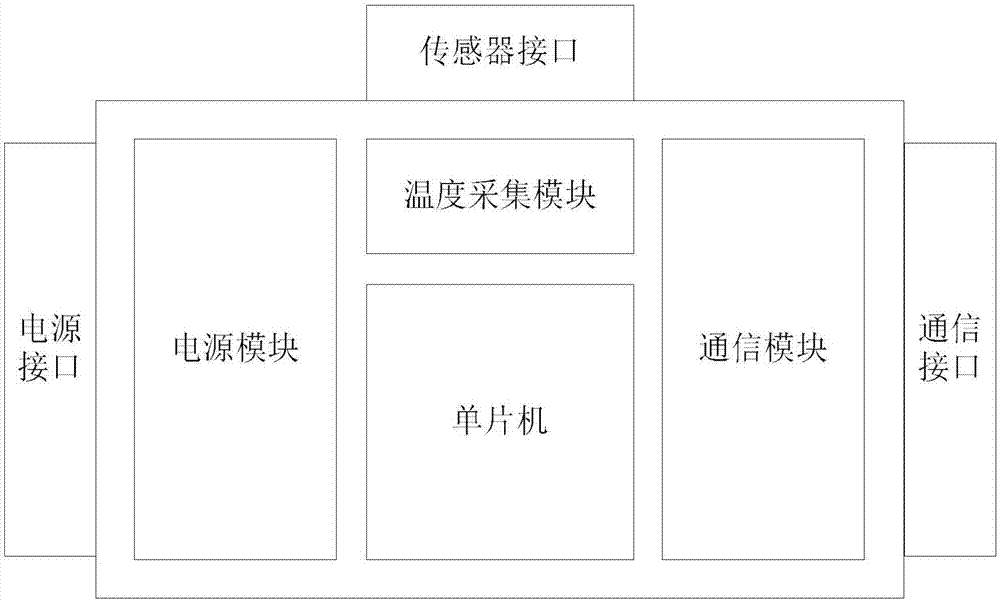

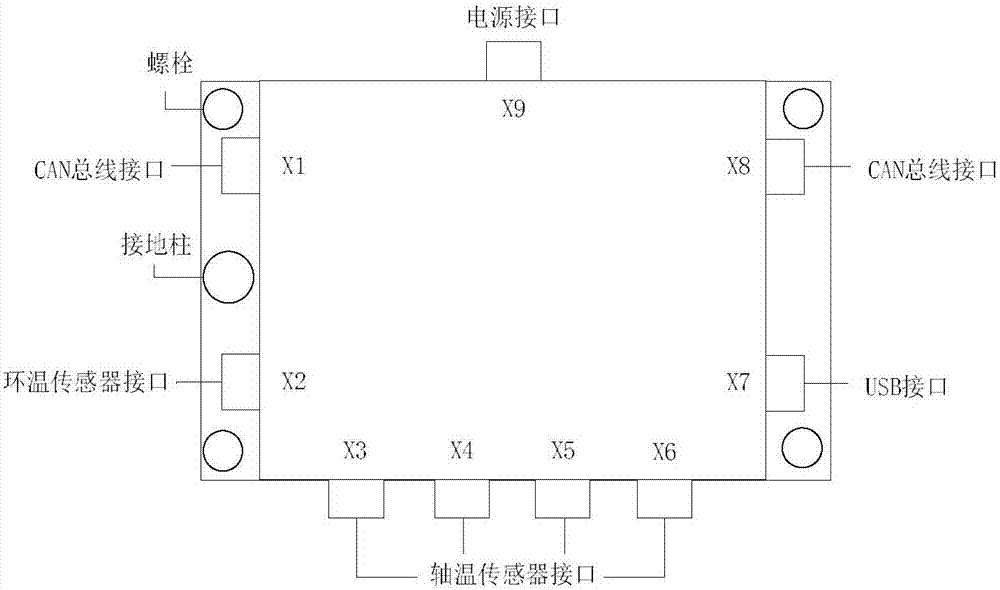

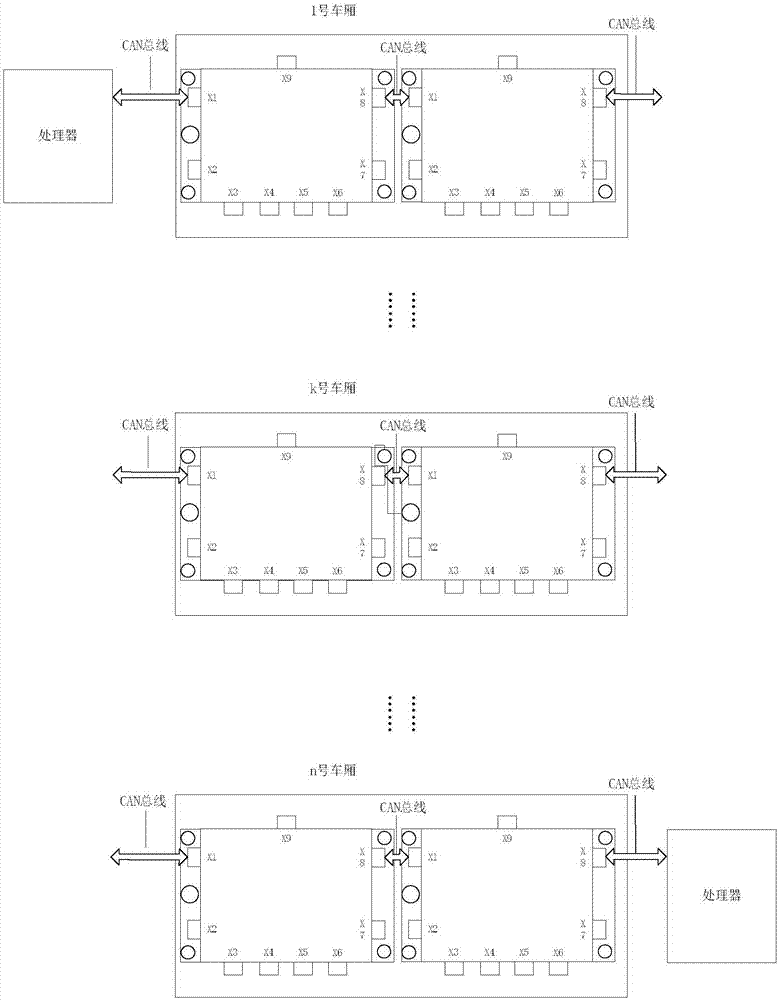

Low-power-consumption axle bearing temperature detecting device for locomotive

InactiveCN107054405AReduce power consumptionEasy wiringRailway auxillary equipmentRailway profile gaugesMicrocontrollerEngineering

The invention discloses a low-power-consumption axle bearing temperature detecting device for a locomotive, comprising a power supply module, a communication module, a temperature collecting module, a microcontroller and a shielding box. The low-power-consumption axle bearing temperature detecting device collects the temperature from four axle bearing temperature sensors and an ambient temperature sensor connected therewith, and sends temperature data to an upper level processor at regular intervals. In addition, four different alarm modes can be chosen to process the temperature data, and if alarm conditions are met, a corresponding alarm code is sent to the upper level processor. The low-power-consumption axle bearing temperature detecting device for the locomotive provided by the invention has the characteristics of simple structure, wide measuring range, high measuring precision, fast response speed, low power consumption and good reliability.

Owner:SOUTHEAST UNIV

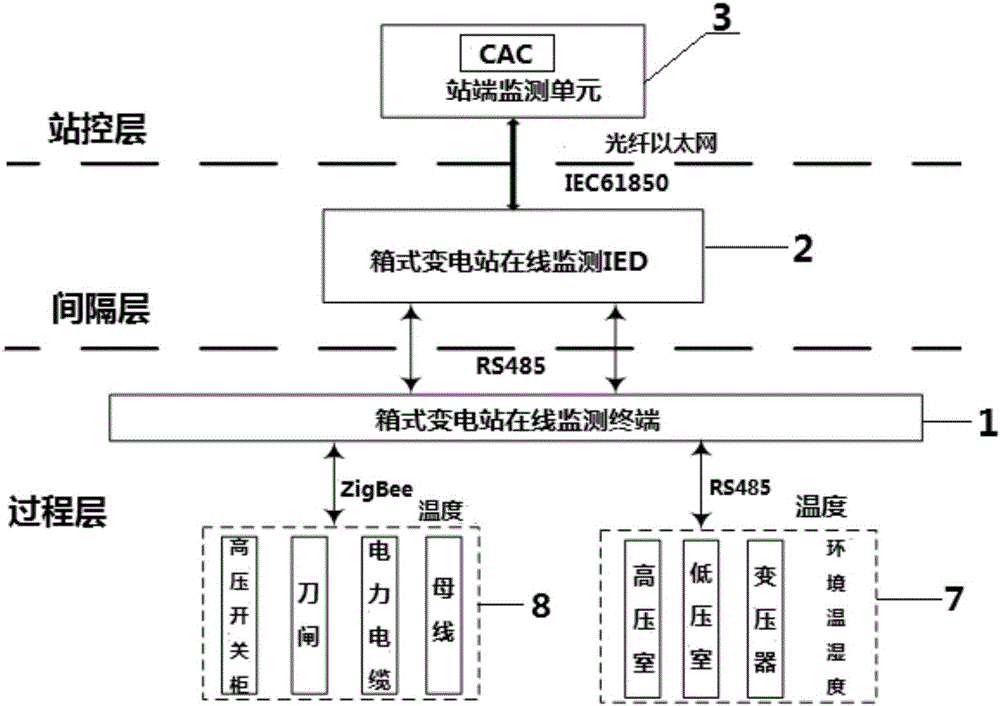

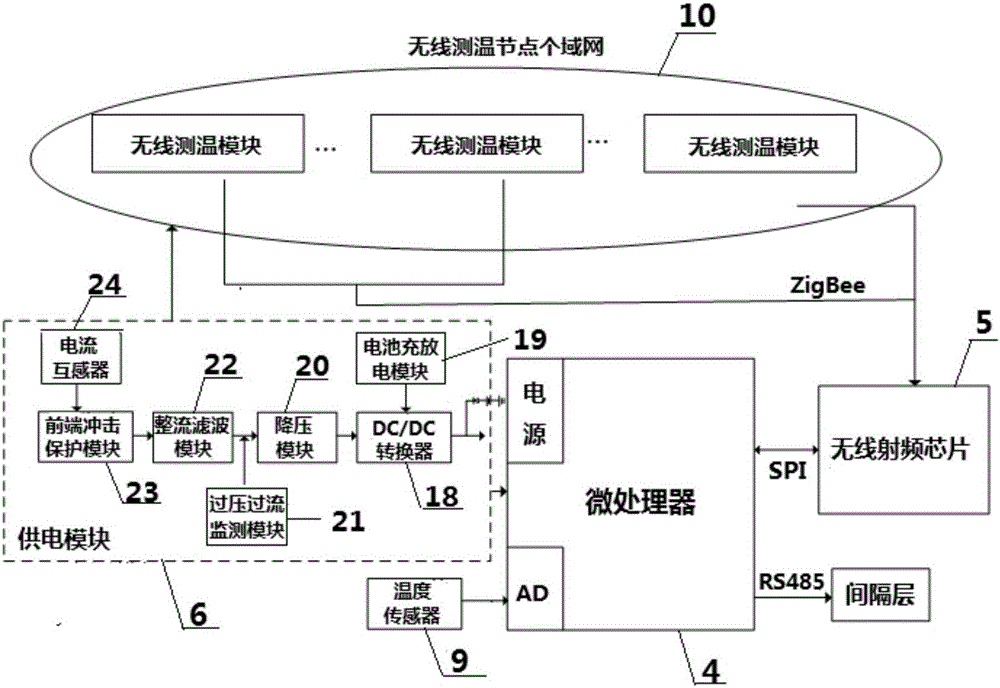

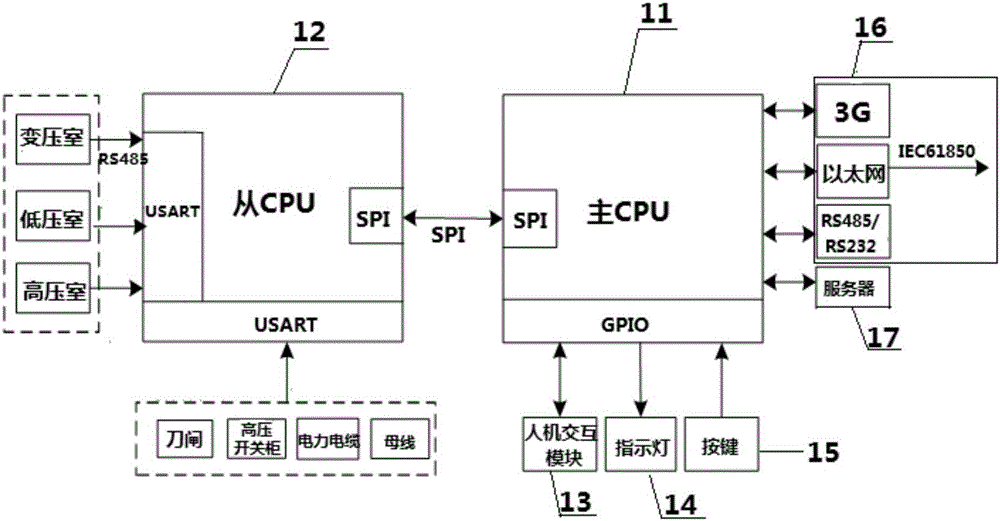

Box type transformer station current-carrying fault prediction system and application thereof

ActiveCN106059086AEfficient handlingEfficient and real-timeCircuit arrangementsInformation technology support systemControl layerTransformer

The invention discloses a box type transformer station current-carrying fault prediction system. The system comprises a process layer, an interval layer and a station control layer, wherein the process layer is internally provided with a box type transformer station online monitoring terminal, the box type transformer station online monitoring terminal is connected with a wired temperature measurement module temperature measurement point, and the box type transformer station online monitoring terminal is also connected with a wireless temperature measure module temperature measurement point through a wireless personal area network; the interval layer is internally provided with a box type transformer station online monitoring IED, and the box type transformer station online monitoring IED is connected with the box type transformer station online monitoring terminal; and the station control layer is internally provided with a station end monitoring unit, and the station end monitoring unit is connected with the box type transformer station online monitoring IED. The invention further discloses an application method of a box type transformer station current-carrying fault prediction system. The box type transformer station current-carrying fault prediction system and the application thereof can monitor temperature change of contacts in an online mode and can also accurately position contacts with faults or hidden risks.

Owner:西安金源电气股份有限公司

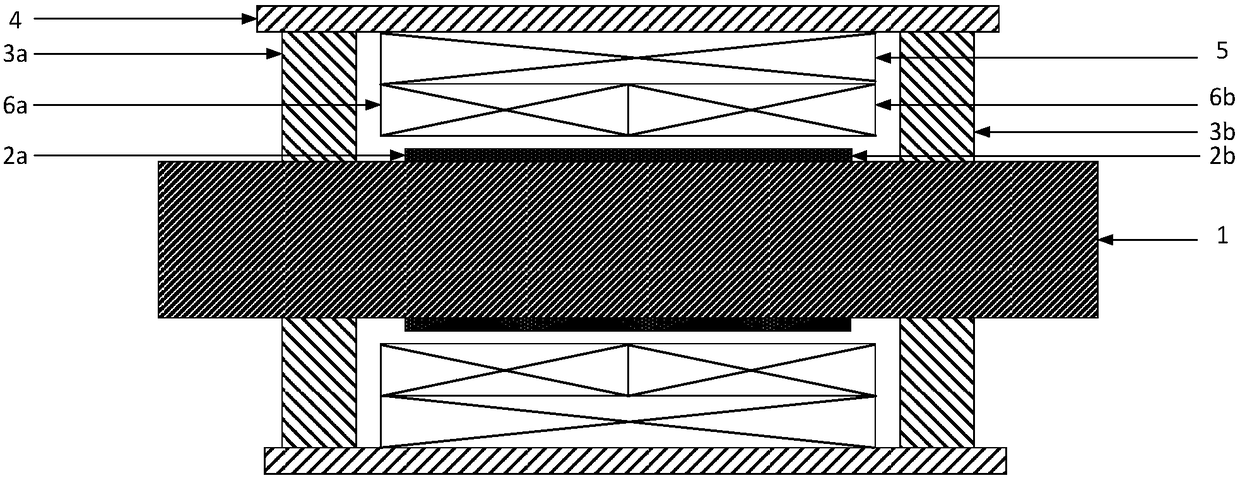

Non-contact robot joint torque measuring device based on inverse magnetostrictive effect

InactiveCN108548622ASimple measuring principleImprove accuracyWork measurementTorque measurementInverse magnetostrictive effectMeasurement device

The invention relates to a non-contact robot joint torque measuring device based on the inverse magnetostrictive effect and belongs to the sensing measurement technology of robot robotic arm precisioncontrol. The measuring device is characterized in that an output shaft of the robot joint torque is coated with giant magnetostrictive material coating strips, the giant magnetostrictive material coating strips comprise positive giant magnetostrictive material coating strips and negative giant magnetostrictive material coating strips, the positive giant magnetostrictive material coating strips and the negative giant magnetostrictive material coating strips are obliquely coated on the output shaft at equal intervals along the axial direction symmetrically left and right, a sleeve is sleeved onthe output shaft on the outer side of the giant magnetostrictive material coating strips, an excitation coil is mounted on an inner wall of the sleeve, and left and right measuring coils in the samespecification are mounted side by side on the inner wall of the excitation coil in the axial direction. The measuring device is advantaged in that high-accuracy high-precision real-time dynamic measurement of the torque is carried out without touching a driving shaft and without changing the force condition of the driving shaft and rotary and dynamic working conditions, and thereby precise controlon robot arms is realized.

Owner:HARBIN INST OF TECH

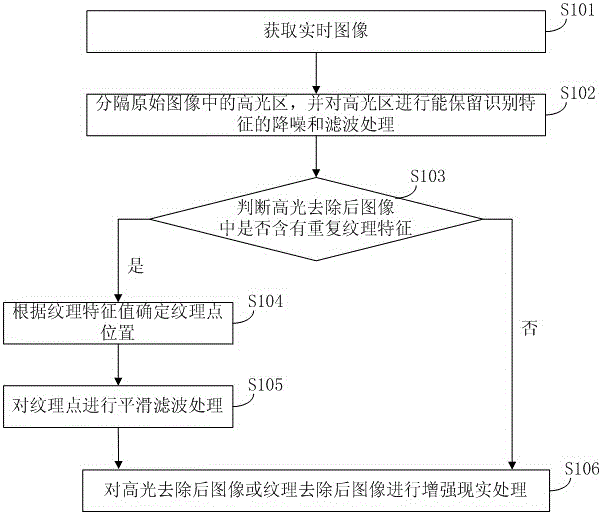

Augmented reality method for elimination of highlight and repeated texture, and creep pad application

ActiveCN106327438AKeep the core feature pointsFast matchingImage enhancementImage analysisPattern recognitionImaging processing

The invention discloses an augmented reality method for the elimination of highlight and repeated texture and a creep pad application, and belongs to the technical field of augmented reality. The method comprises the steps: obtaining a real-time image; separating a highlight region in an original image, and carrying out the noise reduction and filtering processing, which can keep the recognition features, of the highlight region; judging whether the image comprise the repeated texture features or not after the highlight elimination; determining the position of a texture point according to the texture features if there are the repeated texture features; carrying out the smooth filtering of the texture point; and carrying out the augmented reality processing of the image after texture elimination. The creep pad application comprises a creep pad, a camera, an image processing module, an augmented reality module, and a mobile terminal. The method is high in matching speed, is small in number of errors, and is low in resolution. Moreover, the creep pad application can improve the playability and education performances.

Owner:WUHAN AR SHOW SOFTWARE CO LTD

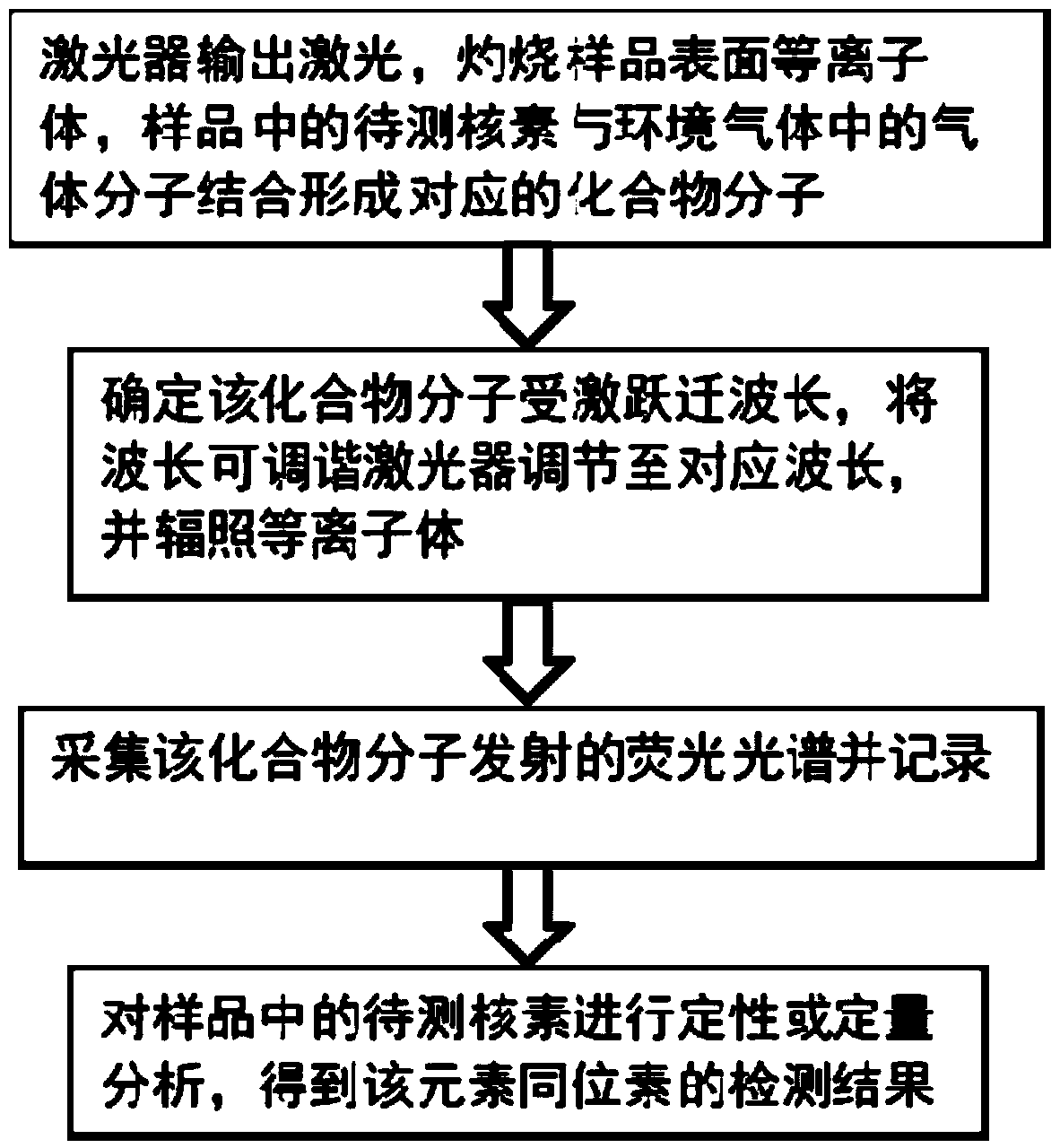

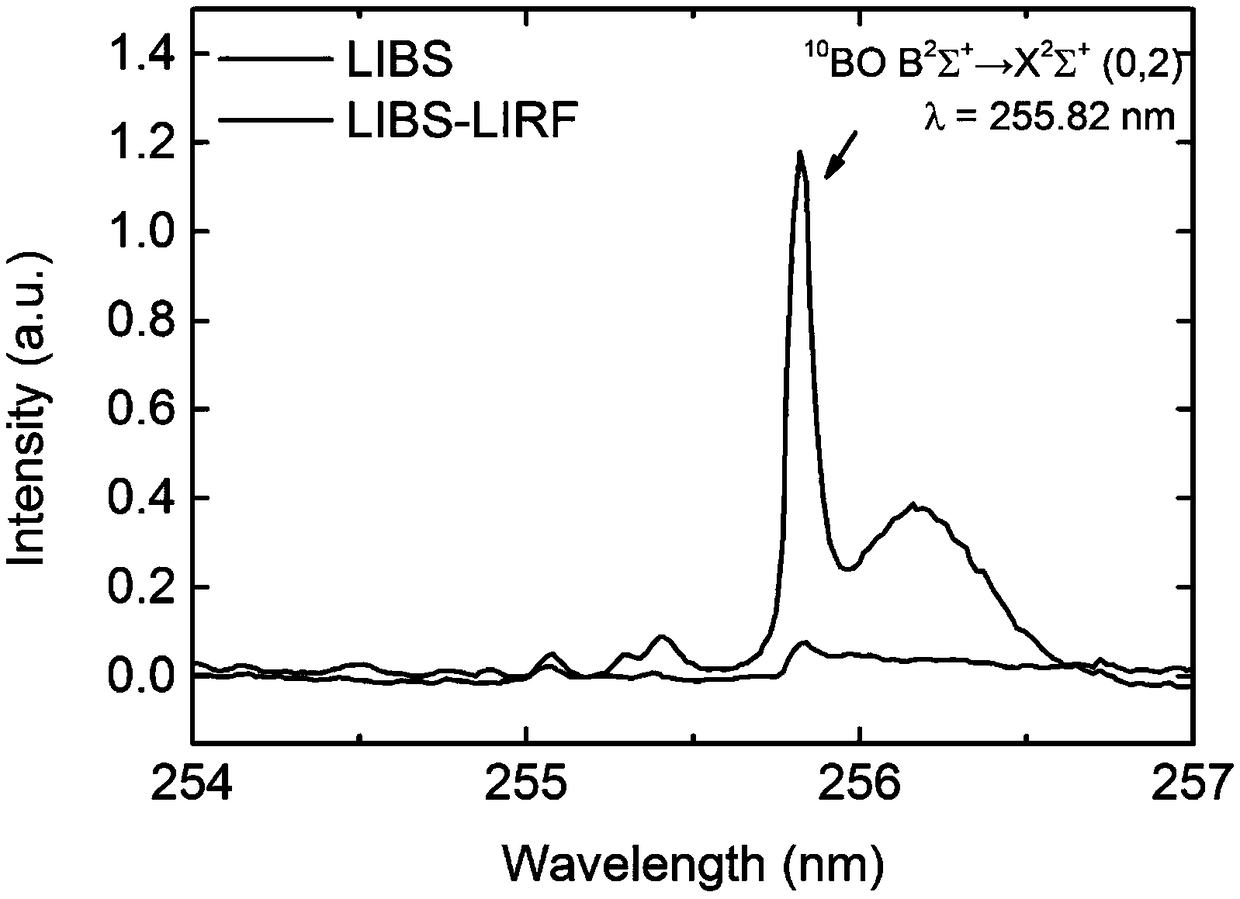

Laser probe molecular resonance excitation detection method for isotopes

ActiveCN108872161AHigh precisionLarge spectral line wavelength intervalFluorescence/phosphorescenceLaser probeSpectroscopy

The invention discloses a laser probe molecular resonance excitation detection method for isotopes and belongs to the field of laser plasma emission spectroscopy. The method comprises the following steps: adopting laser for ablating a sample and generating corresponding compound molecules through the reaction between to-be-detected nuclides in the sample and gas molecules in environment gas; adjusting a wavelength tunable laser to the wavelength required by stimulated transition of electrons of the molecules, outputting laser and irradiating the plasma; triggering radiative transition of the electrons in the molecules, emitting fluorescent light, collecting the emitted fluorescence spectrum and recording, and performing qualitative or quantitative analysis on the to-be-detected nuclides. According to the method, spectral peak signals of the to-be-detected nuclides in the compound molecule are specifically enhanced under the condition that the matrix spectrum is almost not influenced, and the interference of other nuclides can be effectively eliminated, so that the quick and accurate detection of the isotopes through a laser probe can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

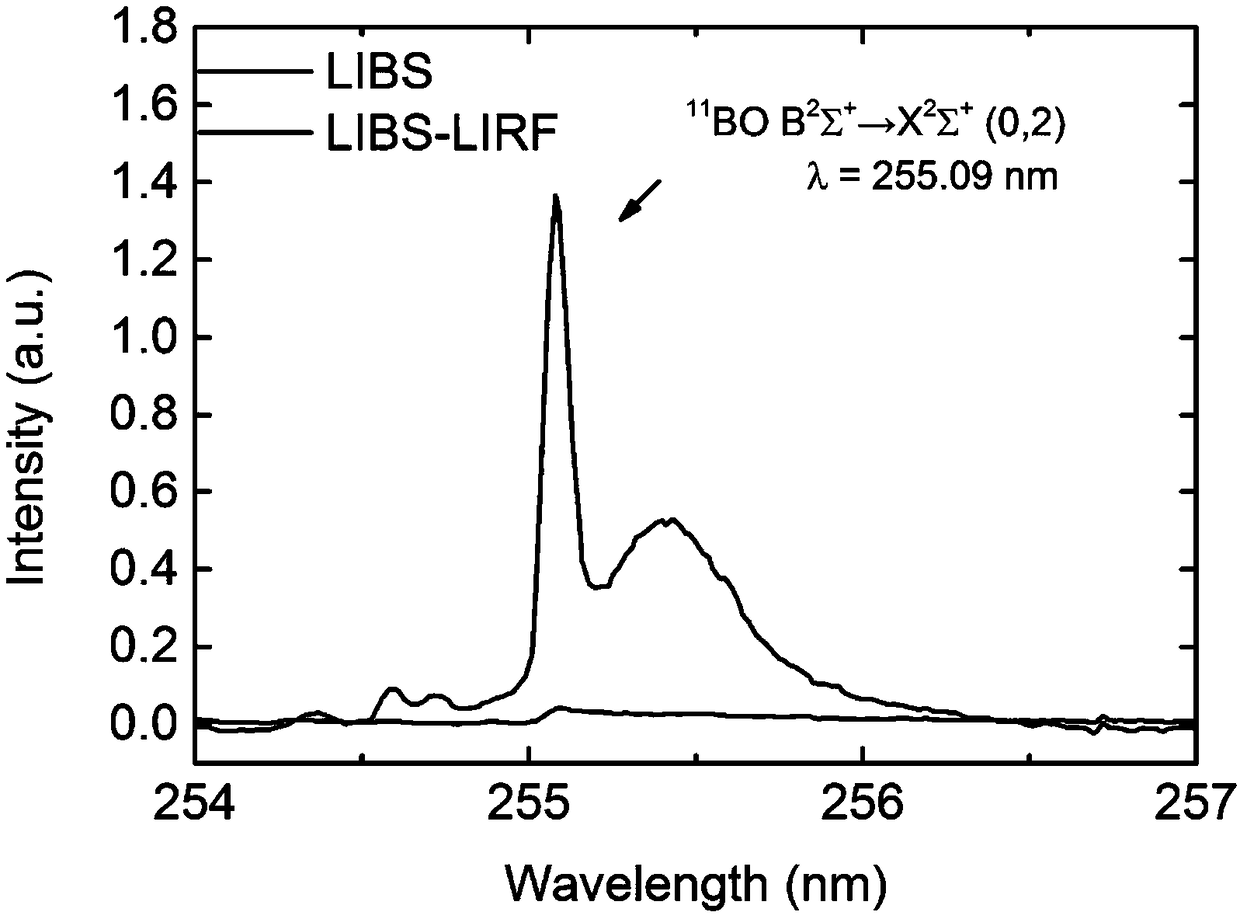

Method for judging polymerization reaction condition at initial production stage of polyethylene process

The present invention relates to an initial stage polymerization reaction condition of a polymer resin, and particularly to a method for judging a polymerization reaction condition at an initial production stage of a polyethylene process. The technical scheme of the present invention is that: with the method for judging the polymerization reaction condition at the initial production stage of the polyethylene process, the polyethylene process adopts a chromium catalyst, a gas chromatography method is adopted to detect light olefin in fluidized bed reactor circulation gas to judge whether the chromium catalyst initiates the polymerization reaction, and the production speed of the light olefin is adopted to judge the intensity degree of the polymerization reaction initiated by the chromium catalyst. With the present invention, the rapid detection and the real time monitoring of the polymerization reaction initiation condition at the initial production stage of the polyethylene process can be achieved, wherein the polymerization reaction is initiated by the chromium catalyst; the reaction process can be accurately predicted, the addition amount of the catalyst can be adjusted timely, the production safety can be ensured, and the polymerization accident caused by excessive initiation can be prevented, or the large waste of nitrogen and ethylene can be prevented, wherein the large waste of the nitrogen and the ethylene is caused by no initiation of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP

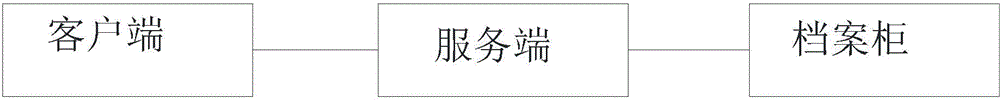

Document management device and method based on RFID technology

InactiveCN105469174APrevent openingImprove securityCo-operative working arrangementsResourcesClient-sideDocumentation

The invention provides a document management device and method based on RFID technology. The device comprises clients, a server, RFID tags and file cabinets. The clients are used for realizing remote search of documents; the server is used for managing the clients and the file cabinets and is connected with the clients and the file cabinets; the RFID tags are used for differentiating different documents; the file cabinets are used for storing the documents; the more than two clients are connected with the server; and controllers in the more than two file cabinets are connected with the server. The beneficial effects are that the document management device has high safety, high positioning precision and quick reaction capability, has an automatic access function and a reminding function, and is capable of fast searching, positioning and checking the documents; and the file cabinet and document management device based on RFID technology for realizing document safety and rapid management are realized.

Owner:TIANJIN GAOSIEN SCI & TECH DEV CO LTD

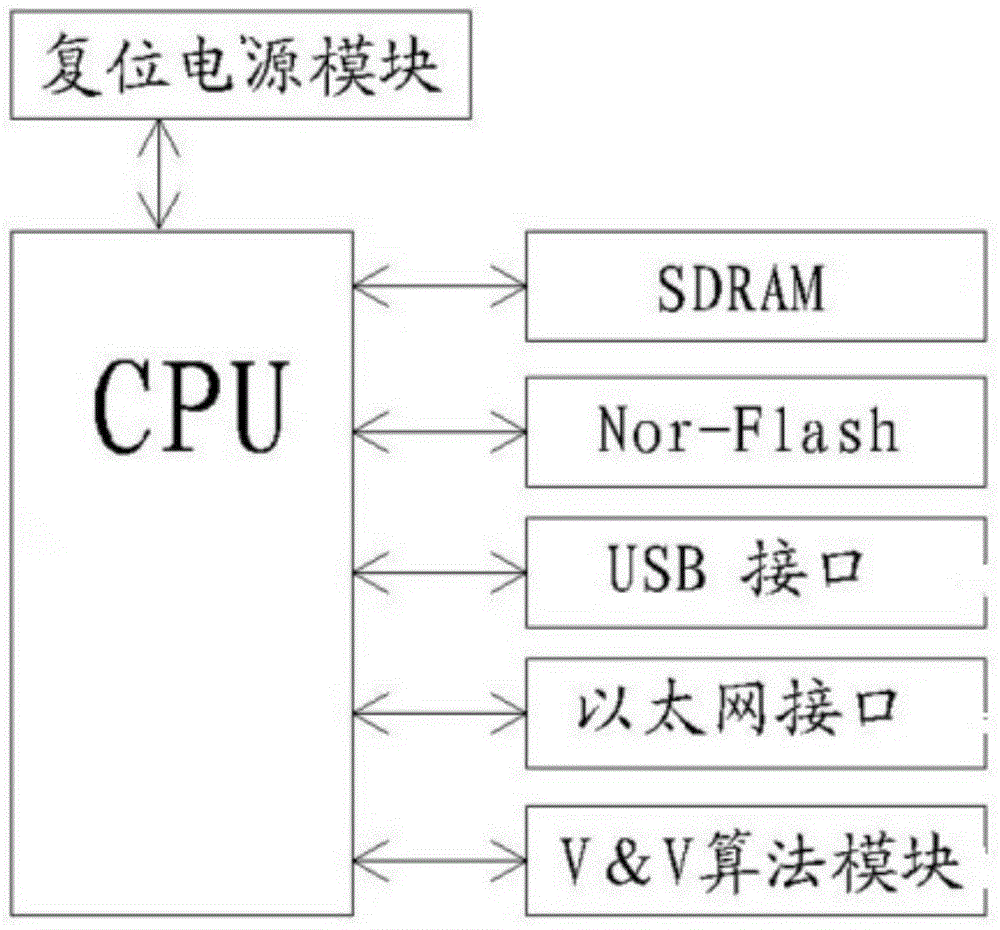

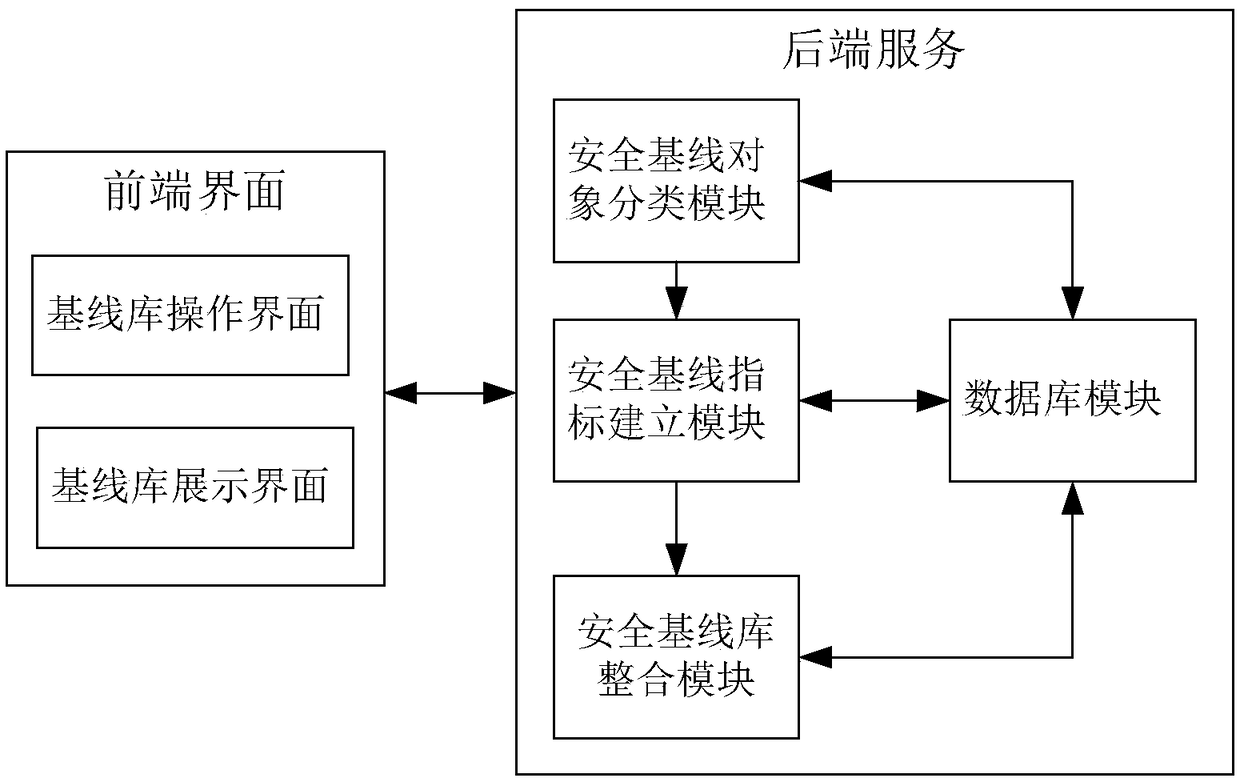

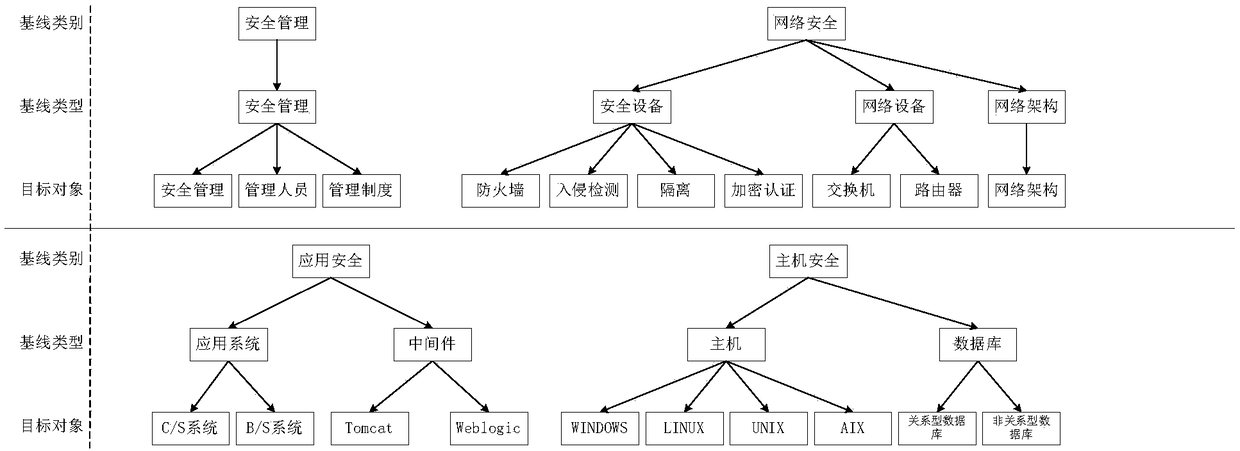

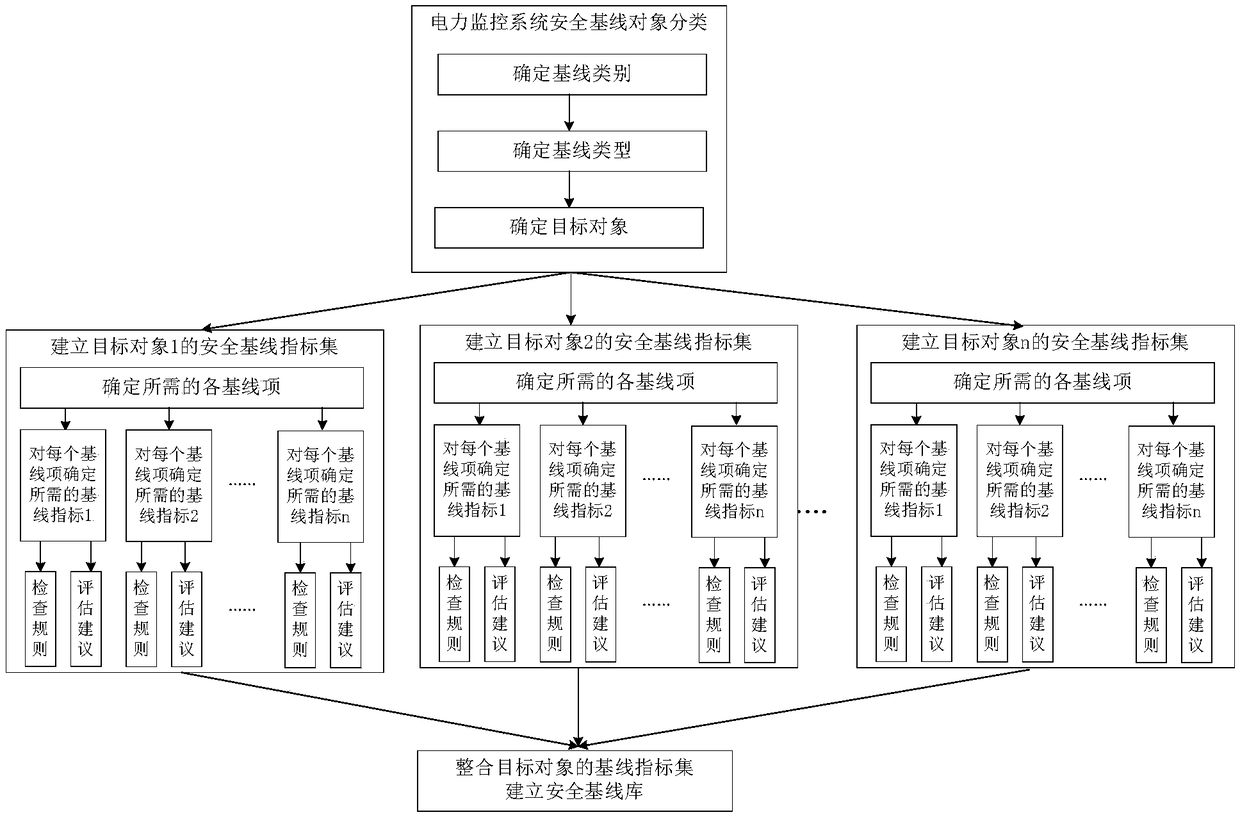

A system and a method for establishing a safety baseline database of a power monitoring system

ActiveCN109460400AFast real-timeFor quick maintenanceDatabase design/maintainanceSystem safetyBaselining

The invention relates to a system and a method for establishing a safety baseline database of a power monitoring system. Firstly, the safety baseline objects involved in the power monitoring system are classified, and the baseline categories, baseline classes and target objects are sequentially determined. Then, a baseline indicator set is determined for each target object. The baseline indicatorset includes baseline items, baseline indicators, inspection rules and evaluation recommendations. Finally, the security baseline indicator set of each target object is selected according to the requirements and the security baseline library is formed.

Owner:JIANGSU ELECTRIC POWER CO +2

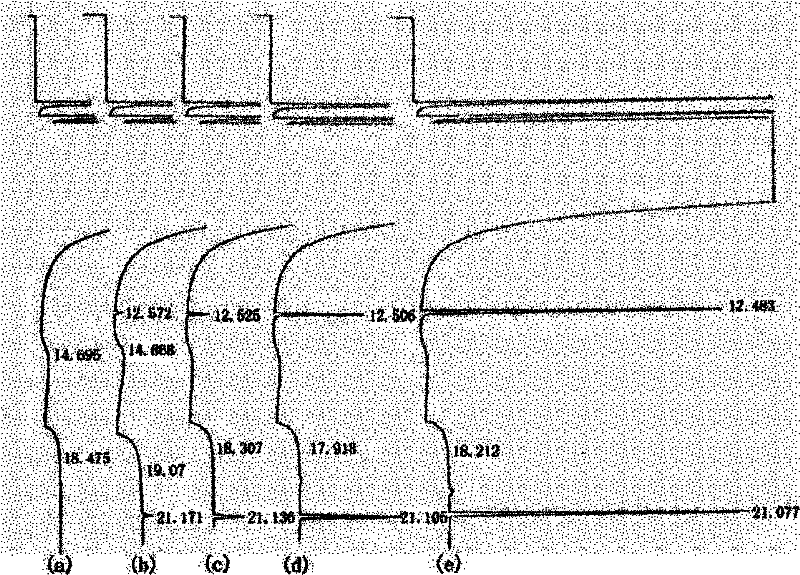

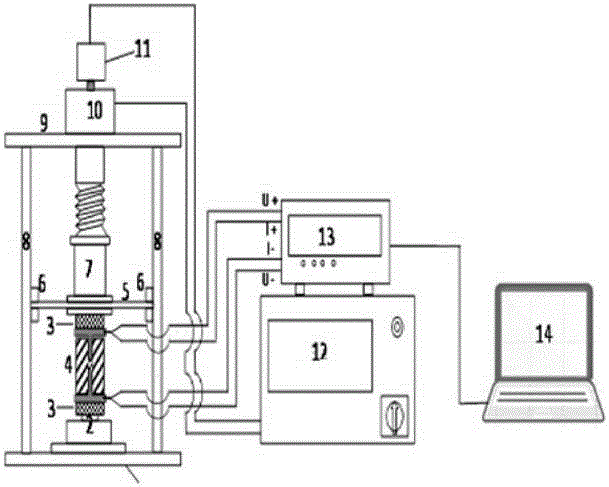

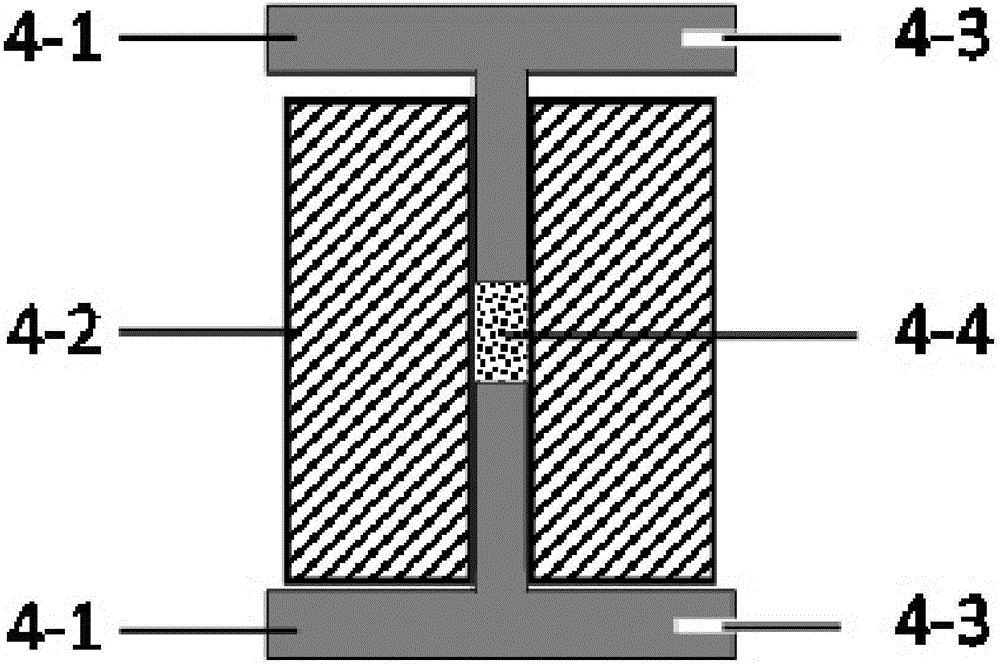

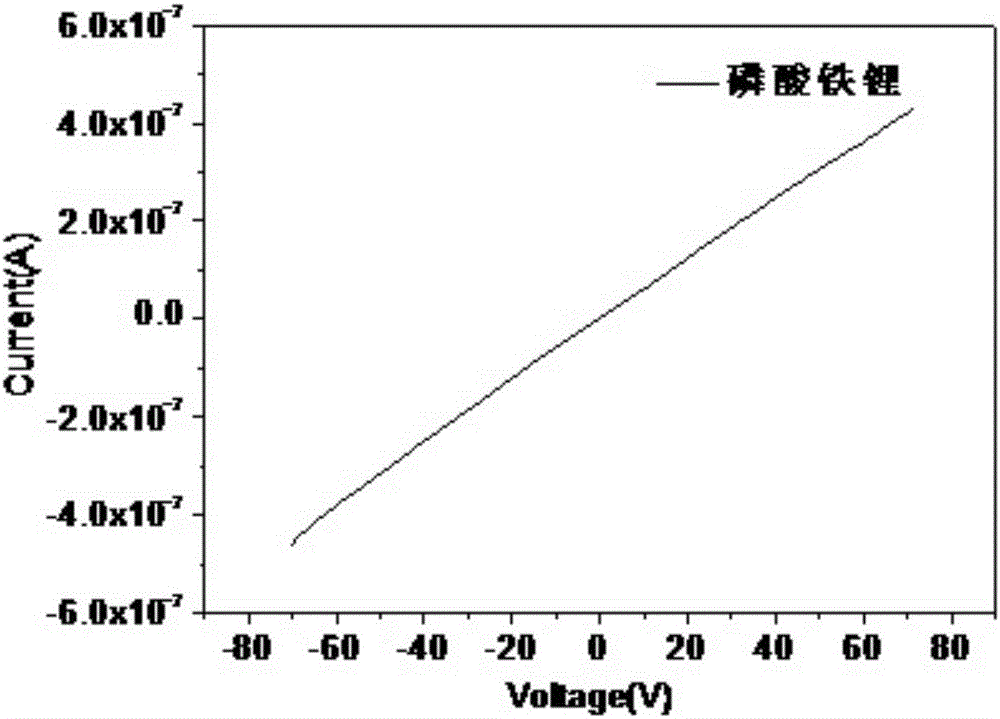

Pressure intensity-controllable solid power electric conductivity test device

InactiveCN106680588AReal-time pressureReal-time conductivityResistance/reactance/impedenceElectrical conductorLithium iron phosphate

The invention relates to a pressure intensity-controllable solid power electric conductivity test device. The pressure intensity-controllable solid power electric conductivity test device comprises a core component, a commercial digital source meter and a computer data processing system; the core component is composed of a base, a load sensor, an insulation pad, a positioning cross beam, slide rail locators, a roller, slide rails, an upper baffle, a servo motor, a rotary encoder, a controller, a sample test mold and so on; the load sensor can detect the intensity of pressure applied onto the load sensor; the sample test mold is composed of an upper part, a middle part and a lower part, wherein the upper part and the lower part are electric conduction bodies, and the middle part is an insulating hollow mold; the positioning cross beam, the slide rail limiters, the roller, the slide rails and the like can control the servo motor to advance or retreat according to signals; the speed of the movement of the servo motor is provided by the controller; and the rotary encoder transfers a sample thickness value to the controller. The test range of the device covers materials from materials of which the electric conductivities are extremely low to conductor materials, for example, the electric conductivities of lithium iron phosphate and carbon nanocages, which are detected by using the method, are 8.23*10<-9> and 6.44 Scm<-1> respectively.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST

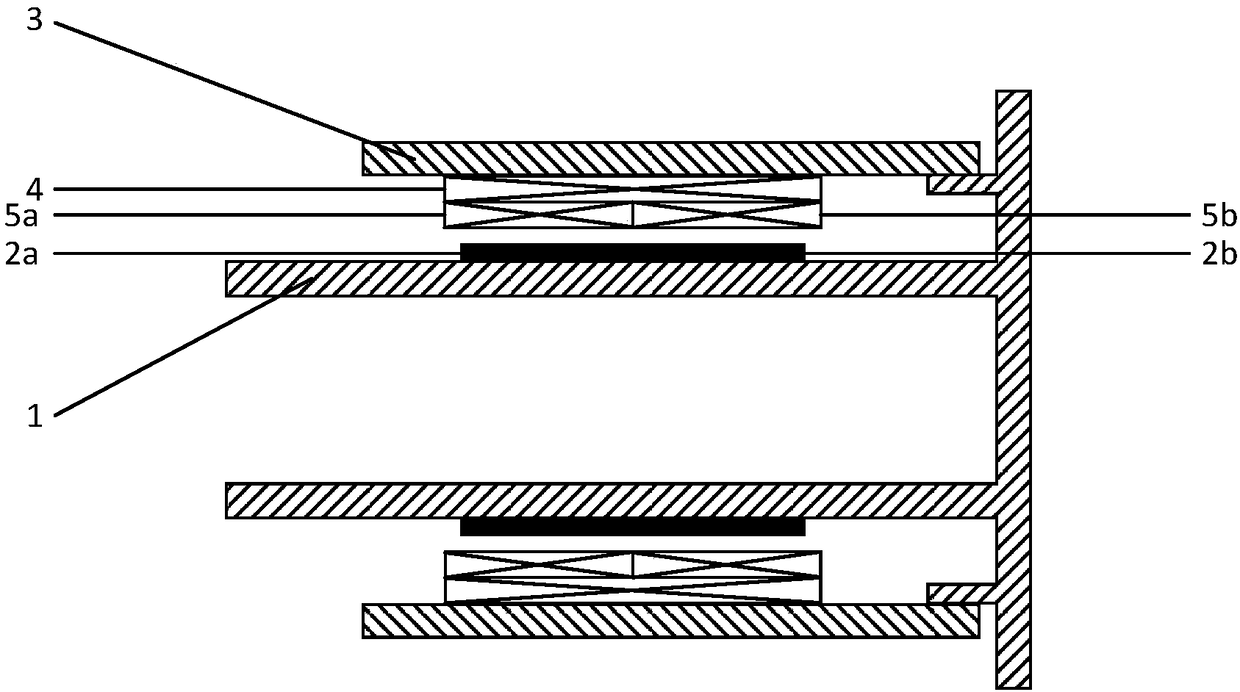

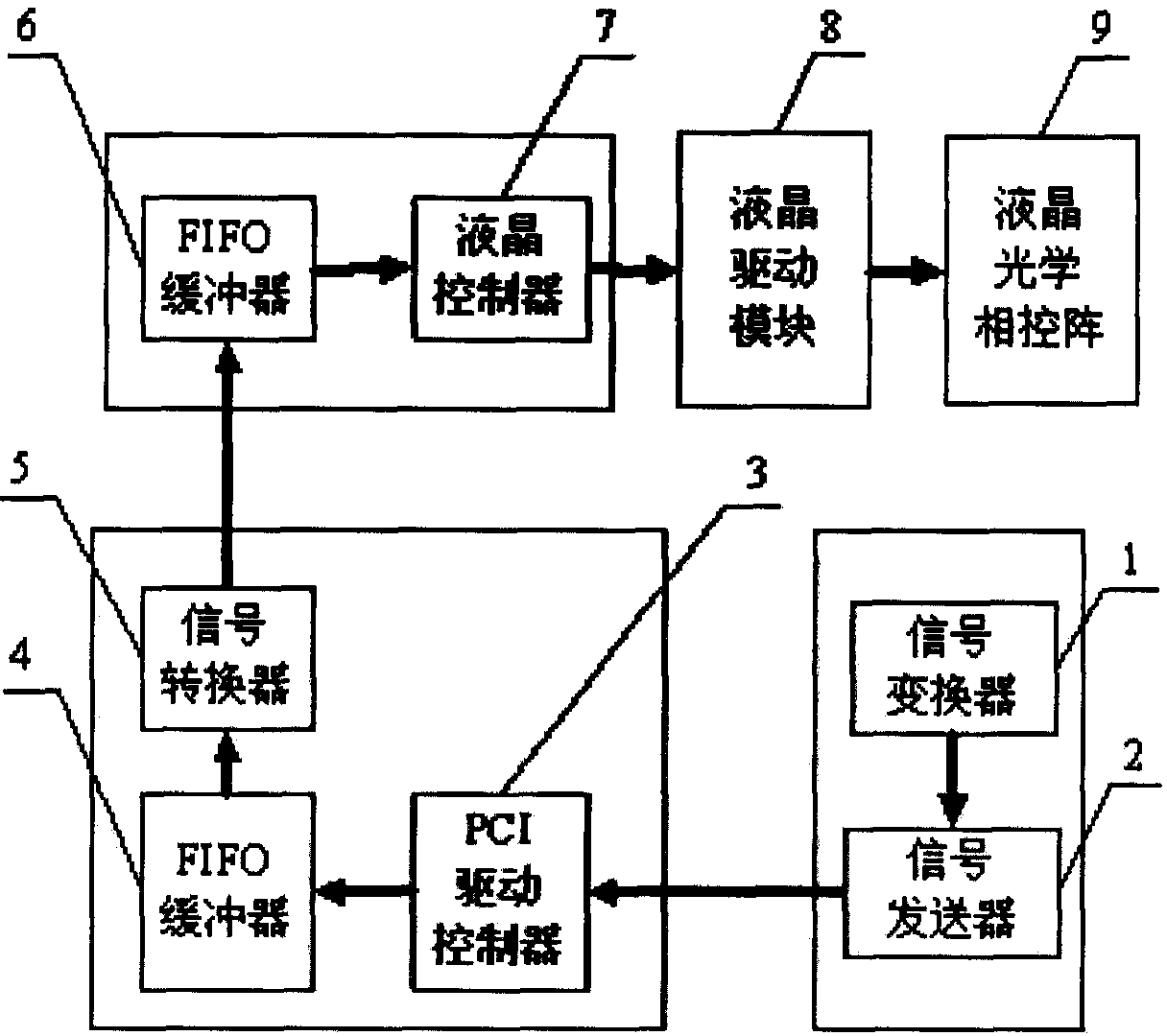

A transmissive liquid crystal optical phased array drive and control device

ActiveCN106134467BHigh orientation accuracyHigh speedStatic indicating devicesOperational systemControl system

The invention relates to a transmissive liquid crystal optical phased array drive and control system, which mainly includes a signal converter 1 and a signal transmitter 2 which are VC programs running in the operating system of a PC; a PCI drive controller 3 and a FIFO buffer 4. The signal converter 5 is a Verilog program running inside the data acquisition card; the FIFO buffer 6 and the liquid crystal controller 7 are Verilog programs running inside the FPGA target board. The transmission type liquid crystal optical phased array drive control system of the present invention, through the high-precision control and sampling of the voltage input end of each pixel electrode, the high-speed switching and accurate control of multi-channel signals, has high orientation accuracy and orientation speed, and is a transmissive The liquid crystal optical phased array provides a drive and control system that can be used in practice, and lays the foundation for the realization of the transmissive liquid crystal optical phased array equipment.

Owner:CHINA WEAPON EQUIP RES INST

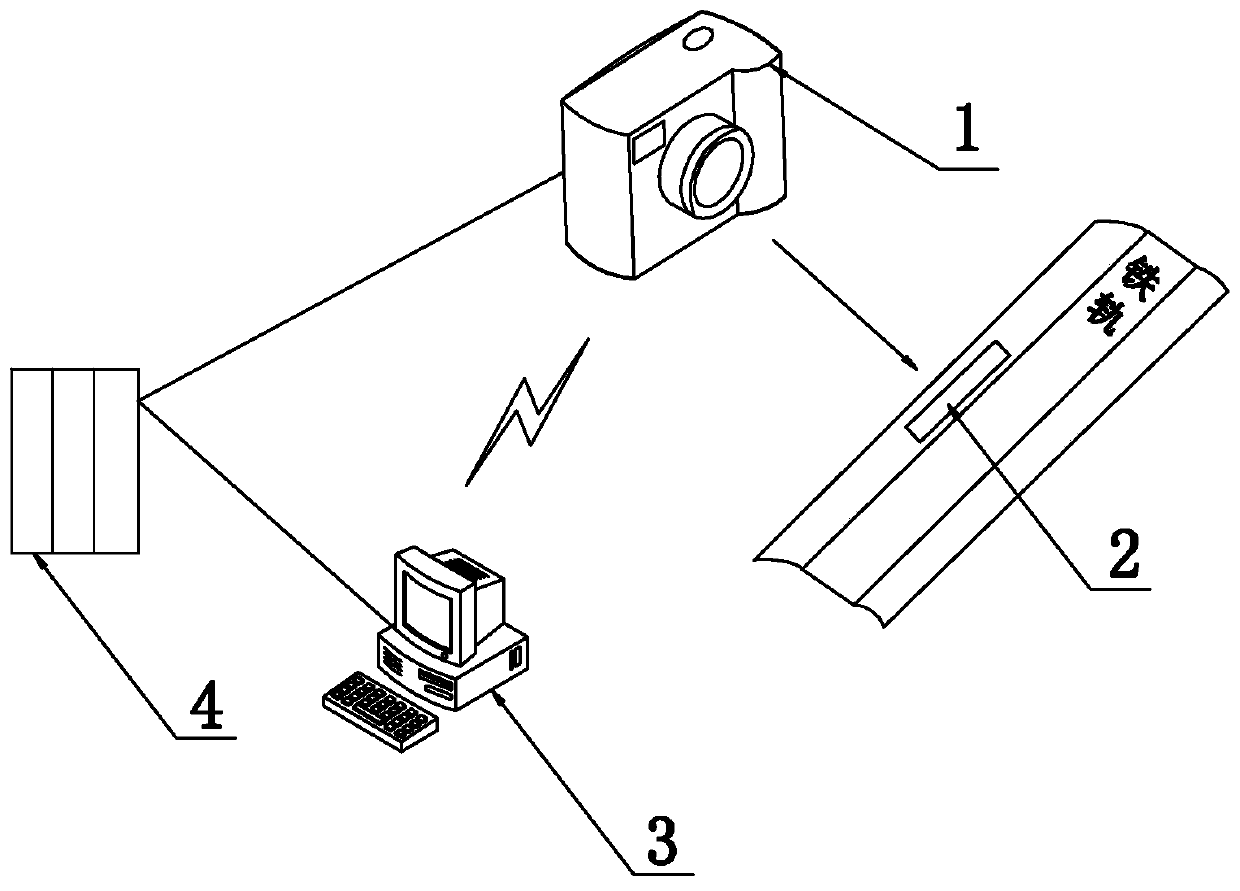

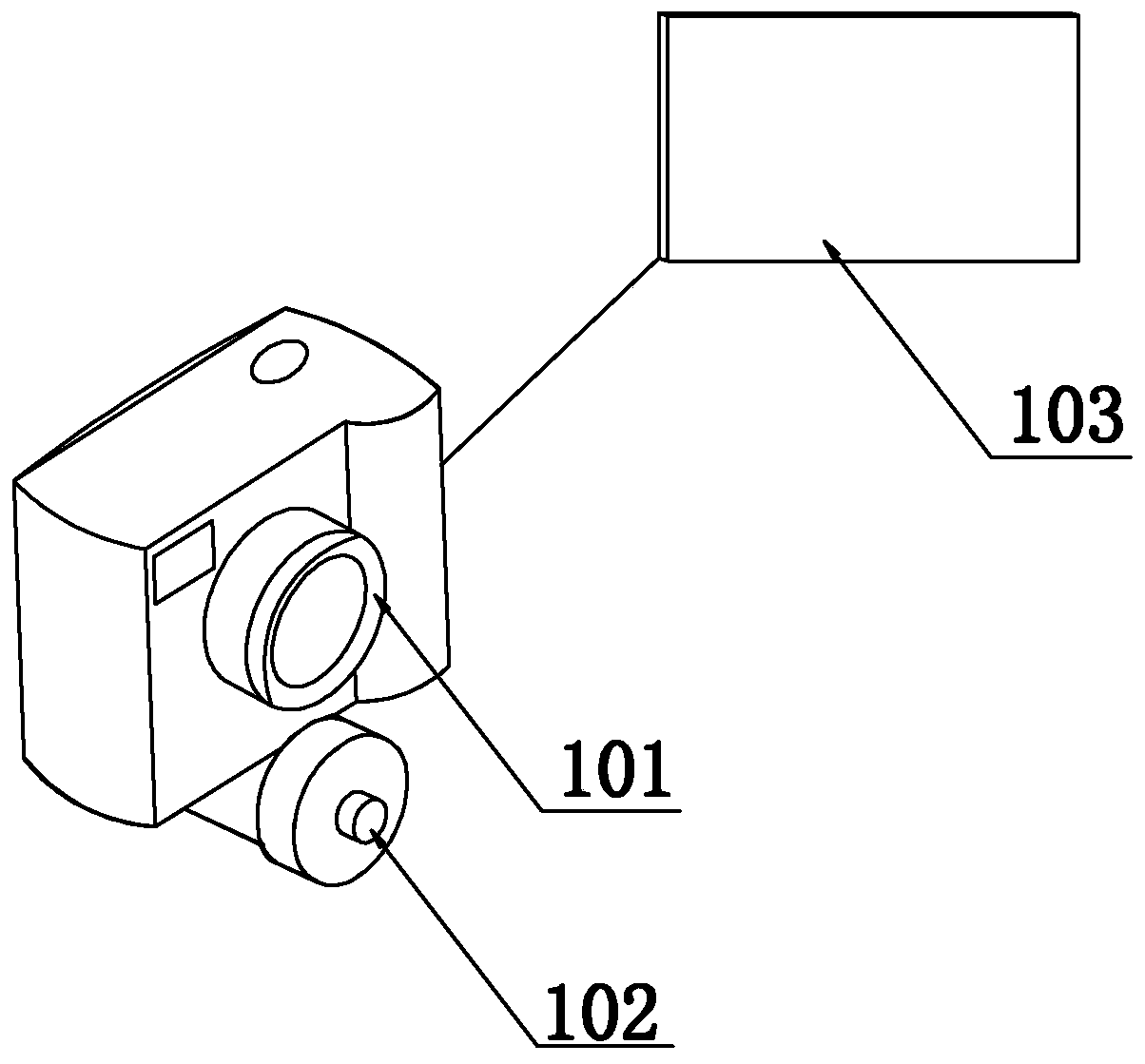

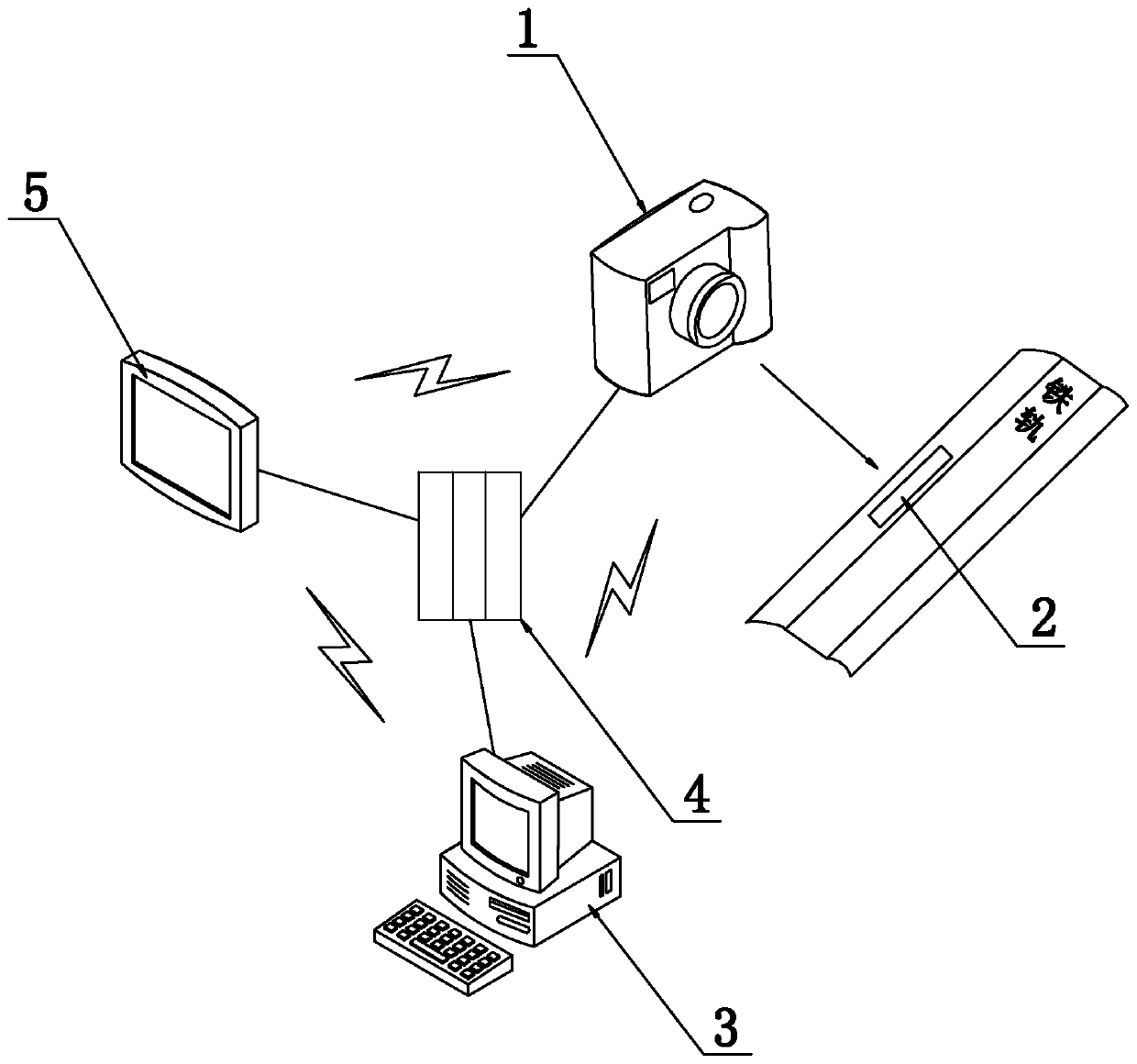

A seamless track rail displacement crawling detection system

ActiveCN108482421BIngenious designSimple designRailway auxillary equipmentRailway profile gaugesControl engineeringImage pair

The invention provides a continuously welded rail track rail displacement crawling detection system. The system comprises field basic equipment, a main control operating system and a power supply system. The field basic equipment comprises an image acquisition system and a scale ruler, and the image acquisition system is used for emitting a light mark illuminating on the scale ruler and used for collecting the displacement image of the light mark on the scale ruler in real time and sending the displacement image to the main control operating system. The main control operating system is used for receiving the displacement image sent by the image acquisition system in real time, and measuring and saving the displacement based on the positional change of the light mark according to the comparison of the displacement image and a preset original image. The continuously welded rail track rail displacement crawling detection system realizes the intelligent design of accurate measurement, storage, statistics and management integration of the rail displacement, the rail displacement detection of multiple lines can be quickly and accurately completed through the single-person operation, staff does not need to perform cross-line operation, the personnel safety risk is eliminated, and the data is stored in real time and can be quickly exported for easy management.

Owner:南京城铁信息技术有限公司

A power calibration and real time correction device for CDMA receiver and its implementation method

ActiveCN101188463BSave resourcesAccurate correctionReceivers monitoringWireless communicationTerminal equipmentNonlinear gain

The invention relates to a CDMA receiver power calibration and real-time correction device and the realization method thereof, and the method can be used for the power calibration and the real-time correction of terminal equipment such as the CDMA system, the base station facilities, and the road measurement meter. The method adopts a segment look-up table approach, and not only uses the fastness and simplicity of the look-up table approach but also combines segment treatment, thereby reducing the consumption of the storage room as much as possible. For linear gain section of a receiving link, i.e. the so-called big signal calibration, the look-up table approach is used directly; for non-linear gain section, i.e. small signal calibration, a noise compensation calibration method is adopted. The invention is used especially for the power calibration and the real-time correction of the massive equipment, and the power calibration method can meet the demand of automation and have the advantages of low cost, fast speed and high calibration precision.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

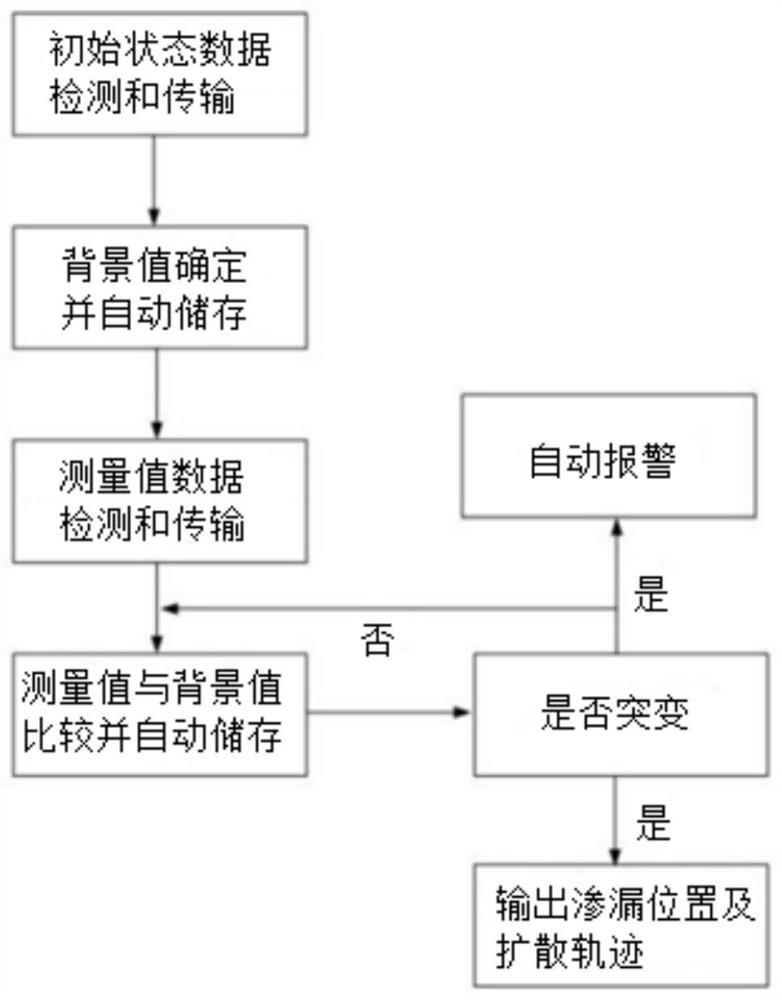

Oil product leakage monitoring technology adopting radioactive tracer

InactiveCN112177600AReduce churnEasy to recycleConstructionsEvaporationRadioactive tracerIsotopic tracer

The invention provides an oil product leakage monitoring technology adopting a radioactive tracer, and relates to the technical field of oil product permeation detection. A preparation method of the radioactive tracer comprises the following steps of: loading an isotope tracer on a porous carrier in an acid solution; providing a precipitant solution, wherein the precipitant can react with the isotope tracer to form an insoluble substance; and providing a hydrophobic solvent, performing surface hydrophobic treatment on the porous carrier loaded with the insoluble substance by the hydrophobic solvent, and drying to obtain the radioactive tracer. The monitoring technology comprises the following steps: acquiring initial state data by using a detection module; transmitting the initial state data to a server side for automatic storage, and determining a background value; measuring measured signal values at various moments, and transmitting the measured signal values to the server side for automatic storage; and comparing the measured signal values at various moments with the background value, transmitting an alarm signal to an alarm module by the server side when result data changes suddenly, and outputting information of a leakage position and an oil substance diffusion track in an area.

Owner:ZHEJIANG OCEAN UNIV

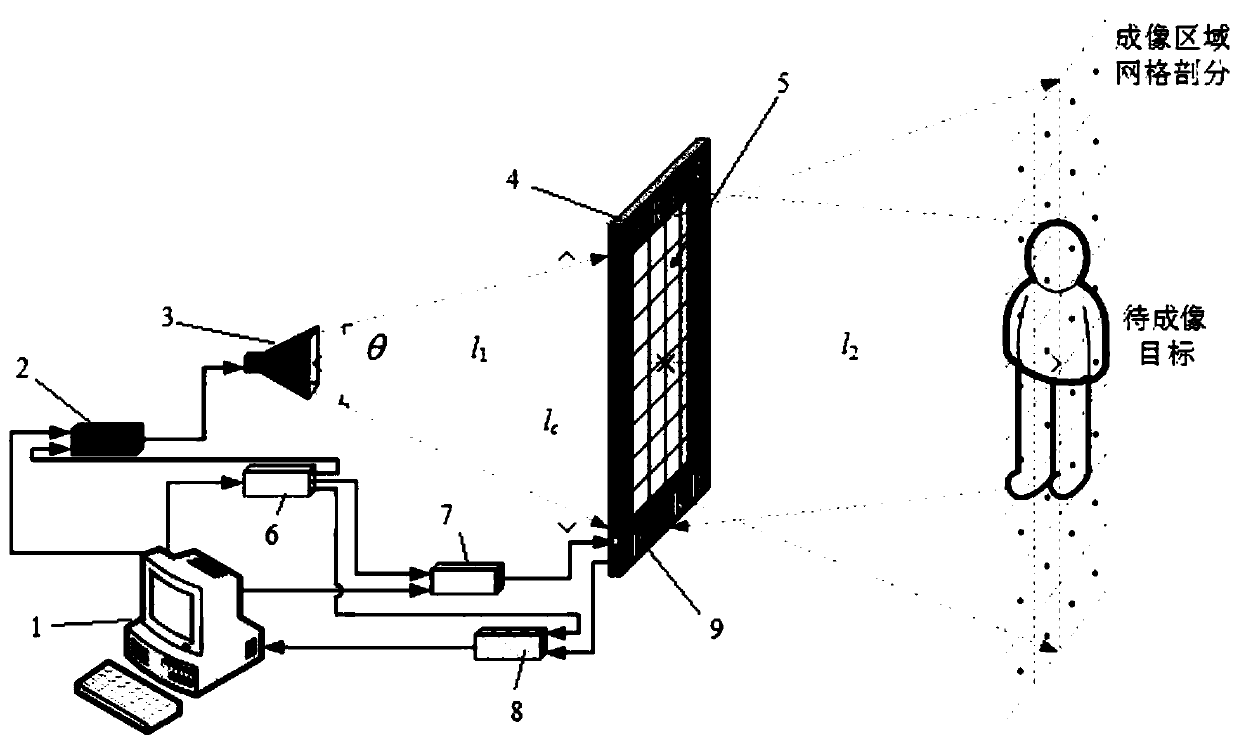

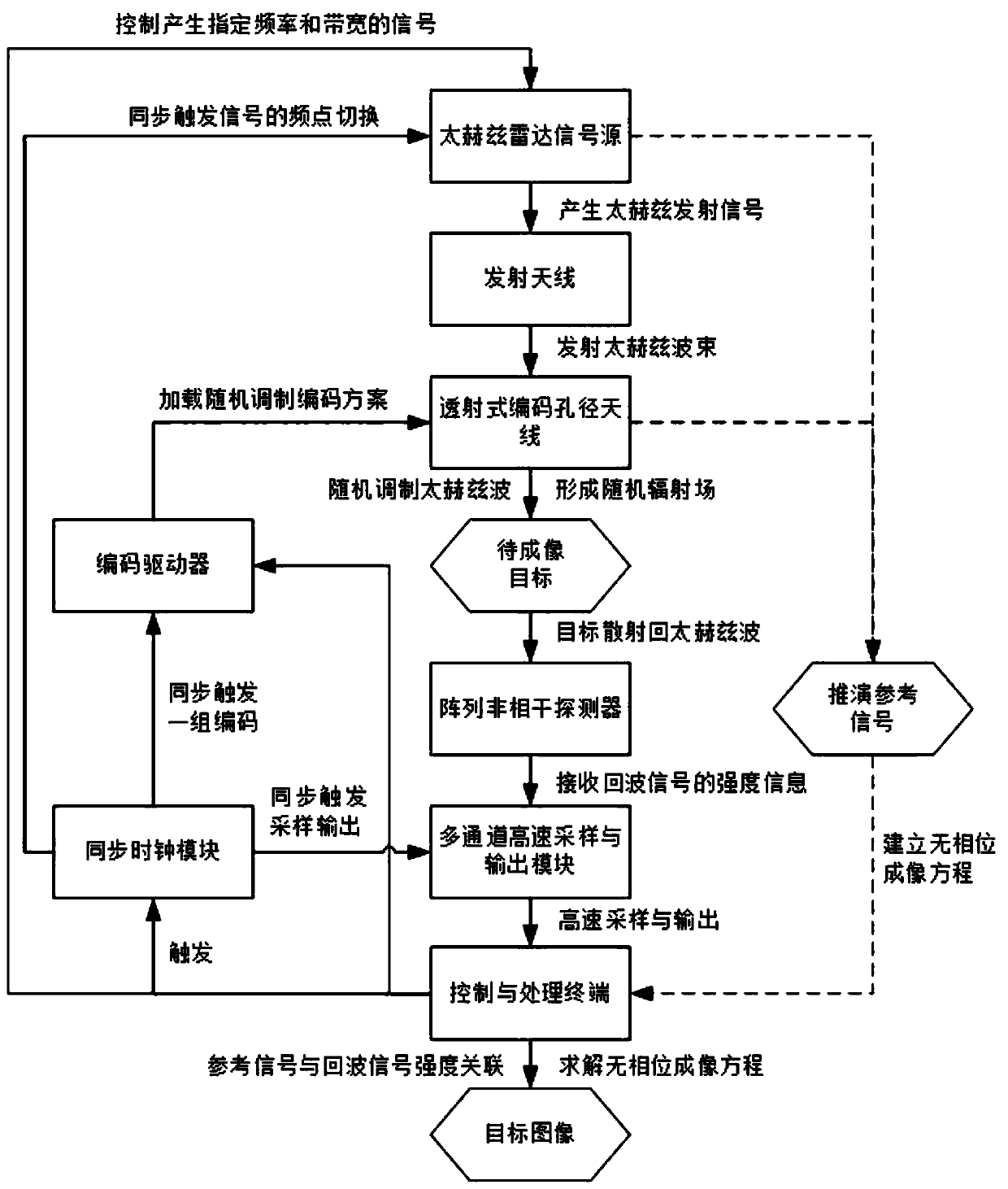

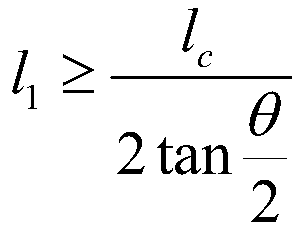

Terahertz aperture coding phase-free imaging device and method based on array incoherent detector

ActiveCN110764107ALow costReduce volumeElectromagnetic wave reradiationRadar imagingSoftware engineering

The invention provides a terahertz aperture coding phase-free imaging device and method based on an array incoherent detector. The invention aims to replace a plurality of coherent detectors in a traditional terahertz aperture coding imaging radar by using the array incoherent detector, only the intensity information of an echo signal is received in the receiving process, the phase information isnot received, so that a system receiving link is simplified, the system complexity is reduced, the manufacturing cost is reduced, and meanwhile, the integration and miniaturization are easy; and the array incoherent detector adopts a multi-channel output technology to complete high-speed acquisition of echo data, so that the coding and sampling times can be effectively reduced, and high-speed imaging or real-time imaging of terahertz aperture coding is realized.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com