Pressure intensity-controllable solid power electric conductivity test device

A testing device and technology of solid powder, applied in the direction of measurement device, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., to achieve the effects of accurate results, rapid measurement, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

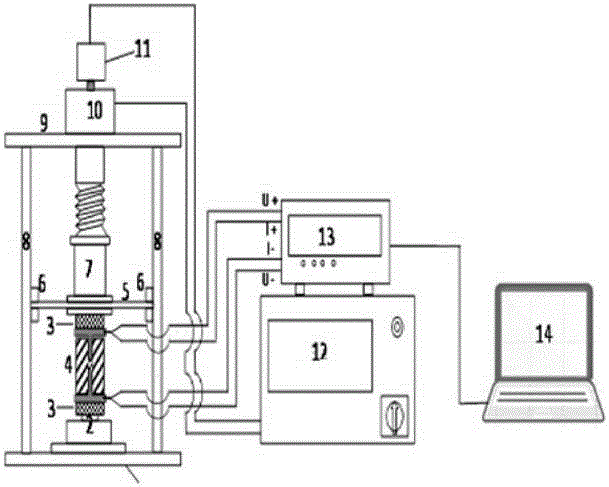

Method used

Image

Examples

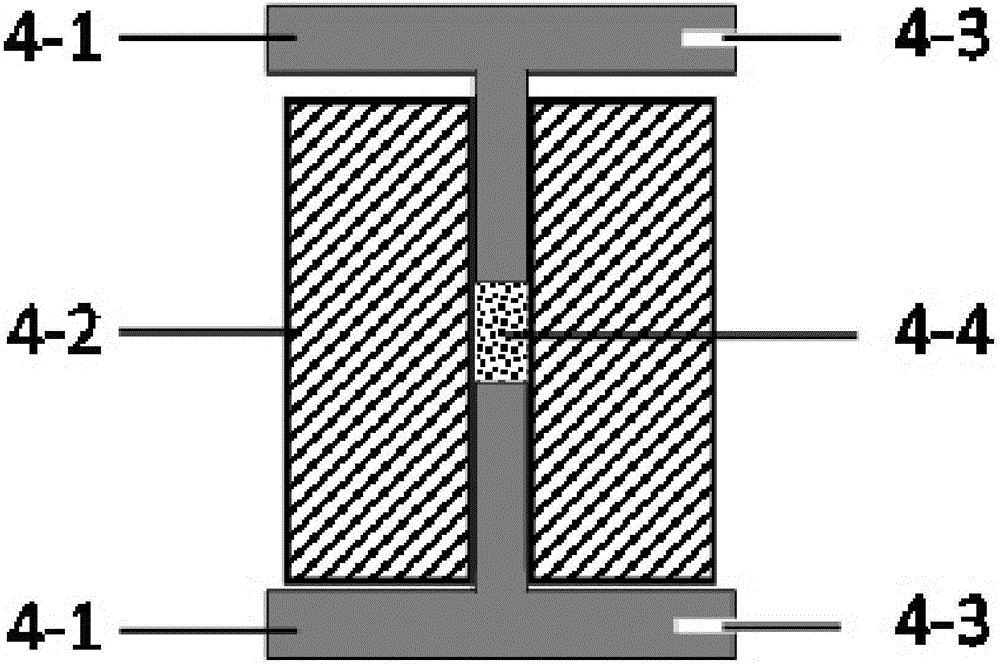

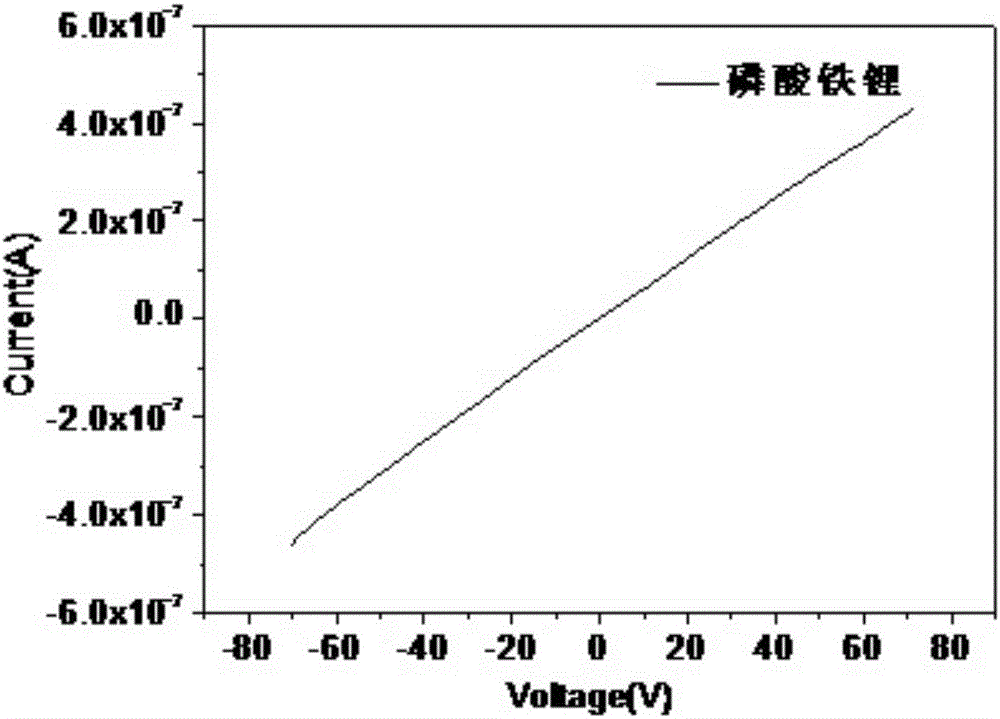

specific example 1

[0018] Specific example 1: In a mold with r=3mm, at 0.2mm s -1 The speed makes the positioning beam (5) travel, at 10kgcm -2 (1MPa) pressure, the blank impedance value R measured by digital source meter (13) and computer data processing system (14) 0 =0.001Ω, at this time the height is marked as 0; add a certain amount of lithium iron phosphate (LiFePO 4 ) powder, according to the above-mentioned operation steps, the measured sample thickness is L=3.648mm, obtain voltage (U) and electric current (I) through digital source meter (13, Keithley 6430) and computer data processing system (14) measurement, do U-I As shown in Figure (3), the curve shows a good linear relationship. According to Ohm's law (R=U / I), the slope of the straight line is the resistance R value. Then measure the material resistance R at different thicknesses i , do R-L / πr 2 The figure shows a good linear relationship, and its slope is the resistivity ρ. According to the formula κ=1 / ρ, the conductivity of l...

specific example 2

[0019] Specific example 2: In a mold with r=3mm, at 0.2mm s -1 The speed makes the positioning beam (5) travel, at 10kgcm -2 (1MPa) pressure, the blank impedance value R measured by digital source meter (13) and computer data processing system (14) 0 =0.001Ω, now the height is marked as 0; add a certain amount of carbon nanocage powder, according to the above operation steps, the thickness of the sample measured is L=3.354mm, through the digital source meter (13, Keithley 6430) and computer data processing system (14) Measure the voltage (U) and current (I), and make the U-I curve as shown in Figure (4), showing a good linear relationship. According to Ohm's law (R=U / I), the slope of the straight line is the resistance R value . Then measure the material resistance R at different thicknesses i , do R-L / πr 2 The graph shows a good linear relationship, and its slope is the resistivity ρ. According to the formula κ=1 / ρ, the conductivity of the carbon nanocage is 6.44Scm -1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com