Low armored resistance load-bearing detection cable

A technology for detecting cables and resistance, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large armored resistance, etc., and achieve the effects of improving service life, increasing friction area, and ensuring tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

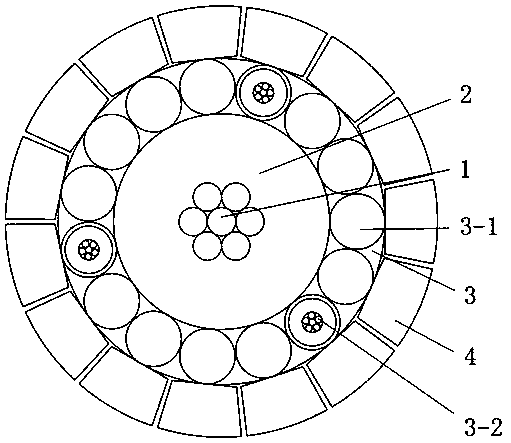

[0020] The low armor resistance load-bearing detection cable of the present invention comprises a group of annealed copper stranded wires 1 located in the center, the outer ring of annealed copper stranded wires 1 is covered with an insulating layer 2 of modified polypropylene, and its thickness is 0.88mm; The outer stranded ring of the insulating layer 2 is covered with an inner steel wire armor layer 3, and the inner steel wire armor layer 3 is surrounded by a group of steel wires 3-1 with a circular cross section and a microscopic steel pipe cable 3-2 to form a closed ring shape, the diameter of the steel wire 3-1 and the fine steel pipe cable 3-2 is 0.94mm; the inner steel wire armor layer 3 twisted ring is covered with an outer steel wire armor layer 4, and the outer steel wire armor layer 4 is formed by a set of cross sections as a fan The trapezoidal steel wires form a closed circular ring, and the inner thickness of the outer steel wire armor layer 4 is 0.9mm. The cros...

Embodiment 2

[0022] The low armored resistance load-bearing detection cable of the present invention comprises a group of annealed copper stranded wires 1 located in the center, the outer ring of annealed copper stranded wires 1 is covered with an insulating layer 2 of modified polypropylene, and its thickness is 0.55 mm; The outer stranded ring of the insulating layer 2 is covered with an inner steel wire armor layer 3, and the inner steel wire armor layer 3 is surrounded by a group of steel wires 3-1 with a circular cross section and fine steel pipe 3-2 cables to form a closed ring The diameter of the steel wire 3-1 and the fine steel pipe 3-2 is 0.4mm; the inner steel wire armor layer 3 twisted ring is covered with an outer steel wire armor layer 4, and the outer steel wire armor layer 4 consists of a set of cross-sections that are fan-trapezoidal The steel wires form a closed circular ring, and the thickness in the outer steel wire armor layer 4 is 0.4mm. The cross section of each copp...

Embodiment 3

[0024] The low armor resistance load-bearing detection cable of the present invention comprises a group of annealed copper stranded wires 1 located in the center, the outer ring of annealed copper stranded wires 1 is covered with an insulating layer 2 of modified polypropylene, and its thickness is 1.2mm; The outer stranded ring of the insulating layer 2 is covered with an inner steel wire armor layer 3, and the inner steel wire armor layer 3 is surrounded by a group of steel wires 3-1 with a circular cross section and fine steel pipe 3-2 cables to form a closed ring shape, the diameter of the steel wire 3-1 and the fine steel pipe 3-2 is 1.47mm; the inner steel wire armor layer 3 twisted ring is covered with an outer steel wire armor layer 4, and the outer steel wire armor layer 4 consists of a set of cross sections that are fan-trapezoidal The steel wires form a closed circular ring, and the thickness in the outer steel wire armor layer 4 is 1.47mm. The cross section of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com