Patents

Literature

329results about How to "Increase friction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

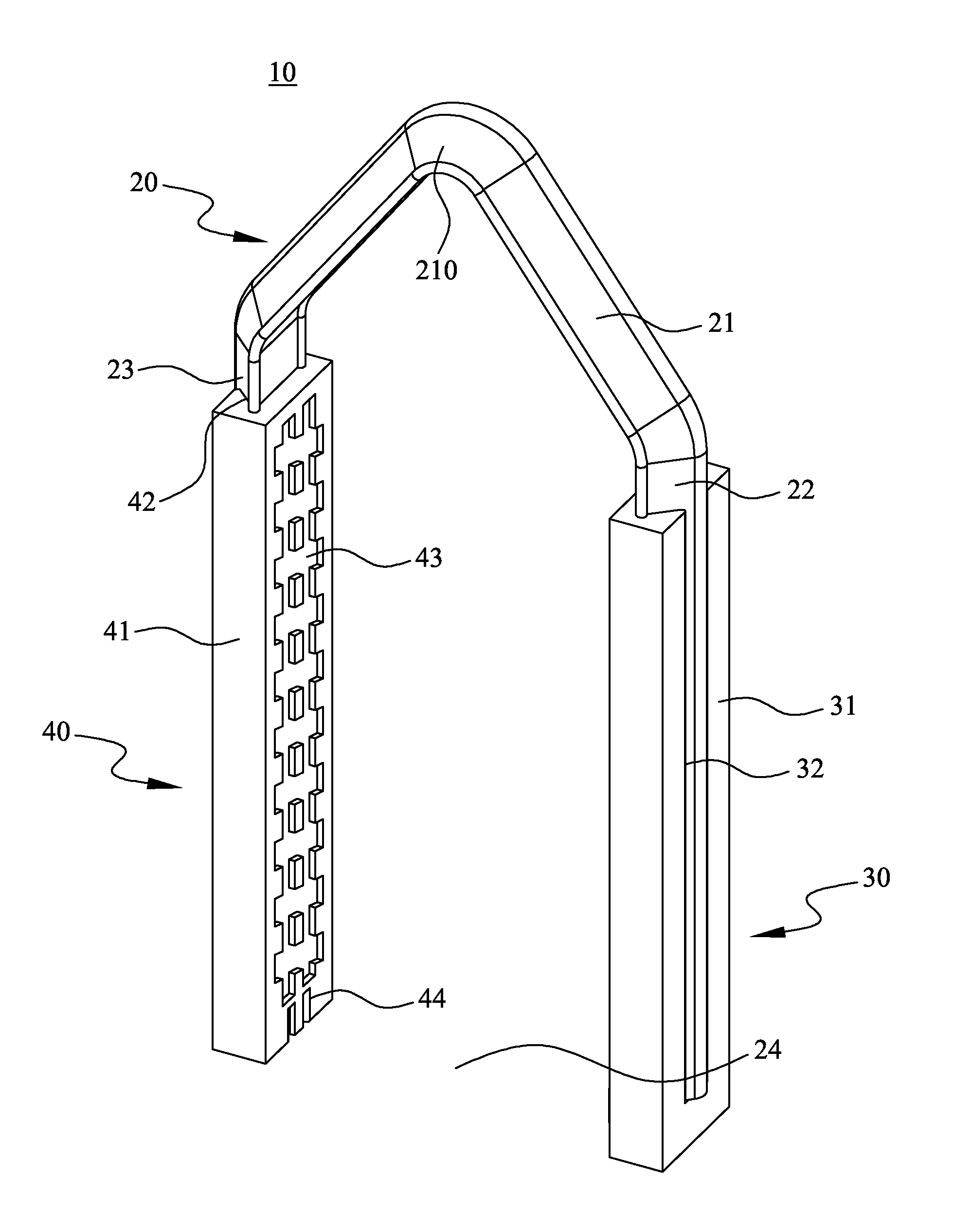

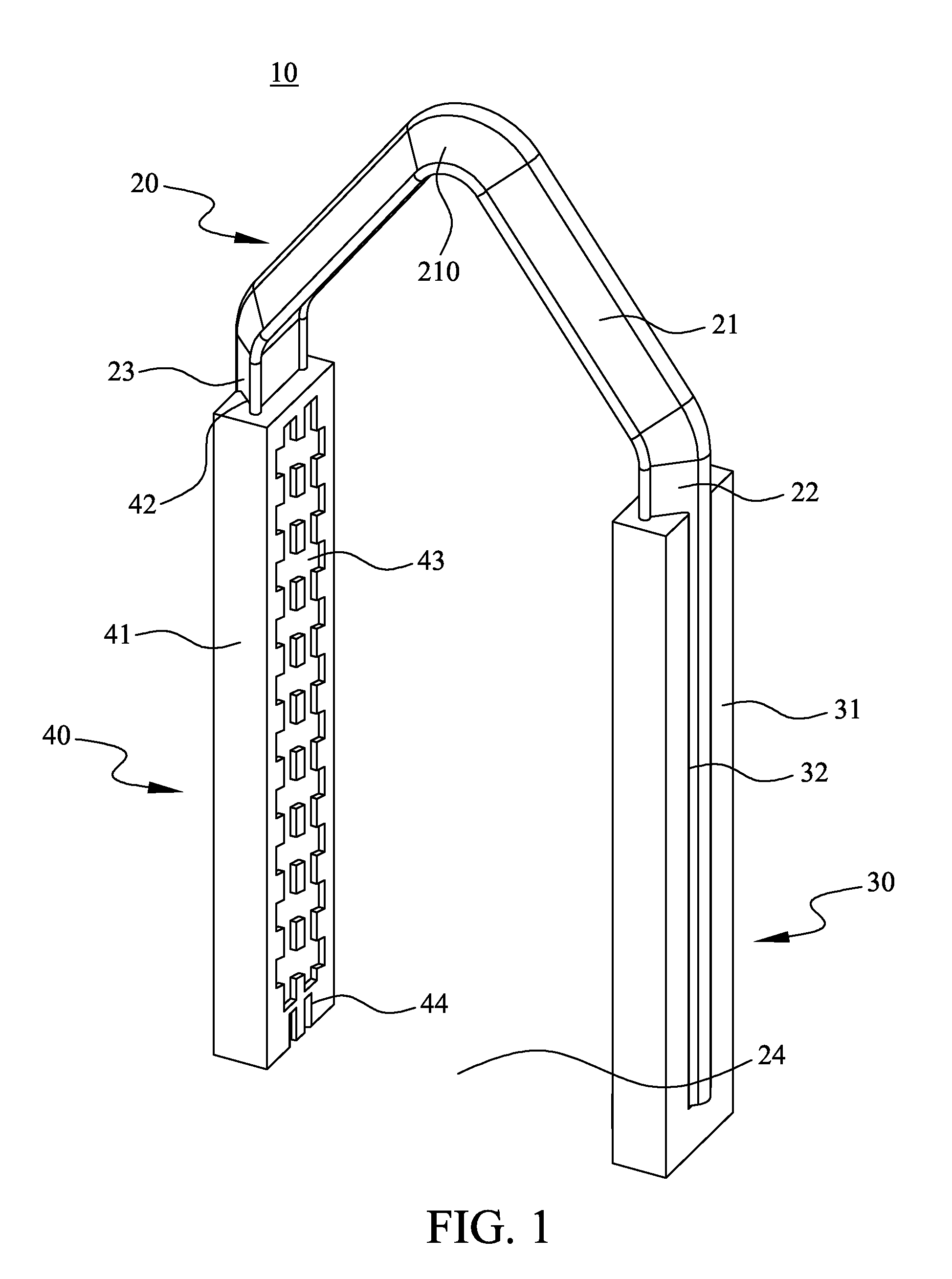

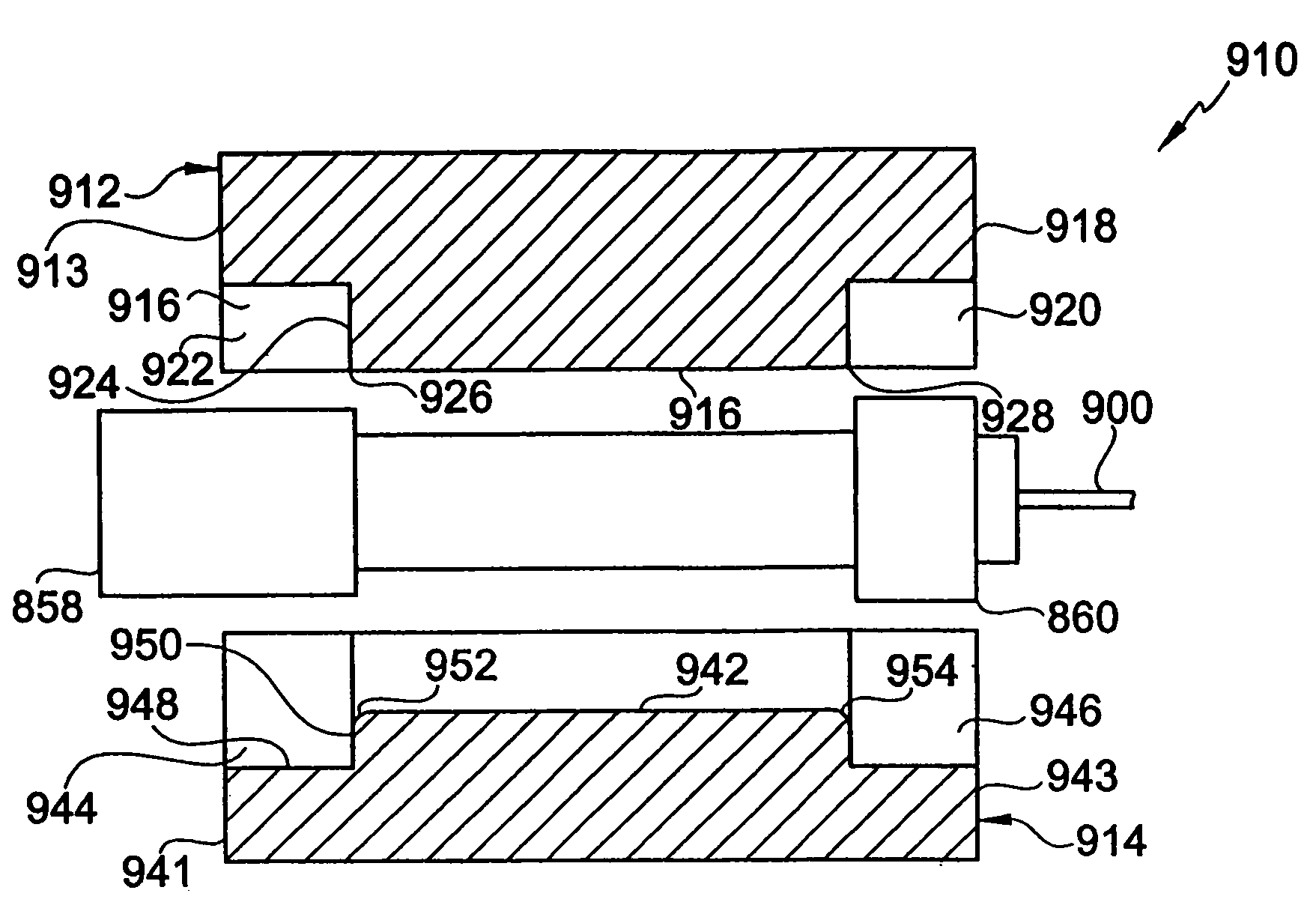

Vascular clamp structure

InactiveUS20110313437A1Improved vascular clamp structureIncrease shear forceSurgical staplesWound clampsEngineeringBlood vessel

An improved vascular clamp structure is comprised of a clip body and two clipping pieces, all of which constitute a vascular clamp used cooperatively for medical clamping pliers. The clip body is arranged with a bridge part, and from two ends of which a clipping part extends respectively and making one side of the clip body forming an opening; the clipping piece is arranged with a clipping body with a fitting slot. The fitting slot and the clipping part can be assembled together. Both adjacent faces of the clipping bodies are respectively arranged with a groove and at least one male or female fastener inter-buckled together. Wherein, the clip body is set as a memory metal. By arranging clipping pieces, the vascular clamp of the present invention enhances the frictional areas of inter-contact. Arranging male and female fasteners at the adjacent faces of clipping pieces also enhances the clipping force, and effectively improves the slipping drawback of traditional vascular clamp. In addition, the vascular clamp is made of memory metal; by the separation of male and female fasteners, the vascular clamp further possesses the function of dismantlement.

Owner:TOP BOUND ENTERPRISE +1

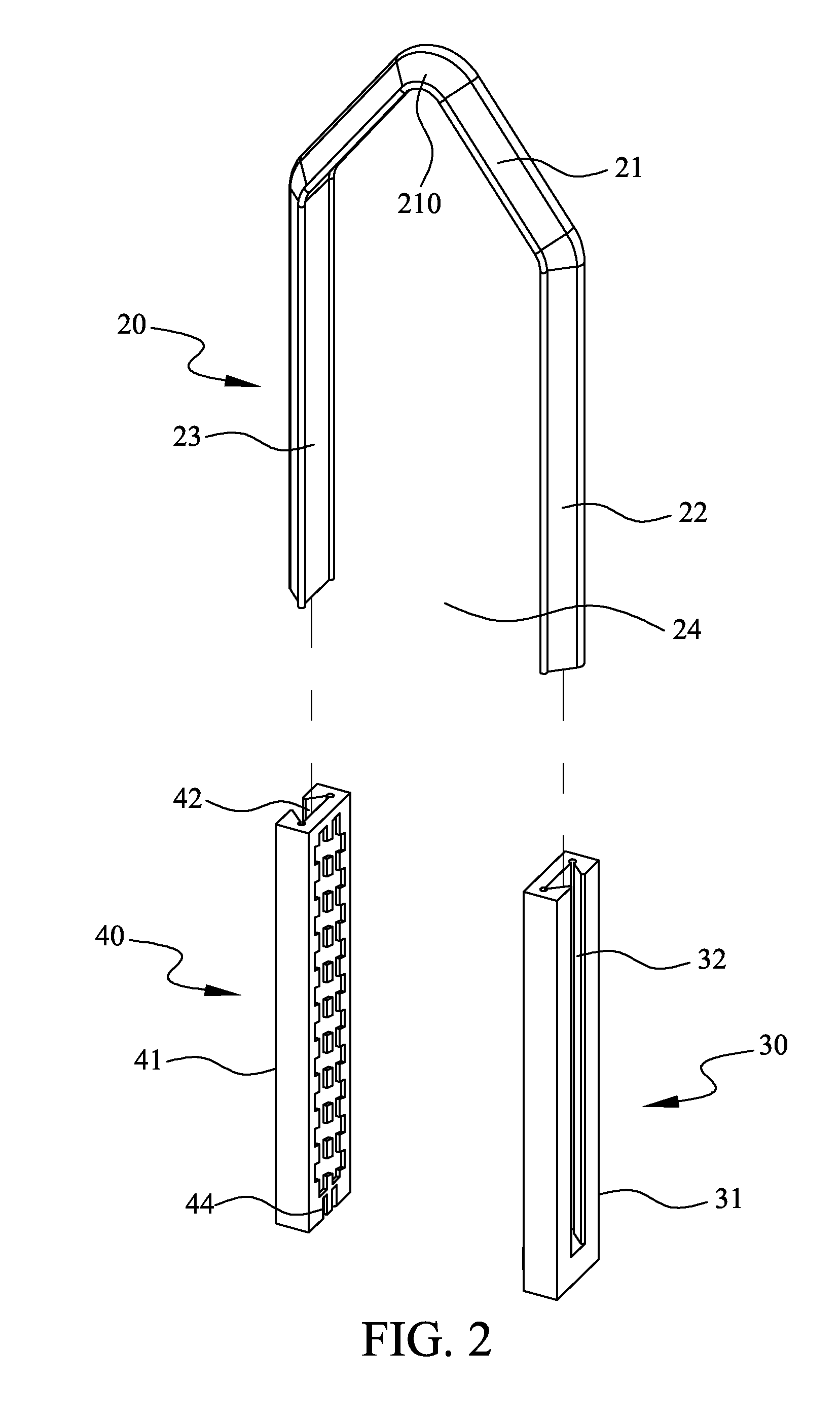

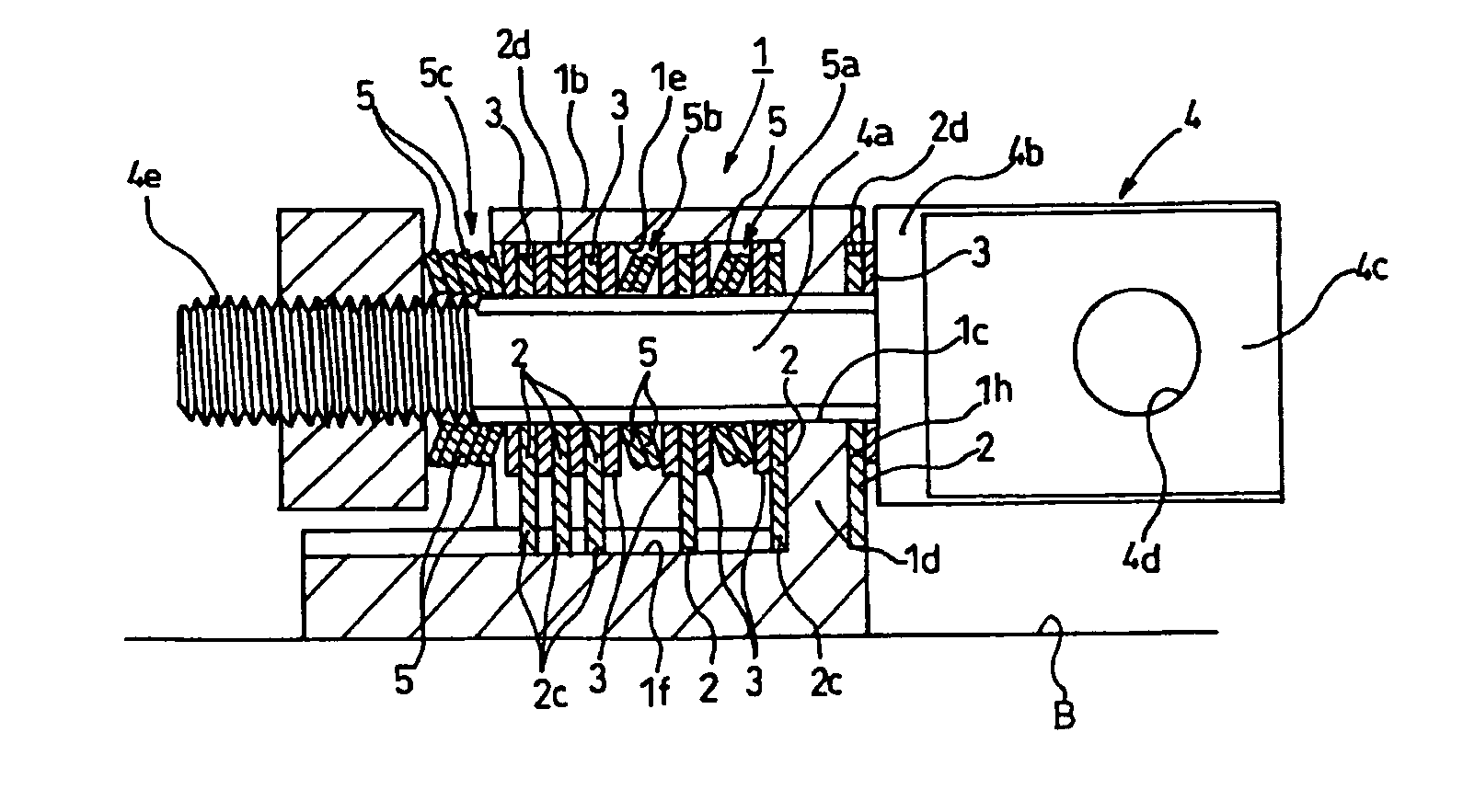

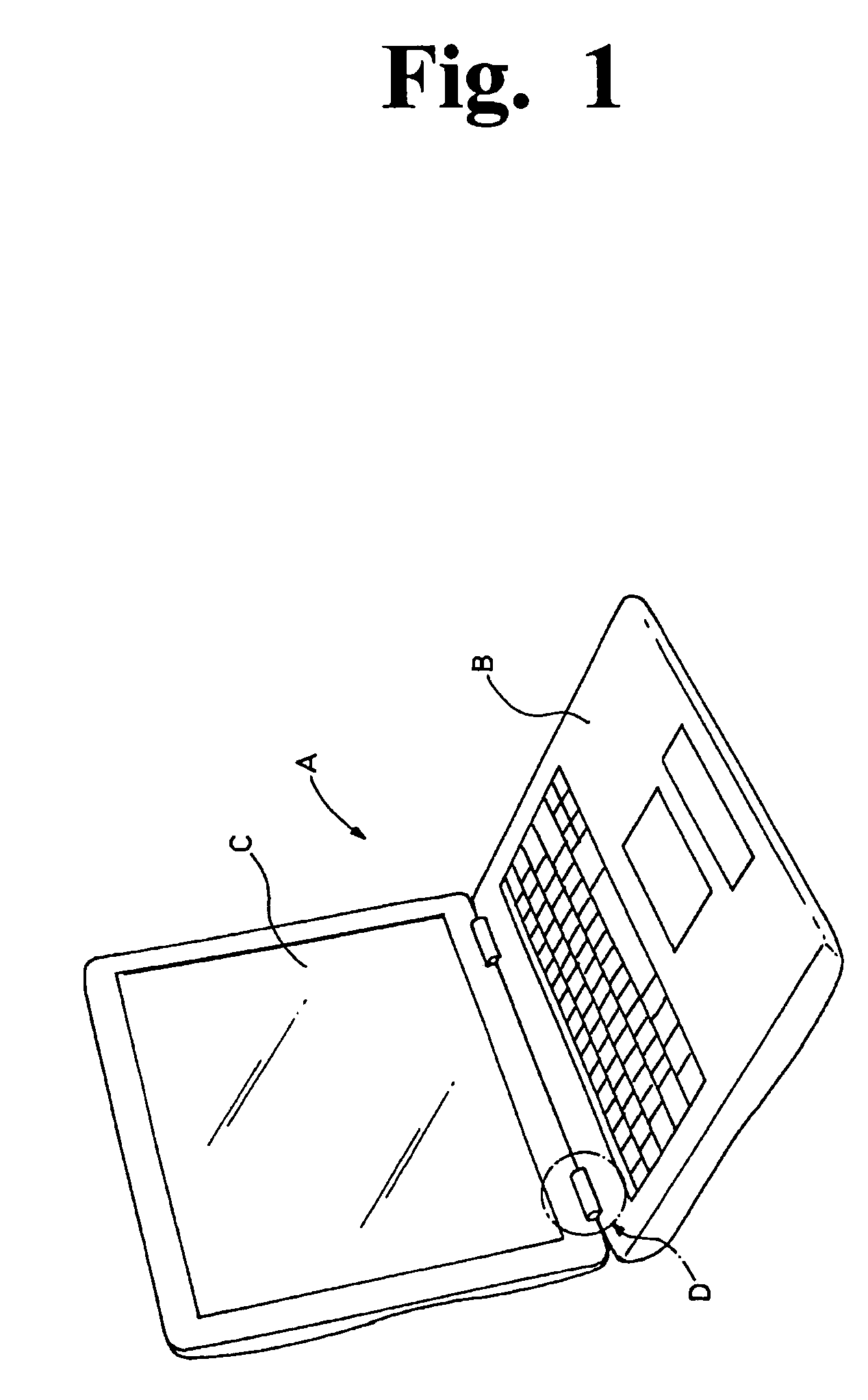

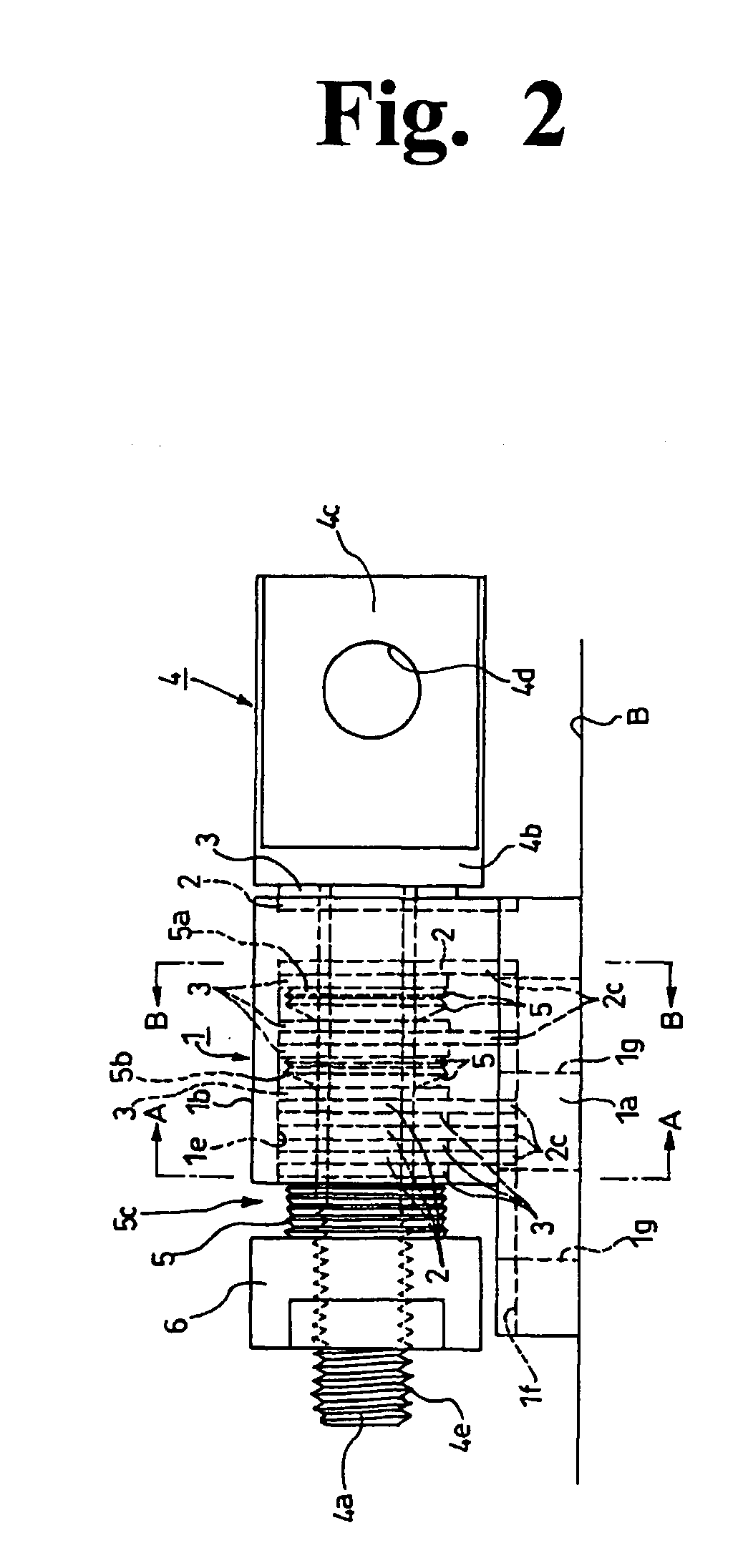

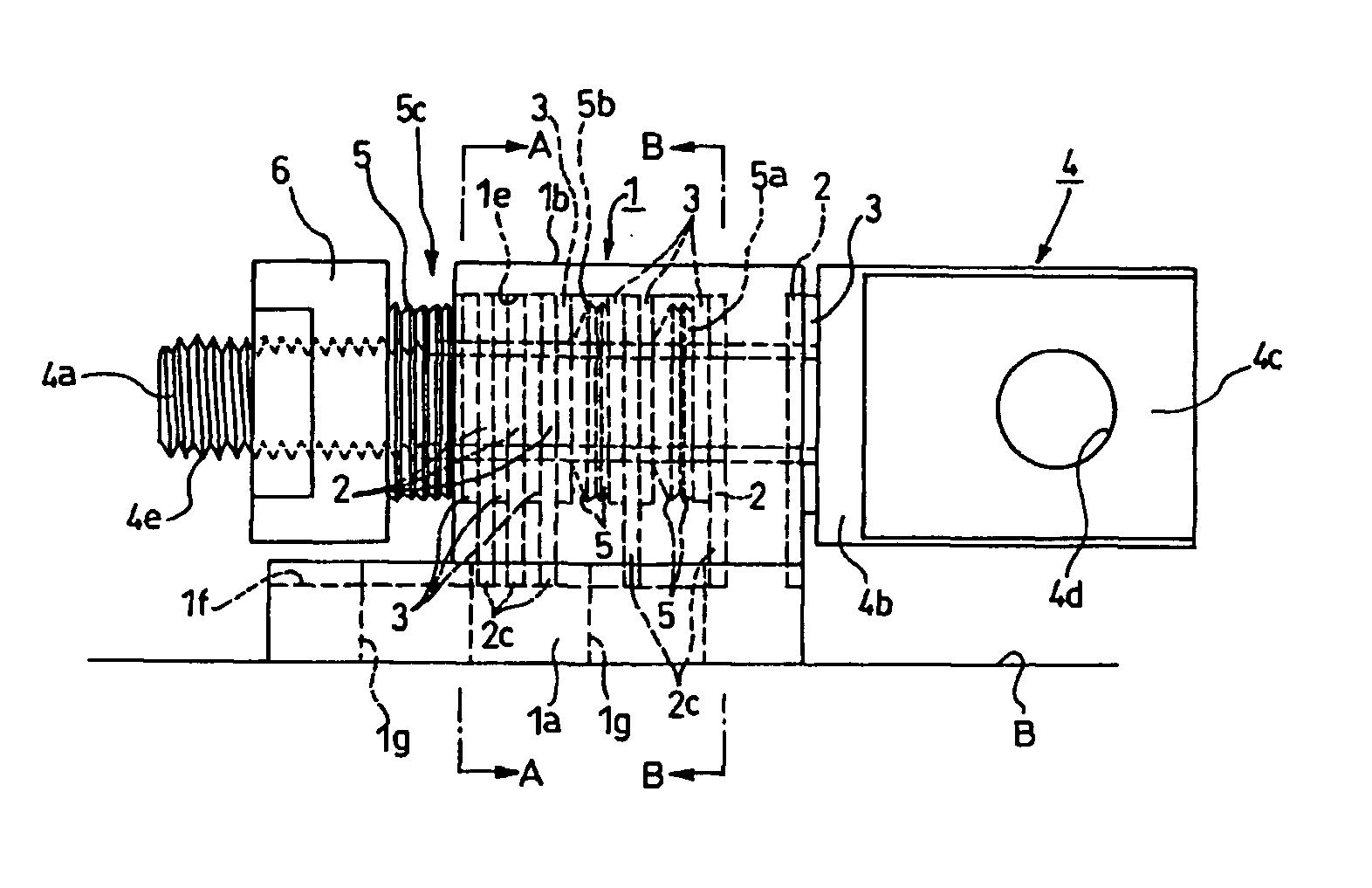

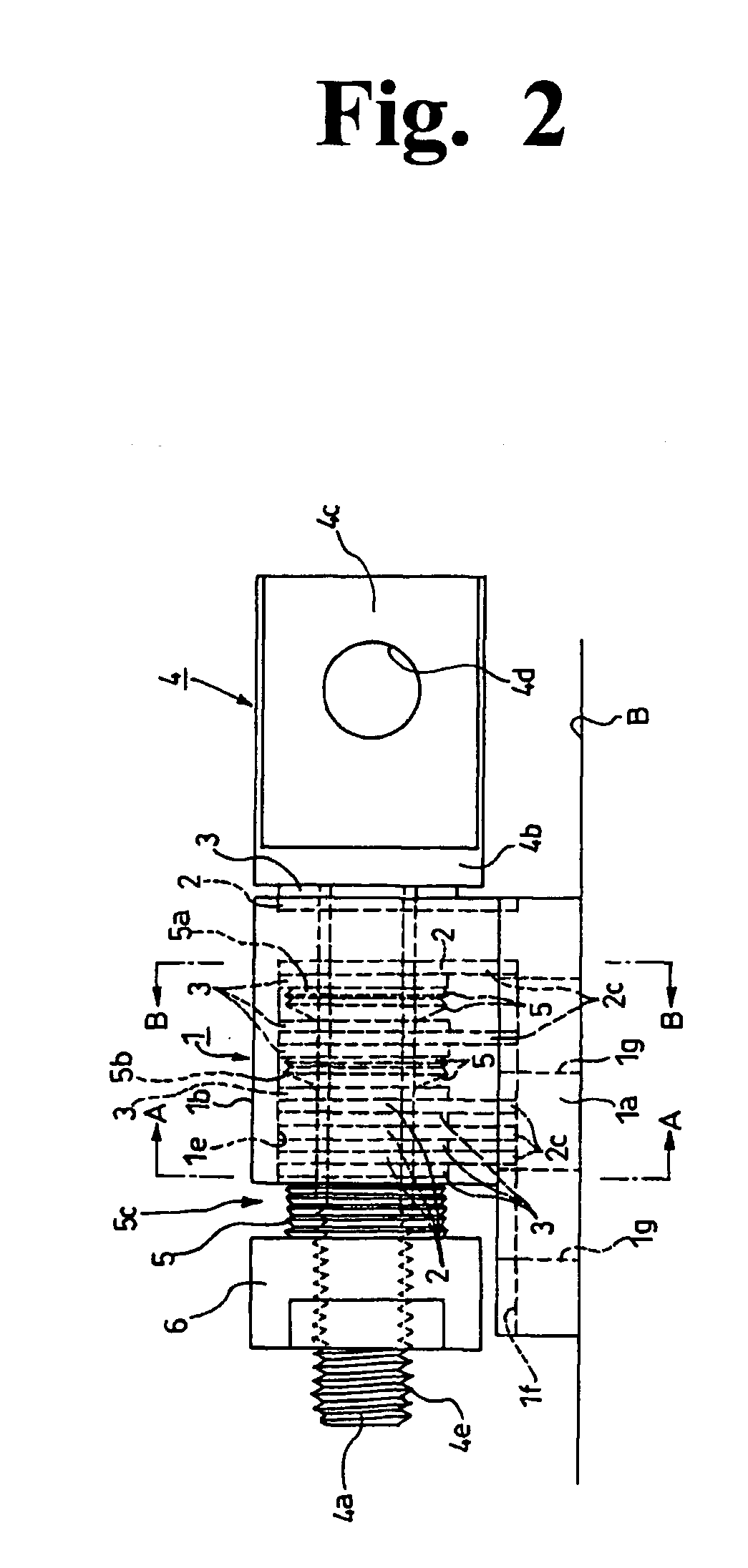

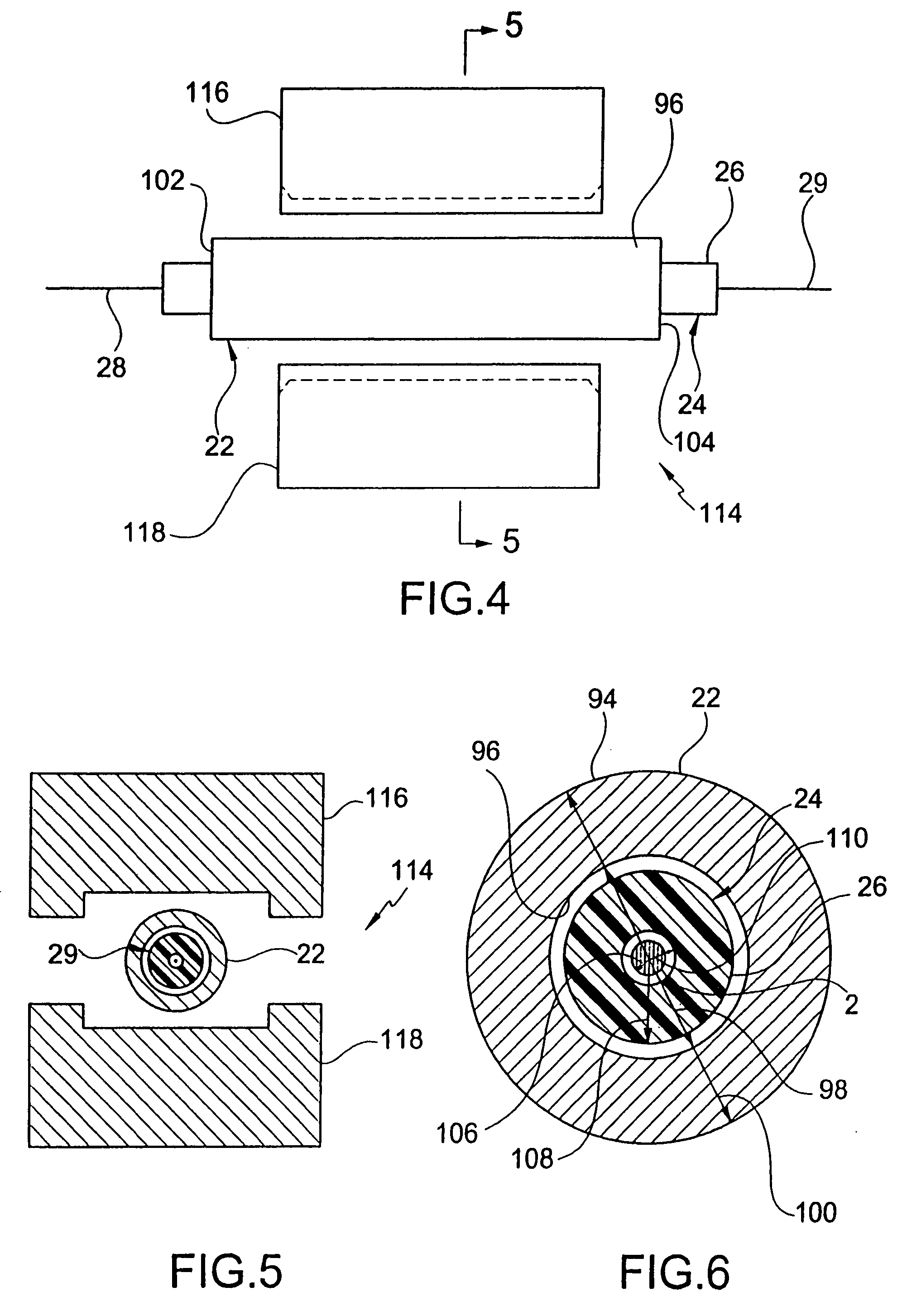

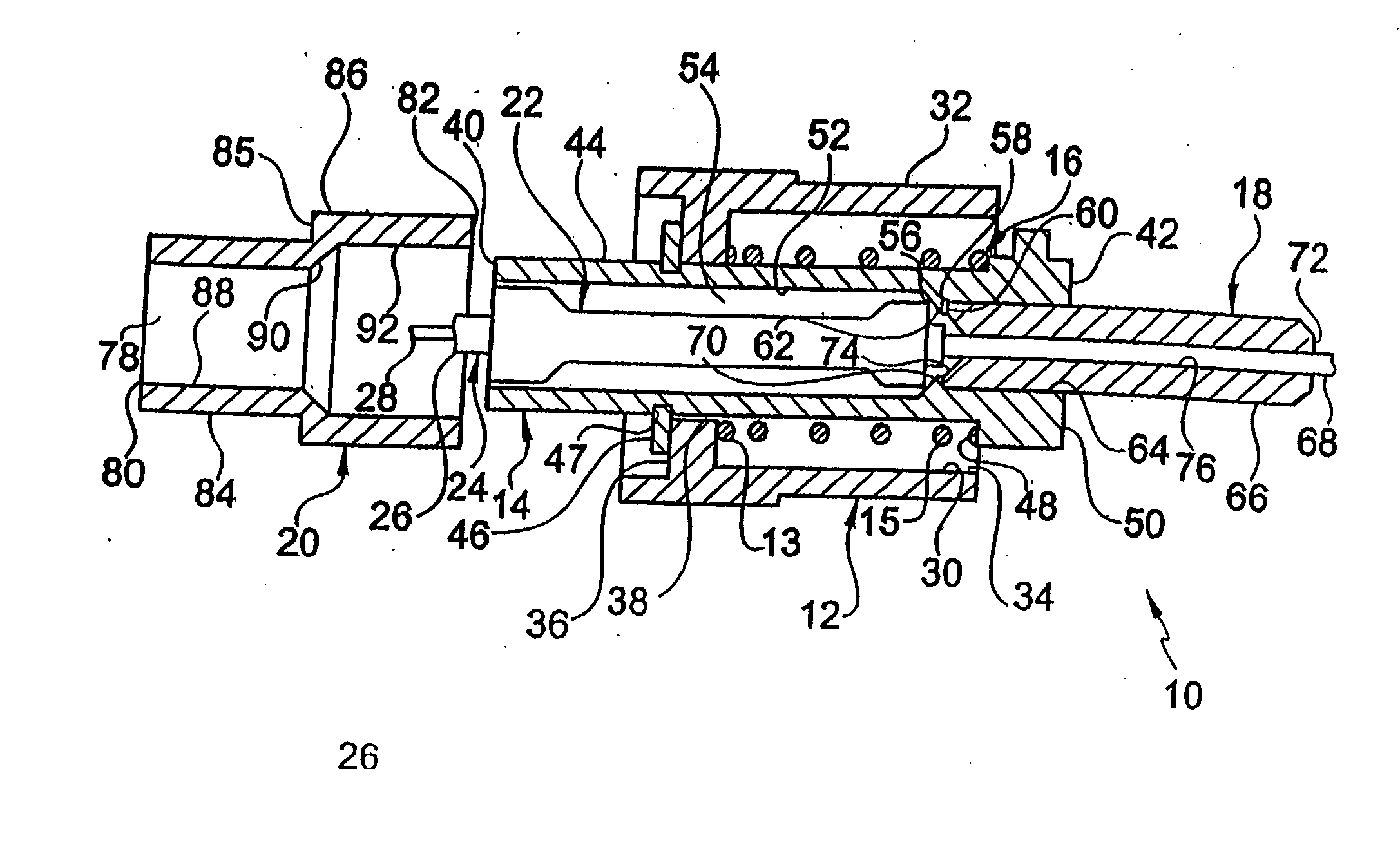

Tilt hinge

InactiveUS7143476B2Increase friction areaIncrease frictionWing fastenersDetails for portable computersFriction torqueEngineering

In order to provide a tilt hinge small in size and diameter capable of generating a stable friction torque of approximately 100 kgf / mm, a hinge friction-rotatably coupling a first member and a second member that are relatively opened / closed includes: a holder attached to one of the first member and the second member; a shaft attached to the other one of the first member and the second member to be rotatable relative to the holder and immovable in an axial direction; a plurality of first friction discs restrained by the holder to be rotatable and movable in the axial direction, with the shaft being inserted through insertion holes thereof; a plurality of second friction discs interposed between the first friction discs to be movable in the axial direction with rotation thereof restrained by the shaft; and a plurality of disc springs and / or spring washers attached to the shaft so as to bring the first friction discs and the second friction discs to be in contact with each other by pressing the first friction discs and the second friction discs in the axial direction, wherein the disc springs and / or the spring washers are provided outside the holder in which the first friction discs and the second friction discs are stacked on each other and inside the holder.

Owner:KATOH ELECTRIC MACHINERY

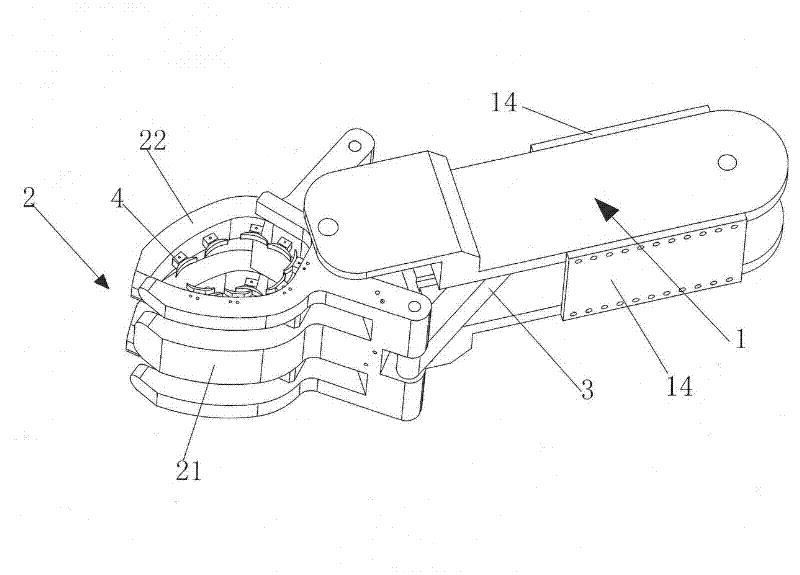

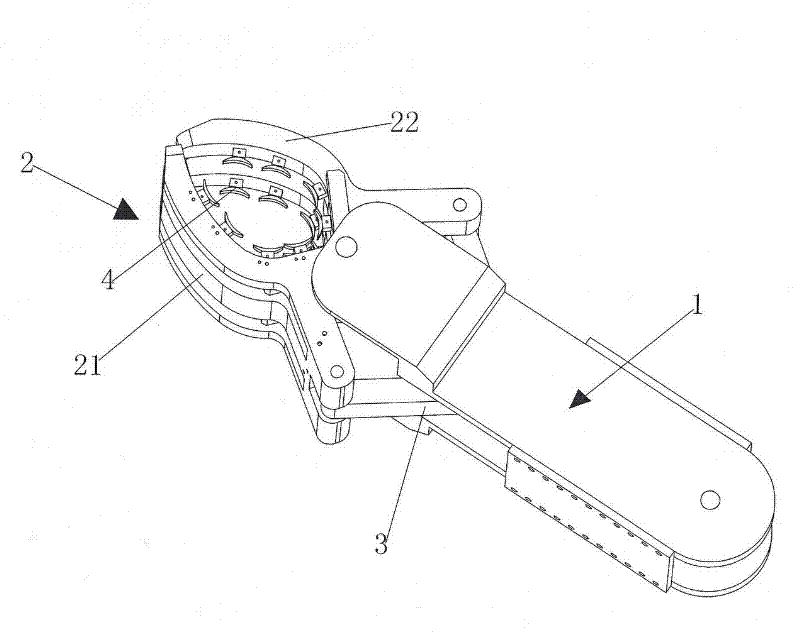

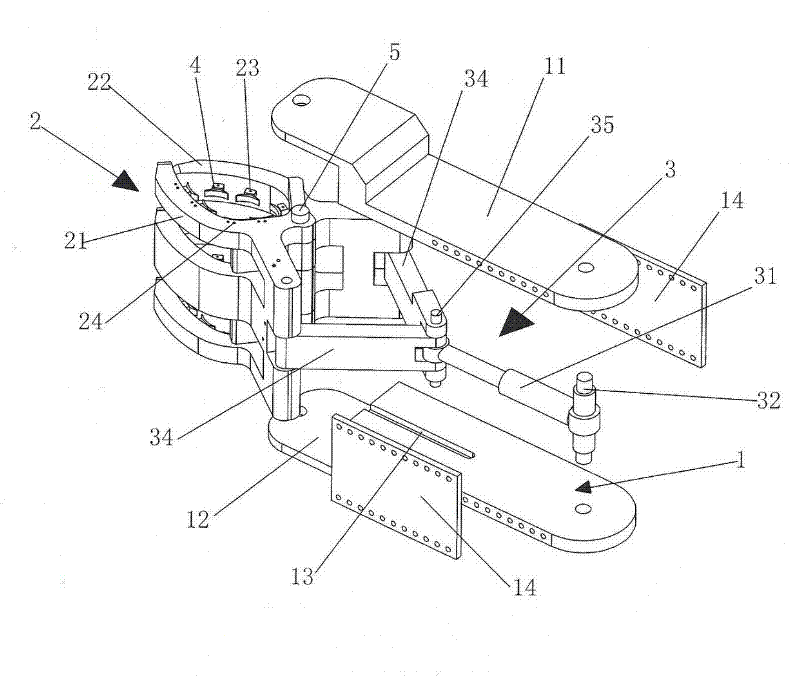

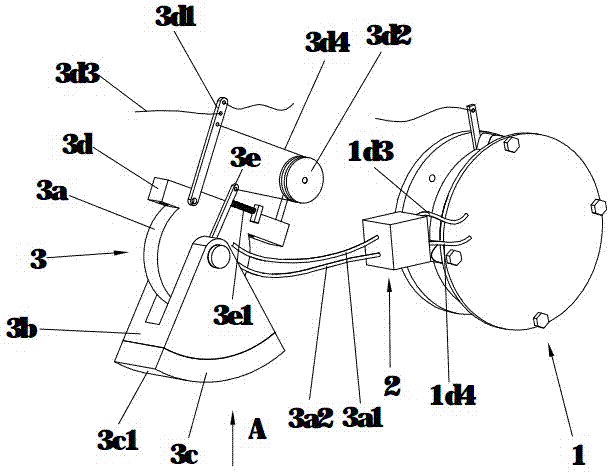

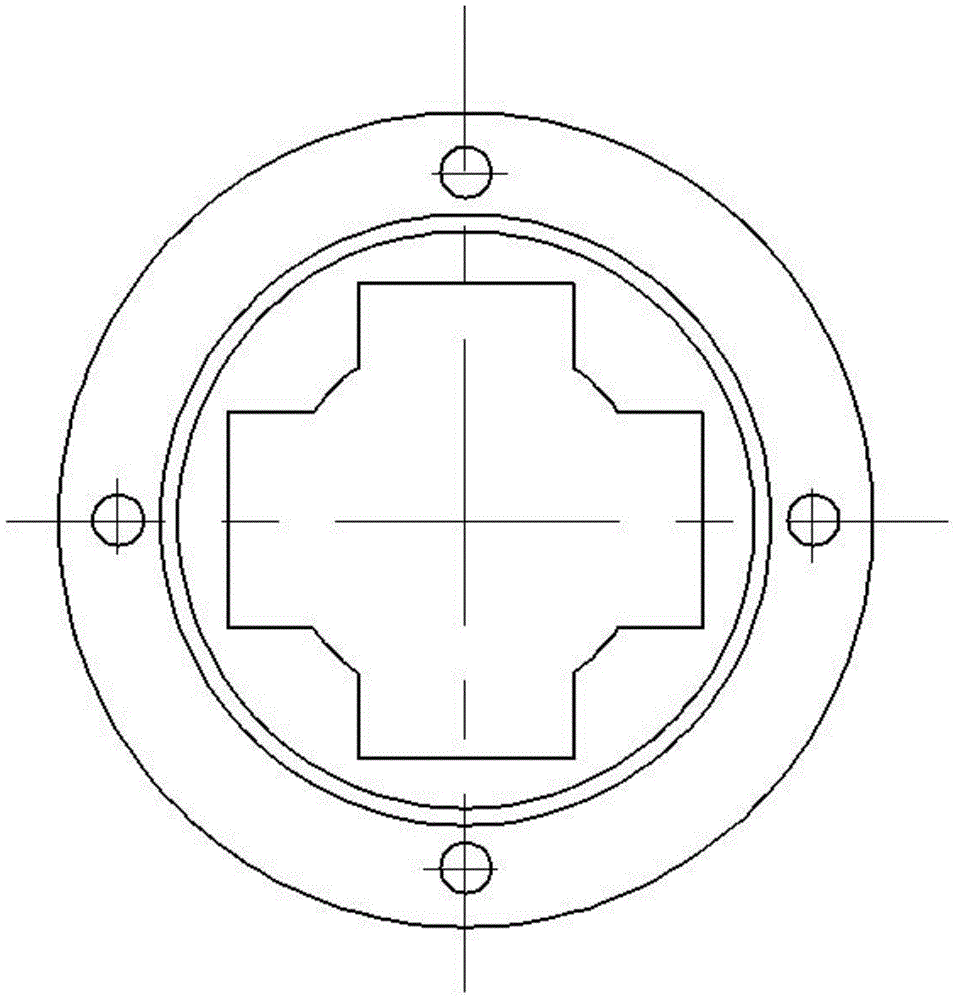

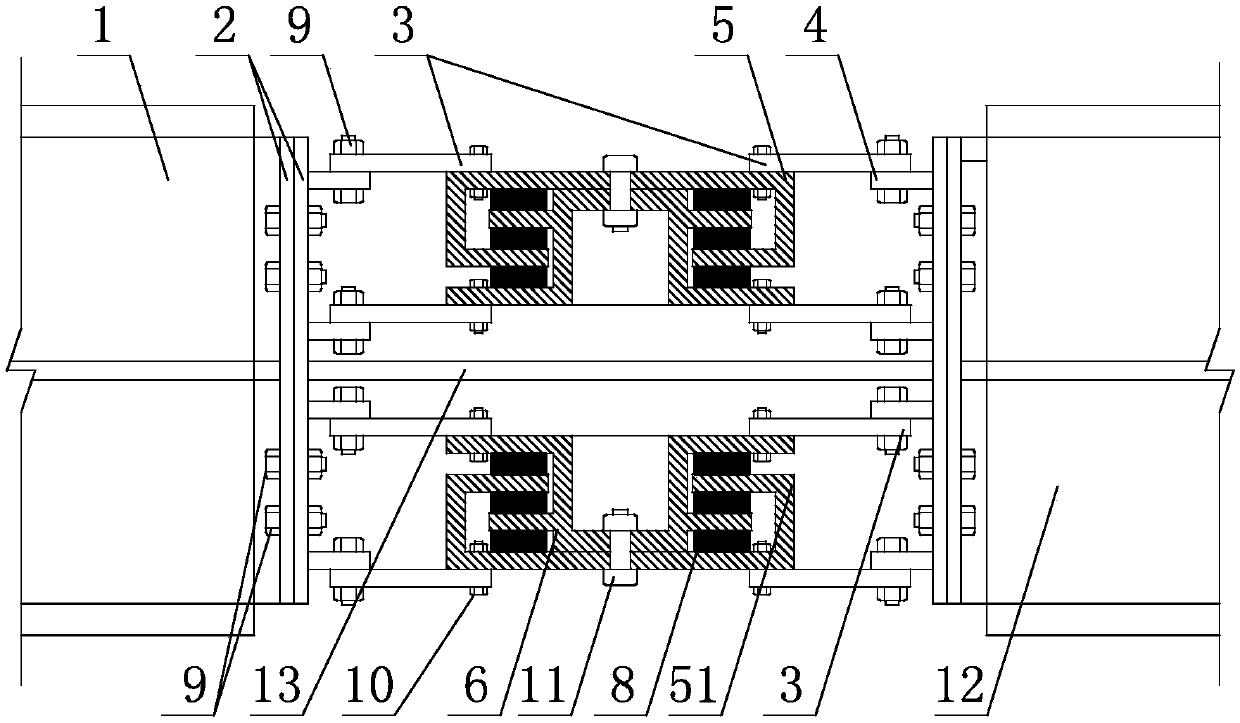

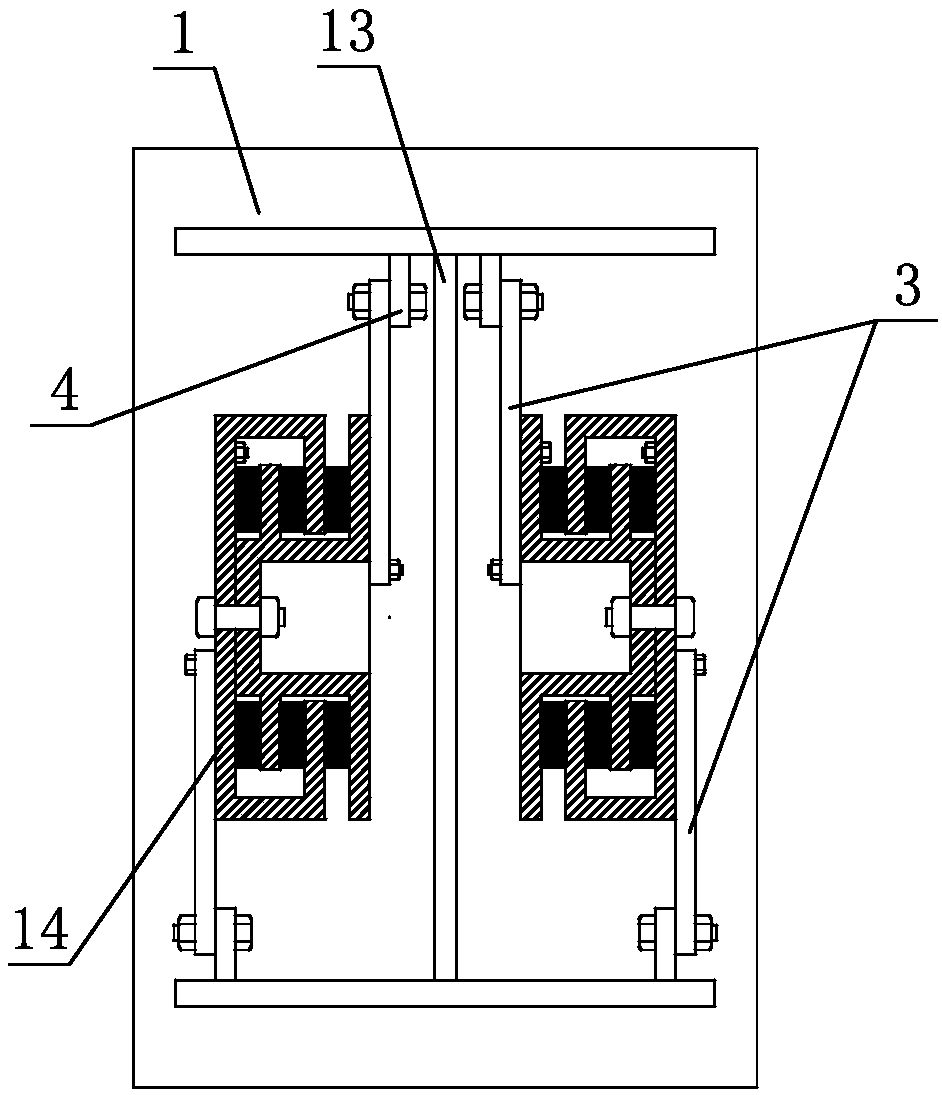

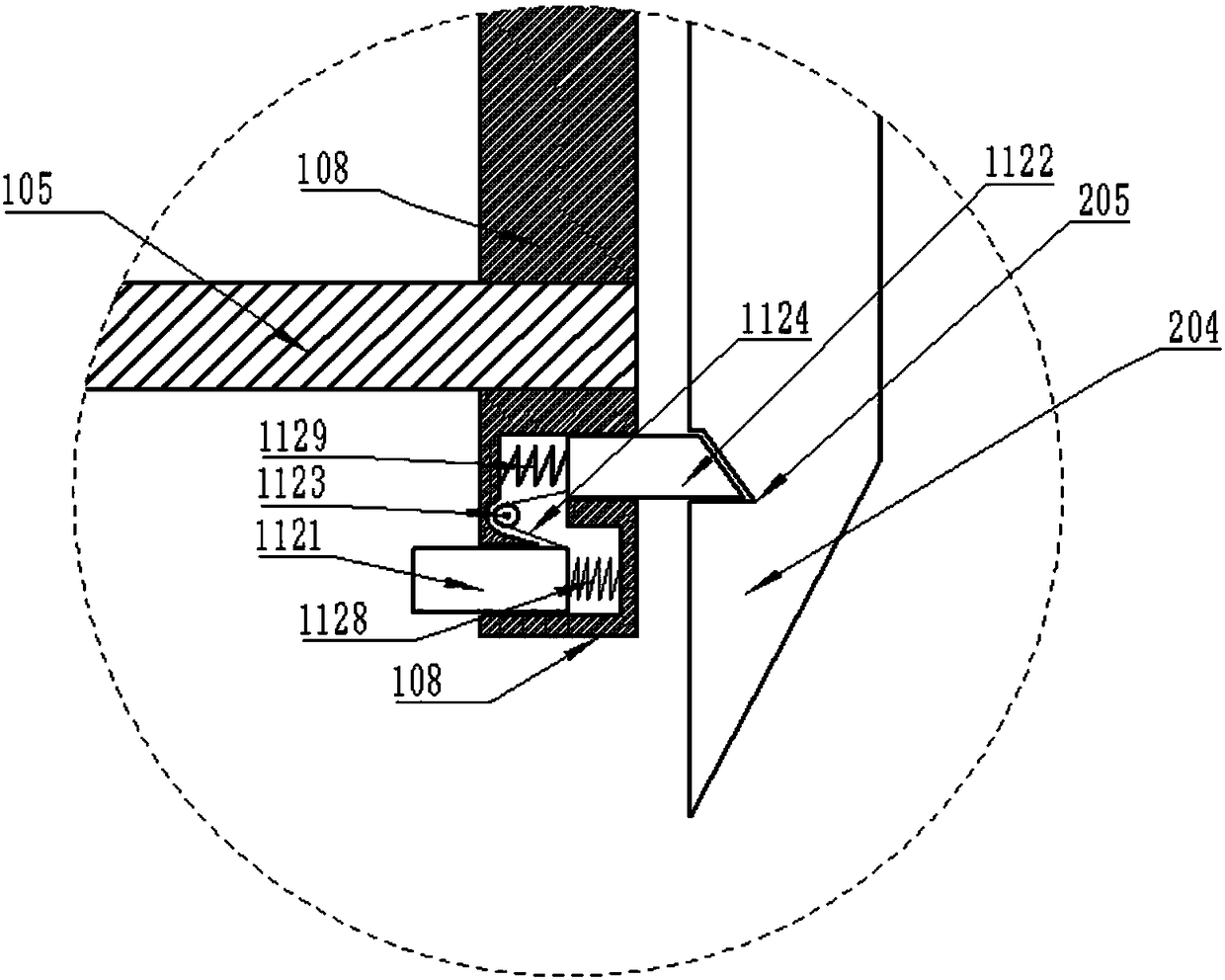

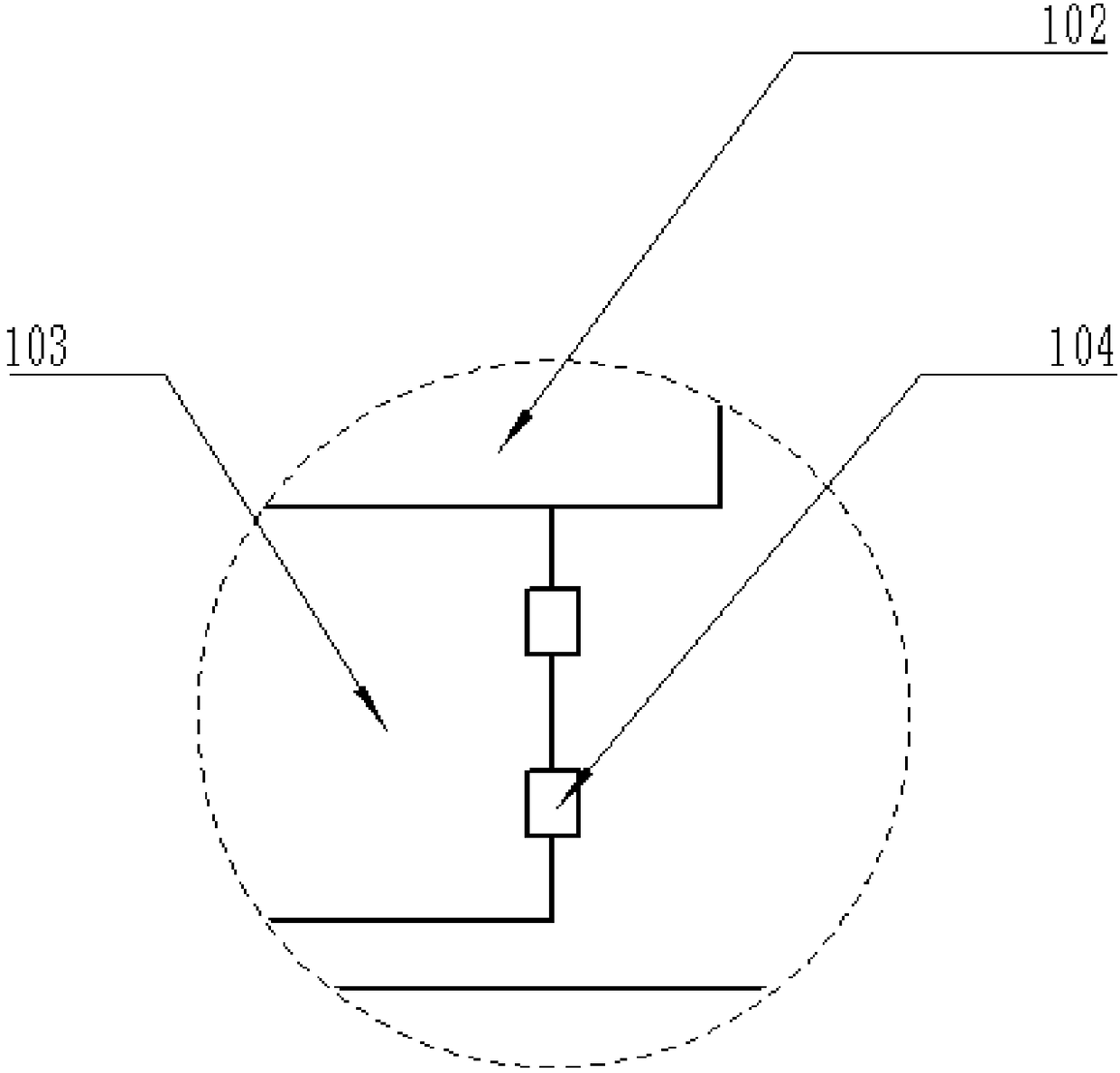

Multipoint mechanical hand for myriametre well drill

The invention discloses a multipoint mechanical hand for a myriametre well drill, which comprises an arm, a crossed hand, a hand driving mechanism and an elastic floating friction mechanism. The hand driving mechanism drives the crossed hand to open or close to clamp or release a tubular column, and the elastic floating friction mechanism is arranged on the inner side of the crossed hand. The crossed handle can be crossed to achieve grab of well casings with different pipe diameters, and one well drilling equipment only needs one handle. The elastic floating friction mechanism can automatically and slightly adjust angles to achieve a multipoint and force-equipotent clamping mode, and clamping points are evenly distributed around the well casing, so that too much clamping force is not required, and deformation of the well casing is avoided. An elastic friction sheet of the elastic floating friction mechanism is in a floating mode, so that friction area can be enlarged, the clamping force can be further reduced, and clamping can be reliable and safe.

Owner:JILIN UNIV

Dry type asbestos-free friction sheet

The invention relates to a dry-type friction plate without mineral cotton, comprising a metal frame of powder metallurgy and following compositions with weight, 1-5 iron oxide black, 5-10 cashew shell oil resin friction powder, 30-50 barium sulfate, 1-8 vermiculite, 5-10 molybdenum disulfide, 10-20 colloidal graphite, 15-20 binding agent, 20-30 ceramic fiber, 8-10 epoxide resin solidifying agent, and 5-6 antiaging agent, wherein the binding agent is constituted by 60%-70% formaldehyde-phenol resin and 30%-40% cashew shell oil resin friction powder. The preparation method of the friction plate comprises casting the metal frame by utilizing powder metallurgy, smearing the binding agent on the surface of the metal frame, preparing friction material with even mixture according to the composition, directly pressing the even mixing powder on the metal frame, and sintering 3-15 minutes with 200-220kg / mm2 of pressure in 180-210 DEG C of controlling temperature, and then heat pressing to shape.

Owner:杭州汉乐科新材料科技有限公司

Tilt hinge

InactiveUS20050066475A1Simple structureReduce manufacturing costWing fastenersDetails for portable computersFriction torqueEngineering

In order to provide a tilt hinge small in size and diameter capable of generating a stable friction torque of approximately 100 kgf / mm, a hinge friction-rotatably coupling a first member and a second member that are relatively opened / closed includes: a holder attached to one of the first member and the second member; a shaft attached to the other one of the first member and the second member to be rotatable relative to the holder and immovable in an axial direction; a plurality of first friction discs restrained by the holder to be rotatable and movable in the axial direction, with the shaft being inserted through insertion holes thereof; a plurality of second friction discs interposed between the first friction discs to be movable in the axial direction with rotation thereof restrained by the shaft; and a plurality of disc springs and / or spring washers attached to the shaft so as to bring the first friction discs and the second friction discs to be in contact with each other by pressing the first friction discs and the second friction discs in the axial direction, wherein the disc springs and / or the spring washers are provided outside the holder in which the first friction discs and the second friction discs are stacked on each other and inside the holder.

Owner:KATOH ELECTRIC MACHINERY

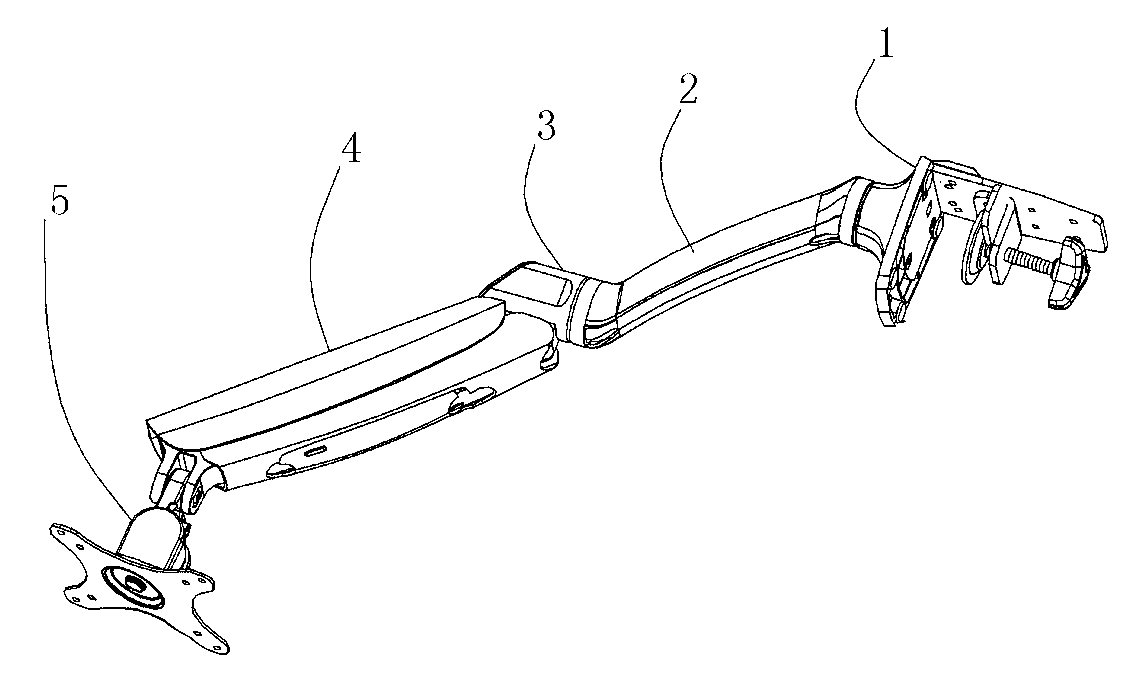

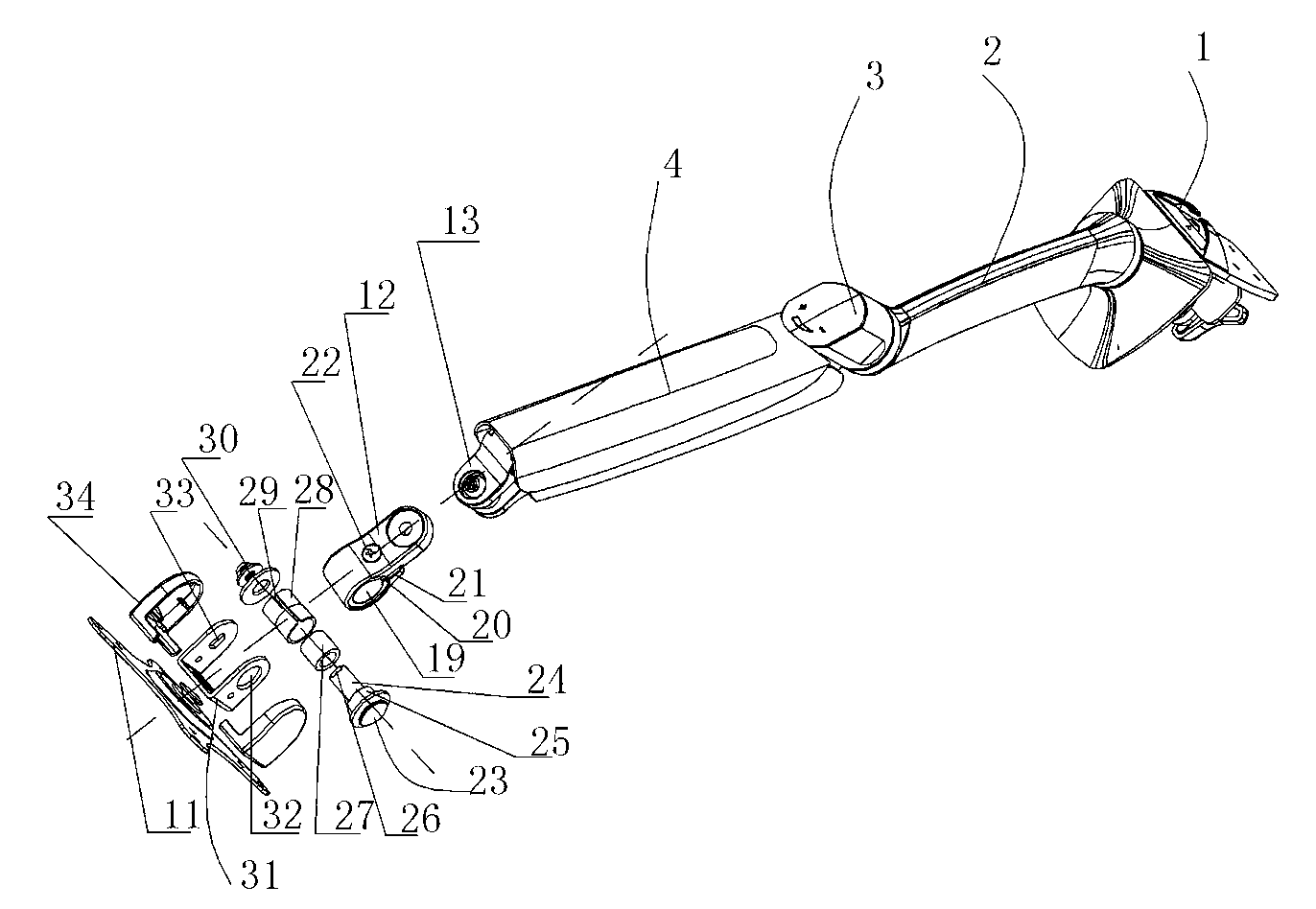

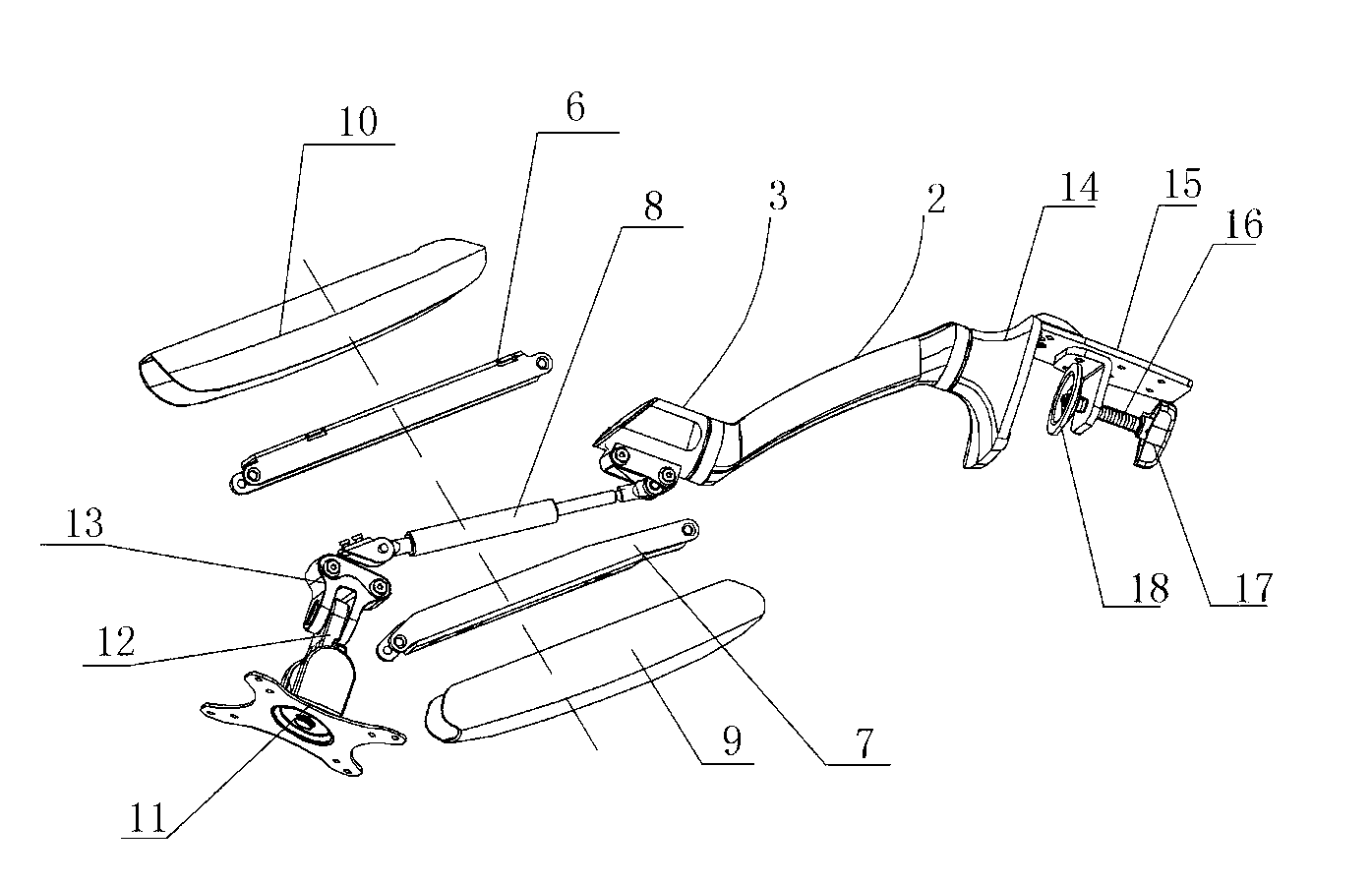

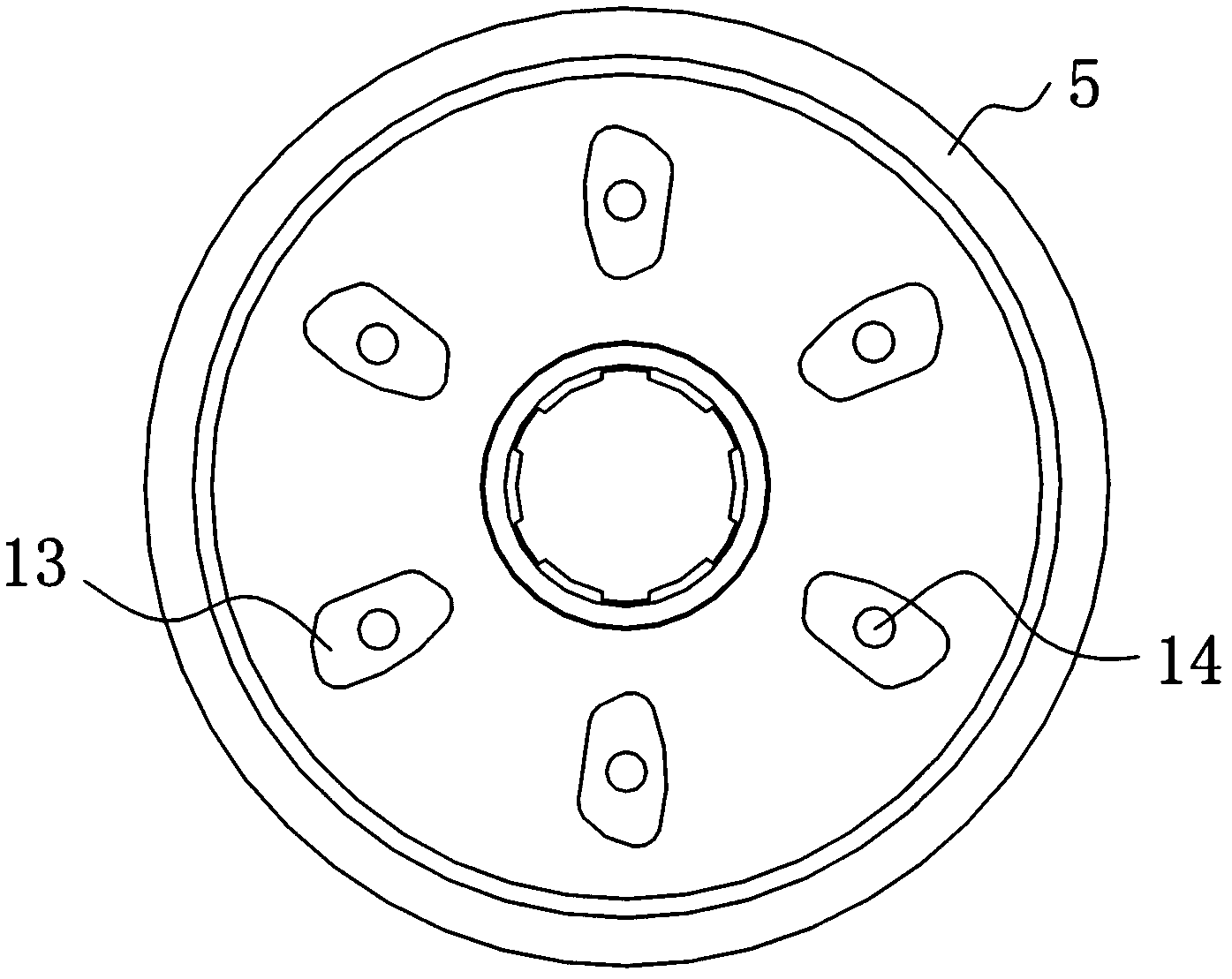

Display support

The invention discloses a display support. The display support comprises an angle-adjustable support body and a display hanging plate component (5). A joint (13) is connected on the support body. The display hanging plate component (5) comprises a hanging plate (11), a connector (31) and a connecting block (12), the hanging plate (11) is rotationally connected with the connector (31), one end of the connecting block (12) is rotationally connected with the joint (13), the other end of the connecting block (12) is provided with a shaft hole (19), a rotary shaft (23) is in close fit in the shaft hole (19), a one-way bearing (27) is connected on the rotary shaft (23), an outer circle of the one-way bearing (27) is in close fit with the inner wall of the shaft hole (19), and two ends of the rotary shaft (23) are fixedly connected with the connector (31). The display support is capable of protecting the hanging plate from downward inclining due to dead weight of a display and the angle of the hanging plate is laborsaving and convenient to adjust.

Owner:LOCTEK ERGONOMIC TECH CORP

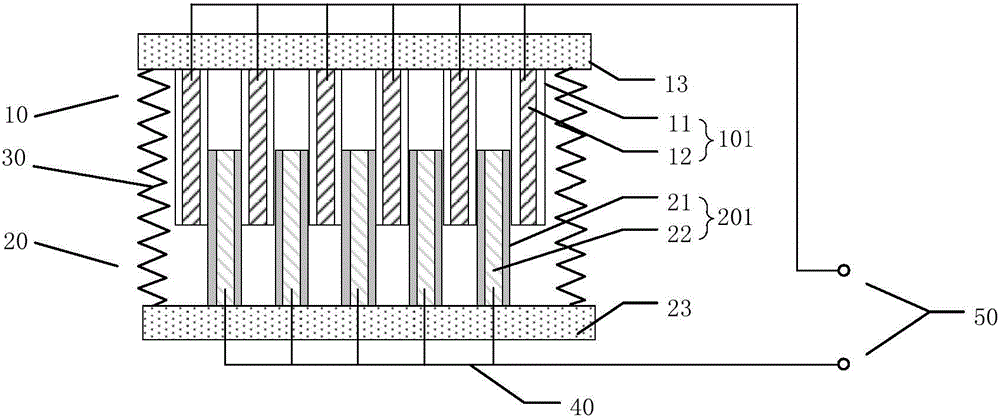

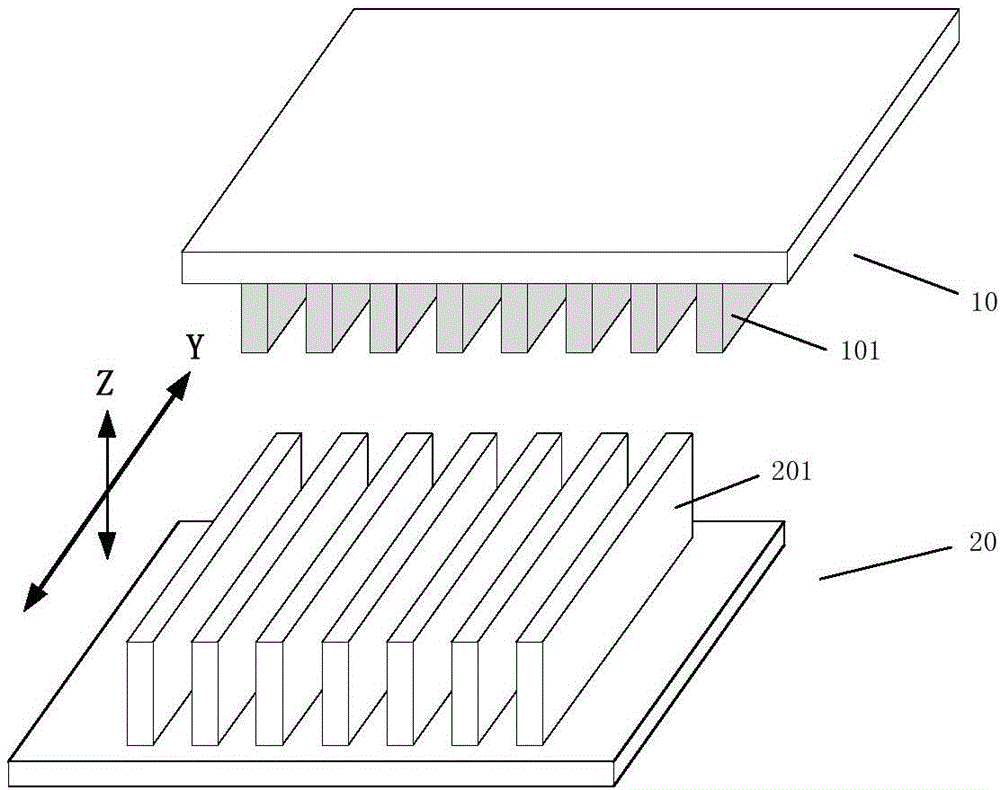

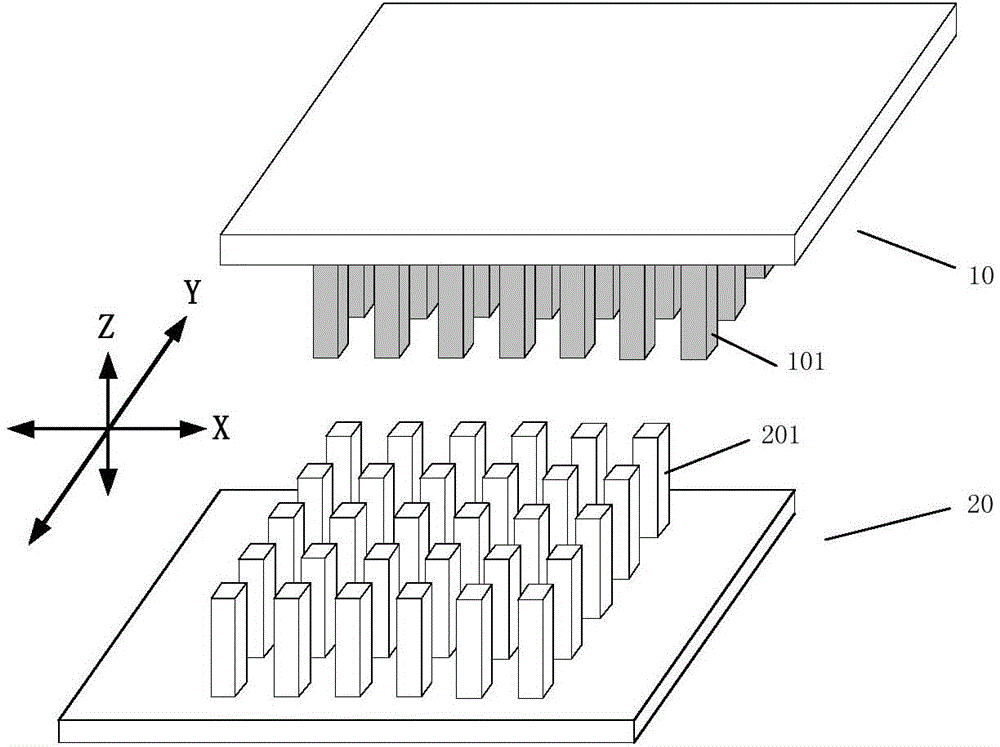

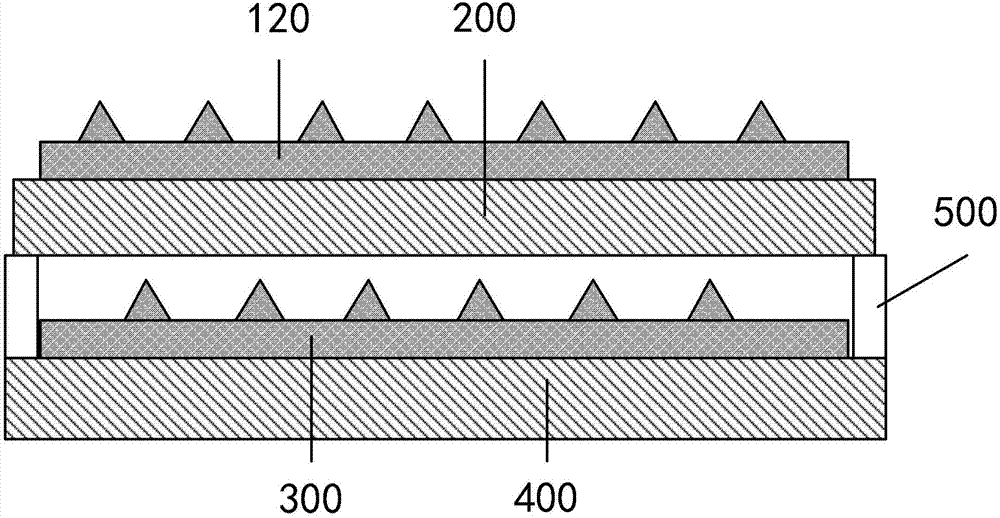

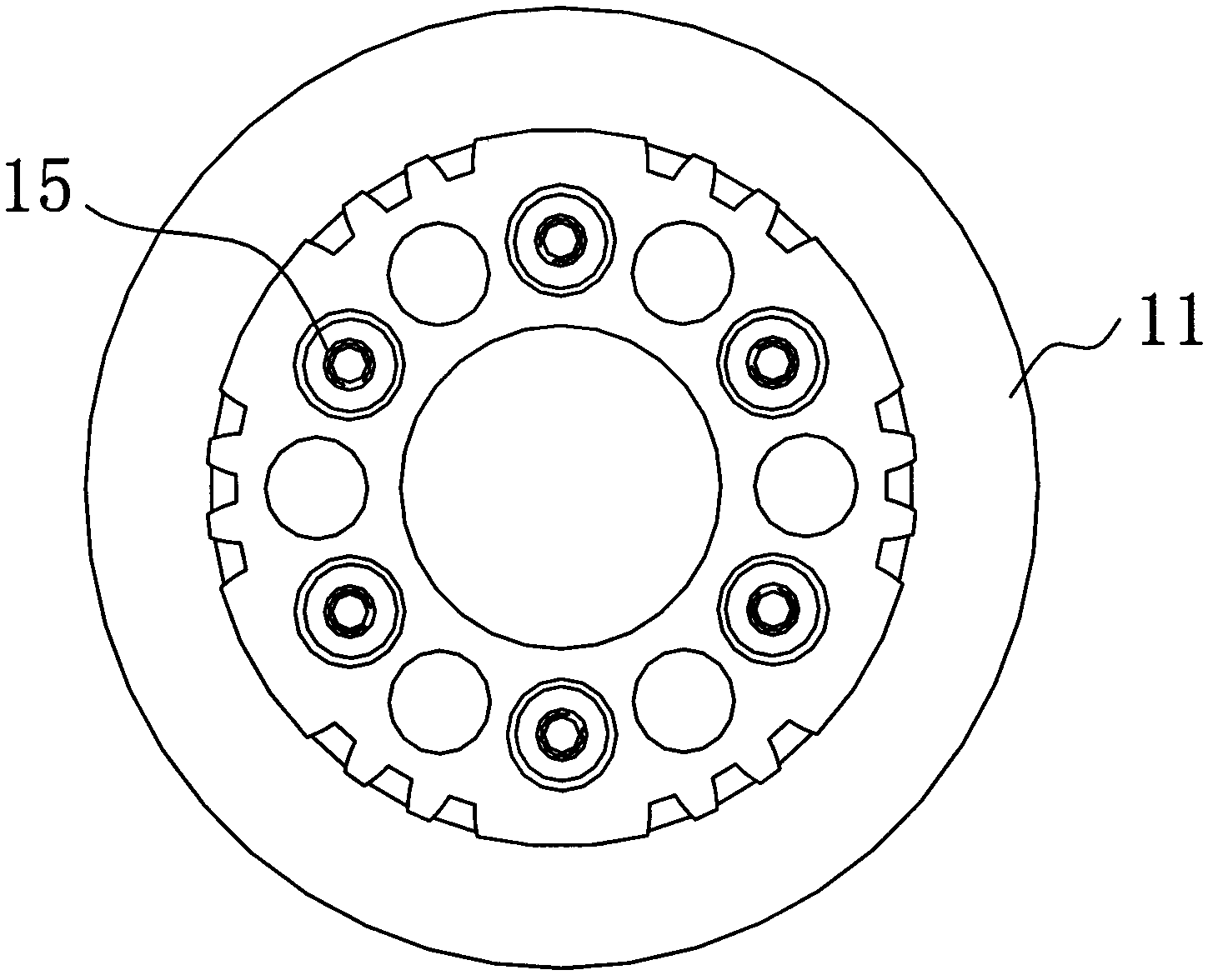

Friction nanometer power generator with gear shaping structure

ActiveCN104426420AImprove output performanceIncrease friction areaFriction generatorsGeneration processElectricity

The invention discloses a friction nanometer power generator with a gear shaping structure. The power generator mainly comprises two friction components which are connected through an elastic component, wherein at least one component is of the gear shaping structure which is formed by arranging a plurality of friction units; the gear shaping structure can form a tight occluding state with a friction unit on the other component; under the action of the elastic components, the relative position between the two components can be periodically changed by external force, so that a friction power generation process is promoted, and an electrical signal can be output outwards by the power generator. Effective extraction of vibration energy by sliding friction is realized for the first time through cooperation between the two friction units and the elastic components; meanwhile, through the occluding between first friction units and second friction units matched with the first friction units which are distributed in a gear shaping state, the area of sliding friction is increased, and the electricity output performance of the power generator is improved.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

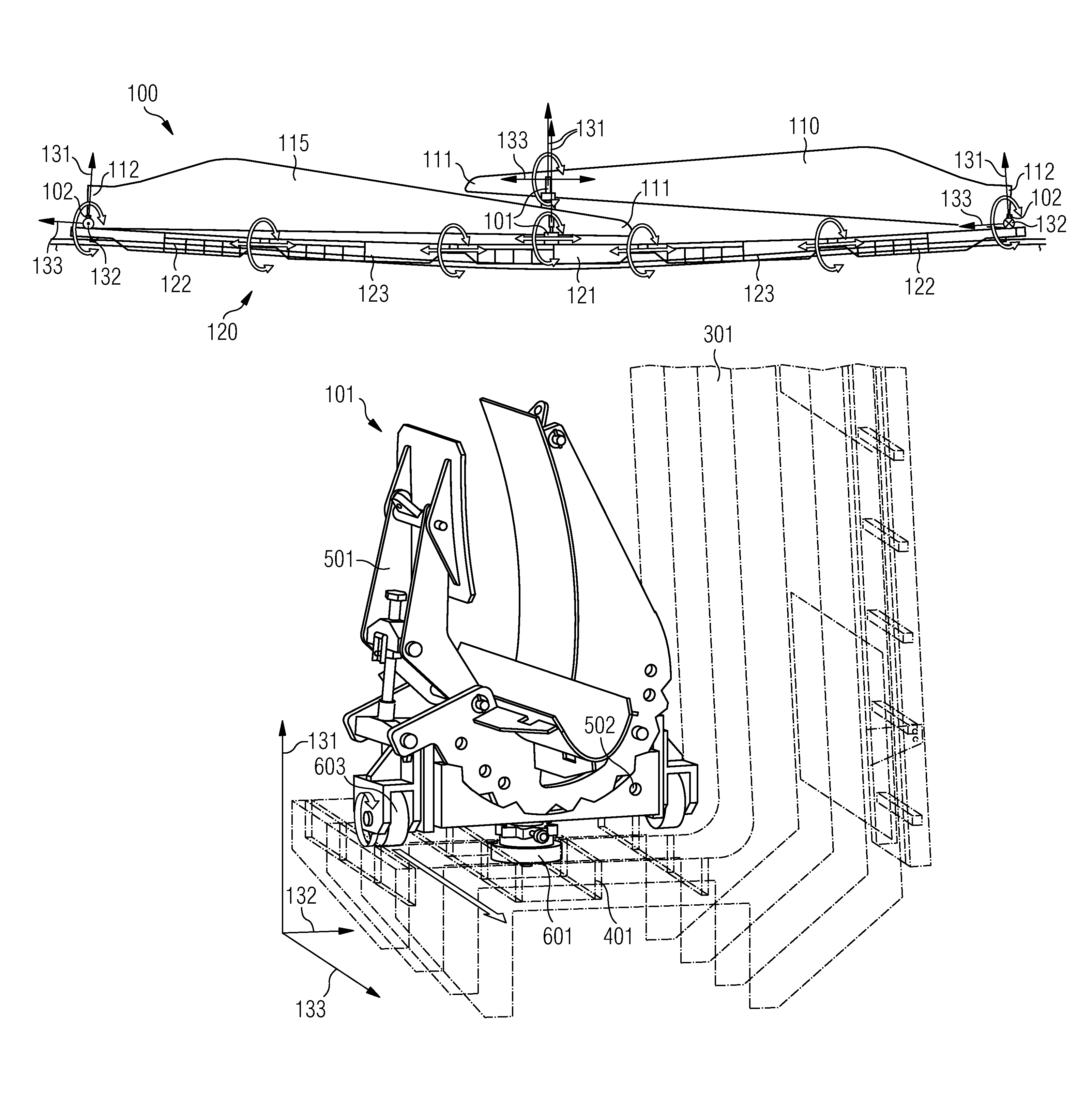

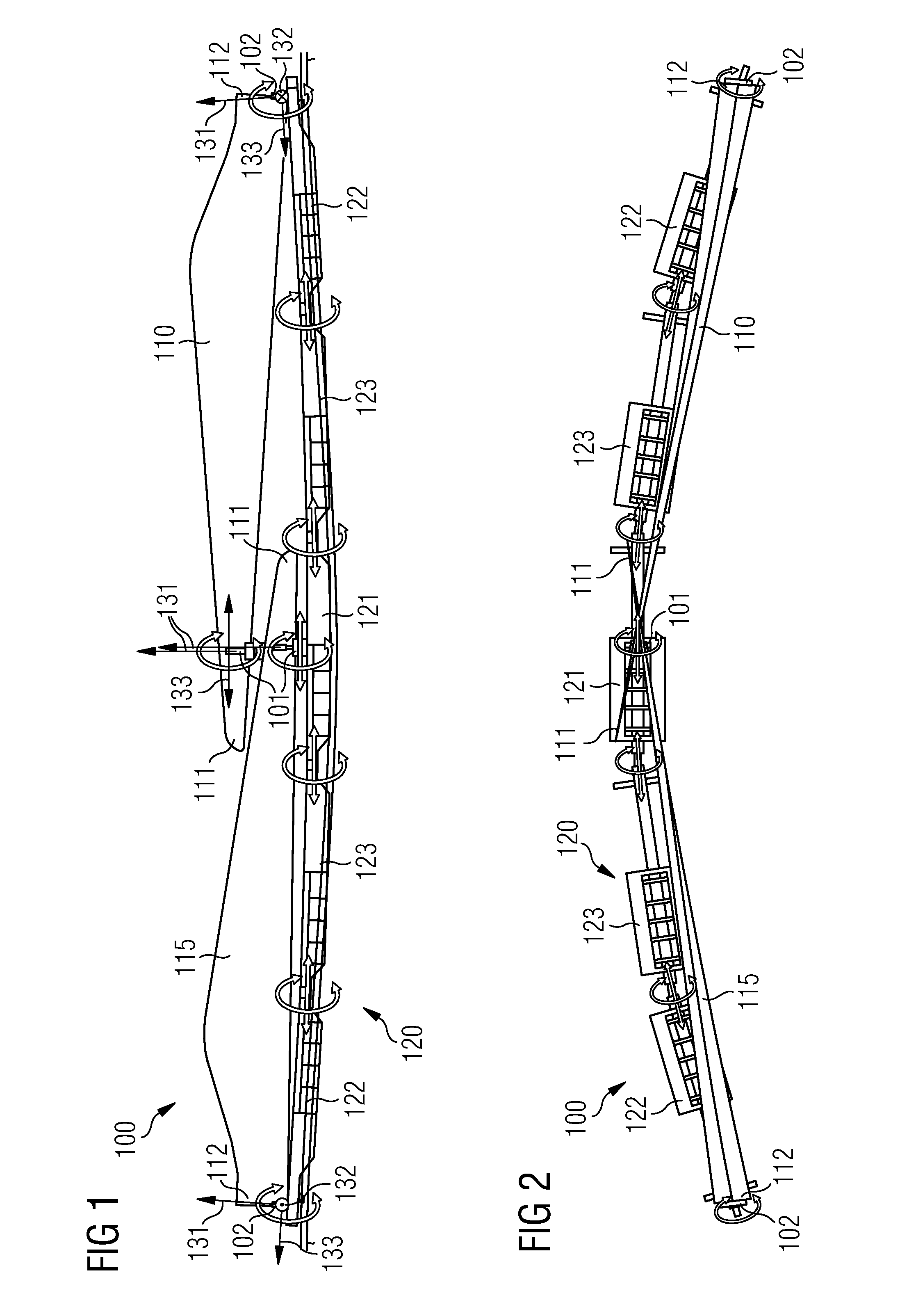

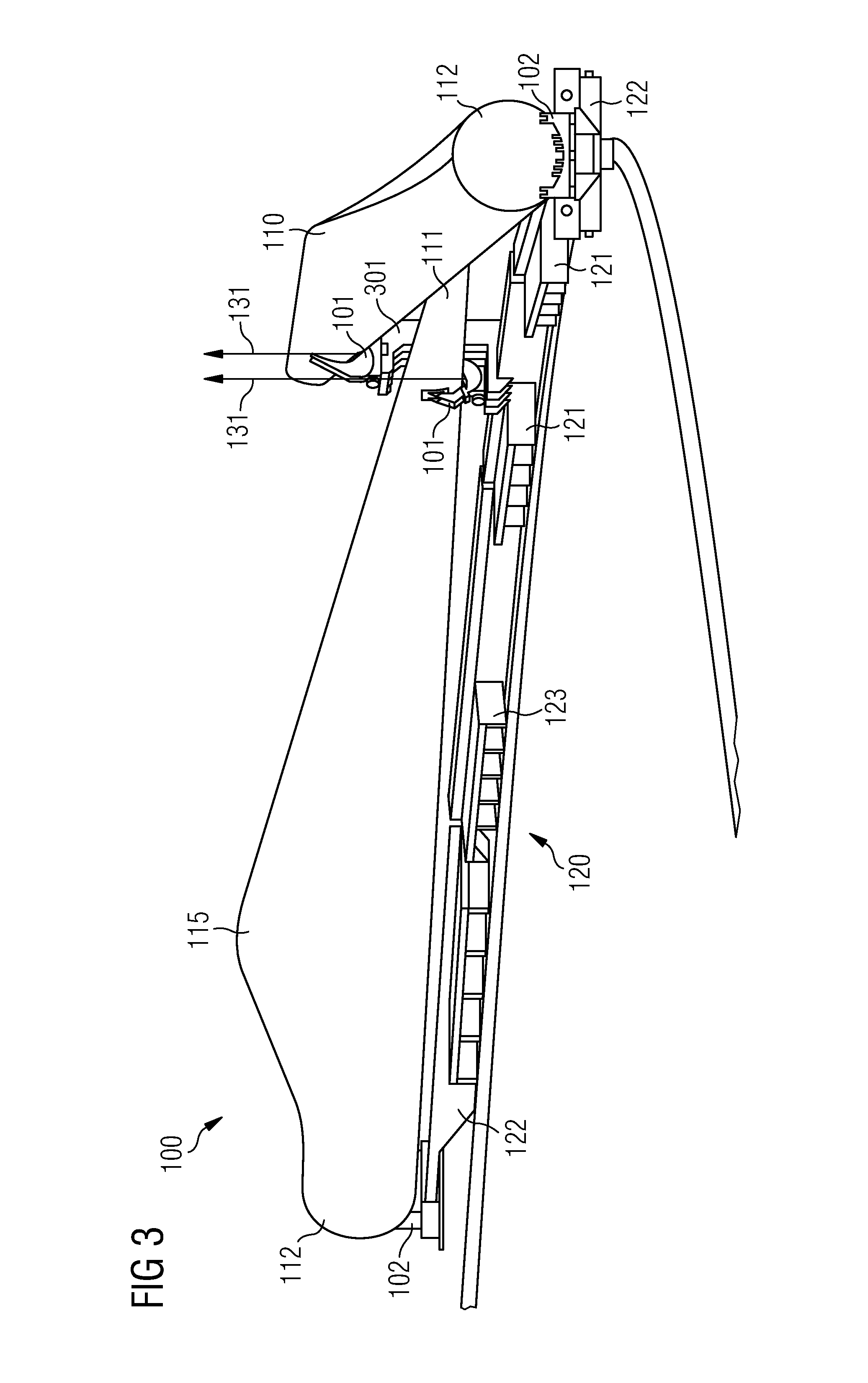

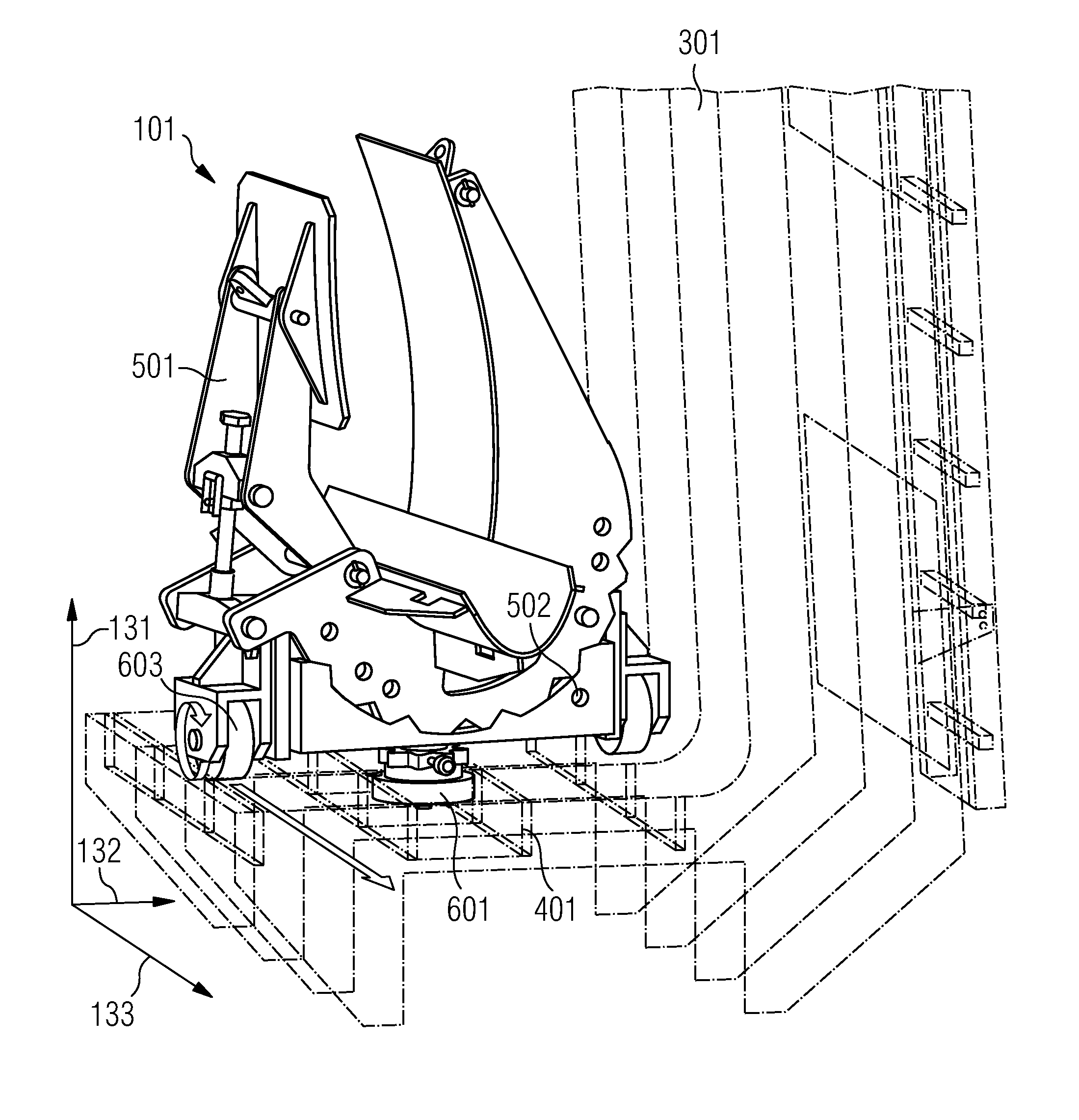

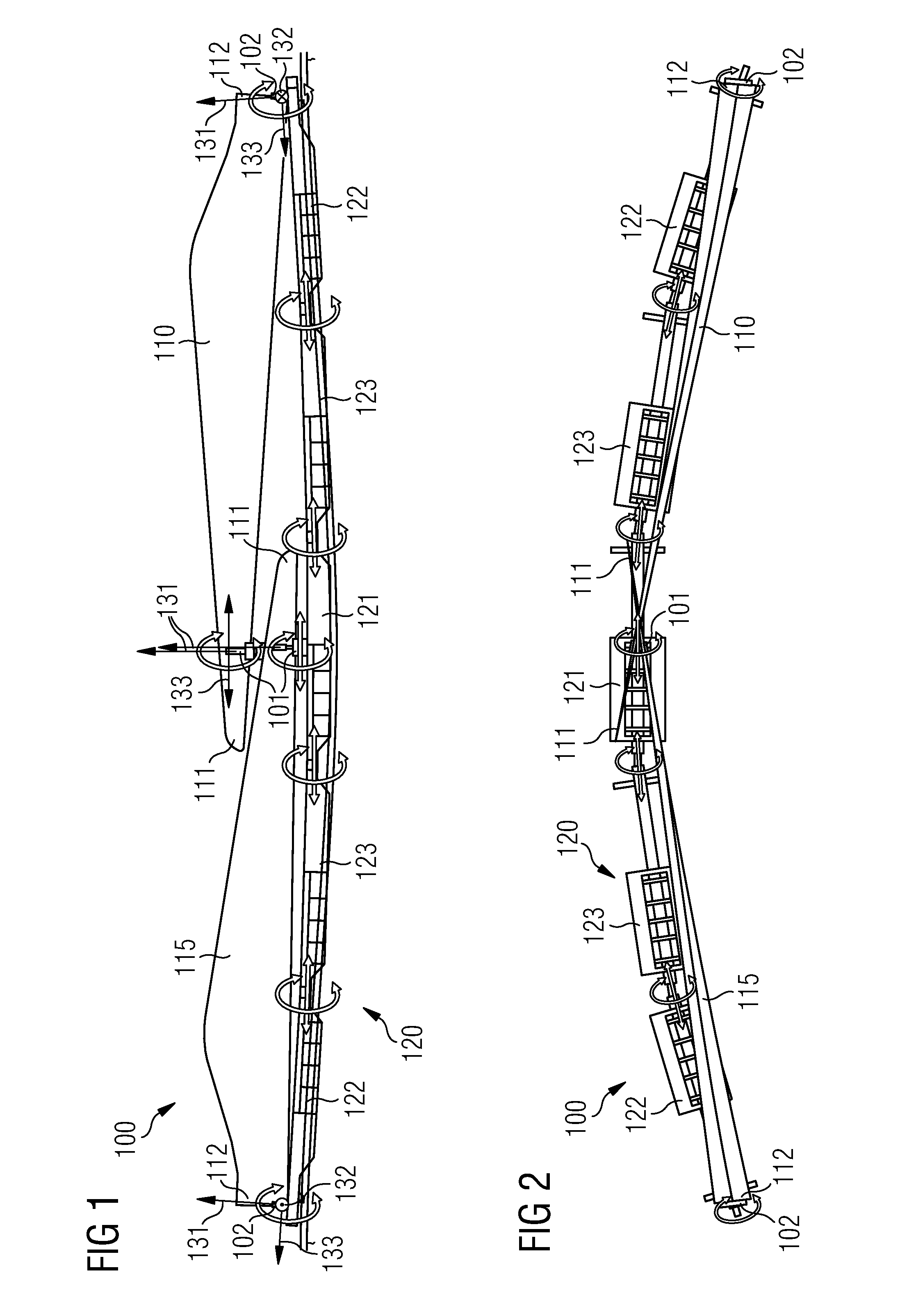

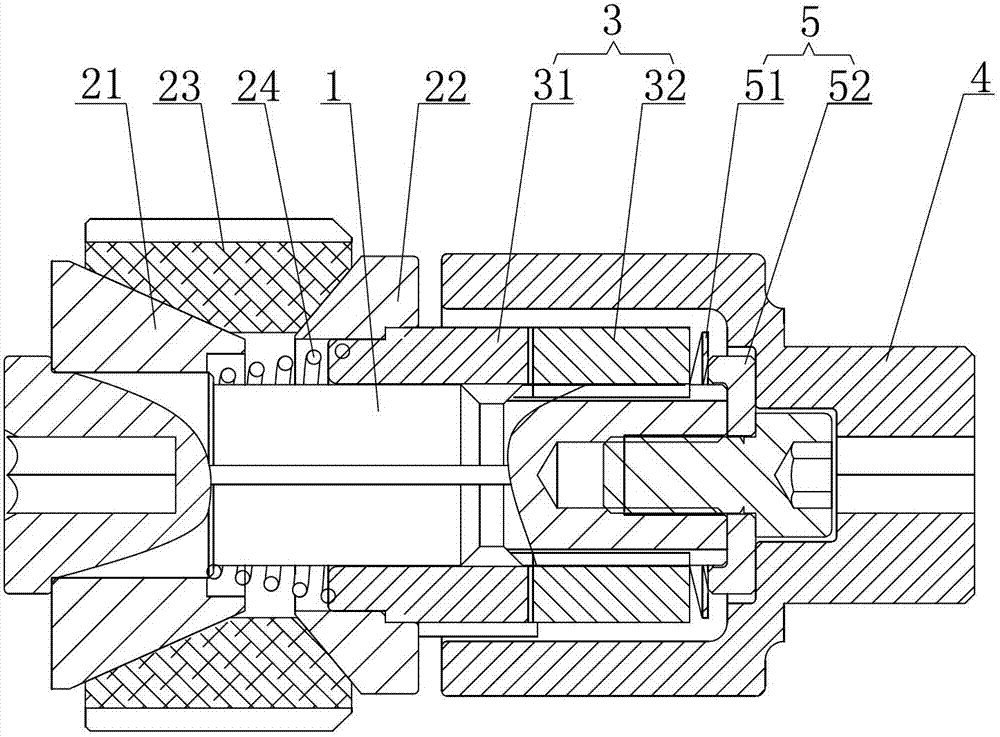

System for transportation of blades on railcars

ActiveUS8056203B2Relieve pressureNo wasteMeasurement/indication equipmentsVehicle to carry long loadsEngineeringTurbine

A fixation system for fixing wind turbine elements of a wind turbine to a vehicle is provided. The fixation system includes a first fixation device for fixing a first portion of a wind turbine element pivotably around a first axis of the first fixation device and around a second axis of the first fixation device to the vehicle. A second fixation device fixes a second portion of the wind turbine element pivotably around a first axis of the second fixation device and around a second axis of the second fixation device. One of the first fixation device and of the second fixation device is adapted for providing a translation movement of the wind turbine element with respect to the vehicle along a third axis. The first axis, the second axis and the third axis are different.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

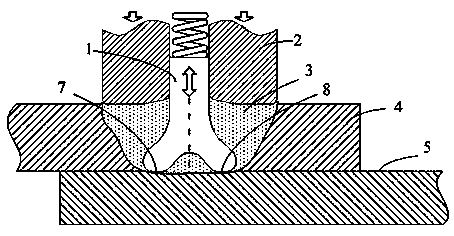

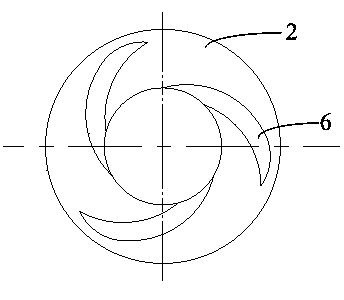

Solid-phase welding method and device of overlap connection of aluminum materials and high melting point metal

ActiveCN103846542AImprove stabilityGuaranteed moderate frictionNon-electric welding apparatusEngineeringDisplacement control

The invention relates to a solid-phase welding method of overlap connection of aluminum materials and high melting point metal. The solid-phase welding method comprises a solid-phase welding process. A solid-phase welding device comprises welding tools. The solid-phase welding method and device is characterized in that the welding tools comprise a double motion control stirring pin and a shaft shoulder separation tool; the axial motion of the stirring pin is controlled by the constant pressure; a shaft shoulder is controlled by the displacement; large area contact and friction characteristics are formed between the end portion of the stirring pin and base metal; a three involute groove is formed in the end surface of the shaft shoulder and accordingly a cohesion trend of the materials is formed; the welding tools are matched with appropriate welding parameters to control an interface intermetallic compound layer and accordingly the stirring friction welding connection with no inclination is achieved. According to the solid-phase welding method of the overlap connection of the aluminum materials and the high melting point metal, the high-strength and high-stability connection between the aluminum materials and the high melting point metal can be achieved and the problem of control of dissimilar metal welding interface intermetallic compounds is solved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

System for Transportation of Blades on Railcars

ActiveUS20110131785A1Relieve pressureNo wasteVehicle to carry long loadsMachines/enginesTurbineTruck

A fixation system for fixing wind turbine elements of a wind turbine to a vehicle is provided. The fixation system includes a first fixation device for fixing a first portion of a wind turbine element pivotably around a first axis of the first fixation device and around a second axis of the first fixation device to the vehicle. A second fixation device fixes a second portion of the wind turbine element pivotably around a first axis of the second fixation device and around a second axis of the second fixation device. One of the first fixation device and of the second fixation device is adapted for providing a translation movement of the wind turbine element with respect to the vehicle along a third axis. The first axis, the second axis and the third axis are different.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

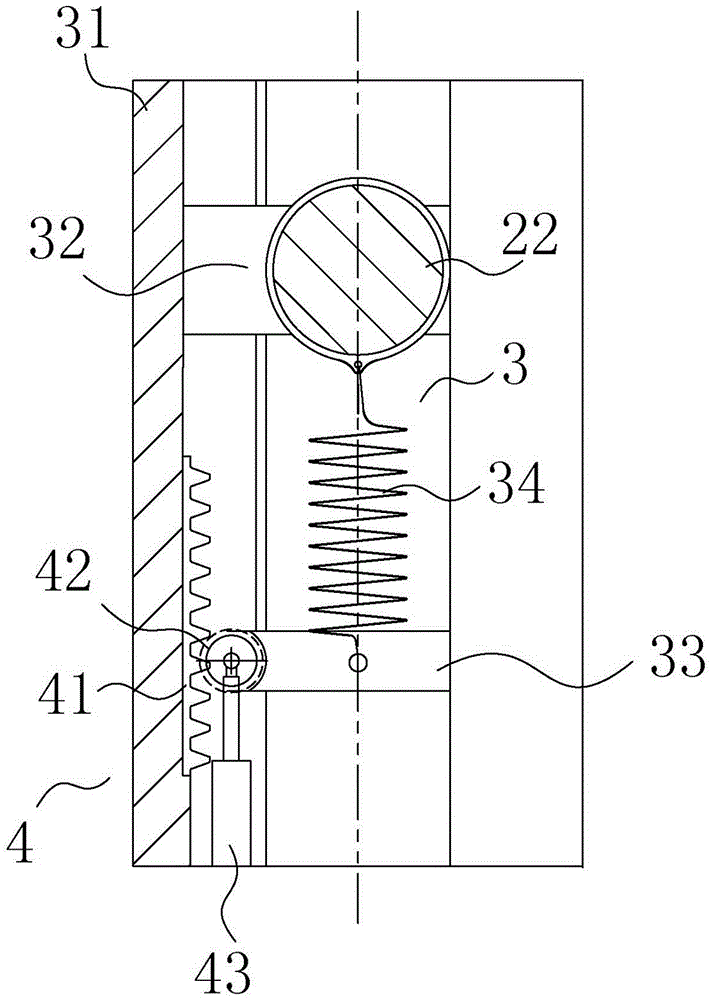

Winch brake device

InactiveCN102730591AImprove braking performanceIncrease the areaHoisting equipmentsWinchFriction force

The invention discloses a winch brake device which comprises a brake shaft, an outer brake cone plate, an inner brake cone plate, a brake hub, a spiral clutch mechanism and a brake coupling band, wherein the outer brake cone plate, the inner brake cone plate, the brake hub, the spiral clutch mechanism and the brake coupling band are arranged on the brake shaft; a brake drum is meshed with drum key teeth of the winch; the brake shaft drives the spiral clutch mechanism to separate; the outer brake cone plate and the inner brake cone plate respectively clamp the brake hub by the separating process of the spiral clutch mechanism; the outer brake cone plate and the inner brake cone plate are adopted to clamp the brake hub; and the brake hub and the cone plate are in conical contact, the area is larger, the friction force is increased, and brake is reliable. Compared with the existing conical drum tensioning brake, the brake hub is meshed with the drum key teeth of the winch, so the brake force loss is small, the brake response is effectively improved, and the brake performance of the winch is comprehensively improved.

Owner:ZHEJIANG NOWVOW MECHANICAL & ELECTRICAL

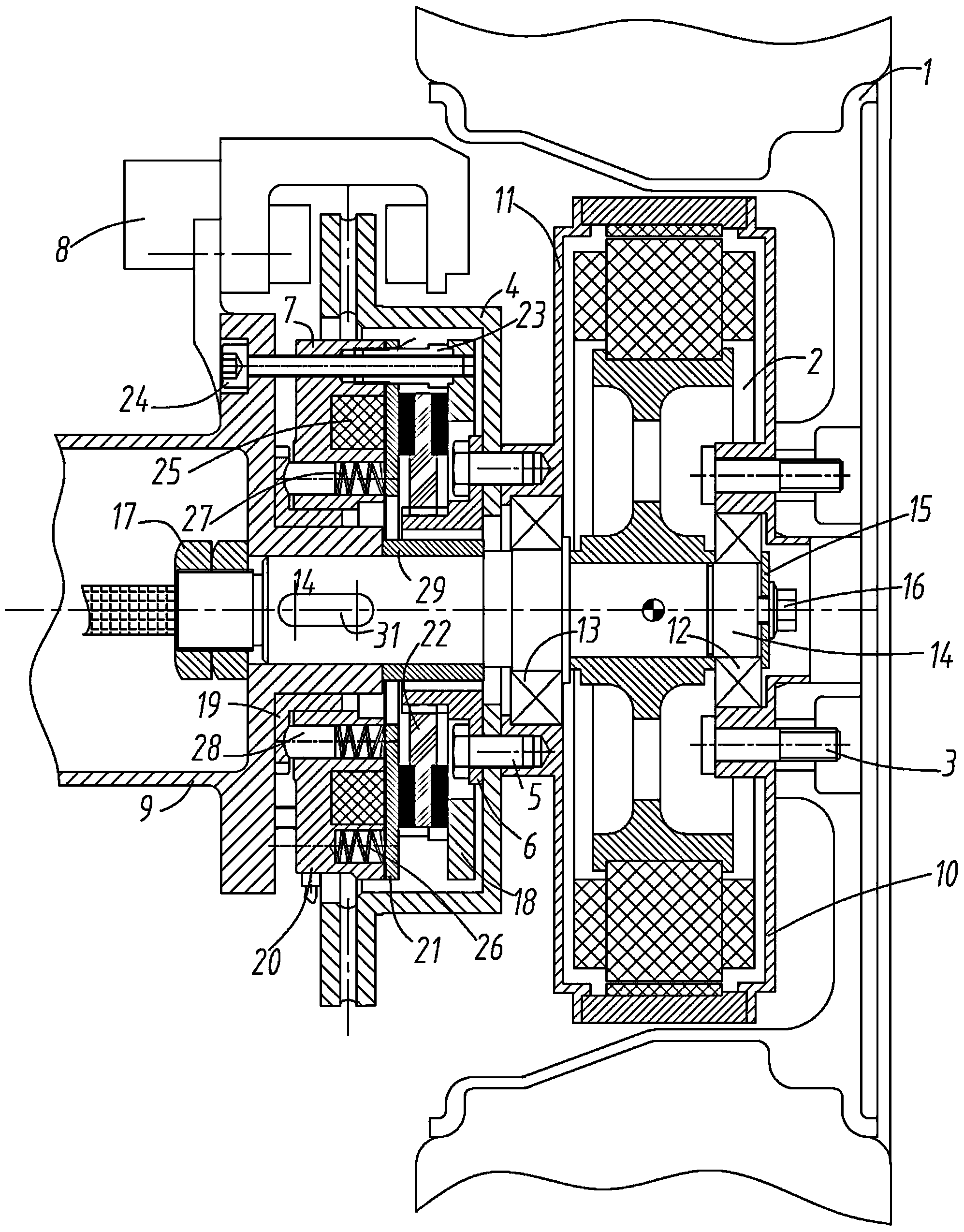

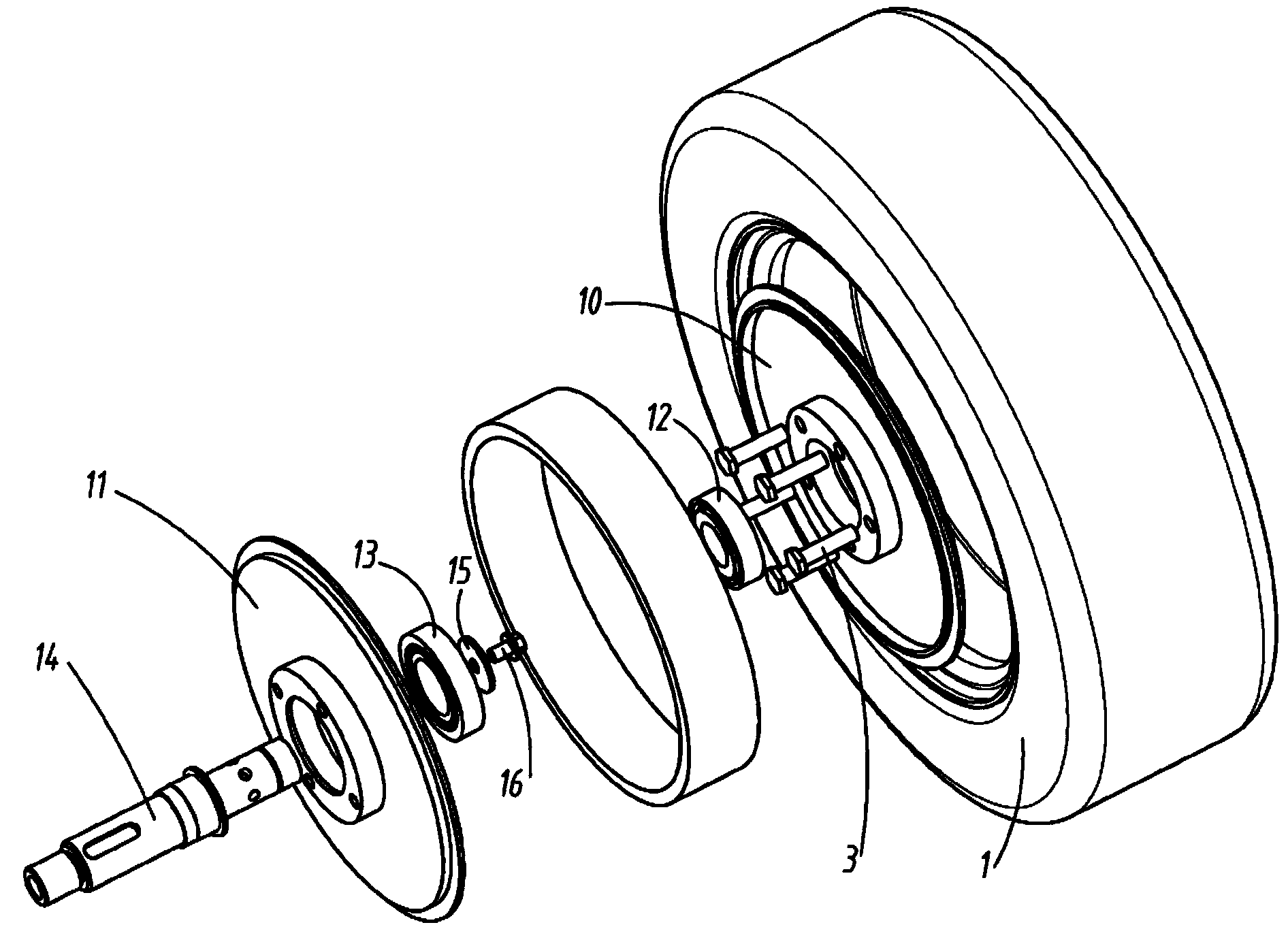

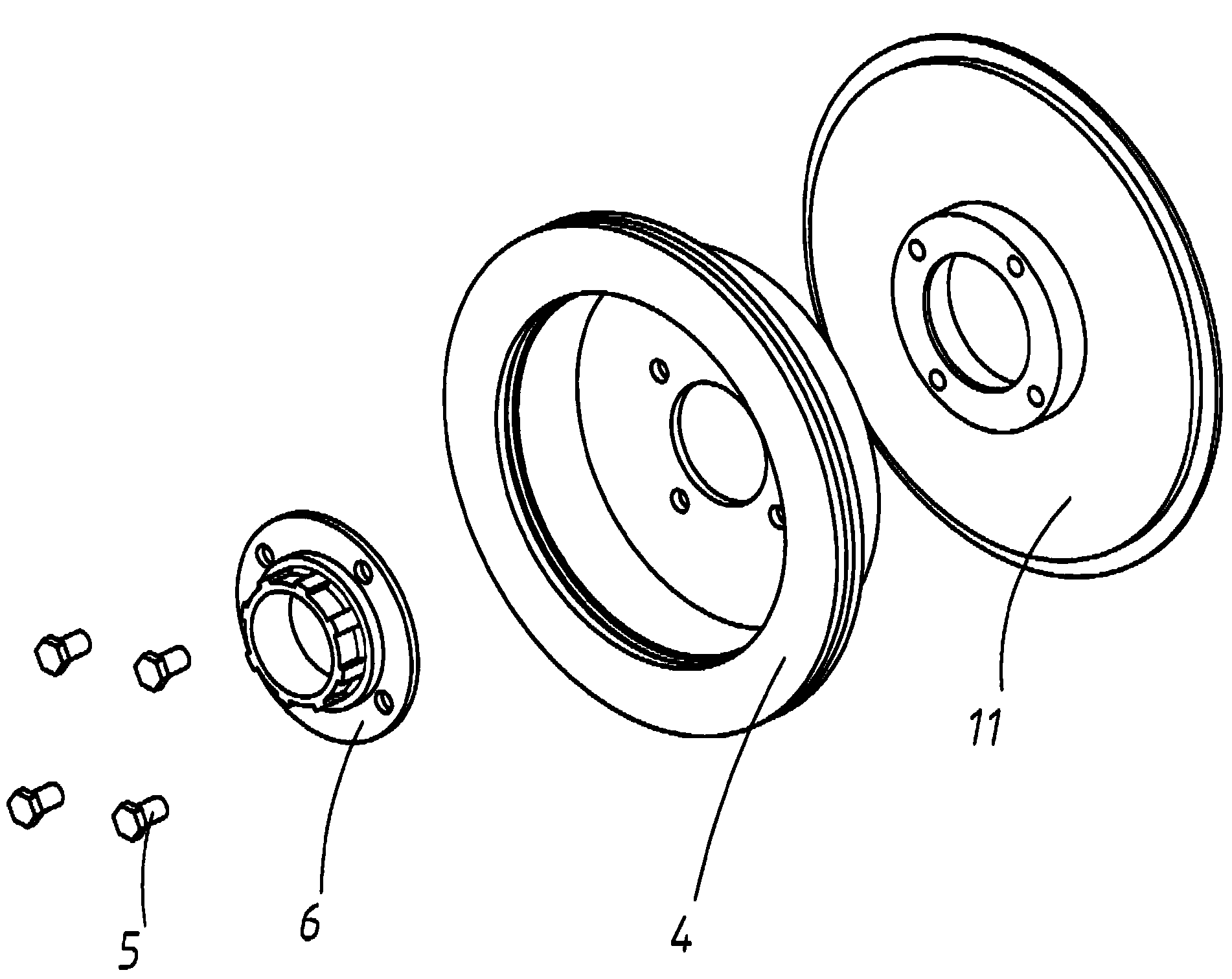

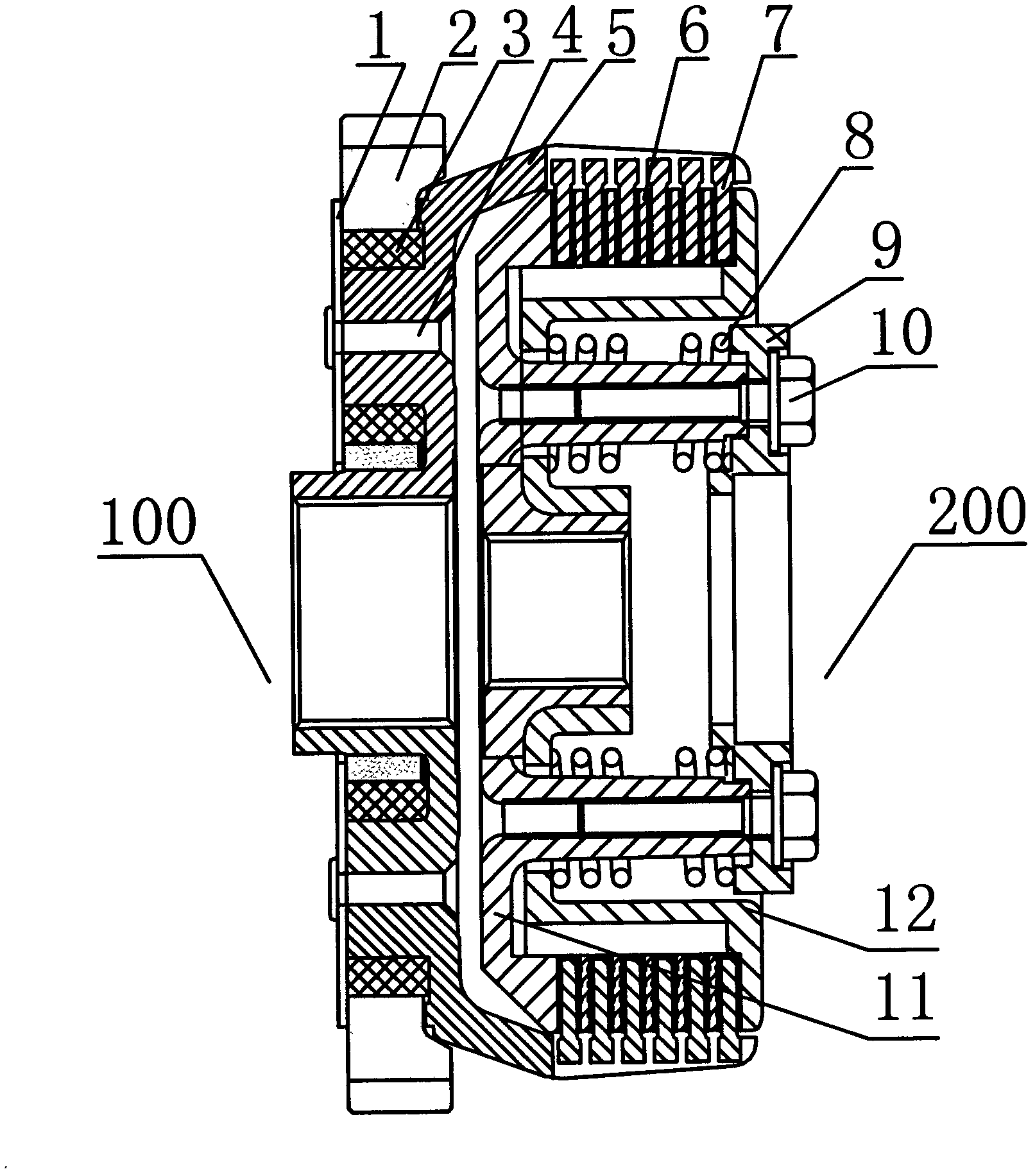

Split electric wheel system with excitation-free electromagnetic parking braking device

ActiveCN103821847AAvoid thermal damageParking realizationAxially engaging brakesBrake actuating mechanismsElectric machineEngineering

The invention discloses a split electric wheel system with a thin excitation-free electromagnetic parking braking device. The split electric wheel system is applied to a wheel hub motor, aims to solve the problem of complex structure of the existing electric wheel vehicle braking system, and comprises a wheel, the wheel hub motor, a brake disc, a motor shell crossover flange, an electromagnetic brake, a suspension beam end part and a sleeve, wherein the suspension beam end part, the electromagnetic brake, the motor shell crossover flange, the brake disc, the wheel hub motor and the wheel are sleeved on a motor shaft in sequence, the sleeve is hollowly sleeved on the motor shaft and is located between the motor shaft and the motor shell crossover flange, one end of the sleeve is in contact with the flange of the suspension beam end part, the other end of the sleeve is in contact with the shaft shoulder of the motor shaft, the wheel and a shell on the outer side of the wheel hub motor are fixedly connected by rim bolts, the motor shell crossover flange, the brake disc and a shell on the inner side of the wheel hub motor are fixedly connected in sequence by brake disc bolts, one end of the electromagnetic brake is in splined joint with the motor shell crossover flange, and the other end of the electromagnetic brake is sleeved on the flange of the suspension beam end part.

Owner:JILIN UNIV

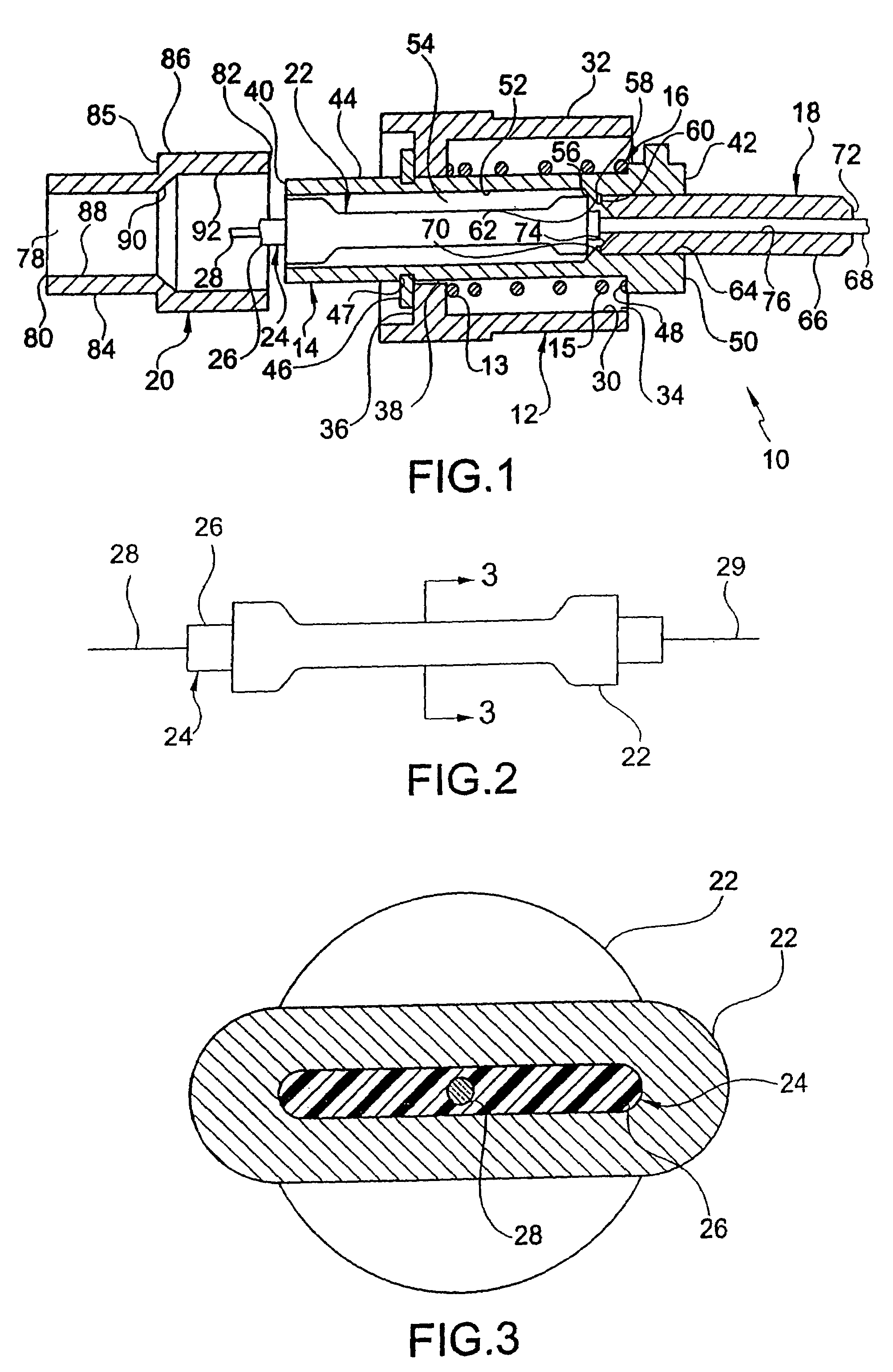

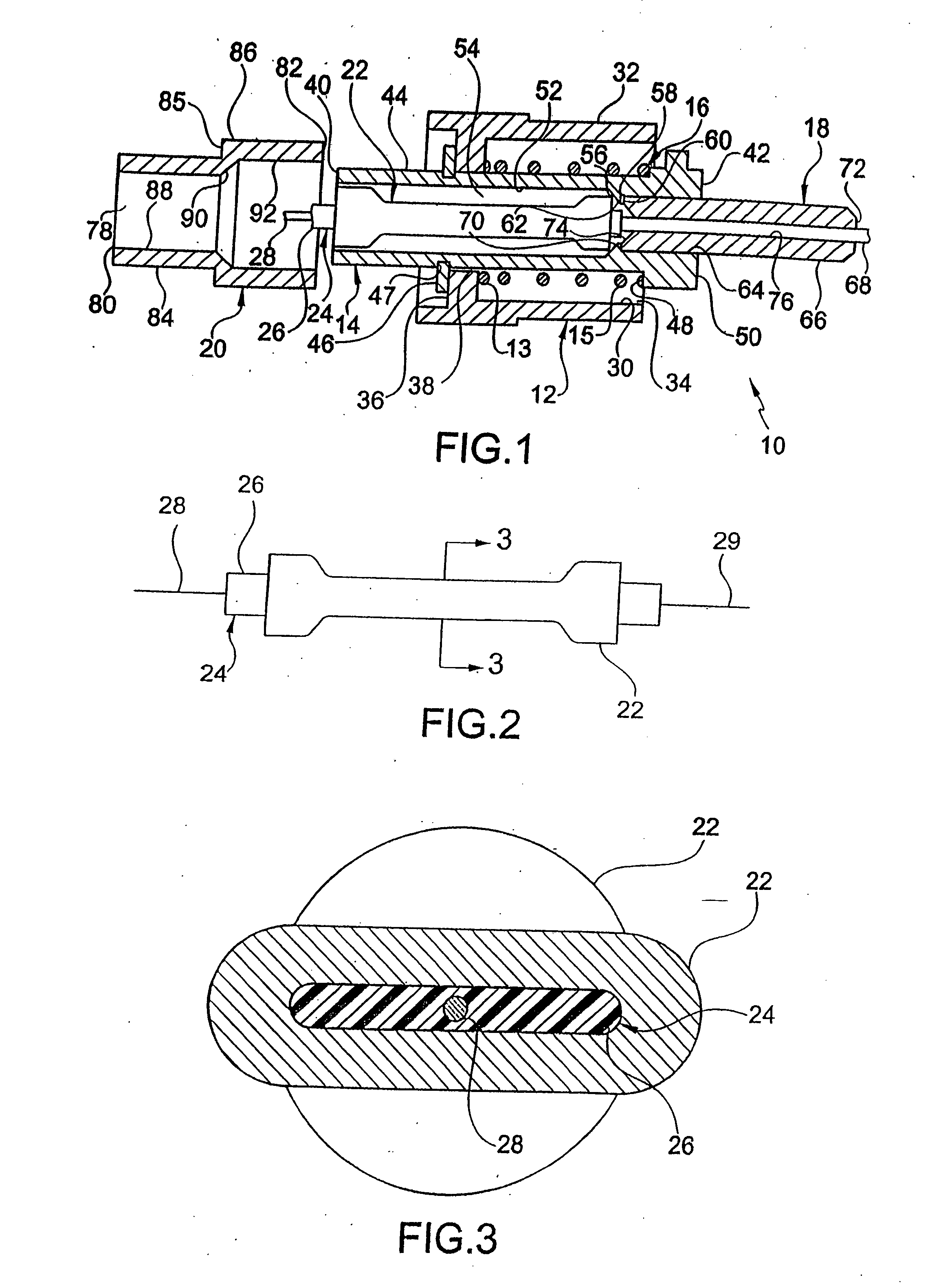

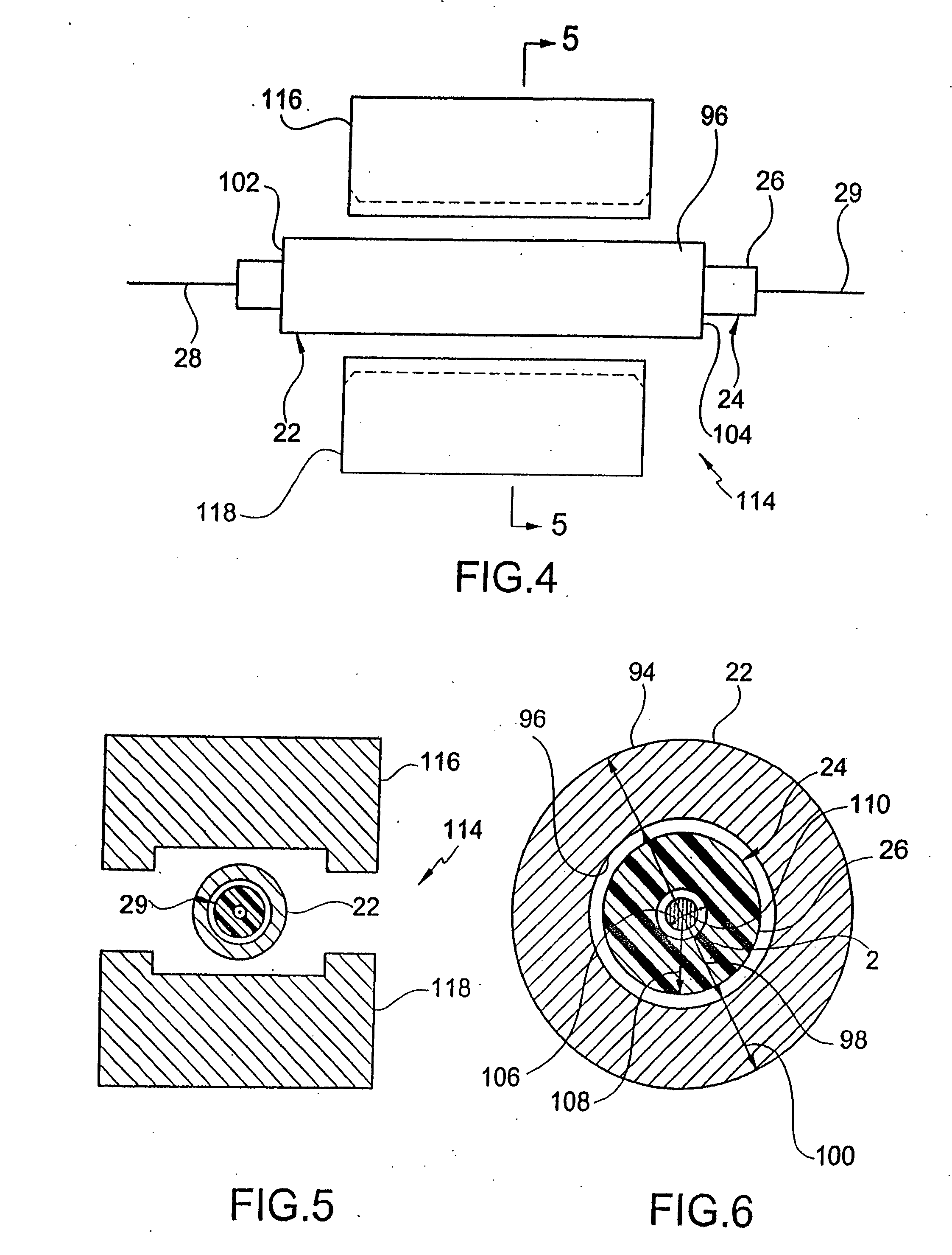

Crimp tool for strain relief connector and method of forming a strain relief connector

InactiveUS7003869B2Increase friction areaAverage pressureCoupling light guidesConnection formation by deformationMechanical engineeringStrain relief

Crimp tool is for and a method forms a strain relief connector including an optical fiber, a cover enclosing the optical fiber. The cover has an inner surface, an outer surface, a first end and a second end, the first end having a tapered portion that extends radially outwardly. A sleeve surrounds the cover and has a first inner volume and a first interior shoulder, a portion of the outer surface of the tapered portion abuts the first interior shoulder. The sleeve and the cover are simultaneously compressed forming a compressed portion. The cover and the sleeve are deformed such that the cover substantially fills the first inner volume of the sleeve.

Owner:HUBBELL INC

Crimp tool for strain relief connector and method of forming a strain relief connector

InactiveUS20050281512A1Increase friction areaGuaranteed to be strong and durableCoupling light guidesEngineeringMechanical engineering

Crimp tool is for and a method forms a strain relief connector including an optical fiber, a cover enclosing the optical fiber. The cover has an inner surface, an outer surface, a first end and a second end, the first end having a tapered portion that extends radially outwardly. A sleeve surrounds the cover and has a first inner volume and a first interior shoulder, a portion of the outer surface of the tapered portion abuts the first interior shoulder. The sleeve and the cover are simultaneously compressed forming a compressed portion. The cover and the sleeve are deformed such that the cover substantially fills the first inner volume of the sleeve.

Owner:LUTZEN JON A +2

Passive force/moment feedback driver of man-machine interface device for controlling remote-control operation robot

InactiveCN101642908AContinuous and stable feedback forceIncrease the number ofManipulatorElectricityRemote control

The invention discloses a passive force / moment feedback driver of a man-machine interface device for controlling a remote-control operation robot, comprising a shell, a moment feedback shaft, dynamical friction pieces, magneto-rheological fluid and an electric signal input coil, wherein the moment feedback shaft, the dynamical friction pieces and the magneto-rheological fluid are arranged into theshell, the electric signal input coil is used for inputting an electric signal converted by a long-distance force signal, the dynamical friction pieces are fixed on the moment feedback shaft, at least one static friction piece is arranged in the shell, the static friction pieces are arranged among the dynamical friction pieces at intervals, the magneto-rheological fluid is filled around the dynamical friction pieces and the static friction pieces, and the electric signal input coil is coiled outside the static friction pieces. The passive force / moment feedback driver adopts a magneto-rheological fluid technology and converts the magneto-rheological fluid into the electric signal to be input into the electric signal input coil, a passive feedback moment is generated on the moment feedbackshaft under the action of a coil magnetic field to the magneto-rheological fluid, and feedback force is continuous and stable. The passive force / moment feedback driver has simple and compact structure, light weight, small size and friction force and stable and safe characteristics and can transfer a larger moment.

Owner:SOUTHEAST UNIV

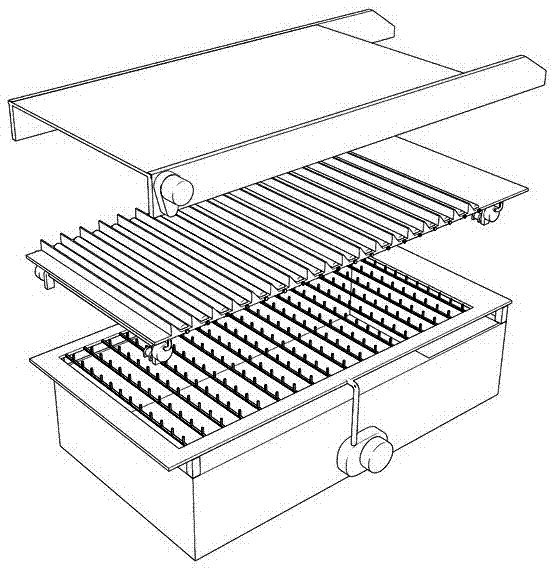

Shellfish washing apparatus

ActiveCN105432762AIncrease friction areaIncrease frictionBivalves processingElectric machineAquatic product

The invention discloses a shellfish washing apparatus, and relates to the technical field of equipment for aquatic product processing. The shellfish washing apparatus comprises a vibrating enclosed sieve, a water supply device, and a support frame; the vibrating enclosed sieve comprises a rectangular support rack, an enclosed shell, and a driving motor (A); ribs are evenly arranged on the rectangular support rack along the length direction to form a washboard shape; between two neighbored ribs, the rotation shaft on the rectangular support rack is connected to a roller brush; the driving motor (A) is arranged on the enclosed shell; each roller brush is linked with the output terminal of the driving motor (A); two sides of the upper end of the support frame are both provided with a driving motor (B), the output terminal of each driving motor (B) is connected to two vibrating wheels, which are parallelly arranged in the cross direction; the lower end of each L-shaped transmission rod is connected to a vibrating wheel through an eccentric shaft; and the water supplying device comprises a row of water spraying pipes arranged on the support frame and a water tank arranged in the lower part of the support frame. The shellfishes are washed by roller brushes, the operation is simple, and the cleaning effect is good.

Owner:HAIMEN CANGYUN MACHINERY CO LTD

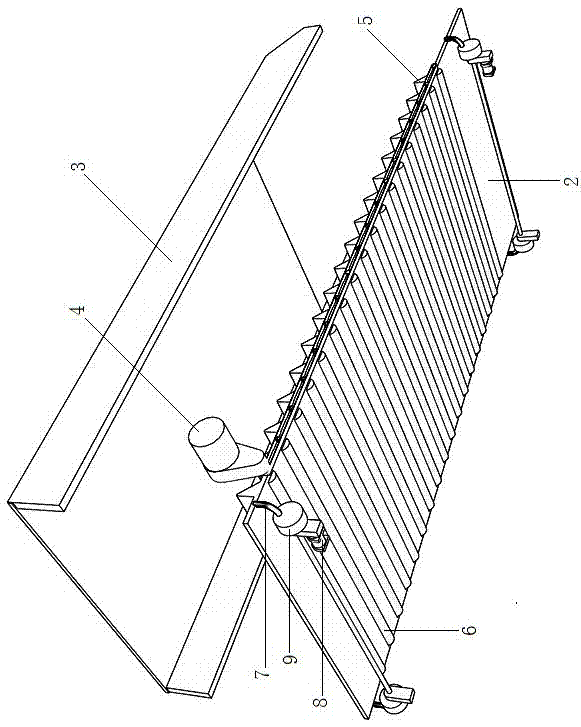

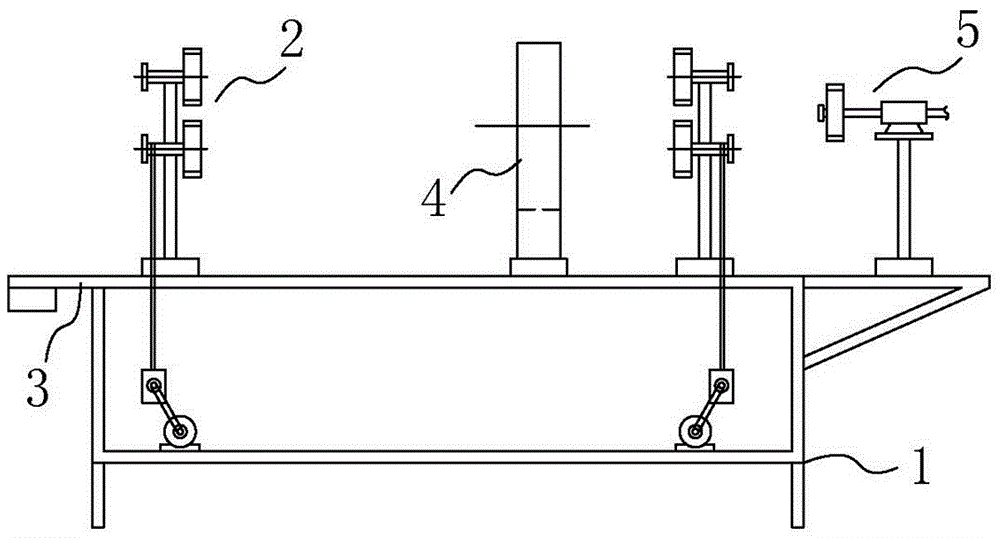

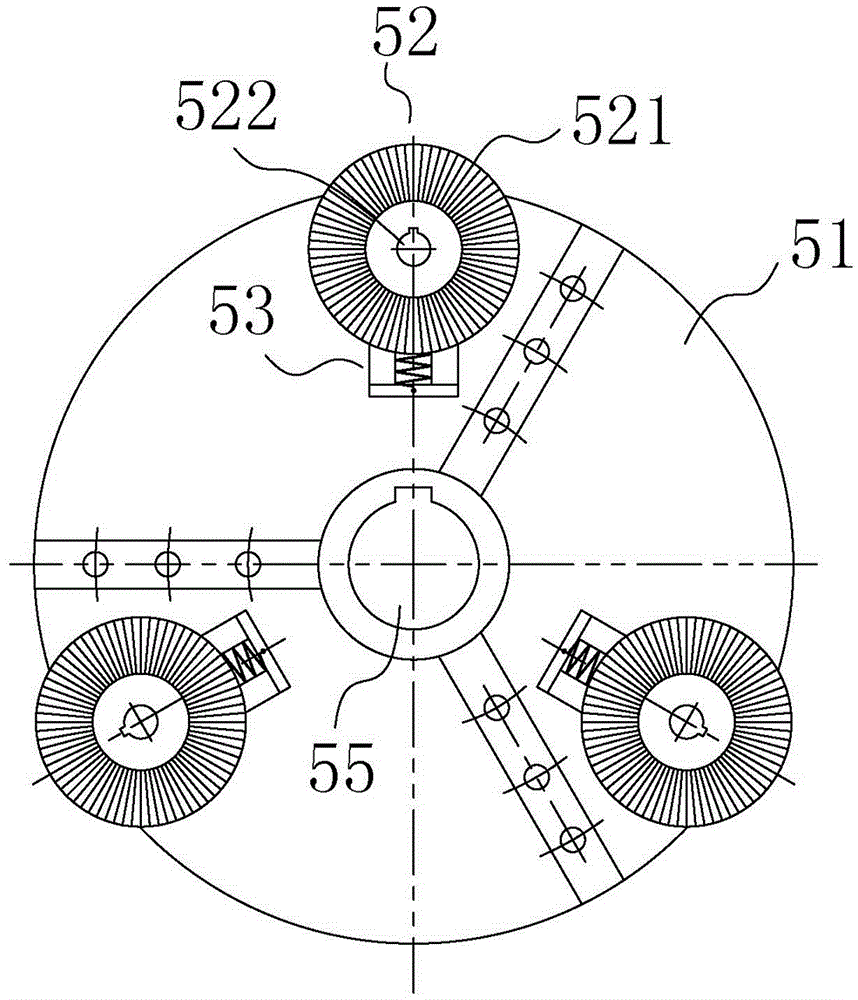

Titanium alloy pipe grinding device

ActiveCN106625059AReduce jitterImprove stabilityGrinding carriagesRevolution surface grinding machinesEngineeringMulti stream

The invention discloses a titanium alloy pipe grinding device. The titanium alloy pipe grinding device comprises a rack provided with a rail, a rotary support assembly, a feeding assembly for driving the rotary support assembly to move forward or backward on the rail, a grinding assembly and a cooling assembly. The grinding assembly comprises a turn plate, grinding wheels and grinding wheel regulating assemblies, wherein the grinding wheels and the grinding wheel regulating assemblies are arranged on the turn plate. The grinding wheel regulating assemblies are used for elastically regulating the located positions of the grinding wheels in the radius direction of the turn plate relative to the center of the turn plate, and enabling the grinding wheels to be in a trend far away from the center of the turn plate in the radius direction of the turn plate all the time. The cooling assembly provides multi-stream air flows in a direction consistent with the direction of the tangent line of an outer circle of a pipe, and the flow direction of the main air flow converged by the multi-stream air flows is consistent with the autorotation direction of the pipe. The titanium alloy pipe grinding device has the advantages that during work, the shaking of the pipe is small and the stability is high.

Owner:宁波盛普泰精密制管有限公司

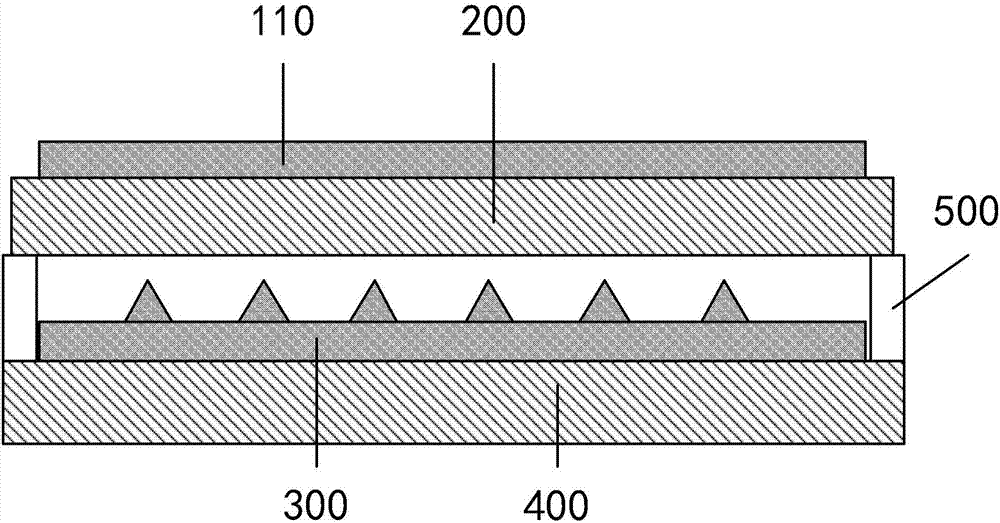

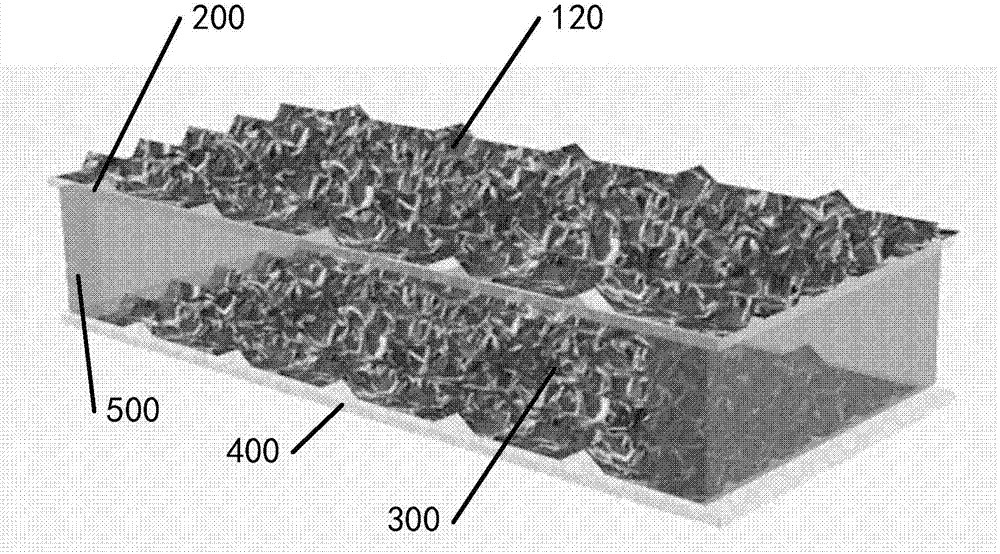

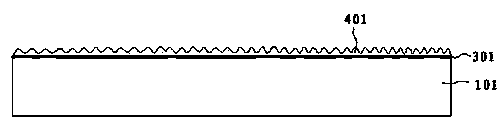

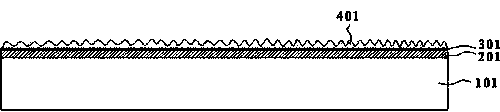

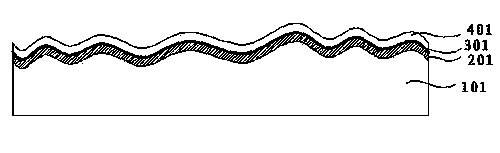

Friction generator based on folded conductive film, preparation method thereof, and integrated structure

ActiveCN106877732AIncrease the output voltageHigh output voltage and output powerFriction generatorsDuctilityFilm material

The present invention provides a friction generator based on a folded conductive film. The friction generator comprises an upper friction layer which comprises an upper insulating layer (200) made of a flexible material and an upper electrode (100) on the upper insulating layer, a lower friction layer which comprises a substrate (400) made of a flexible material and a lower electrode (300) which is on the substrate and is made of a folded conductive film material. According to the folded design, a friction area and a friction effect are improved, thus a device with a same area has larger output voltage, in a same space structure, the output voltage and output power of the friction generator are effectively improved, the integration and promotion of multiple friction generators are facilitated, the scalability of a device is also improved through folded electrodes in upper and lower positions, thus a power generation mode is broadened, power can be generated through pressure, power can be generated through drawing and bending, the versatility of the device is enhanced, and the application of the friction generator in the aspects of complex environment and the man-machine interface is facilitated.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for manufacturing anti-slip glazed tile

The invention relates to a method for manufacturing an anti-slip glazed tile, which comprises the following steps: step1) printing; selecting a dried ceramic green body, printing on the surface of the ceramic green body to form a printing layer; Step2) coating high temperature transparent frit; coating the high temperature transparent frit particles with particle size of less than or equal to 20 meshes on the surface of the printed green body in the step1); step3)roasting in kiln; roasting the green body of the high temperature transparent frit particles coated in the step2) under the roller-way kiln oxidation atmosphere, wherein the roasting temperature is 1150-1230 DEG C and the roasting period is 80-120 minutes; and step4) edge rounding grinding; after cooling the roasted green body in the step 3), rounding and grinding edge to obtain the anti-slip glazed tile finished product. Compared with the prior art, the anti-slip glazed tile has anti-slip projection on the surface, the friction area is larger, the anti-slip effect is good, the glaze quality is good, and the anti-slip glazed tile has no influence to decorative effect on the printing layer.

Owner:广东金牌陶瓷有限公司

Brake system of motor vehicle

ActiveCN102248934APrevent sideslipAdaptableBraking element arrangementsFluid braking transmissionClutchBrake shoe

The invention discloses a brake system of a vehicle, which comprises a power conversion part, a hydraulic control assembly and a brake part. The brake system of the vehicle is characterized that the power conversion part comprises a flange plate and a clutch for combining with an oil pump or separating the flange plate or from the oil pump; a swinging motor is driven by the oil pump via the hydraulic control assembly; and a brake shoe is driven by the swinging motor. According to the invention, the traditional technical scheme of braking through complete wheel lock is greatly improved and sideslip and drift of the vehicle caused by wheel lock are avoided. The braking shoe is driven to swing through soft hydraulic energy so that the braking shoe generates friction with the ground for braking; and the braking force of the braking shoe touching the ground in a slow swinging process is gradually increased to be well adapted to the speed of the vehicle so that the harmful trend of sideslipcaused by high speed and forced brake is effectively reduced.

Owner:NANTONG ZHONGYI BOILER EQUIP

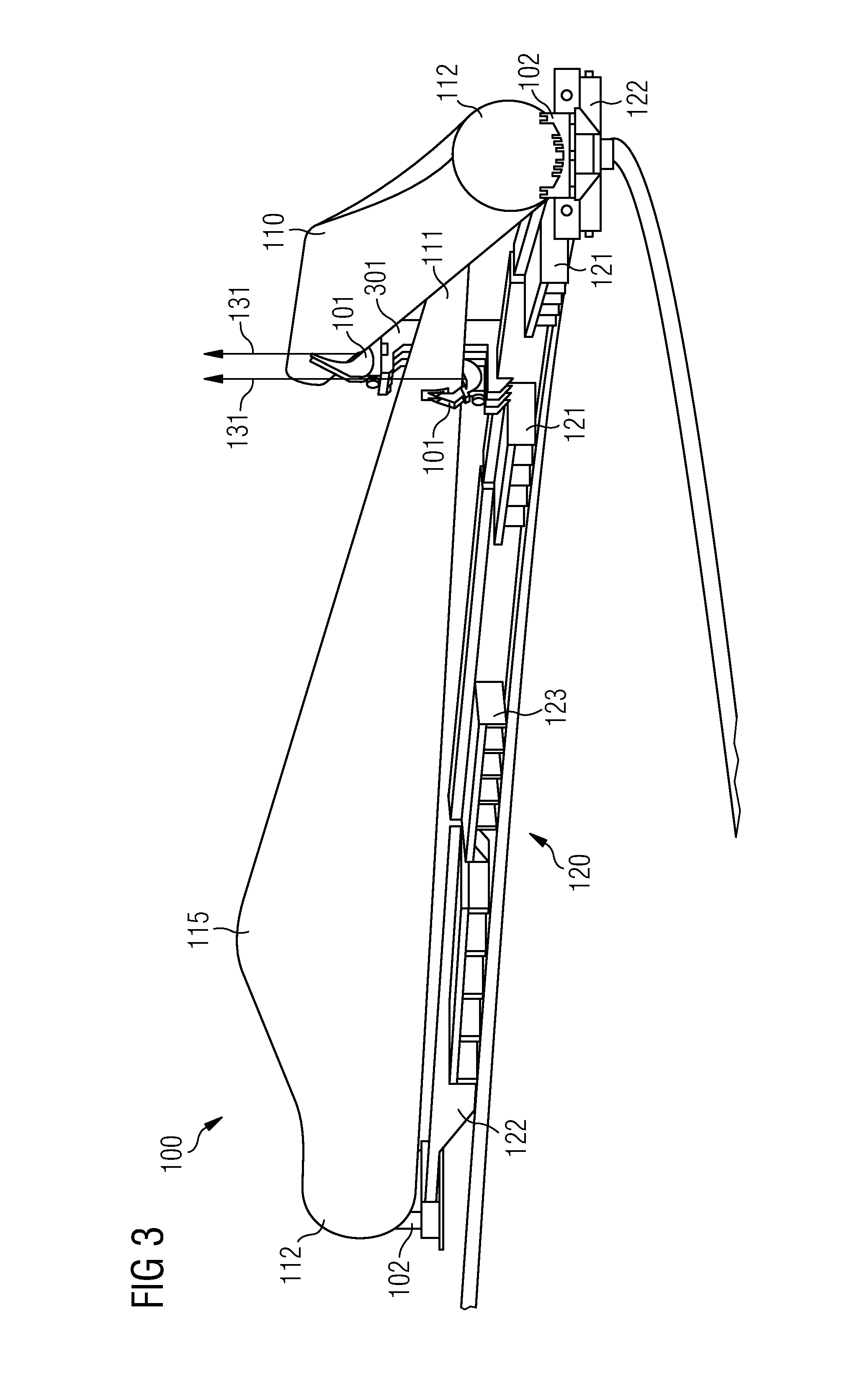

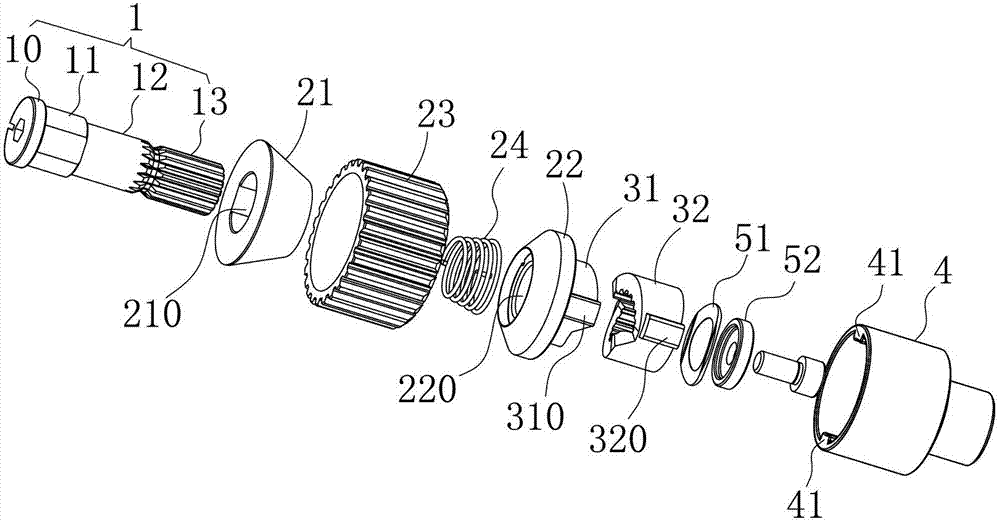

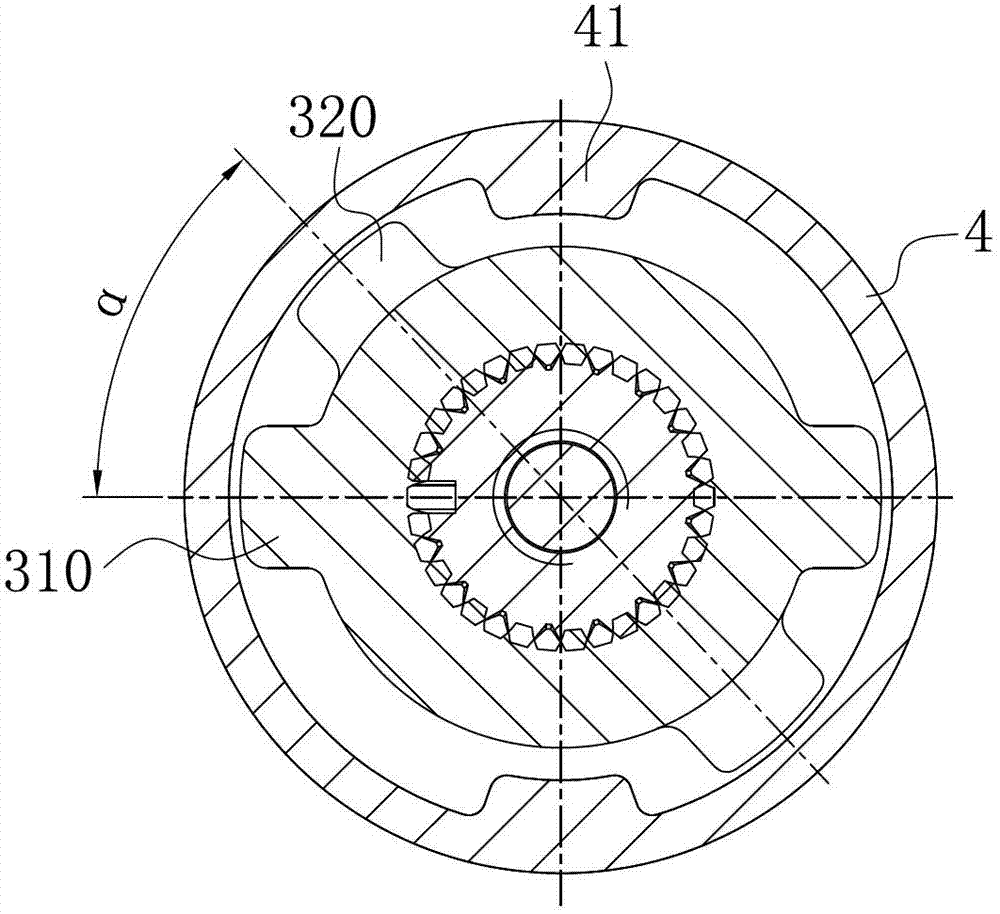

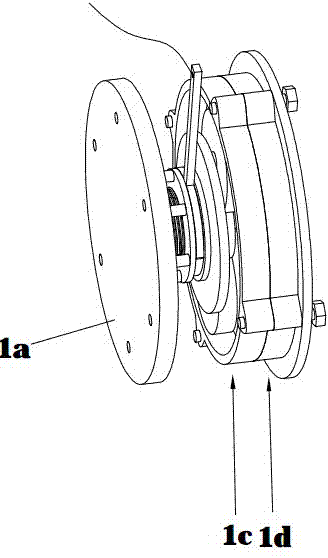

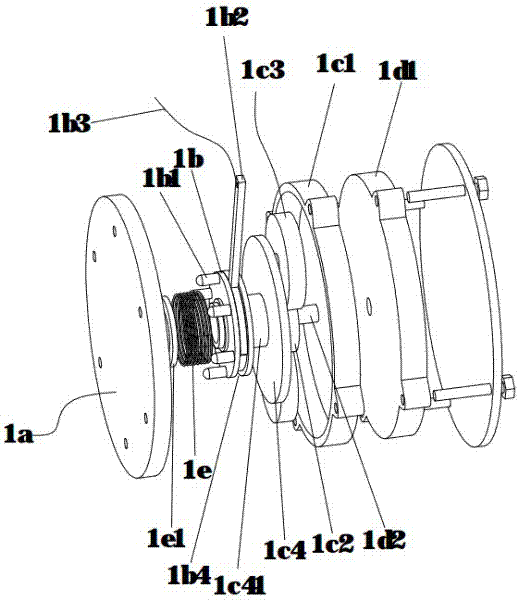

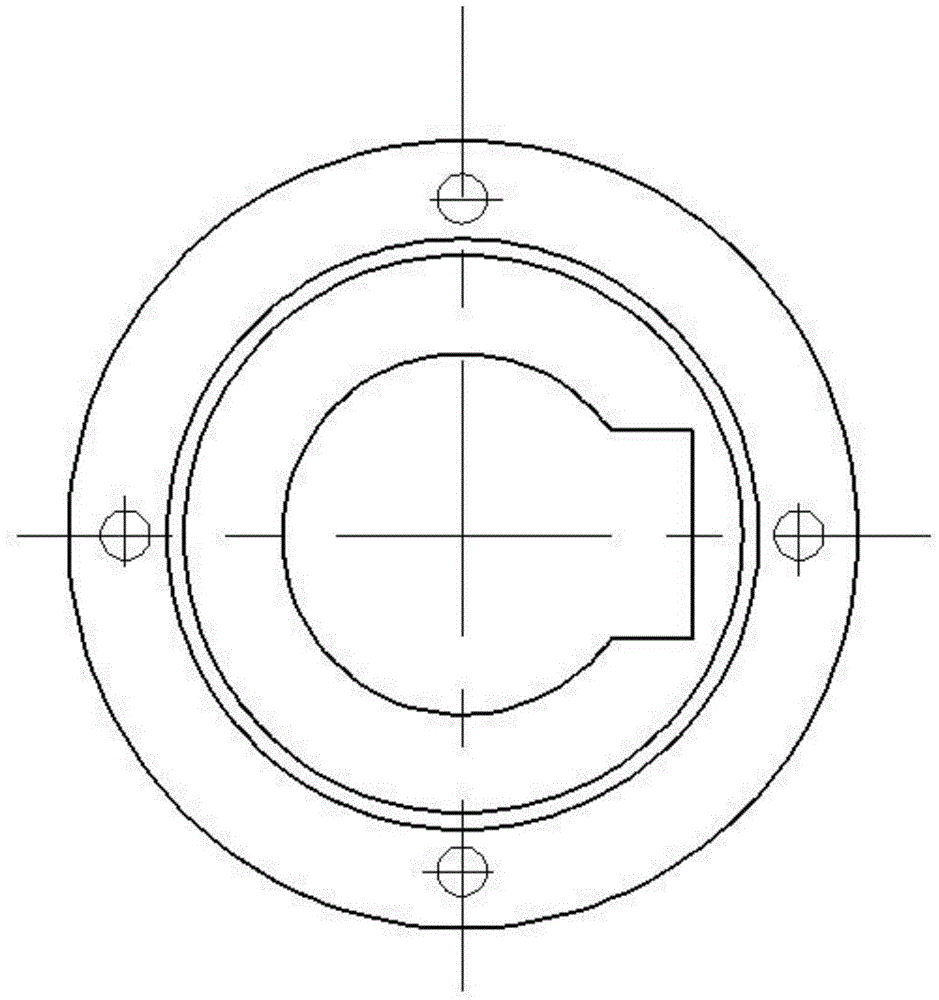

Novel clutch for tricycle

InactiveCN102661330ALarge radius of actionIncrease friction areaFriction clutchesDrive wheelWear resistant

The invention relates to a clutch, in particular to a novel clutch for a tricycle. The novel clutch comprises a driving disc component and a driven disc component, wherein the driving disc component comprises an outer cover, and a driven wheel is arranged on the outer cover; the driven disc component comprises a central sleeve, a plurality of driving friction plates matched with the axial inner grooves of the outer cover in a sliding manner are sleeved on the central sleeve, a plurality of driven steel sheets are matched with the periphery of the central sleeve in a sliding manner, and the driven steel sheets and the driving friction plates are sequentially superposed to form a friction pair; the two ends of the friction pair are positioned by the central sleeve and a platen, and the relative position between the central sleeve and the platen is limited by an elastic part arranged between the central sleeve and the platen. The novel clutch for the tricycle is stable in use, not easy in sliding, high temperature resistant, wear resistant, convenient in operation, long in service life and is suitable for popularization.

Owner:张捍宏 +1

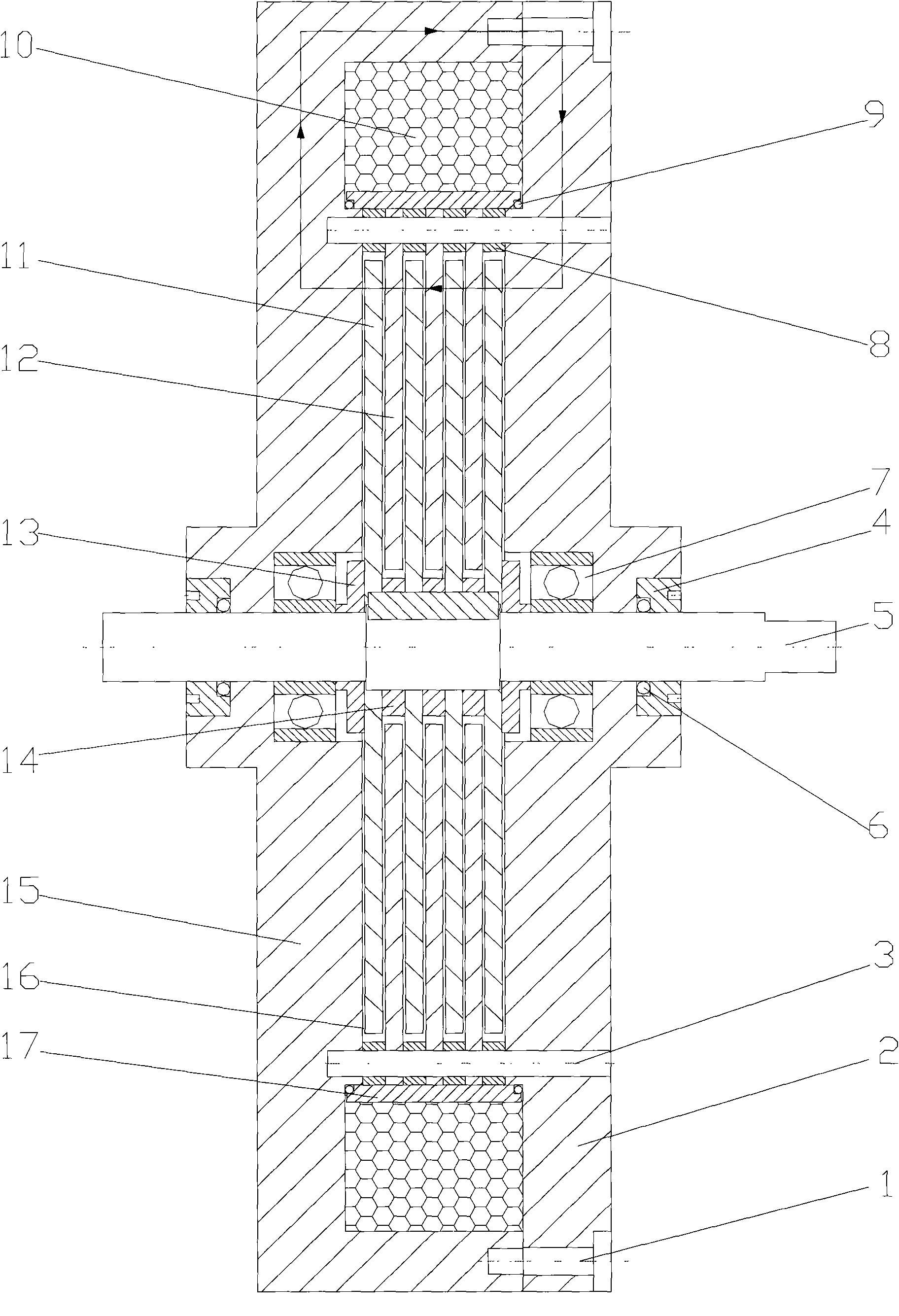

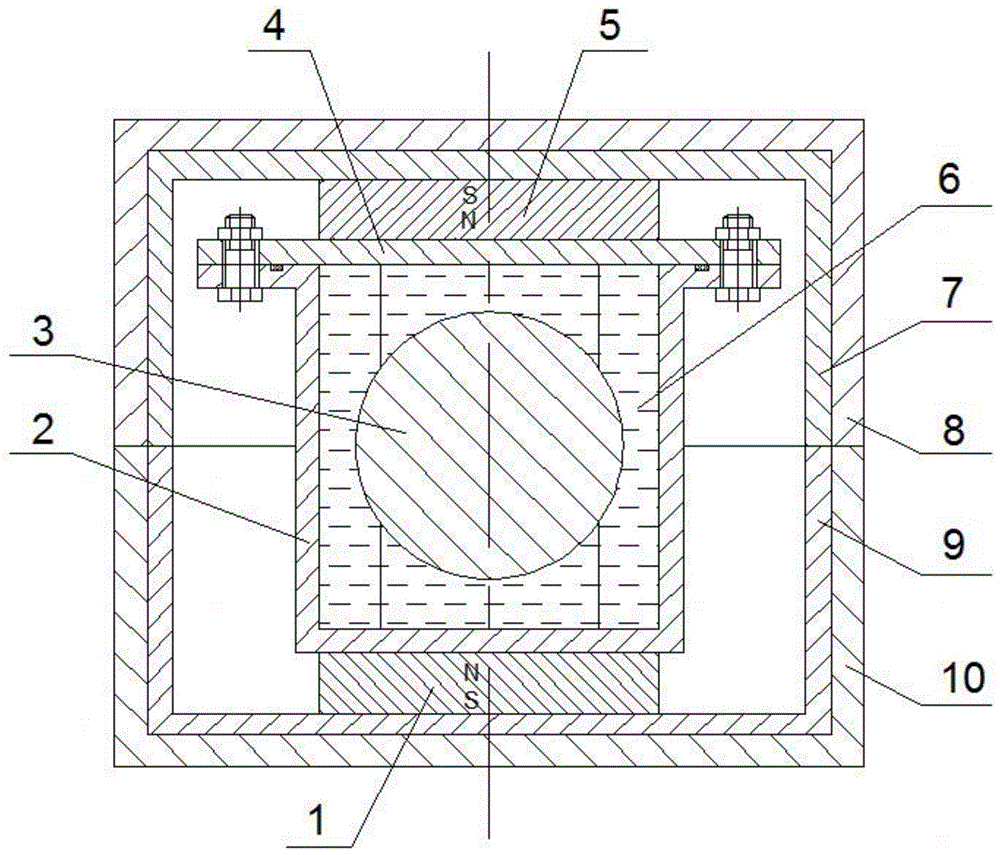

First-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers

InactiveCN104948627ASuspension stabilityAvoid liquidityVibration dampersMagnetic springsStructural ProblemAbsorbed energy

The invention relates to a first-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers, belongs to the field of mechanical engineering vibration, and successfully solves the problem that the existing magnetic liquid damping shock absorbers cannot be applied in engineering practice due to various structural problems. The absorber comprises a first permanent magnet (1), a housing (2), a mass (3), an end cap (4), a second permanent magnet (5), magnetic fluid (6), an upper magnetic inner sleeve (7), an upper magnetic shielding outer sleeve (8), a lower magnetic inner sleeve (9) and a lower magnetic shielding outer sleeve (10). When the external vibration occurs, a non-magnetic ball moves in a chamber, the magnetic fluid flows in a recess of the housing (2) to absorb energy, first-order buoyancy formed within the magnetic fluid by the first permanent magnet (1) and the second permanent magnet (5) allows frequency difference to be formed between the mass (3) and the housing (2), so that the maximum vibration damping efficiency is achieved, and the upper and lower magnetic shielding covers effectively prevent magnetic flux leakage of the permanent magnets.

Owner:BEIJING JIAOTONG UNIV

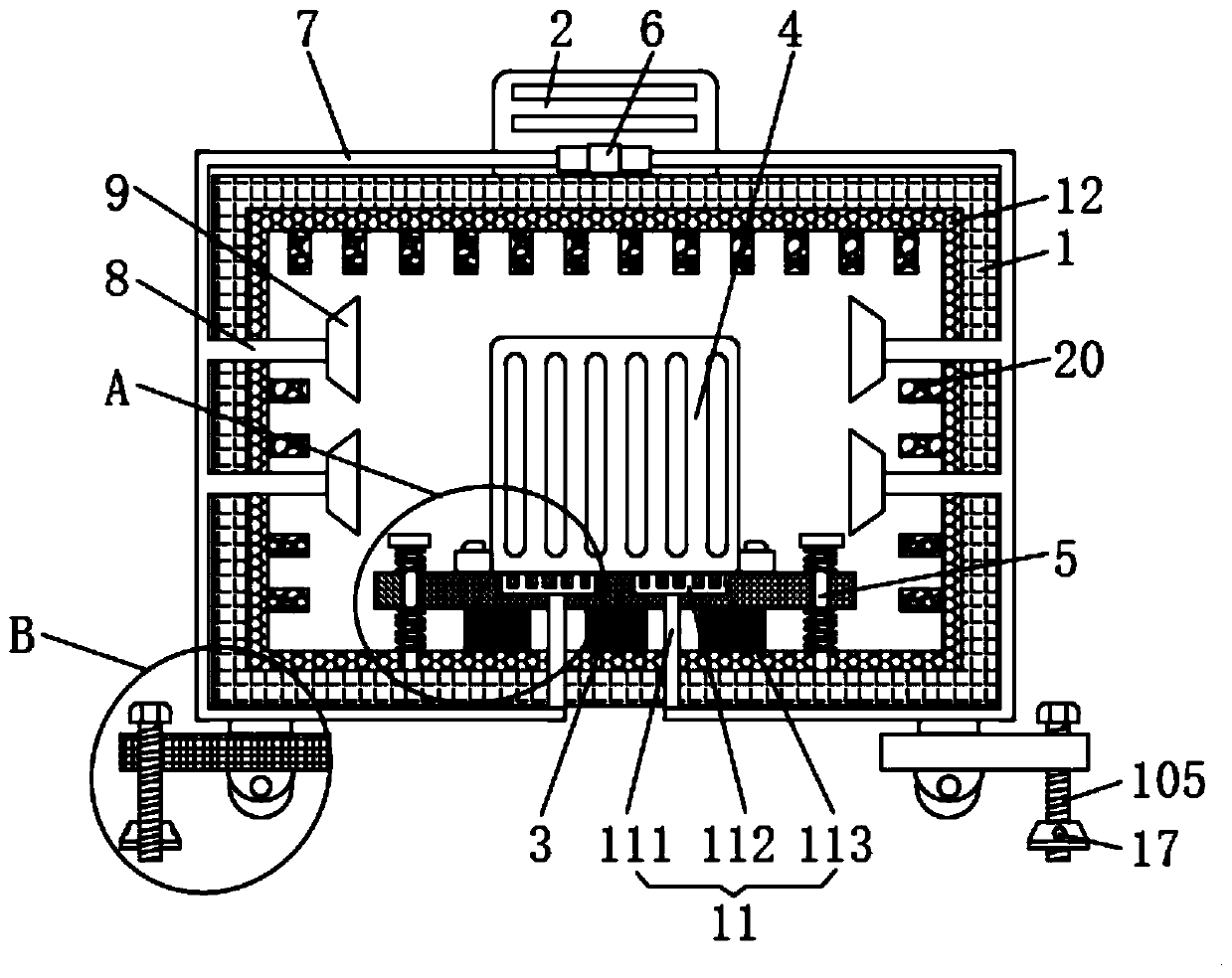

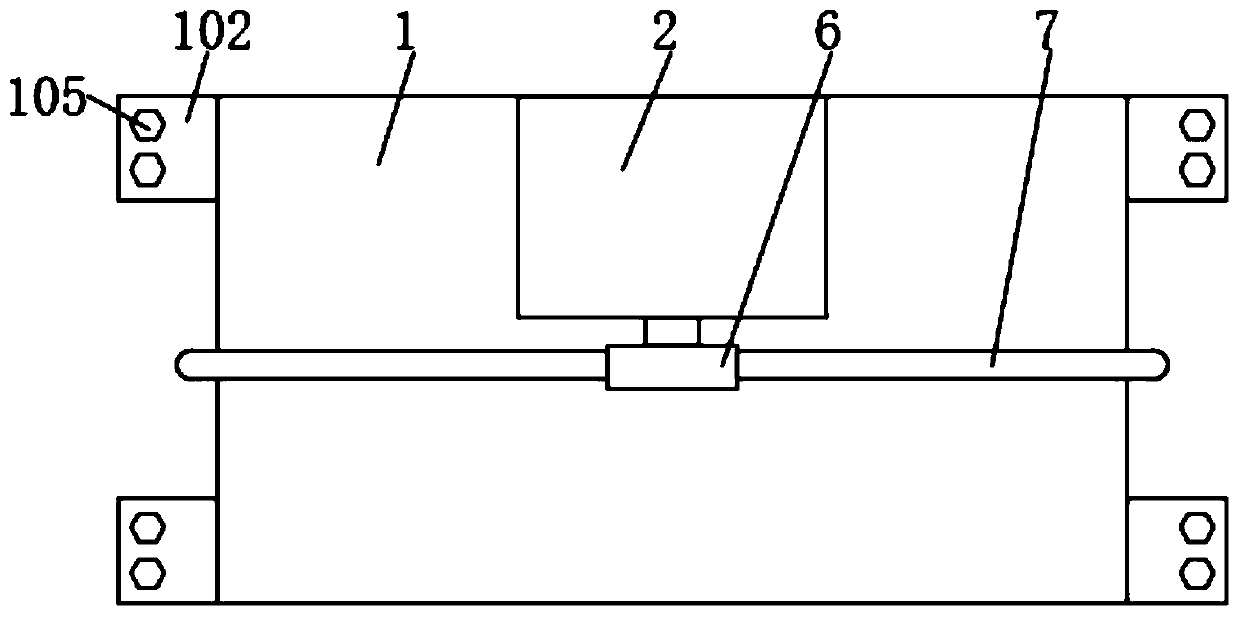

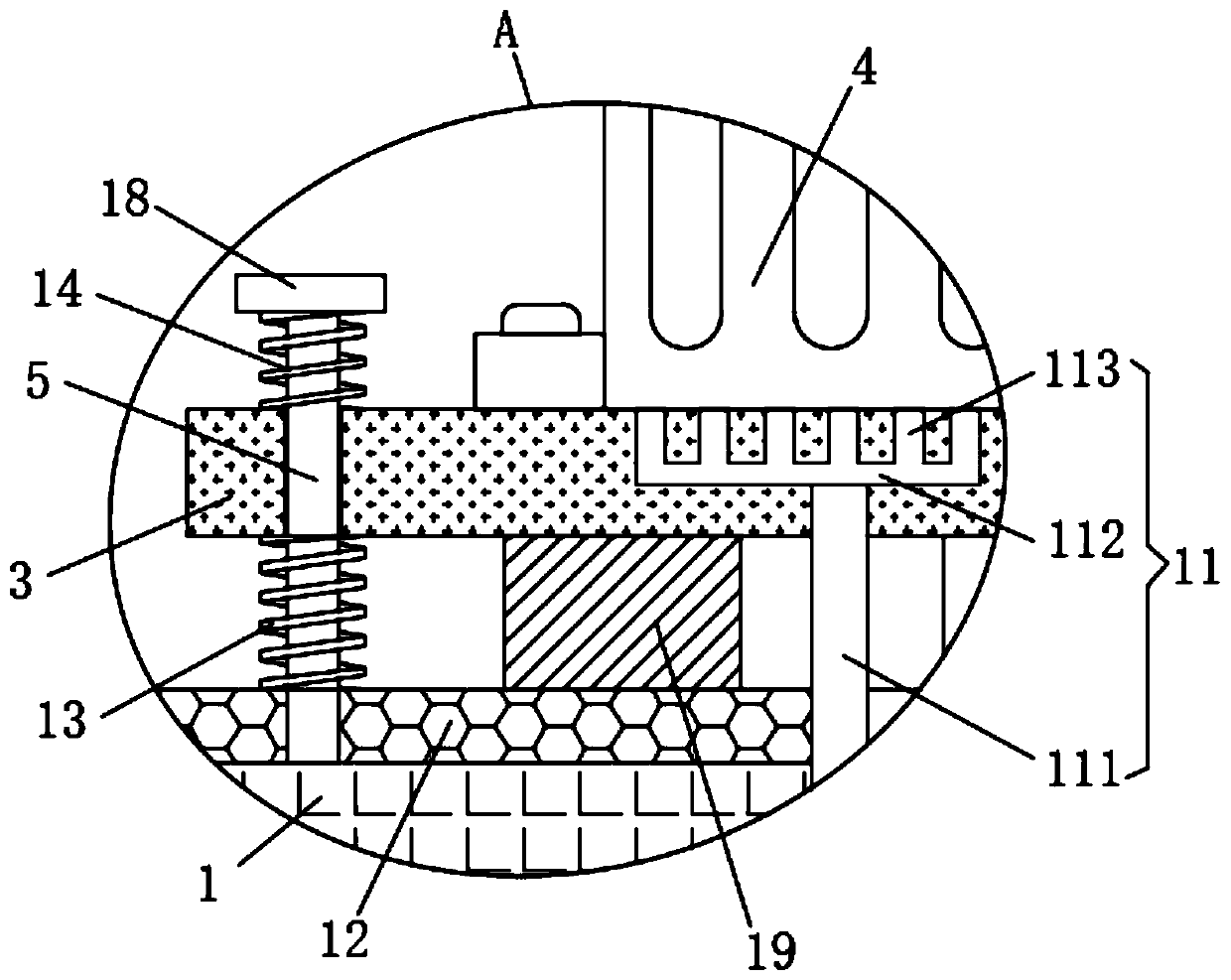

Silent diesel engine unit with cooling function

ActiveCN109973215AReduce vibration noiseEasy to carry and useAir coolingMachines/enginesDiesel engineCooling efficiency

The invention discloses a silent diesel engine unit with a cooling function. The silent diesel engine unit with the cooling function comprises a machine box. The back side of the top of the machine box is fixedly connected with an air cooler. An installation plate is arranged at the bottom of the inner wall of the machine box. According to the silent diesel engine unit with the cooling function, afirst spring and a second spring conduct damping on the installation plate, so that jolt noise of the engine is lowered, and noise can be absorbed by a sound insulation cotton board and prevented from being spread outwards; meanwhile, the bottom of the engine is cooled through an installation portion cooling mechanism; a user can conveniently move and use the engine through a convenient and rapid movement mechanism; and in this way, the problems that an existing engine unit cannot dissipate heat at the installation position generally, and a large inner space of the unit causes high noise, and the engine unit is inconvenient to move and use are solved. The silent diesel engine unit with the cooling function has the advantages of being capable of achieving complete heat dissipation, smallin noise space and convenient to move and improving the cooling efficiency, the noise lowering efficiency and the convenient movement and use performance.

Owner:JIANGSU TAIPU POWER MACHINERY

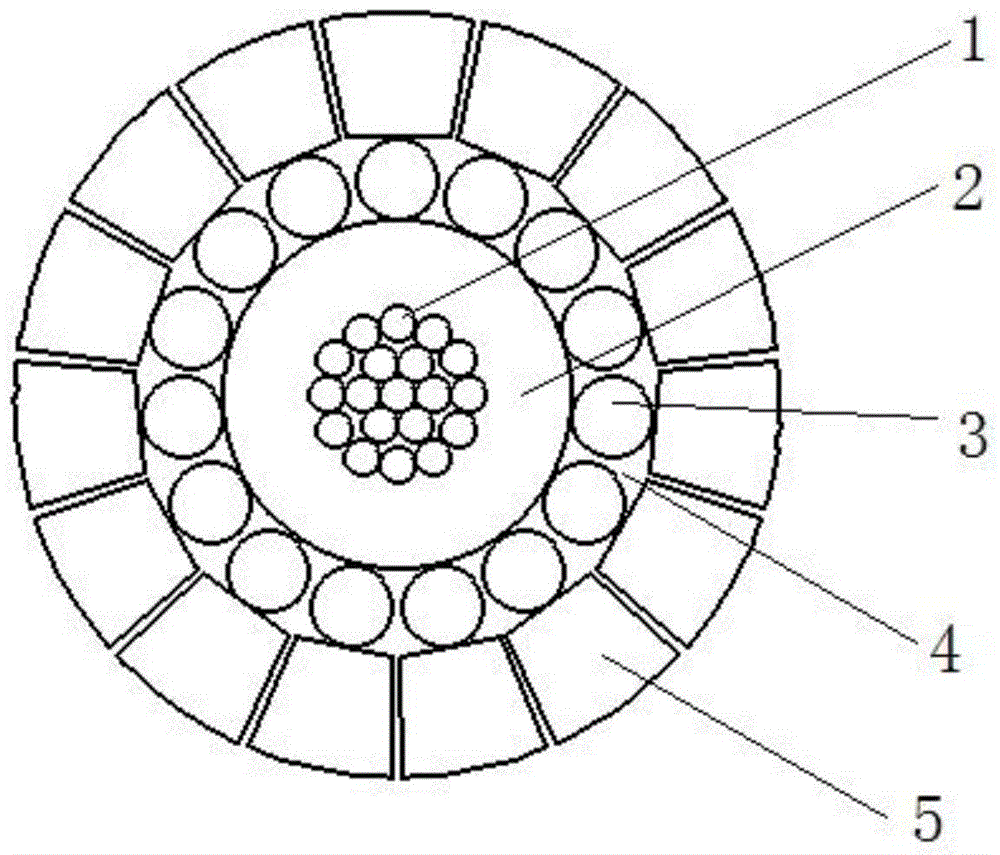

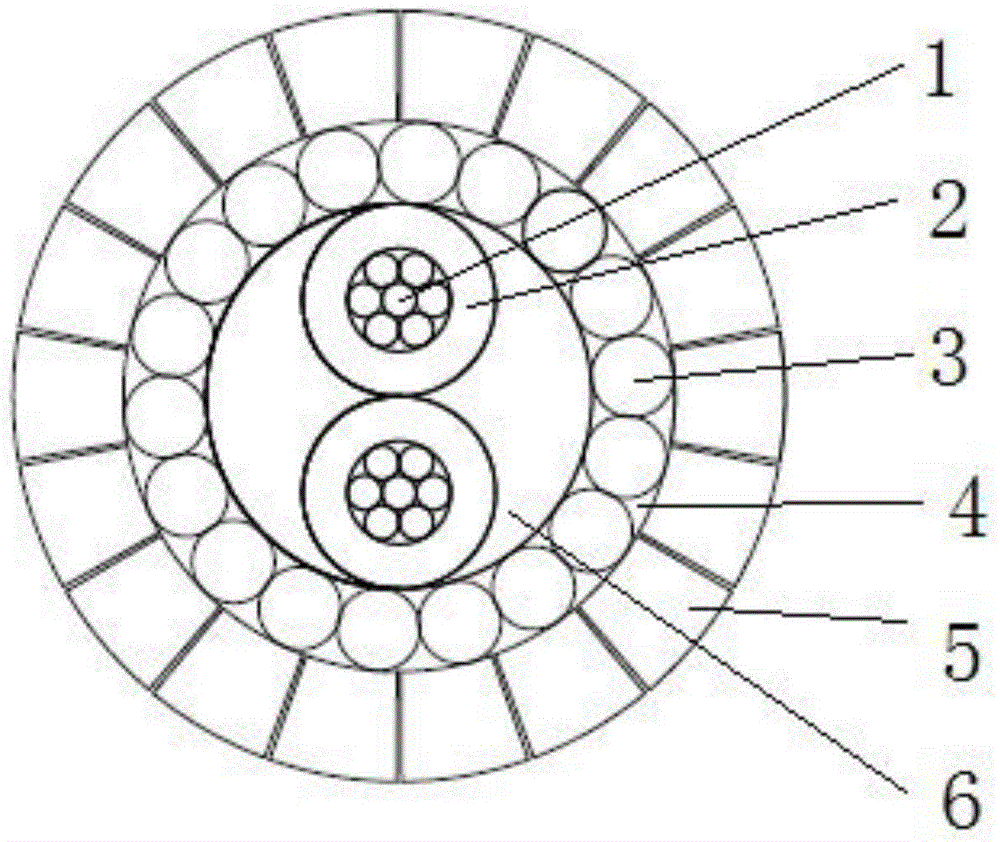

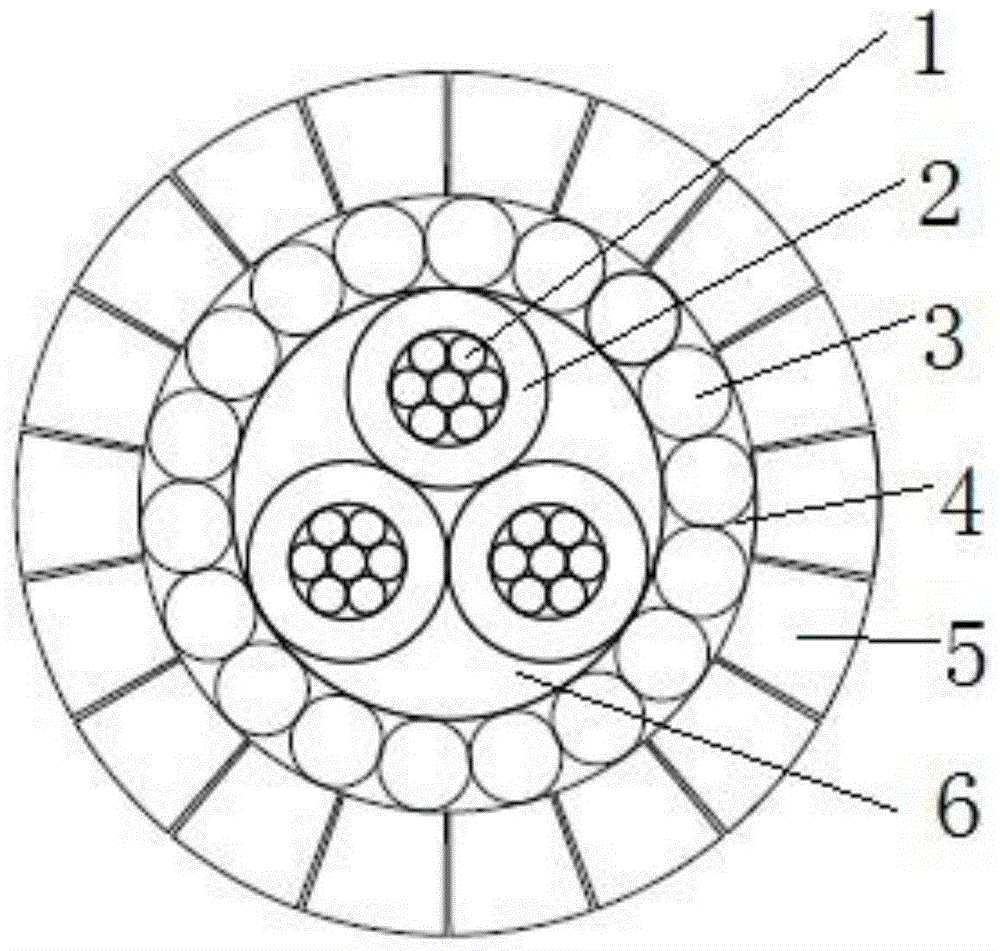

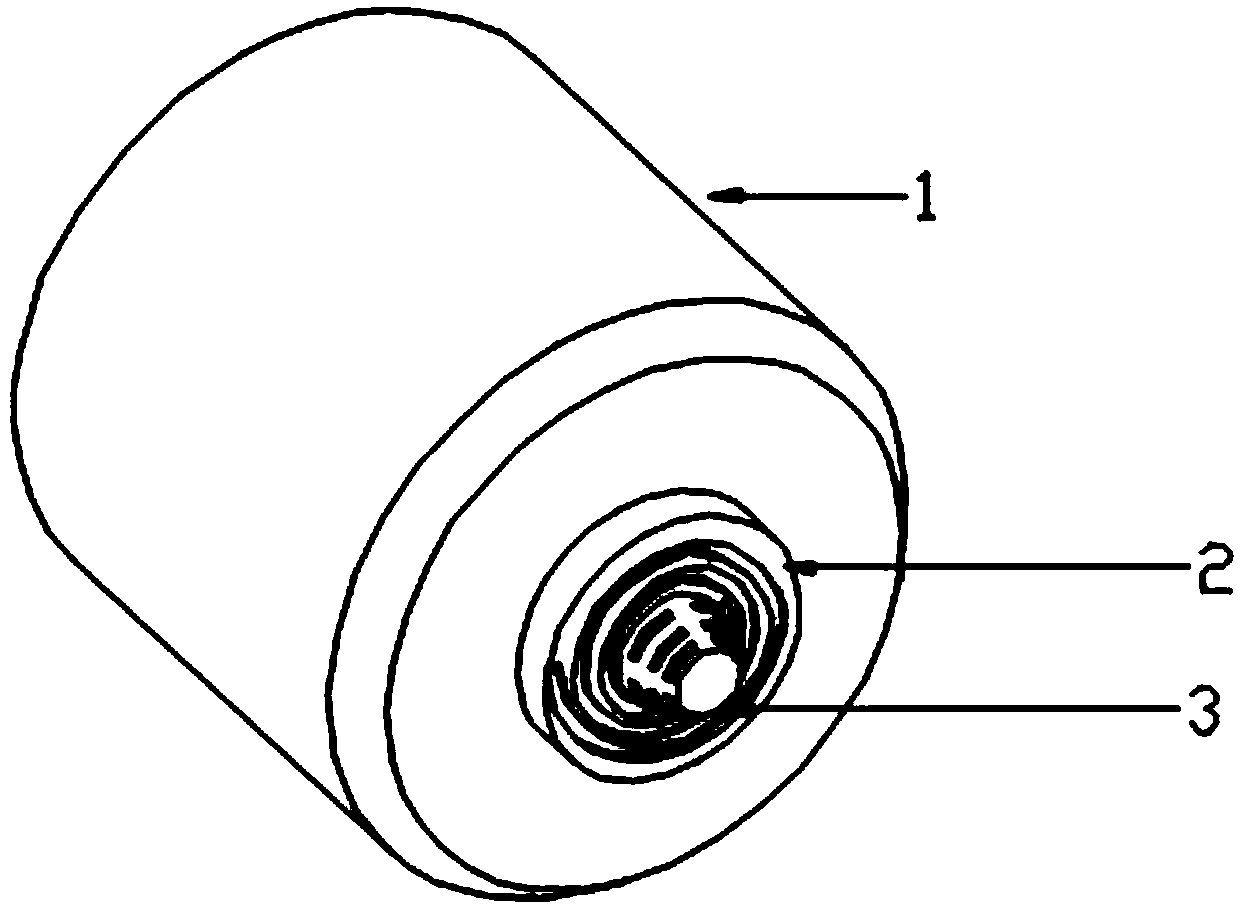

Anti-overflow sealed bearing loading and detecting cable

ActiveCN104681166AIncrease friction areaImprove wear resistanceInsulated cablesInsulated conductorsCopperSealant

The invention relates to an anti-overflow sealed bearing loading and detecting cable which comprises a copper stranded wire, wherein the outer layer of the copper stranded wire is annularly sleeved by an insulating layer, the insulating layer is annularly sleeved by an inner armor layer, and the inner armor layer is annularly sleeved by an outer armor layer; the inner armor layer is composed of steel wires with a circular section and sealant layers, and the outer part of the insulating layer is annularly sleeved by a plurality of circular steel wires; gaps between the adjacent circular steel wires are filled with the sealant layers, and the sealant layers and the circular steel wires constitute the sealed structure with the circular section together; the outer armor layer is formed by annularly sleeving the steel wires with a fan-shaped section, and the outer armor layer also forms a sealed structure with a circular section after a plurality of fan-shaped steel wires are annularly sleeved. The cable provided by the invention has the novel inner and outer armor layer structures, so that the bearing capacity of the cable is improved, while the sealing performance and the reliability of the cable are improved.

Owner:山东希尔电缆有限公司

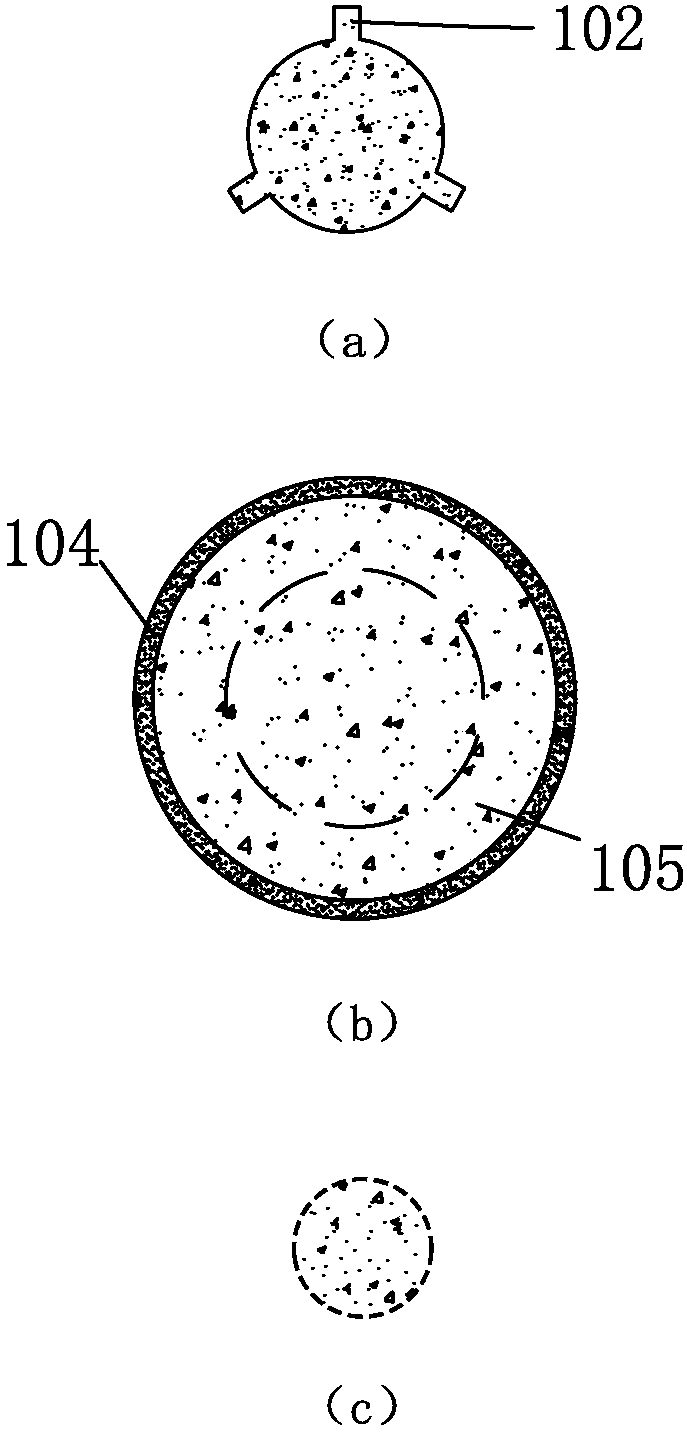

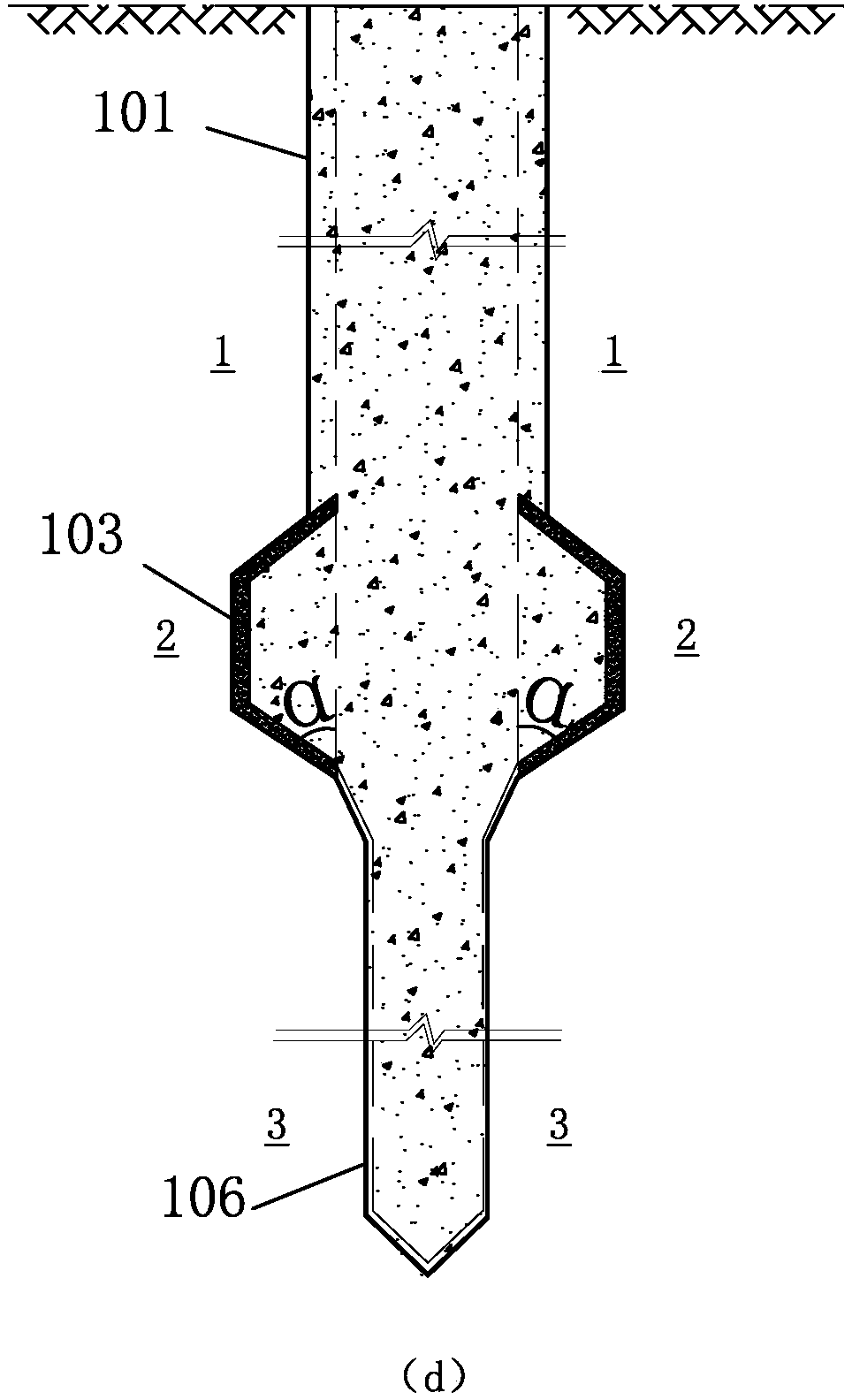

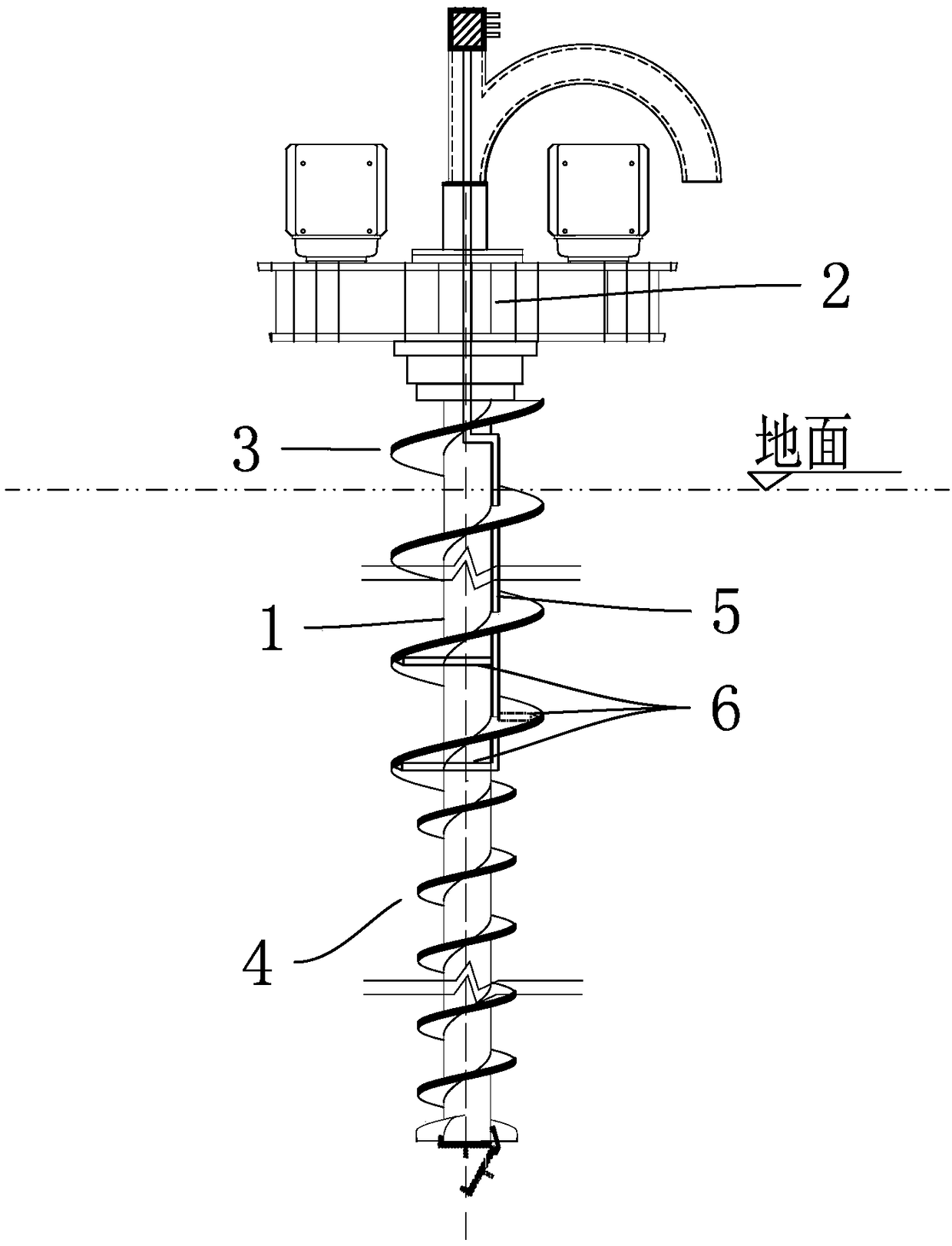

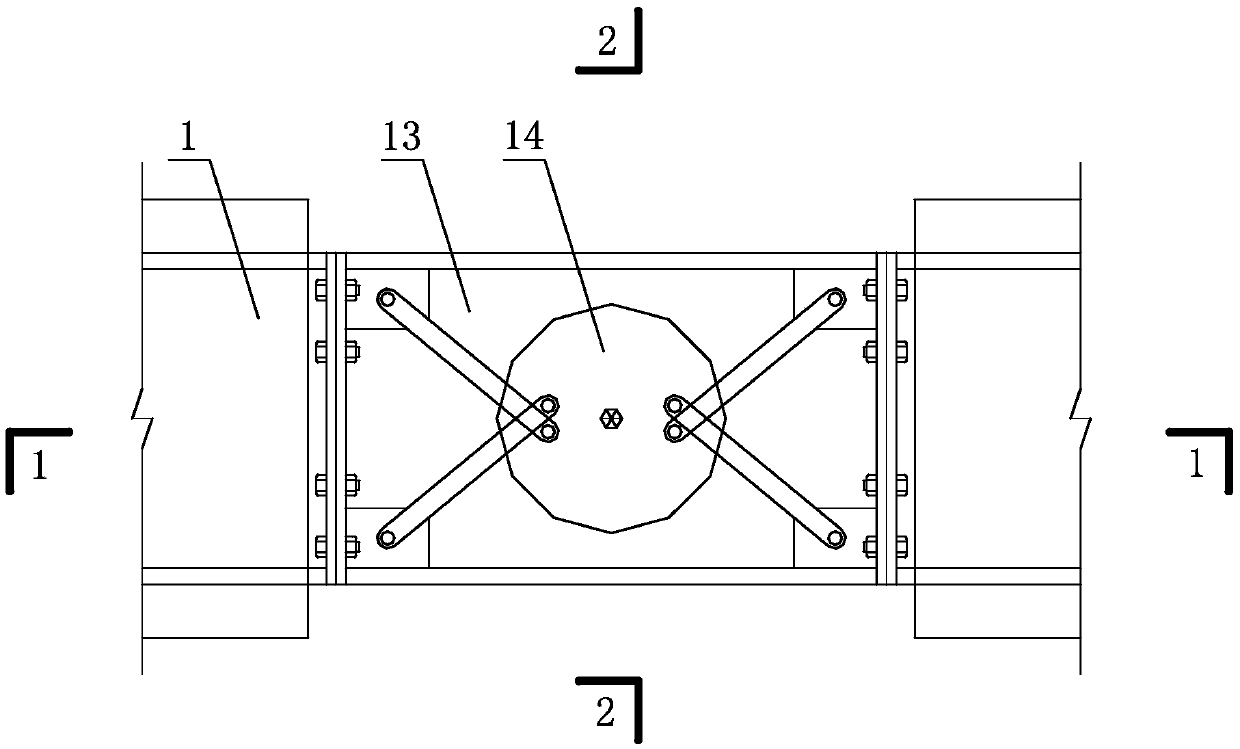

Jetting, expansion and extrusion combined pile, construction method thereof and spiral jetting, expansion and extrusion drilling rig used in method

ActiveCN108330959AEasy to makeReduce dosageDrilling with mechanical conveyingBulkheads/pilesDeformation modulusStructural engineering

The invention discloses a jetting, expansion and extrusion combined pile, a construction method thereof and a spiral jetting, expansion and extrusion drilling rig used in the method. A pile of the combined pile comprises a pile body, at least one expanded body and a pile end, and the at least one double-frustum-shaped expanded body integrally formed with the pile body is arranged on the pile body.Each expanded body is located in a vertical soil layer position, which has higher deformation modulus and shear strength, of the pile body, and at least two wing plates which are uniformly distributed in the circumference direction and basically perpendicular to the axis of the pile are arranged on the pile body. The diameter of the pile above the at least one expanded body is larger than or equal to that of the pile below the at least one expanded body. The drilling rig comprises an upper section and a lower section, the diameter of the upper section is larger than that of the lower section,and the at least one expanded body can be produced in any required position conveniently. When the at least one expanded body is located at the upper part or in the middle of the combined pile, if the diameter of the pile above the at least one expanded body is larger than that of the pile below the at least one expanded body, the consumption of concrete can be greatly reduced.

Owner:SHANDONG BEI TE LI FOUND ENG TECH CO LTD

Rotary friction type replaceable energy dissipation connecting beam

PendingCN109629744AImprove comfortProtect the main structureGirdersJoistsEngineeringStructure system

The invention provides a rotary friction type replaceable energy dissipation connecting beam which comprises a replaceable section positioned at a center of a connecting beam and non-energy dissipation sections which are distributed at two sides of the replaceable section and are arranged at positions of shear wall limbs, wherein two ends of the replaceable section are fixedly connected with the non-energy dissipation sections respectively, the replaceable section comprises two rotary friction energy dissipation damper monomers which are arranged back and forth and a profile steel plate whichis positioned at a middle space of the replaceable section, and the profile steel plate is integrally connected to the non-energy dissipation sections so as to enhance integrity and action consistencyof the replaceable section; a bottom plate of an outer sleeve of a rotary friction energy dissipation damper monomer is fixedly connected with a bottom plate bolt of an embedded cylinder and is respectively connected with a transmission rod bolt at the left side and the right side along different diagonal lines, and a high-damping rubber core is filled in a cylinder wall formed by the embedded cylinder and the outer sleeve. By the adoption of the rotary friction type replaceable energy dissipation connecting beam, the connecting beam can be properly adjusted according to requirements by meansof replacing the connecting beam, installation is convenient, and applicability is strong, so that the anti-seismic performance of a structure is improved, and the structure is used for restoring a functional shear wall structure system.

Owner:TONGJI UNIV

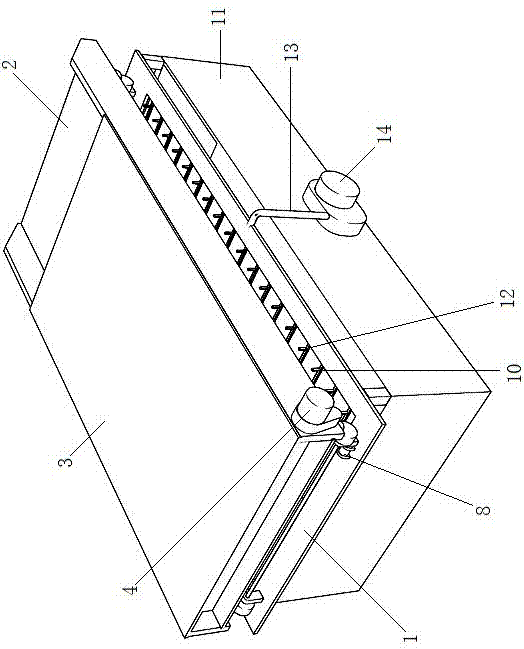

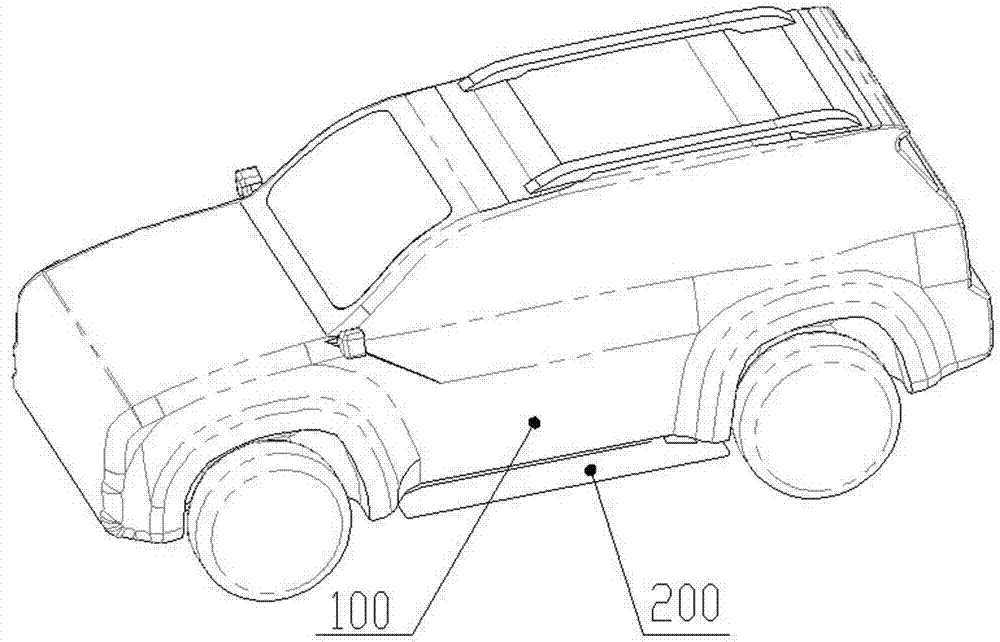

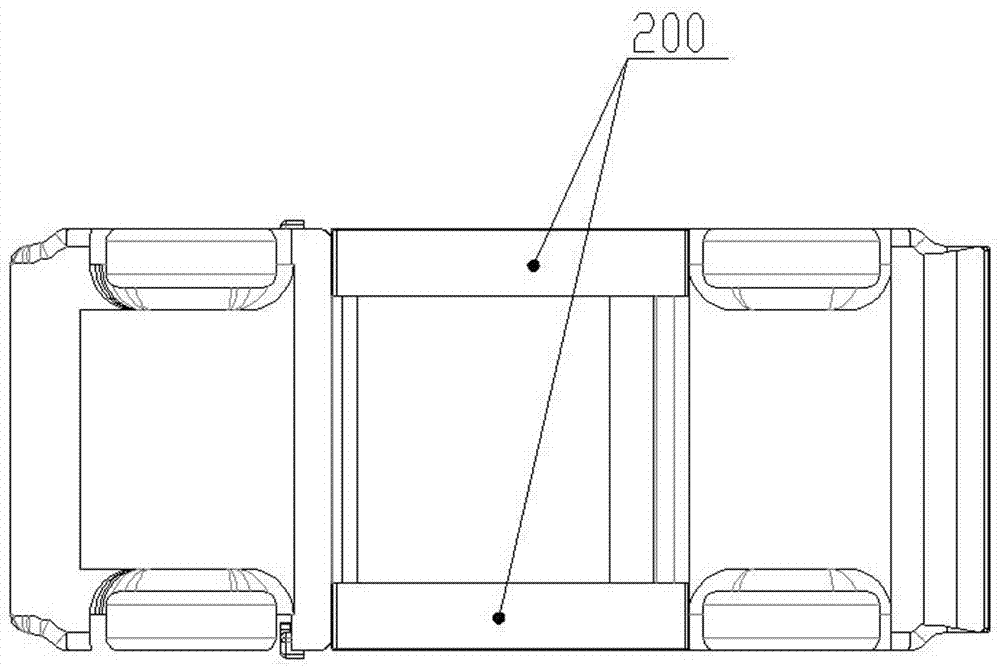

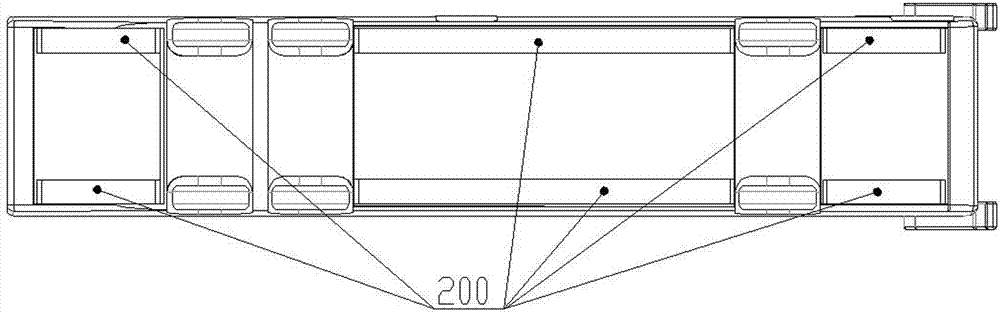

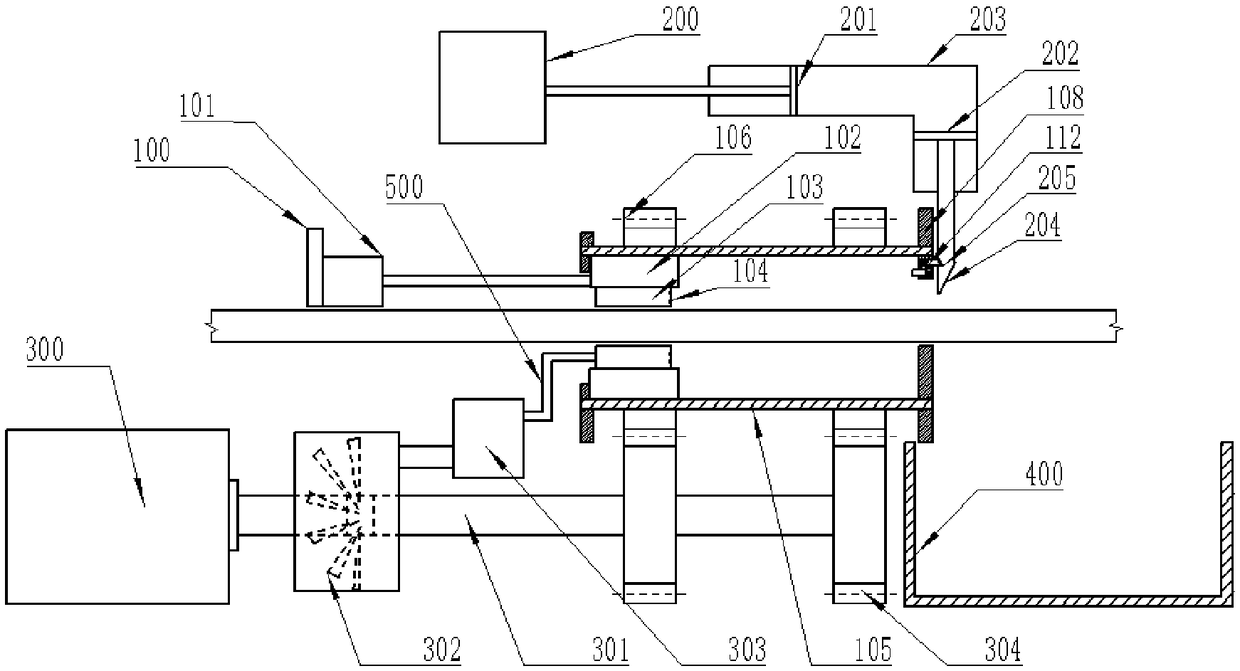

Auxiliary driving system and vehicle

ActiveCN106864430AIncrease friction area and friction capacityImprove the ability to get out of troubleVehicle modificationsEndless track vehiclesEngineeringRoad condition

The invention discloses an auxiliary driving system and a vehicle. According to the embodiment of the invention, the auxiliary driving system is constructed on the basis of a parallelogram mechanism, the rack part and a framework opposite to the rack part of the of the parallelogram mechanism can keep parallel all the time, so that bearing of a supporting framework is distributed relatively evenly in the front and back directions and not affected by opening stroke. When in the opening state, the auxiliary driving system is used for extricating of the vehicle or auxiliary driving under a certain road condition; and when in a folded state, greater influence on traversability of the vehicle is reduced, so that the auxiliary driving system can be always prepared on the vehicle, and the situation that the auxiliary driving system is mounted only when the vehicle is caught in a sandy land and the like is not needed. The auxiliary driving system can effectively increase the friction area and friction ability, so that the auxiliary driving system is used for improving the extricating ability.

Owner:JINAN JIANGFUWAN AUTOMATION TECH

Automobile pipe cutting device

ActiveCN108453303ASave spaceControl recoveryWork clamping meansTube shearing machinesEngineeringDrive motor

The invention discloses an automobile pipe cutting device. The automobile pipe cutting device comprises a rack, an air cylinder telescopic rod and a driving motor. The rack is fixedly provided with the telescopic rod and rotationally connected with a rotary barrel. The telescopic rod is connected with an annular clamping piece. An air bag is connected with the inner wall of the annular clamping piece. An air pressure valve is installed on the air bag. The outer wall of the annular clamping piece is in thread connection with the inner wall of the rotary barrel. A gear ring is fixedly arranged on the outer wall of the rotary barrel. A piston cylinder with an L-shaped section is arranged on one side of the air cylinder telescopic rod. A first piston is connected with the air cylinder telescopic rod. A second piston is connected with a cutter knife for cutting pipes. A clamping groove is formed in the cutter knife. The clamping groove is correspondingly provided with a cutting control piece. The cutting control piece can be in clamping combination with the clamping groove. The annular clamping piece triggers the cutting control piece. With the automobile pipe cutting device, the problem that according to an existing cutting device, cut automobile pipes have burrs and unsmooth cuts is particularly solved.

Owner:重庆广福科技有限公司

Titanium alloy friction stir welding stirring head and welding method thereof

InactiveCN107649780AWear-resistantExtended service lifeWelding/soldering/cutting articlesNon-electric welding apparatusTitanium alloyWear resistance

The invention relates to the field of welding of a titanium alloy, in particular to a titanium alloy friction stir welding stirring head and a welding method thereof. The stirring head comprises a clamping part, a shaft shoulder and a stirring needle and is characterized in that the stirring needle is located below the shaft shoulder, the stirring needle is of a conical structure with the large upper and the small lower, and an annular groove is formed in the outer wall of the stirring needle; the stirring head is used for welding of the titanium alloy board of 4 mm to 10 mm. The stirring headis made of a W-Re alloy and has the wear resistance. According to the welding head, the rotating speed and the welding speed are controlled, the microscopic structure of the welding seam can be controlled, the aim of being capable of controlling the structure is achieved, and after welding, the obtained welding seam has the excellent mechanical property.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

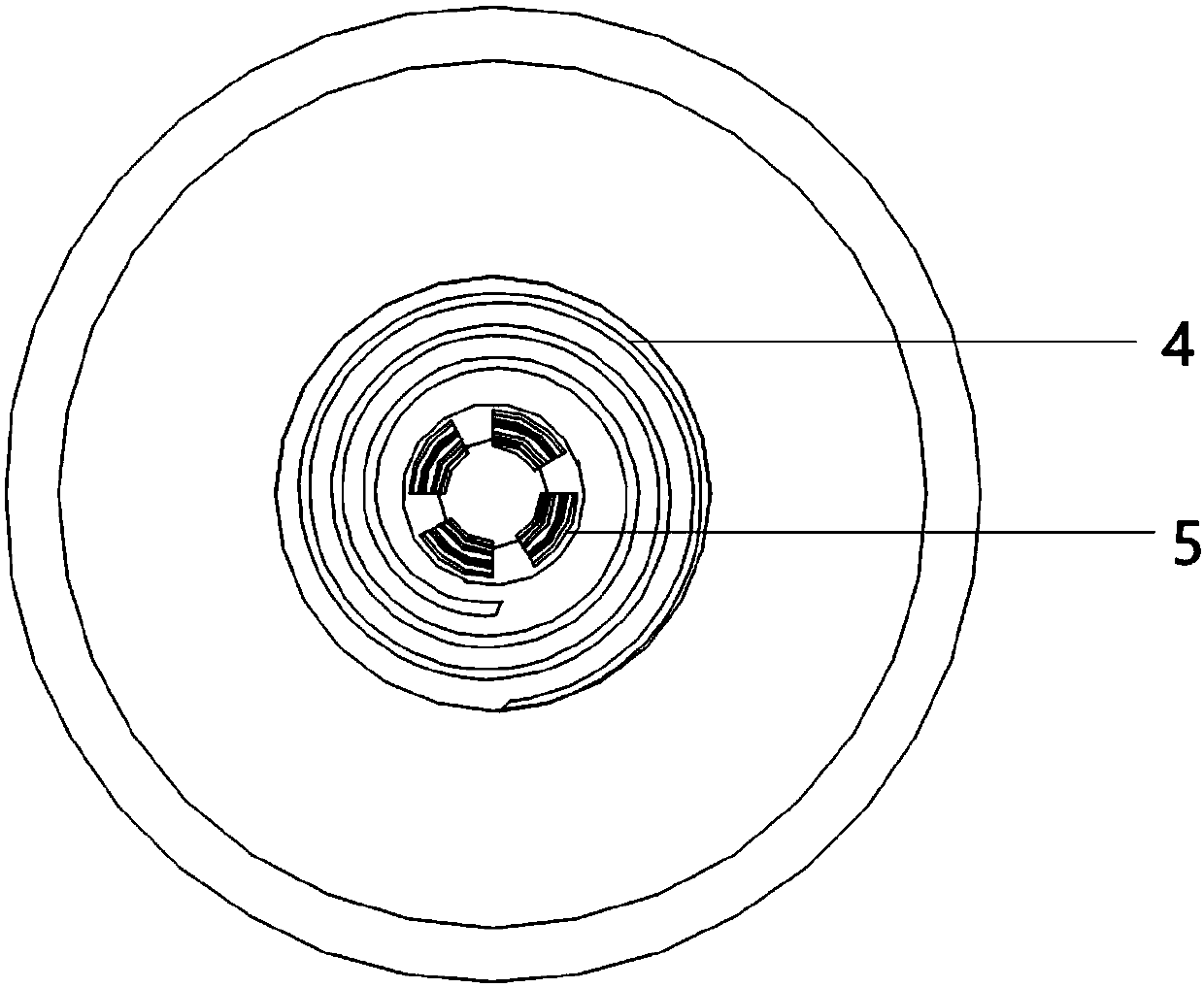

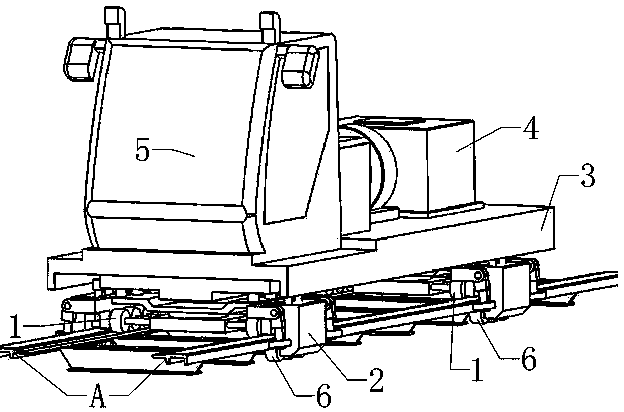

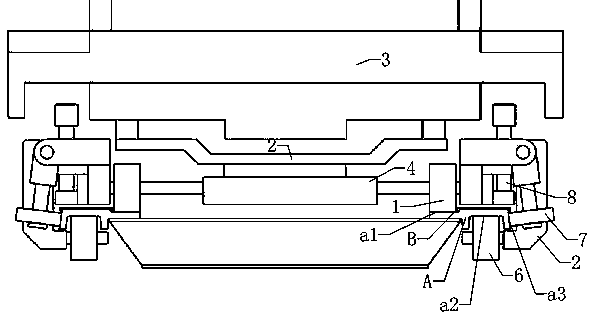

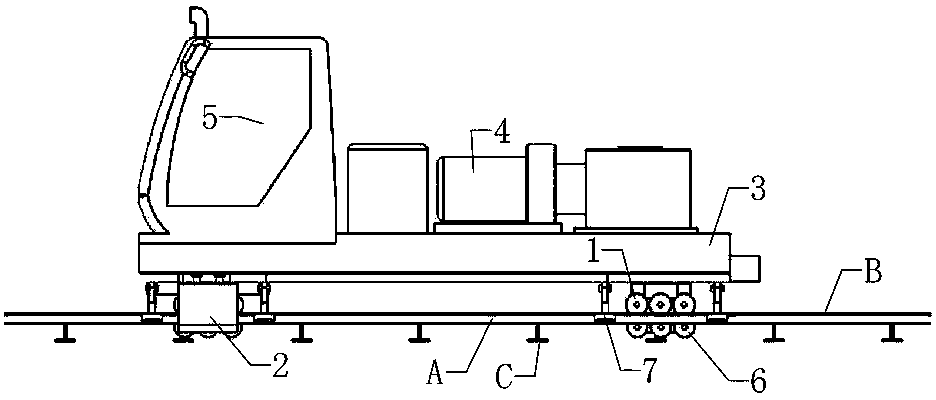

Tractor for magnetic levitation traffic installation routing inspection rescue

The invention discloses a tractor for magnetic levitation traffic installation routing inspection rescue. The tractor is composed of a bearing driving wheel (1), a loading driving wheel (6), a bogie (2), a tractor body (3), a power transmission system (4) and a driving braking system (5). The bearing driving wheel (1) walks on a sliding face (a1) of a rail F (A). The loading driving wheel (6) additionally walks inside a groove-shaped face (a2) opposite to the sliding face (a1) of the rail F (A), so that the friction area of the wheels and the positive pressure of the upper and lower wheels are increased, the frictional force is effectively improved, large traction is obtained, meanwhile, the interior of the groove-shaped face of the reverse face of the rail F is not affected by rain or snow or freeze weather, and it is better ensured that the larger traction is obtained.

Owner:成都金和工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com