Solid-phase welding method and device of overlap connection of aluminum materials and high melting point metal

A high melting point metal, welding method technology, applied in welding equipment, metal processing equipment, non-electric welding equipment and other directions, can solve problems such as aluminum melting, welding tool wear, high temperature, etc., to improve the friction area, improve the interface connection strength, The effect of overcoming the difficulty of inseparable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention are described below through preferred embodiments, but the following embodiments cannot limit the protection scope of the present invention.

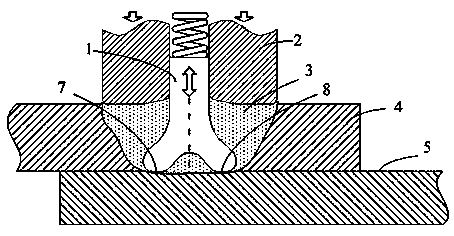

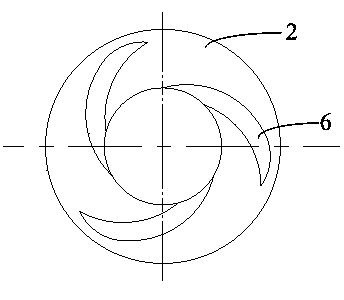

[0027] like figure 1 and figure 2 As shown, a method for lapping solid-phase welding of an aluminum material and a high-melting-point metal includes an aluminum material (4) and a high-melting-point metal (5) and a welding tool. The welding tool mainly includes a stirring pin (1) and a shaft shoulder ( 2), the axial movement of the stirring needle (1) is controlled by constant pressure, and the stirring needle (1) is rubbed against the overlapping interface of the high melting point metal (5) under the action of a constant axial upsetting force; The shaft shoulder (2) adopts displacement control, and the pressing amount of the shaft shoulder can be adjusted according to the flatness of the workpiece to be welded and the welding quality.

[0028] In this embodiment, the welding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com