Patents

Literature

112results about How to "Sufficient temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

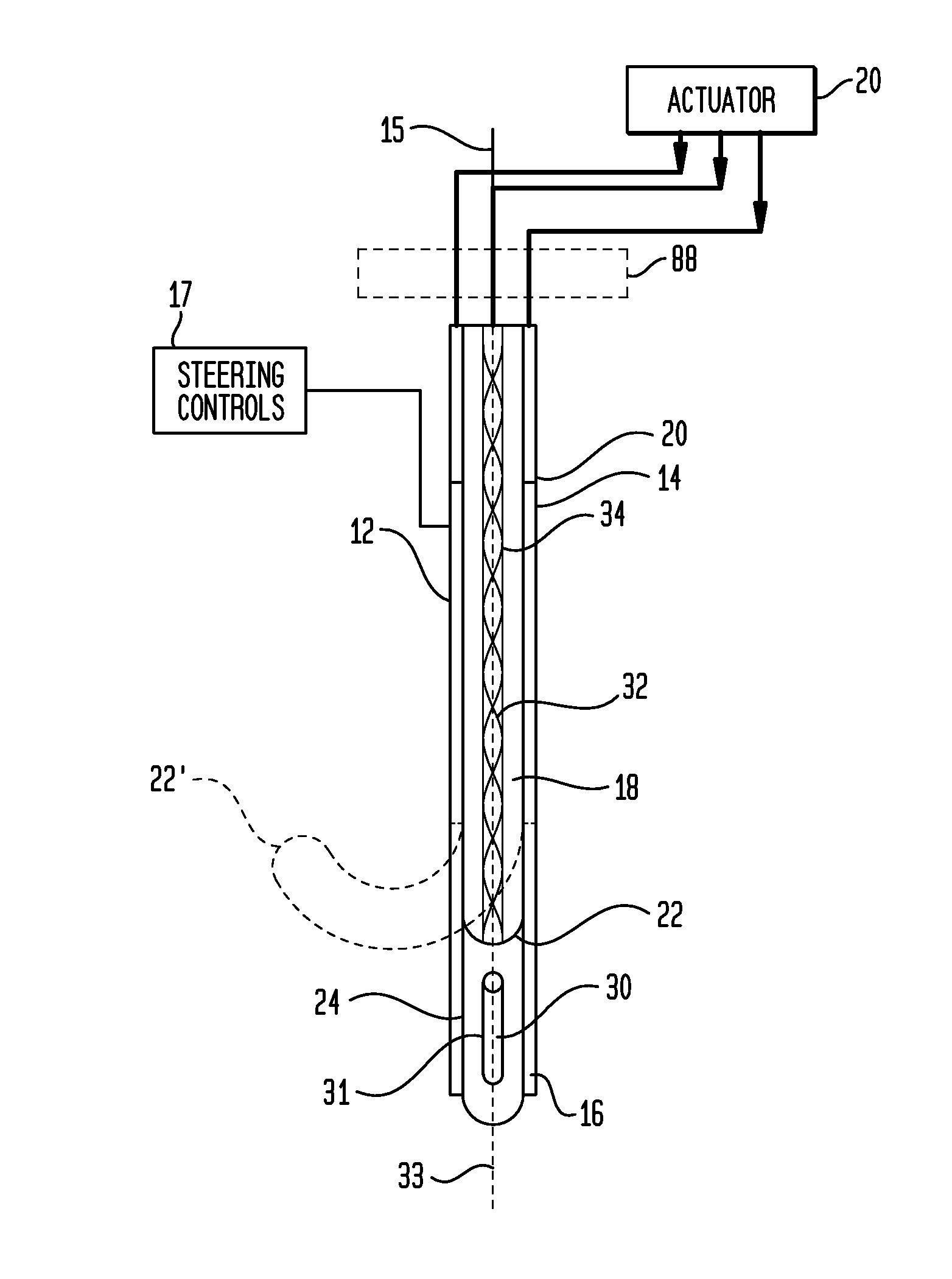

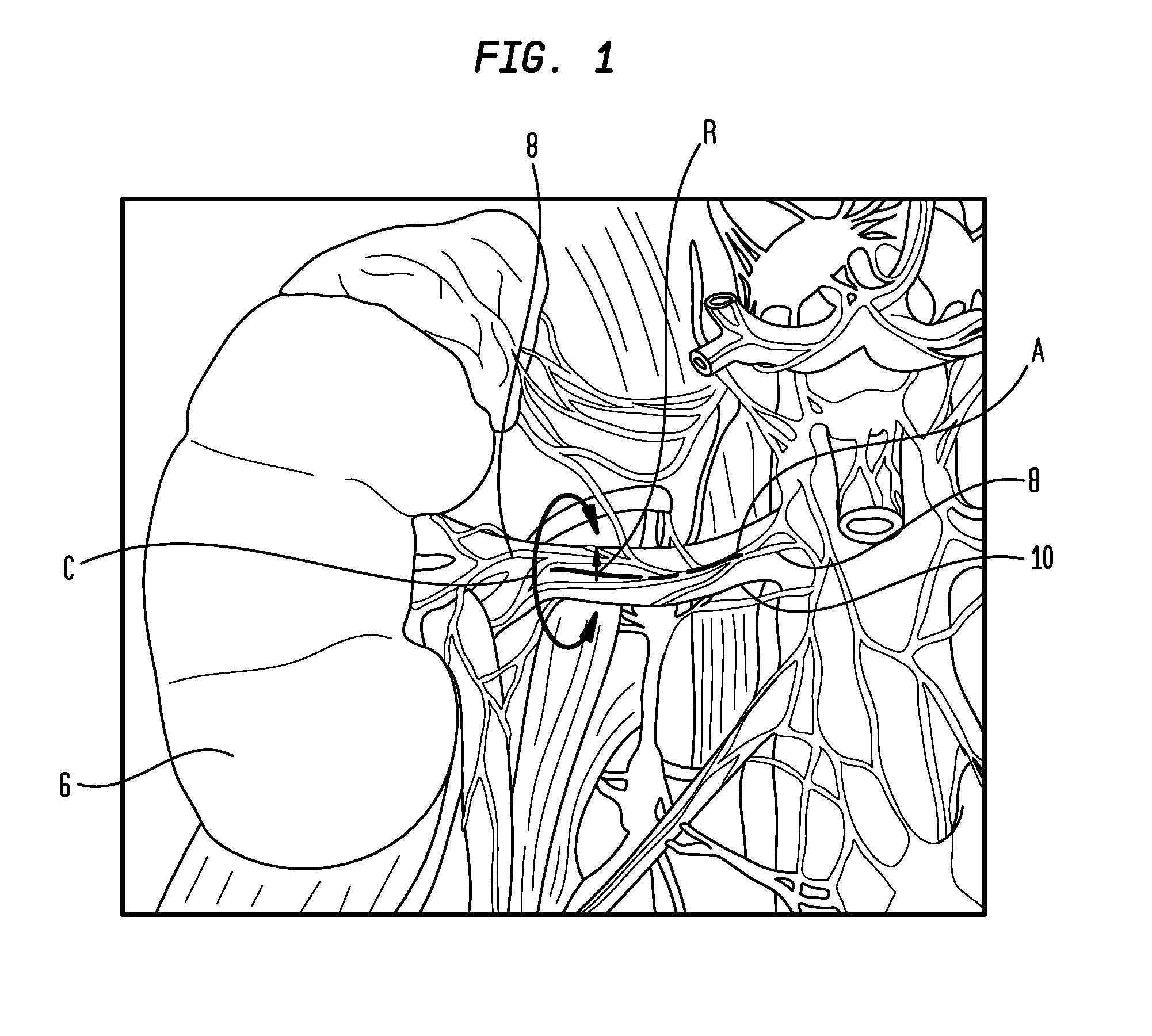

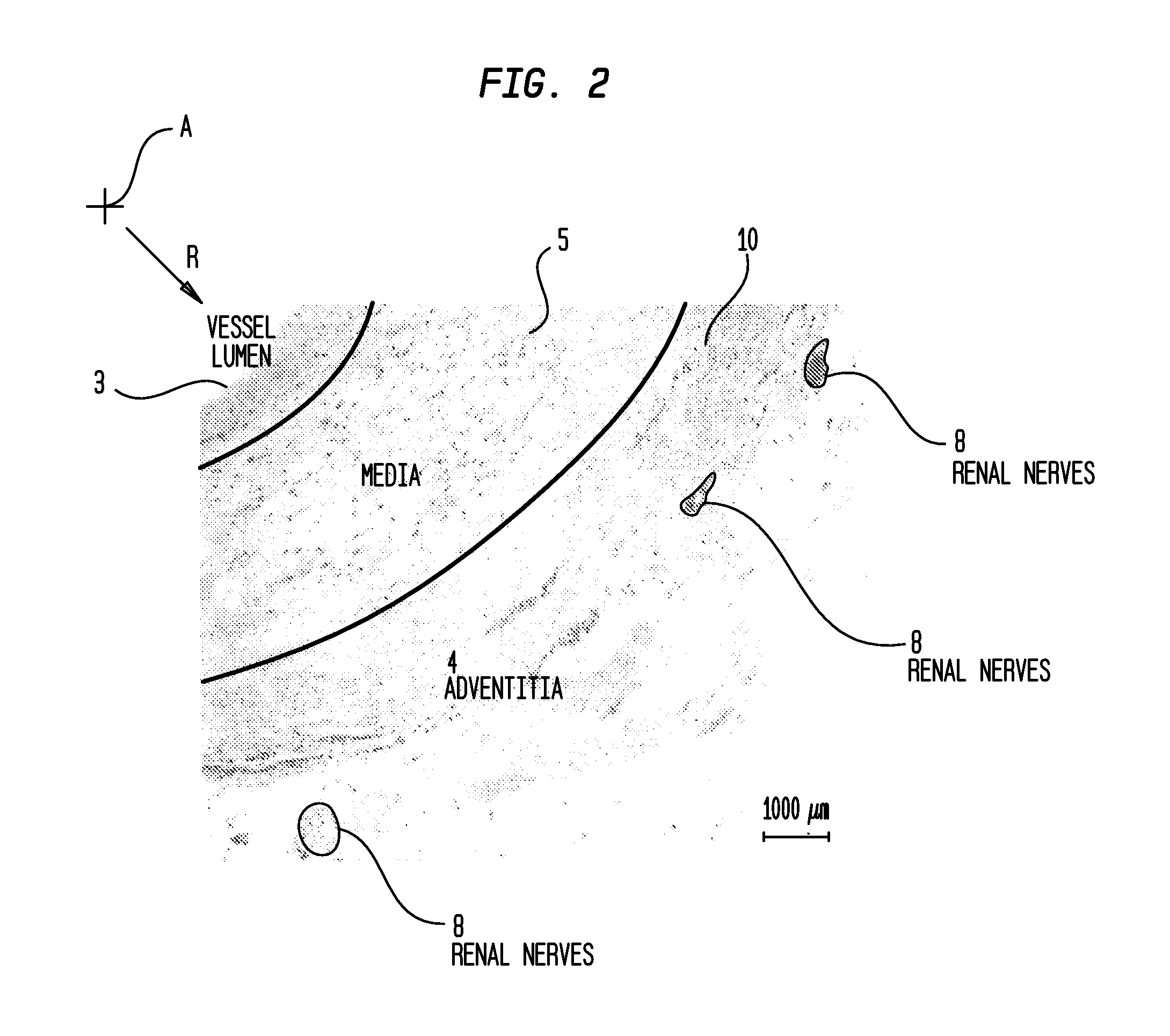

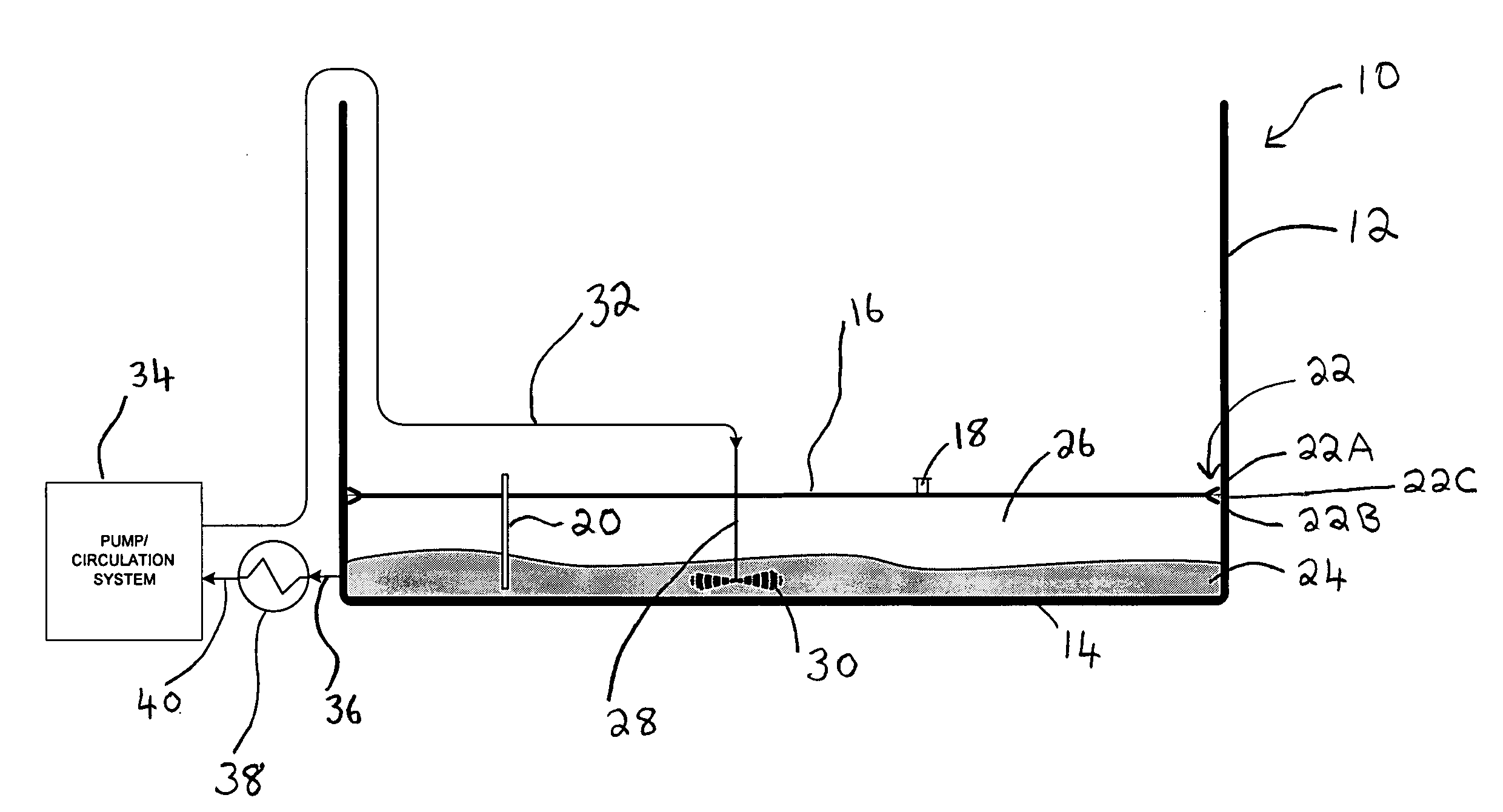

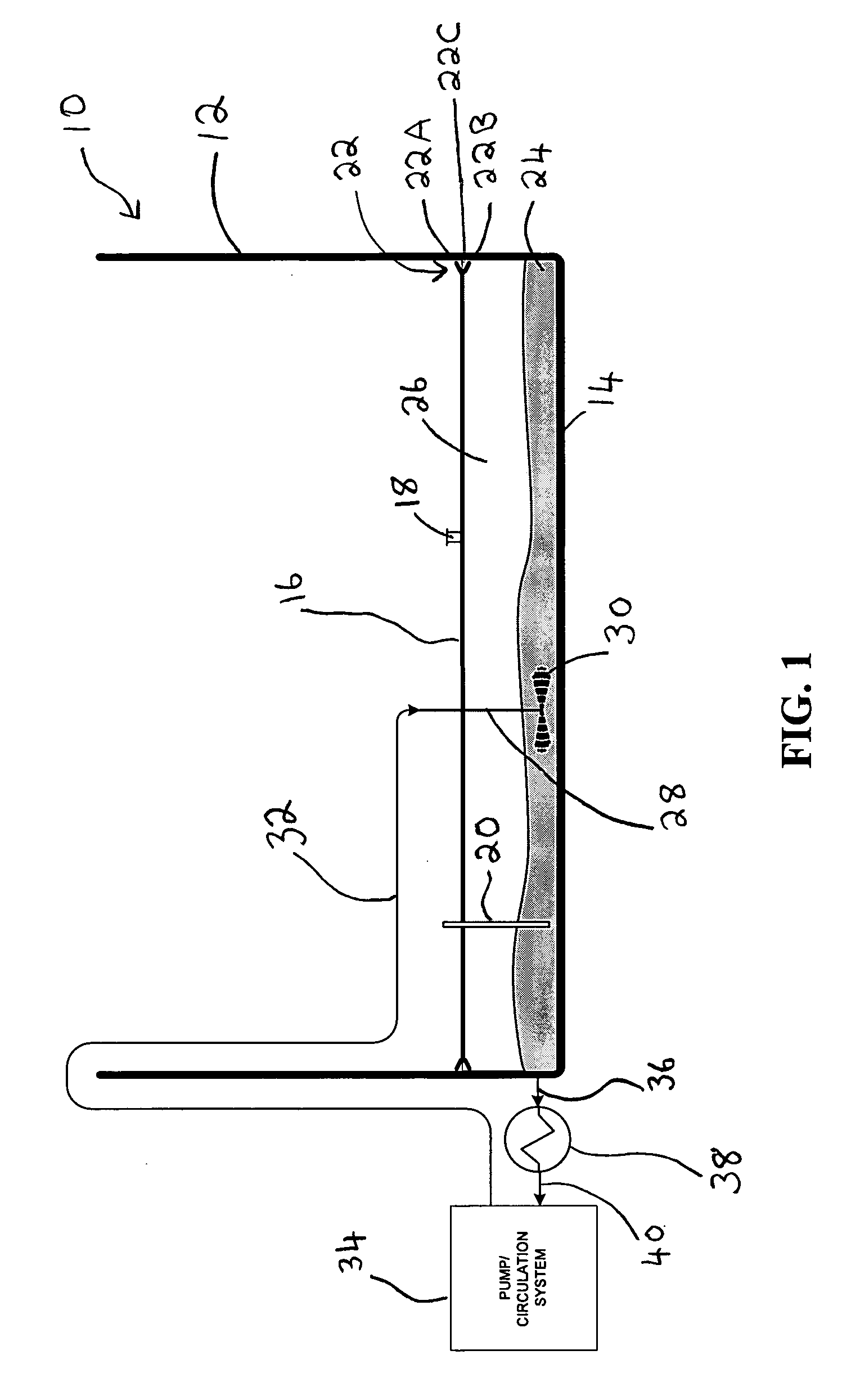

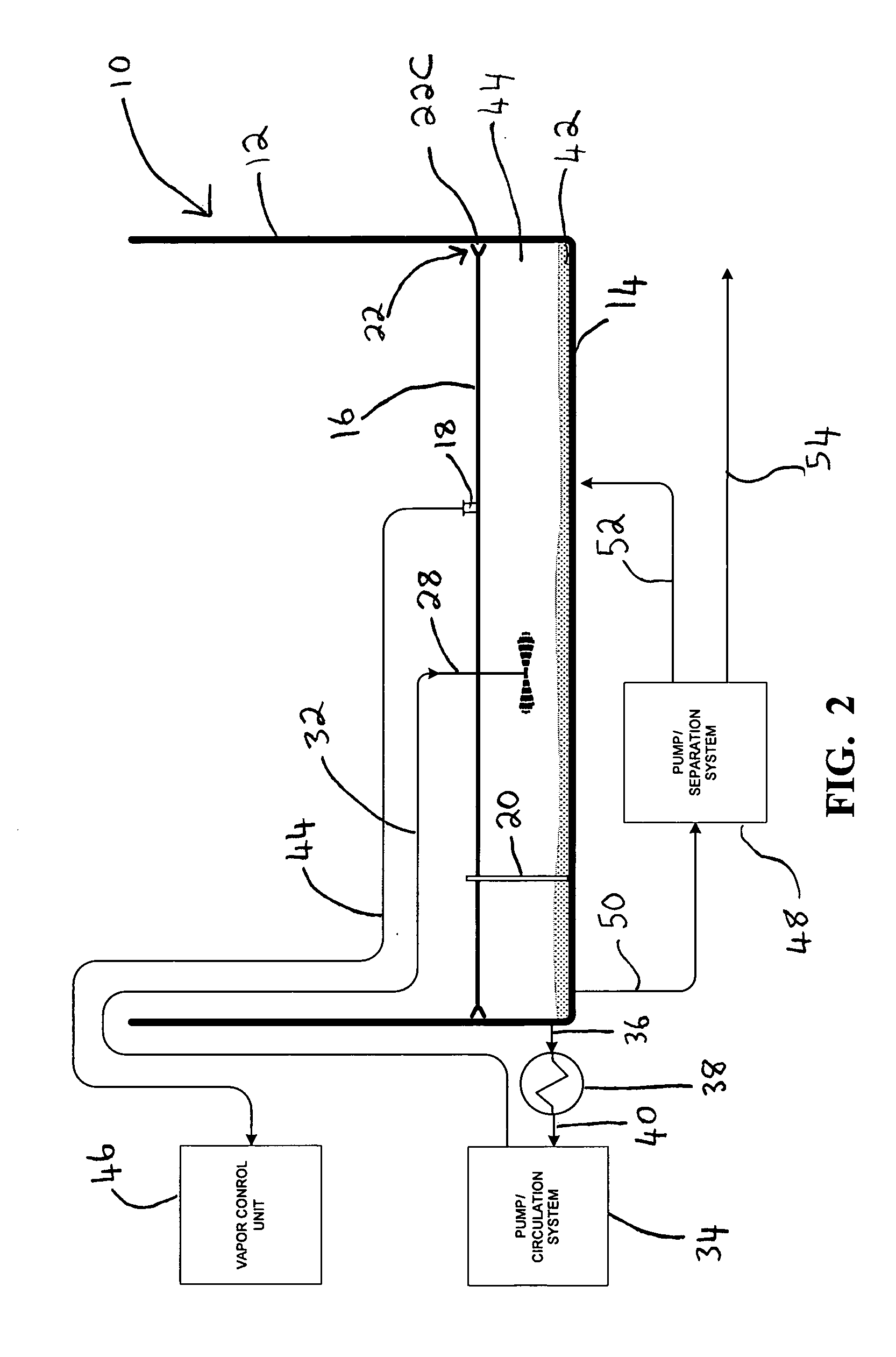

Method and Apparatus for Treatment of Hypertension Through Percutaneous Ultrasound Renal Denervation

ActiveUS20120232436A1Reduce possibilitySufficient temperatureUltrasound therapyStentsUrologyRenal nerve

Apparatus and methods for deactivating renal nerves extending along a renal artery of a mammalian subject to treat hypertension and related conditions. An ultrasonic transducer (30) is inserted into the renal artery (10) as, for example, by advancing the distal end of a catheter (18) bearing the transducer into the renal artery. The ultrasonic transducer emits unfocused ultrasound so as to heat tissues throughout a relatively large impact volume (11) as, for example, at least about 0.5 cm3 encompassing the renal artery to a temperature sufficient to inactivate nerve conduction but insufficient to cause rapid ablation or necrosis of the tissues. The treatment can be performed without locating or focusing on individual renal nerves.

Owner:RECOR MEDICAL INC

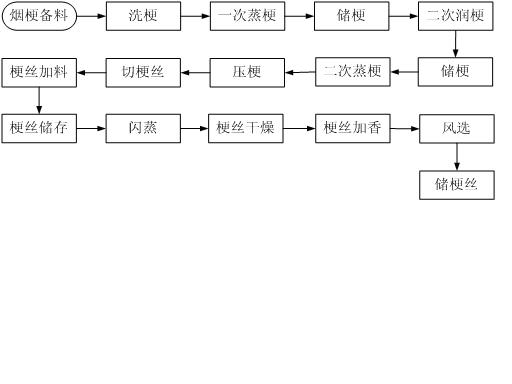

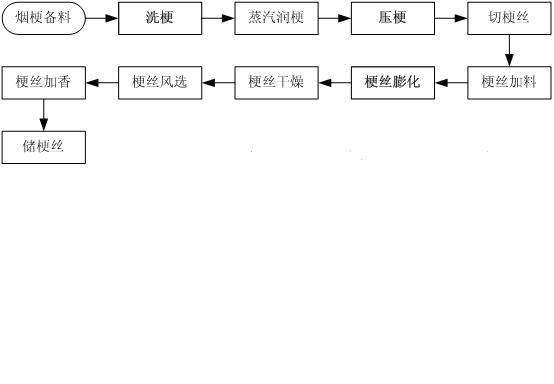

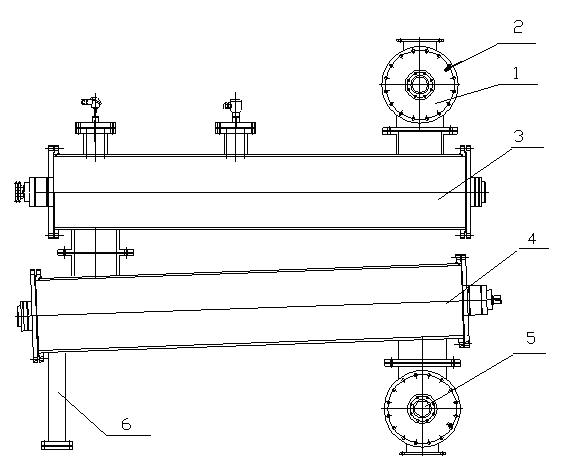

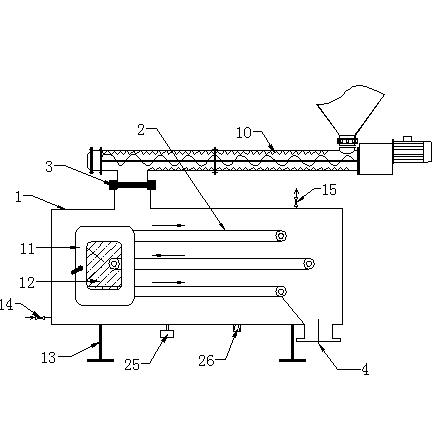

Steam stalk moistening method and equipment for implementing same

ActiveCN101862021AEnough pressureSufficient temperatureTobacco preparationPretreatment methodPulp and paper industry

The invention provides a tobacco stalk pre-processing method and tobacco stalk pre-processing equipment which can shorten the water permeability time of the tobacco stalk, ensure consistent moisture of the soaked tobacco stalk, save the storage process of the moistening of the tobacco stalk and simplify the process flow. The method comprises the following steps of: feeding a tobacco stalk material into a screw conveyer which is filled with steam and keeps proper pressure and proper temperature; continuously feeding the tobacco stalk material into the screw conveyer through a feeding vapor lock; continuously discharging the tobacco stalk material through a discharging vapor lock; and increasing the moisture and the temperature of the tobacco stalk to meet the requirements of the stalk pressing and cutting process on the discharging temperature and the moisture. The equipment comprises a bearing screw conveyer with a steam inlet and a water drainage port; a feed port and a discharge port of the screw conveyer are provided with the feeding vapor lock and the discharging vapor lock respectively; and the feeding vapor lock is provided with a water replenishing port. The water permeability of the tobacco stalk is improved by increasing the pressure and the temperature of the moistening environment of the tobacco stalk, so that the method and the equipment shorten the water permeability time of the tobacco stalks, quickly realize the pre-processing effect of the moistening of the tobacco stalk, save the storage process of the moistening of the tobacco stalk and greatly simplify the process flow of the stalk processing.

Owner:ZHISI HLDG GRP

Aluminium alloy foil and its producing method

InactiveCN1473949ARaise the recrystallization temperatureImprove welding strengthMetal rolling arrangementsManganeseCopper

The present invention discloses a kind of aluminum alloy foil for heat exchanger of air conditioner, cooler, heater unit, radiator, etc. in automobile and its production process. The aluminum alloy foil is produced with Al, Fe, Si, Mn, Zn, Cu, Mg, Zr and Ti, and through smelting, casting, homogenizing, cutting, milling, heating, rolling, annealing, finish rolling and other steps. The aluminum alloy foil thus produced has no deformation, subsidence and collapse.

Owner:沈健生

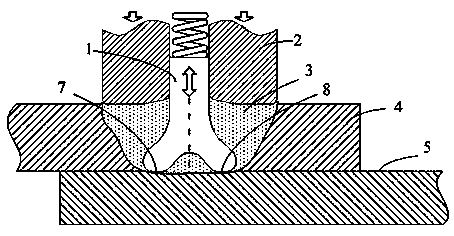

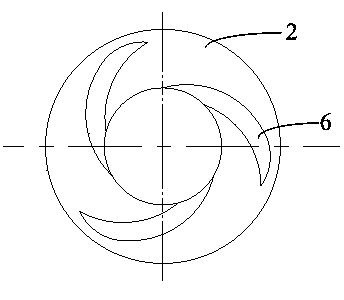

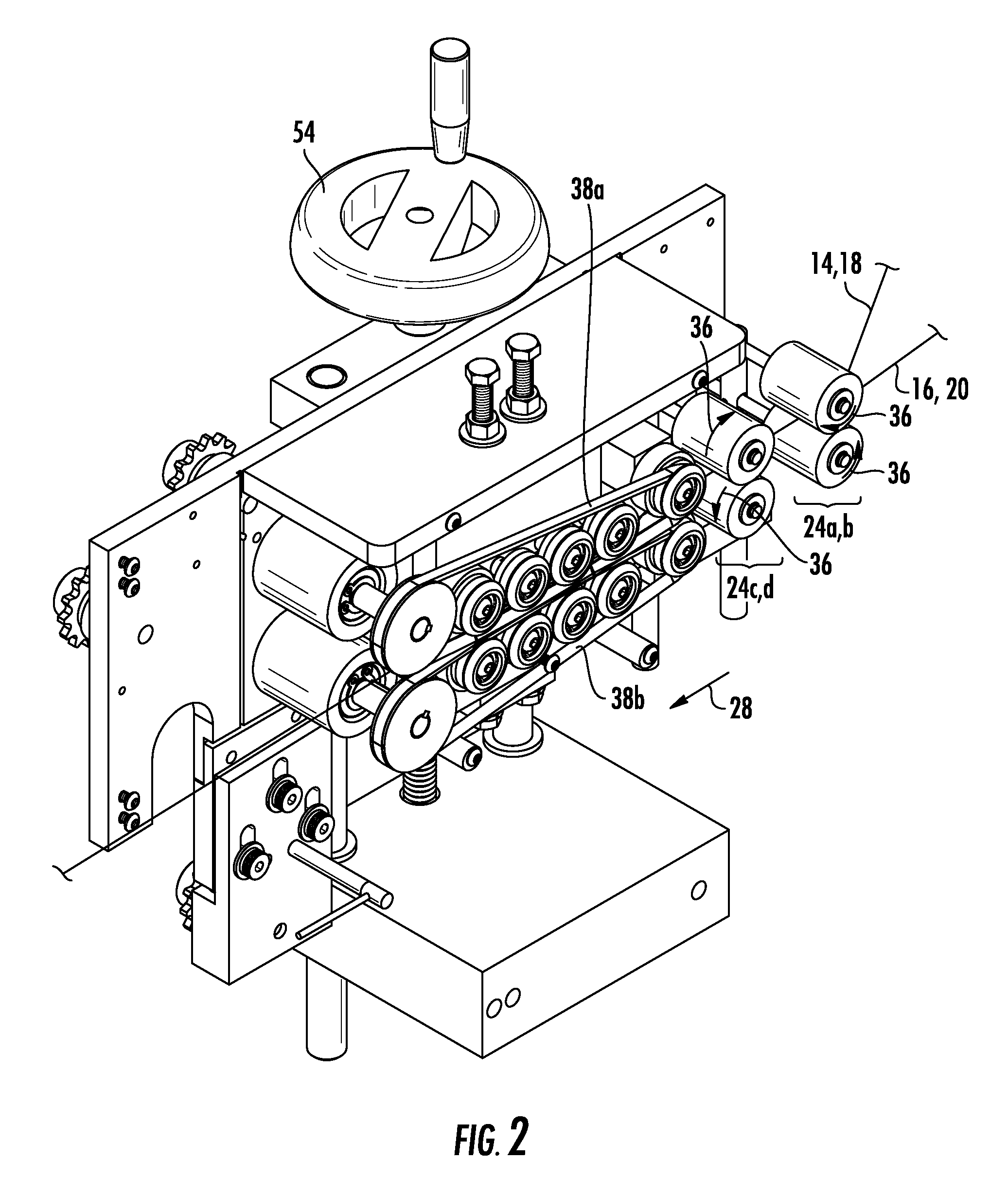

Solid-phase welding method and device of overlap connection of aluminum materials and high melting point metal

ActiveCN103846542AImprove stabilityGuaranteed moderate frictionNon-electric welding apparatusEngineeringDisplacement control

The invention relates to a solid-phase welding method of overlap connection of aluminum materials and high melting point metal. The solid-phase welding method comprises a solid-phase welding process. A solid-phase welding device comprises welding tools. The solid-phase welding method and device is characterized in that the welding tools comprise a double motion control stirring pin and a shaft shoulder separation tool; the axial motion of the stirring pin is controlled by the constant pressure; a shaft shoulder is controlled by the displacement; large area contact and friction characteristics are formed between the end portion of the stirring pin and base metal; a three involute groove is formed in the end surface of the shaft shoulder and accordingly a cohesion trend of the materials is formed; the welding tools are matched with appropriate welding parameters to control an interface intermetallic compound layer and accordingly the stirring friction welding connection with no inclination is achieved. According to the solid-phase welding method of the overlap connection of the aluminum materials and the high melting point metal, the high-strength and high-stability connection between the aluminum materials and the high melting point metal can be achieved and the problem of control of dissimilar metal welding interface intermetallic compounds is solved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

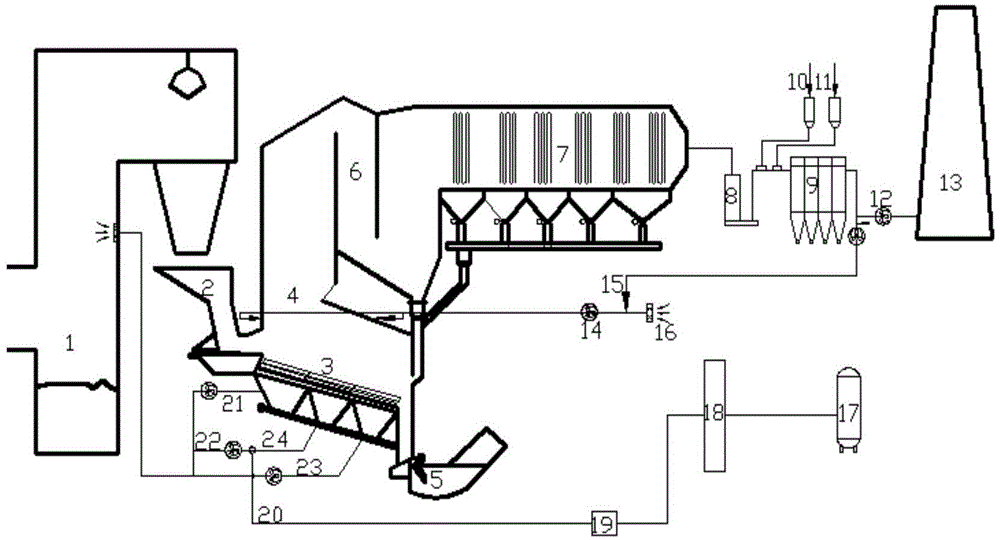

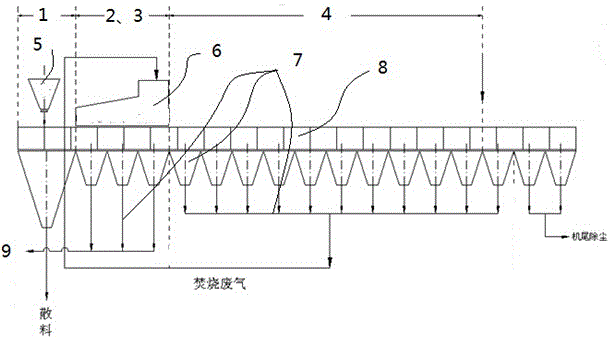

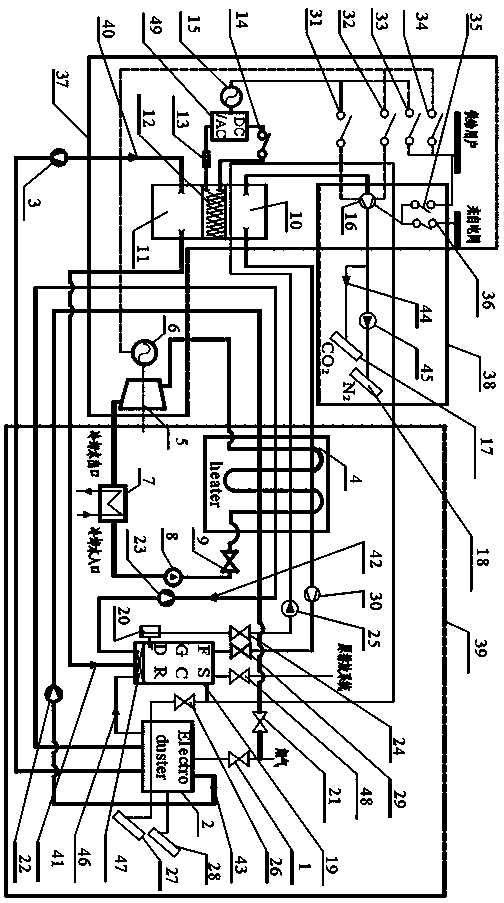

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

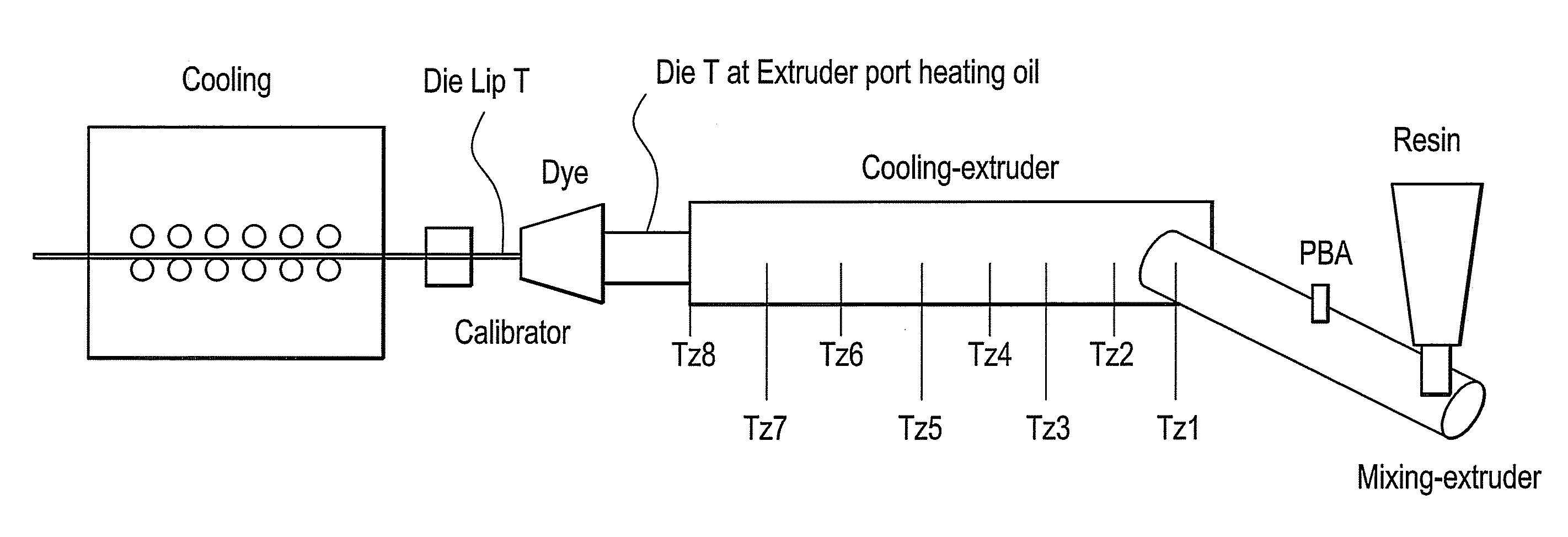

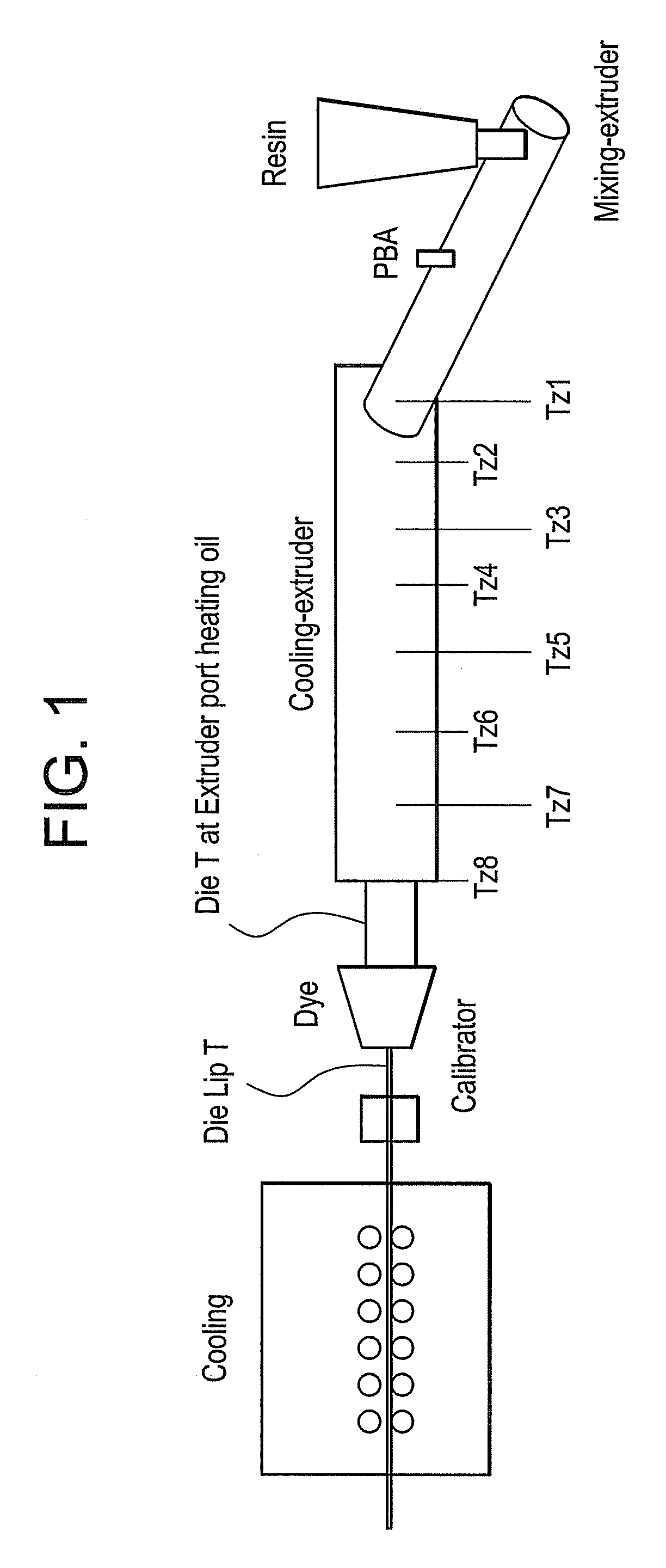

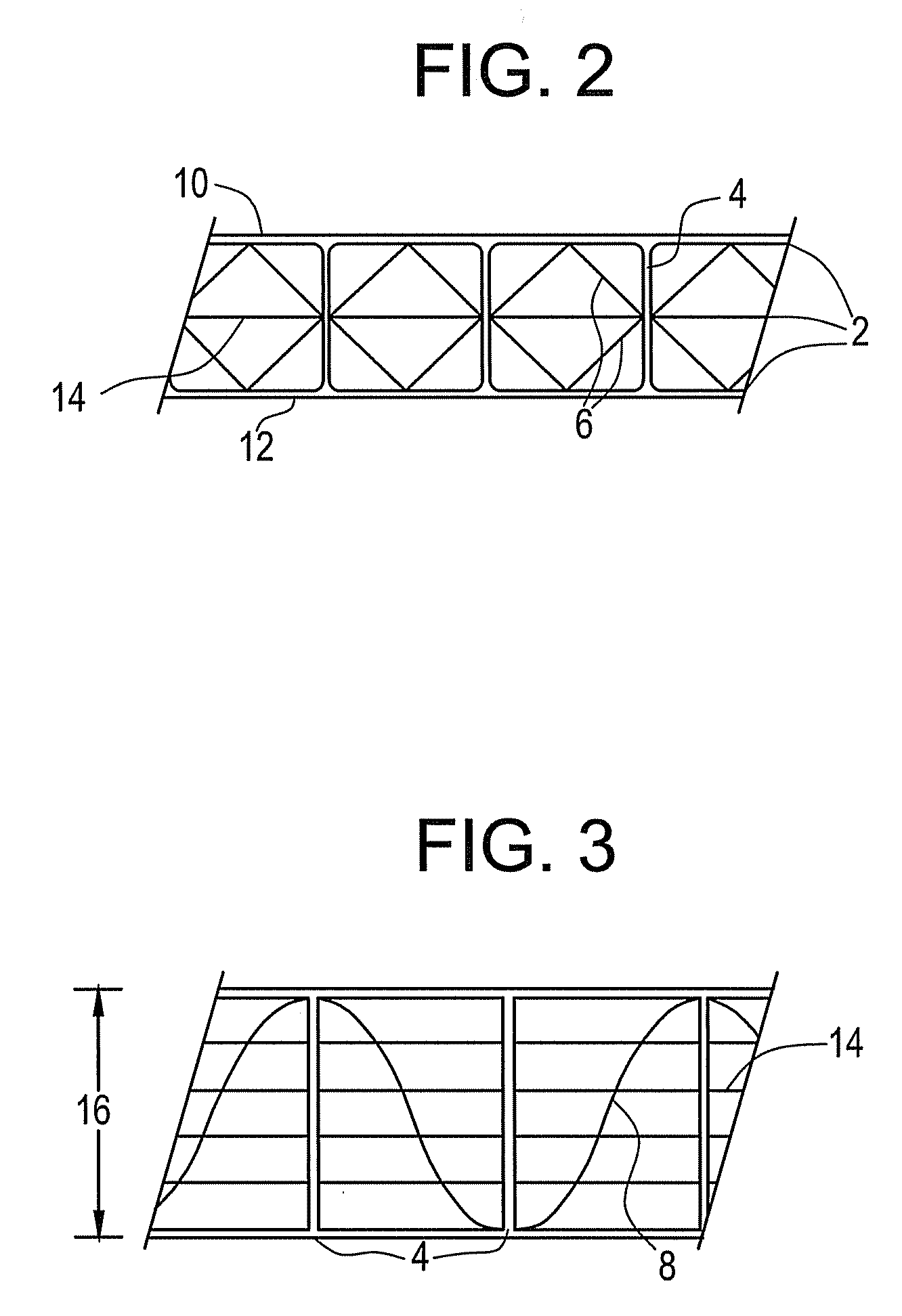

Light Transmissive Foamed Polymer Sheet and Methods for Making the Same

ActiveUS20090029144A1Sufficient temperatureSynthetic resin layered productsConstructions elementsPolymer chemistryAverage diameter

In some embodiments, a foamed polymer sheet comprises: a polymeric material and cells located in the polymeric material. The cells have a size distribution, D90 of greater than or equal to 300 μm and the sheet has a light transmission of greater than or equal to about 5%. In another embodiment, the cells have an average diameter, as measured along a major axis, of about 1 mm to about 4 mm, and the sheet has a light transmission of greater than or equal to about 5%. In another embodiment, a method of making a foamed polymeric sheet comprises: combining a blowing agent with a polymeric material to form a mixture, nucleating bubbles in the mixture, and cooling the mixture. The mixture is at a sufficient temperature and the cells have a sufficient cell size such that the sheet has a light transmission of greater than or equal to 10%.

Owner:SABIC GLOBAL TECH BV

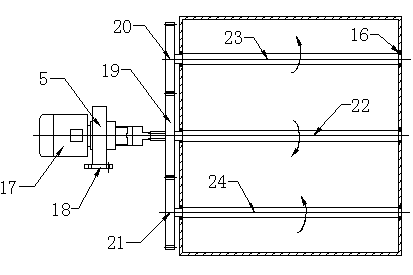

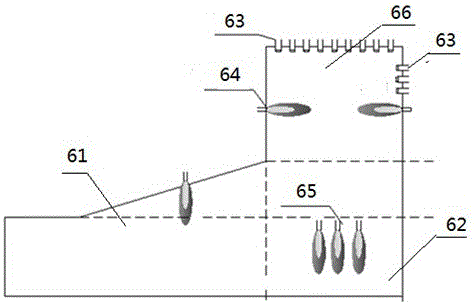

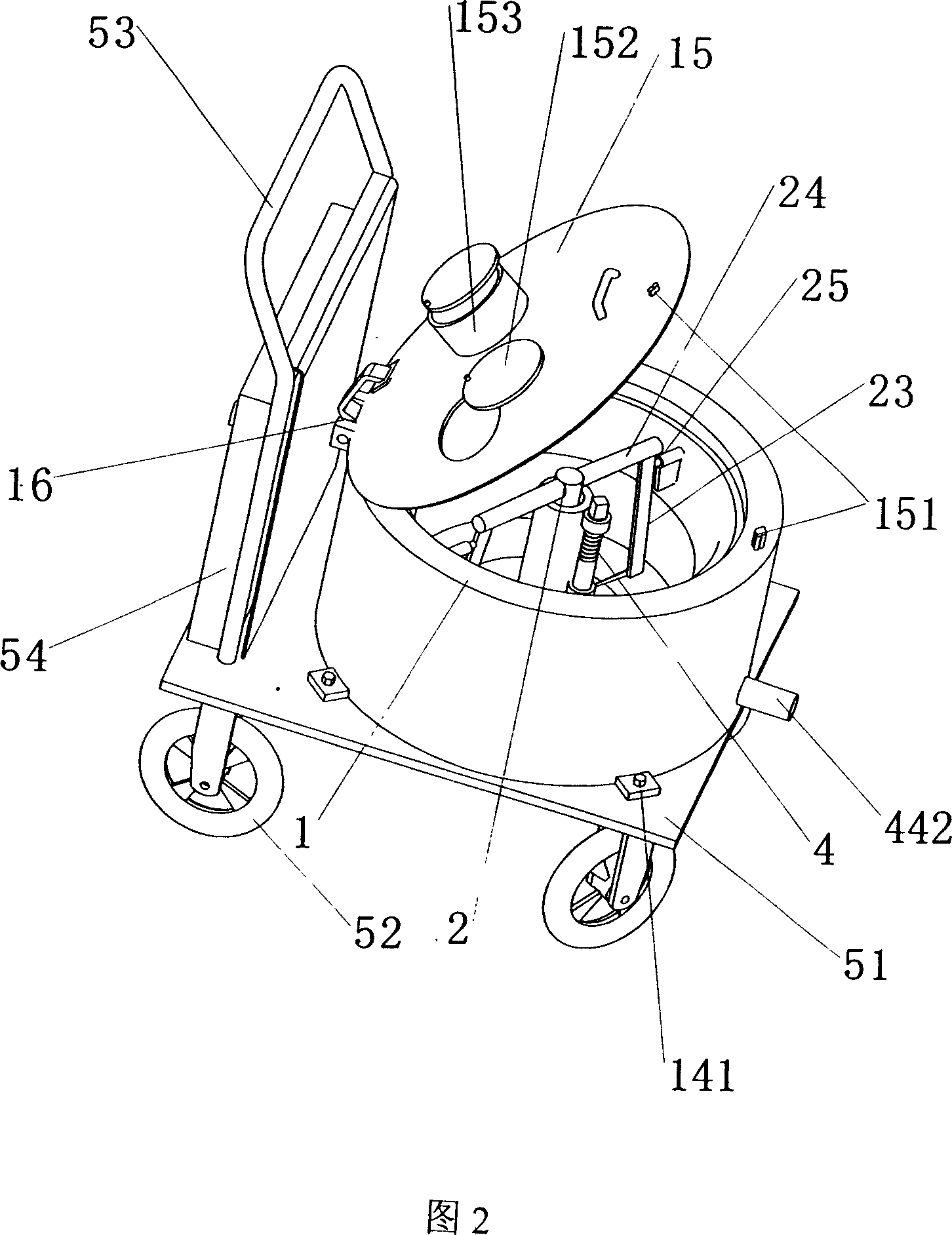

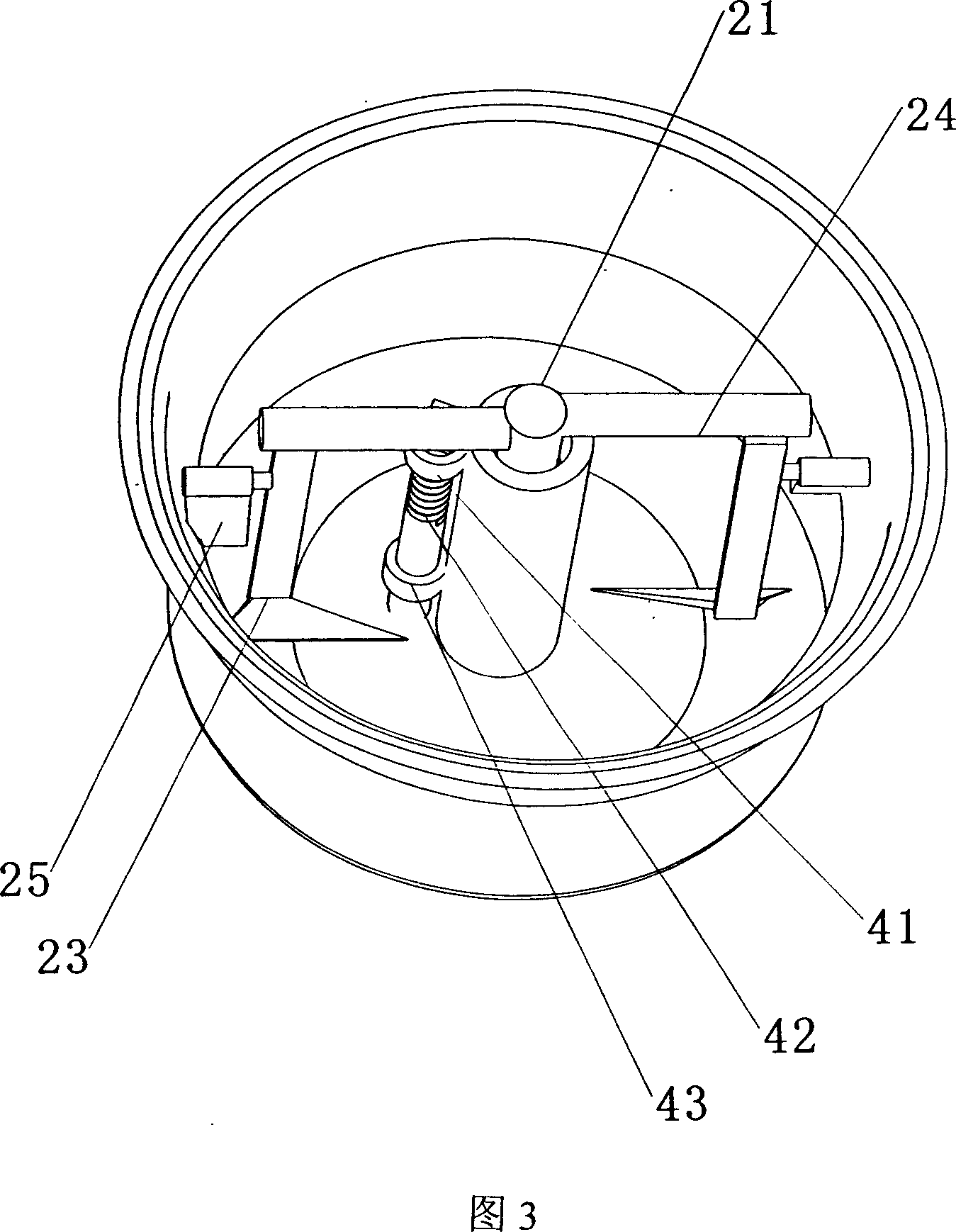

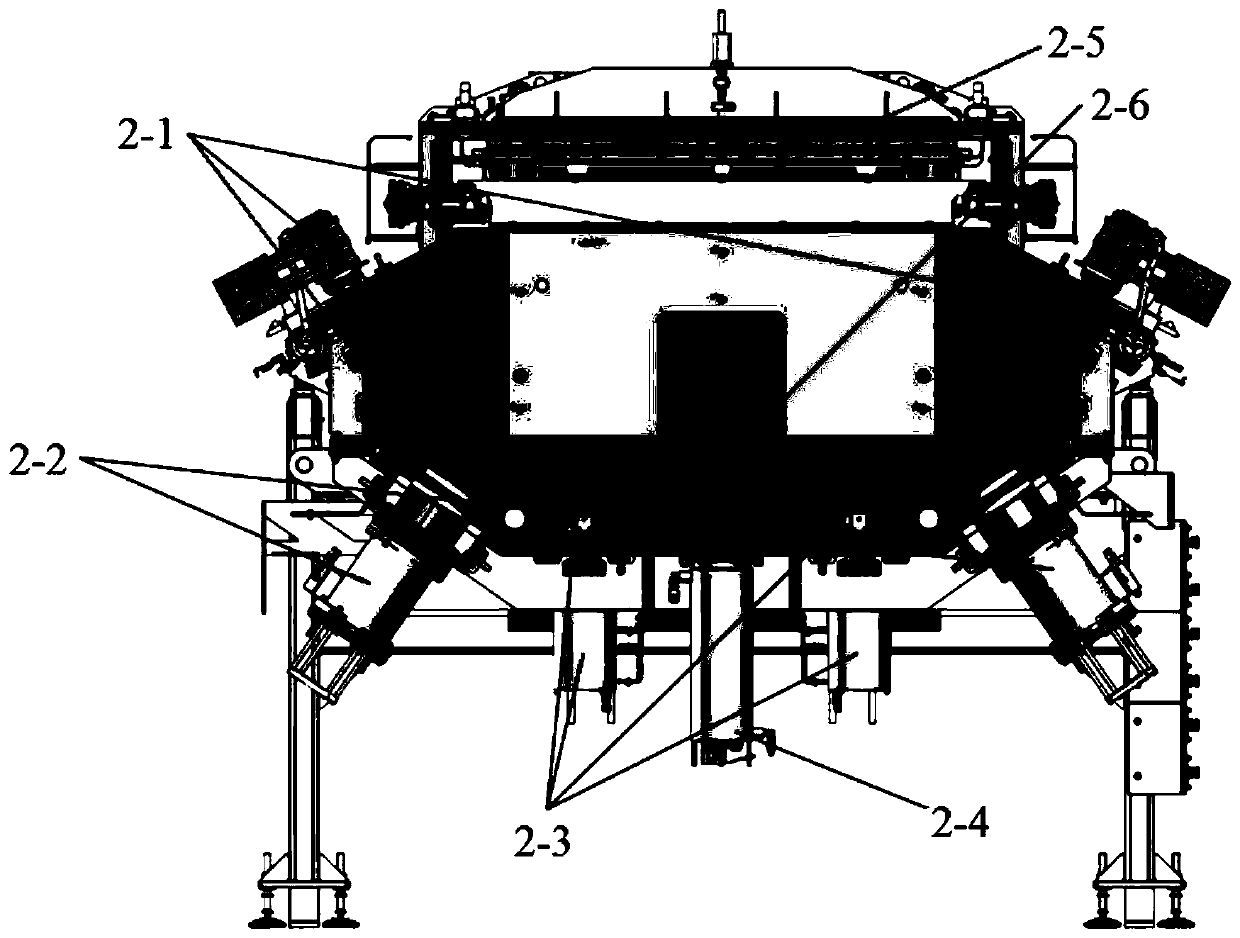

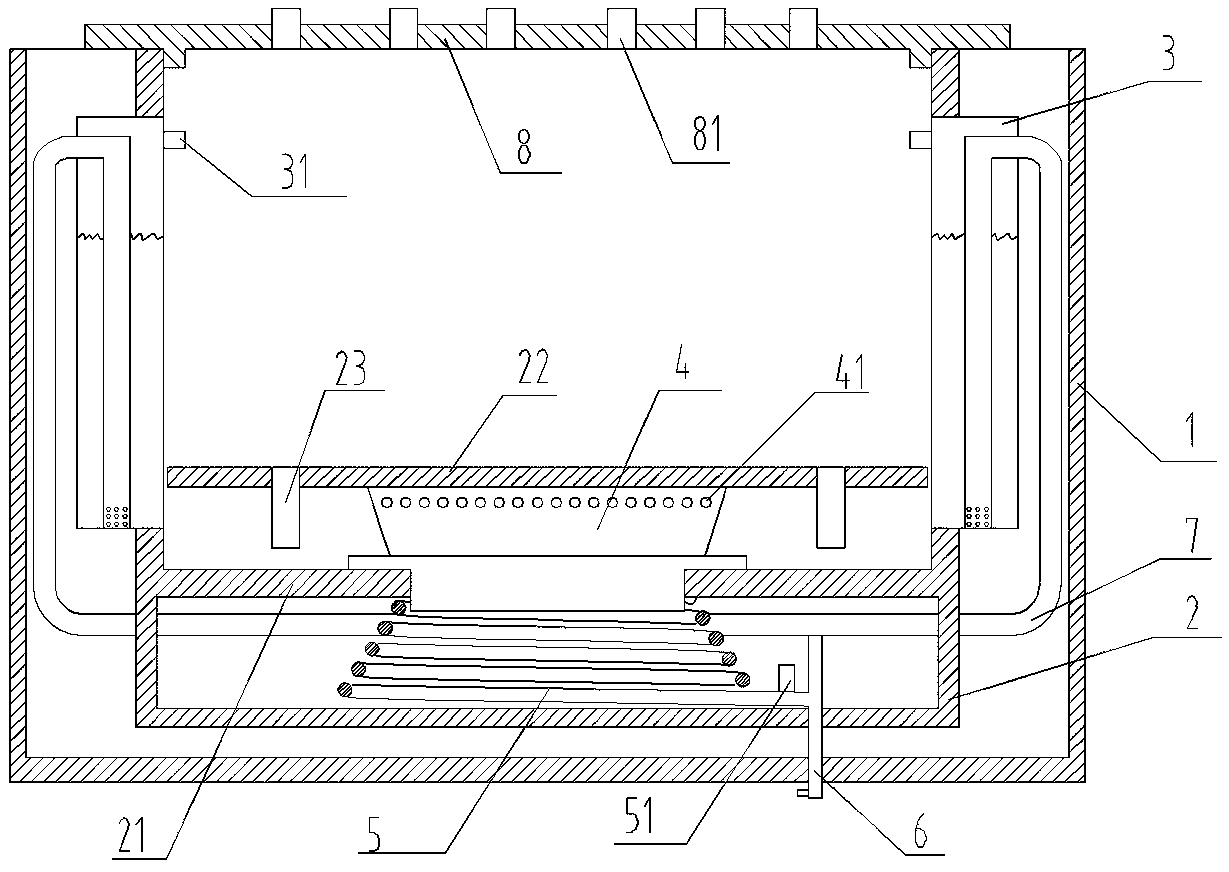

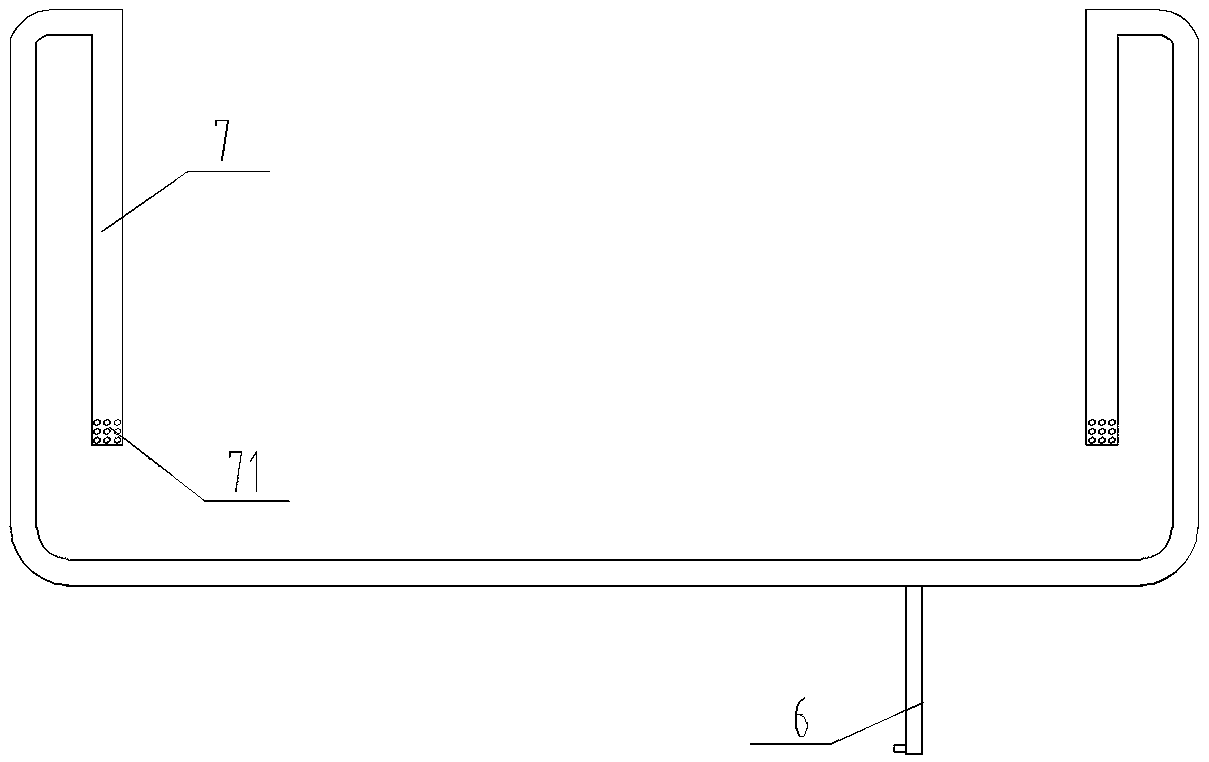

Solid state fermentation device

InactiveCN103122305AUniform evacuationGood evacuationBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSolid-state fermentation

The invention discloses a material fermentation device, and in particular relates to a solid state fermentation device, which comprises a fermentation box body, wherein a feeding port is arranged above the fermentation box, a discharging port is arranged below the fermentation box body, the fermentation box body is internally provided with more than two layers of parallel devices as well as staggered fermentation beds capable of undertaking materials falling off from an upper layer, a drive mechanism is arranged outside the fermentation box body, a spiral conveying device is arranged above the feeding port and is internally provided with spiral conveying blades, the fermentation box body is internally provided with more than one blank baffle which is respectively arranged between two adjacent fermentation beds, and a discharging baffle is arranged at the bottom of one side of the fermentation box body. Due to the adoption of the structure, the spiral conveying blades are used for conveying so that the material can be kept in a certain dispersing degree, therefore, the material is guaranteed to be uniform, zigzag teeth are arranged so as to enable the material to be better dispersed, an access door is arranged on the fermentation box body, and an inspection window arranged on the access door is convenient to overhaul the fermentation bed.

Owner:江苏麦客生物科技有限公司

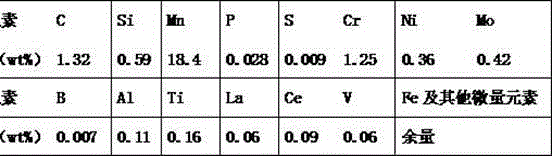

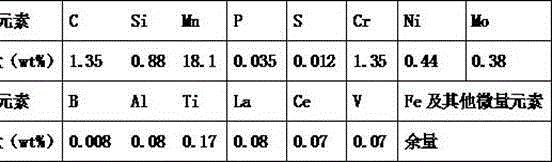

High-strength high-wear-resistance steel casting for super-huge type crusher and production process of steel casting

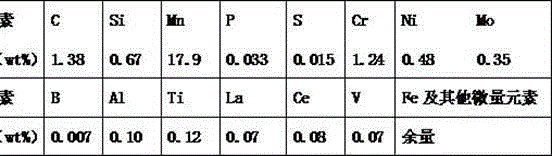

ActiveCN104911504AExtend the life cycleImprove work efficiencyFoundry mouldsFoundry coresHigh wear resistanceCrusher

The invention discloses a high-strength high-wear-resistance steel casting for a super-huge type crusher. The high-strength high-wear-resistance steel casting is characterized by comprising the following chemical components in percentage by weight: 1.31%-1.40% of C, 0.50%-0.90% of Si, 17.5%-19.0% of Mn, P is less than or equal to 0.040, S is less than or equal to 0.020, 1.00%-1.40% of Cr, Ni is less than or equal to 0.60, Mo is less than or equal to 0.50, 0.005%-0.010% of B, 0.08%-0.12% of Al, 0.10%-0.18% of Ti, 0.05%-0.09% of La, 0.05%-0.10% of Ce, 0.05%-0.10% of V and the balance of Fe and unavoidable trace impurities. The invention further discloses a process for producing the high-strength high-wear-resistance steel casting. The high-strength high-wear-resistance steel casting is relatively good in tenacity and wear resistance, long in service life and applicable to the super-huge type crusher.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

Method for producing active carbon for gasoline vapor adsorption

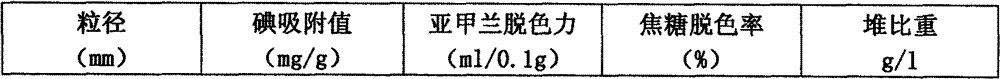

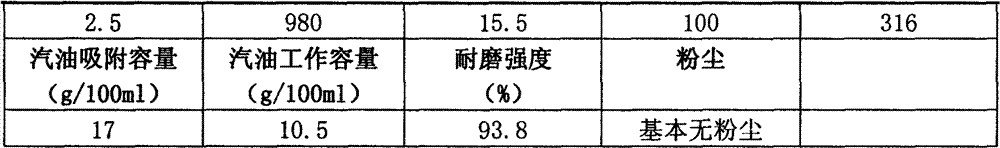

InactiveCN102698724AIncrease weight absorption capacityReduce working volumeOther chemical processesCarbon compoundsPhosphoric acidMechanical wear

The invention discloses a method for producing active carbon for gasoline vapor adsorption. The method comprises the steps of: taking other wood material containing carbon as raw materials, and taking zinc chloride, phosphoric acid and the like as activating agents, and mixing, kneading, extruding, drying, activating, soaking and conducting other steps to prepare a finished product. According to the method disclosed by the invention, bulk specific weight can be improved effectively, namely the weight adsorption amount of the carbon is improved, so that the gasoline adsorption amount of the active carbon for gasoline vapor adsorption can be improved to be 16g / 100ml; the displacement volume is improved to be 9g / 100ml; the working volume of an adsorption plant is reduced; the application range is expanded; the abrasive resistance of the active carbon for gasoline vapor adsorption is improved to be over 93%; mechanical wear of the active carbon in the using process is reduced; the operating life is prolonged; the floating dust on the surface of the active carbon is basically removed; airflow resistance is reduced, and the method is not only used for gasoline vapor adsorption, but also suitable for recovery of benzene and high-boiling point solvents.

Owner:淮北市大华环保科技有限公司

Solid waste incineration system with exhaust gas secondary combustion drying ignition device and treatment method thereof

ActiveCN105910111ALow investment costReduce operating expensesIncinerator apparatusCombustion chamberFlue gas

The invention discloses a solid waste incineration system with an exhaust gas secondary combustion drying ignition device and a treatment method thereof. The solid waste incineration system comprises an incineration device and an air extraction system, wherein the incineration device comprises a cloth section, a drying section, an ignition section and an incineration section; operation at the drying section and the ignition section is achieved through the exhaust gas secondary combustion drying ignition device; the exhaust gas secondary combustion drying ignition device is in a cover body form, covers sintering materials, and is divided into an exhaust gas secondary combustion drying part at the front section and an ignition part arranged at the tail end; the incineration exhaust gas returns to the ignition device and burns in the situation that gas fuel is externally added, and a secondary combustion chamber is formed; and combustible matters in the flue gas are completely combusted, and harmful substances such as CO, NOx and dioxin in the flue gas are decomposed and are effectively treated. According to the solid waste incineration system, a high temperature gas generated during combustion ignites the materials, and waste heat of the exhaust gas dries and preheats the materials before ignition.

Owner:CHONGQING ANGRUIYUE SCI & TECH

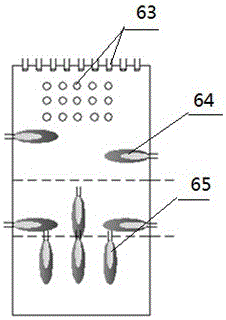

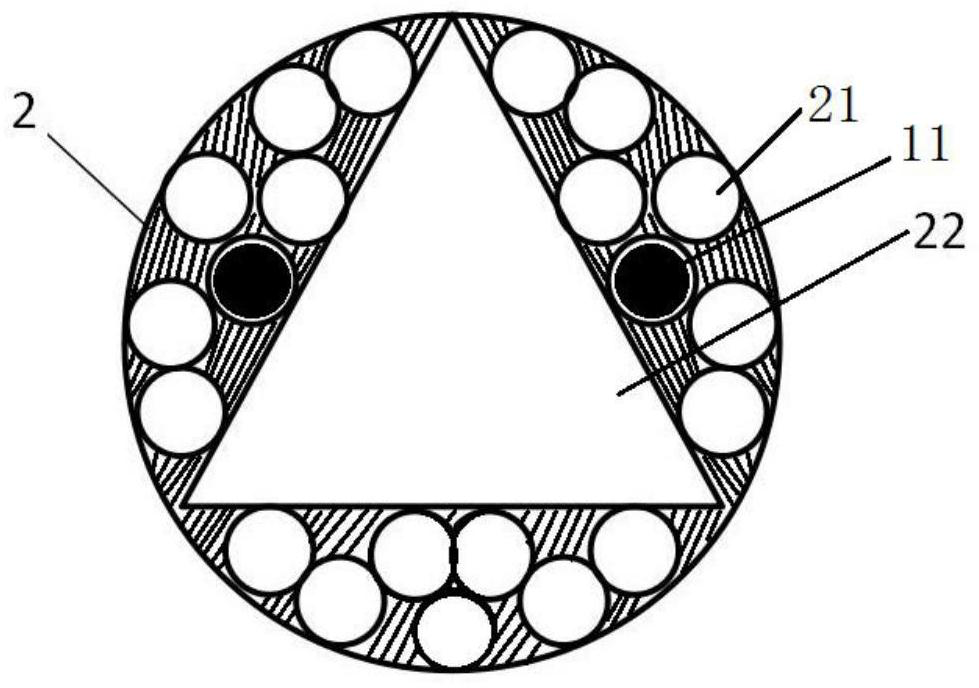

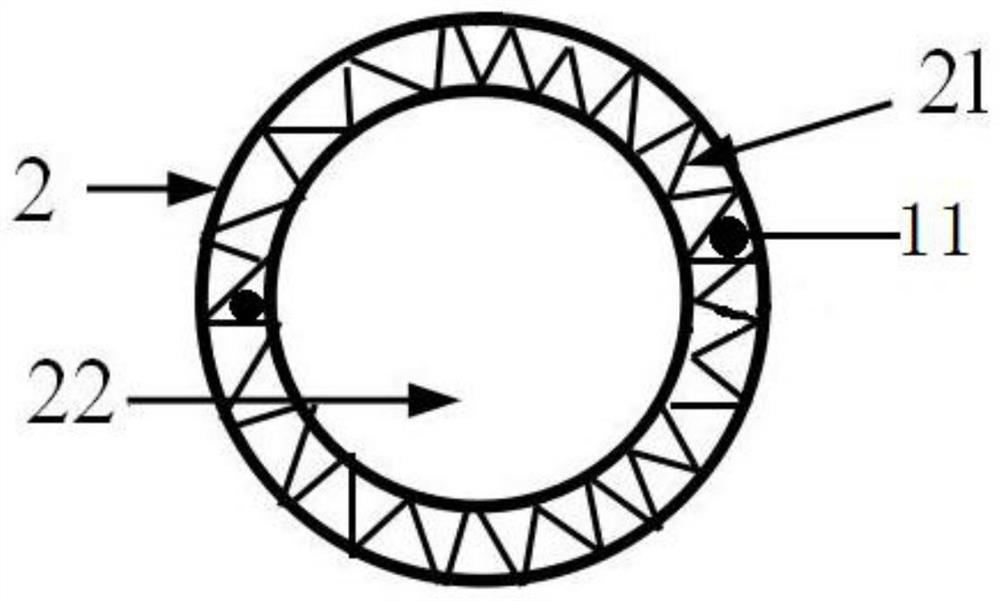

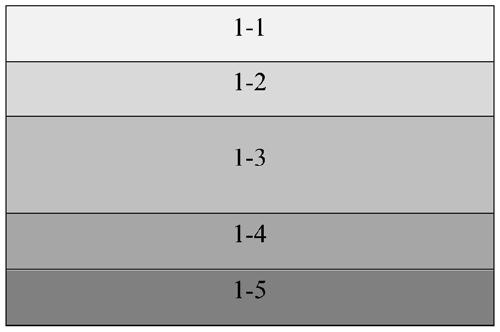

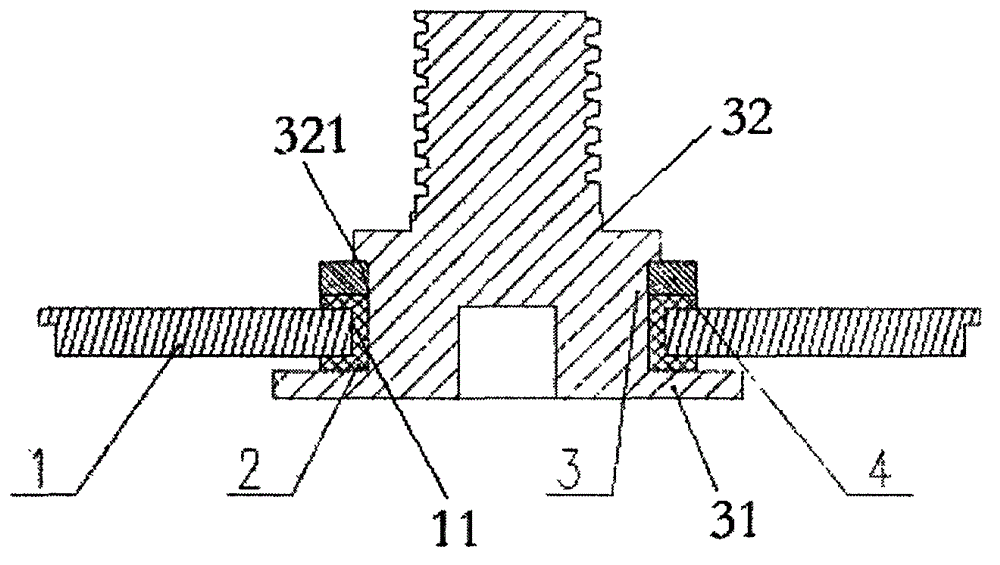

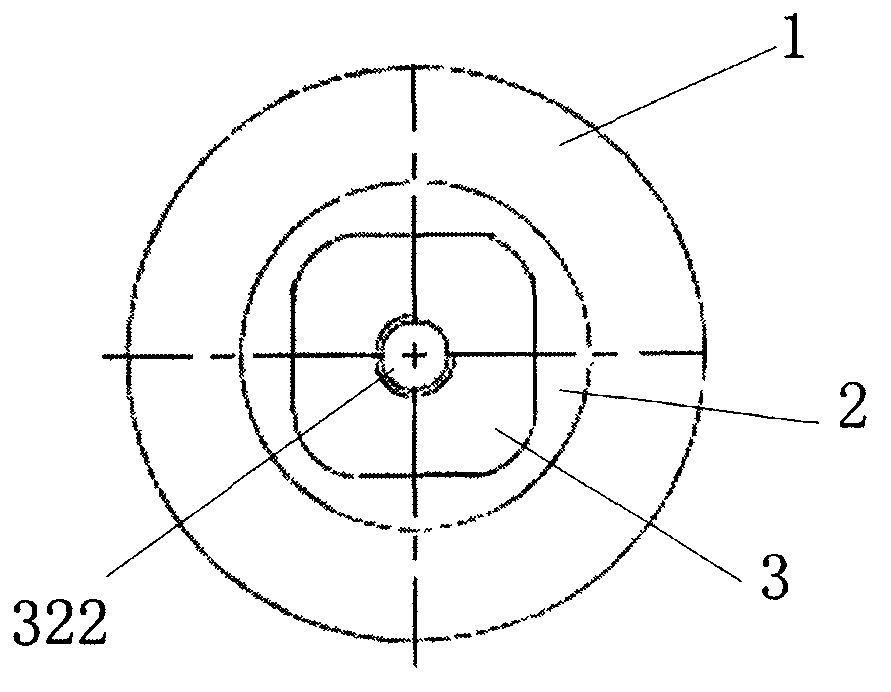

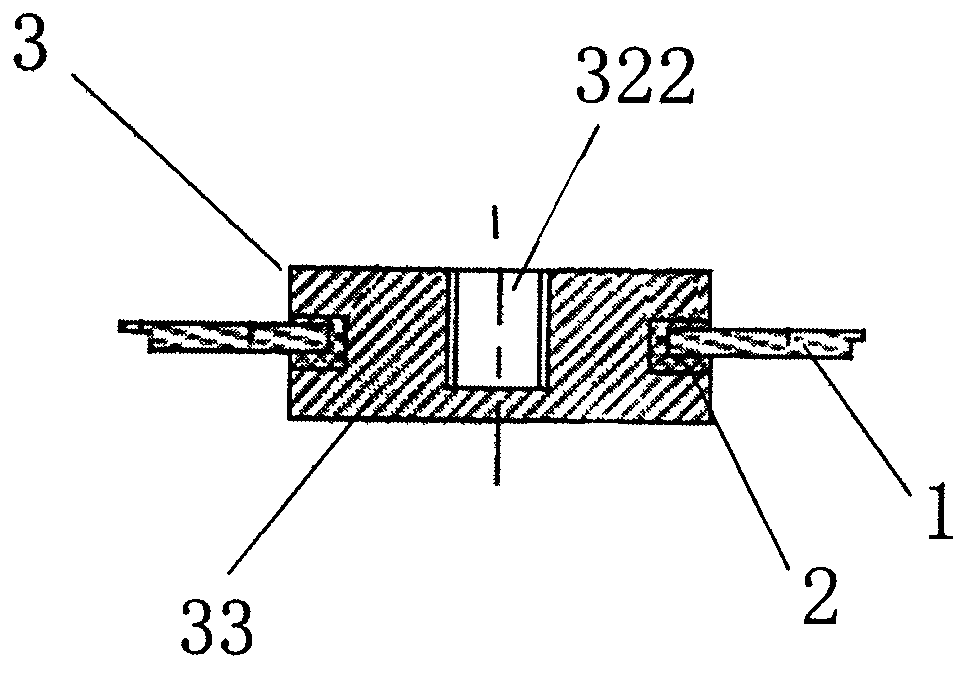

Aerosol generating product with perfumed cigarette core section

PendingCN113662239AGood ventilationReduce flue gas temperatureCigar manufactureChemistryComposite material

The invention discloses an aerosol generating product with a perfumed cigarette core section. The aerosol generating product comprises a fuming core material section (1), a supporting section (2), a breathable hollow section (3) and a filtering section (4) which are arranged in sequence. The supporting section (2) has a perfuming function and is provided with a large hollow hole (22) and a plurality of small perfuming holes (21); the multiple small perfuming holes (21) surround the outer side of the large hollow hole (22), and perfuming capsules (11) are arranged at the ends of the sides, close to the fuming core material section (1), in part of the small perfuming holes (21); an impermeable layer is arranged in forming paper (5); and ventilation holes (31) penetrating through the ventilation hollow section (3) in the radial direction are formed in the ventilation hollow section (3). According to the invention, a mode of preposed blasting beads is adopted, and when an aerosol generating product is used, perfuming is automatically carried out so that the perfuming efficiency and the fragrance release stability are improved. Meanwhile, the supporting section (2) supplements fragrance again, and the ventilation hollow section (3) introduces air so that the suction resistance can be reduced, the comfort can be improved, and the smoke amount and the proper smoke temperature are further guaranteed.

Owner:CHINA TOBACCO YUNNAN IND

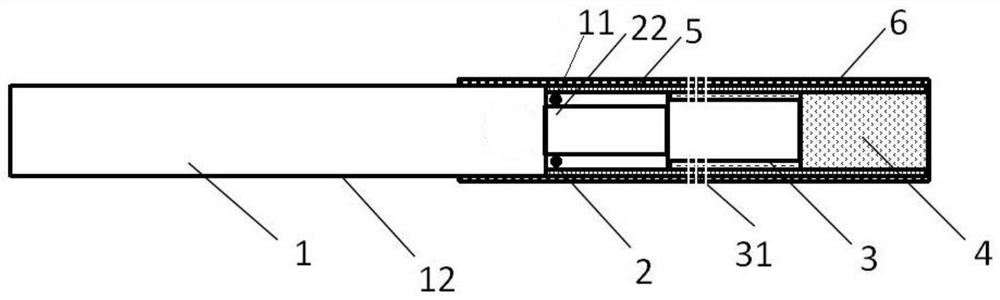

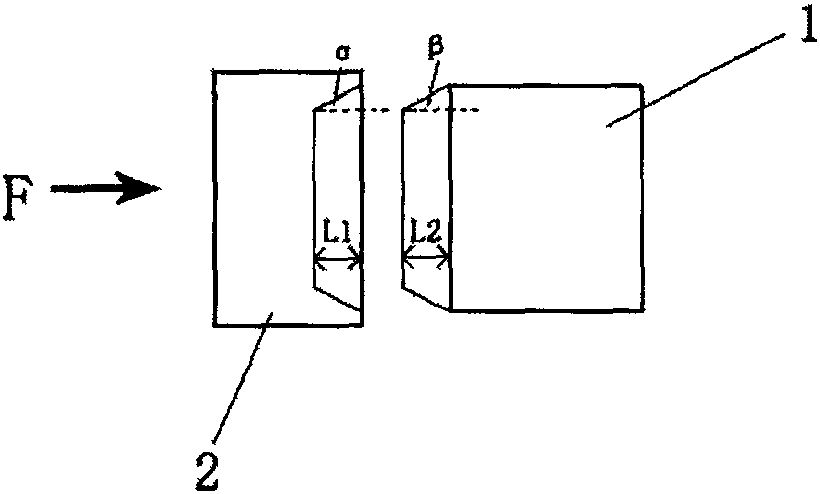

Welding method for aluminum-steel composite member and aluminum-steel composite member

ActiveCN105033438AImprove connection strengthSufficient temperatureWorkpiece edge portionsNon-electric welding apparatusSurface roughnessAluminum substrate

The invention provides a welding method for an aluminum-steel composite member. The surface roughness, the pressure, the number of revolution, the inserting speed and the cooling speed are reasonably set, enough temperature can be provided during welding to cause a plastic deformation in metal at the solder side, and generate an aluminum-steel combination area having enough thickness in the weld after welding, no bubbles, cracks and other defects generate in the weld, and the tensile strength of the weld is larger than that of an aluminum substrate. Residual stress of the weld can be removed through local heating the solder side after welding, and the joint strength of the weld can be raised.

Owner:SICHUAN ANQINGFU ELECTRONICS TECH CO LTD +1

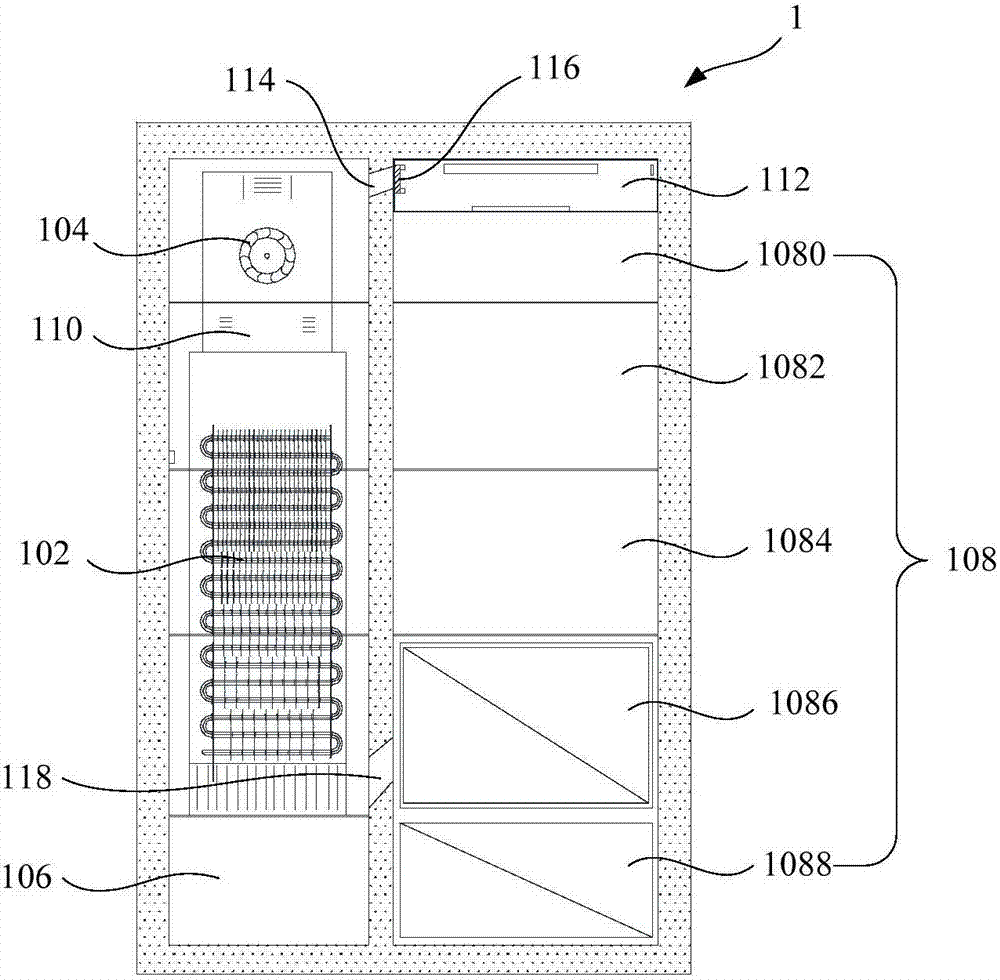

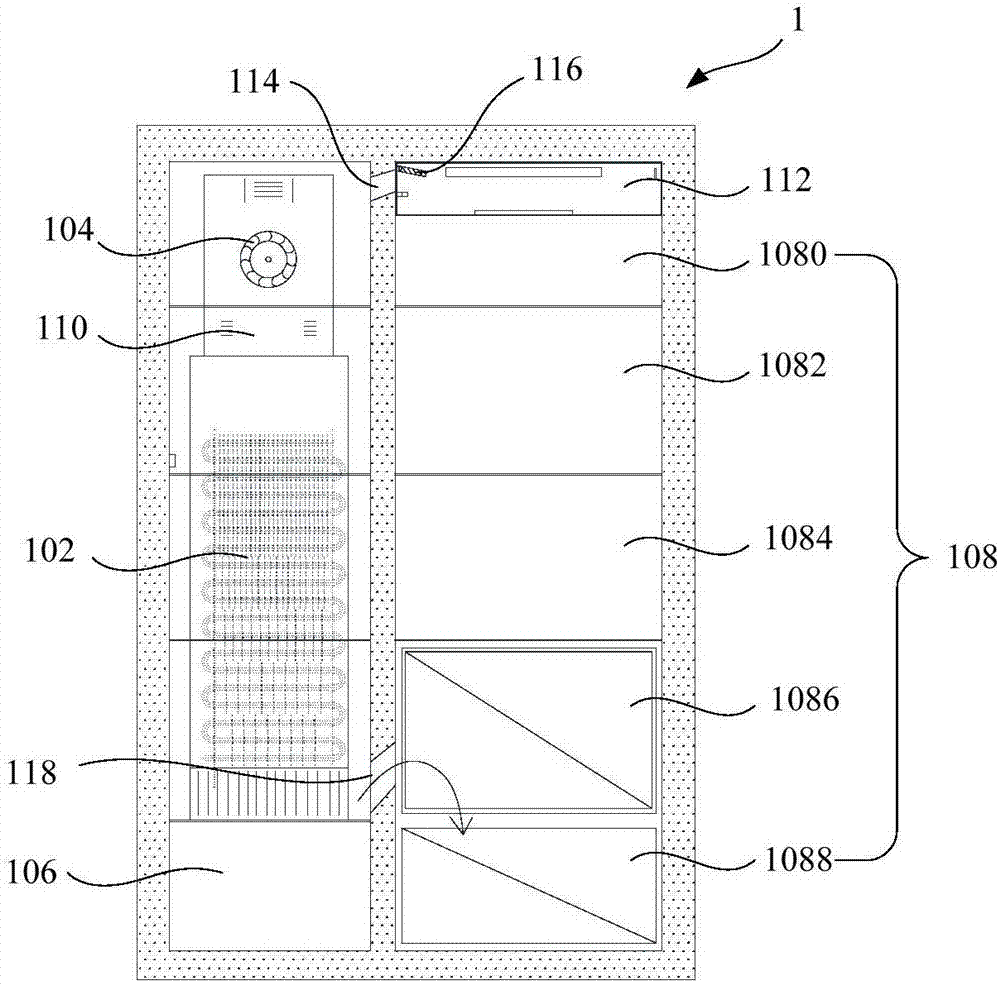

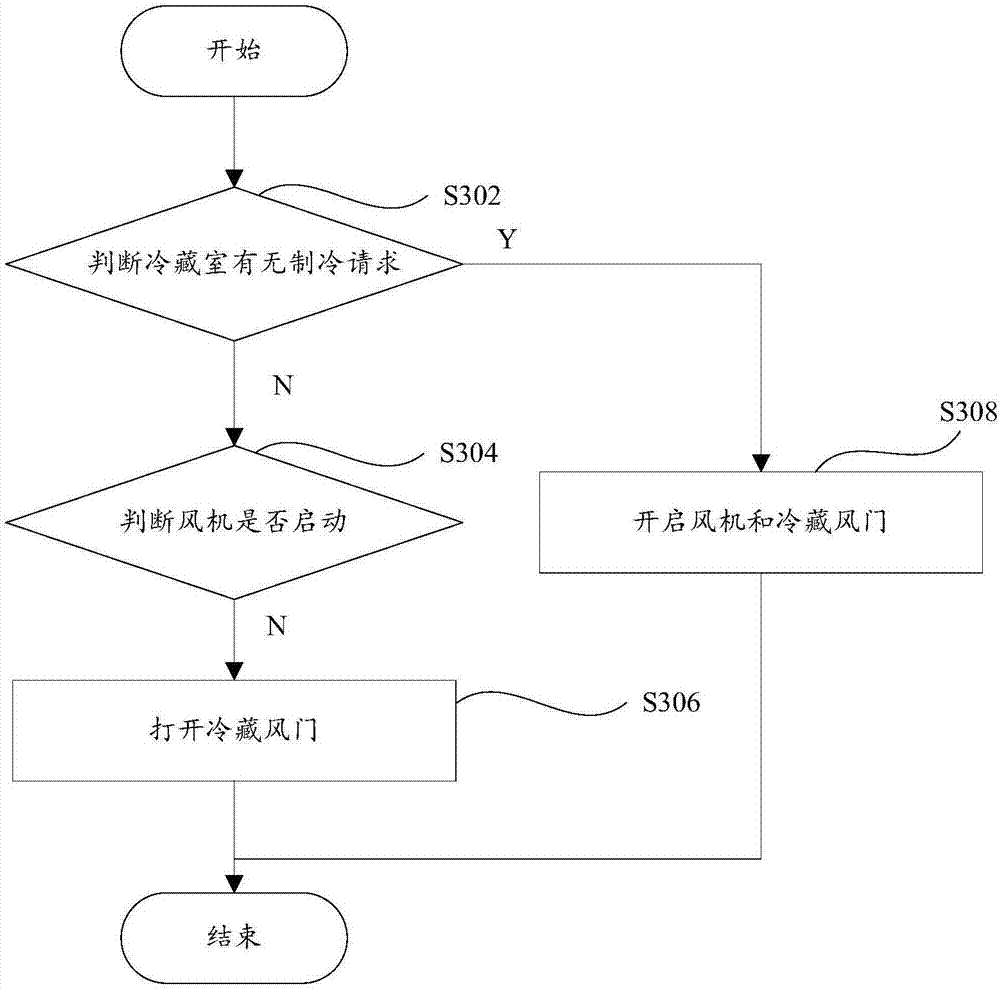

Refrigerator control method, refrigerator control system and refrigerator

ActiveCN106918194AIncrease temperature differenceGood fresh-keeping effectDomestic cooling apparatusLighting and heating apparatusCold airInlet channel

The invention provides a refrigerator control method, a refrigerator control system and a refrigerator. The refrigerator control method comprises the following steps: judging whether a refrigerating chamber has a refrigerating request or not; detecting whether a fan is started up or not if the refrigerating chamber does not have the refrigerating request; and opening a refrigerating air door when the fan is not started up to allow air in a freezing chamber to enter the lower part of the refrigerating chamber through a refrigerating air return channel and to allow air at the upper part of the refrigerating chamber to enter the freezing chamber through a refrigerating air inlet channel. According to the refrigerator control method, natural convection is formed due to a relatively great temperature difference between the freezing chamber and the refrigerating chamber by opening the refrigerating air door, cold air enters the refrigerating chamber from the freezing chamber along the refrigerating air return channel, is deposited downwards, and performs complementary cooling on the space at the lower part of the refrigerating chamber, so that the lower part of the refrigerating chamber with higher temperature is fully cooled down, the temperature is reduced, the temperature difference of the whole refrigerating chamber is reduced, and the preservation effect of the whole refrigerating chamber is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

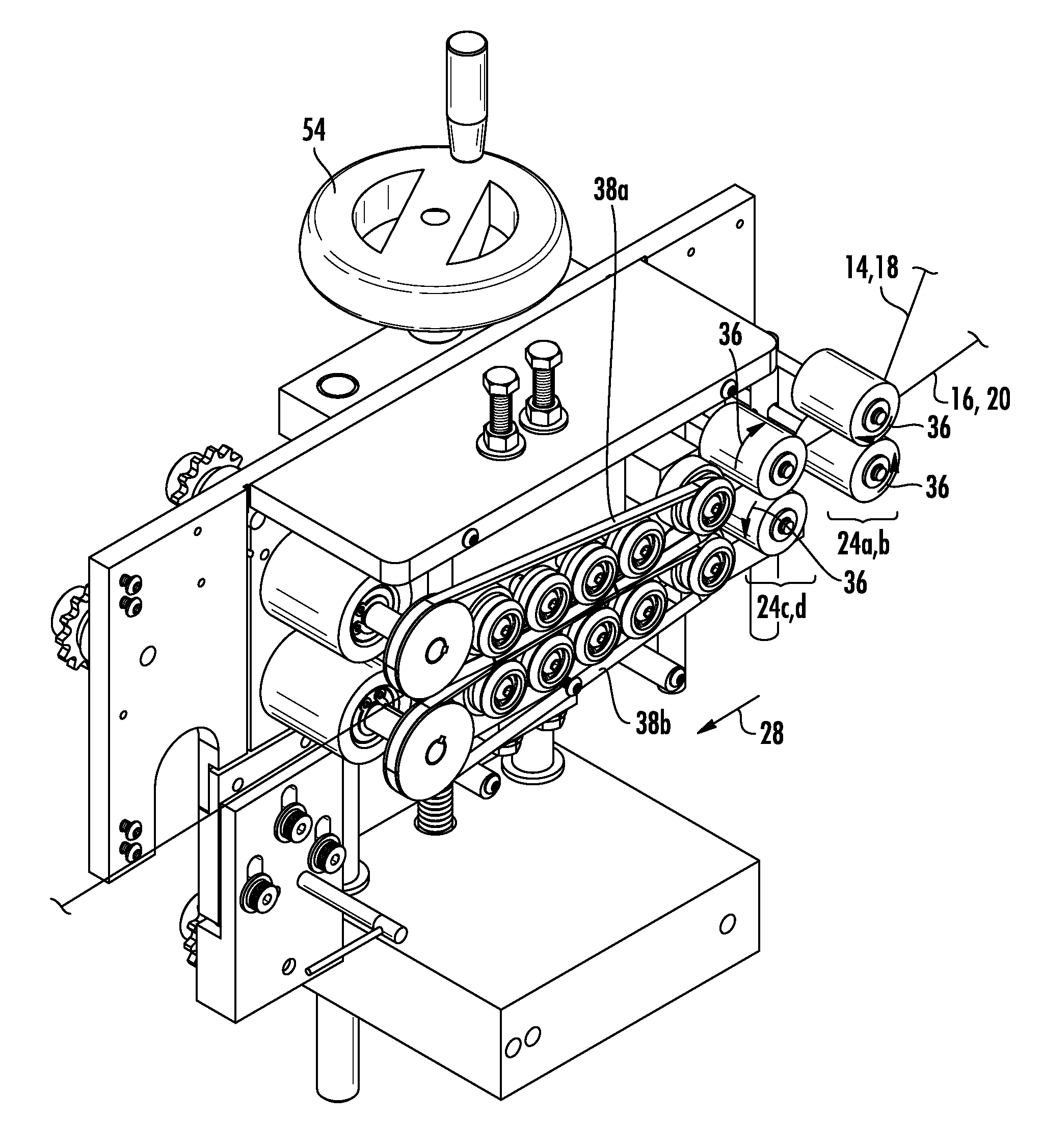

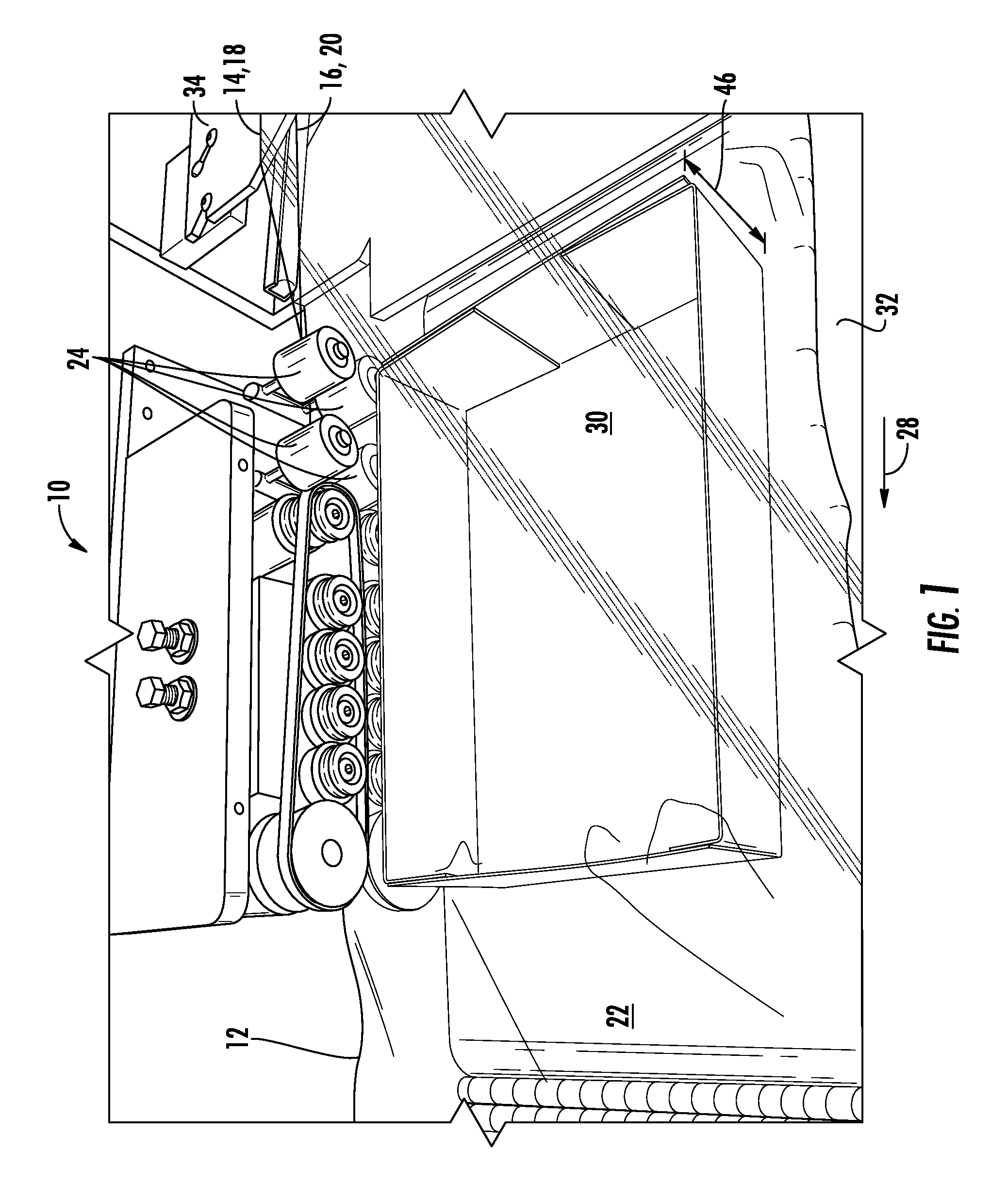

Tin dross processor

InactiveCN1962903AHeating up fastImprove heating efficiencyProcess efficiency improvementTemperature controlElectric machine

The invention discloses a tin slag disposer, which comprises the following parts: pot cover, temperature control electric smelting stove, stirring device anchored by motor and heat liquid discharging device, wherein the motor is placed on the electric smelting stove bottom, which connects stirring device through vertical convex pipe-shaped shaft in the center of stove cavity; the stirring device contains stirring arm on the vertical top to do hard connection driving, stirring spade in connection with stirring arm vertically; the notch of stirring spade is next to electric smelting stove tightly; the heat liquid discharge device concludes start and stop screw, fixing nut, liquid discharge pipe; the start and stop screw is fixed on the pipe-shaped cylinder through fixing nut, whose upper end displays square shape and heat displays spherical shape with bottom aligning channel hole of liquid discharge pipe; the upper end of start and stop screw is rotated to switch the vent of liquid discharge pipe.

Owner:朱岳恩

Film edge sealing device

ActiveUS9499289B1High coefficientSufficient temperatureFlexible coversWrappersThermoplasticEngineering

A film edge sealing device is disclosed herein which has a groove defining a base. The base of the groove of the edge sealing device is oriented at a skewed angle with respect to a longitudinal direction of the conveyor of the heat sealing machine. Edges of a thermoplastic sheet or two stacked layers of thermoplastic sheets are introduced into the groove of the edge sealing device and placed in contact therewith to both heat and melt the edges of the thermoplastic sheet(s) to form a bead and join the edges thereof to form an edge bead seal.

Owner:EXTREME PACKAGING MACHINERY

Method for cultivating smallanthus sonchifolius

ActiveCN105557261AIncrease productionImprove qualityBiocideFertilising methodsSmallanthus sonchifoliusGreenhouse

The invention provides a method for cultivating smallanthus sonchifolius. The method comprises the following steps: firstly, seedball segmentation, wherein the seed bud weight is 30-50g; secondly, seed bud treatment, wherein a seed bud is soaked in whitewash for 5 min and subjected to seed soaking after drying; thirdly, seedling culture, wherein the seed bud after treated in the second step is planted in a nutrition pot which is sequentially filled with 30 parts of ceramic granules, 40 parts of composite soil and 30 parts of sandy soil from bottom to top, the composite soil is formed by mixing humus with sandy soil in a weight ratio of 1 to 3, the nutrition pot is placed in a greenhouse for culture, and a seedling is obtained for spare when 6-8 leaves grow out; fourthly, transplanting in a field, wherein the seedling obtained in the step three is placed in a seed pit together with the nutrition pot; fifthly, field management, wherein field planting water is watered on the very day of transplanting and comprises bitter melon juice and clean water in a weight part proportion of 1 to 50. The method for cultivating smallanthus sonchifolius is directed at characteristics of smallanthus sonchifolius and has the advantages that steps are simple, operation is facilitated, manpower and material resources are saved, and yield and fruit quality of the northern planted smallanthus sonchifolius are improved.

Owner:苏州福羊自控科技有限公司

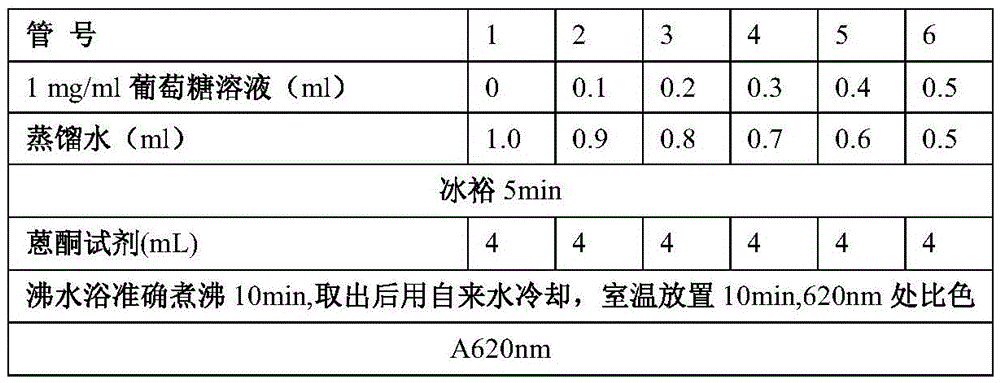

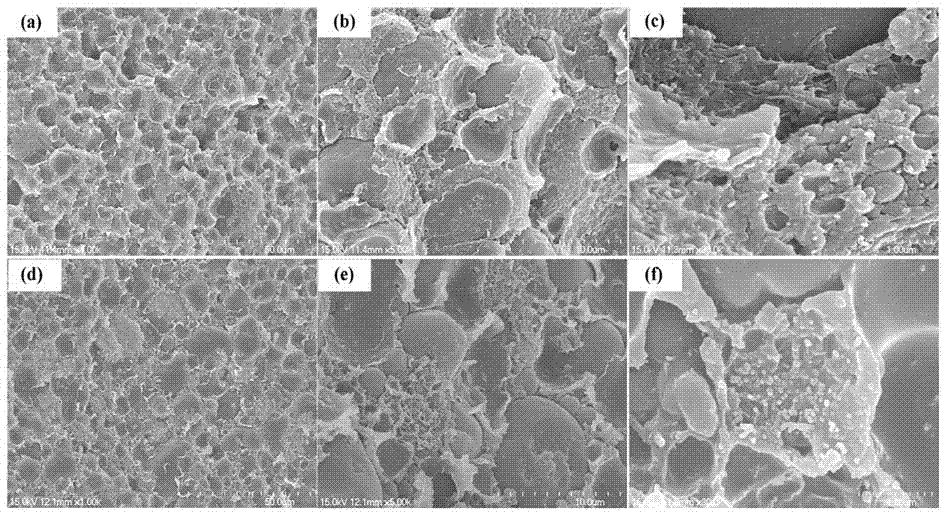

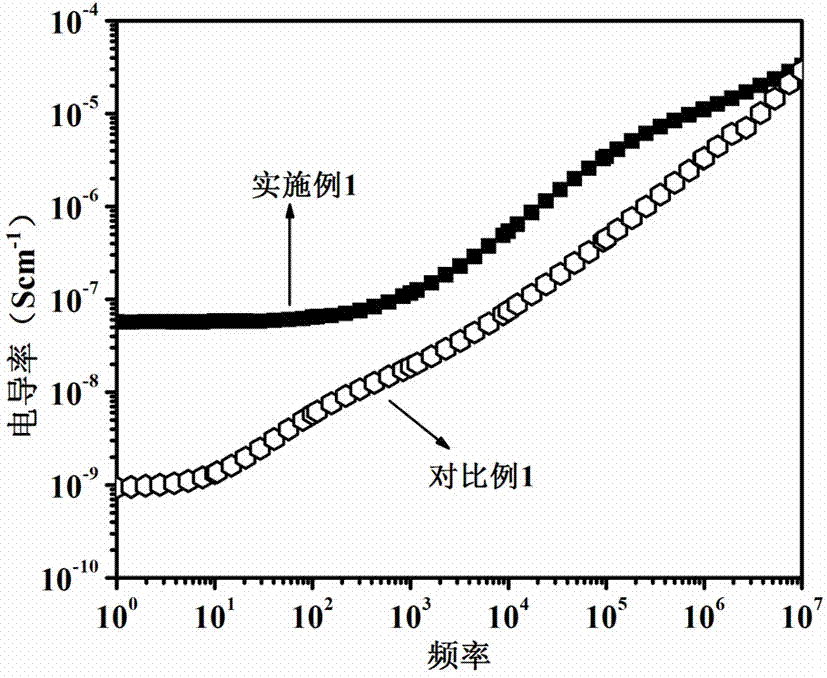

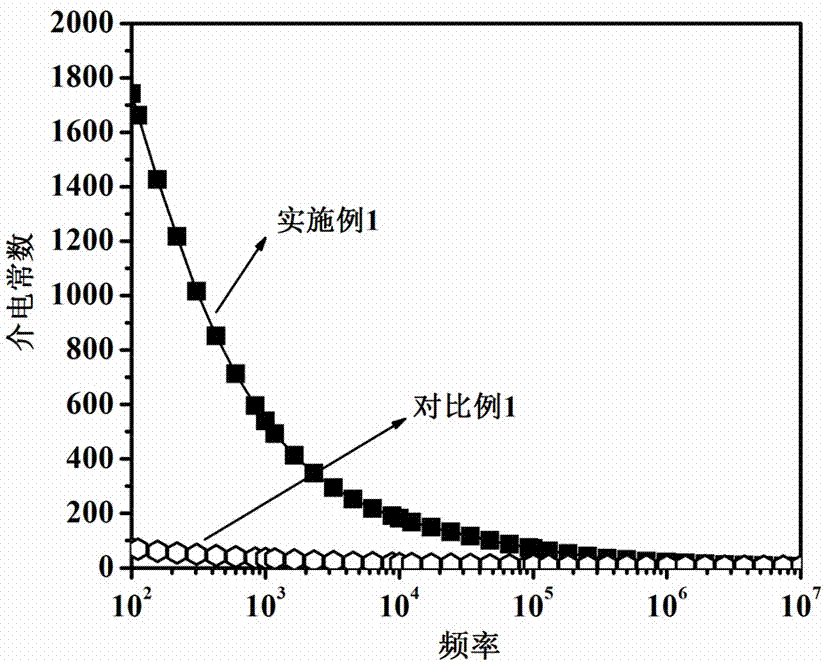

Carbon nanotube/polyetherimide/thermosetting resin dielectric composite material and preparation method thereof

ActiveCN104513485AGood physical propertiesSuitable for direct contactPlastic/resin/waxes insulatorsPolyetherimideDielectric loss

The invention discloses a carbon nanotube / polyetherimide / thermosetting resin dielectric composite material and a preparation method thereof. The preparation method comprises the following steps: in parts by weight, uniformly mixing 100 parts of polyetherimide and 1-7 parts of carbon nanotubes in a Haake torque molting cavity to obtain a carbon nanotube / polyetherimide composite; dissolving 20 parts of the carbon nanotube / polyetherimide composite into 100-150 parts of dichloromethane, adding a mixed solution into 100 parts of molten thermocurable thermosetting resin, mixing, preserving heat, stirring until a mixture is in a uniform state, curing, and post-treating to obtain a carbon nanotube / thermosetting resin dielectric composite material, wherein a substrate of the carbon nanotube / thermosetting resin dielectric composite material has a typical reverse phase structure, while the carbon nanotubes are dispersed in a polyetherimide phase. The carbon nanotube / polyetherimide / thermosetting resin dielectric composite material has a relatively low percolation threshold, a high dielectric constant and low dielectric loss. The preparation method is simple in process and suitable for large-scale production.

Owner:SUZHOU UNIV

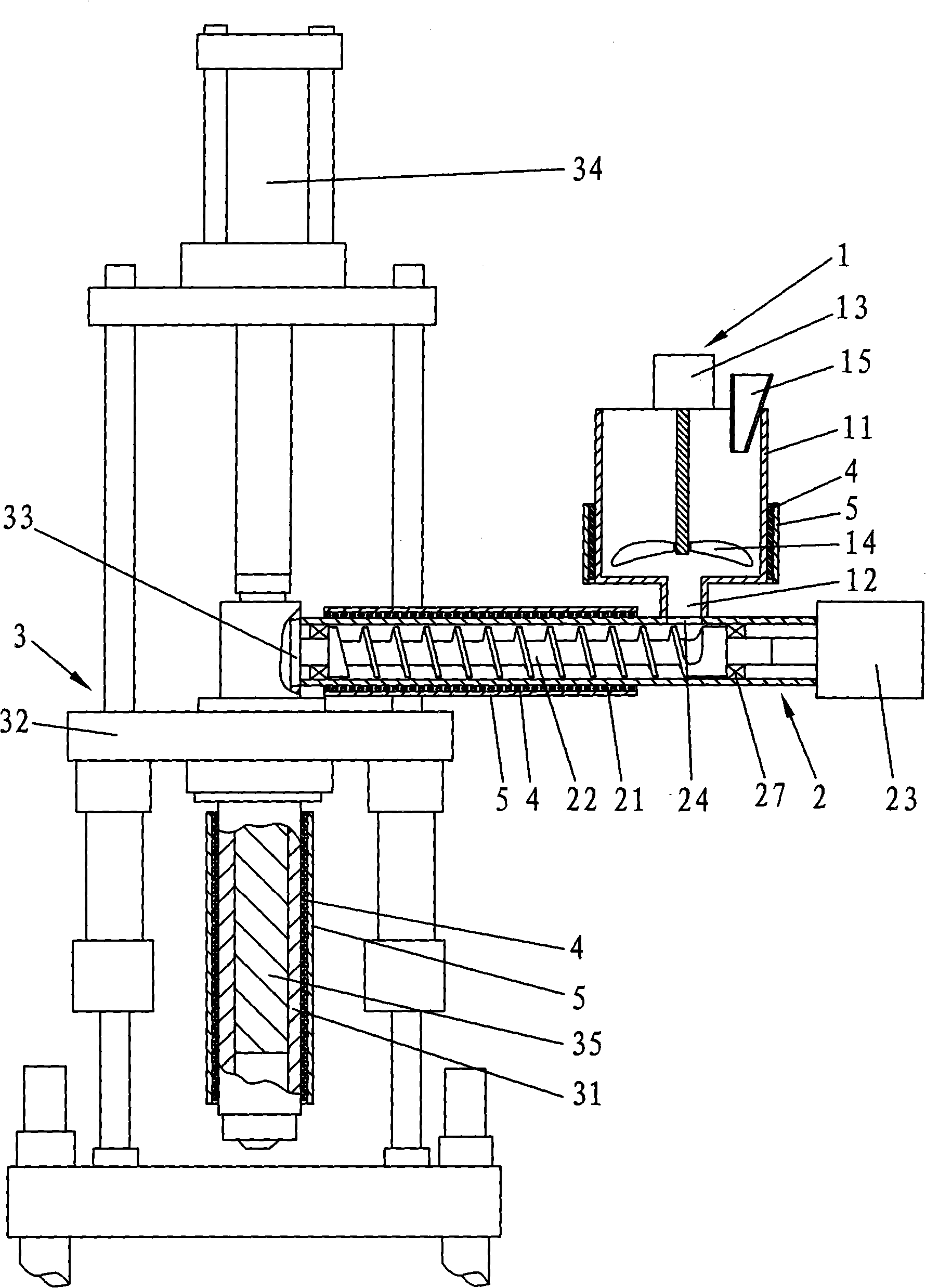

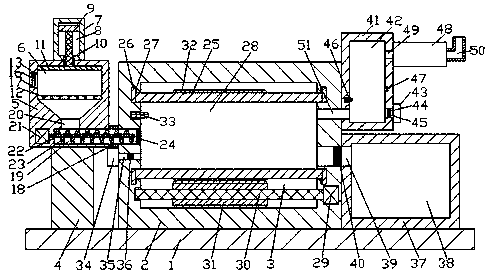

Vertical type ceramic injection machine

InactiveCN101347948ANo wasteImprove injection molding performanceCeramic shaping apparatusClay processing apparatusElectric machineryEngineering

The invention relates to the technical filed of injection machines, in particular to a vertical ceramic injection machine. The injection machine comprises a feeding device and a jet device; wherein, the feeding device comprises a charging basket; the top of the charging basket is provided with an opening, and the bottom is opened with a discharge hole. The feeding device is connected with the jet device by a conveying device. The interior of the charging basket is provided with a stirring device. The conveying device comprises a feeding barrel, a feeding screw, and a servo Motor. The feeding barrel is provided with a delivery opening communicated with the discharge hole of the charging basket. After being stirred by the stirring device, the slurry stirred by the stirring device enters the feeding barrel from the delivery opening of the feeding barrel. The feeding screw is rotated due to being driven by the servo motor and pushes the slurry to the jet device from the feeding barrel. The feeding quantity and flow speed of the slurry delivered into the jet device can be controlled by adjusting the rotational speed and the rotational time of the servo motor. After injection molding, products have good quality, therefore, the conveying device additionally arranged for vertical ceramic injection machine increases the injection molding effect of the ceramic slurry.

Owner:东莞市天合电子陶瓷制品有限公司

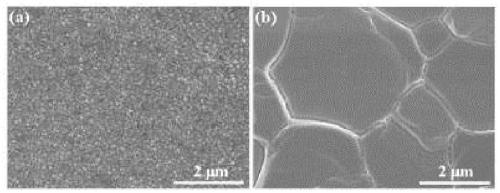

Method and device for preparation perovskite layer and application of perovskite layer

PendingCN109904317ARefine the grain sizeReduce compoundingSolid-state devicesVacuum evaporation coatingIodideSingle crystal

The invention belongs to the technical field of solar battery preparing, and specifically relates to a method and device for preparation a perovskite layer and application of the perovskite layer. Themethod includes the steps that raw materials are deposited on a substrate to form the perovskite layer by adopting a vacuum evaporation way, during depositing, the depositing temperature is controlled to be 100 to 300 DEG C, and a quasi-monocrystal perovskite film is obtained; when the perovskite layer is prepared, the temperature during depositing is controlled to improve the crystal particle size of a perovskite layer film to the micron level, a corresponding crystal boundary is reduced, the longitudinal transferring speed of a carrier in the perovskite film is accelerated, recombination ofthe carrier at the crystal boundary is reduced, the collecting efficiency of the carrier is improved, and thus the photoelectric conversion efficiency is improved. In addition, an evaporator source of PbI2 and organic halides are opened at the same time, thus the evaporator source is deposited on the substrate to form the perovskite layer, and the PbI2 can react with methyl iodide amine, methyl ether bromide amine, methyl amine chloride and methyl ether iodide amine more fully and evenly.

Owner:上海祖强能源有限公司

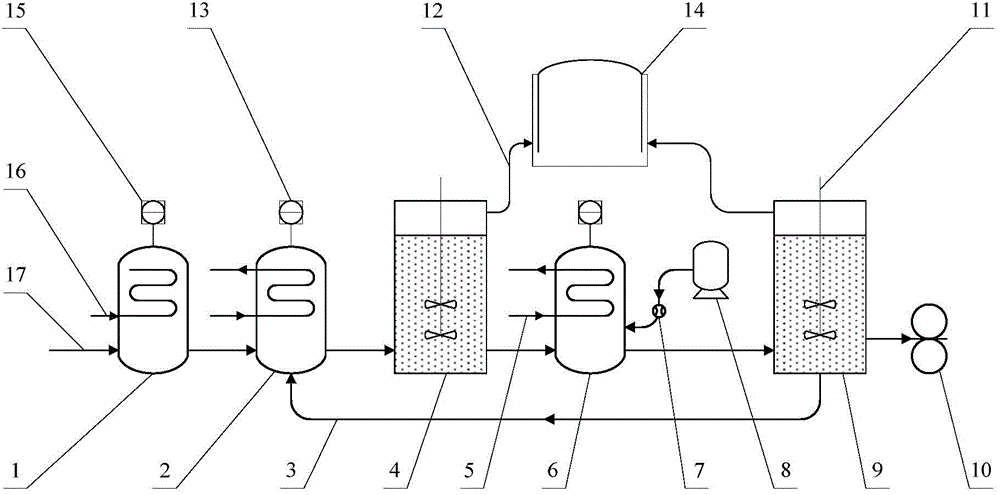

System and method for treating sludge with efficient recycling and low pollution emission

ActiveCN104150729AReduce the concentration of ammonia nitrogenImprove reduction efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHigh concentrationSludge

The invention relates to the field of sludge treatment and in particular relates to a system and a method for treating sludge with efficient recycling and low pollution emission to reduce the ammonia nitrogen concentration of deaminated sludge, reduce the organic matter consumption, increase the biogas yield and reduce the pollutant emission in sludge treatment. The invention adopts the technical scheme as follows: the method comprises the following steps: thermally hydrolyzing the sludge, cooling, performing anaerobic fermentation to generate biogas, cooling the fermented sludge, mixing with a nitrite solution, deaminating in an anaerobic ammonia oxidation tank, circularly returning one part of the deaminated sludge to an anaerobic fermentation tank to reduce the ammonia nitrogen concentration of the anaerobic fermentation tank and prevent the inhibition effect of high-concentration ammonia nitrogen on the biogas, and performing anaerobic fermentation on organic matters in the part of the deaminated sludge to generate more biogas; dehydrating another part of the deaminated sludge to greatly reduce the ammonia nitrogen concentration and the organic matter content of the dehydrated sludge and filter liquor. The system and the method have the advantages of efficient recycling and low pollution emission in sludge treatment, and have high economic and environmental benefits.

Owner:广州谦宇电力科技有限公司

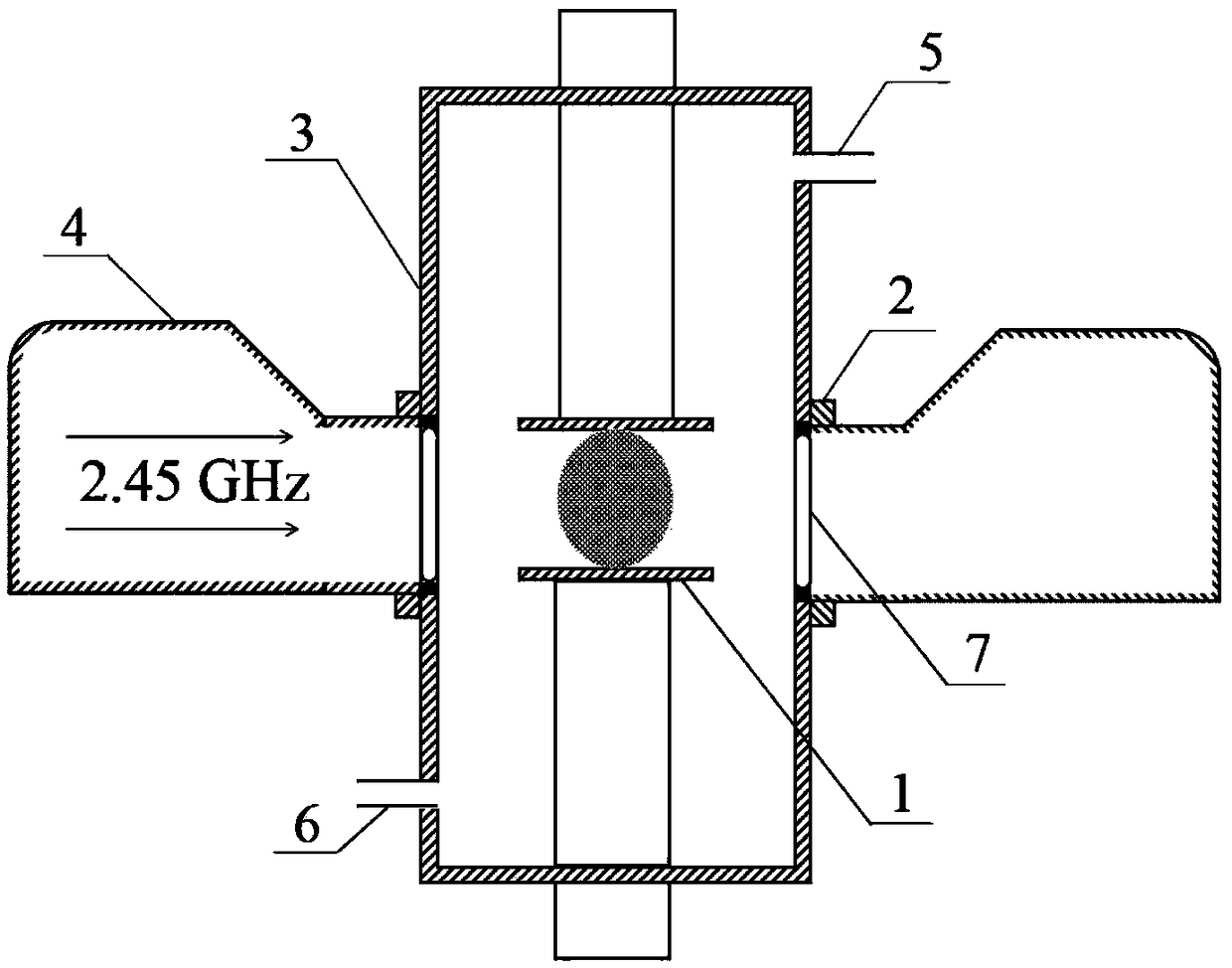

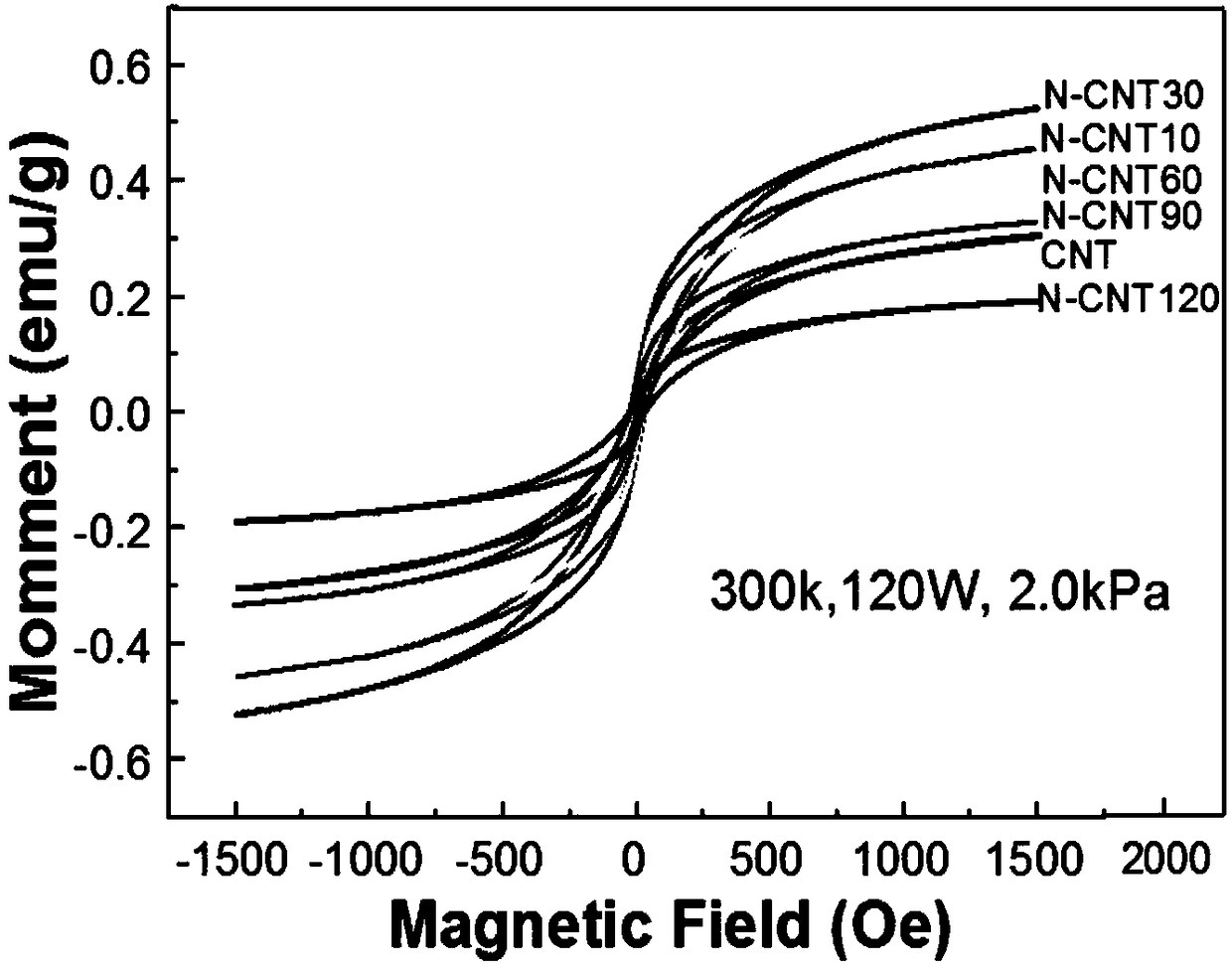

Method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition

InactiveCN108190862AIncrease the chance of ionizationLow deposition pressureCarbon nanotubesNitrogen doped carbon nanotubeChemistry

The invention discloses a method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition. The method comprises the following steps that carbon nanotube powder is placed in a closed cavity, and the cavity is vacuumized; nitrogen gas is introduced to the cavity, the flow rate and air pressure of the nitrogen gas are adjusted, and meanwhile microwave irradiation is conducted to make the gas in the cavity absorb microwave energy and be excited to generate plasma; nitrogen atoms after plasma treatment can be doped into the surfaces and internal structures of carbon nanotubes to form the nitrogen-doped carbon nanotubes, and by controlling the microwave power and nitrogen doping time, the nitrogen carbon nanotubes with different nitrogen contents are obtained.A nitrogen gas source is subjected to plasma treatment by adopting a microwave plasma technology. Since the microwave power and the energy density are high and radical groups have high activity, thegas can be easily dissociated; the nitrogen carbon nanotubes prepared by means of the method are high in quality and purity and facilitates the test and characterization of ferromagnetic properties, optical properties and other properties, and prepared samples show good ferromagnetism.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

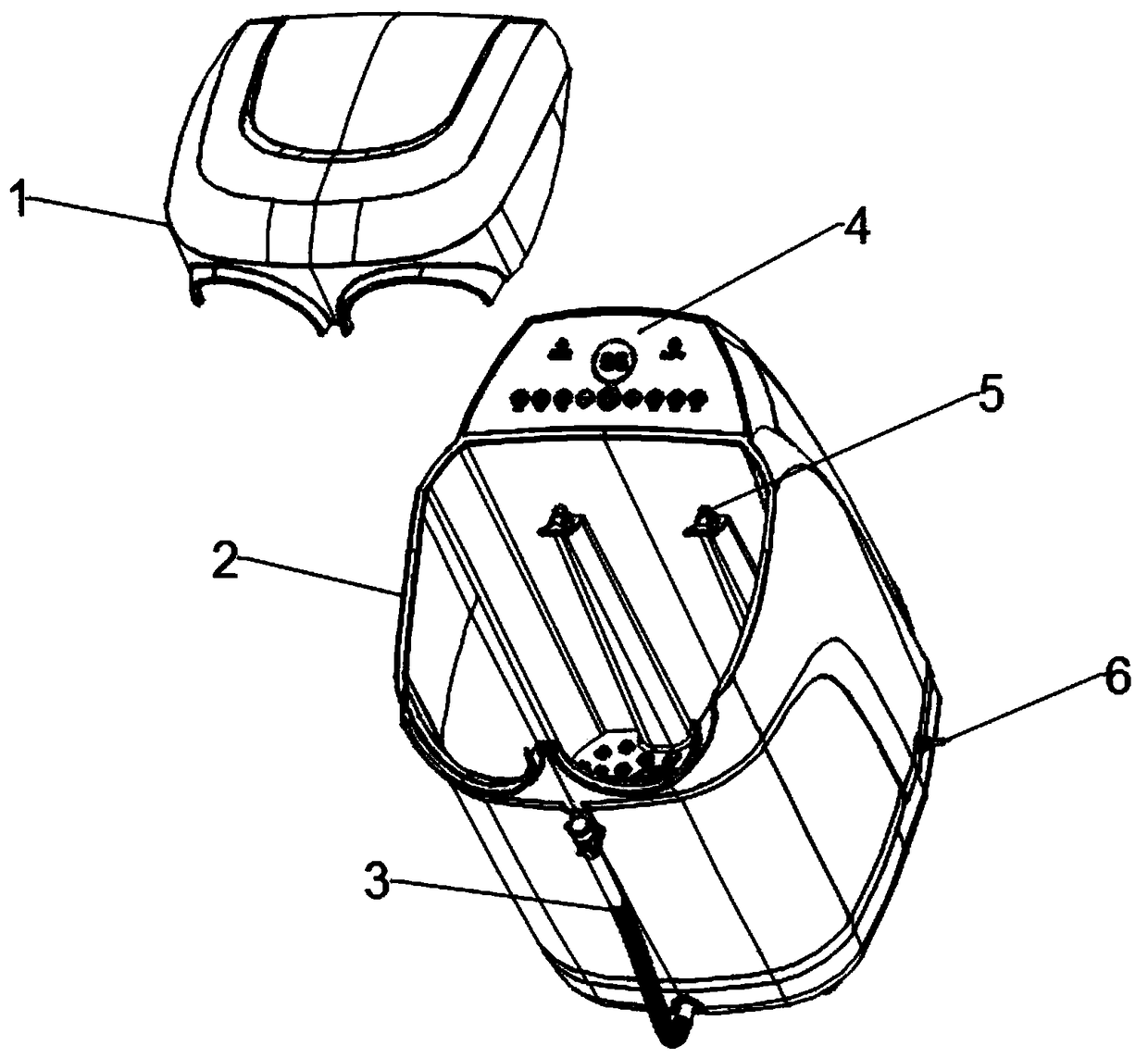

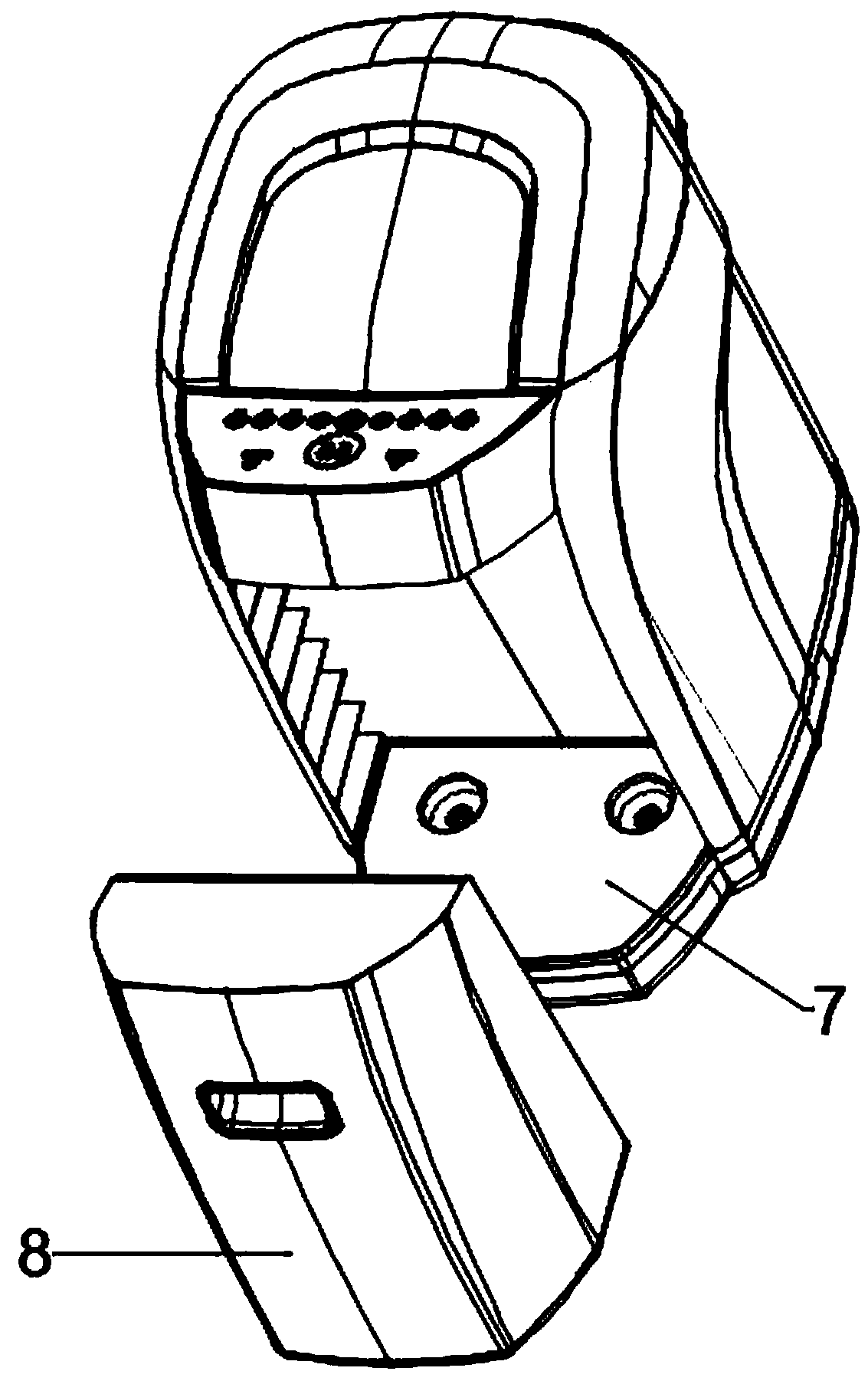

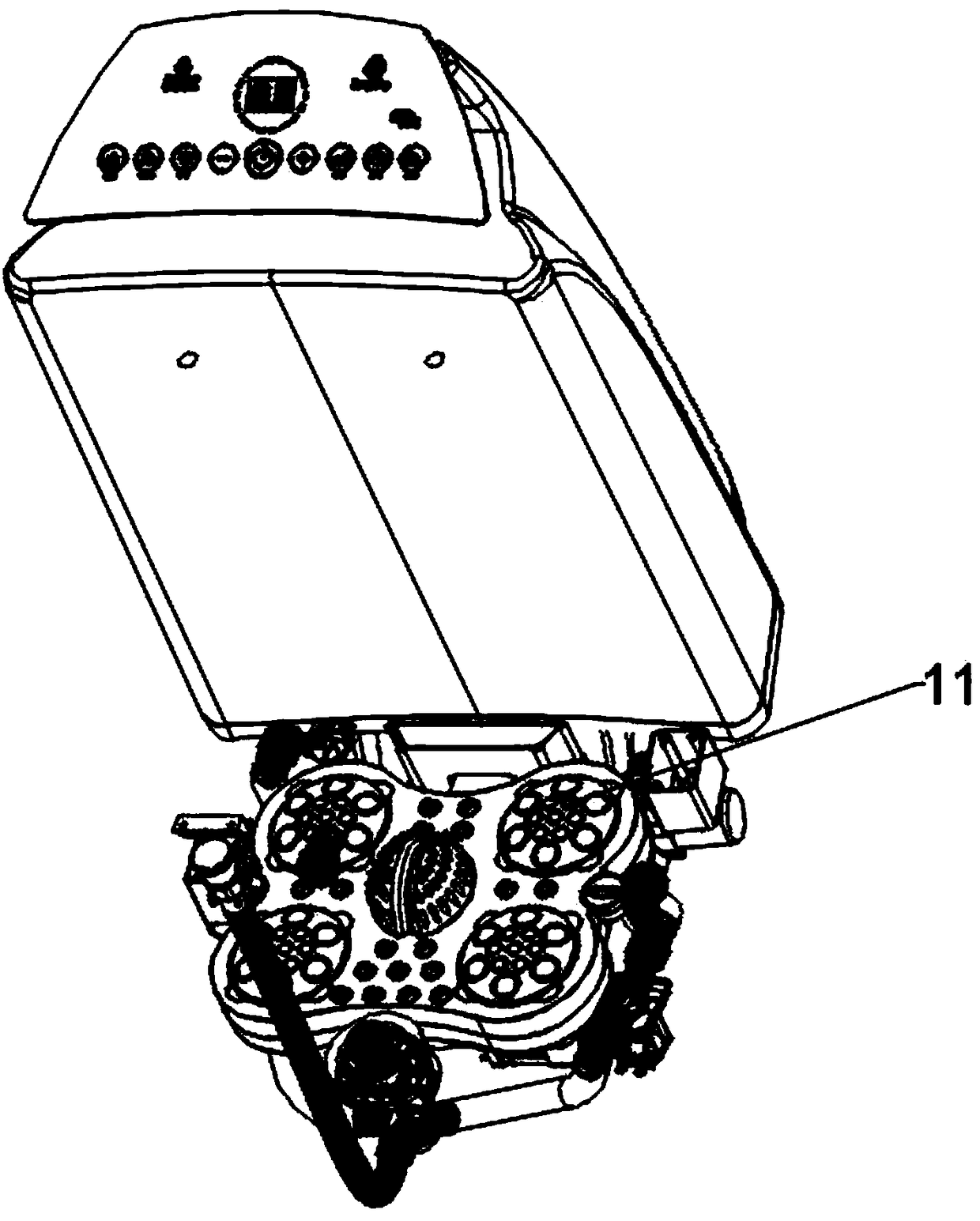

Energy-saving and environment-friendly foot-bath barrel

InactiveCN108784468AReduce pollutionGuaranteed recyclingWater/sewage treatment by irradiationBathsEngineeringElectromagnetic valve

The invention discloses an energy-saving and environment-friendly foot-bath barrel, which comprises a barrel body, wherein the barrel body comprises a control panel and a barrel cover; a duckbill spraying port and a massaging disc are arranged in the barrel body, and a water tank is movably arranged on the barrel body; a circulating water exchanging path is arranged on the lower bottom surface ofthe barrel body; the circulating water path comprises a PTC heating pipe, an electromagnetic valve and a five-way filter valve; the PTC heating pipe, the electromagnetic valve and the five-way filtervalve are coordinated with the circulating water path via pipelines, so that a water circulating system is defined; and the PTC heating pipe, the electromagnetic valve and the five-way filter valve communicate with the water tank via pipelines. The device (the foot-bath barrel) provided by the invention, through cooperation between the water tank and the water circulating system, can guarantee circulating of foot-bath water, and by arranging the five-way filter valve, the foot-bath water can be filtered when water circulating is guaranteed, so that the foot-bath water is kept clean; in addition, by arranging the PTC heating pipe, the foot-bath water can be heated in a circulating process of the foot-bath water, so that the foot-bath water can be prevented from getting cold; and by virtue of the massaging disc in cooperation of the duckbill spraying port, consumers' demands on foot bath can be satisfied.

Owner:安徽省龙凤科技有限公司

Hazardous waste efficient incineration device

The invention discloses a hazardous waste efficient incineration device which comprises a fixed base plate. A fixed shell is fixedly arranged at the middle position of the upper end face of the fixedbase plate, a sealed space is arranged inside the fixed shell, a supporting table is arranged on the left side of the upper end face of the fixed base plate, a pre-treating box is fixedly connected tothe upper end face of the supporting table, a hydraulic shell integrated with the pre-treating box is arranged at the middle portion of the upper end face of the pre-treating box, an incineration pipe is arranged inside the sealed space, a collecting box is fixedly arranged at the position, on the right side of the fixed shell, on the upper end face of the fixed base plate, a burning box extending upwards is fixedly arranged on the upper side of the right end face of the fixed shell, and a heat recovering device is fixedly arranged at the upper end of the right end face of the burning box. When the device works, the heat recovering device can absorb heat of gas discharged from the burning space, the quick cooling effect is achieved, and regeneration of harmful gas is prevented; and meanwhile, the heat energy is absorbed through the heat recovering device, and energy saving is saved.

Owner:石力峰

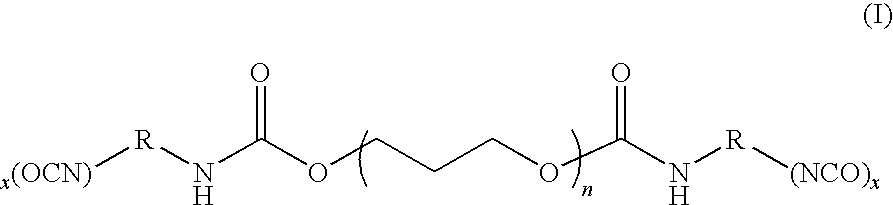

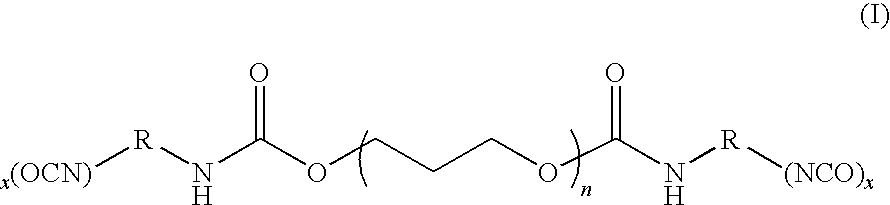

Isocyanate terminated polytrimethylene ether polyol and process for making same

InactiveUS20100267892A1Sufficient temperaturePolyurea/polyurethane coatingsIsopropylene glycolIsocyanate compound

Polyethers of 1,3-propane diol are terminated with polyisocyanates. The isocyanate terminated polytrimethylene ether polyols provide crosslinking agents that provide coating compositions having short dry time, excellent appearance, and resistance to chipping damage.

Owner:AXALTA COATING SYST IP CO LLC

Agricultural seedling raising device

InactiveCN108243800AIncrease the itineraryIncrease the heat exchange areaClimate change adaptationGreenhouse cultivationAgricultural engineeringCheck valve

The invention relates to an agricultural seedling raising device. The agricultural seedling raising device comprises an inner barrel and an outer barrel; a water tank is arranged between the inner barrel and the outer barrel, and the inner top of the water tank is provided with an exhaust pipe which is arranged inside the inner barrel; the top of the inner barrel is provided with a cover plate with air holes, the inside of the inner barrel is provided with an air inlet tank which is provided with an air inlet holes, the top of the air inlet tank is provided with a baffle, gaps are formed between both sides of the baffle and the inner wall of the inner barrel, and the baffle is provided with an air pipe; the air inlet tank is communicated with one end of an air duct arranged at the bottom of the inner barrel, the inside of the air duct is provided with a fan, the outside of the air duct is wound with electric heating wires which are wrapped by a thermal insulating layer, the other end of the air duct is communicated with a water injecting pipe through a check valve, one end of the water injecting pipe is communicated with the outside, the other end of the water injecting pipe is communicated with an input pipe, and the end portion of the input pipe is provided with a through hole, penetrates through the inner barrel and the water tank and is arranged at the inner bottom of the water tank. The agricultural seedling raising device can heat air in the environment where seedlings are arranged and meanwhile continuously supplement water to meet the growth requirements of the seedlings on suitable environment.

Owner:何振贤

Method for cleaning storage tanks

A method of removing sludge from hydrocarbon storage tanks comprising introducing a hydrocarbon diluent into the storage tank to form a diluent / sludge mixture, circulating this mixture through the tank to obtain a blend of sludge and / or diluent, removing the bulk of the blend from the storage tank to leave a residuum, creating a non-combustible atmosphere in the storage tank, introducing an aqueous wash into the storage tank, the aqueous wash being at a temperature sufficient to heat the residuum to a temperature of not less than about 40° C., circulating the aqueous wash through the storage tank, separating hydrocarbons from a stream of residuum / aqueous wash removed from the storage tank to produce an aqueous wash recycle stream and introducing the recycle stream into the storage tank.

Owner:ENVIROTANK INT

System for capturing carbon dioxide through power plant flue gas waste heat power generation and control method

ActiveCN109681284ASufficient temperatureSufficient heat exchangeSteam engine plantsFlue gasPower grid

The invention discloses a system for capturing carbon dioxide through power plant flue gas waste heat power generation and a control method, and belongs to the technical field of flue gas waste heat utilization and carbon dioxide capturing. The system comprises a power generation system, a carbon dioxide compression separation system and a flue gas waste heat cascade recovery system. The power generation system comprises a combined type heat exchanger, an expander, an ORC generator, a cooler, a working medium pump, a thermoelectric power generation chip low temperature side, a thermoelectric power generation chip high temperature side, a thermoelectric power generation chip, a thermistor, a thermoelectric power generation switch, a thermoelectric power generation group, a DC / AC inverter, an ORC generator connection compression separator switch, a thermoelectric power generation group connection supply user switch, an ORC generator connection supply user switch, an ORC generator and thermoelectric power generation group power supply power grid switching switch, a grid-compression separator switch and a thermoelectric power generation chip high temperature side adjusting valve outletcheck valve. The waste heat recovery rate and power generation efficiency are improved, carbon dioxide capturing efficiency is improved, and energy saving and emission reduction effects are achieved.

Owner:SHANXI UNIV

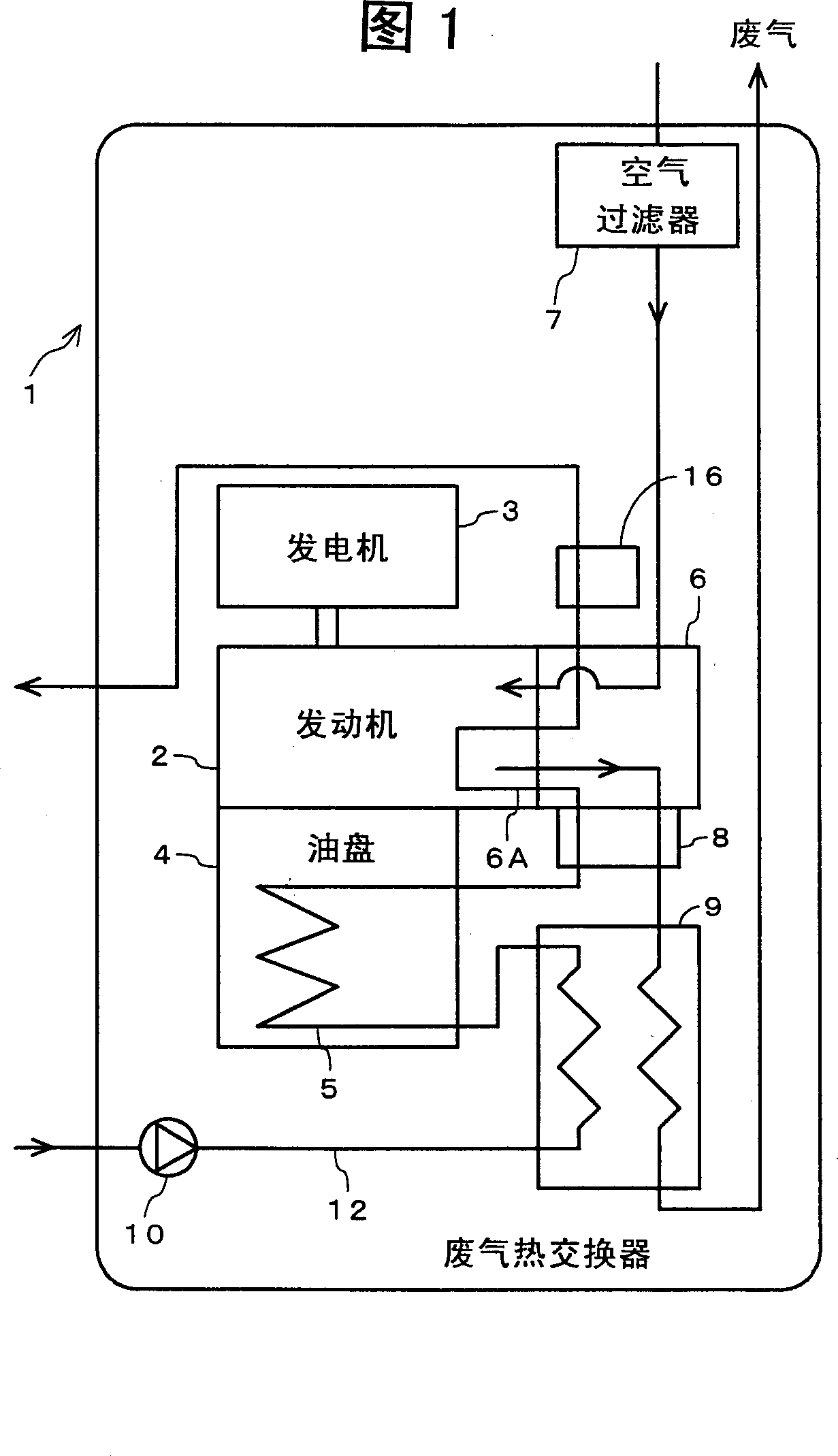

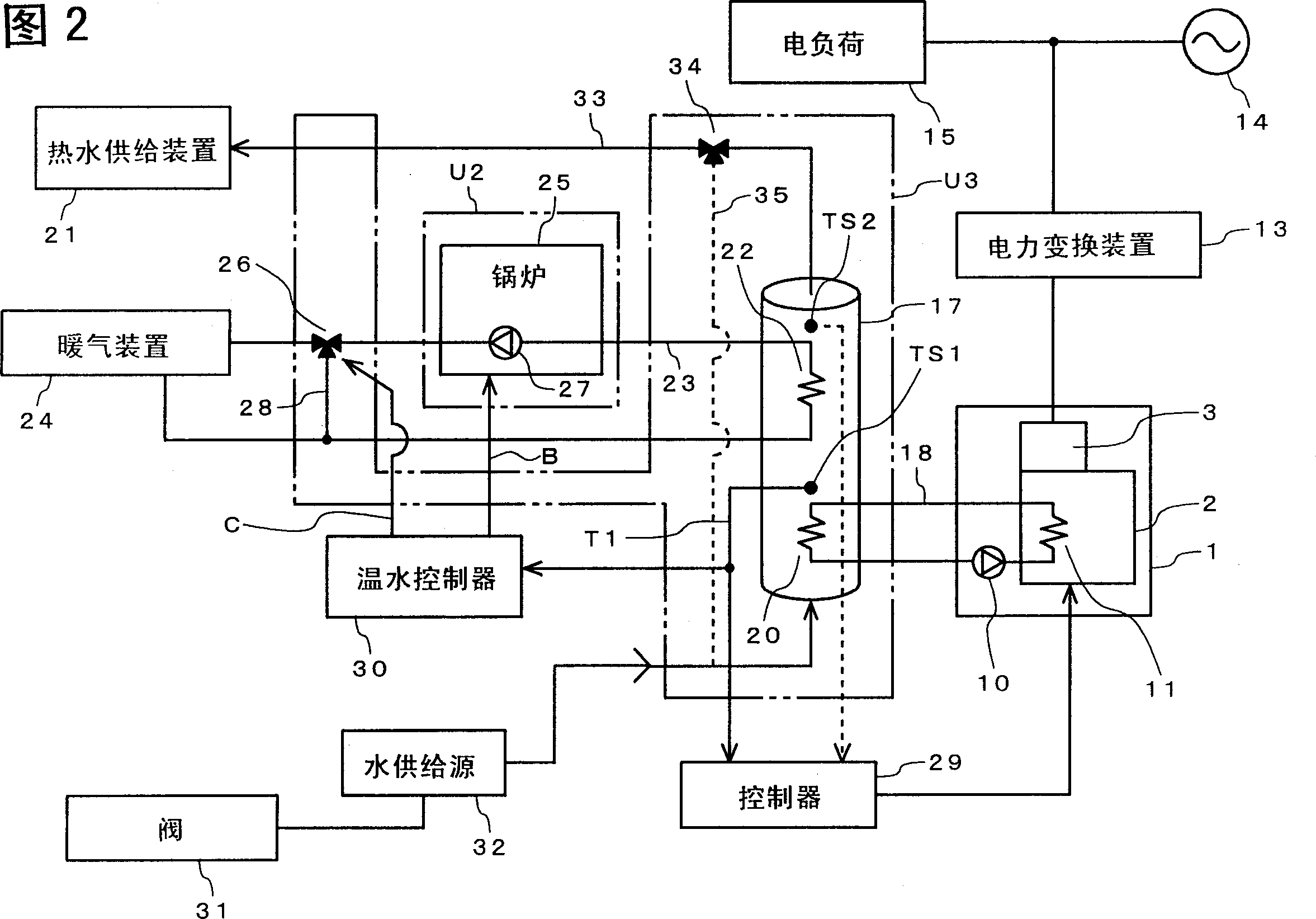

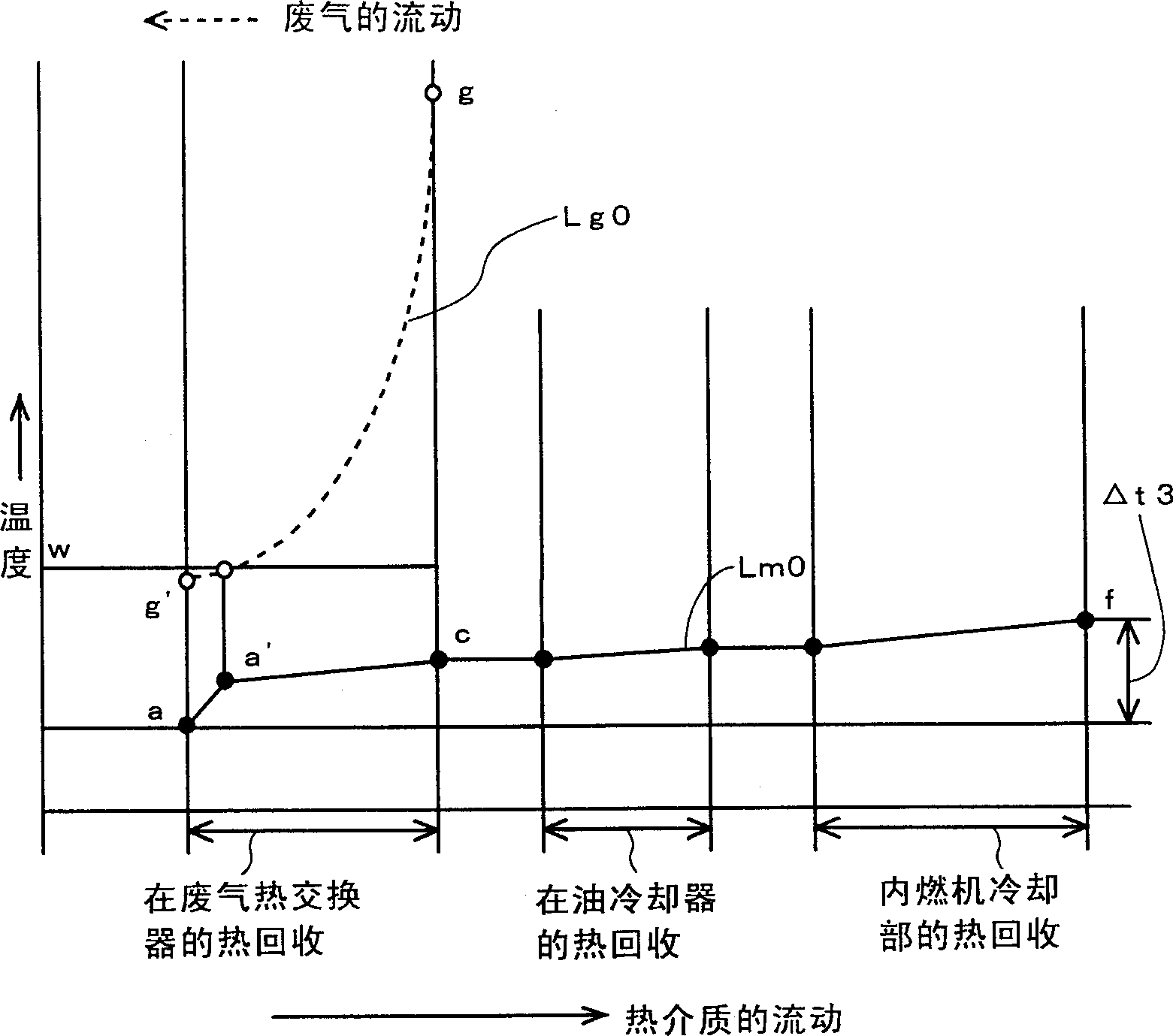

Afterheat recovering device of I.C. engine

InactiveCN1382902ASufficient temperatureAvoid contactInternal combustion piston enginesEngine componentsPlate heat exchangerWater vapor

Owner:HONDA MOTOR CO LTD

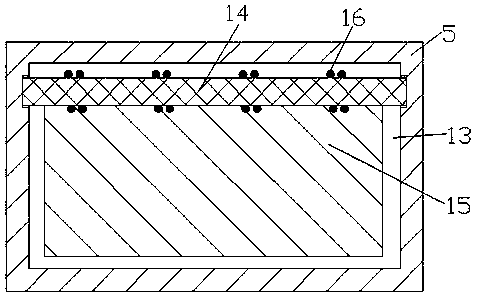

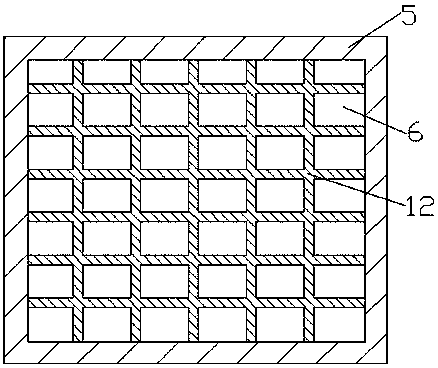

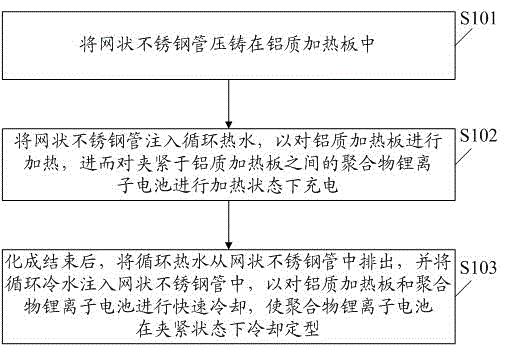

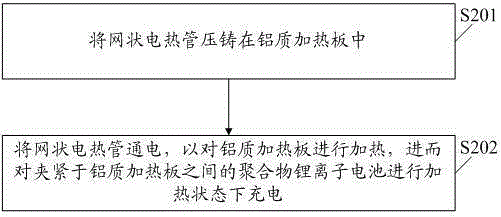

Heating method of polymer lithium ion battery high-temperature fixture formation equipment

InactiveCN105206877AEvenly heatedFast heatingCell electrodesFinal product manufacturePressure castingMetallurgy

A heating method of polymer lithium ion battery high-temperature fixture formation equipment comprises the following steps: casting reticulation electrothermal tubes or reticulation stainless steel tubes respectively under pressure in two aluminum heating plates; electrifying the reticulation electrothermal tubes or injecting circulating hot water into the reticulation stainless steel tubes, so as to heat the aluminum heating plates, and further charging a polymer lithium ion battery tightly clamped between the aluminum heating plates when the battery is being heated. Therefore, the reticulation electrothermal tubes or the reticulation stainless steel tubes are cast into the aluminum heating plates under pressure through heating of aluminum ingots for melting, pressure casting and integral formation; when the reticulation electrothermal tubes are electrified or circulating hot water is injected into the reticulation stainless steel tubes, the aluminum heating plates are heated, and both surfaces of each aluminum heating plate radiate heat uniformly, so that the upper and lower aluminum heating plates can be used for charging the polymer lithium ion battery tightly clamped between the aluminum heating plates when the polymer lithium ion battery is in a heated state, both sides of the battery are heated uniformly, temperature rise is fast, the capacity of a formed battery plays a role sufficiently, and the battery is thinner, even in surface, and beautiful.

Owner:杨国乐

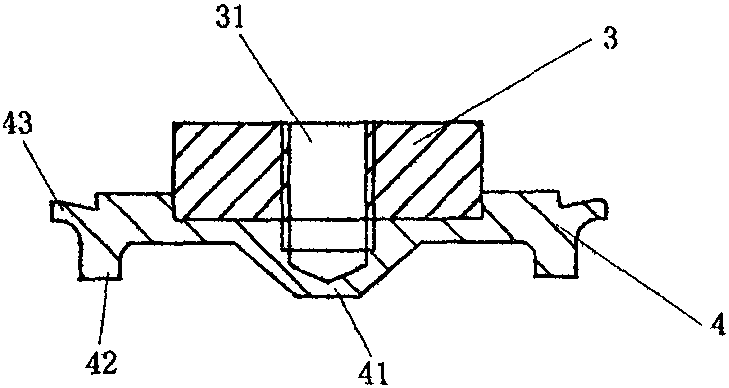

Battery anode/cathode cover board production method and battery anode/cathode cover board

ActiveCN104795516AIncrease tightnessImprove connection strengthLi-accumulatorsCell component detailsFriction weldingEngineering

The invention relates to a battery anode / cathode cover board production method. A copper work piece is fixed in a mounting hole of an insulating ring through copper-copper friction welding; enough temperature is generated during welding by reasonably selecting and arranging technological parameters; the metal on the welding surfaces of the two copper work pieces is subjected to plastic deformation, and such defects as bubbles and cracks are not generated at the welding seam part; meanwhile, the welding surfaces of the two copper work pieces are subjected to rotating friction under the action of pressure, so that the two copper work pieces are subjected to deformation in the axial direction, the radial size of the welding surfaces and the area near the welding surfaces is expanded and enlarged, the outer walls of the two copper work pieces are clung to the insulating ring, the insulating ring and an aluminum work piece are fit together tightly, the bonding strength among the components of the battery anode / cathode cover board is improved, and the service life is prolonged; besides, the cross section of the copper work piece is I-shaped, and the two ends of the copper work piece are both larger than the diameter of the mounting hole, so that the copper work piece can be prevented form being squeezed out from one side in the axial direction of the mounting hole.

Owner:SICHUAN ANQINGFU ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com