Method and device for preparation perovskite layer and application of perovskite layer

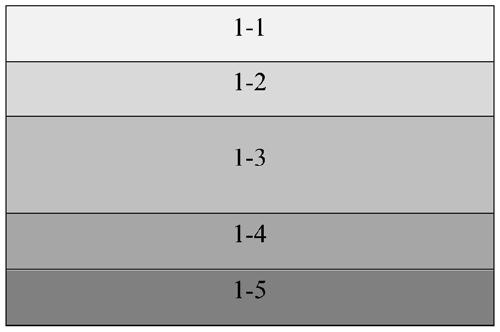

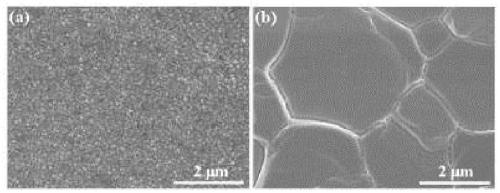

A technology of perovskite and absorbing layer, applied in the field of preparation of perovskite layer, can solve the problems of reducing carrier collection efficiency and photoelectric conversion efficiency, incomplete reaction of perovskite layer, unfavorable industrial application, etc. Conversion efficiency, grain boundary reduction, and effect of grain boundary recombination reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

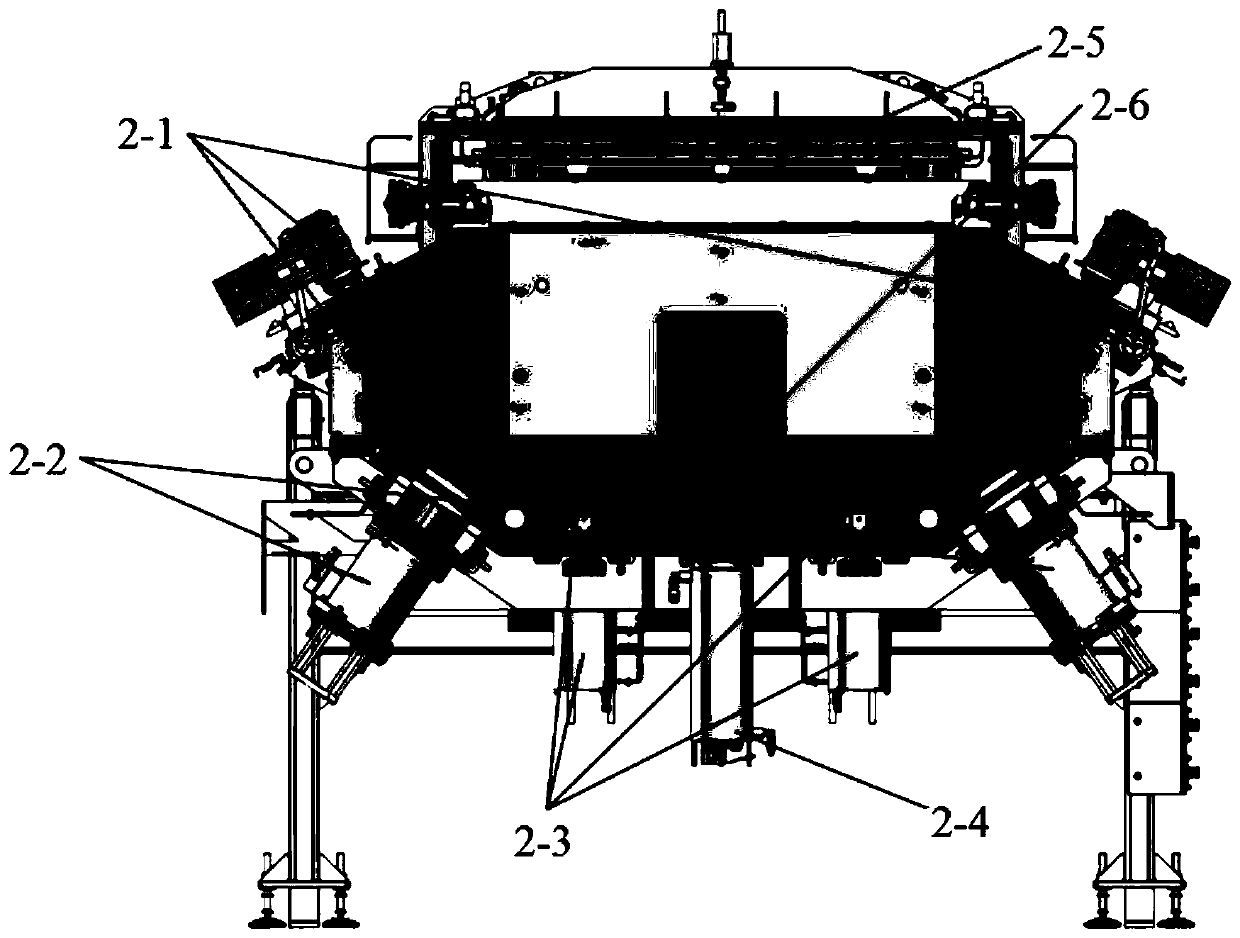

[0045] The present embodiment provides a kind of preparation method of perovskite solar cell, specifically as follows:

[0046] Using the spray pyrolysis process, dissolve the precursor solution of titanium dioxide with a volume ratio of 1:25 in ethanol, spray it on the conductive glass FTO layer, spray 16 times, and sinter at 450°C for 30 minutes to obtain TiO 2 Electron transport layer;

[0047] By vacuum evaporation, the PbI 2 Powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, and methyl ether ammonium iodide were vapor deposited on the electron transport layer to prepare the perovskite absorbing layer, wherein, PbI 2 Powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, methyl ether ammonium iodide molar ratio is 0.8:0.7:0.1:0.1:0.1, evaporation rate is 0.8°A / s, 0.7° A / s, 0.1°A / s, 0.1°A / s, 0.1°A / s, put them into the crucible respectively, then put the crucible into the evaporation source, control th...

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of perovskite solar cell, specifically as follows:

[0053] Using the spray pyrolysis process, dissolve the precursor solution of titanium dioxide with a volume ratio of 1:20 in ethanol, spray it on the glass conductive layer FTO, spray 13 times, and sinter at 400°C for 40 minutes to obtain TiO 2 Electron transport layer;

[0054] By vacuum evaporation, the PbI 2 Powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, and methyl ether ammonium iodide were vapor deposited on the electron transport layer to prepare the perovskite absorbing layer, wherein, PbI 2 The molar ratio of powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, and methyl ether ammonium iodide is 1:0.8:0.1:0.05:0.05, and the evaporation rates are 1°A / s and 0.8° respectively A / s, 0.1°A / s, 0.05°A / s, 0.05°A / s, put them into the crucible respectively, then put the crucible in...

Embodiment 3

[0059] The present embodiment provides a kind of preparation method of perovskite solar cell, specifically as follows:

[0060] Using the spray pyrolysis process, dissolve the precursor solution of titanium dioxide with a volume ratio of 1:25 in ethanol, spray it on the FTO layer of conductive glass, spray it 13 times, and sinter at 460°C for 40 minutes to obtain TiO 2 Electron transport layer;

[0061] By vacuum evaporation, the PbI 2 Powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, and methyl ether ammonium iodide were vapor deposited on the electron transport layer to prepare the perovskite absorbing layer, wherein, PbI 2 The molar ratio of powder, methyl ammonium iodide, methyl ether ammonium bromide, methyl ammonium chloride, and methyl ether ammonium iodide is 1.5:0.5:0.1:0.1:0.3, and the evaporation rates are 1.5°A / s and 0.5° respectively A / s, 0.1°A / s, 0.1°A / s, 0.3°A / s, put them into the crucible respectively, then put the cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com