Aerosol generating product with perfumed cigarette core section

An aerosol and cigarette core technology, applied in tobacco, cigar manufacturing, application, etc., can solve problems such as insufficient mixing, blockage of smoke volume, and increased suction resistance, so as to achieve good ventilation effect, reduce smoke temperature, increase The effect of air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

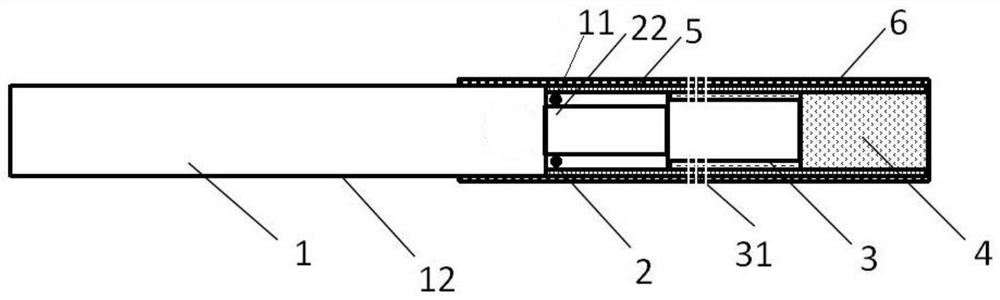

[0046] Such as figure 1 with 2 As shown, this embodiment provides an aerosol-generating product with aromatized cigarette core segments, which includes a smoking core material segment 1, a support segment 2, a ventilating hollow segment 3 and a filter segment 4 arranged in sequence, and the support segment 2 . The air-permeable hollow section 3 and the filter section 4 are wrapped with molding paper 5 to form a mouthpiece, and the smoking core section 1 and the mouthpiece are tipped with natural air permeability tipping paper 6;

[0047] The smoking core material section 1 is wrapped by anti-seepage cigarette paper 12;

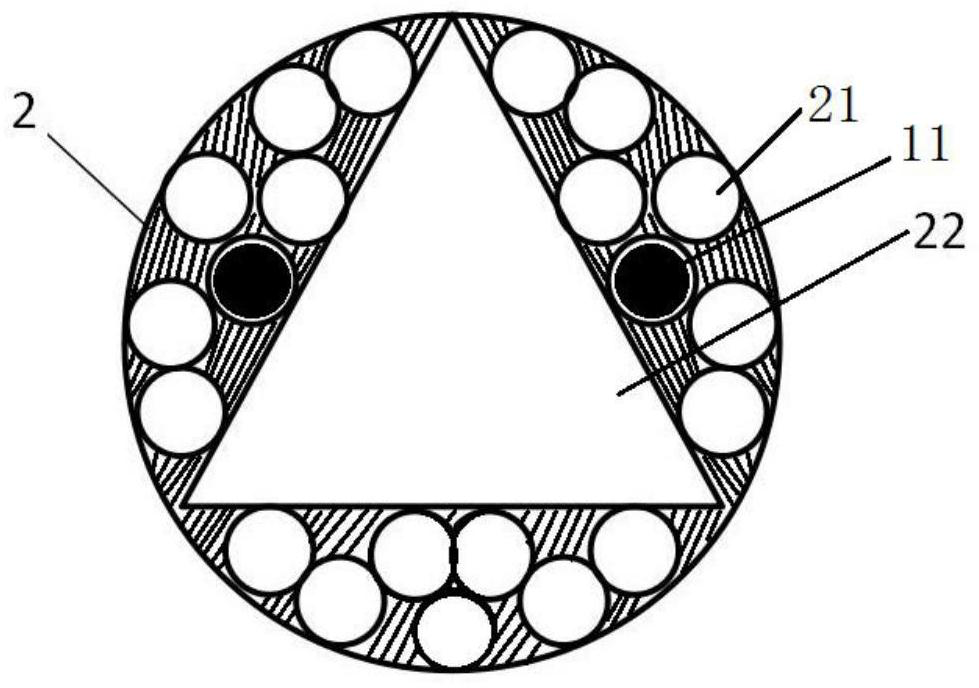

[0048] The support section 2 has a fragrance function, which has a large hollow hole 22 and a plurality of small holes 21 for fragrance; the plurality of small holes 21 surround the outside of the large hole 22, and some of the small holes 22 There is a flavoring capsule 11 in the small hole 21 near the end of the side of the smoking core material section 1;...

Embodiment 2

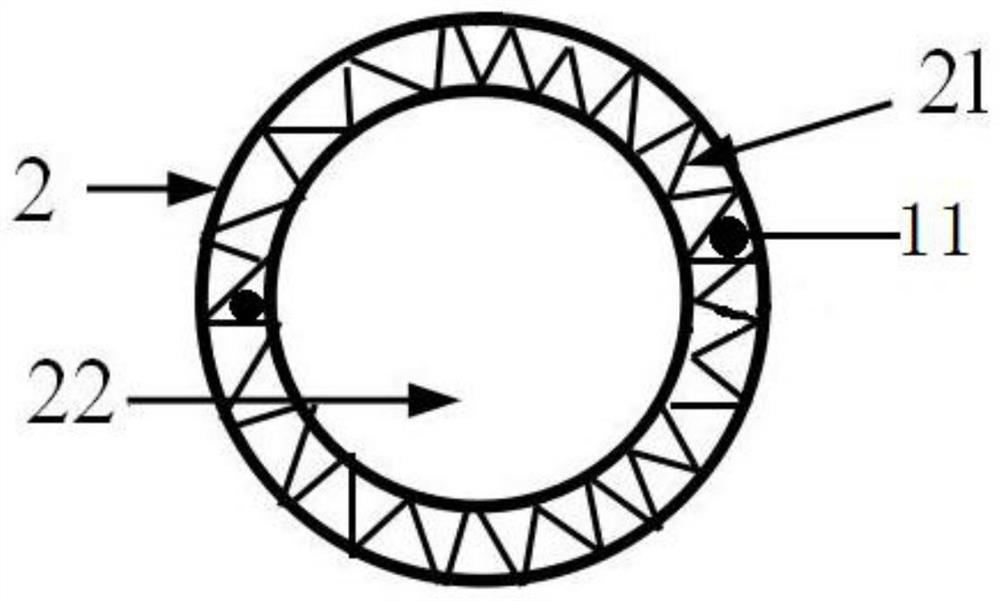

[0063] Such as image 3 As shown, this embodiment is the preparation of aerosol-generating product sample 2, which is similar in structure to the aerosol-generating product sample 1 in Example 1, and the only difference lies in the structure of the supporting section. The supporting section of the aerosol-generating product sample 2 is a combination of corrugated perfuming small holes and hollow large holes in the inner cavity.

[0064] The supporting section 2 includes two materials, the first material and the second material, wherein the perfuming small hole 21 is defined by the first material, the second material or a combination of the first material and the second material, and the hollow large Holes 22 are defined by the first material.

[0065] The first material is selected from paper; the second material is selected from non-woven fabric.

[0066] The large hollow hole 22 is located at the center of the mouthpiece, and its cross-sectional area is 1 / 5-1 / 2 of the cros...

Embodiment 3

[0069] The aerosol-generating product sample 1 and the aerosol-generating product sample 2 were respectively smoked with the supporting heat-not-burn cigarette smoking set under the same conditions. During the smoking process, the temperature of the aerosol-generating product smoking core section 1 was 200°C about. The sensory evaluation of aerosol-generating products is carried out by multiple sensory evaluation personnel, mainly investigating six indicators of smoke volume, aroma and fragrance, energy, coordination, irritation, and mouthfeel; the scoring values of the six quality inspection indicators are respectively: 0-10 points for smoke volume, 0-30 points for aroma, 0-10 points for vigor, 0-10 points for coordination, 0-15 points for irritation, and 0-25 points for mouthfeel. The total score of the 6 evaluation indicators is 100. The higher the score of the five evaluation indicators of smoke volume, aroma, strength, coordination, and taste, the stronger the feeling o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com