Tin dross processor

A processing machine and tin slag technology, which is applied in the field of metal recycling and processing equipment, can solve the problems of difficult processing of cold block tin slag, low thermal efficiency, complex mechanism, etc., and achieve the effect of simple structure, high heating efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

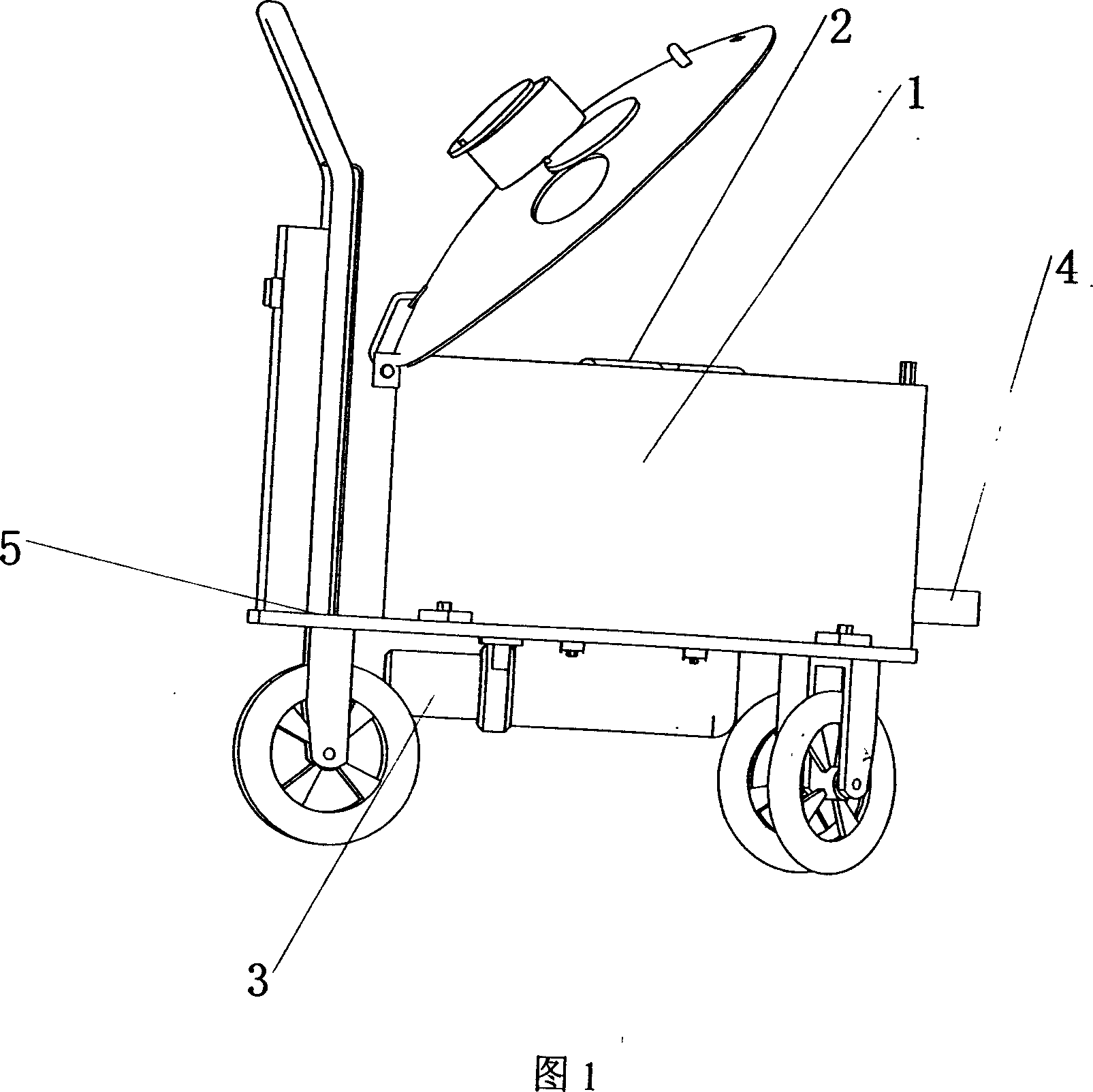

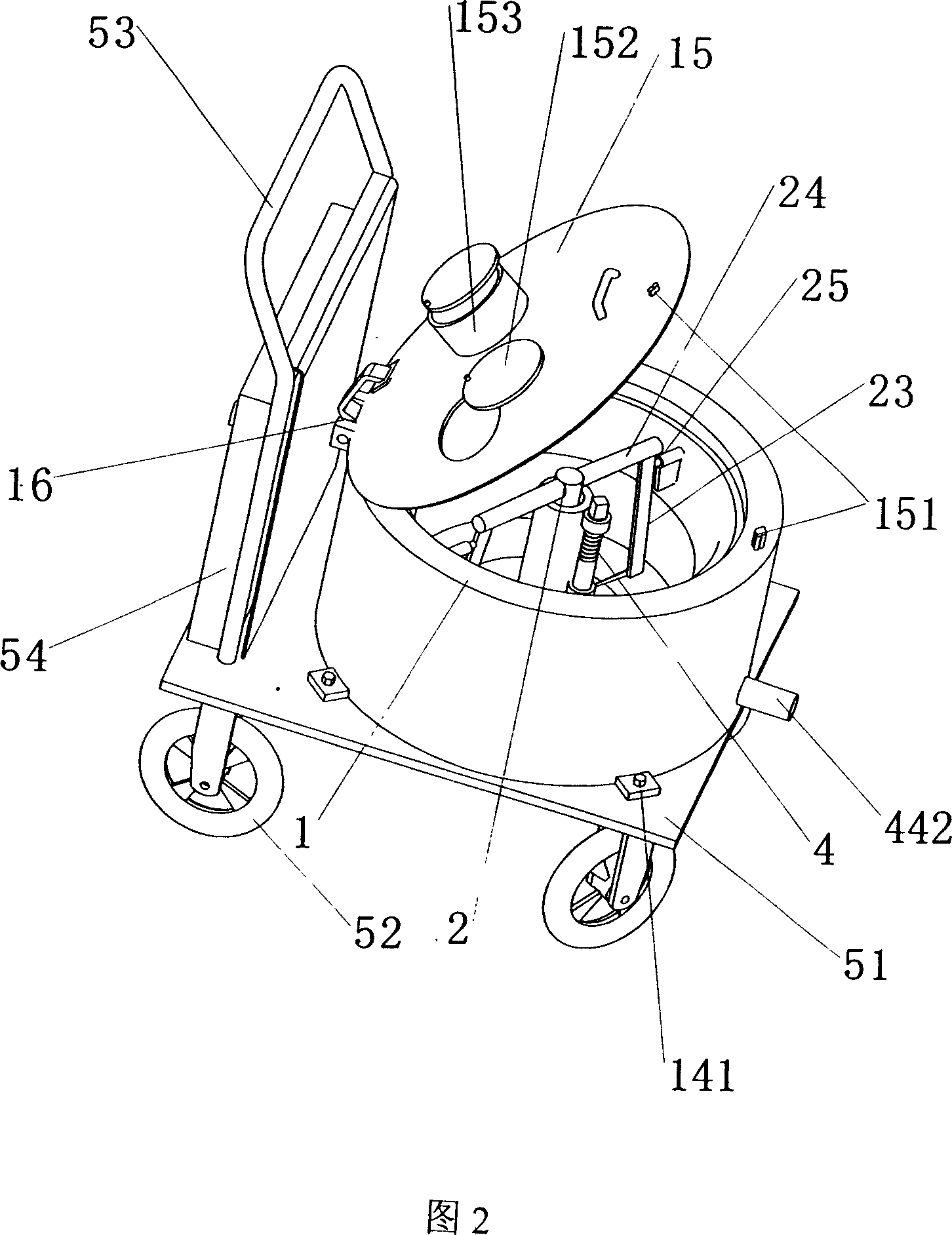

[0029] As shown in Fig. 1 and Fig. 2, the device of the present invention includes a temperature-controllable tin slag electric heating melting pot device 1, a tin slag stirring combination device 2, a motor and a reducer driving device 3, a hot liquid releasing device 4, a The wheel frame device 5 that makes the whole machine move flexibly.

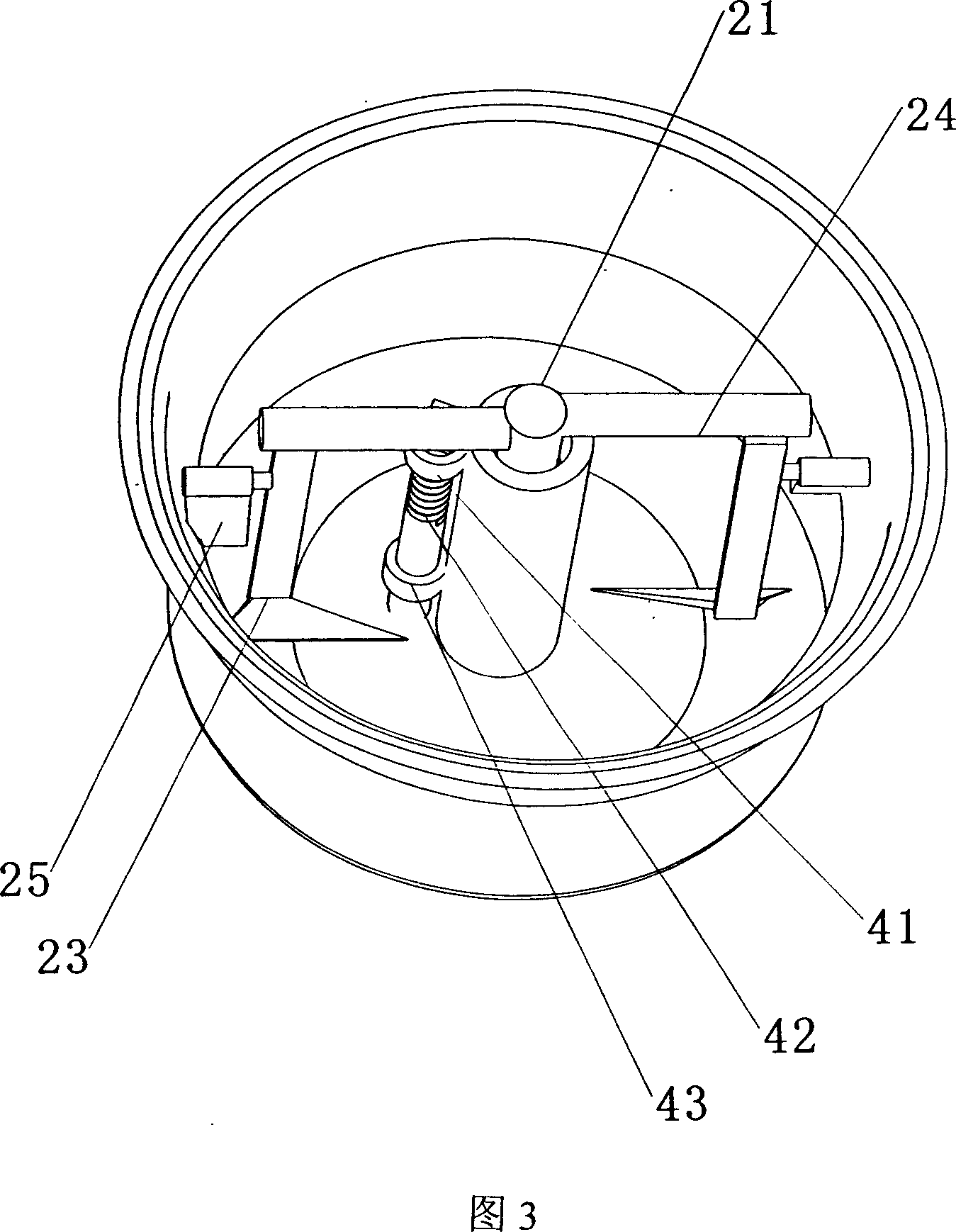

[0030] As shown in Figure 5, the tin slag melting pot device 1 includes: a pot gall 11, which has a heat-insulating coaming 12, a filling layer of thermal insulation material 13, and a shell 14 surrounding the pot body, which are evenly distributed along the lower edge of the pot body shell 14. An ear buckle 141 is installed, and the pot cover 15 is fixed on the pot body shell 14 by a spring hinge 16, and the pot cover anti-loosening buckle 151 is provided on the other side, and the electric hob 17 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com