Patents

Literature

133results about How to "Increase fill value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

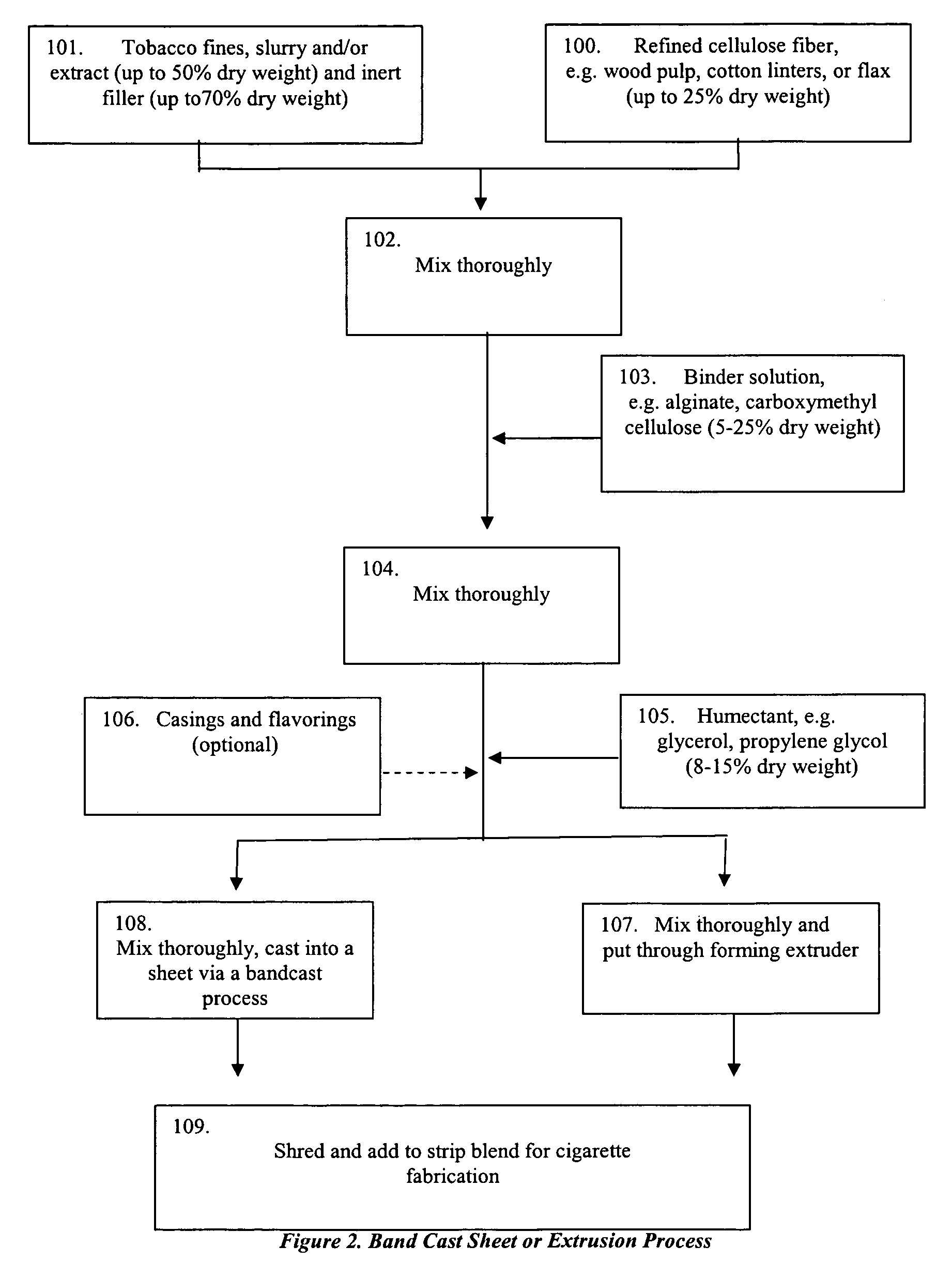

Smokeable tobacco substitute filler having an increased fill value and method of making same

ActiveUS20060021626A1Increase fill valueImproved tobacco taste and flavor characteristicTobacco preparationNon-fibrous pulp additionCelluloseFilling materials

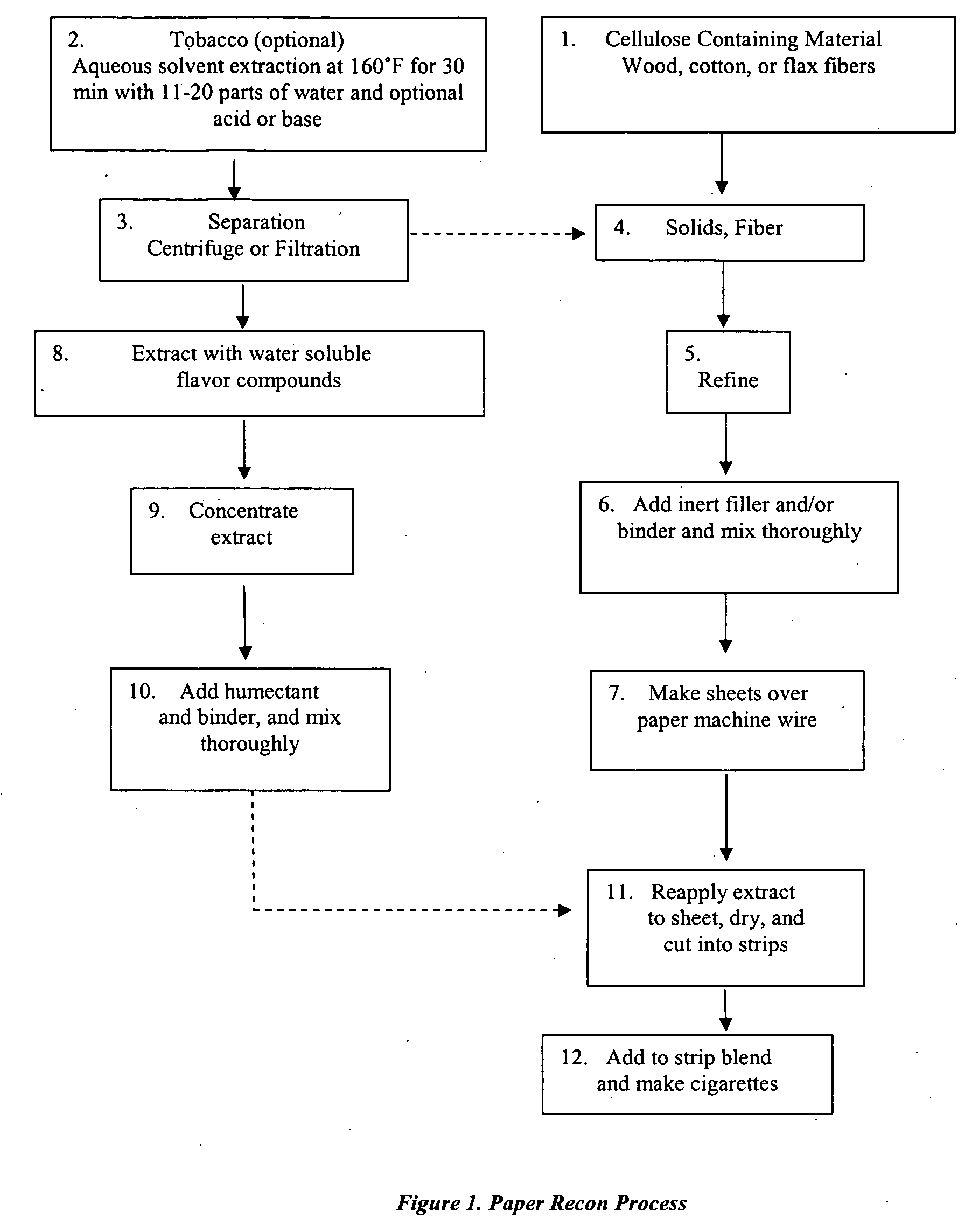

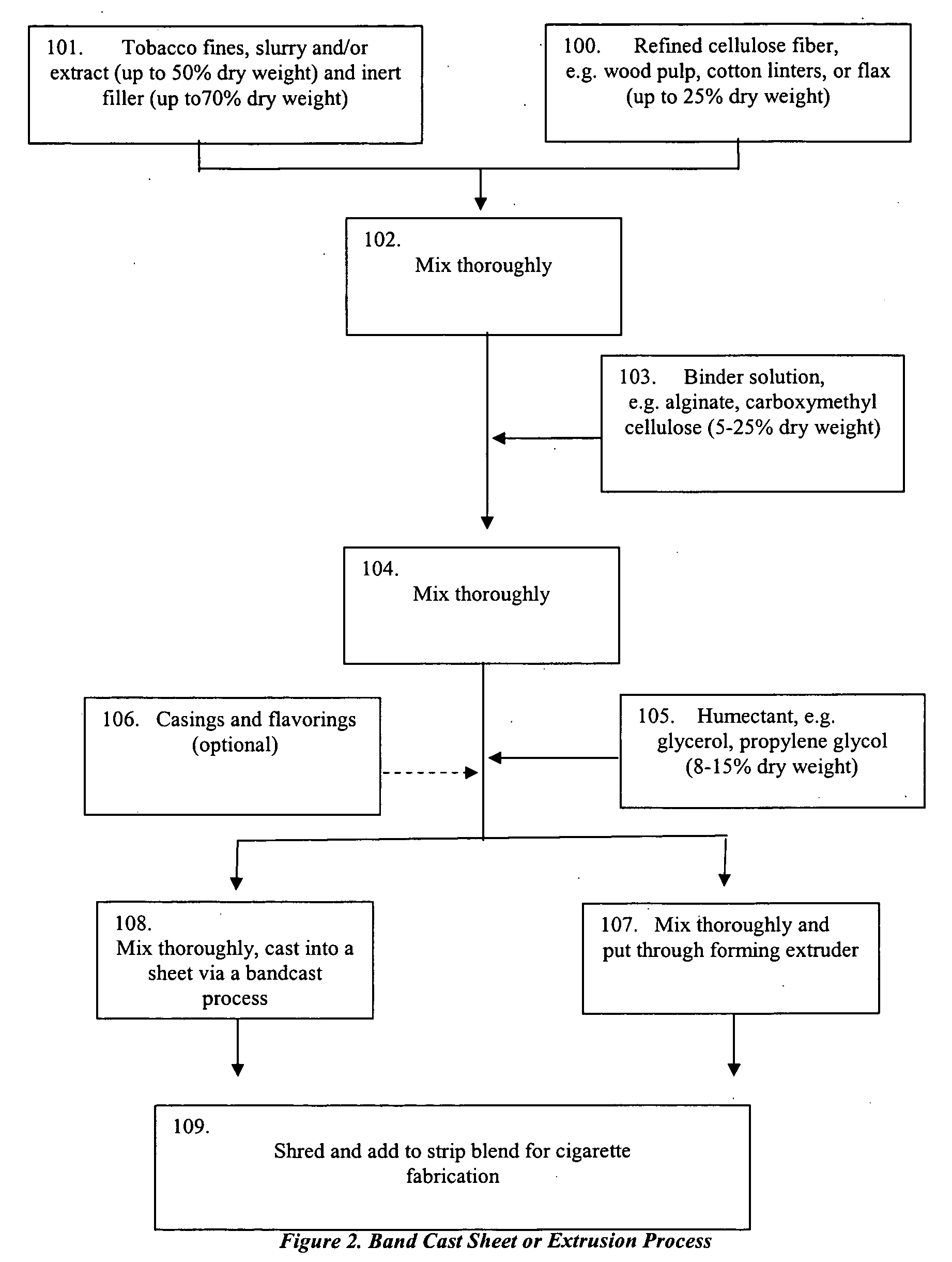

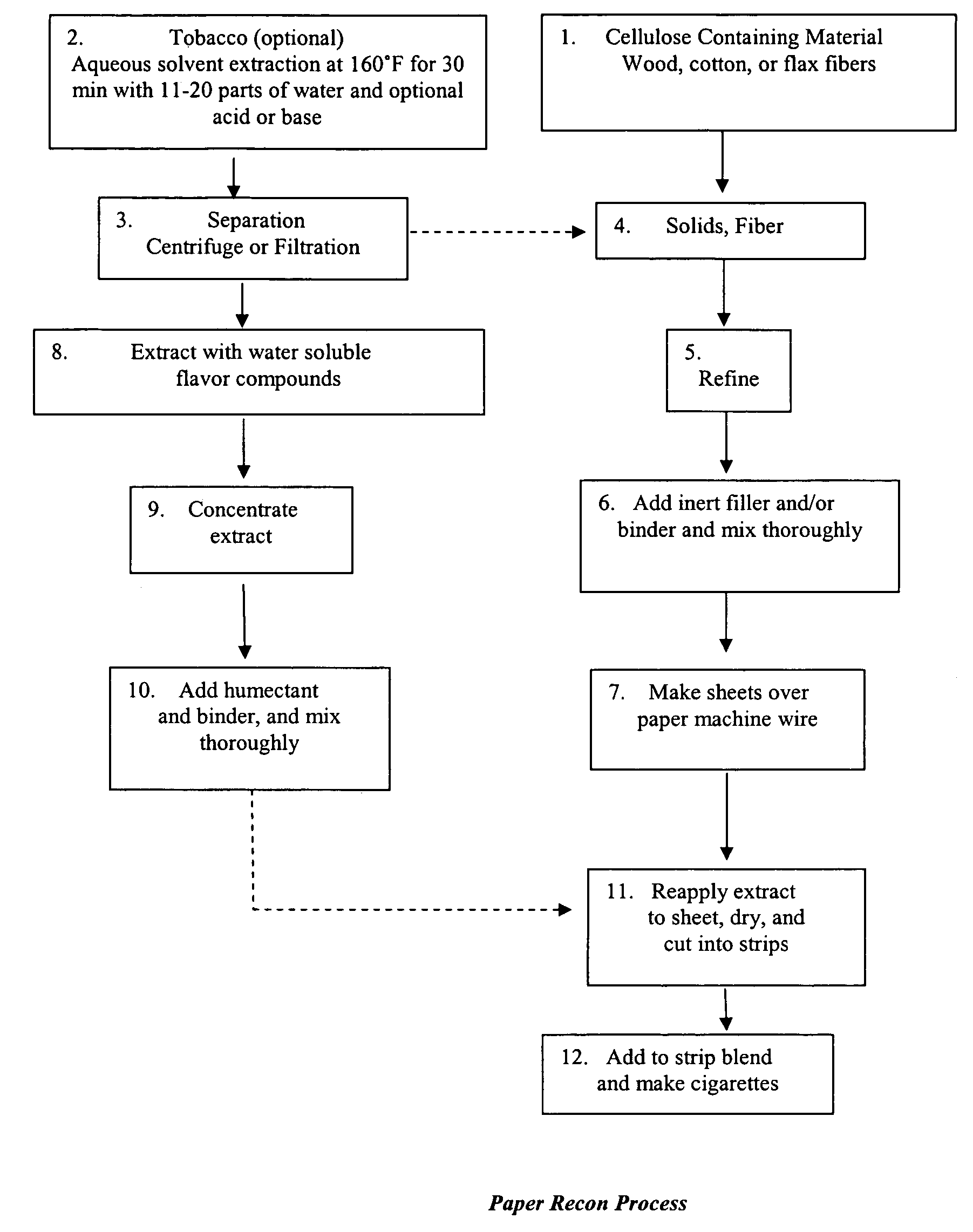

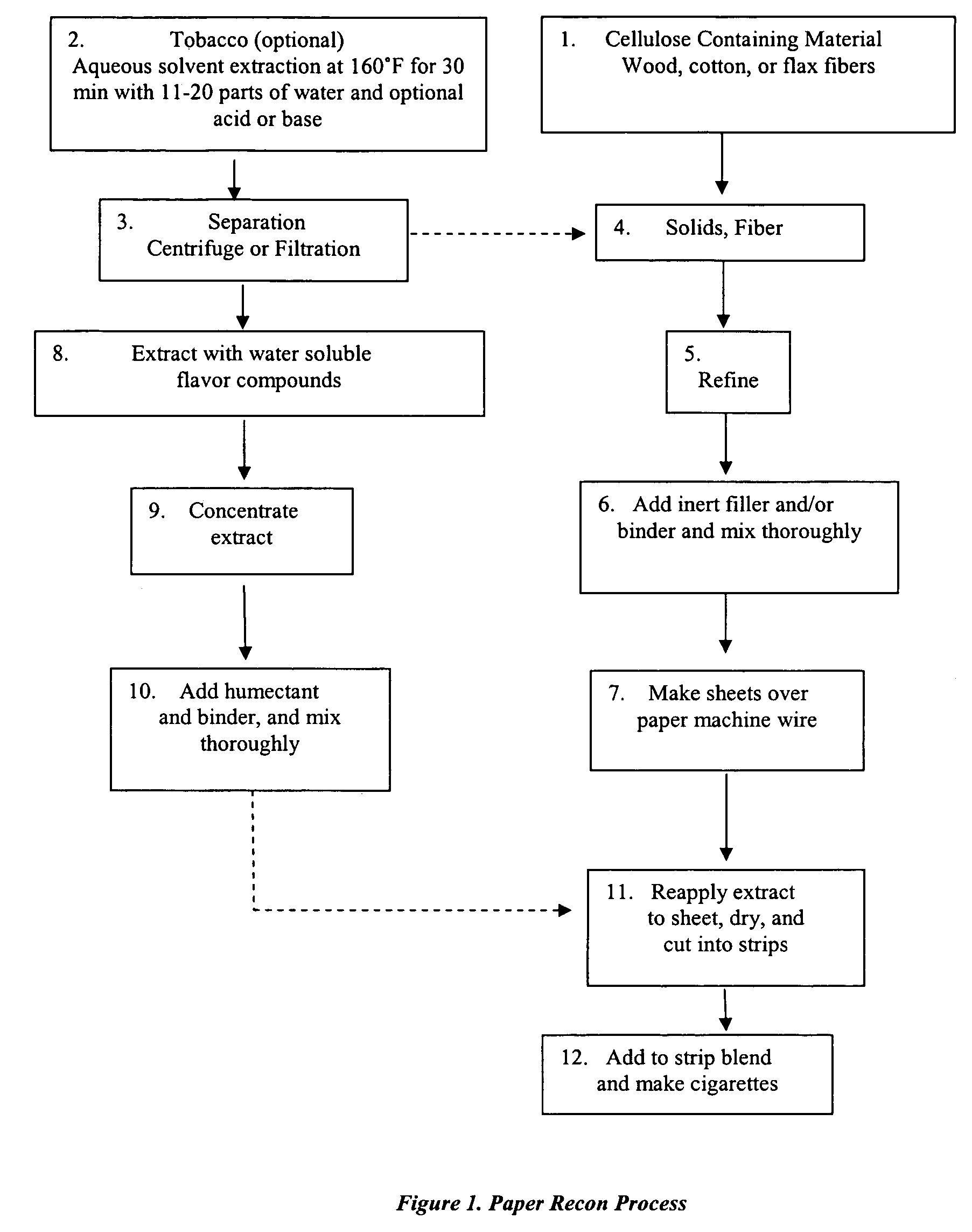

The invention relates to a smokeable filler material having an increased fill value and processes for making the smokeable filler. The smokeable filler has a fill value of at least 5 cc / g and comprises a cellulose material, a humectant, an inert filler, a binder, and optionally a tobacco containing material.

Owner:BROWN & WILLIAMSON TOBACCO

Method of making smokeable tobacco substitute filler having an increased fill value

ActiveUS7428905B2Increase fill valueImproved tobacco taste and flavor characteristicTobacco preparationTobacco treatmentCelluloseMaterials science

The invention relates to a smokeable filler material having an increased fill value and processes for making the smokeable filler. The smokeable filler has a fill value of at least 5 cc / g and comprises a cellulose material, a humectant, an inert filler, a binder, and optionally a tobacco containing material.

Owner:BROWN & WILLIAMSON TOBACCO

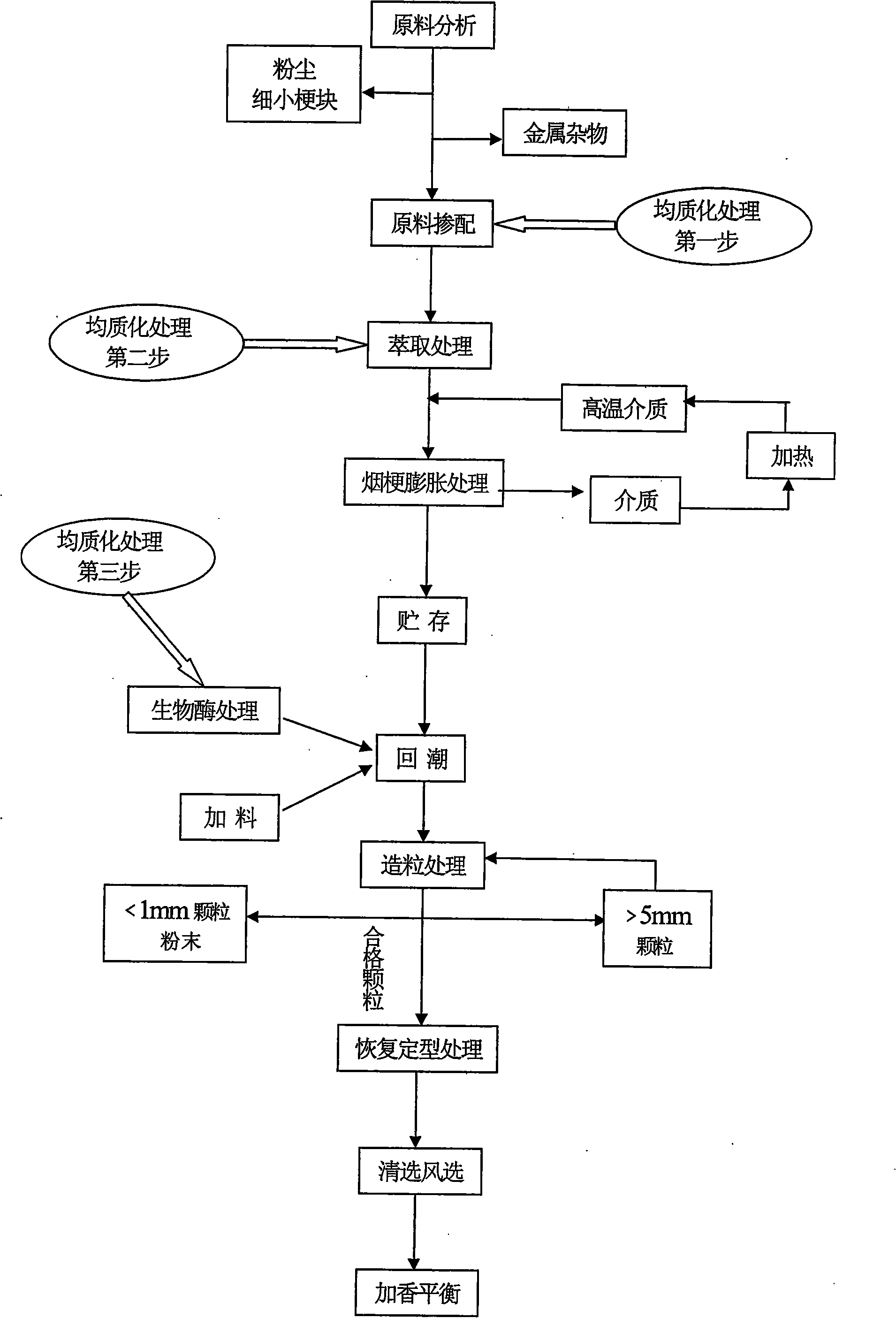

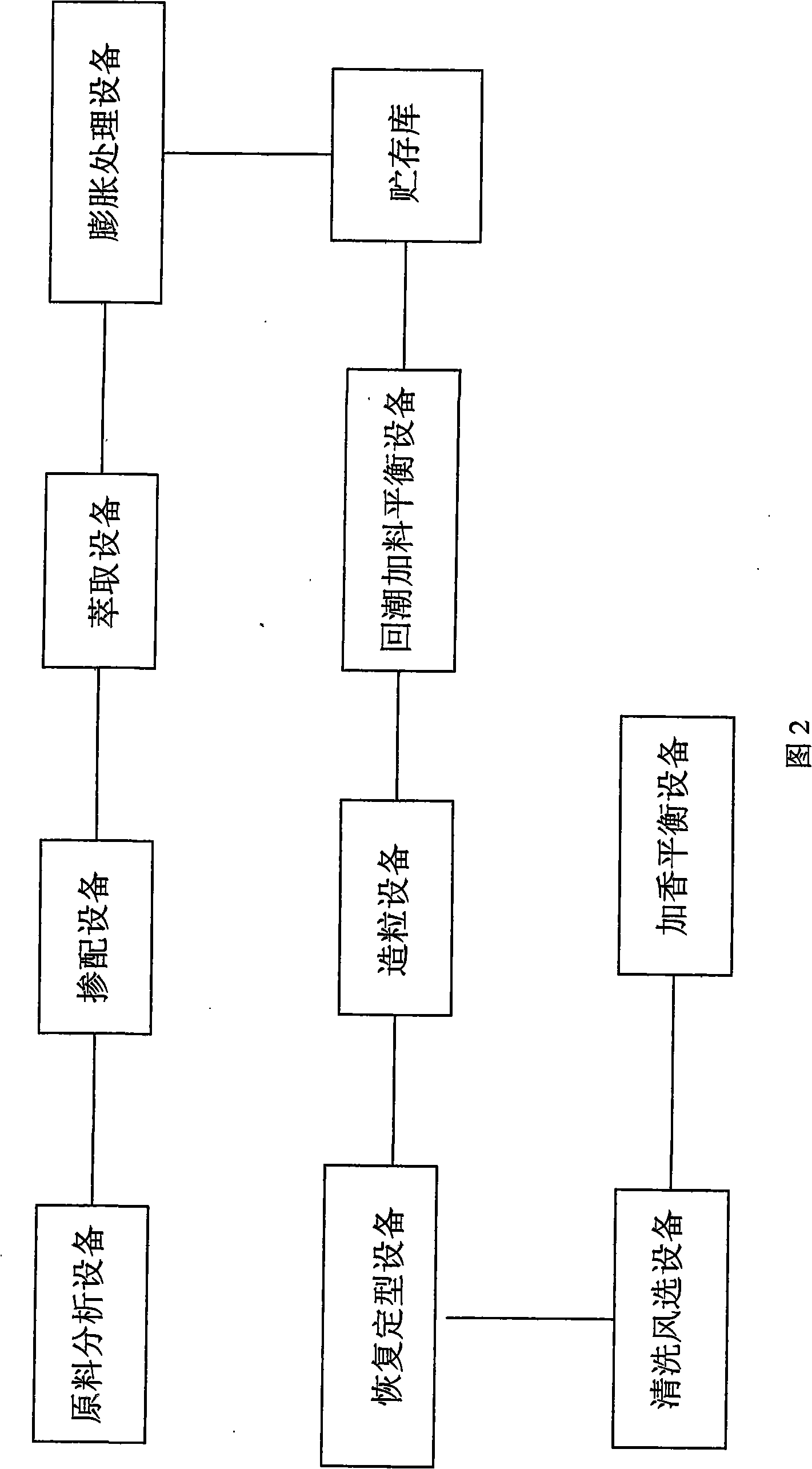

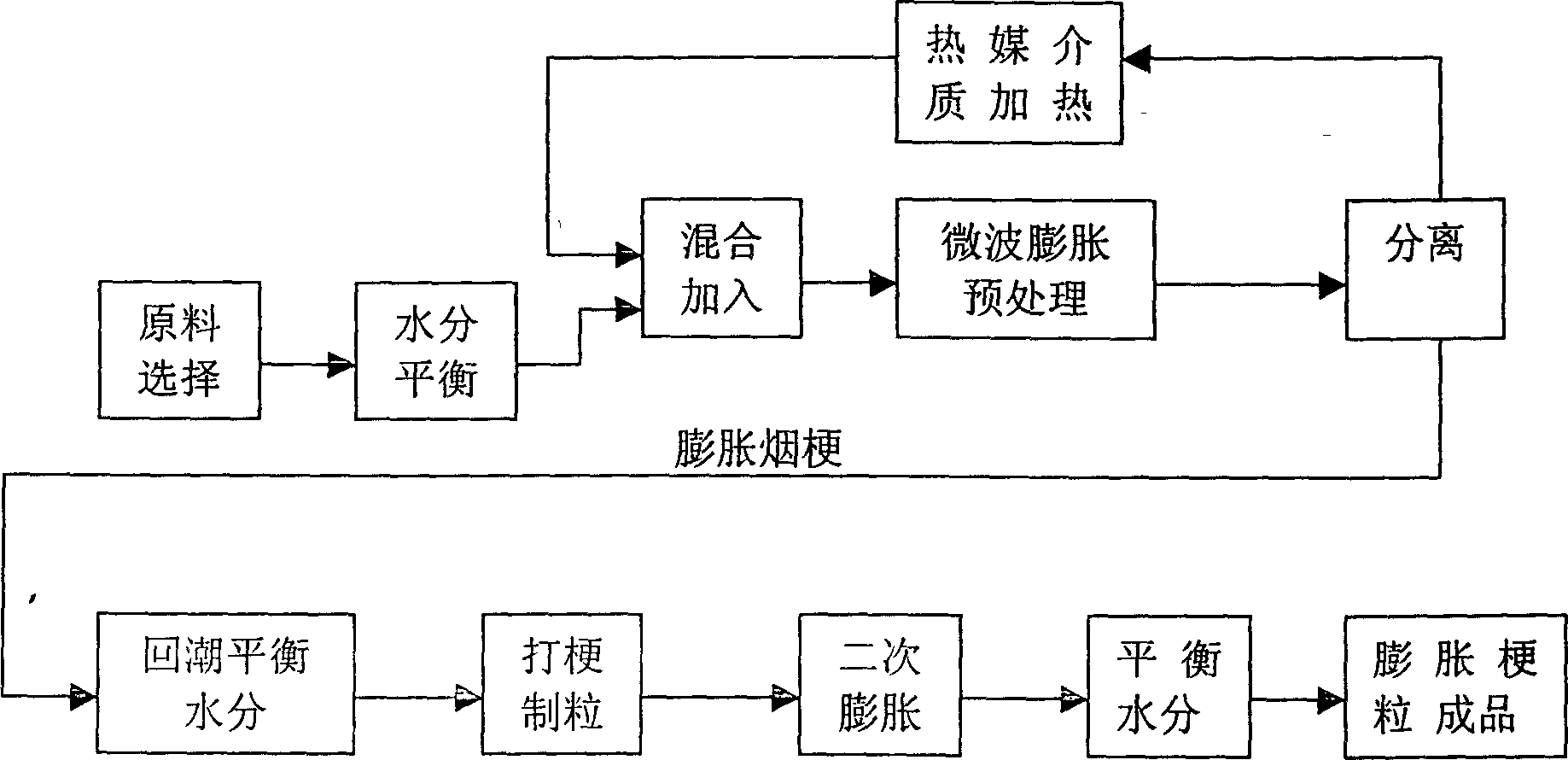

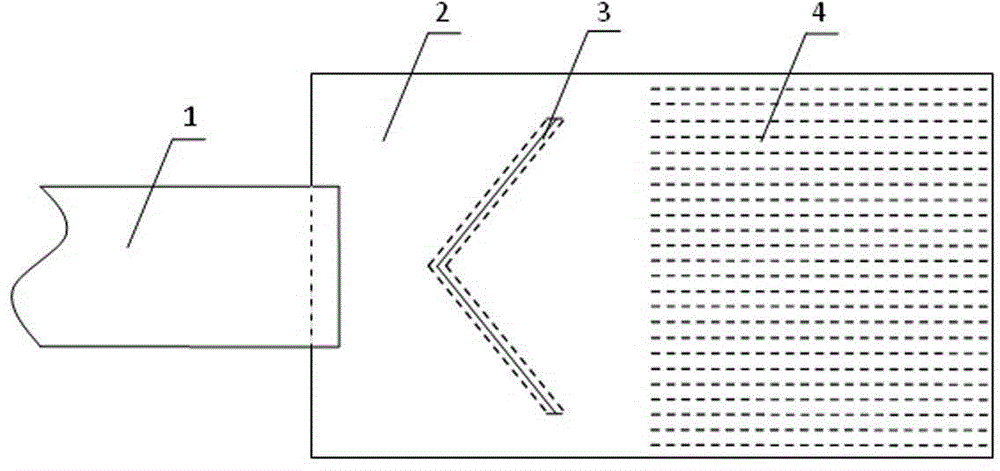

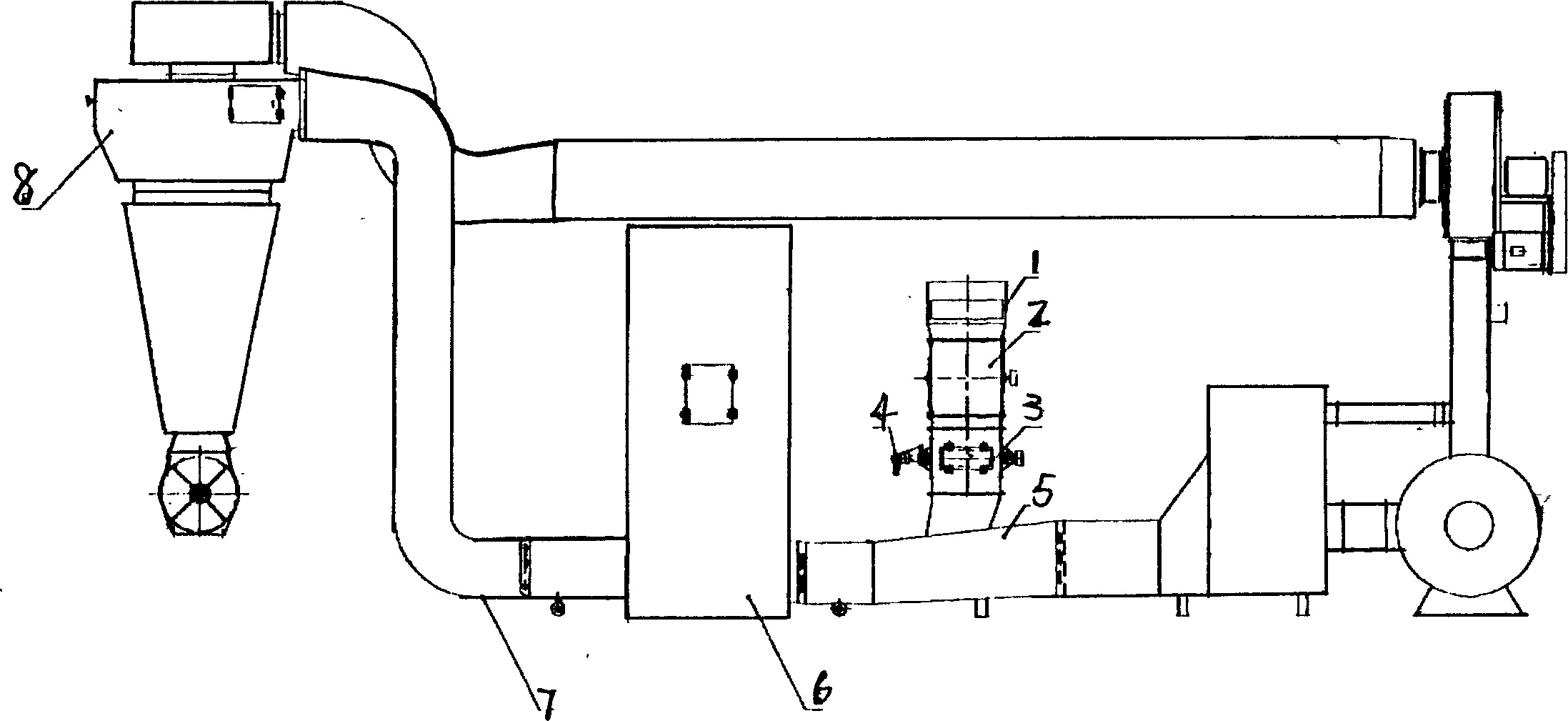

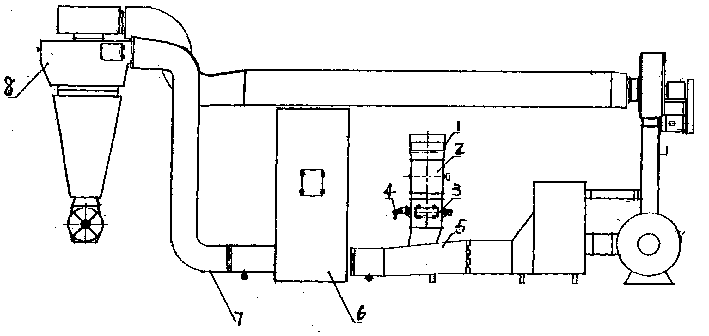

Method and device for preparing expanded stem granule

ActiveCN101305836AWide variety of sourcesAchieve expansionTobacco preparationTobacco treatmentTotal nitrogenSugar

The invention discloses a method for preparing expanded tobacco stem particles and the equipment thereof. The method is characterized in that the method can control the mixed ratio of tobacco stems on the basis of raw material analysis. The method comprises the following steps: mixing materials to obtain tobacco stem containing 10 to 18%of total sugar, 8 to 16% of reduced sugar, 0.3 to 1.5% of nicotine, and 1.0 to 2.0% of total nitrogen, extracting, expanding, storing, regaining moisture, granulating, recovering, shaping, cleaning and air-sorting, flavoring, and balancing to obtain the required expanded tobacco stem particles. The invention eliminates the influences of material difference on the quality of the expanded tobacco stem particles to ensure the stability and the uniformity of the product quality, thus improving the utilization rate of the tobacco stem and further improving the production process of the expanded tobacco stem particles. The method has the advantages of simple, reasonable and easy process flow, stable equipment operation, high efficiency, low energy loss, and good application prospect.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

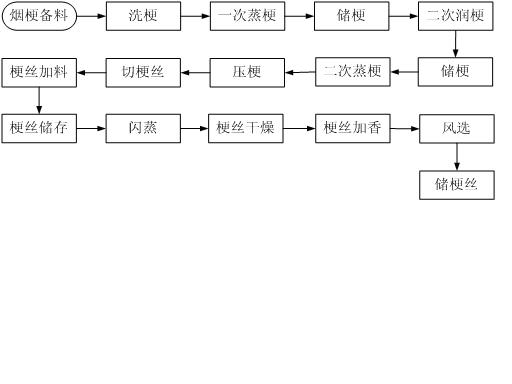

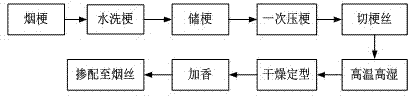

Technology for processing tobacco stalk into shreds

ActiveCN102631016AUniform expansionSimilar expansion rateTobacco preparationTobacco treatmentMicrowaveTar

The invention provides a technology for processing tobacco stalk into shreds, and belongs to the technical field of tobacco processing. The technology disclosed by the invention has the following steps of: pretreating tobacco stalk, expanding the tobacco stalk with microwave, washing the tobacco with water, storing the tobacco stalk, straightening out the tobacco stalk, slicing the tobacco stalk, charging and storing stalk slices, shredding the stalk slices, drying and shaping the stalk shreds, and perfuming the stalk shreds and storing the stalk shreds. Equipment used in the technology is purchased from the market, wherein the equipment which is purchased from the market, adopts a low-frequency (915MHz) high-power (more than 10kW) microwave magnetron, and transports the tobacco stalk by a belt is improved into equipment which adopts an ultrahigh-frequency (2450MHz) single-pipe low-power (1.5kW) microwave magnetron, performs group control on the microwave magnetron and transports tobacco stalk by a drum. The technology has the characteristics that the tobacco stalk shreds are good in quality consistency and more similar to tobacco leaf shreds in the physical property, and have high sensory quality and filling value; and uniformity, stability and mixing proportion of the tobacco stalk shreds are improved when the tobacco stalk shreds are mixed with the tobacco leaf shreds, the quality of cigarette is improved, the application range and use ratio of the tobacco stalk shreds in the cigarette are improved, and the aims of tar reducing, harm reducing, cost reducing and efficacy enhancing are achieved.

Owner:YUNNAN RES INST OF TOBACCO SCI

Preparation method of cigarette expansion cabo granule filling material

The invention discloses a preparation method of cigarette expansion cabo granule filling material, which comprises subjecting expanded cabo containing 5-9% of water to moisture regaining and balanced water treatment, loading into wind separation cabo beating machine, conveying bulked cabo particles into drying equipment for quick-speed drying till the moisture content is 7-14%, resulting cabo particles reexpansion, finally balancing water content of the cabo particles to 13+-0.5%.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

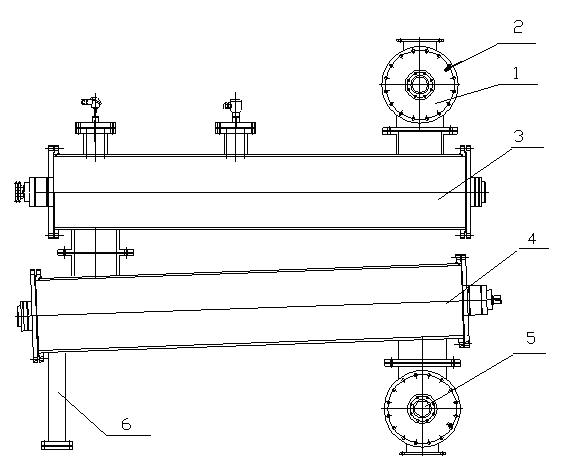

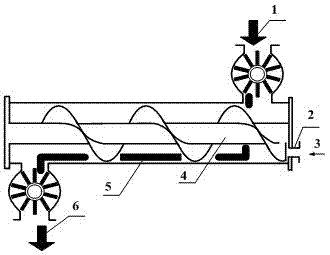

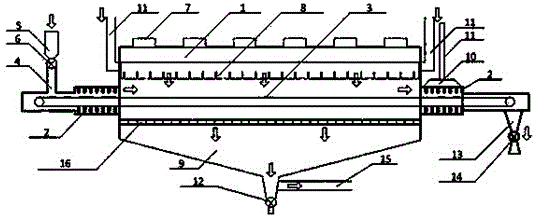

Steam stalk moistening method and equipment for implementing same

ActiveCN101862021AEnough pressureSufficient temperatureTobacco preparationPretreatment methodPulp and paper industry

The invention provides a tobacco stalk pre-processing method and tobacco stalk pre-processing equipment which can shorten the water permeability time of the tobacco stalk, ensure consistent moisture of the soaked tobacco stalk, save the storage process of the moistening of the tobacco stalk and simplify the process flow. The method comprises the following steps of: feeding a tobacco stalk material into a screw conveyer which is filled with steam and keeps proper pressure and proper temperature; continuously feeding the tobacco stalk material into the screw conveyer through a feeding vapor lock; continuously discharging the tobacco stalk material through a discharging vapor lock; and increasing the moisture and the temperature of the tobacco stalk to meet the requirements of the stalk pressing and cutting process on the discharging temperature and the moisture. The equipment comprises a bearing screw conveyer with a steam inlet and a water drainage port; a feed port and a discharge port of the screw conveyer are provided with the feeding vapor lock and the discharging vapor lock respectively; and the feeding vapor lock is provided with a water replenishing port. The water permeability of the tobacco stalk is improved by increasing the pressure and the temperature of the moistening environment of the tobacco stalk, so that the method and the equipment shorten the water permeability time of the tobacco stalks, quickly realize the pre-processing effect of the moistening of the tobacco stalk, save the storage process of the moistening of the tobacco stalk and greatly simplify the process flow of the stalk processing.

Owner:ZHISI HLDG GRP

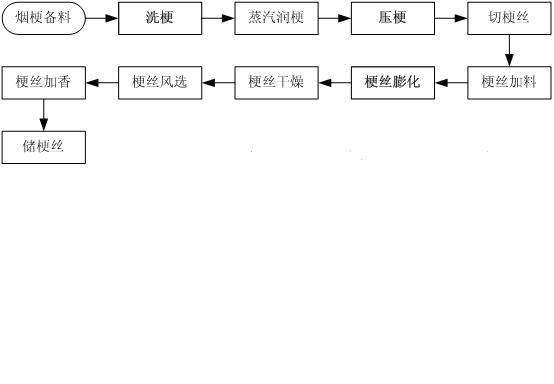

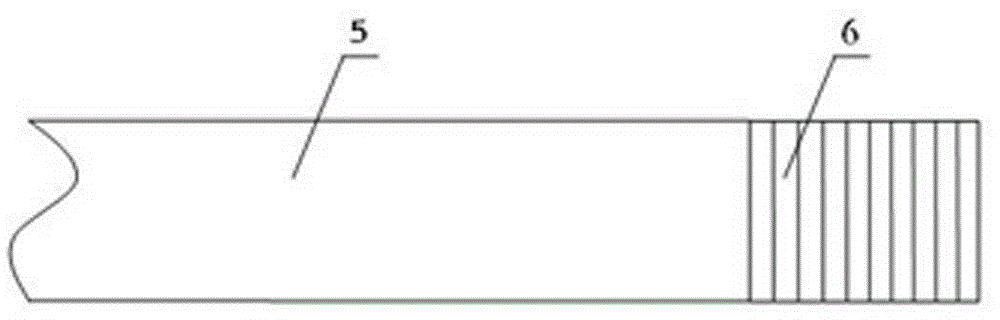

Novel production process for cut tobacco stems

InactiveCN102972856AIncrease softnessIncrease fill valueTobacco preparationTobacco treatmentAgricultural engineeringDrum drying

The invention discloses a novel production process for cut tobacco stems. The novel production process comprises the steps as follows: carrying out vacuum moisture regaining and evaporating the stems; storing the stems; heating and humidifying; straightening the stems; pressing the stems; arranging the stems; cutting the stems; feeding; expanding and drying; and perfuming. According to the novel production process, the vacuum moisture regaining and stem evaporating mode is adopted for moisture regaining of the tobacco stems, so that the impurity gases in the tobacco stems can be removed and the smoke softness is improved. The thinly pressing and cutting mode is adopted, so that the physical forms of the formed cut stems are threadlike and are closer to cut tobaccos. The flash evaporation, expansion and drum drying mode is adopted for drying of the cut stems, so that the cut stems are better in crimpiness and are closer to the form of the cut tobaccos and the filling capability of the cut stems can be improved. The cut steams produced by the production process has the advantages that the filling value is high, the impurity gases in the tobacco stems are reduced, the fragrance is increased, cigarettes can be endowed with a certain burned sweet fragrance, the physical forms of the cut stems are closer to the cut tobaccos, and the suitability is better in the cigarettes.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Tobacco stem pressing and shredding technology

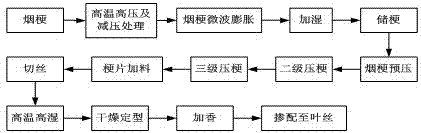

The invention discloses a tobacco stem pressing and shredding technology and belongs to the technical field of tobacco processing. The technology comprises the steps of conducting high-temperature high-pressure and decompression preprocessing on tobacco stems, conducting microwave expansion on tobacco stems, humidifying and storing tobacco stems, heating and humidifying tobacco stems, pre-pressing tobacco stems, conducting secondary stem pressing, conducting ternary stem pressing, feeding stems, shredding stems, shaping and drying stem shreds, and perfuming and storing stem shreds. The technology has the advantages that the quality consistency of stem shreds is good, the physical property of stem shreds is closer to that of leaf shreds, organoleptic quality and padding value are high, the uniformity, stability and blending ratio of stem shreds blended with leaf shreds are improved, cigarette quality is improved, the application range and utilization rate of stem shreds in cigarettes are increased, and tar reduction, harm reduction, cost reduction and benefit increasing are realized.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Process for processing filament-shaped stem and strip-shaped stem simultaneously

ActiveCN103960769AQuality improvementImprove quality uniformityTobacco preparationTobacco treatmentMicrowaveBiology

Provided is a process for processing a filament-shaped stem and a strip-shaped stem simultaneously. The process is characterized in that the first step of tobacco stem expansion, the second step of tobacco stem storage, the third step of tobacco stem separation and the fourth step of tobacco stem classification processing are included; in the first step of tobacco stem expansion, fed tobacco stems are expanded in a stem explosion mode or a microwave mode; in the second step of tobacco stem storage, the expanded tobacco stems are stored for 5 days to two years, so that the tobacco stems are structurally solidified; in the third step of tobacco stem separation, two types of the expanded tobacco stems obviously different in size are separated through tobacco stem separation equipment, one type of tobacco stem is thin expanded tobacco stems, the width or the diameter of each tobacco stem is smaller than 5 mm, and the other type of tobacco stem is thick expanded tobacco stems, and the width or diameter of each tobacco stem is larger than 5 mm; in the fourth step of tobacco stem classification processing, according to the characteristics of the thin expanded tobacco stems and the characteristics of the thick expanded tobacco stems, classification processing is carried out in the corresponding processing process, the thin expanded tobacco stems are processed to be filament-shaped stems and the thick expanded tobacco stems are processed to be strip-shaped stems.

Owner:CHINA TOBACCO HENAN IND

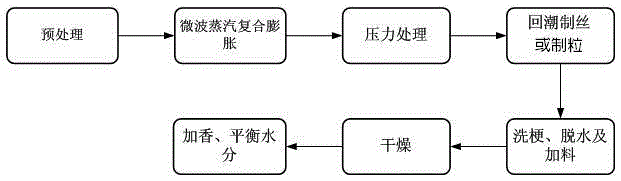

Preparation process of expanded stem products by microwave

InactiveCN105105313AAvoid surface scorchingPrevent microwave ignitionTobacco treatmentTobacco productManufacturing engineering

The invention provides a preparation process of expanded stem products and belongs to the technical field of tobaccos. The preparation process comprises the following steps of: removing impurities such as metal, hemp ropes, stem heads and stem picks in tobacco stems; expanding the tobacco stems by microwave and steam; conveying the expanded tobacco stems into a pressure container to carry out pressure treatment; carrying out moisture regaining on the tobacco stems after pressure treatment and preparing into a certain product form; adopting a soaking mode to wash the stems, then dewatering by a physical mode till the water content is below 70%, and then adding additive feed liquid extracted from the tobaccos; adopting the traditional equipment in the tobacco industry to dry the stem products added with the feed liquid till the water content is 11 to 12%, adopting a flavoring machine to carry out flavoring treatment on the dried stem products, and balancing the water content to 11 to 12%. The preparation process provided by the invention has the advantages that the whole process is simple, the energy consumption is low, the quality of the expanded stem products obtained is close to that of the shredded tobacco product, the filling value is high, and large-scale adding can be achieved, so that the expanded stem product is an excellent tobacco additive.

Owner:周川

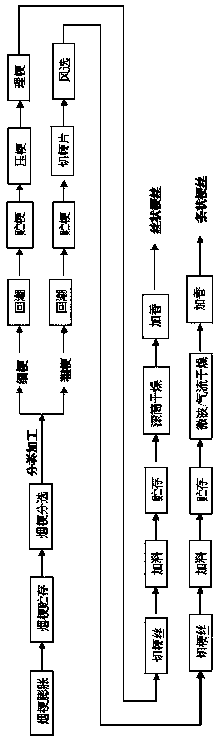

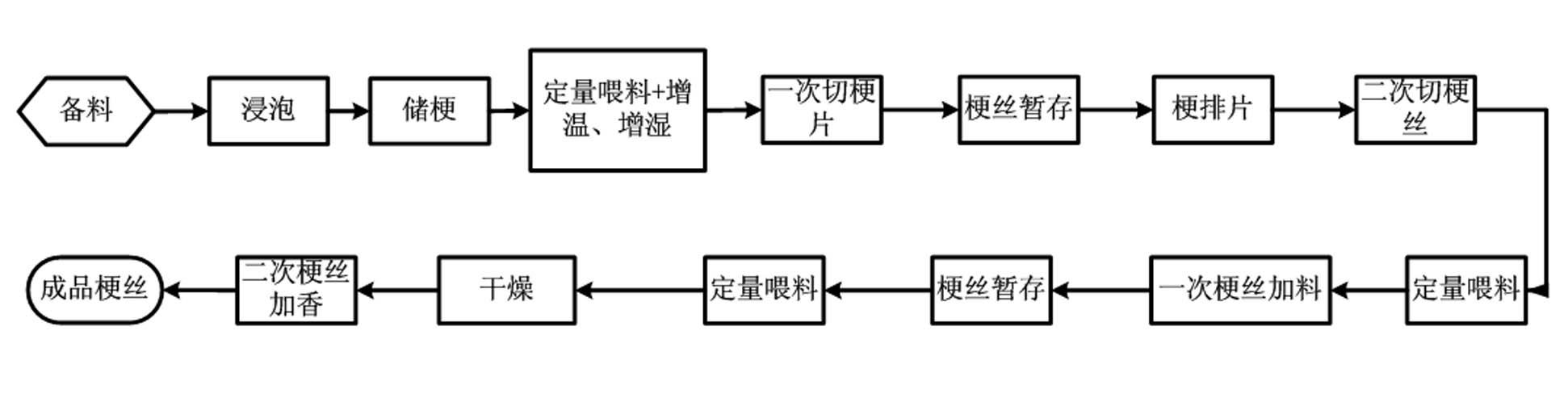

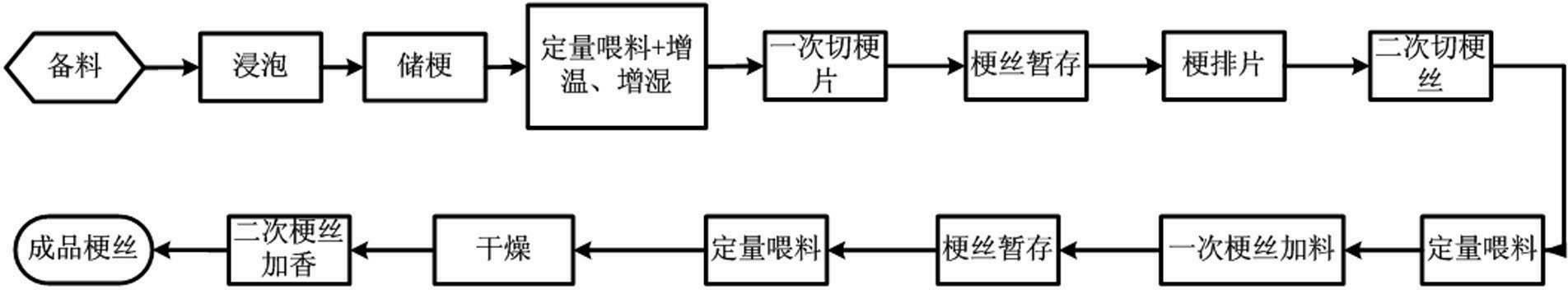

Technology for treating expanded stems

The invention discloses a technology for treating expanded stems, belongs to the technical field of shred making of tobacco, and in particular relates to the technical field of shred making with tobacco stems. The technology comprises the following steps of: soaking the tobacco stems, storing the stems, quantitatively feeding, heating and humidifying, slicing the stems for the first time, temporarily storing the stem slices, discharging the stem slices, cutting the stems into shreds for the second time, quantitatively feeding, adding the primary stem shreds, storing the stem shreds, quantitatively feeding, drying, and performing secondary flavoring, thus obtaining a stem shred finished product. The obtained product has the advantages of good bulkiness, low breaking rate, low production cost, pure aroma, high filling value, light wood mixed gas, comfortable mouthfeel, soft smoke, capability of reducing tar of cigarettes and good compatibility with the tobacco shreds.

Owner:HONGTA TOBACCO GRP

Supercritical expansion processing method for drying cigarette

ActiveCN101406317AIncrease fill valueReduce formulation costsTobacco preparationTobacco treatmentTarTobacco product

The invention discloses a method for processing supercritical expansion of cigarettes dried in the air, which comprises the following steps: a. tobacco leaves are loosened and humidified to increase the water ratio and the temperature of the tobacco leaves so that the tobacco leaves are loosened and the moisture content is even, materials are added to humidify the tobacco leaves; b. the tobacco leaves are cut into leaf threads; c. the leaf threads are stored; d. the leaf threads are put into a dipping mangle to be dipped for 20 to 60 seconds; e. the loosening, storage and feeding are performed; f. the leaf threads are expanded; g. the cooling, resurgence and perfuming processes are performed; and h. the foreign matters in the expanded leaf threads are removed. The method can apparently reduce the tar content, meet the style feature of cured tobacco products, and increase the dried tobacco filing value, thereby reducing the usage amount of finished products of tobacco shreds, and reducing the formulation cost; moreover, the method sufficiently adopts the function of expanded tobacco shreds on the specific incense and the form of smoke gas; and the formulation structure has relatively high adjustability, thereby effectively adjusting indexes such as the incense, concentration, taste, comfort and the form of smoke gas, and improving the formulation usability.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Low-temperature Microwave Vacuum Drying Technology of Shredded Tobacco

The invention relates to a low-temperature microwave vacuum drying process for tobacco shreds and belongs to the field of processing of the tobacco shreds. The process comprises the following step of: after carrying out moisture regaining, moisture balancing and low-temperature treatment on the tobacco shreds, feeding the tobacco shreds into vacuum drying equipment to be dried so as to obtain tobacco shred finished products with the moisture content of 11.5 percent to 13.5 percent. The drying process is carried out under the conditions of a vacuum pressure of 200Pa to 30kPa, a temperature of 0 DEG C to 70 DEG C and higher moisture content of 30 percent to 70 percent of the tobacco shreds, so that not only color, aroma and taste of the tobacco shreds are maintained, but also a certain filling value is improved. Moreover, the low-temperature microwave vacuum drying process for the tobacco shreds has low tobacco damage ratio and processing resistance performance. Odor and foreign flavor are obviously decreased.

Owner:康琪

Method for preparing burley tobacco stems into stem particles or strip-shaped stem threads

InactiveCN102972859AGreat tasteNo pollution in the processTobacco preparationTobacco treatmentPectinaseCellulase

A method for preparing burley tobacco stems into stem particles or strip-shaped stem threads comprises the following steps: taking burley tobacco stems and placing the burley tobacco stems in a storage cabinet; adding one or more expansion mediums of 5-10 % of anhydrous alcohol, 2-5 % of ligninase, 2-4 % of pectinase and 2-5 % of cellulase according to the weight percentage of the burley tobacco stems to the burley tobacco stems; and / or adding one or more flavor absorbing treatment materials of 0.5-1.5 % of plum extract, 0.5-1.5 % of red date extract, 0.5-1.5 % of citric acid and 1-2 % of glycerol to the burley tobacco stems; carrying out osmotic equilibrium on the burley tobacco stems for 4-48 hours; setting the temperature in the storage cabinet at 25-40 DEG C and relative humidity in the storage cabinet at 30-60 %; then carrying out expansion treatment on the burley tobacco stems; adding water to the burley tobacco stems to dampen the burley tobacco stems until the water content is 20-35 %; then preparing the burley tobacco stems into stem particles or cutting the burley tobacco stems into strip-shaped stem threads; and finally, after drying and shaping the stem particles or the strip-shaped stem threads, screening the stem particles or the strip-shaped stem threads, wherein the screened stem particles with particle sizes of 1-3.3 mm or the screened strip-shaped stem threads with widths of 0.9 mm are used as standard materials. According to the invention, the flavors of the tobacco stems can be further improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Cigarette of mixing haulm of fennel and tobacco leaves, and preparation method

ActiveCN101049183AKeep the tasteRemove miscellaneous gasTobacco preparationTobacco treatmentFlavorTar

A cigarette with low tar is prepared from the mixture of fennel's stem and leaf and tobacco shreds through mashing the stems and leaves of fennel, pulping, adding phosphoric acid, citric acid and sodium benzoate, heating, cooling, drying, making sheets, slitting to become shreds, proportionally mixing with tobacco shreds and perfume, and conventionally preparing cigarettes.

Owner:熊锦元 +1

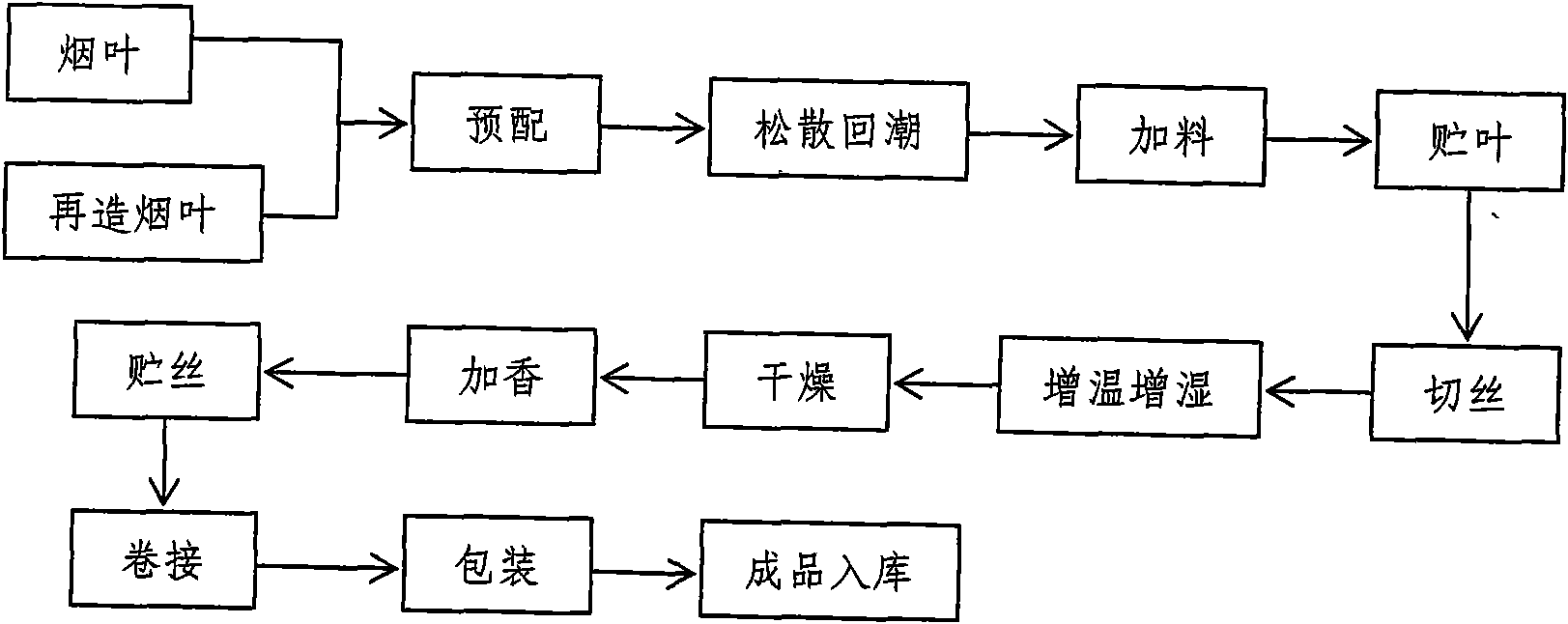

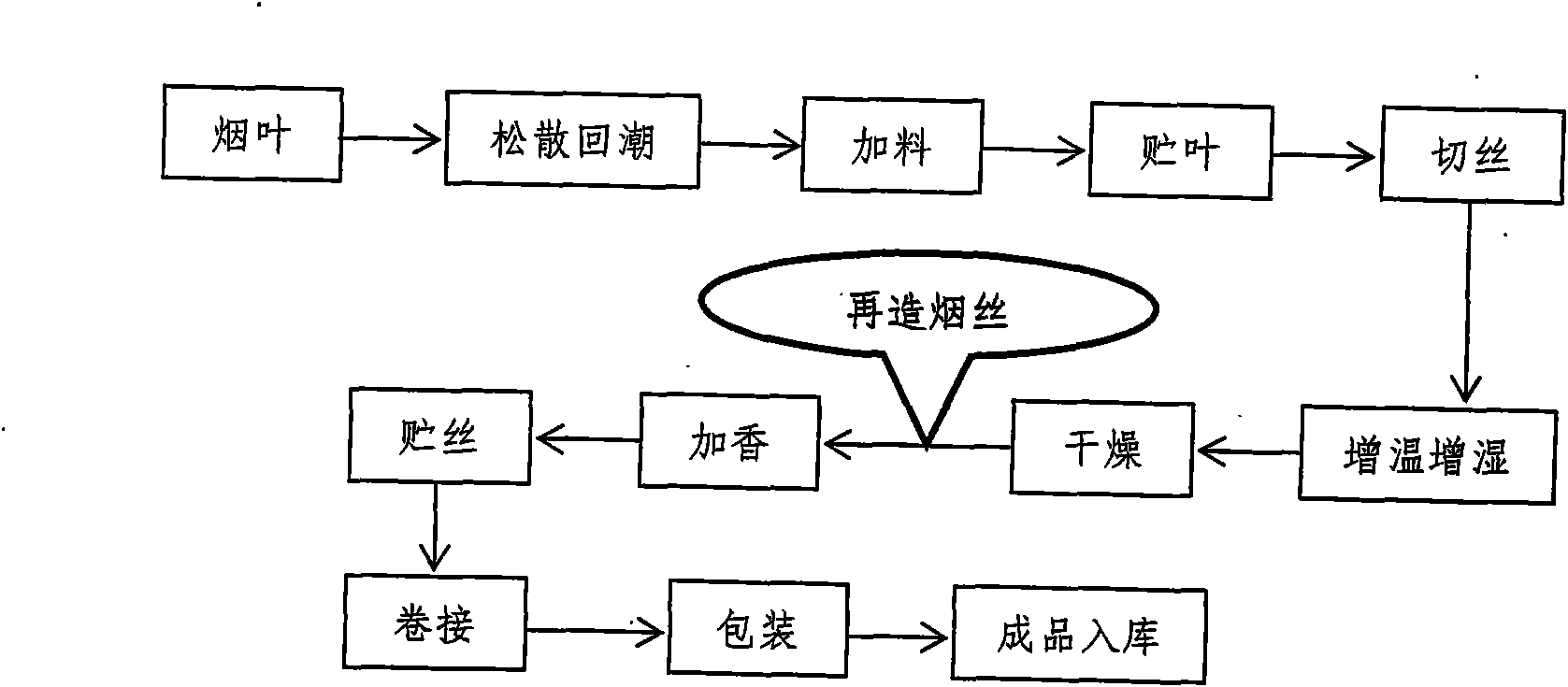

Use method of reconstituted tobacco in production of cigarettes

InactiveCN101669671AEnhanced Blending PerformanceImprove mixing uniformityTobacco preparationTobacco treatmentCartonEngineering

The invention discloses a use method of reconstituted tobacco in production of cigarettes. Firstly, the reconstituted tobacco is cut into threads of the same specification with tobacco threads to be blended for standby; then the standby threads are blended with the tobacco threads after drying process of cigarettes and before aromatic adding process; and finally cigarette making and packaging arecarried out according to normal production process flow of cigarettes. The use method effectively solves the inherent problems of the prior art such as winding, clotting and the like, improves the filling value of finished tobacco threads and reduces the thread consumption amount per carton for cigarette enterprises. The blending performance of the obtained reconstituted tobacco threads is enhanced, the mixing uniformity of the reconstituted tobacco is improved when blending cigarettes and the quality of cigarettes is stabilized and improved. By making the reconstituted tobaccos into the reconstituted tobacco threads to be provided for cigarette enterprises, the use method improves the flexibility when the enterprises develop cigarettes and enhances the controllability of reconstituted tobaccos.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

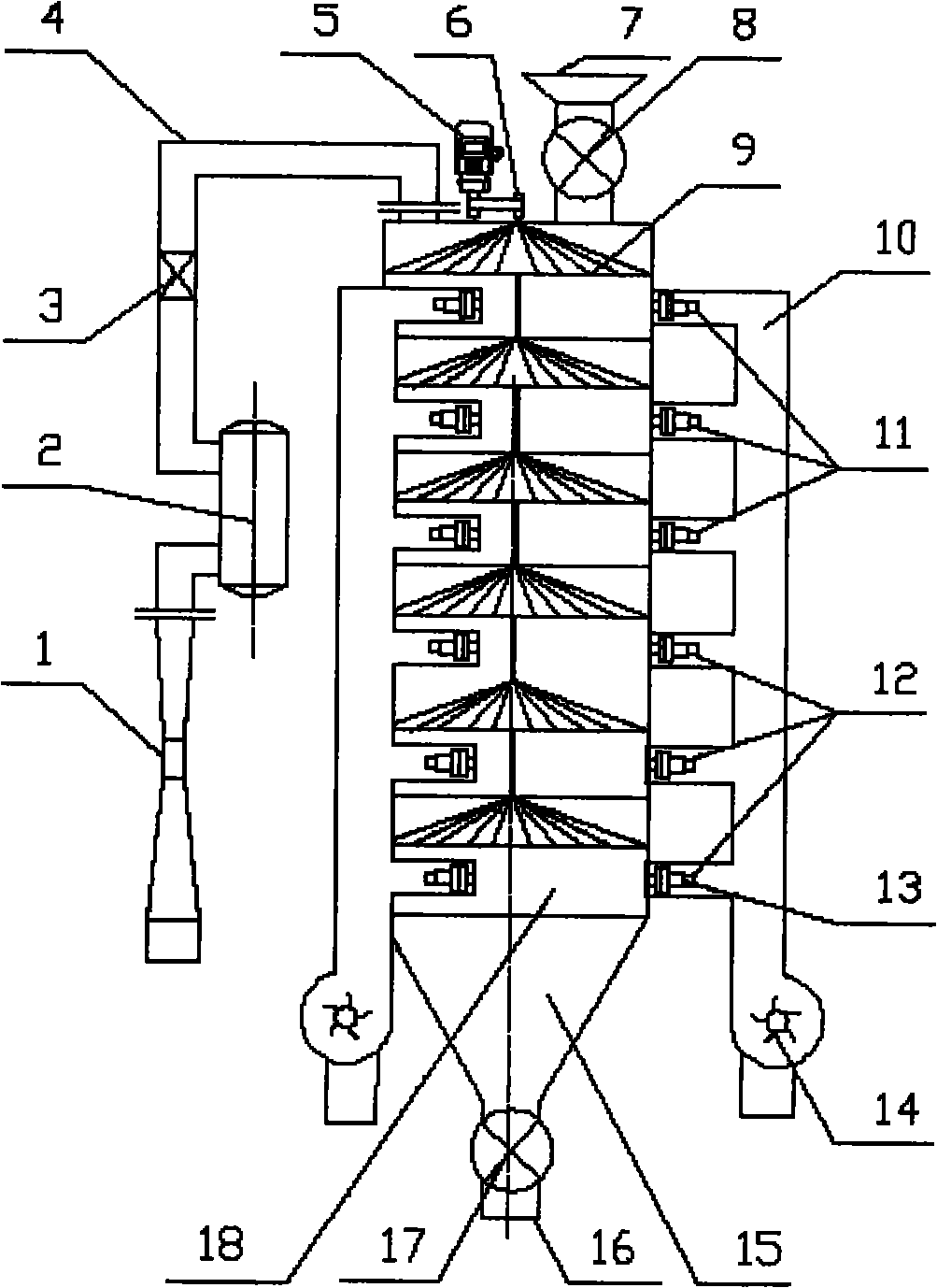

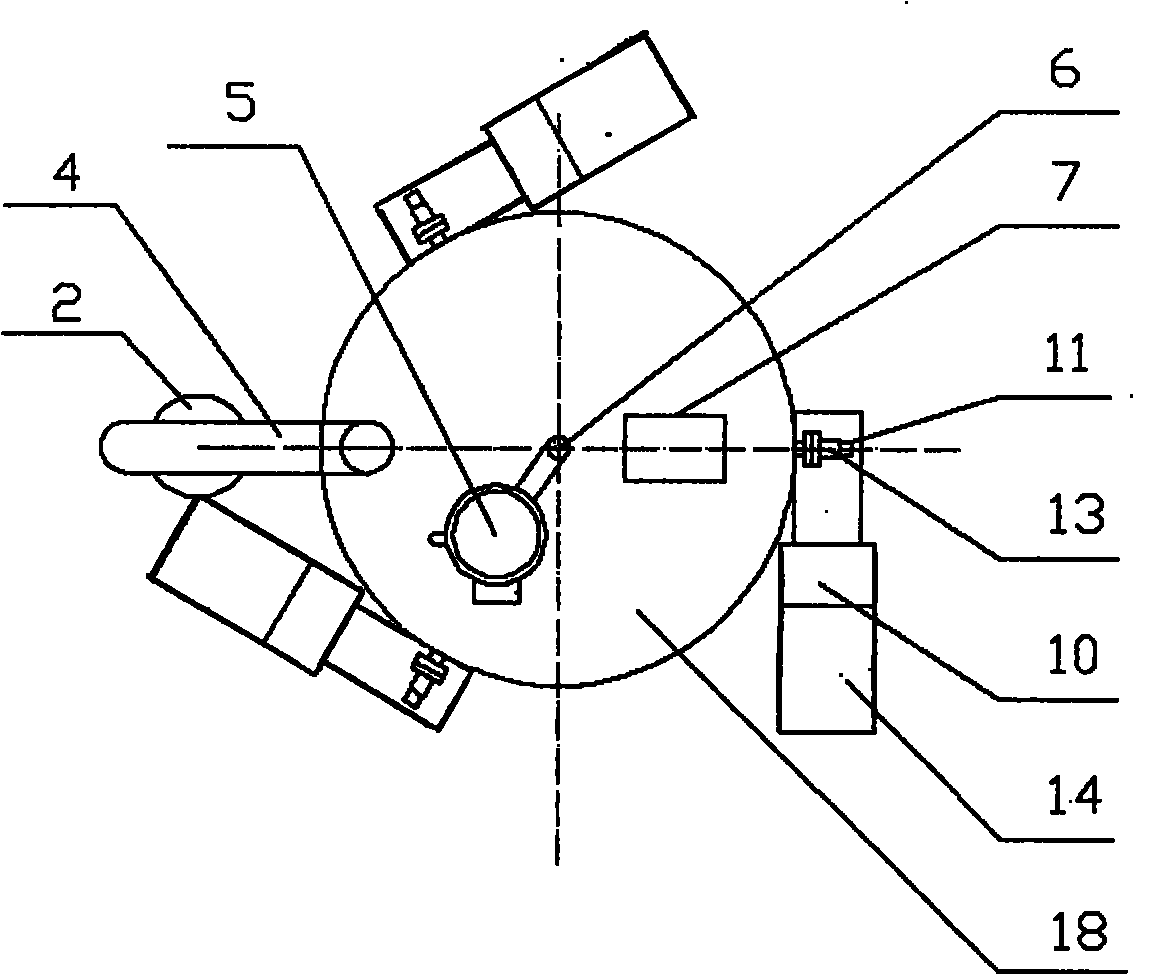

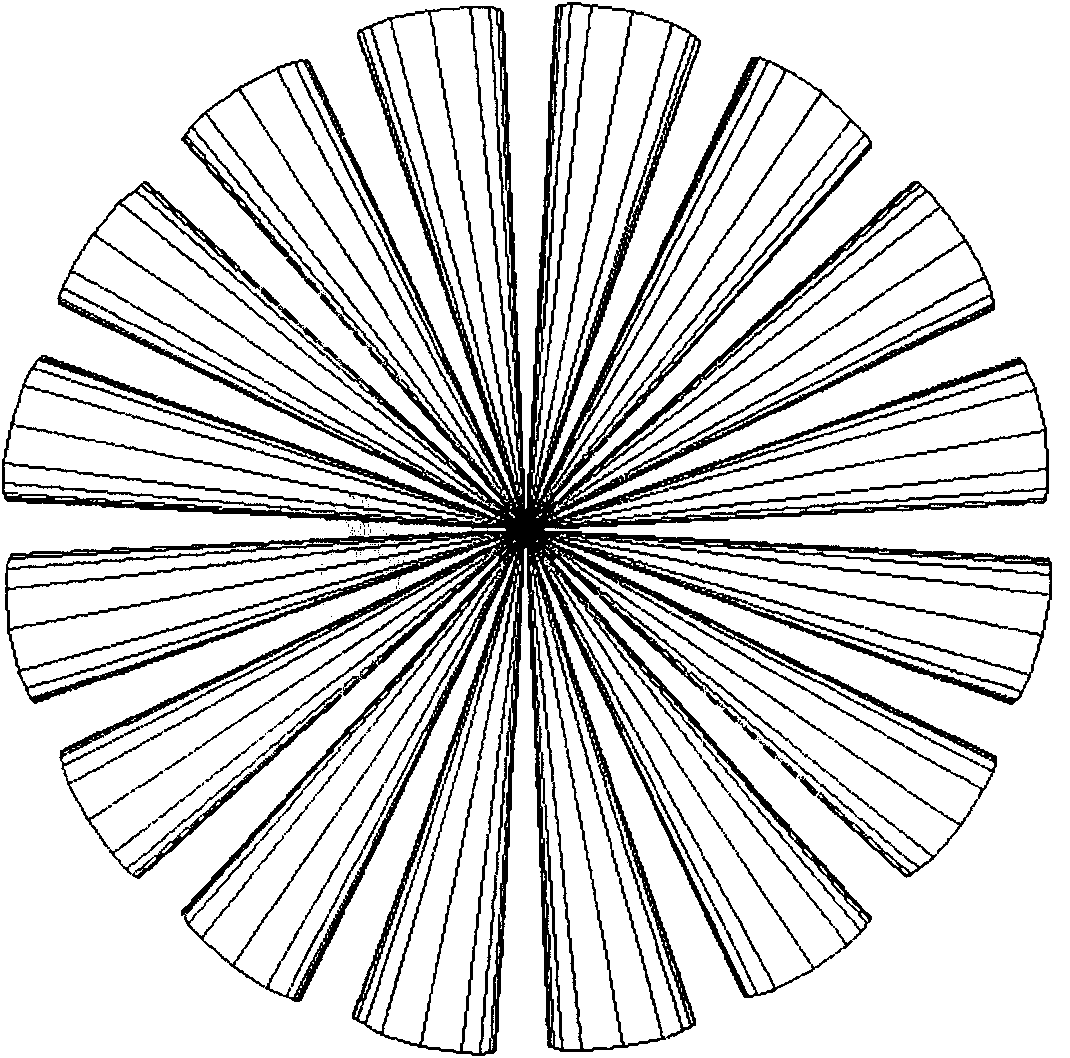

Cut leaf tobacco microwave vacuum drying equipment

ActiveCN101822415AImprove sensory qualityKeep the aromaTobacco preparationVacuum pumpingElectric machinery

Cut leaf tobacco microwave vacuum drying equipment is characterized by comprising a vertical cylinder-shaped drying cavity, a vacuum-pumping system communicated with the drying cavity, and a microwave heating system, wherein the top part and the bottom part of the drying cavity are respectively provided with a feed port and a discharge port, the drying cavity is internally provided with a material dispersion mechanism, the material dispersion mechanism comprises a spindle arranged on the axle center of the drying cavity, and multi-layer material dispersion plates arranged on the spindle, the spindle is driven to rotate by a motor, the microwave heating system is divided into a continuous microwave heating unit arranged on the upper part of the drying cavity and a pulsed microwave heating unit arranged on the lower part of the drying cavity, and the two heating units can respectively hierarchically arranged in multi groups along the shell of the drying cavity. Compared with the prior art, the invention has the advantages that the cut leaf tobacco microwave vacuum drying equipment can carry out the microwave drying in stages to the cut leaf tobacco under the a vacuum status, reduces the drying temperature of the cut leaf tobacco, keeps the fragrant of the cut leaf tobacco, improves the aesthetic quality of the cut leaf tobacco, at the same time, can realize the rapid dehydration and drying of the cut leaf tobacco, and improves the filling value of the cut leaf tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Cut tobacco fast puffing and drying process

InactiveCN1436495AReduce green miscellaneous gasHigh expansion rateTobacco preparationTarLower grade

The present invention relates to the tobacco processing process and is especially the puffing and drying process of cut tobacco. The tobacco process includes feeding material, heating cut tobacco, puffing and discharge. The beneficial effects of the present invention includes reserving tobacco fragrance in cut tobacco, reducing the green and sundry smell in cut tobacco, converting the color of low-grade cut tobacco, raising the puffing rate of cut tobacco, reducing cost of cigarette, raising filled tobacco amount, decreasing tar content in cigarette, making cut tobacco soft, loose elastic and no oxidation and browning, killing bacteria and other toxic microbes and producing no environmental pollution.

Owner:江苏智思机械制造有限公司

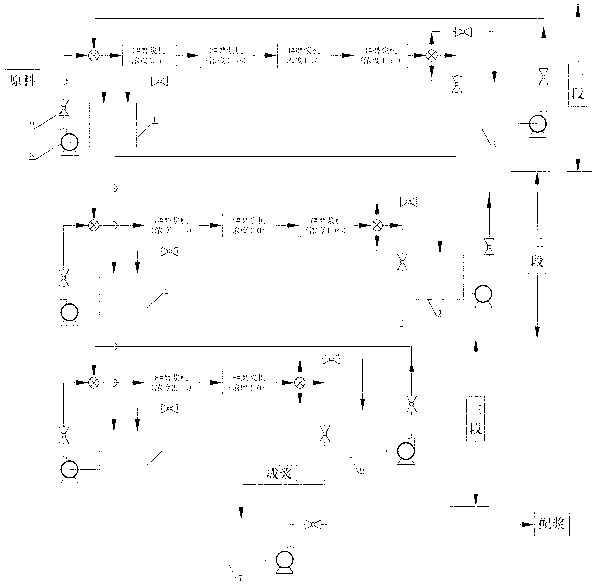

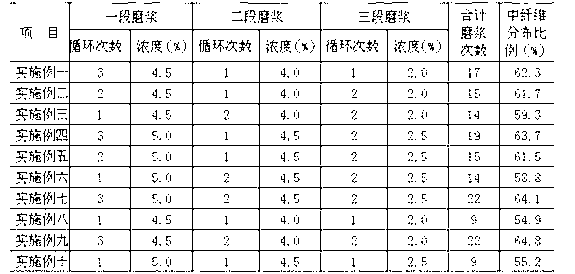

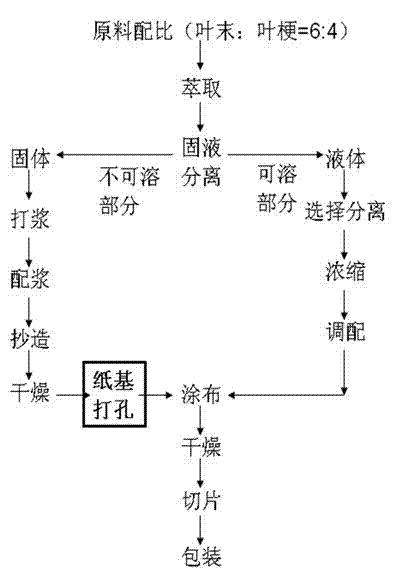

Papermaking tobacco sheet pulp grinding process

The invention discloses a papermaking tobacco sheet pulp grinding process. Specifically speaking, under the light beating condition, three-stage light beating flexible pulp grinding is adopted, each stage needs at least two pulp grinding machines, pulp concentration is decreased gradually, and size circulation process is controlled. In prepared size, fibers with the length of 0.5-1.25mm reach more than 63%, bulk degrees of base tabs reach 2.8-3.0cm <3> / g, spreading rates, filling values, burning velocity of finished sheets are improved greatly, tar contents and carbon oxide contents are reduced greatly, and the bulk degrees of the finished sheets reach 2.3-2.5cm<3> / g. The number of pulp grinding machines arranged in the first stage, the second stage and the third stage in a serial connection mode is respectively 4, 3 and 2. The pulp grinding concentration in the first stage, the second stage and the third stage are respectively set to be 4.5-5.0%, 4.0-4.5% and 2.0-2.5%. Times of self-circulation of the size in the first stage, the second stage and the third stage are respectively 1-3 times, 1-2 times and 1-2 times. The times for which mixed size prepared in different components passes through the pulp grinding machines in the whole process are 9-22 times actually, and all nine pulp grinding machines allow constant power regulation independently.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

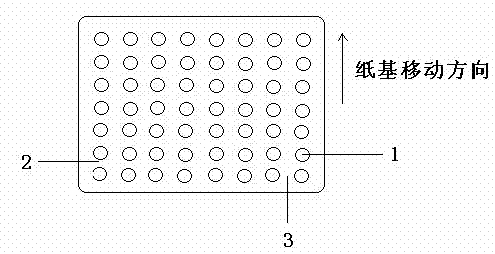

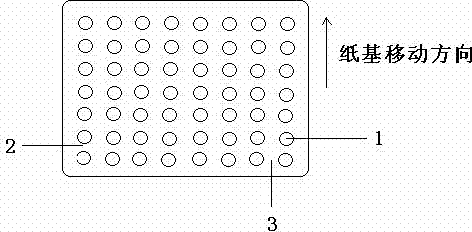

A kind of reconstituted tobacco leaf and its preparation method and application

The invention discloses a reconstituted tobacco leaf and a preparation method and application thereof. The reconstituted tobacco leaf is prepared by a papermaking method; a paper base formed by using pulp is perforated and then coated with a coating solution; and in the paper base, the aperture is 0.4 to 0.8 millimeter, the hole pitch is 1.0 to 3.0 millimeters, and the hole row pitch is 1.5 to 2.0 millimeters. The structure of the paper base is optimized, and perforation design is adopted, so that the contact area of the paper base and the coating solution is increased; and the coating solution is easily penetrated into the paper base, so that the absorption performance of the paper base on the coating solution is remarkably improved, the coating rate is finally remarkably improved, full bearing of soluble components and aroma components of the reconstituted tobacco leaf is ensured, the sensory quality is greatly improved, aroma quality and impurity gas are obviously improved, and the quality of the reconstituted tobacco leaf is integrally improved.

Owner:CHINA TOBACCO GUANGDONG IND

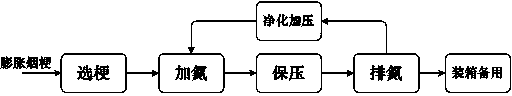

Treatment process for expanded tobacco stems

The invention relates to a treatment process for expanded tobacco stems, and belongs to the technical field of main material and auxiliary material processing in the tobacco industry. The microwave expanded tobacco stems are classified according to the thickness and / or the length, the expanded tobacco stems are placed into a pressure vessel, nitrogen with the purity being larger than 78% is connected into the pressure vessel, the tobacco stems and the nitrogen are evenly mixed, the pressure in the vessel is normal pressure to 8 MPa, the pressure is kept for 10 seconds to 40 minutes, the nitrogen in the pressure vessel is exhausted, the nitrogen can be recycled after purification and compressing treatment, the expanded tobacco stems after treatment are taken out, and the expanded tobacco stems are boxed or bagged in a classified mode for standby application; or moisture regain is conducted directly, so that products such as stem shreds, stem strip shreds and stem particles are manufactured. The microwave expanded tobacco stems treated through the process do not need to be stored any more, wooden odors and offensive odors in the tobacco stems are reduced, the tobacco stems cannot retract after moisture regain, and good elasticity and processing resistance are achieved. By means of the treatment process for the expanded tobacco stems, the requirement for the conditions such as warehouse space, manpower and logistics in the storage link is met, and therefore enterprise cost is greatly lowered.

Owner:姚波

Method for treating tobacco stem

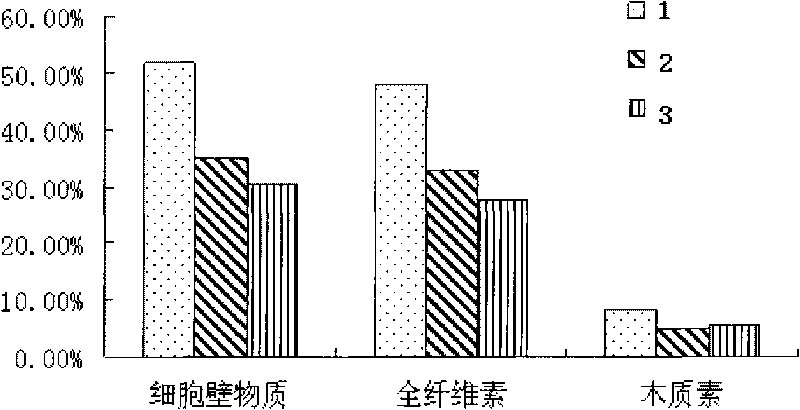

The invention relates to the field of tobacco, and more particularly relates to a method for treating tobacco stem, comprising the steps of: soaking the tobacco stem into the mixed solution of NH3.H2O and H2O2; filtering and washing filter residue; and roasting the washed filter residue. The invention also provides the best technical condition for the treatment of the tobacco stem: the tobacco stem is soaked into the mixed solution of 1.5% of NH3.H2O and 1.0% of H2O2 for 1h at 60 DEG C; and the ratio between liquid and material is 1:10. Compared with the untreated tobacco stem, the treated tobacco stem respectively reduces the content of cell wall material, lignin and total nitrogen by 12.71%, 2.14% and 1.24%; the filling quantity is increased, and impurity gas is reduced by sensory smoking; therefore, the method not only can increase the filling quantity of the tobacco stem, but also obviously reduces the content of lingo-cellulose the smell of lignin of the tobacco stem and improves the using value thereof, thus having industrial application prospect.

Owner:CHINA TOBACCO GUANGDONG IND

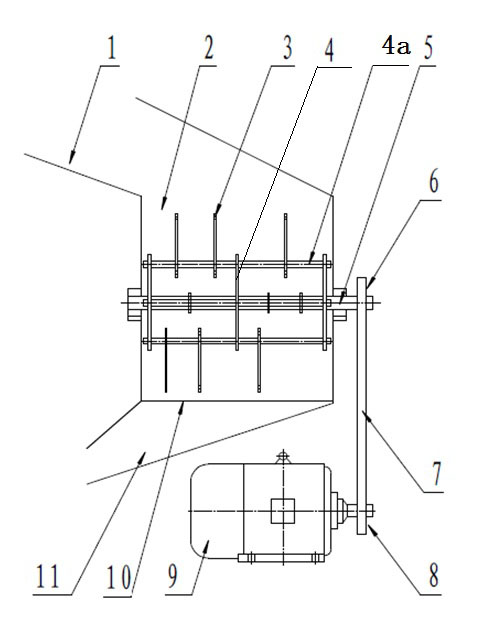

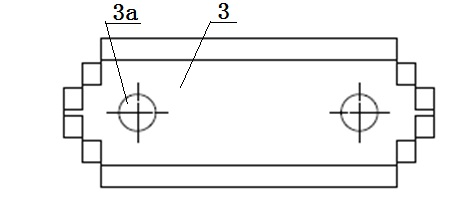

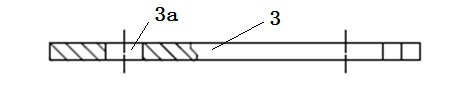

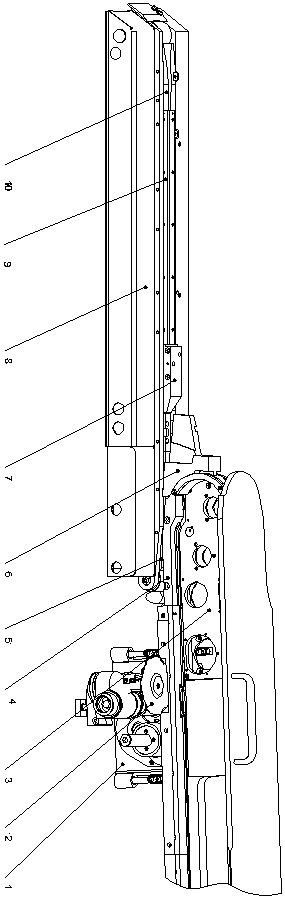

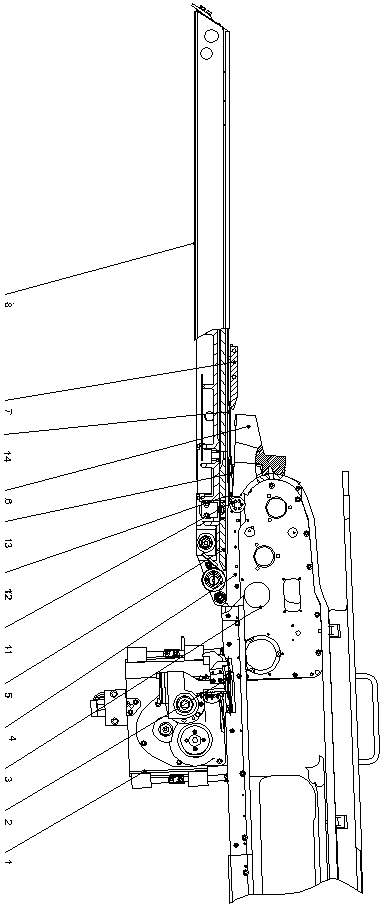

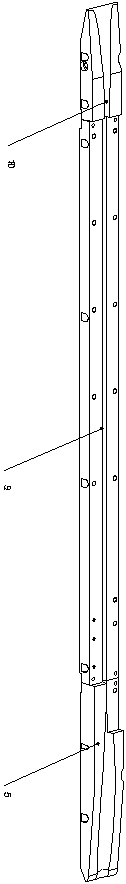

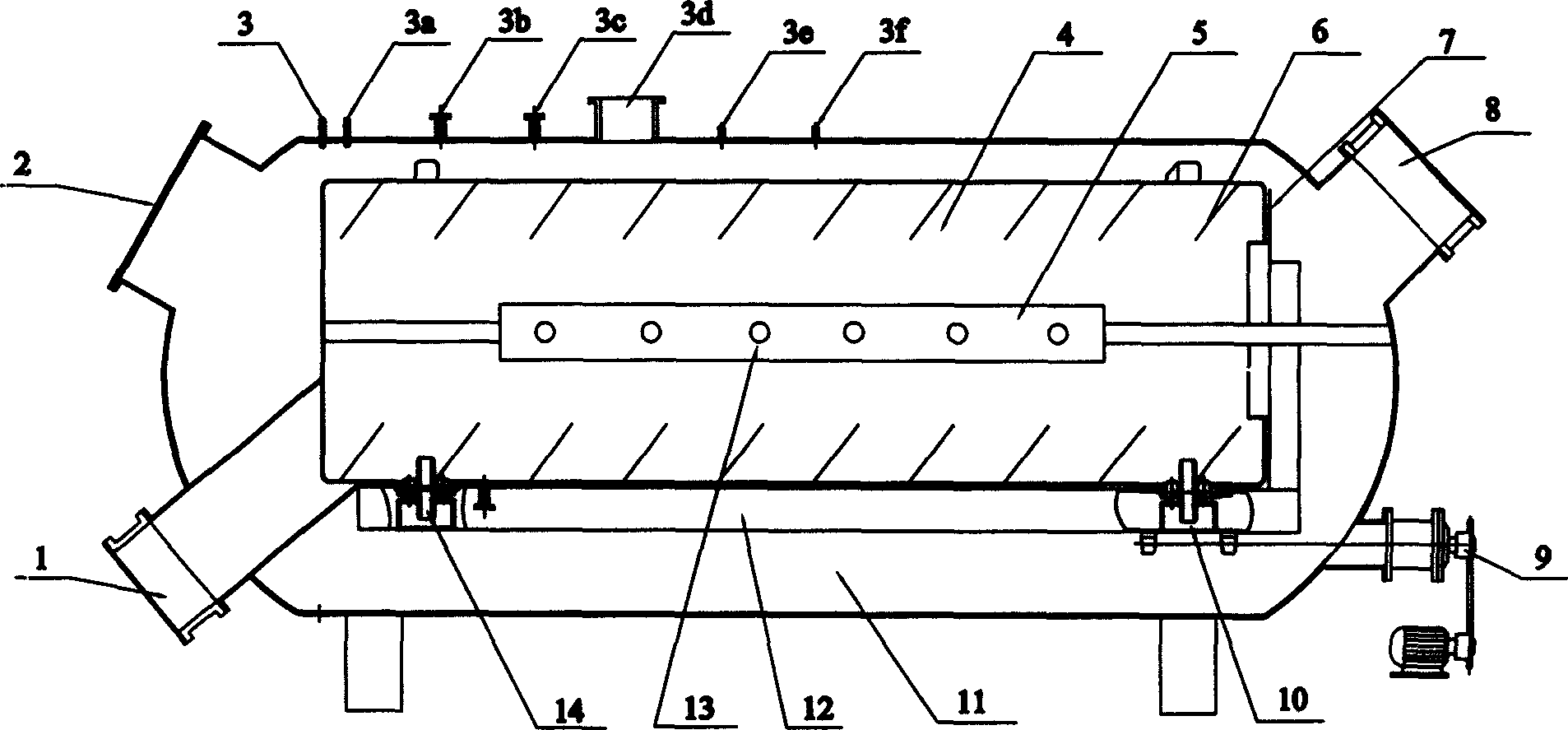

Hammer type shearing granulator

A hammer type shearing granulator comprises a granulating cabin (2) provided with a feeding port (1) and a discharging port (11), a blade support (4) and shearing blades (3) installed on the blade support, wherein the blade support (4) is installed in the granulating cabin and can rotate around a horizontal central shaft (5). The outer end of the central shaft of the blade support is connected with a power transmission device. The blade support is of a transversely arranged cylindrical-cage-shaped structure, cylindrical-cage-shaped strips (4a) are evenly distributed on the outer circumferential face of the blade support, each blade is of a structure with a single side or double sides provided with edges, installation holes (3a) capable of being freely sleeved on the cage strips (4a) are arranged at one ends or two ends of the blades, at least two blades are evenly installed on each cage strip, the blades on two adjacent cage strips are arranged in staggered mode, and a screen net (10) is arranged at the position of the discharging port of the granulating cabin. Expansion tobacco stalk granulation is performed by means of the hammer type shearing granulator, particle shape of ternary porous particles of expansion tobacco stalk is changed, production yield is improved, a product filling value is improved, and service life of the blades is prolonged.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

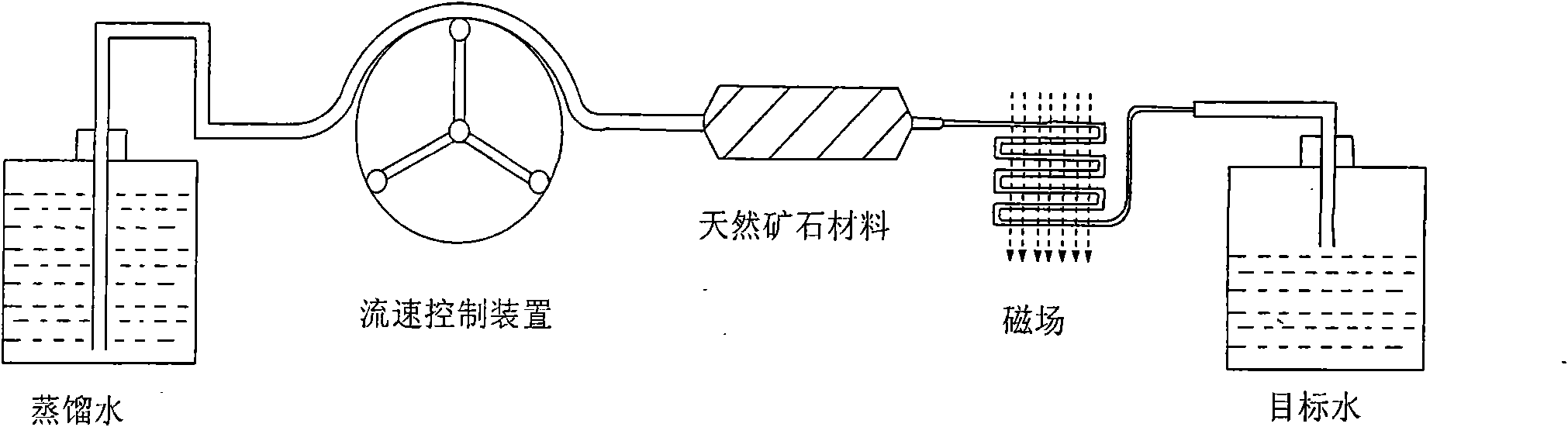

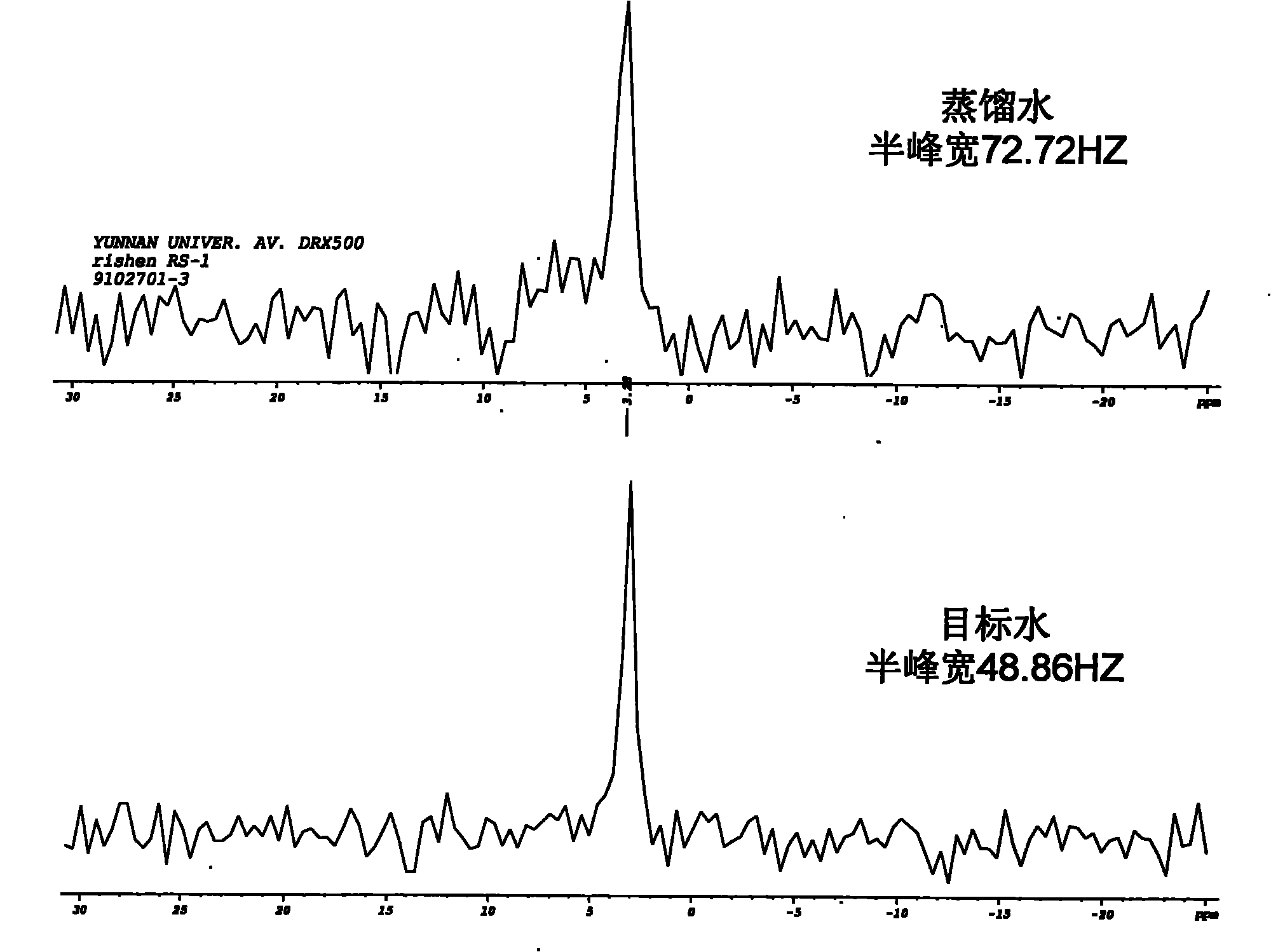

Characteristic water for improving flavor quality of cigarette and application thereof

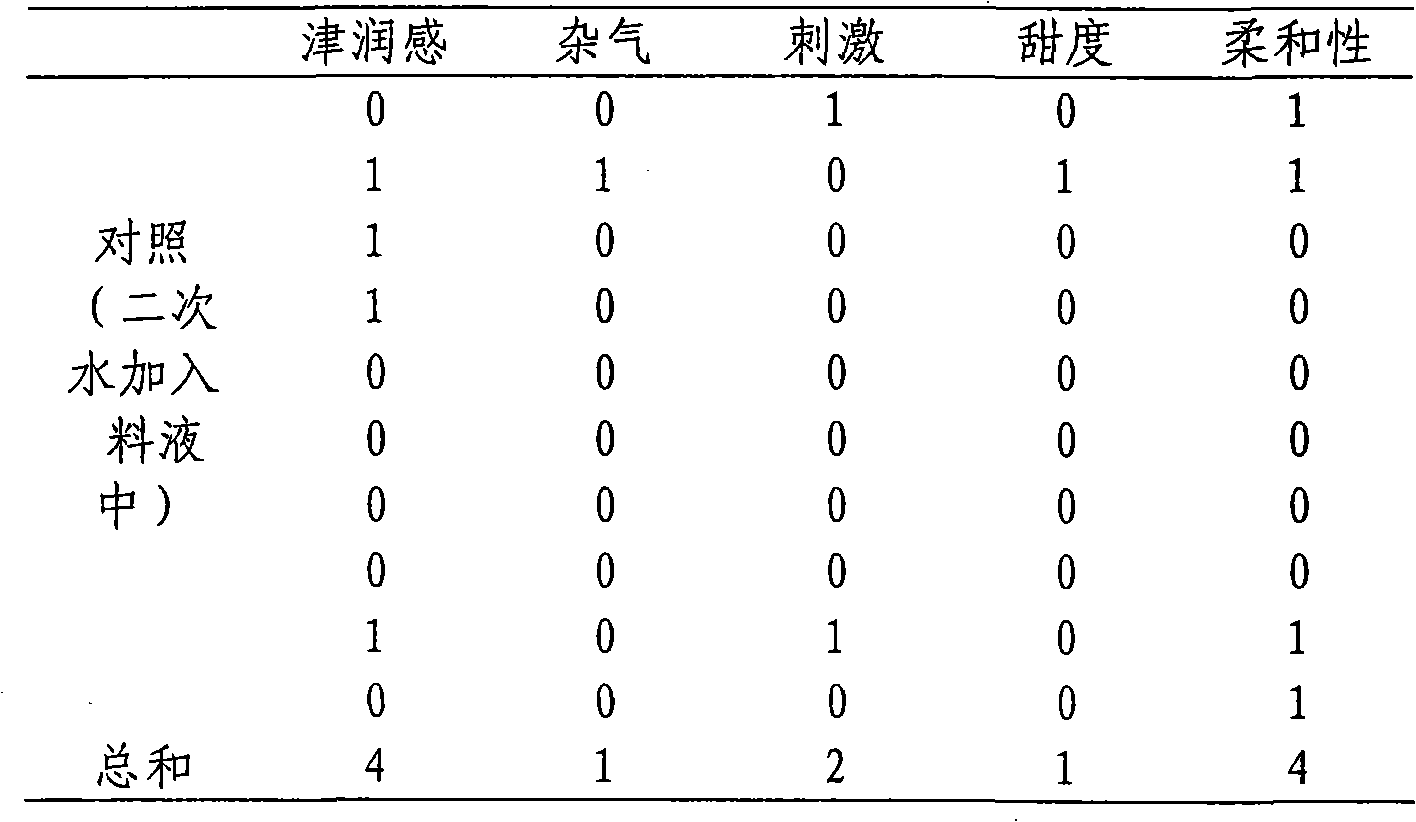

ActiveCN101863582AImprove suction qualityHigh in trace elementsMultistage water/sewage treatmentDistilled waterSweetness

The invention discloses characteristic water for improving flavor quality of cigarette and an application thereof. Pure water is controlled to flow by a natural mineral filling column with the flow speed of 350 to 380 ml / min and then to flow by a magnetic field, the strength of the magnetic field is 9000 to 9500 Gs, the acting time of the water in the magnetic field is more than or equal to 15 min, so the water with the pH value of 9 to 9.5, i.e. the characteristic water is obtained. When blending the perfume of the cigarette, the characteristic water is adopted as solvent or thinner to substitute the conventional pure water, primary distilled water or the second distilled water, so on the premise that the characteristic of the fragrance is not influenced, the stimulation is reduced, the sweetness and the moisture of the smoke can be improved. The tourmaline ceramic ball which is doped with other mineral ceramic ball is innovatively utilized to process the water, and then stabilization treatment on the water is performed by the magnetic field, so a new thought for improving the smoking quality of the cigarette is provided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for increasing production quality stability of thin cigarettes

ActiveCN108323788ASimple structureImprove stabilityTobacco preparationTobacco treatmentCombustionHazardous substance

The invention relates to a method for increasing the production quality stability of thin cigarettes and belongs to the technical field of cigarette production. The method includes: selecting tobaccocutting width, selecting drying intensity and moisture, purifying cut tobacco, optimizing tobacco structures, reasonably screening and selecting, selecting the type of a cigarette making machine, improving the cigarette making machine, and optimizing the parameters of the cigarette making machine. Compared with the prior art, the method has the advantages that the weight standard deviation of thethin cigarettes produced by the method is lowered from 13mg to 11mg, and the smoking resistance standard deviation of the thin cigarettes is lowered from original 90pa to 40pa; the produced cigarettesare low in main stream smoke tar content and CO content, sufficient combustion is achieved due to the fact that the looseness and filling value of the cut tobacco are increased, few harmful substances are generated during smoking, and low tar and CO generation quantity is achieved; the sensory quality of the produced cigarettes is improved the cigarettes are low in smoking resistance due to the fact that the looseness and filling value of the cut tobacco are increased, and the cigarettes are full and penetrating in aroma and high in smoke concentration.

Owner:CHINA TOBACCO HENAN IND +1

Process for treating cut stems of tobacco leaves

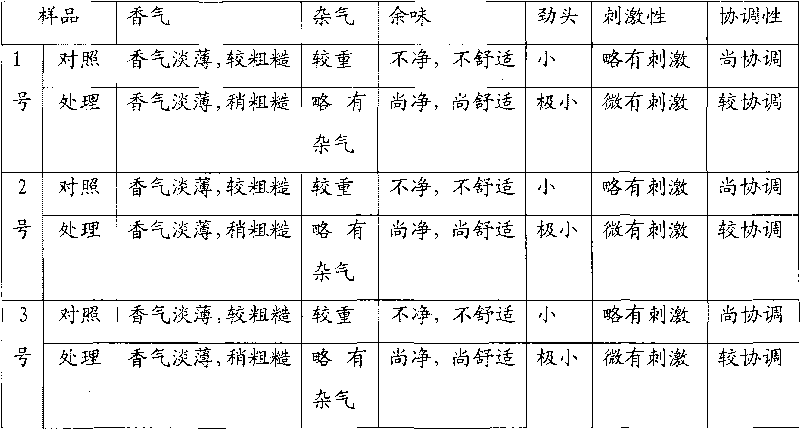

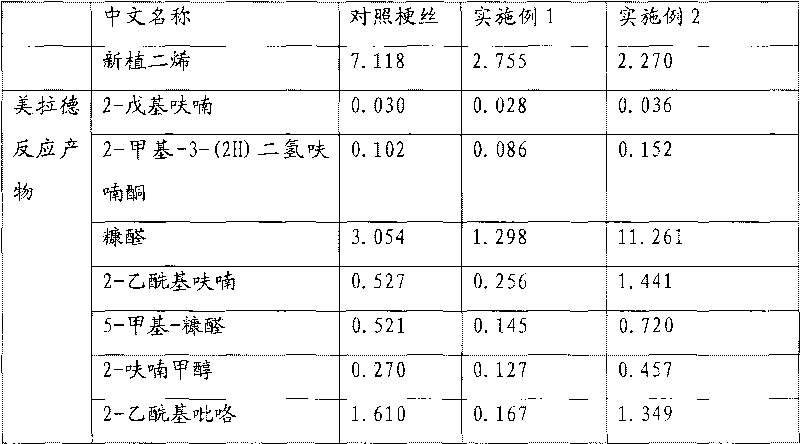

The invention relates to the field of tobacco, in particular to a method for treating cut stems of tobacco leaves. The method comprises the steps of reducing the content of cell wall substances through H2O2 and ammonia, improving the reactivity of the cut stems with an enzyme, further utilizing the compound enzyme for catalytic degradation of proteins, starch, cellulose and other macromolecules, generating an aroma precursor, sugar and amino acids and further generating aroma substances by further decomposition. The adoption of the method for treating the cut stems can improve the filling value by 27.6%, improve the sugar / nicotine ratio by 49.5% and reduce the content of the cell wall substances by 42.3%, and the analysis of main aroma components shows that the total content of the aroma components is improved by 25.7%, wherein the content of Maillard reaction products is improved by 140.5%, and the content of carotenoid degradation products is improved by 115.6%. The sensory evaluation shows that the effects of reducing wood flavor, reducing irritation, increasing aroma quantity and leading the smoke to be coordinated and thicker can be realized after the treatment of the cut stems of the tobacco leaves by using the method, indicating that the method has good application prospect in the tobacco industry.

Owner:CHINA TOBACCO GUANGDONG IND

Equipment for processing tobacco leaves

InactiveCN1559312AImprove physical shapeImprove combustion effectTobacco preparationEngineeringTobacco leaf

A tobacco leaves processing apparatus for removing free nicotine, odor and stimulating substance from tobacco leaves iscomposed of a cylindrical body with drum, supporting frame and spray tube in it. Said drum is supported by the rollers on said supporting frame and is rotating on the rollers under the action of external driver. The liquid additive is sprayed onto the tobacco leaves via said spray tube.

Owner:于开平 +3

Method for increasing retention rate of calcium carbonate in paper-making reconstituted tobacco

InactiveCN104957755AImprove retentionImprove bindingTobacco preparationFlocculationAluminium sulfate

The invention relates to a method for increasing a retention rate of calcium carbonate in paper-making reconstituted tobacco. The method comprises the steps that the calcium carbonate is added into a wood pulp fiber sizing agent with a certain beating degree to enable the calcium carbonate and the wood pulp fiber sizing agent to be fully adsorbed to form a compound; the compound is wrapped by carboxymethylcellulose to form a larger flocculation body; modification and stability treatment are performed on the surface of the flocculation body by aluminum sulfate; the modified calcium carbonate and a tobacco sizing agent are mixed with the help of a multi-element composite retention and drainage system and then processed into the reconstituted tobacco through papermaking, squeezing, coating, drying and slitting. By means of the method for increasing the retention rate of the calcium carbonate in the paper-making reconstituted tobacco, the binding force of the modified calcium carbonate and the sizing agent is enhanced, the modified calcium carbonate and the sizing agent are not likely to run off, and the retention rate of the modified calcium carbonate in the reconstituted tobacco is high.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +3

Processing method for reconstituted tobacco through paper-making method

The invention relates to a processing method for reconstituted tobacco through a paper-making method. According to the method, calcium carbonate is added into fiber slurry with a certain beating degree so as to enable calcium carbonate and fiber slurry to fully adsorb to form a compound, the compound is wrapped with a modifier to form a larger flocculation body, a surfactant and a cross-linking agent are respectively used for carrying out surface modification and stability treatment on the flocculation body, after modified calcium carbonate and tobacco slurry are mixed by virtue of a multielement compound retention and drainage aid system, the mixture is processed into reconstituted tobacco through papermaking, squeezing, coating, drying and cutting. By adopting the method provided by the invention, the binding force of modified calcium carbonate and slurry is enhanced, low possibility in loss is realized, and the retention ratio of modified calcium carbonate and slurry in the reconstituted tobacco is high.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +2

Processing method of heat-not-burn cigarette with curling structure

ActiveCN110810897AFacilitated releaseEasy to overflowTobacco preparationTobacco treatmentAdhesiveCarbonization

The invention discloses a processing method of a heat-not-burn cigarette with a curling structure. The method comprises the following steps of rolling and pressing a dry and wet material mixture to obtain atomized reconstituted tobacco leaves; dispersing a graphene nanometer material, a solid adhesive and an atomization agent mixture into water; uniformly spraying the solution onto one sides of the atomized reconstituted tobacco leaves; performing primary heating drying to obtain semi-dried heat-not-burn reconstituted tobacco leaves; performing shredding to obtain semi-wet heat-not-burn reconstituted tobacco leaves; performing secondary heating drying to obtain cut tobacco of the heat-not-burn reconstituted tobacco leaves; and performing rolling connection and packaging to obtain the heat-not-burn cigarette with the curling structure. The problem of great addition proportion of atomization agents is solved, so that the cut tobacco is changed from a straight shape to a naturally curlingshape; a filling value is increased; the smoke overflowing is easy; the smoke release quantity is increased; the smoking feeling is improved; the cut tobacco elasticity is improved; the holding forceis increased; the cut tobacco cannot easily fall; the tensile strength of the heat-not-burn reconstituted tobacco leaves is improved; breakage cannot easily occur; rolling packaging processing is convenient to perform; and the heat conductivity is improved, so that the carbonization of heating cigarettes is safer.

Owner:HUBEI CHINA TOBACCO IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com