Method for increasing production quality stability of thin cigarettes

A technology for quality stability and slim cigarettes, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, and can solve problems such as poor quality stability of slim cigarettes, large fluctuations in cigarette quality and draw resistance, and fewer slim cigarettes , to achieve the effects of reducing the amount of stem sticks and residual smoke removed, reducing the number of running and stopping times, and reducing the smoking resistance of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

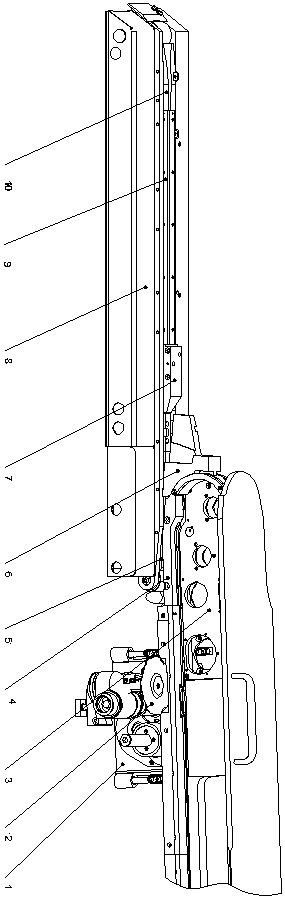

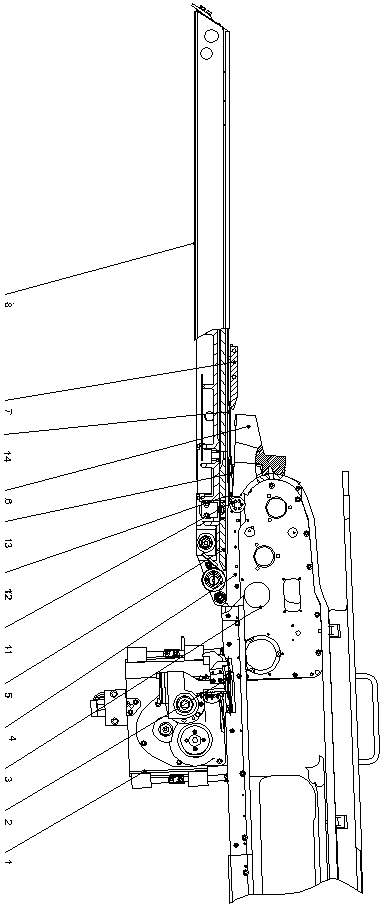

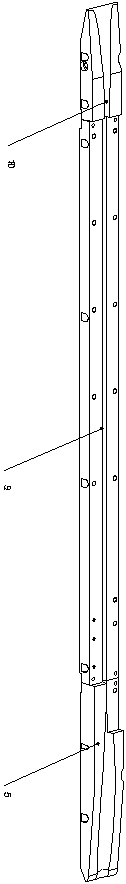

Image

Examples

Embodiment 1

[0031] A method for improving the quality stability of slim cigarettes, the specific steps are as follows:

[0032] (1) Moisture screening: Send the tobacco leaves that have undergone vacuum moisture resurfacing to the screening machine for secondary screening. The mesh diameter of the primary screen is 10mm, and the sieve of the primary screening is directly sent to the moisture regaining machine for loose moisture regain , the undersize of the primary screening enters the secondary screen, the mesh diameter of the secondary screen is 2.5mm, and the oversize of the secondary screening is transported by the belt into the outlet of the moisture conditioner and combined with the tobacco leaves coming out of the moisture conditioner After mixing, it enters the pre-mixing cabinet, and the undersize of the secondary screening is collected to produce reconstituted tobacco leaves by papermaking method; the vacuum degree of vacuum resurgence is set to 900pa, and the vacuum degree of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com