Preparation process of expanded stem products by microwave

A microwave expansion and preparation technology technology, applied in the field of tobacco, can solve the problems of low product filling rate, complex process equipment, low expansion rate, etc., and achieve the effects of reducing the loss of effective ingredients, saving warehouse space, and reducing odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

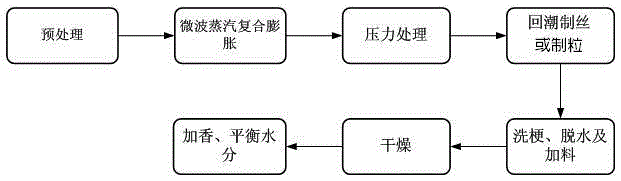

[0032] A preparation process of microwave expansion stalk products, the process steps are as follows:

[0033] A. Pretreatment: remove metal, hemp rope, stem head, stem stick and other impurities in the tobacco stem;

[0034] B. Microwave Steam Composite Expansion: According to the process steps recorded in the patent CN102613687A "A Method for Microwave Expansion of Tobacco Stem Using Gas Heating Medium", specifically adopt the method of Example 3, the steam temperature is 150°C, and the microwave frequency is 915MHz , the expansion rate of the available expanded tobacco stems is 98%, the expansion degree is 280%, and the moisture content is less than 8%;

[0035] C. Pressure treatment: according to the process steps recorded in the patent CN104207322A "A treatment process for expanded tobacco stems", according to the different properties of tobacco stems from different origins, the pressure is 0.8MPa, the pressure medium is air, and keep for 30 minutes;

[0036] D. Moisturi...

Embodiment 2

[0042] A preparation process of microwave expansion stalk products, the process steps are as follows:

[0043] A. Pretreatment: remove metal, hemp rope, stem head, stem stick and other impurities in the tobacco stem;

[0044]B. Microwave Steam Composite Expansion: According to the process steps recorded in the patent CN102613687A "A Method for Microwave Expansion of Tobacco Stem Using Gas Heating Medium", specifically adopt the method of Example 3, the steam temperature is 150°C, and the microwave frequency is 915MHz , the expansion rate of the available expanded tobacco stems is 98%, the expansion degree is 280%, and the moisture content is less than 8%;

[0045] C. Pressure treatment: according to the process steps recorded in the patent CN104207322A "A treatment process for expanded tobacco stems", according to the different properties of tobacco stems from different origins, the pressure is 3MPa, the pressure medium is air, and keep for 30 minutes;

[0046] D. Moisturizin...

Embodiment 3

[0052] A preparation process of microwave expansion stalk products, the process steps are as follows:

[0053] A. Pretreatment: remove metal, hemp rope, stem head, stem stick and other impurities in the tobacco stem;

[0054] B. Microwave Steam Composite Expansion: According to the process steps recorded in the patent CN102613687A "A Method for Microwave Expansion of Tobacco Stem Using Gas Heating Medium", specifically adopt the method of Example 3, the steam temperature is 150°C, and the microwave frequency is 915MHz , the expansion rate of the available expanded tobacco stems is 98%, the expansion degree is 280%, and the moisture content is less than 8%;

[0055] C. Pressure treatment: According to the process steps recorded in the patent CN104207322A "A treatment process for expanded tobacco stems", according to the different properties of tobacco stems from different origins, the pressure is 8MPa, the pressure medium is air, and keep for 10 minutes;

[0056] D. Moisturize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com