A donut forming frying equipment

A doughnut and equipment technology, which is applied in the field of doughnut forming and frying equipment, can solve the problems of poor doughnut taste and inability to achieve the same taste of the two sides of sweet and sweet, so as to improve the taste, avoid surface coking, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

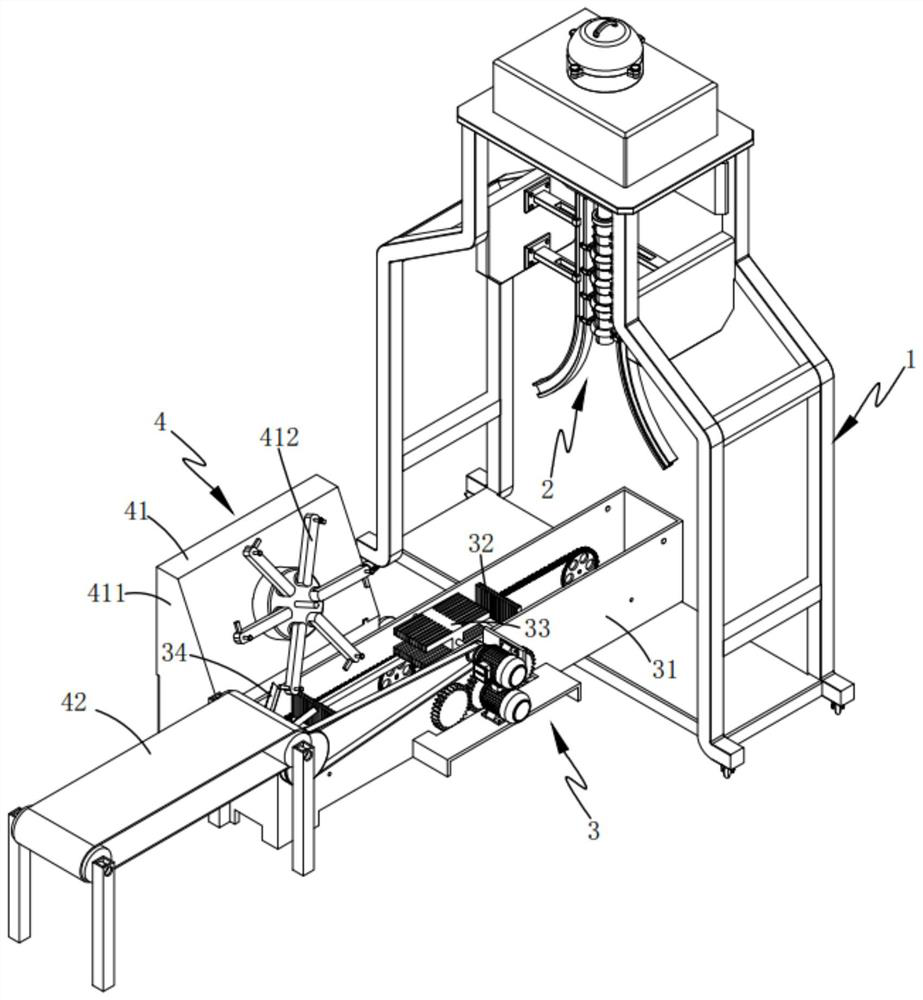

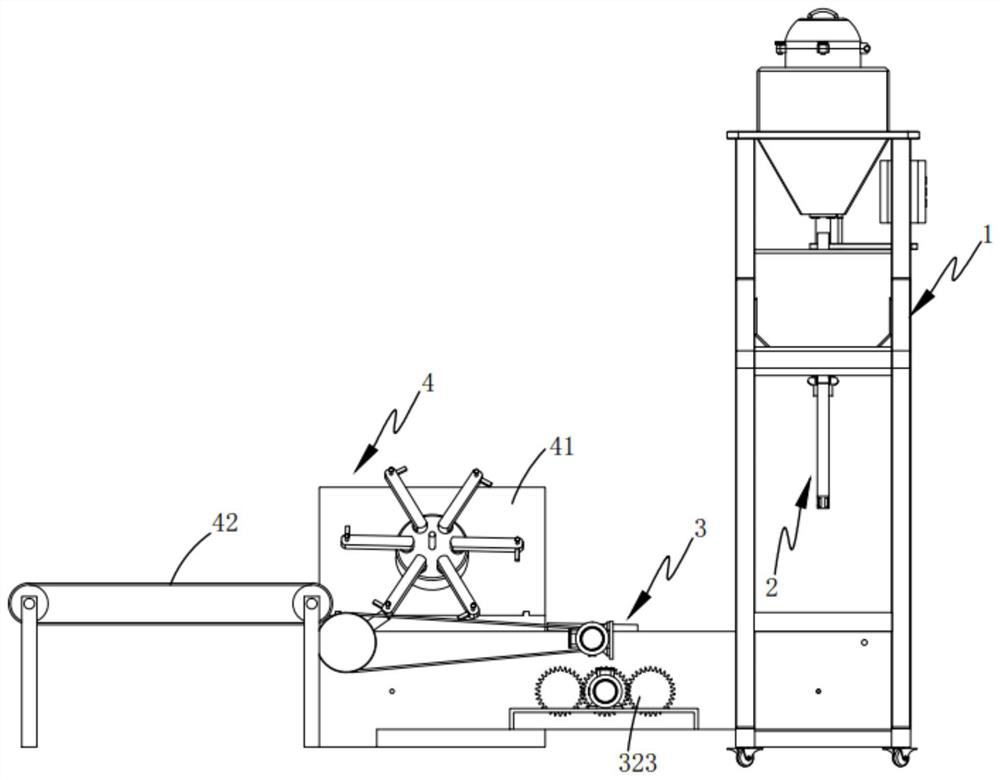

[0051] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Shown, a kind of donut forming frying equipment comprises support 1, the molding mechanism 2 that is installed on the support 1, also includes:

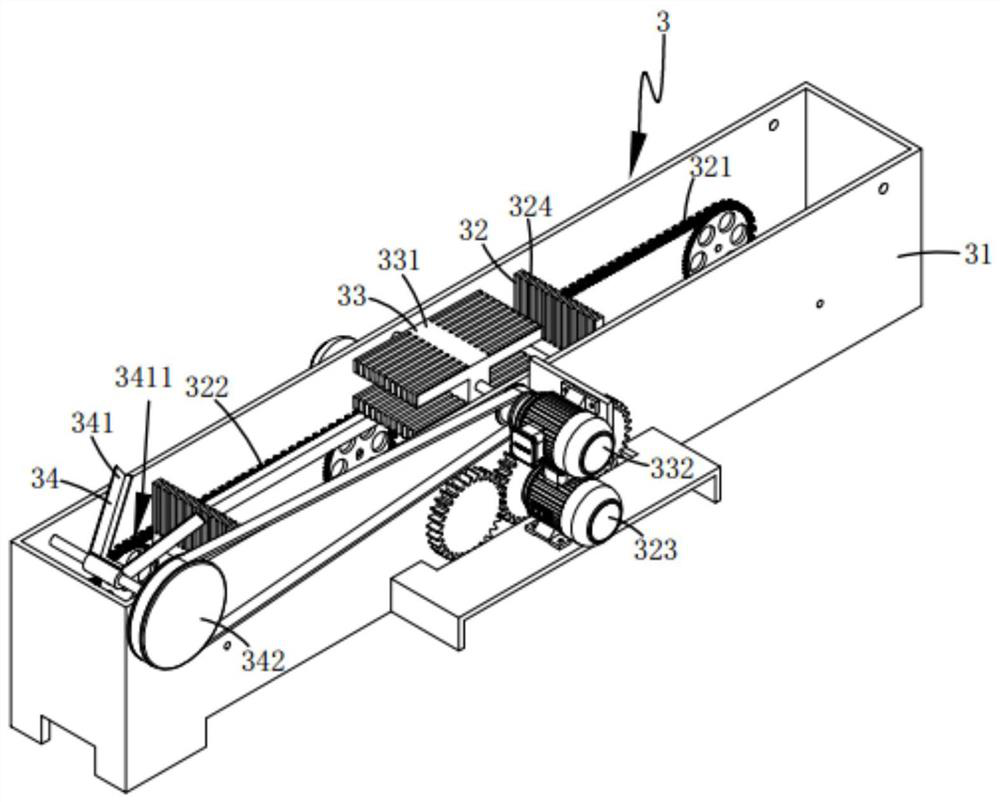

[0052] Frying mechanism 3, described frying mechanism 3 is arranged under described forming mechanism 2, and this frying mechanism 3 comprises oil pot 31, is arranged on the pushing assembly 32 in described oil pot 31, is arranged on described oil pot 31 and the turning assembly 33 located in the middle of the pushing assembly 32 and the lifting assembly 34 arranged at the pushing output end of the pushing assembly 32; during operation, the flour material falls into the oil pan after being extruded by the molding mechanism 2 31, push the molded donuts to the flipping assembly 33 during the rotary motion of the pusher assembly 32, and then push it to the lifting assembly 34 again ...

Embodiment approach

[0062] As a preferred embodiment, the turning assembly 33 includes:

[0063] An overturn frame 331, the overturn frame 331 is rotatably arranged on the oil pan 31 and is located between the first rotary member 321 and the second rotary member 322;

[0064] An overturn driving part 332 , the overturn driving part 332 is fixedly arranged on the outer wall of the oil pan 31 , and the driving end of the overturn driving part 332 is fixedly connected with the middle of the overturn frame 331 .

[0065] As a preferred embodiment, the lifting assembly 34 includes:

[0066] Lifting frame 341, the lifting frame 341 is rotatably arranged on the oil pan 31 and is located at one end of the pushing material transmission direction of the pushing component 32;

[0067] A linkage 342 , the linkage 342 is rotatably arranged on the oil pan 31 , and one end of the linkage 342 is fixedly connected to the lifting frame 341 and the other end is fixedly connected to the turning drive 332 .

[0068...

Embodiment 2

[0070] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0071] As a preferred embodiment, the two ends of the turning frame 331 along the length direction are symmetrically provided with turning spaces 3313 , and the first pushing plate 3241 and the second pushing plate 3242 move in the turning space 3313 .

[0072] It should be noted that the oil surface in the oil pan 31 is at the bottom of the turning space 3313, and the pusher assembly 32 will transfer the donuts floating on the oil surface into the turning space 3313 during the rotary motion, and the turning The driving member 332 turns over the turning frame 331 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com