An automatic flipping donut frying guiding device

A technology of a guiding device and a donut, which is applied in the field of an automatic flipping doughnut frying guide device, can solve the problems of low frying efficiency, difficulty in ensuring consistent frying time, affecting the taste of finished doughnuts, etc. Consistency, improved frying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

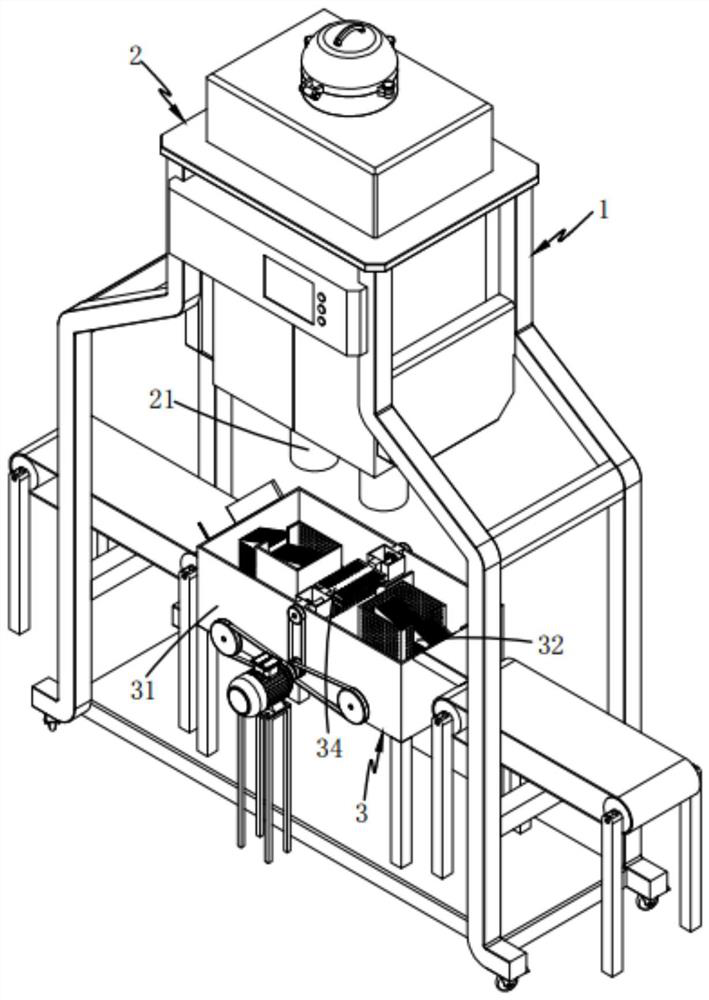

[0054] Such as figure 1 , 2 , 3, 4, 5, 6, 7 and 9, a kind of automatic flipping donut frying guiding device, including support 1, forming discharge mechanism 2 installed on the support 1, also includes:

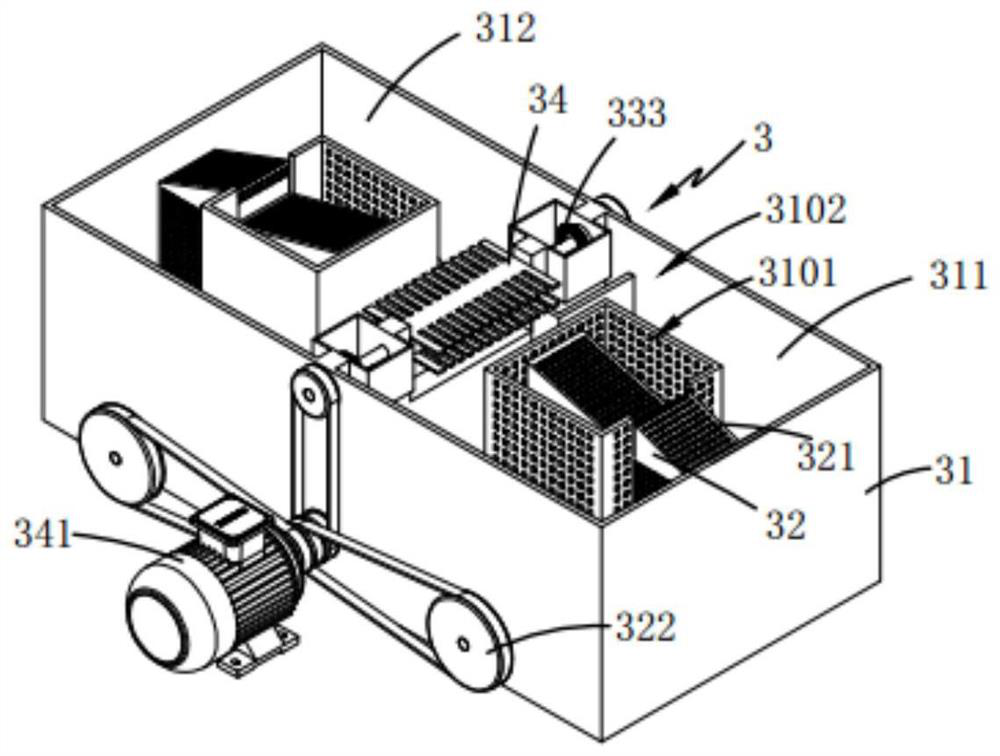

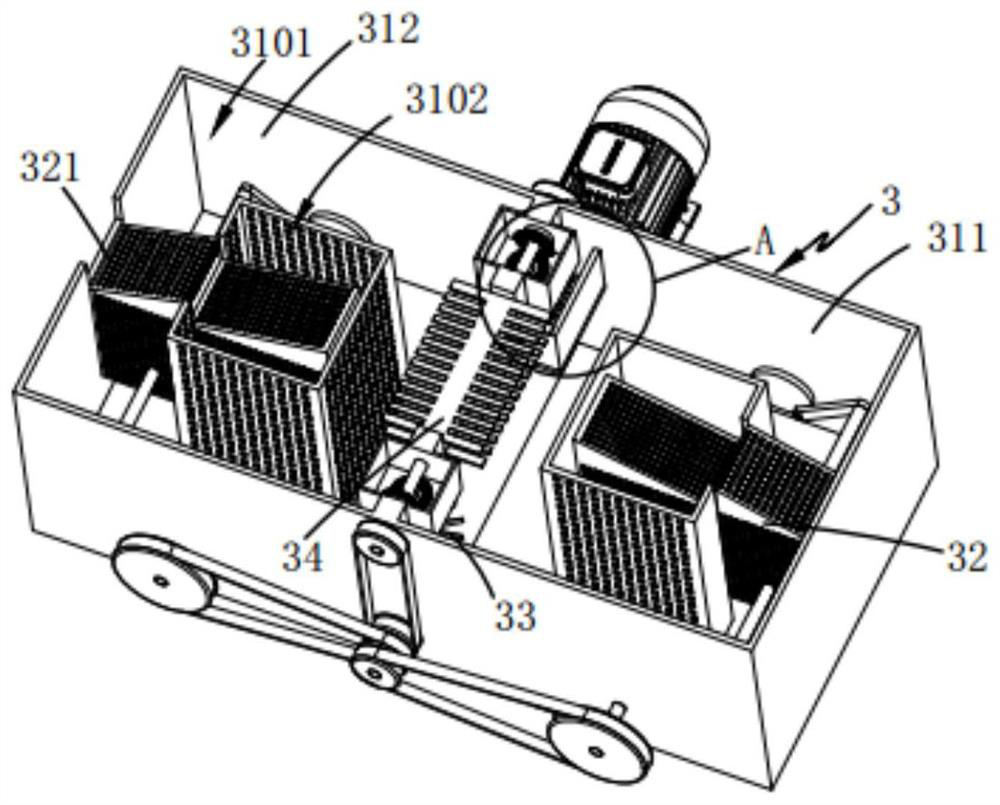

[0055] A backflow frying mechanism 3, the backflow frying mechanism 3 is arranged below the forming discharge mechanism 2, and the backflow frying mechanism 3 includes an oil pan 31, a lifting assembly 32 arranged on the oil pan 31, and a The guide return assembly 33 at the middle position of the oil pan 31 and the turning ass...

Embodiment 2

[0085] Figure 8 It is a structural schematic diagram of Embodiment 2 of an automatic electromagnetic screening device for solid waste impurities of the present invention; Figure 8 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0086] The reflux assembly 33 also includes:

[0087] The first backflow stopper 334, the first backflow stopper 334 is arranged in the second oil pan 312 and covered around the first oil pan backflow piece 331 located in the second oil pan 312;

[0088] The second backflow stopper 335 , the second backflow stopper 335 is disposed in the first oil pan 311 and covers the second oil pan return piece 332 around the part of the first oil pan 311 .

[0089] It should be noted that, by setting the first ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com