Patents

Literature

106results about How to "Improve frying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil composition for reducing generation of polar compounds of frying oil

ActiveCN104171029AExtended service lifeSuppress or reduce harmful substancesEdible oils/fatsChemical compositionTriglyceride

The invention provides an oil composition for reducing the generation of polar compounds of frying oil. Triglyceride comprises 48-65wt% of SUS type triglyceride, 5-10wt% of SSU type triglyceride, 0.5-15wt% of SSS type triglyceride, 15-31wt% of SU2 type triglyceride and 0-10wt% of U3 type triglyceride, and saturated fatty acids in the oil composition account for 42-58% weight of the weight of total fatty acids; and the SUS type triglyceride with the unsaturated fatty acids being oleic acid accounts for 70-90% of the weight of all the SUS type triglyceride. The oil composition obtained in the invention has the characteristics of slow color change, few generated polar compounds, and fast fusing speed as frying oil.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

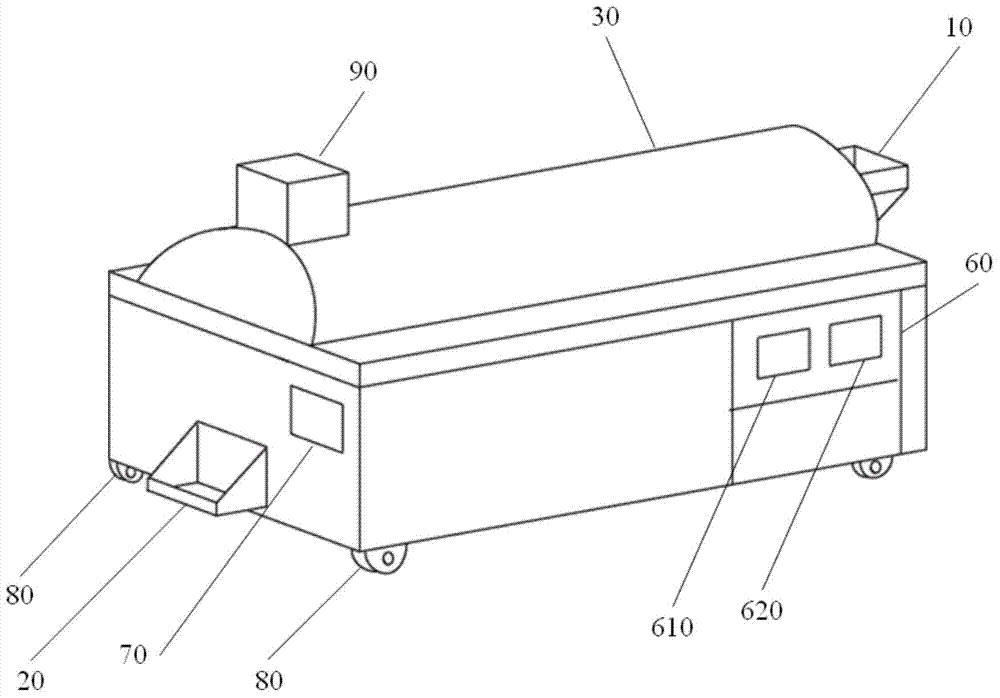

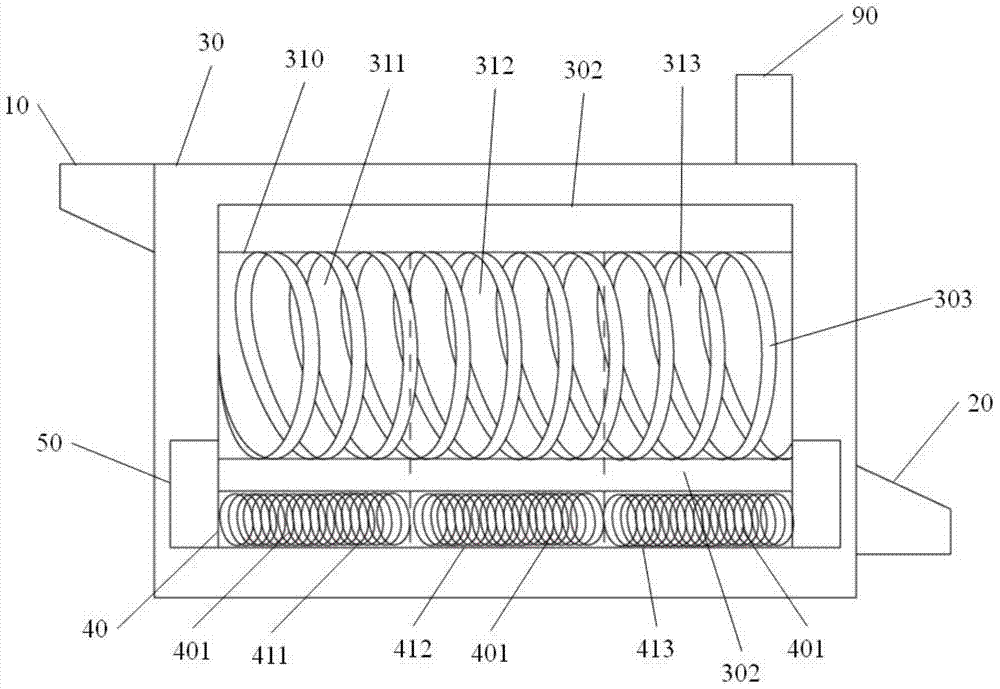

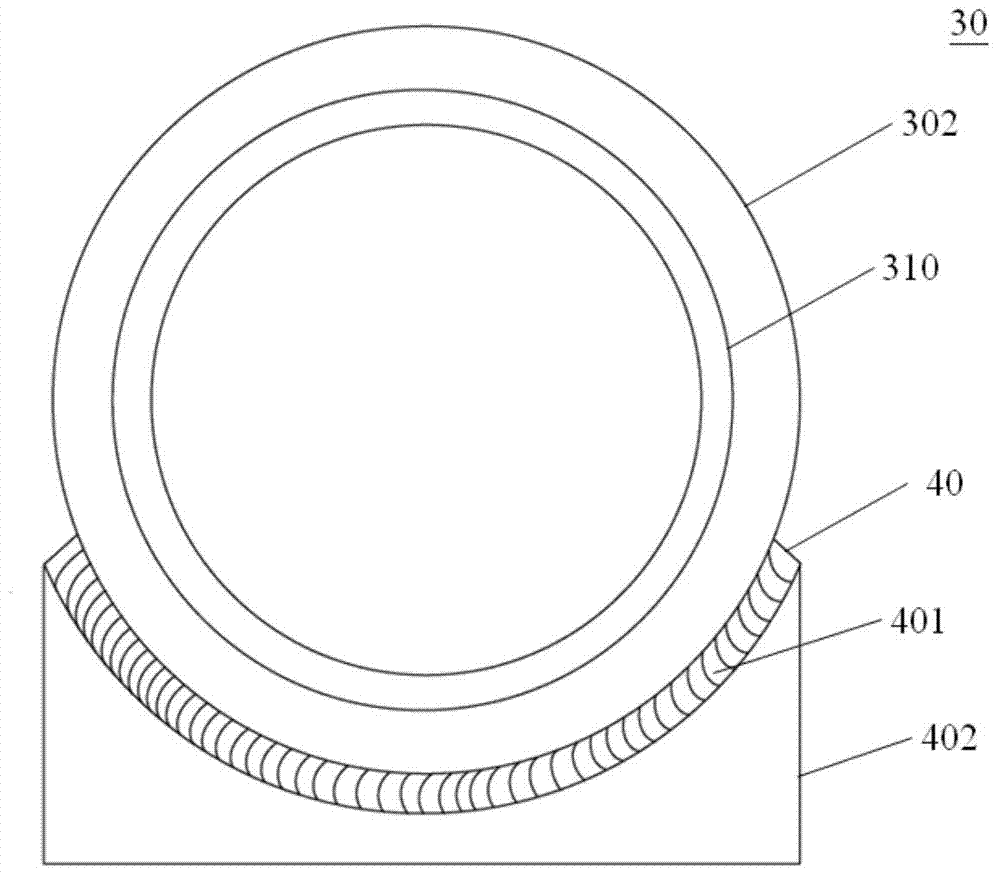

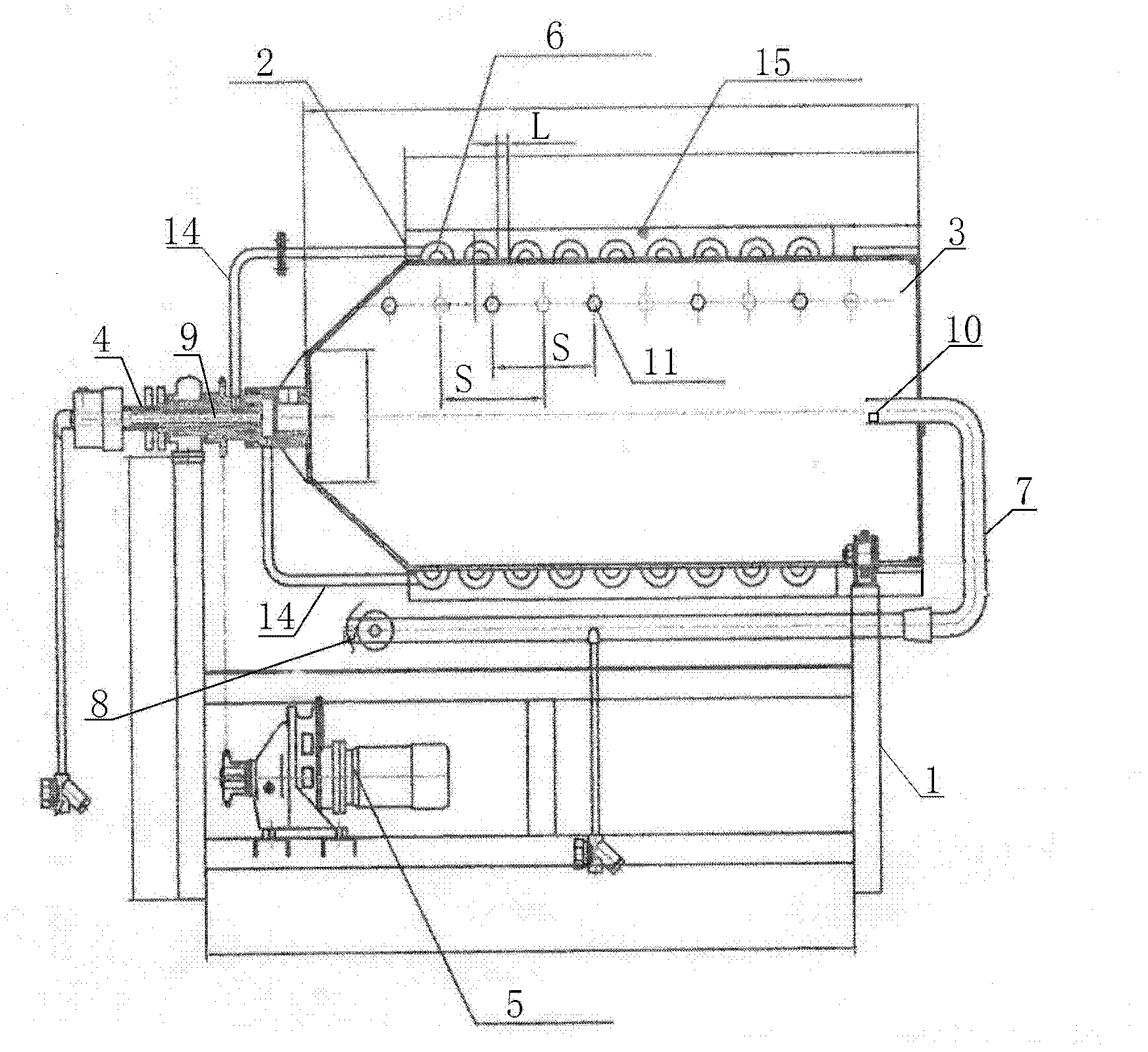

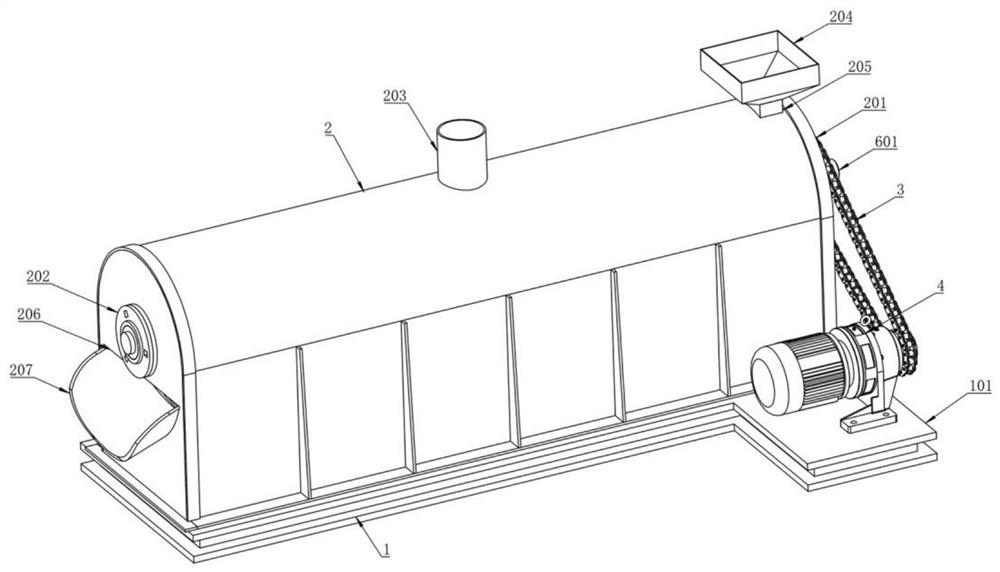

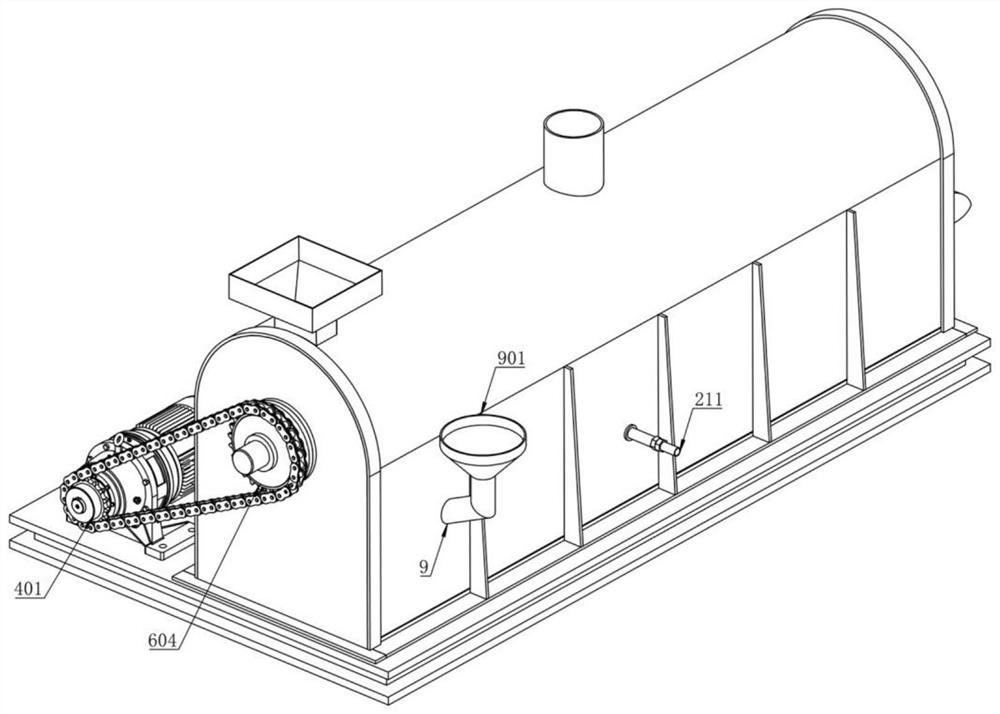

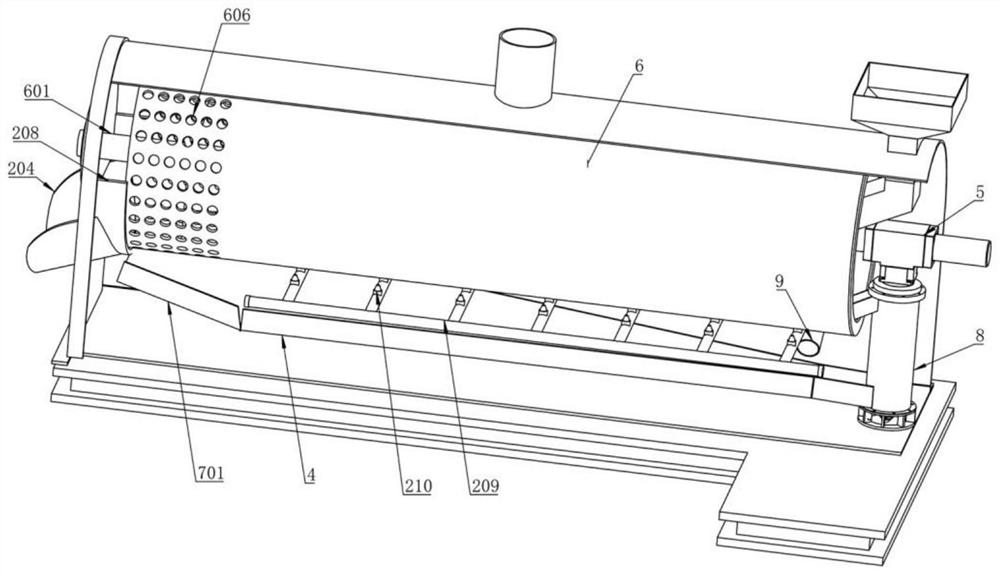

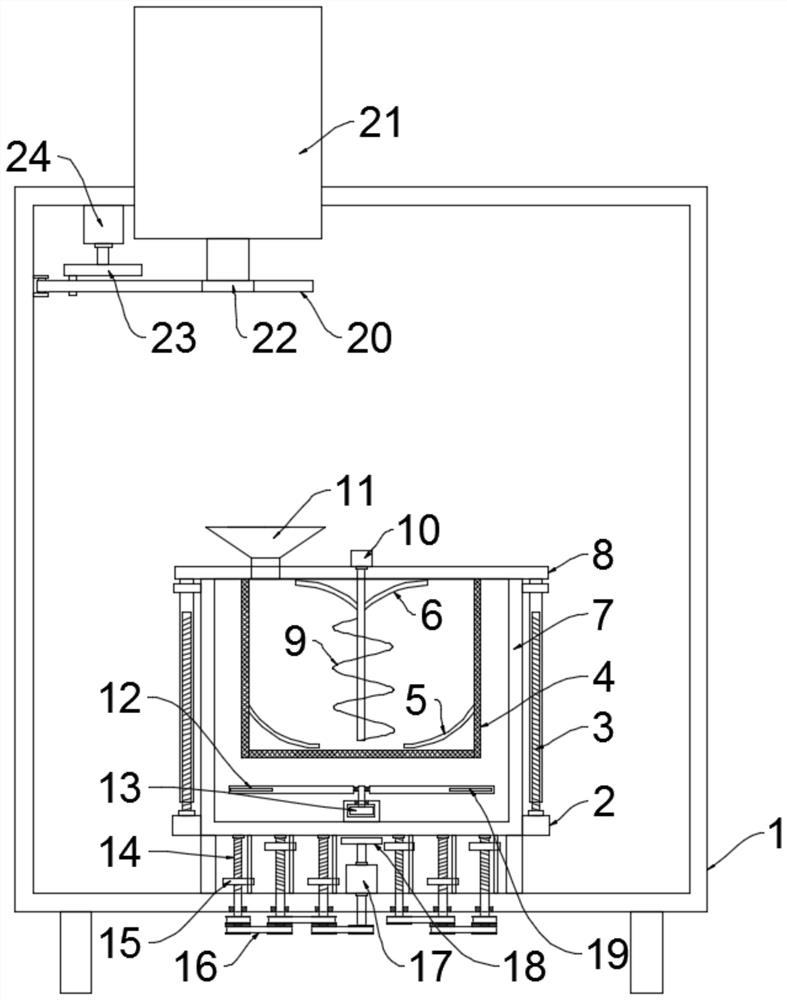

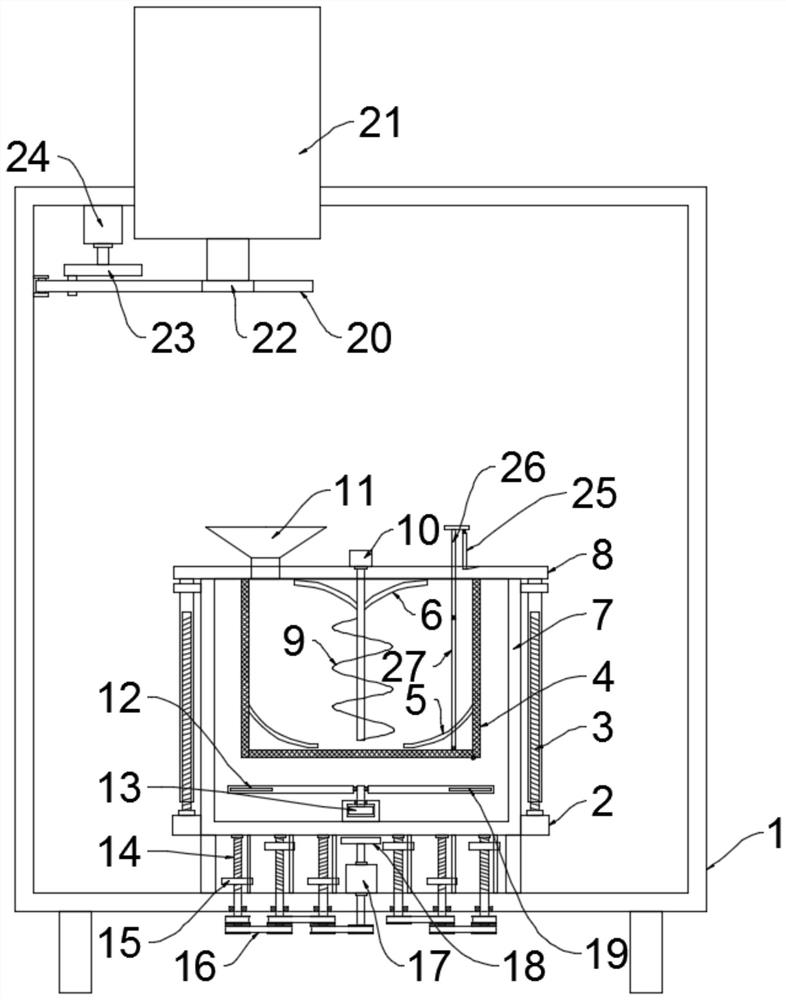

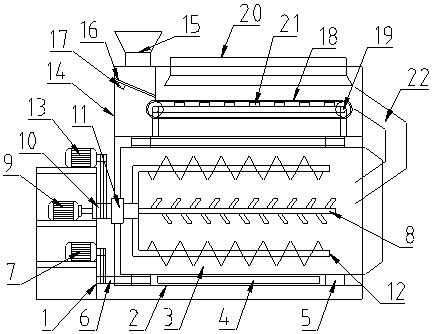

Numerically-controlled continuous automatic herbal medicine roaster

InactiveCN104771314AFlexible handlingUniform handlingPharmaceutical product form changeNumerical controlTemperature control

The invention discloses a numerically-controlled continuous automatic herbal medicine roaster. The numerically-controlled continuous automatic herbal medicine roaster comprises a multi-section heating device, a feed opening, a herbal medicine roasting cylinder, a discharging device, a driving device and a numerical control device, wherein the herbal medicine roasting cylinder is provided with a cylindrical hollow drum; the feed opening and the discharging device are respectively arranged at the two ends of the herbal medicine roasting cylinder and communicated with the hollow drum; the hollow drum is made from a magnetic conducting material and rotatably arranged in the herbal medicine roasting cylinder, and guide grooves in helicoidal distribution are formed in the inner wall of the hollow drum; the multi-section heating device is arranged on the outer side of the hollow drum; the driving device drives the hollow drum to rotate; the numerical control device is used for setting and detecting the temperature of the inner wall of the hollow drum and controls the rotation speed of the hollow drum through the driving device; and the numerical control device comprises a temperature control unit, multi-section temperature can be flexibly set, and multi-section temperature distribution on the inner wall of the hollow drum can be realized in the axial direction of the hollow drum in the same period of time. The numerically-controlled continuous automatic herbal medicine roaster has the advantages of being uniform in heating, safe and clean, low in energy consumption and cost, accurate in temperature control, low in labor intensity and the like.

Owner:BEIJING KANGRENTANG PHARMA

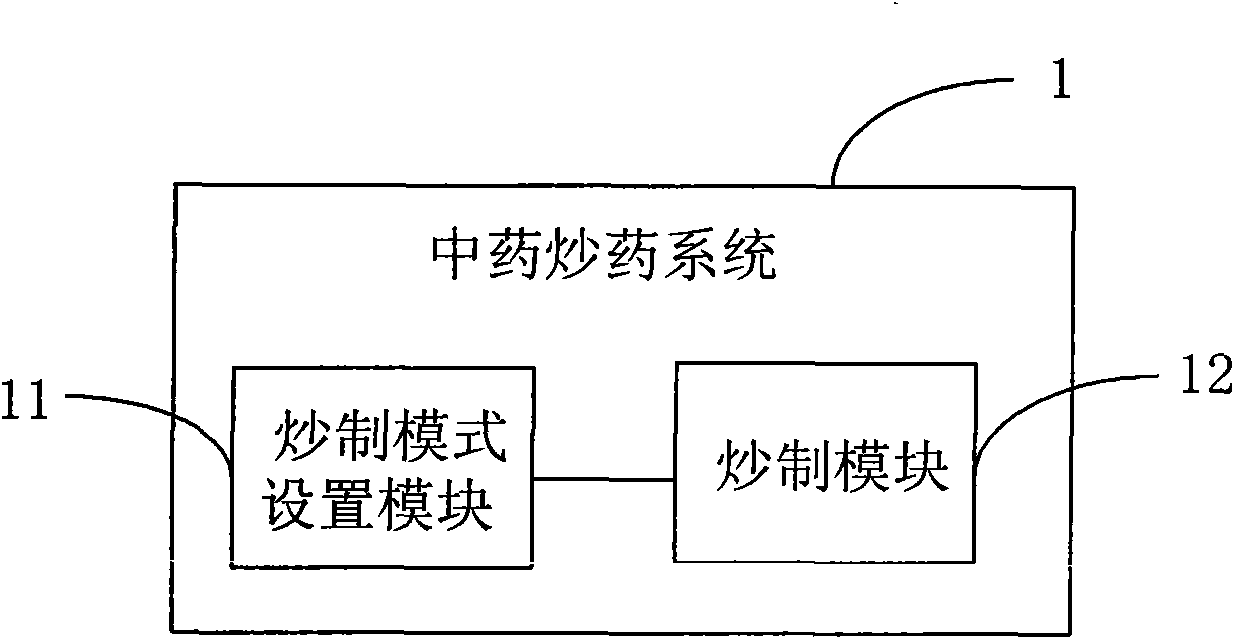

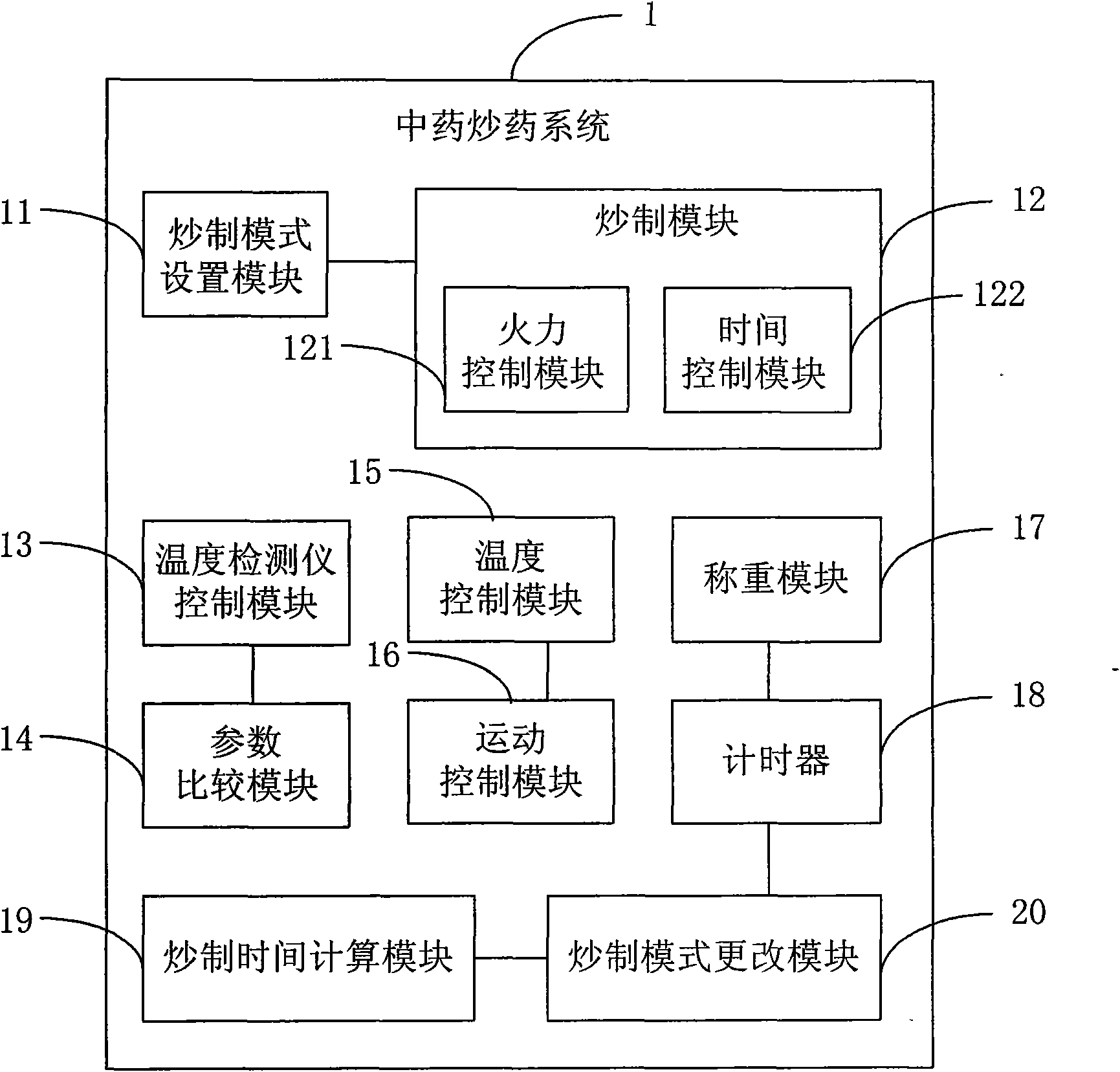

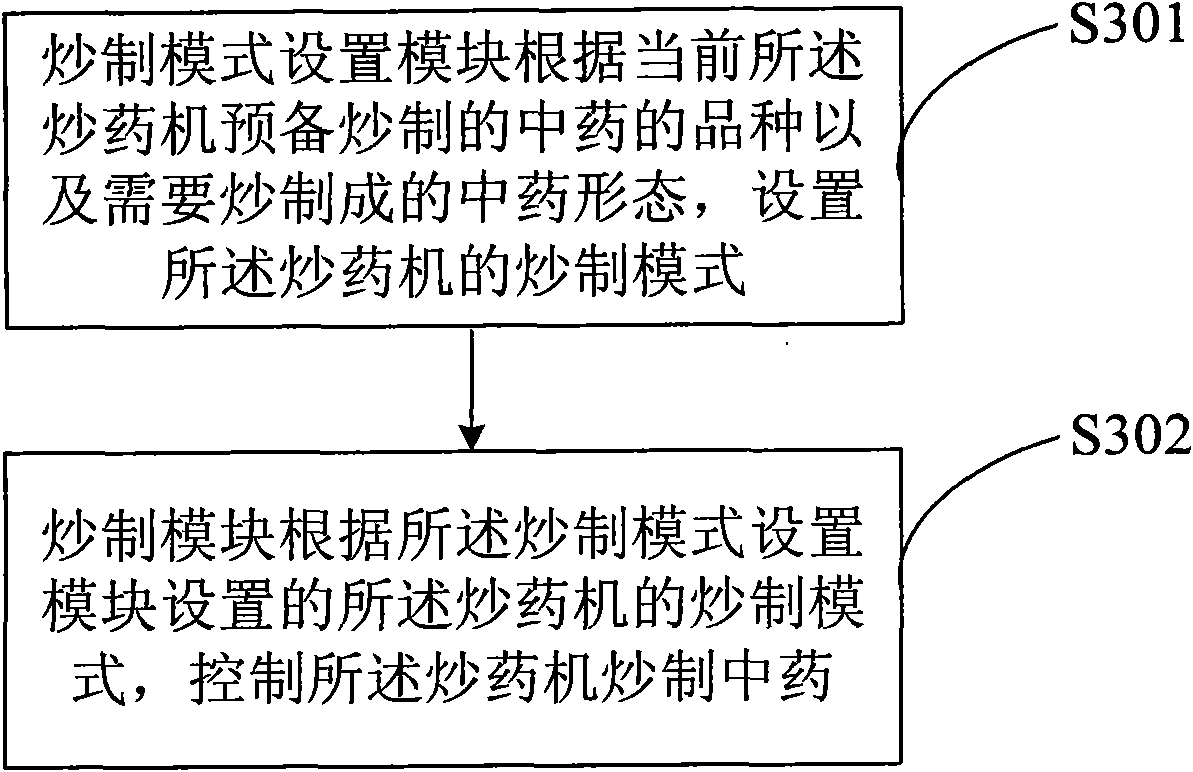

Chinese medicine frying system and its using method

InactiveCN101587341AImprove frying efficiencyQuality improvementDrying solid materials with heatPharmaceutical product form changeTraditional medicineChinese herbology

The invention discloses a Chinese medicine frying system for controlling the medicine frying machine to fry the Chinese medicine. The medicine frying machine comprises a temperature detector and a revolving drum. The temperature detector detects the temperature of the revolving drum inner wall of the medicine frying machine and the temperature of the Chinese medicine or auxiliary materials in the revolving drum. The Chinese medicine frying system comprises: a frying mode setting module for setting the frying mode of the medicine frying machine based on the Chinese medicine variety to be fried and the Chinese medicine state to be fried; a frying module for controlling the medicine frying machine to fry the Chinese medicine based on the frying mode of the medicine frying machine set by the frying mode setting module; the frying mode setting the firepower and time for frying the Chinese medicine based on the fried Chinese medicine characteristic and the Chinese medicine state to be fried. Thus, the invention enhances the efficiency and quality of the fried Chinese medicine.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

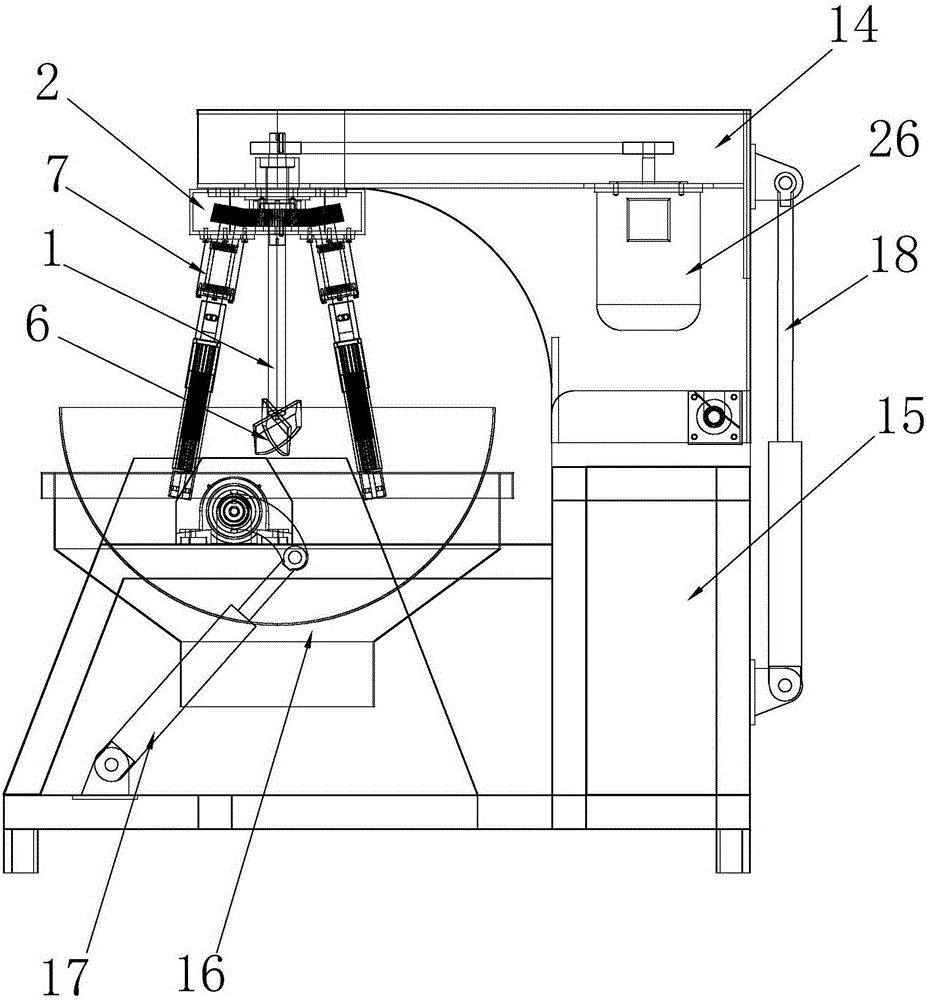

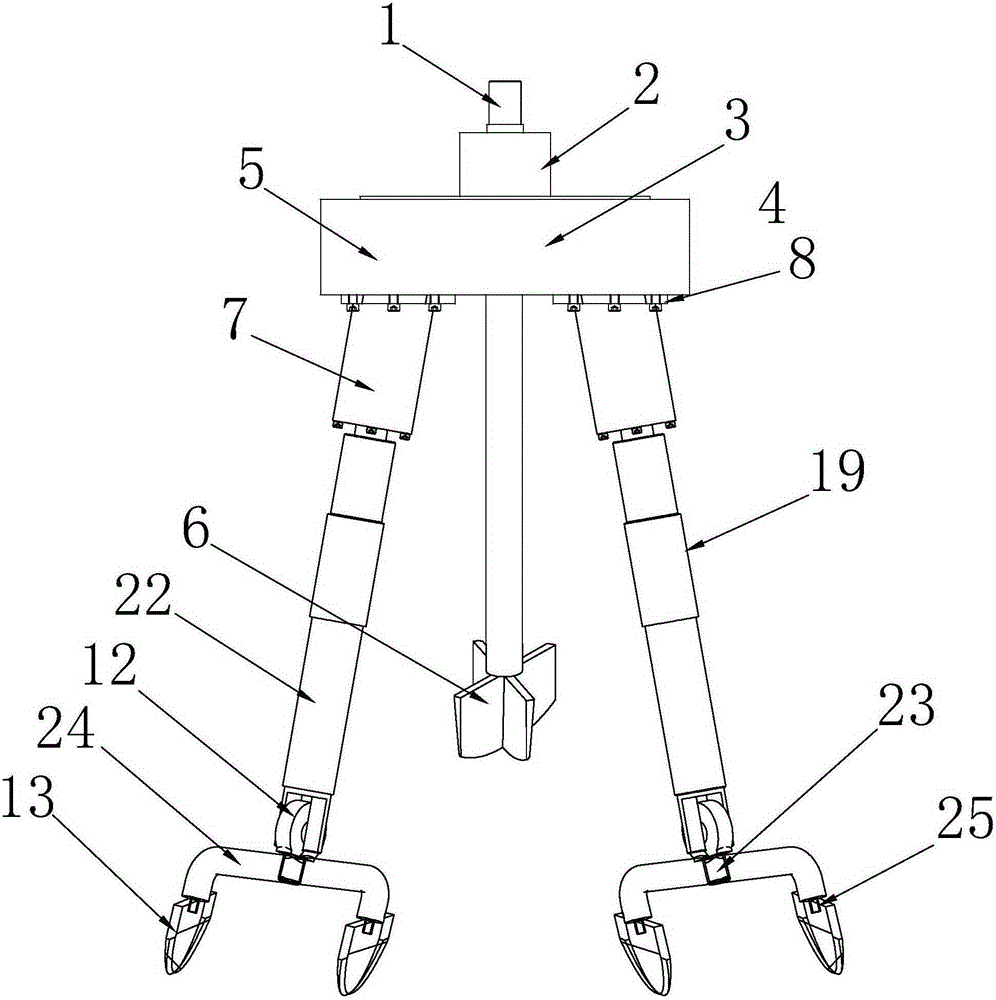

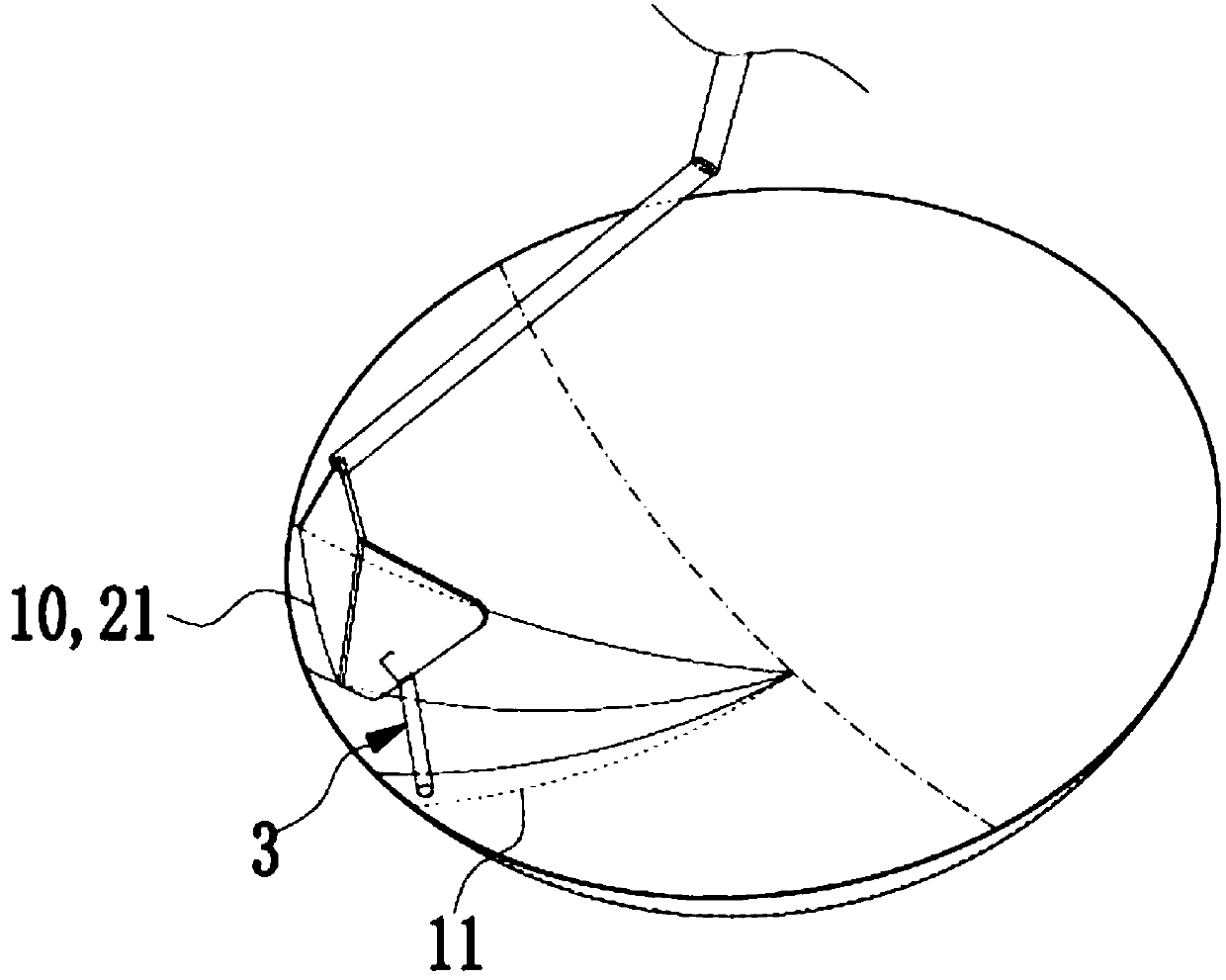

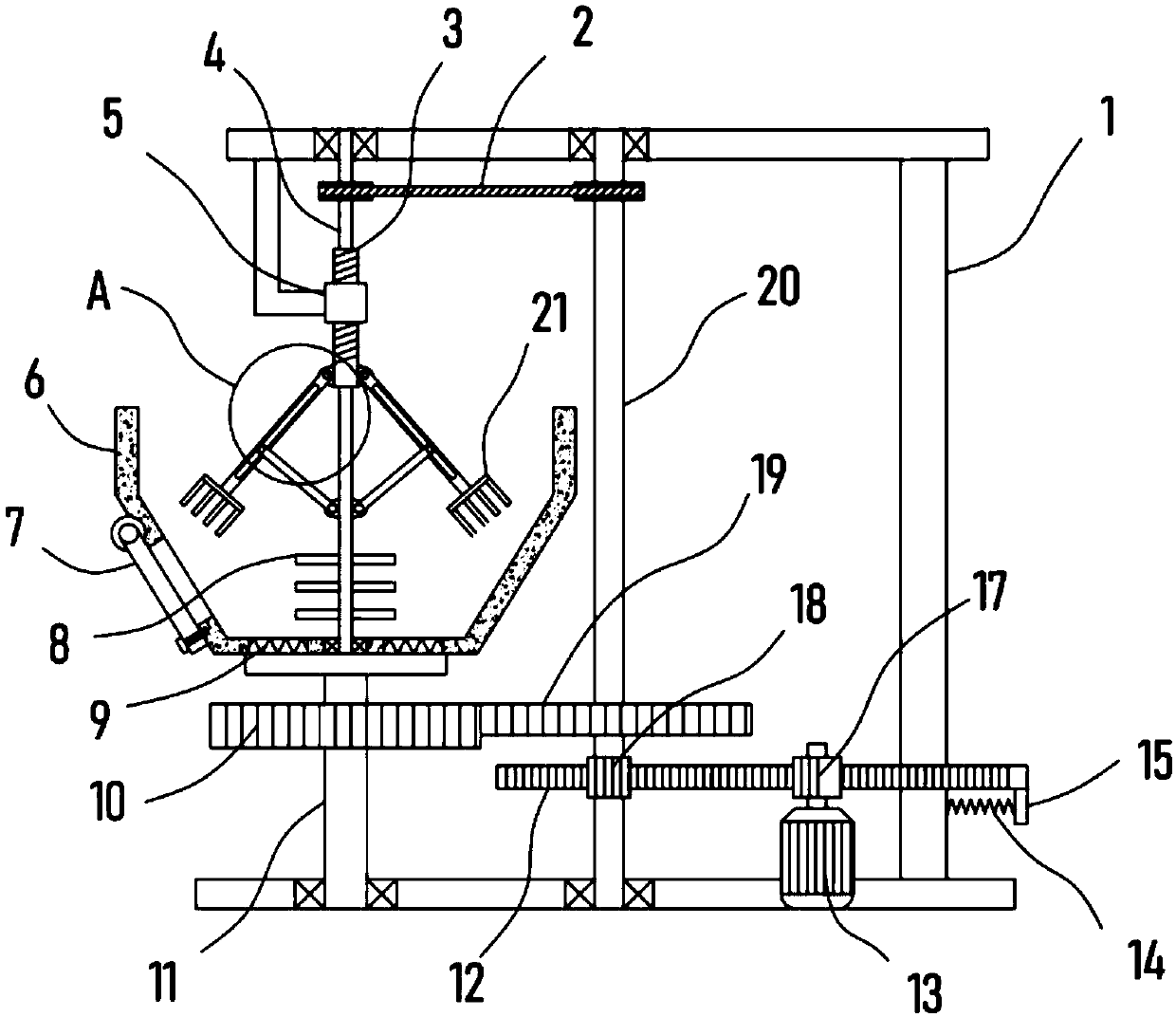

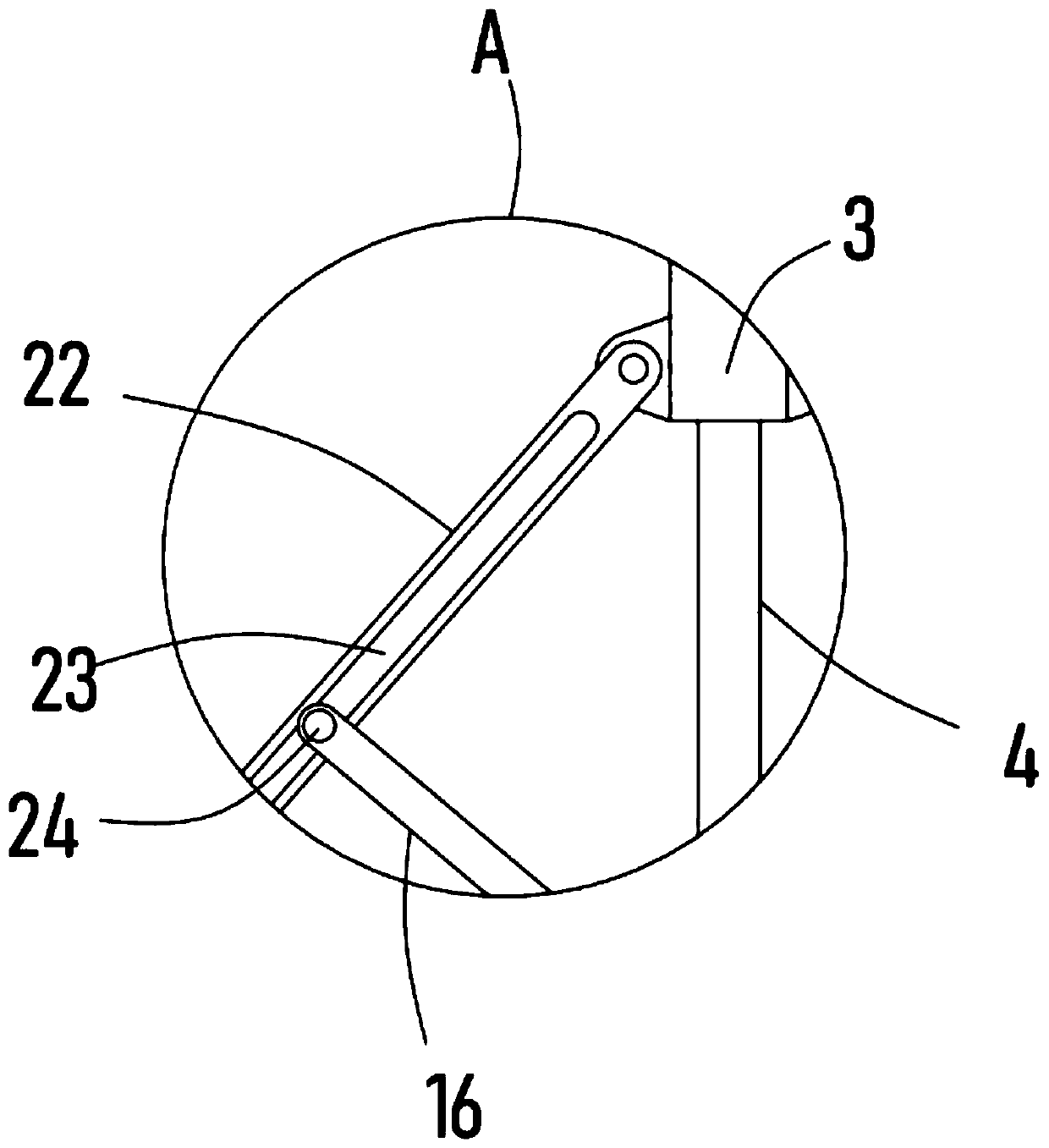

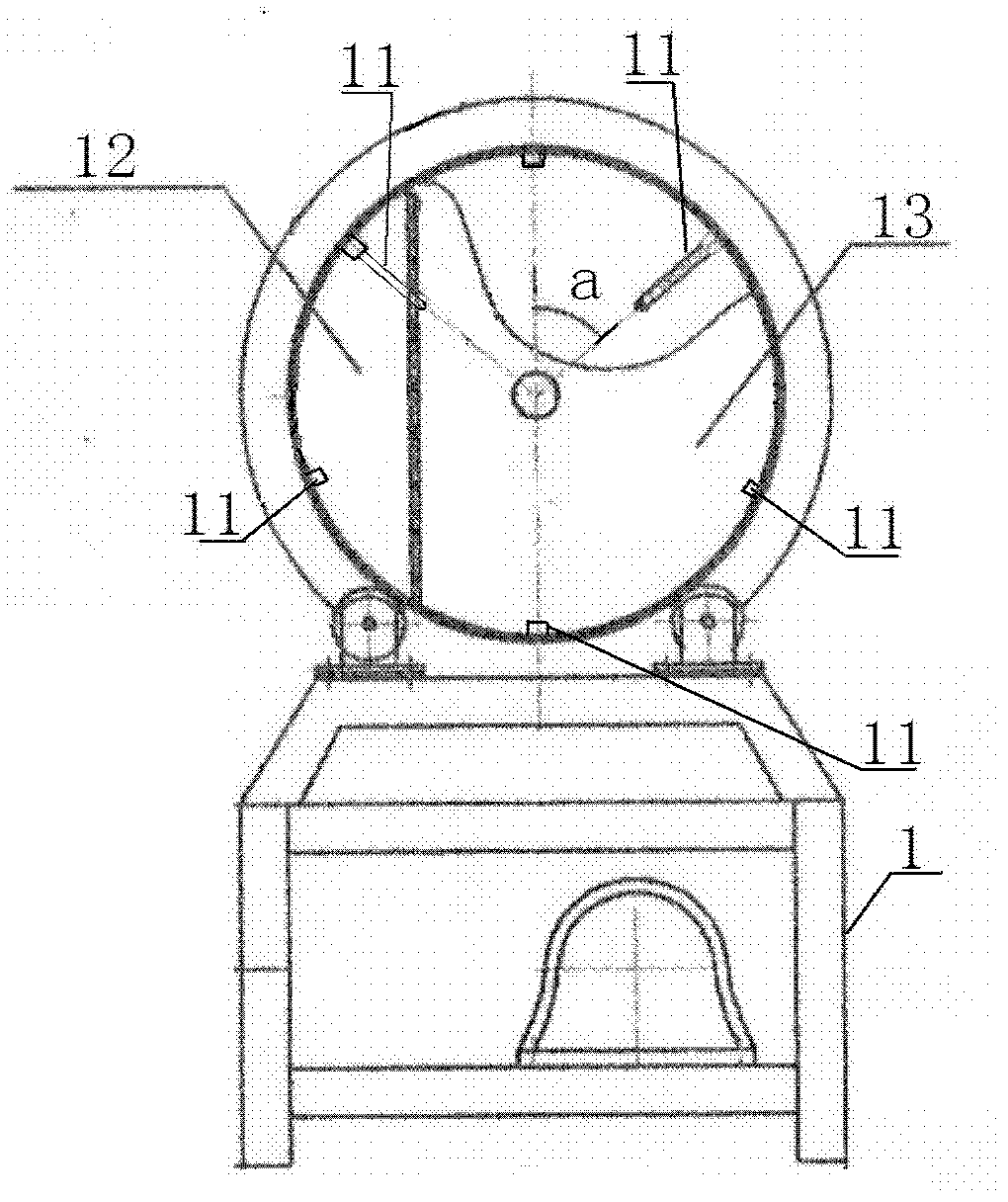

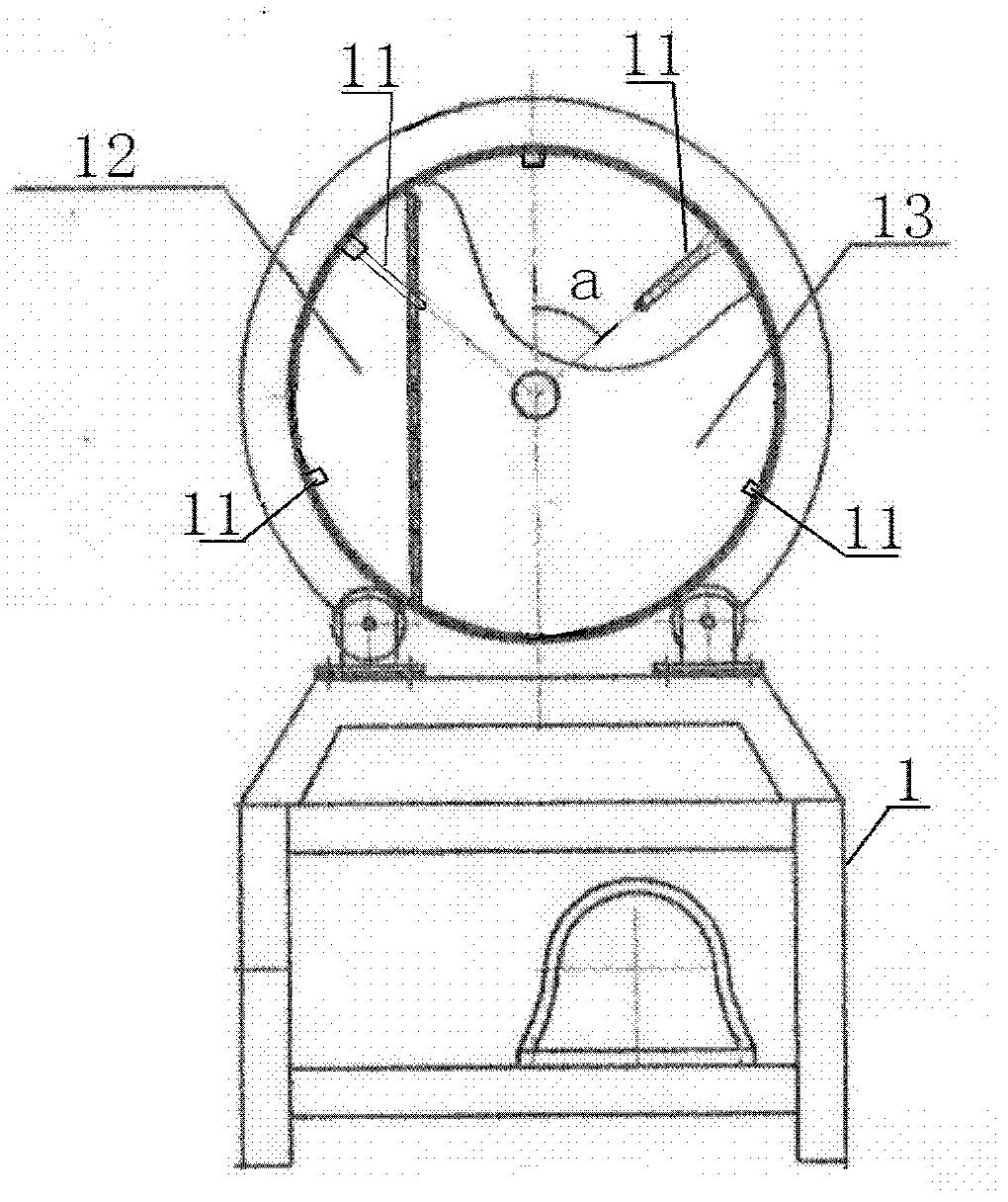

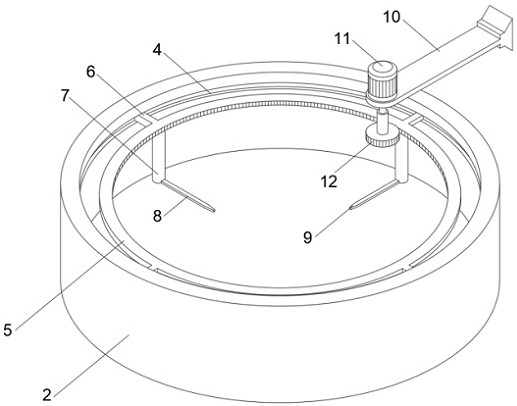

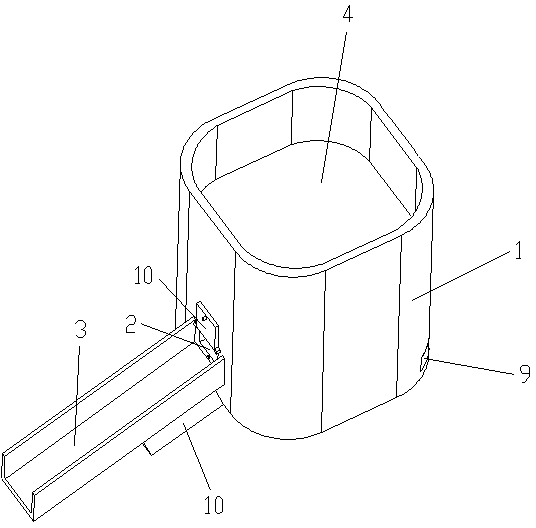

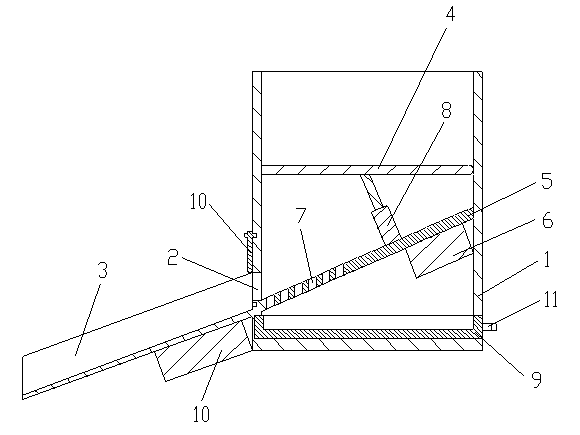

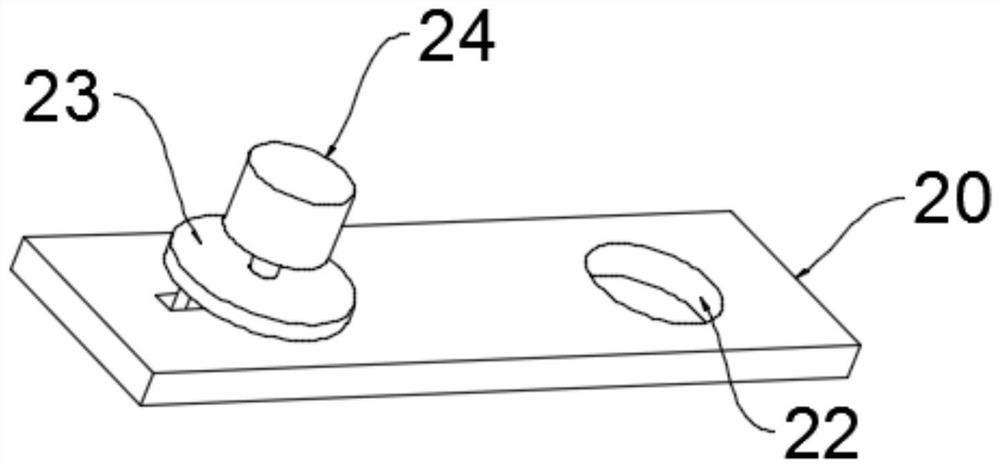

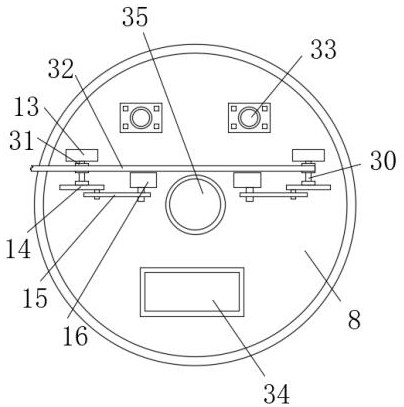

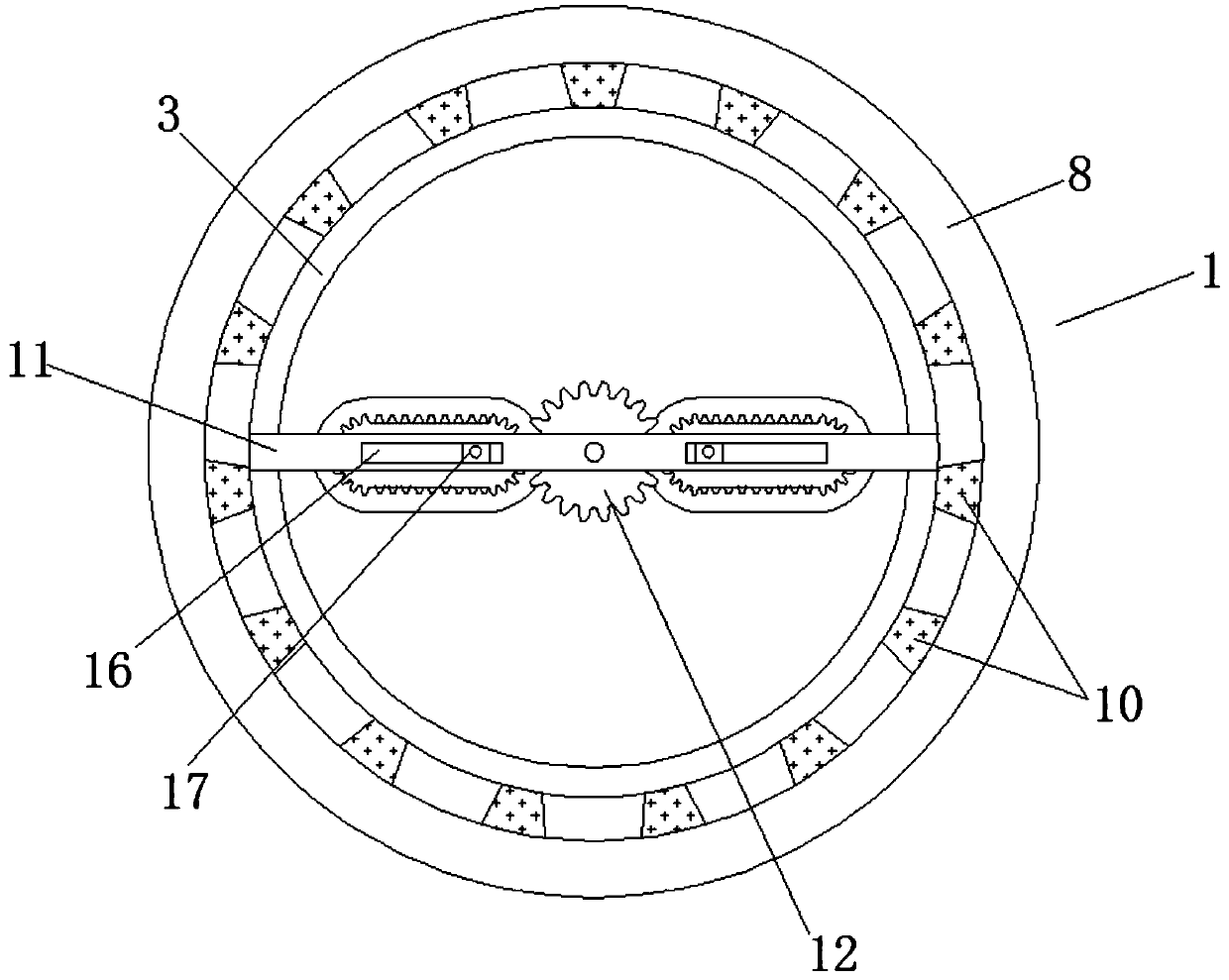

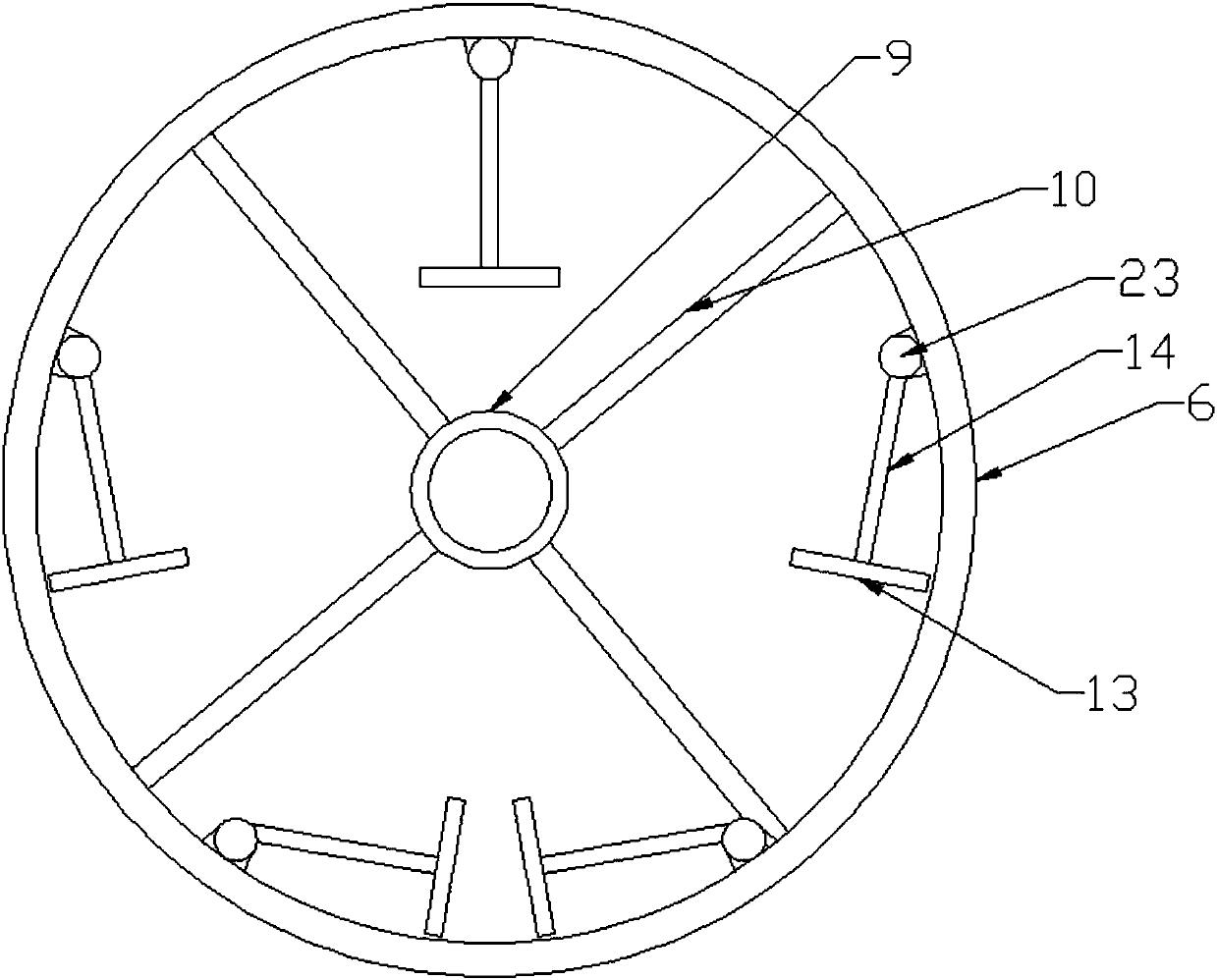

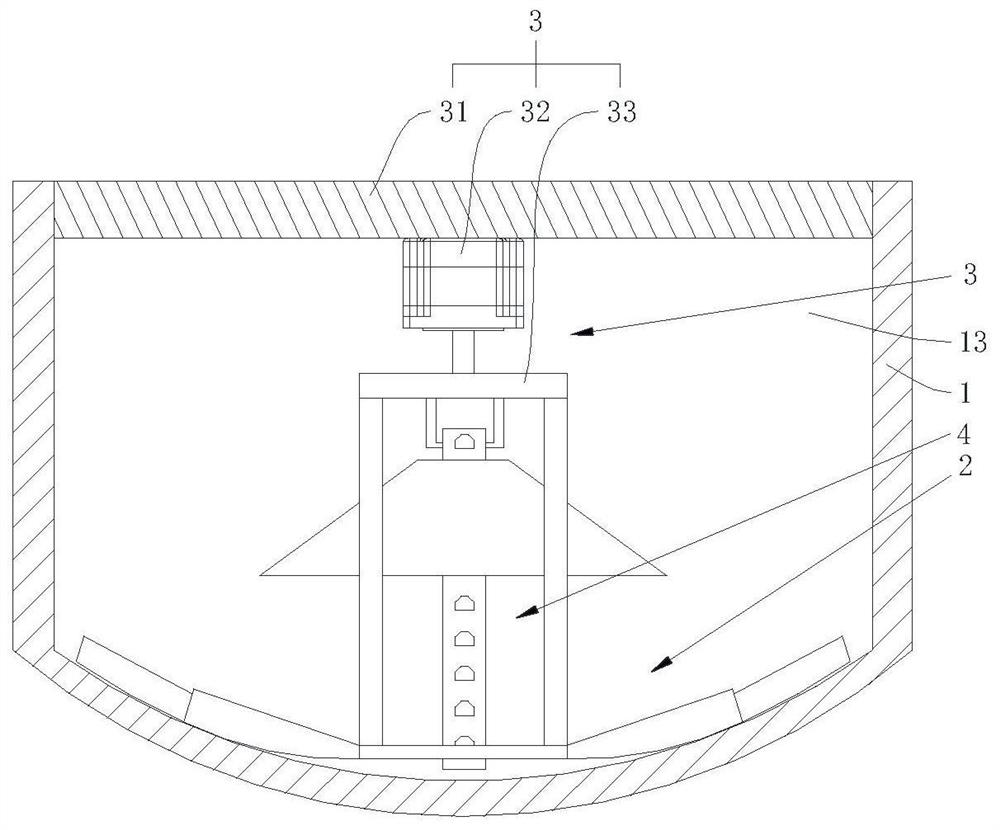

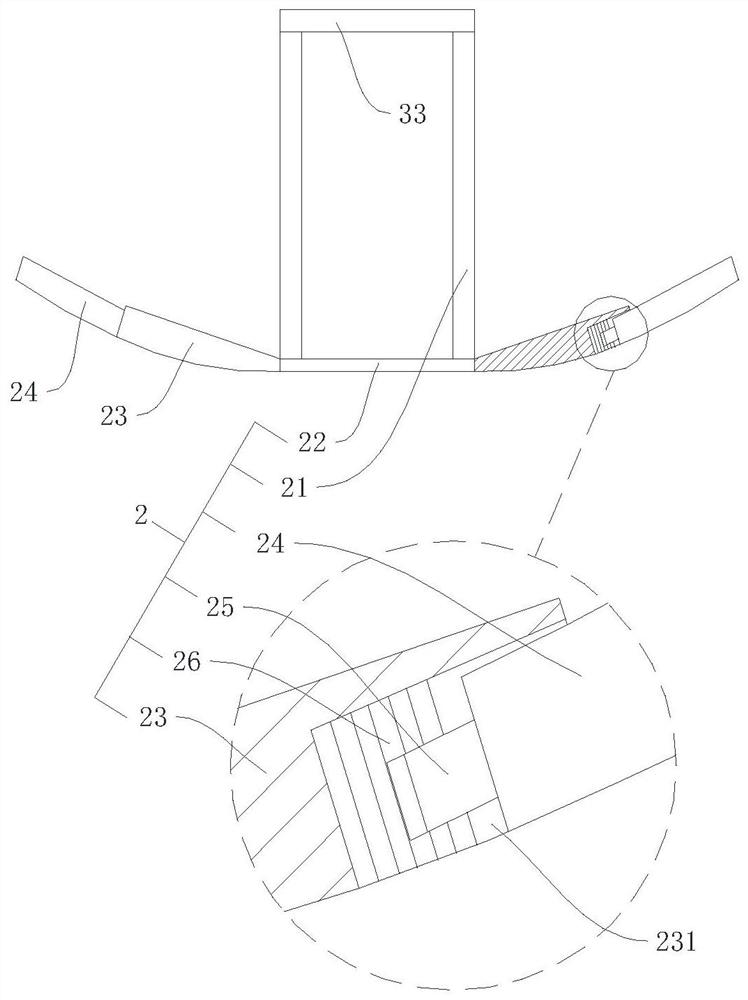

Stirring device for spherical pot body

InactiveCN105251411ASimple structureHigh speedCooking vesselsMixer accessoriesDrive shaftEngineering

The invention discloses a stirring device for a spherical pot body. The stirring device comprises a transmission shaft, a gear transmission system, inclined shaft sleeve positioning devices, a telescopic device and a scraper system. The gear transmission system is arranged in a rotary plate and is composed of a driving gear and two driven gears. The driven gears are symmetrically arranged on the two sides of the driving gear and meshed with the driving gear. A rotating plate for driving the rotary plate to rotate is arranged on the upper surface of the rotary plate. The transmission shaft vertically penetrates through the rotating plate and the rotary plate and penetrates through and drives the driving gear in the rotary plate. A stirring auxiliary gear is arranged at the bottom of the transmission shaft. The inclined shaft sleeve positioning devices are arranged at the positions, at the bottoms of the driven gears, of the rotary plate respectively. Each inclined shaft sleeve position device is composed of an inclined shaft sleeve and an inclined shaft sleeve flange. The stirring device is simple in structure, the defects that food sticks to a pot and is burnt in the pot and not uniformly stirred are perfectly overcome, and the produced product can be higher in speed, higher in quality and better in taste.

Owner:ZHUCHENG XINYE MACHINERY CO LTD

Method for producing low oil content potato chips by combined process of vacuum drying and follow-up microwave vacuum frying

The invention relates to a method for producing low oil content potato chips by a combined process of vacuum drying and follow-up microwave vacuum frying, and belongs to the technical field of fruit and vegetable food processing. The method for producing the low oil content potato chips comprises the following steps: with fresh potatoes as a raw material, performing high vacuum and rough vacuum combined pre-drying on potato chips, alternately freezing with freezing at an ultra-low temperature and slowly freezing, performing microwave vacuum frying, deoiling in vacuum, seasoning, packaging, sterilizing and storing. The potato chips are fried under low-temperature vacuum conditions, and the microwave assistance is utilized; in a first frying stage, the puffing effect and the frying efficiency are improved by large microwave power, the frying process is accelerated and the oil absorption peak is crossed; in a second stage, the color of the potato chips is protected by lowering the microwave power; the two-stage variable frequency microwave vacuum frying technology can be used for keeping the color and luster, special-flavor substances and nutrients of the potato chips, the oil content is low, and oil for frying is not easily oxidized, so that the oil content of the fried potato chips is reduced to 28% to 40% from general 40% to 41%.

Owner:GENERAL MILLS (CHINA) INVESTMENT CO LTD +1

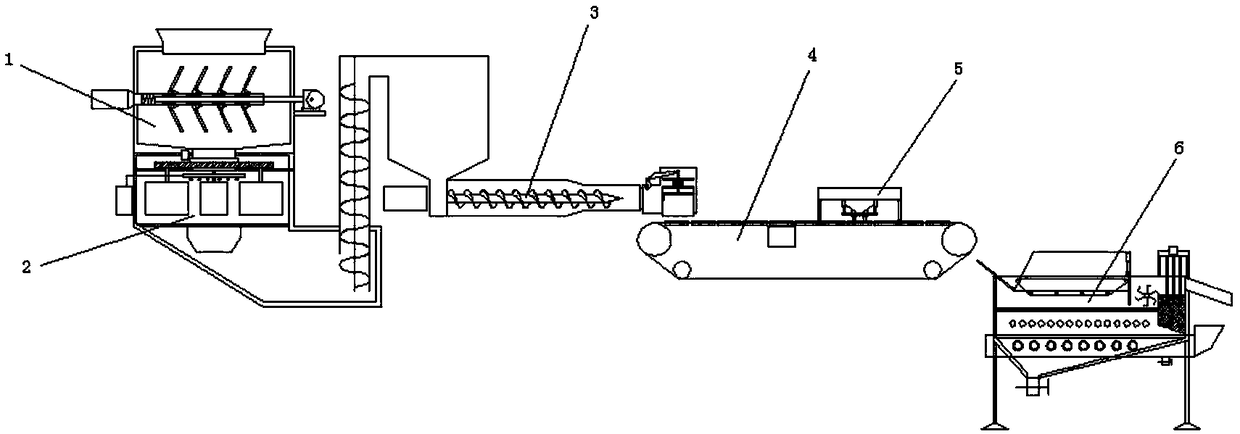

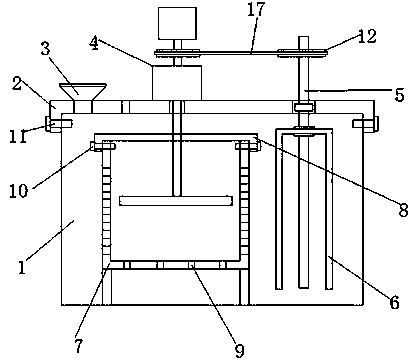

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

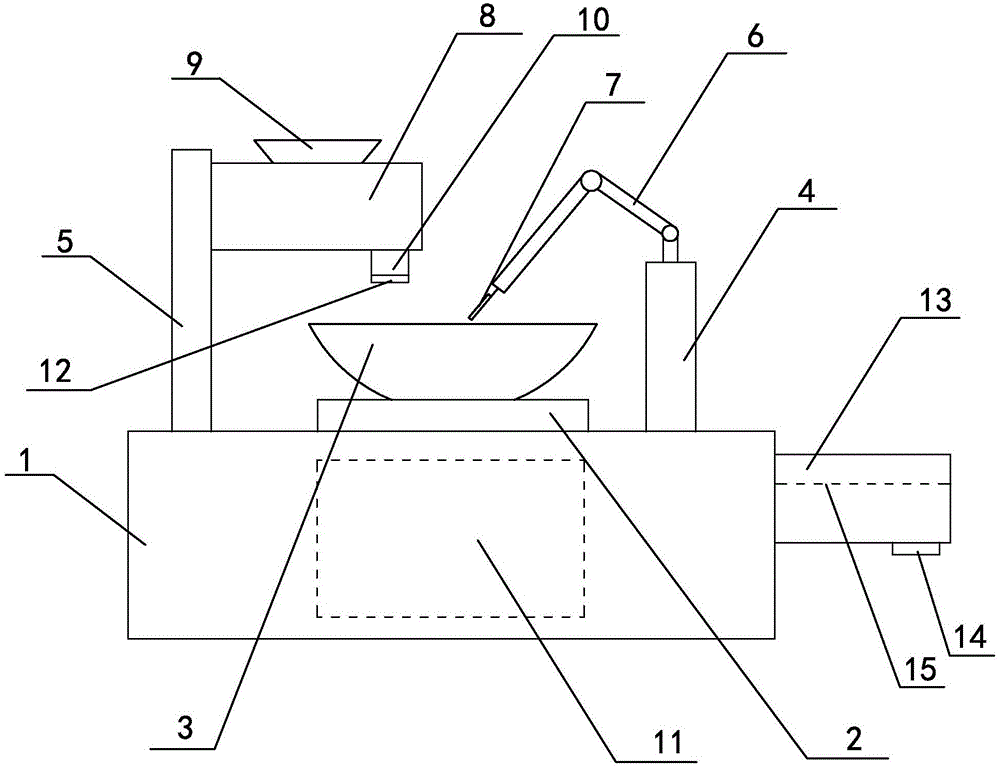

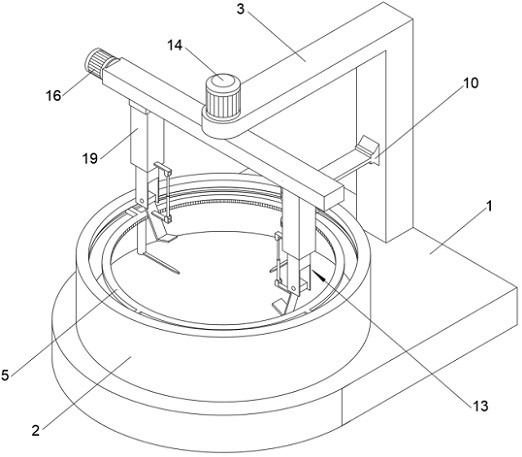

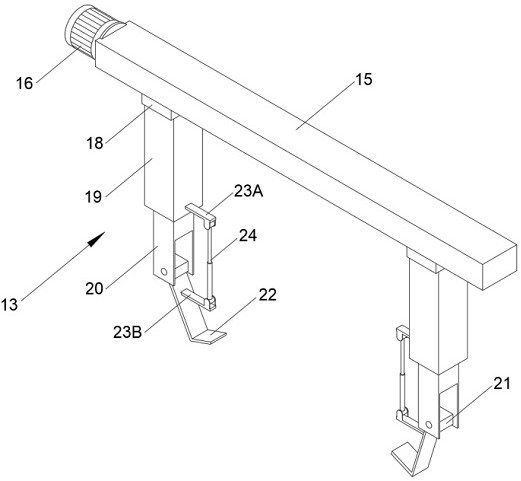

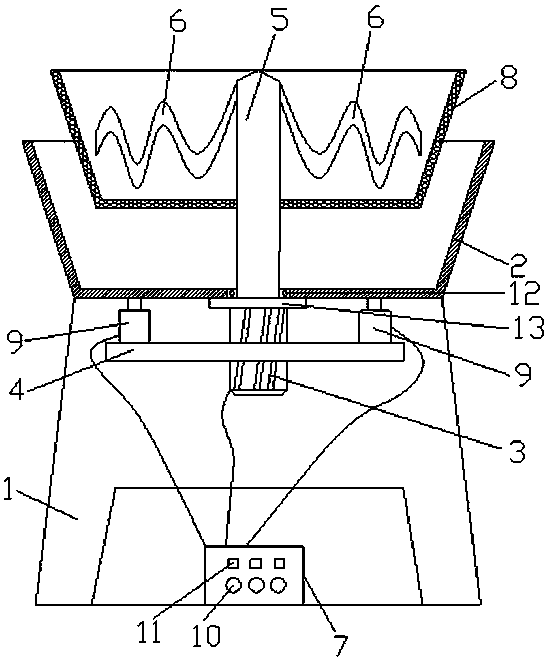

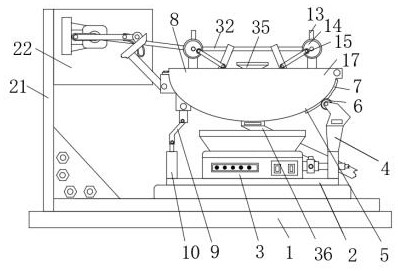

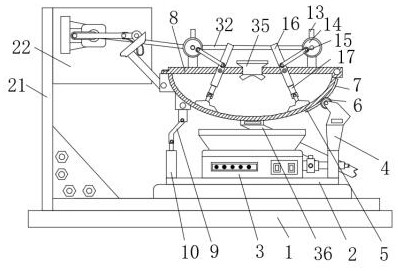

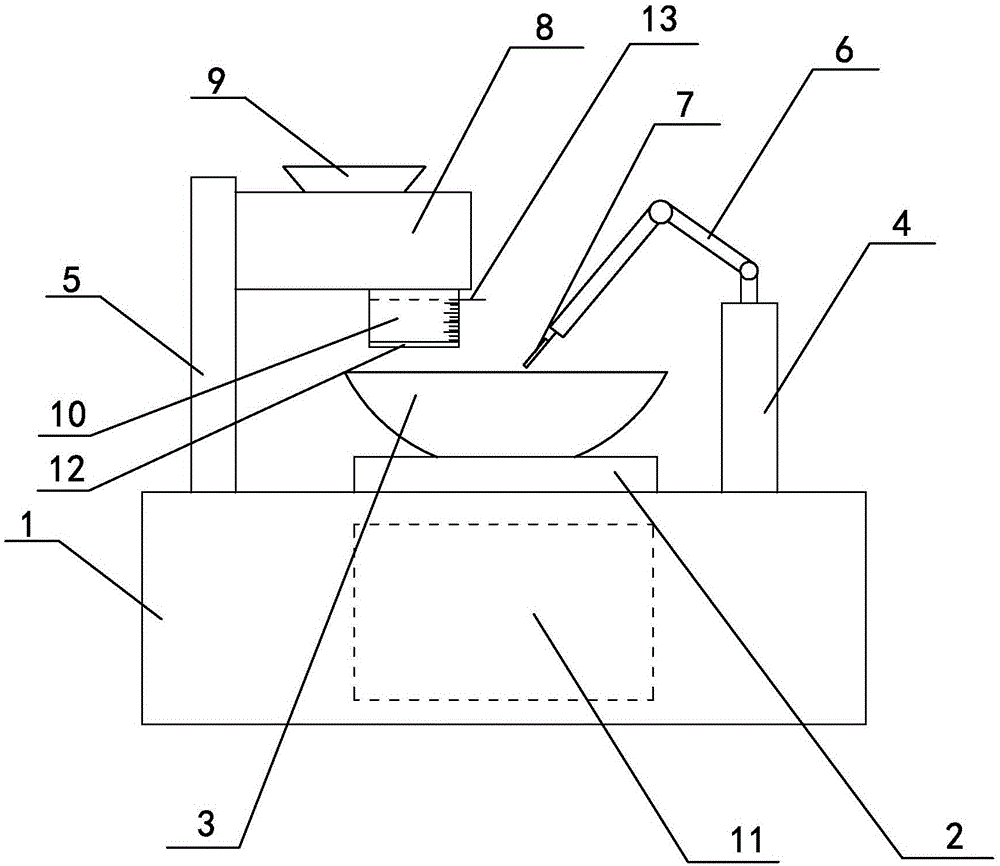

Integrated Chinese chestnut frying machine

InactiveCN106562456AStir fry evenlyImprove frying efficiencyFood treatmentElectrical controlEngineering

The invention relates to an integrated Chinese chestnut frying machine, and belongs to the food processing field. The integrated Chinese chestnut frying machine includes a base; an induction cooker is arranged on the top of the base; a frying pot is arranged on the induction cooker; a mechanical hand support is arranged on one side of the induction cooker, and a seasoning box support is arranged on the other side of the induction cooler; a mechanical hand is arranged on the mechanical hand support; a slice is arranged on the front end of the mechanical hand; a seasoning box is arranged on the seasoning box support; a material adding opening is formed in the top of the seasoning box, and a material discharging opening is formed in the bottom of the seasoning box; an electrical control cabinet is arranged in the base; a Chinese chestnut placement tank is arranged on one side of the base; a screening net is arranged in the Chinese chestnut placement tank; and a sundry outlet is formed in the bottom of the Chinese chestnut placement tank. When the Chinese nut is fried, the Chinese nut is put in the frying pot, a seasoning is added into the frying pot via the material discharging opening, and then the mechanical hand is started, the mechanical hand drives the slice to turn and fry automatically, turning and frying is even, and the frying efficiency is improved; and the fried Chinese nut can be directly put in the Chinese chestnut placement tank, sundries can enter the bottom of the Chinese chestnut placement tank via the screening net, and eating and sale is facilitated.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

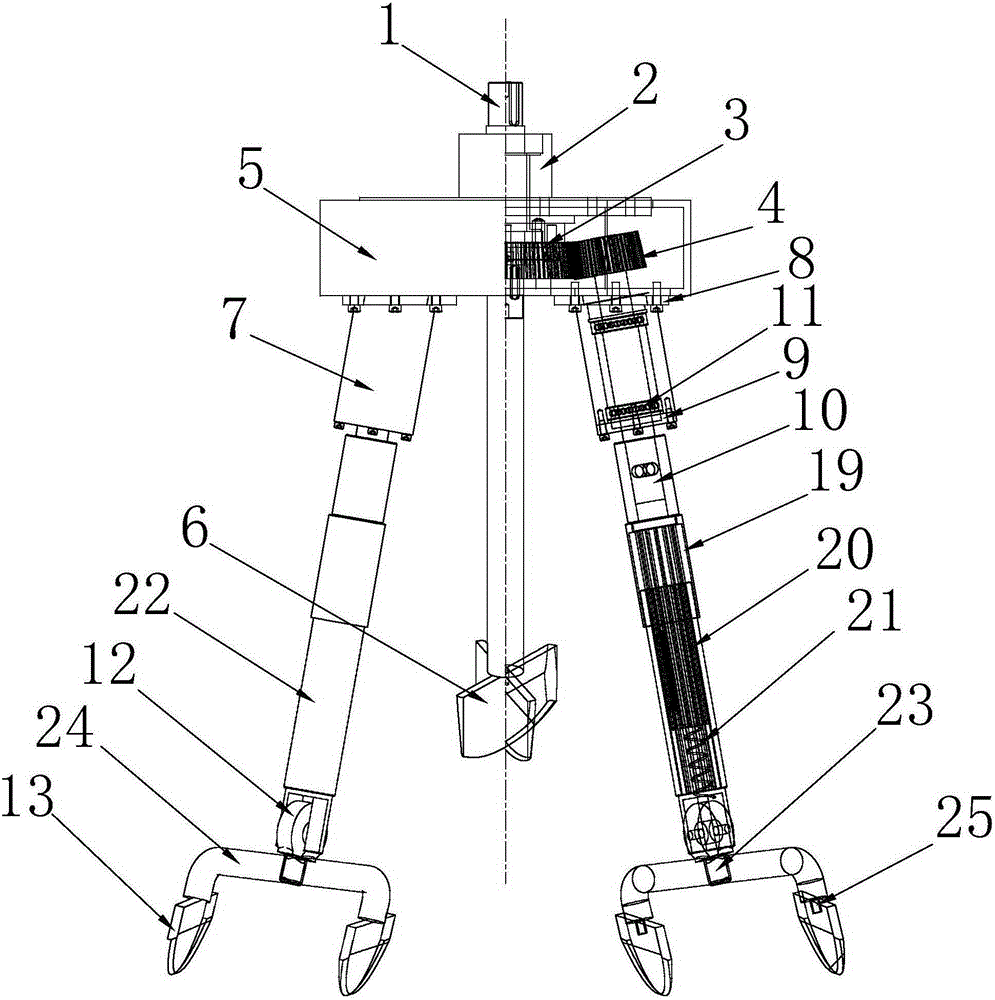

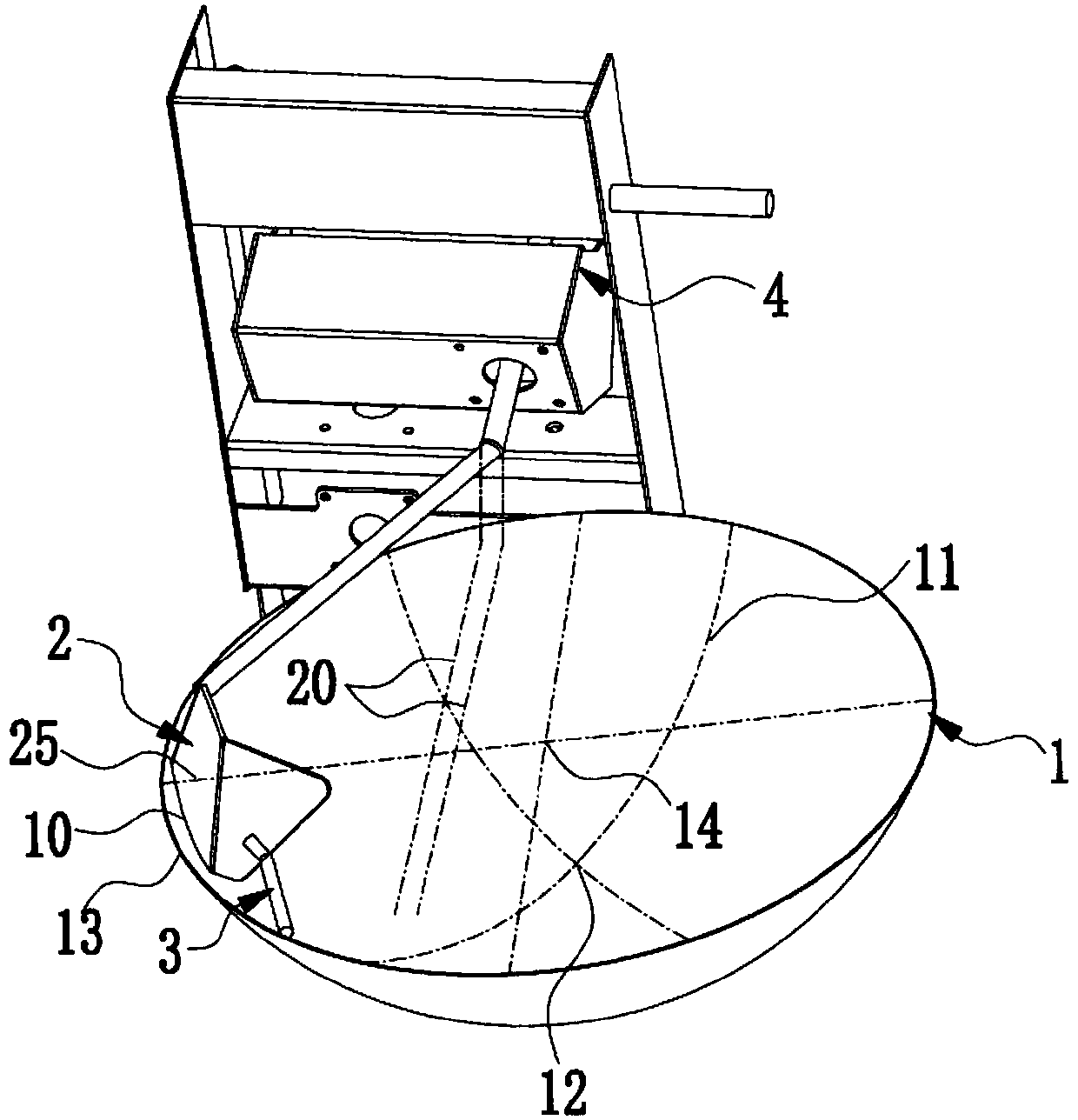

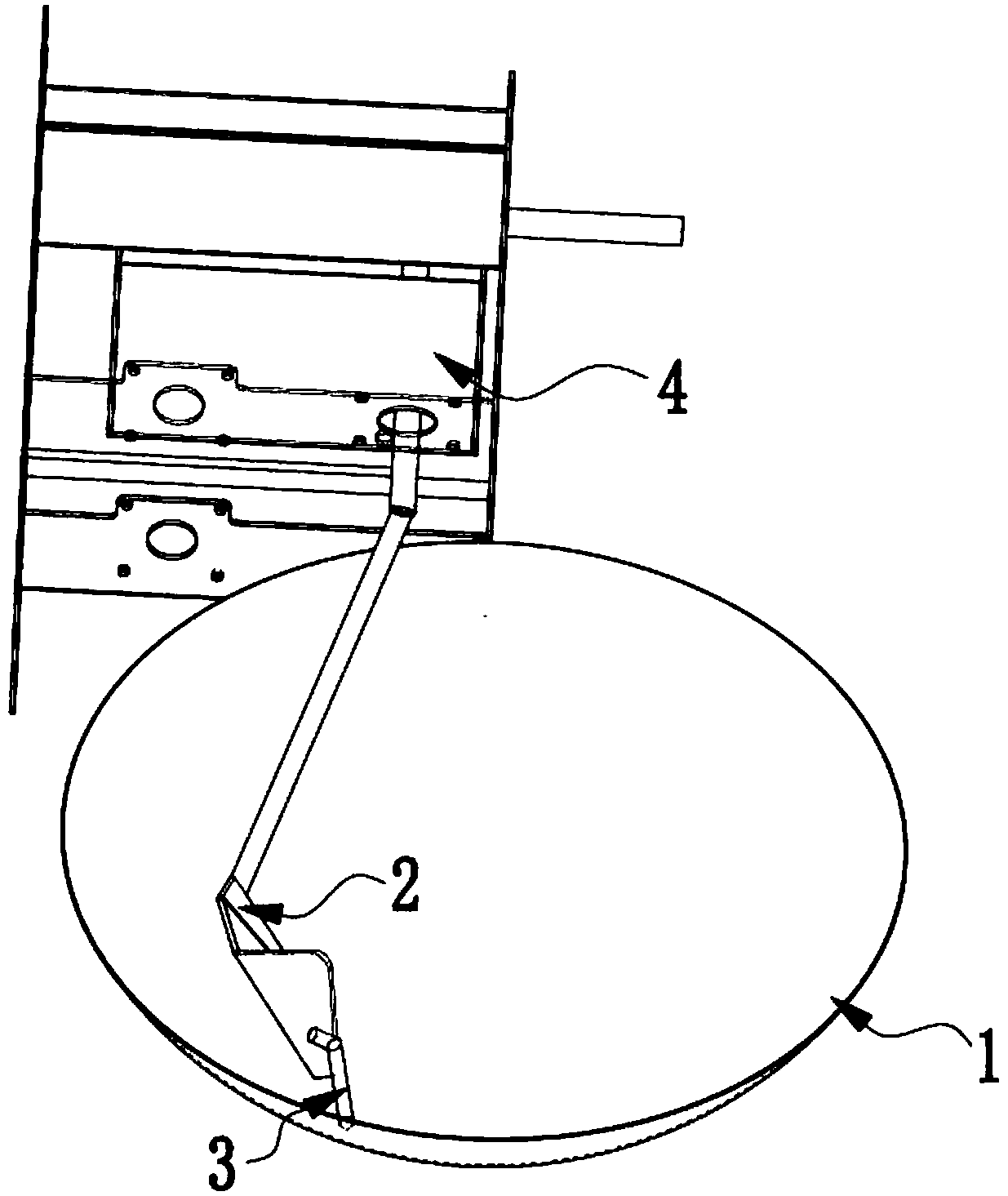

Artificial frying simulation cooking robot and cooking method thereof

The invention discloses an artificial frying simulation cooking robot and a cooking method thereof. The artificial frying simulation cooking robot comprises a pot body, a special spatula, an abuttingrod and a drive device. The abutting rod and the drive device are respectively connected to the special spatula and are matched with the special spatula for switching between a first frying process and a second frying process. In the first frying process, the edge of the special spatula is kept in contact with an inner wall of a pan, the special spatula slides from a tangent point position of thespecial spatula with the inner wall to a pan bottom position of a pan body, and the angle between the spatula surface of the special spatula and the pan mouth of the pan body gradually decreases; in the second pan frying process, the special spatula does not contact with the inner wall, and the special spatula flips from the pan bottom position to the tangent point position. According to the artificial frying simulation cooking robot and the cooking method thereof, the structure is simple, and the problems of sticking, scrap and sticking easily occur when there is a gap between the edge of thespecial spatula and the inner wall of the pan are avoided; besides, after materials are scooped up, the frying of the materials is achieved through the turnover of the special spatula, which effectively simulates the action during the manual frying and helps to make the materials be heated and mixed more evenly.

Owner:方正明

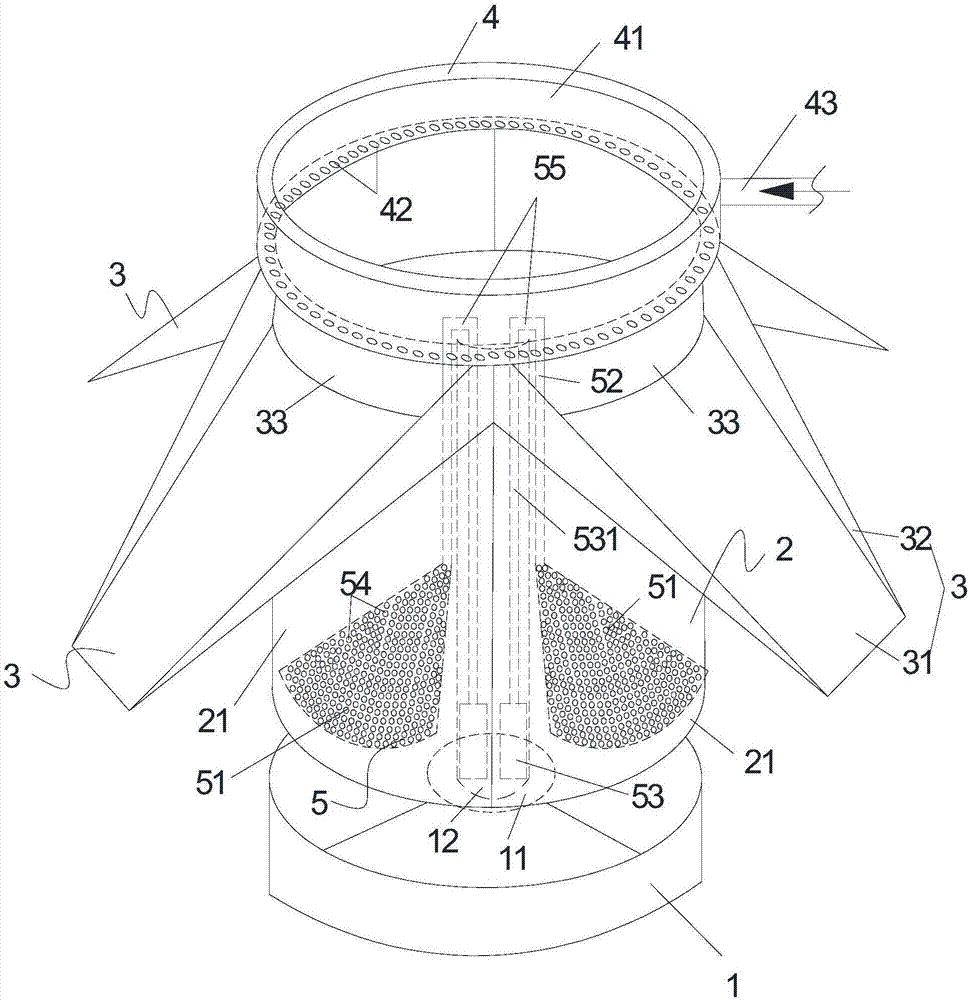

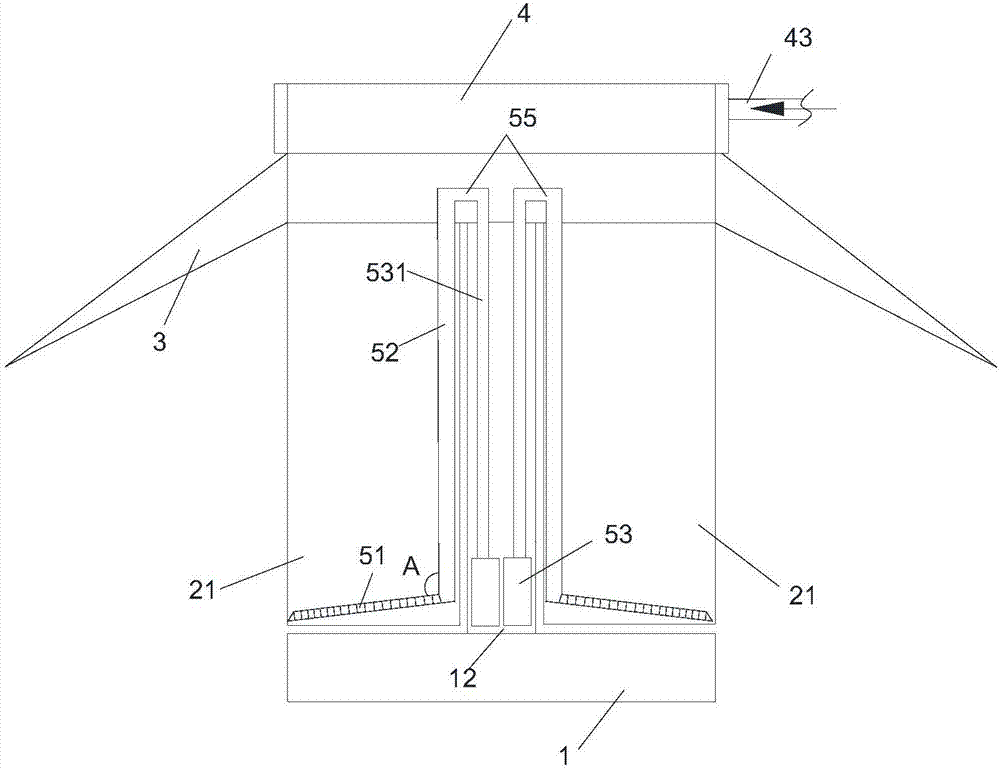

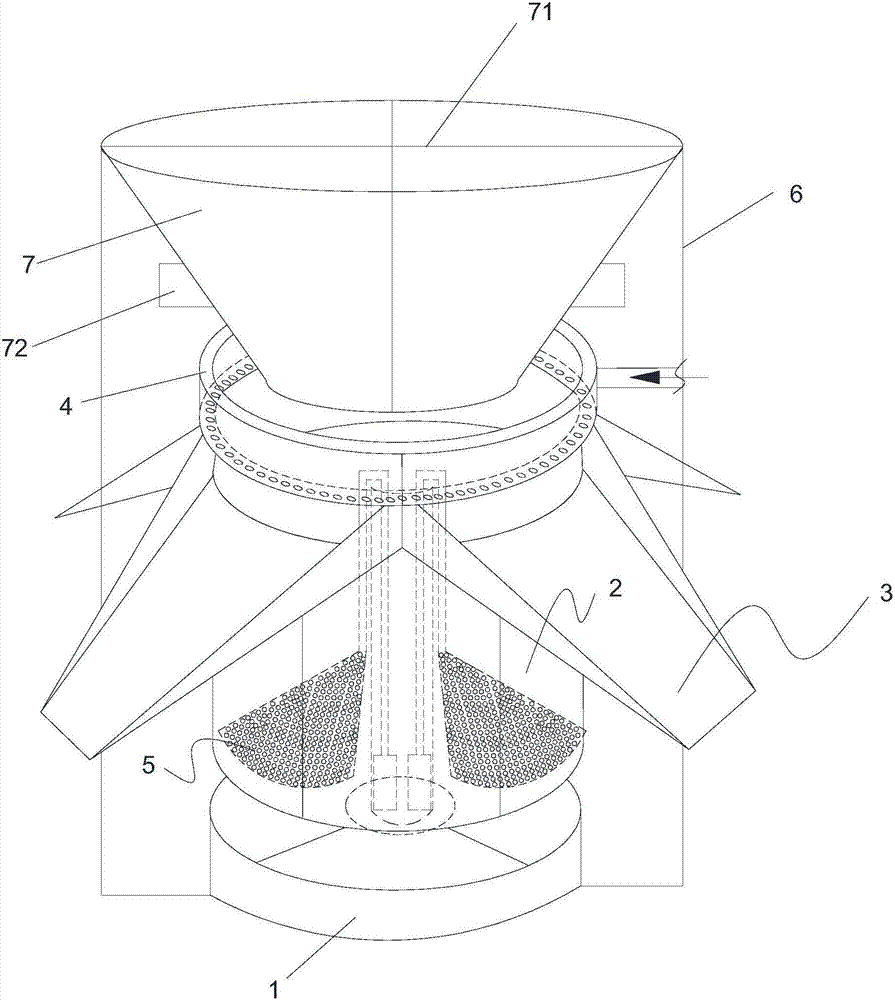

All-dimensional rotary type regional electromagnetic deep frying equipment

ActiveCN107148978AGreat tasteImprove frying efficiencyFood processingOil/fat bakingDeep fryingElectric machinery

The invention relates to all-dimensional rotary type regional electromagnetic deep frying equipment which comprises an induction cooker base and further comprises a cooking assembly. The induction cooker base is divided into four areas, an induction cooker is arranged at the bottom of each area of the induction cooker base, a driving motor is arranged in the induction cooker base, a hollow sleeve is fixed to a rotating shaft of the driving motor, and the top of the sleeve is opened; the cooking assembly comprises four cylindrical deep frying pans, the sections of the four cylindrical deep frying pans are in sector shape, discharging guide grooves are formed in outer walls of the tops of the cylindrical deep frying pans, and fishing assemblies are arranged in the cylindrical deep drying pans; each fishing assembly comprises a sector-shaped fishing plate, a lifting rod and a telescopic air cylinder. The all-dimensional rotary type regional electromagnetic deep frying equipment disclosed by the invention can deep fry balls regionally, so that taste of deep-fried balls is improved.

Owner:陈华应

Stir-frying device for nut processing

The invention discloses a stir-frying device for nut processing, and relates to the technical field of food processing. The stir-frying device comprises a support frame, a stir-frying trough is rotationally mounted in the support frame, the bottom of the stir-frying trough is vertically provided with a rotating shaft, a heater is embedded in the bottom of the stir-frying trough, the support frameis vertically provided with a driven shaft extending downwards to the stir-frying trough in a rotatable mode, a plurality of flipping plates are evenly fixed on the surface of the driven shaft, a driving shaft is fixedly sleeved by a gear, and a driven gear meshed with the driving gear is fixedly disposed on the driven shaft in a sleeving way. According to the invention, through rotation of the flipping plates and a stirring frame, repeated rotary stir-frying of nuts in the stir-frying trough is achieved; through alternate forward and reverse rotation of the driven shaft, vertical reciprocating movement of an external threaded pipe is realized, further swing of a swinging plate is achieved, the stirring range of the nuts in the stir-frying trough is greatly improved, and stir-frying is more sufficient; and since the rotation directions of the stir-frying trough and the driven shaft, the stirring of the nuts is more sufficient and comprehensive, and thus the stir-frying efficiency of the nuts is greatly improved.

Owner:北京臻味坊食品有限公司

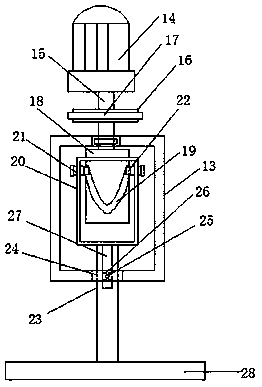

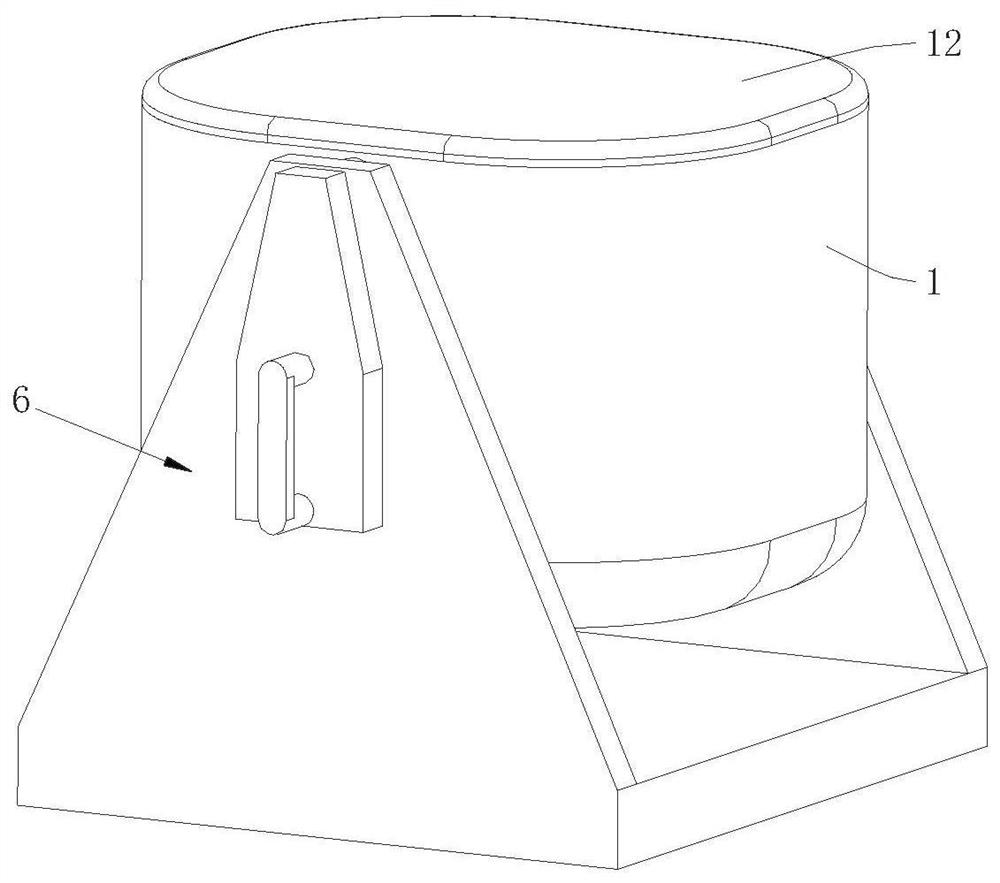

Traditional Chinese medicine decocting device

ActiveCN108836859AImprove frying efficiencyIncrease profitPharmaceutical product form changeDomestic articlesEngineeringChinese herbology

The invention discloses a traditional Chinese medicine decocting device. The decocting device comprises a decocting pot, and the decocting pot is of a cavity structure with an opening in the top end;a pot cover is arranged at the top end of the decocting pot, and the pot cover is connected with the decocting pot through a first fastening rod; an inlet and outlet is formed in one side of the top end of the pot cover, and a movable mechanism is arranged in the middle of the top end of the pot cover; a stirring shaft is arranged on the side, far away from the inlet and outlet, of the pot cover;stirring blades located in the decocting pot sleeve the stirring shaft, and a medicinal material pot is arranged in the decocting pot; the medicinal material pot is of a cavity structure with an opening in the top end, a cover plate is arranged at the top end of the medicinal material pot, and a plurality of through holes are formed in the side wall of the medicinal material pot; the medicinal material pot and the cover plate are connected through a second fastening rod, and the stirring shaft is sleeved with a secondary rotating disc which is located above the pot cover. The decocting devicehas the advantages that used medicinal materials are collected at the same time, the medicinal materials and a solvent are effectively prevented from being stored in a same container, residues are prevented from entering the solvent, the purity of traditional Chinese medicine is improved, and the efficacy of the traditional Chinese medicine is improved.

Owner:莒县中医医院

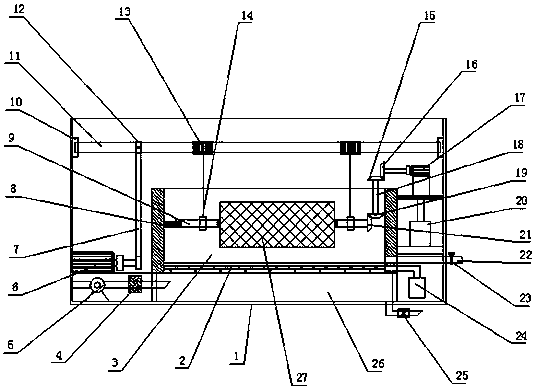

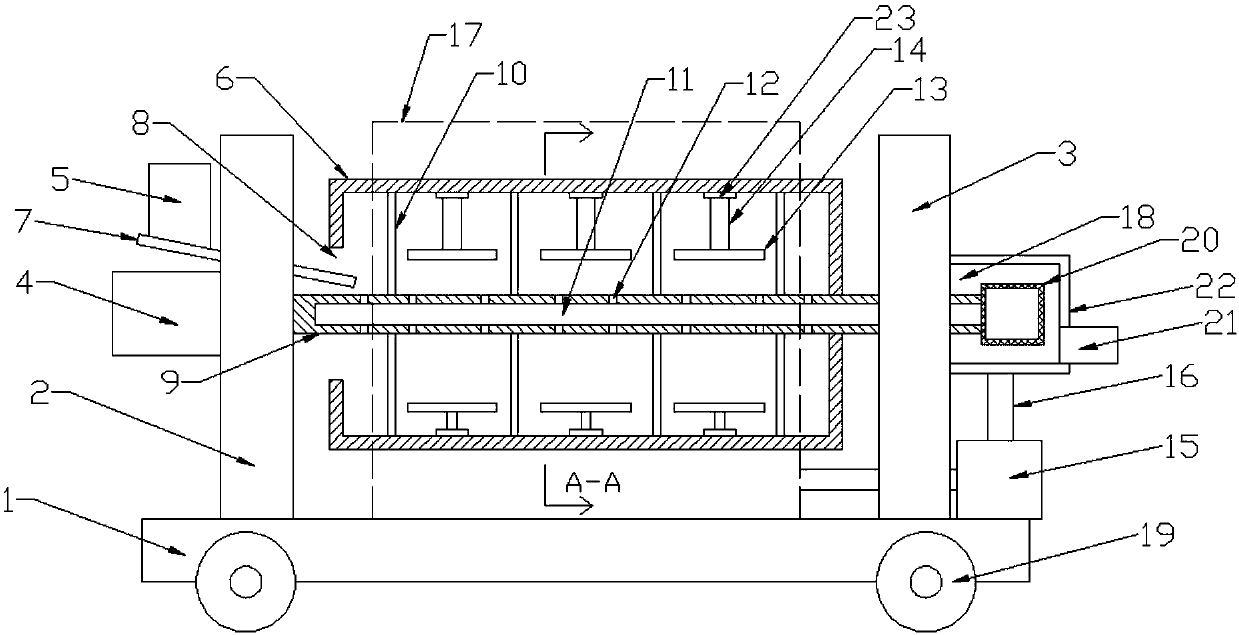

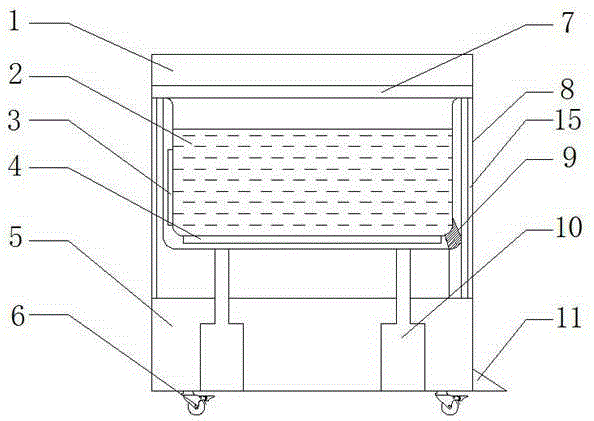

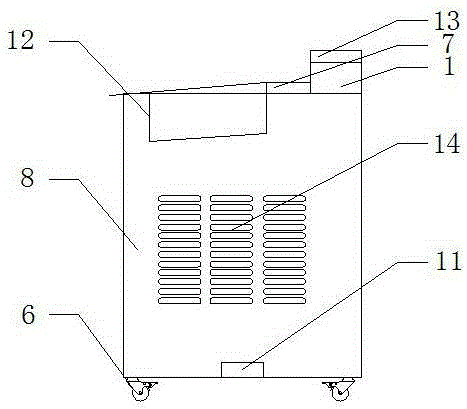

Steam type dried meat floss frying machine

ActiveCN102578595AHeating evenlyTemperature is easier to controlFood preparationDrive motorMeat fibers

The invention discloses a steam type dried meat floss frying machine which comprises a stand. A cylinder is arranged on the stand; an inner container is sleeved in the cylinder; the top of the inner container is provided with a rotary shaft; the rotary shaft is connected with a driving motor through a speed reducer; a steam pipe is arranged in an interlayer between the inner container and the cylinder; the rotary shaft is axially provided with a steam introducing channel in which air can be introduced; a thermobarometer is arranged on the rotary shaft; an air introducing pipe is arranged between the cylinder and the rotary shaft; the bottom of the inner container is provided with a ventilating duct; the other end of the ventilating duct is connected with an air blower; and the rotary shaft is axially provided with an air exhausting channel for exhausting the air in the inner container. The dried meat floss is heated by the rotary cylinder and the steam, thus the dried meat floss is fried in the most suitable heating temperature range, the heating at low temperature and the heating at high temperature are effectively controlled, the dried meat floss is heated more uniformly, the temperature of the dried meat floss is easier to control, the efficiency is improved, the dried meat floss can be prevented from being burnt, the meat fiber can be kept intact, the preparation of high-quality dried meat floss can be guaranteed to a certain extent.

Owner:TAICANG FEIFENG FOOD

Hotpot condiment stir-frying device capable of conveniently detecting moisture content

The hotpot condiment stir-frying device comprises a supporting table, condiment containing pots and an L-shaped bearing beam, the condiment containing pots and the L-shaped bearing beam are fixedly installed on the two sides of the top face of the supporting table respectively, multiple sets of detection mechanisms used for detecting moisture are arranged in the condiment containing pots, and a pressure bearing frame rotating around a fixed axis is arranged in an inner cavity of each condiment containing pot; four bottom supporting columns distributed along the vertical center line of the material containing pot in a circumferential array mode are fixedly welded to the bottom face of the pressure bearing frame, and a mounting piece and a detection foot are sequentially and fixedly connected to the side, facing the center of the material containing pot, of each bottom supporting column; and a second motor is fixedly welded to the top face of one end of the bearing beam, a mounting frame is rotationally connected to the bottom face of the end of the bearing beam, two stir-frying mechanisms are symmetrically arranged below the mounting frame, and a driving assembly for adjusting the positions of the stir-frying mechanisms is further arranged on the bearing beam. According to the hotpot condiment stir-frying device capable of conveniently detecting the moisture content, condiments at all positions in the condiment containing pot are stir-fried more uniformly.

Owner:四川合合谷食品有限公司

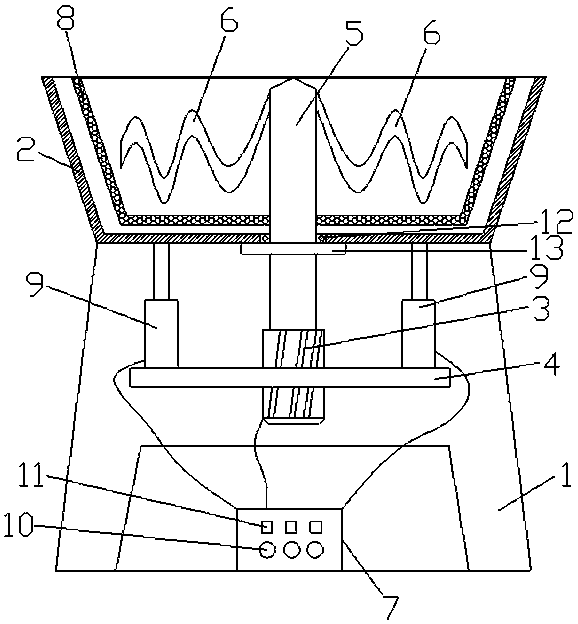

Sesame seed stir-frying device with preheating

The invention discloses a sesame frying device with preheating, which includes a preheating drying device and a roasting device. The preheating drying device includes a drying barrel, a collection chamber and an impurity chamber. The drying barrel includes a fixedly connected drying chamber and a drying chamber. Drying cone, the drying cone is located at the lower part of the drying chamber; the roasting device includes a frying device and a cooling drum, the frying device includes a drum, the cooling drum is arranged at the outlet end of the drum, and the cooling drum passes through the intermediate piece and the drum Connected, the cooling cylinder is provided with a cooling outlet. The sesame frying device with preheating of the present invention has wide applicability, preheating and drying can greatly improve the efficiency of sesame frying, the frying device ensures that the sesame is evenly fried, and the frying situation can be monitored at any time during the frying process, At the same time, the excess high temperature during the frying process can be used to fry the sesame seeds at a low temperature. The fried sesame seeds can be cooled in time, and the entire processing process can also ensure continuity.

Owner:黄林海

Seed and nut roasting machine with sorting mechanism

InactiveCN108433144AQuick clean upSimple structureFood treatmentAgricultural engineeringMaterial resources

The invention relates to a seed and nut roasting machine with a sorting mechanism. The seed and nut roasting machine with the sorting mechanism comprises a base; a shell is fixedly arranged at an upper end of the base; a stirring assembly is perpendicularly arranged at a central part of shell; the stirring assembly comprises a driving motor, a fixed plate, a rotary shaft, stirring blades and a control cabinet; a sorting mechanism comprises a screen frame and telescopic rods, wherein the telescopic rods are arranged at two sides of the driving motor; upper ends of the telescopic rod are fixedlyarranged on a lower end surface of the shell, and lower ends of the telescopic rod are fixedly arranged on an upper end surface of the fixed plate; the screen frame surrounds outside of the stirringblades; and the rotating shaft is fixedly arranged at a central part of the screen frame. The seed and nut roasting machine with the sorting mechanism is simple in structure, and capable of facilitating rapid cleaning on roasted seeds and nuts by operators; and thus, the seed and nut roasting machine with the sorting mechanism is capable of saving manpower and material resources, improving overallstir-frying efficiency, and facilitating wide promotion and usage.

Owner:浙江省长兴泰明食品有限公司

Automatic food deep-frying equipment

ActiveCN107897235AReduce work intensitySimple structureOil/fat bakingHydraulic cylinderBiochemical engineering

The invention discloses automatic food deep-frying equipment. A deep-frying tank is fixedly arranged in a tank body; a first motor is arranged on one side of the deep-frying tank through a motor mounting seat; a second motor is arranged on the other side of the deep-frying tank through the motor mounting seat; a belt is connected to the output end of the first motor, and the other end of the beltis connected with a spur gear; the second motor is fixedly arranged on the surface of a supporting plate through the motor mounting seat; a piston rod of a hydraulic cylinder is connected with the other side of the supporting plate through welding; a bevel gear I is fixedly connected to the output end of the second motor; supporting frames are symmetrically arranged at two ends of a food placing cavity, and are connected to the food placing cavity through welding; lantern rings are sheathed on the supporting frames; a cable is connected to the lantern rings; the other end of the cable is arranged on a winch; and the winch is fixedly connected to a rotating shaft.

Owner:资兴市山水天然食品有限公司

Tea frying machine

InactiveCN102835477AImprove frying efficiencyWith filter functionPre-extraction tea treatmentAgricultural engineeringTea leaf

The invention discloses a tea frying machine, comprising a shell, a discharge hole and a discharge chute; a lower end of one side of the shell is provided with a discharge hole; the discharge chute is aslant arranged under the discharge hole; the shell is provided with a rotatable electric heating plate; an inclined partition board is arranged below the electric heating plate; the lower end of the partition board is connected with the discharge hole; a vibrator is arranged under the partition board; the partition board is provided with filtering holes; the partition board is provided with a cylinder; the other end of the cylinder is connected with the electric heating plate; the cylinder can control the electric heating plate to turn downwards; a slag containing plate is arranged under the partition board; the shell is provided with a discharge door, which can close the discharge hole; a vibrator is arranged under the discharge groove; and the slag containing plate is provided with a handle. The tea frying machine provided by the invention has filtering function and good automatic discharging effect; and the ea frying machine shortens a cycle of a tea frying process, and increases the continuity of the tea frying process, thereby increasing the tea frying efficiency.

Owner:SUZHOU XISHAN HONGYUN MATERIAL ARTICLES FACTORY

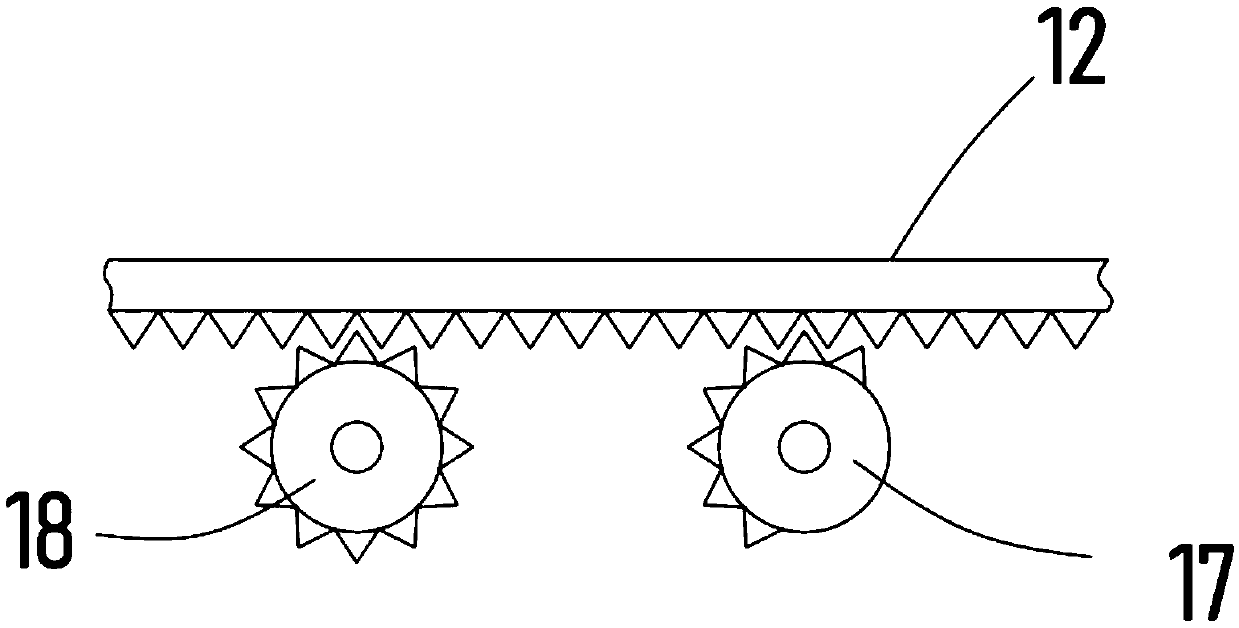

Nut stir-frying machine

InactiveCN111700290ARealize automatic cycle fryingImprove frying efficiencySievingConveyorsEngineeringMechanical engineering

The invention relates to the technical field of stir-frying machines, and particularly relates to a nut stir-frying machine. The nut stir-frying machine comprises a stir-frying roller, wherein sieve holes are formed in the left side of the periphery of the stir-frying roller; ingredients and nuts are pushed forwards in the roller, are stirred and are stir-fried; when the ingredients and the nuts reach the positions of the sieve holes, the ingredients and the nuts are automatically sieved; the nuts are discharged from a stir-frying discharging groove; a material guiding groove is fixedly formedin a housing under the stir-frying roller; the material guiding groove is inclined towards the lower part of the right side; a lifting cylinder is fixedly arranged under the right side of the stir-frying roller in the housing; an auger is arranged on a transmission shaft in the lifting cylinder; the ingredients leak onto the material guiding groove at the positions of the sieve holes, and then slide to the lifting cylinder through the material guiding groove; and the ingredients are circularly conveyed to the roller through the auger, so that the process of automatically and circularly stir-frying the ingredients is realized, time and labor are saved, and the stir-frying efficiency of the nuts is greatly improved.

Owner:加州原野(霸州市)食品有限责任公司

Air fryer with water spraying function

InactiveCN108354467AQuick frying processImprove frying efficiencyBaking ovenRoasters/grillsEngineeringMotor drive

The invention discloses an air fryer with water spraying function, which includes a lower body, an inner container, a food frying screen and a sprayer. The lower part of the lower body is provided with supporting legs. The upper part of the lower body is provided with a top support. A middle supporting body is arranged between the top support and the lower body. The front side of the top support is provided with a display screen and a control button. One side of the display screen is provided with an indicator lamp. The middle part of the inner part of the bottom body is provided with a fryersupport body. The air fryer has the advantages that: the circulating motor drives the circulating blade to rotate to form a high-speed flowing hot air circulation cavity in the air fryer. The rapid frying process of food is realized. The automatic water spraying function is also provided. The range of the fried food is effectively enlarged. The fryer is with simple operation, high frying efficiency and strong practicability.

Owner:郭鑫

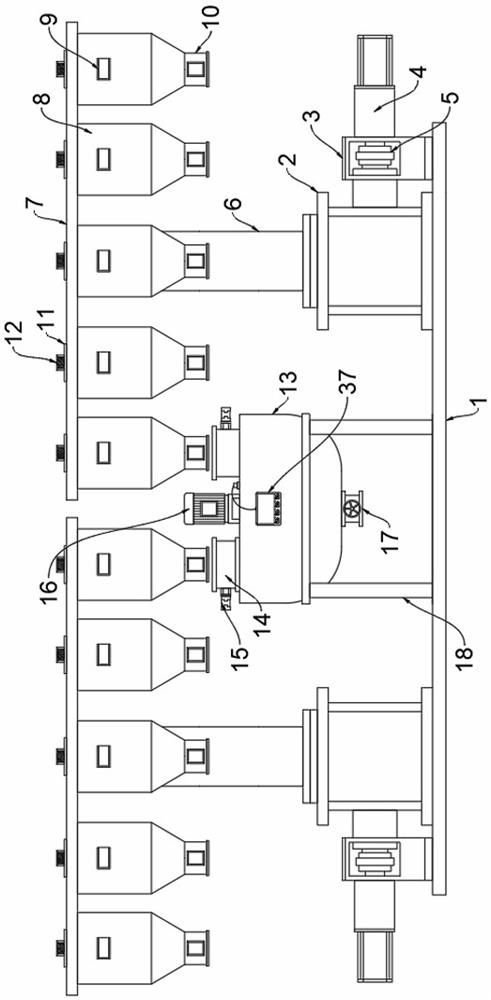

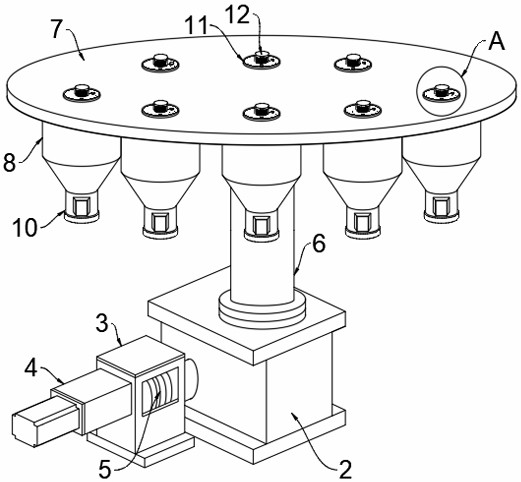

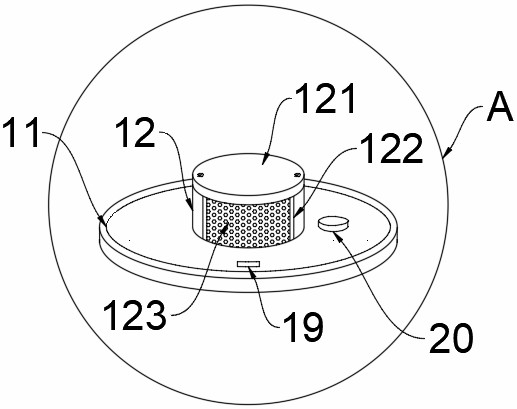

Material quantitative proportioning and mixing device for seasoning production and use method thereof

PendingCN113634190AThe purpose of convenient quantitative additionSolve low production efficiencyTransportation and packagingDispersed particle separationGear driveCoupling

The invention discloses a material quantitative proportioning and mixing device for seasoning production and a use method thereof. The material quantitative proportioning and mixing device comprises a bottom plate and gear transmission boxes arranged on the two sides of the upper surface of the bottom plate; a transmission column installed at the upper end of the gear transmission box, wherein a material disc is installed at the upper end of the transmission column; eight material tanks mounted on the periphery of the lower surface of the material disc; material covers mounted on the upper surface of the material tank, wherein a moisture absorber is mounted at the upper end of the material cover; and a coupling seat installed on one side of the gear transmission box, wherein a servo motor is installed on one side of the coupling seat, and the output end of the servo motor is in transmission connection with the input end of the gear transmission box through a first coupler. According to the device, quantitative feeding is jointly achieved through the synergistic effect of the two feeding mechanisms, and therefore the problems that when existing seasonings are prepared, automatic quantitative feeding work of dozens of raw materials cannot be met, and the production efficiency is low are effectively solved.

Owner:ZHEJIANG WEIHAI FOOD INGREDIENT CO LTD

Deep-frying device for food processing

InactiveCN112056333AEvenly heatedFull and even contactTransportation and packagingBaking ovenElectric machineryEngineering

The invention discloses a deep-frying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problems of insufficient and non-uniform heating of foods in an existing deep-frying device. The deep-frying device comprises a machine frame and a deep-frying unit, wherein the deep-frying unit comprises an oil barrel and a net barrel used for containing foods; the deep-frying device further comprises an agitating assembly, wherein the agitating assembly comprises a double-shaft motor, a first magnet, a second magnet, a turbulence rod, reciprocatingscrew rods, third magnets and fourth magnets; a stirring assembly used for stirring the foods is mounted on a cover body, and the stirring assembly comprises a first motor, a lifting auger, arc-shaped top covers and arc-shaped bottom rings and is provided with a frying unit; and when the double-shaft motor drives the reciprocating screw rods to rotate, the height position of each third magnet onthe corresponding reciprocating screw rod is continuously changed, so that the deflection range of the turbulence rod is changed, the agitating range is expanded, and the agitating efficiency is further improved; and the stirring assembly is arranged, through continuous circulation, movement of the foods is facilitated, food deposition or adhesion is avoided, and the deep-frying efficiency is improved.

Owner:吕瑞雪

Camellia seed stir-frying processing device for preparing camellia oil

PendingCN112094687AImprove uniformityTo achieve the purpose of stir fryingFatty-oils/fats productionOil processingRapeseed

The invention belongs to the field of tea oil processing, and particularly relates to a camellia seed stir-frying processing device for tea oil preparation. The camellia seed stir-frying processing device comprises a processing base, a welding plate is fixedly mounted at the top of the processing base, a gas stove is fixedly mounted at the top of the welding plate, and a supporting rod is fixedlymounted at the top of the welding plate. The top of the supporting rod is slidably connected with a wok, the wok is located over the gas stove, the bottom of the wok is fixedly connected with a connecting rod, the bottom of the connecting rod is elastically and slidably connected with a fixing base, the top of the wok is rotatably connected with a wok cover, and two symmetrically-arranged fixing plates are fixedly installed at the top of the wok cover. The camellia seed stir-frying processing device body designed by the invention is convenient to operate, ensures that rapeseeds are always in arolling state and are uniformly heated in the process of heating and drying the rapeseeds, greatly improves the camellia seed stir-frying efficiency, saves the processing cost, and has relatively strong practicability.

Owner:HUNAN ZHANWANG BIOTECH DEV

Novel adjustable multistage hotpot condiment stir-frying and stirring device

The invention relates to the technical field of kitchenware, and discloses a novel adjustable multistage hotpot condiment stir-frying and stirring device which comprises a carrier plate, a box body isfixedly installed at the top of the carrier plate, a first induction cooker is fixedly installed at the bottom of the box body, and a first stirring pot with one end extending to the upper portion ofthe box body is arranged at the top of the first induction cooker. And positioning rods are fixedly mounted on the left side and the right side of the first stirring pot correspondingly, positioninggrooves are formed in the sides, opposite to each other, of the positioning rods, and threaded cylinders are fixedly mounted on the left side and the right side of the box body correspondingly. According to the novel adjustable multi-stage hotpot condiment stir-frying and stirring device, the second stirring pot, a water suction pipe and a water outlet pipe are arranged, so that when a user uses the device, the second induction cooker is turned on, the whole beef tallow is put into the second stirring pot to be heated, and the beef tallow is pumped out and fed into the first stirring pot through a suction water pump after heating is completed; when the device is used for frying the hotpot condiment, the waiting time is saved, and the frying efficiency is improved.

Owner:重庆桥头食品有限公司

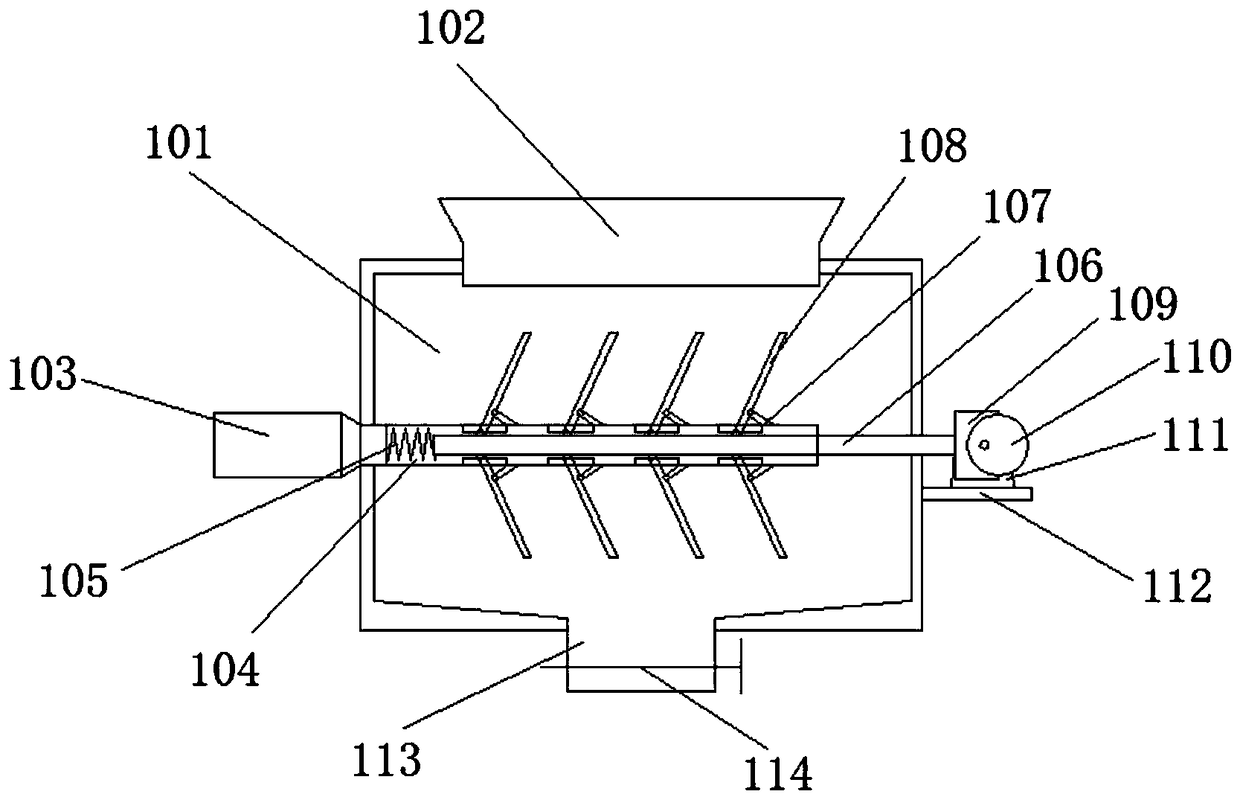

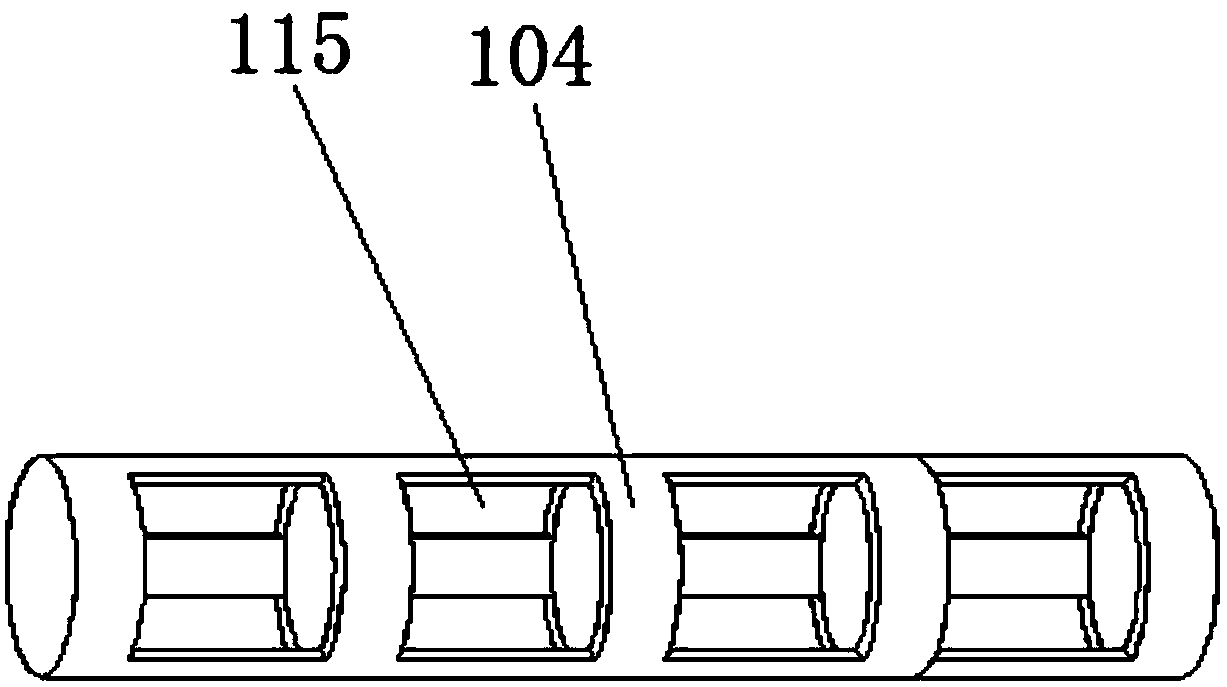

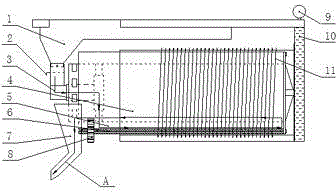

Fully automatic high-frequency highland barley parching machine

InactiveCN104013083ANo pollution in the processRealize automatic separationFood treatmentSpiral bladeProcess engineering

The invention discloses a fully automatic high-frequency highland barley parching machine, which comprises a feeding hopper, a discharging hopper, a material return cylinder, a parching cylinder and a high-frequency coil, wherein the material return cylinder is sleeved by the parching cylinder; the output end of the feeding hopper is connected with the feeding end of the parching cylinder; the discharging end at the head part of the material return cylinder is connected with the feeding end of the discharging hopper; the parching cylinder and the material return cylinder are both internally provided with spiral blades; the spiral direction of the spiral blades in the parching cylinder is opposite to the spiral direction of the spiral blades in the material return cylinder; the tail part of the material return cylinder is provided with filtering holes; the parching cylinder is arranged in the high-frequency coil; and the high-frequency coil is connected in a heating circuit of the parching machine. The fully automatic high-frequency highland barley parching machine has the advantages that a high-frequency induction heating technology is adopted, so that the heating effect is good, the heating is uniform, the preheating time is short, resources are saved, and the environment is protected; the high-voltage dangers are eliminated in the operation process, and the safety is improved; and in addition, parched products and hot media are automatically separated in the machine, so that the labor is saved, the work intensity is reduced, and meanwhile, the production efficiency and the parching efficiency are greatly improved.

Owner:百金(成都)科技发展有限公司

Chinese chestnut frying machine capable of carrying out quantitative charging

The invention relates to a Chinese chestnut frying machine capable of carrying out quantitative charging, and belongs to the field of food processing. The machine comprises a pedestal, and the top of the pedestal is provided with an induction cooker. A frying pan is disposed on the induction cooker. One side of the induction cooker is provided with a mechanical arm support and the other side of the induction cooker is provided with a flavor box support. The mechanical arm support is provided with a mechanical arm, and the front end of the mechanical arm is provided with a turner. The flavor box support is provided with a flavor box, wherein the top of the flavor box is provided with a charging port, and the bottom of the flavor box is provided with a discharging pipe. The interior of the pedestal is provided with an electrical control cabinet, and the bottom of the discharging tube is provided with a cover body. The discharging tube is made of a transparent material, and the discharging tube is provided with scale. The machine is provided with the mechanical arm. During the turning and frying of Chinese chestnuts, the Chinese chestnuts are placed into the frying pan, and flavor is added to the frying pan through the discharging tube. Afterwards, the mechanical arm is started to drive the turner to automatically turn and fry the Chinese chestnuts. The machine is uniform in turning and frying, improves the frying efficiency, and can achieve a purpose of quantitative charging through observing the scale during charging.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

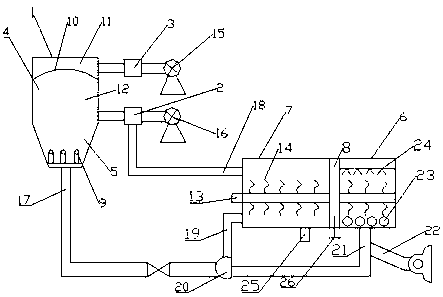

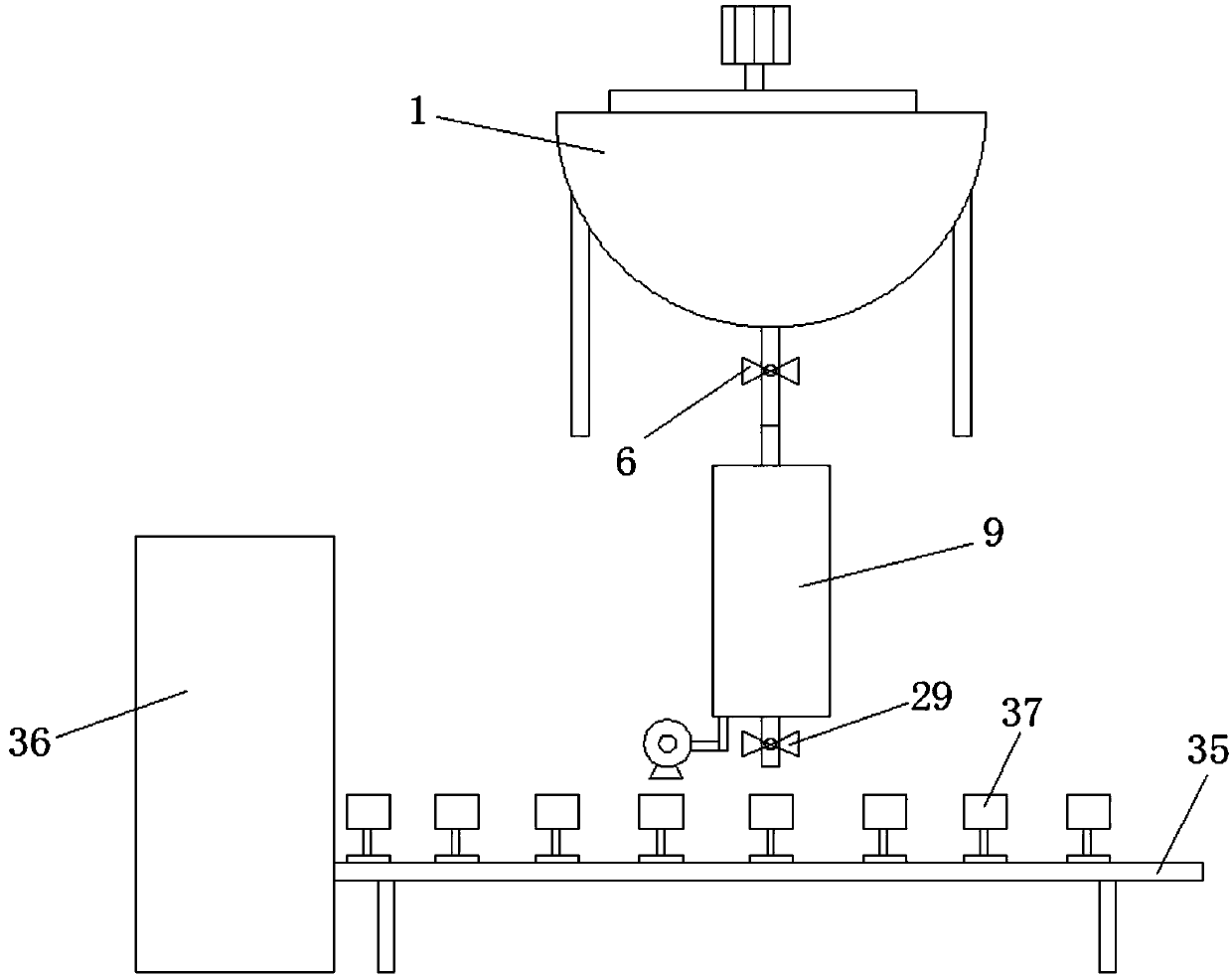

Hotpot condiment and preparation method thereof

InactiveCN108669515AHigh degree of automationImprove frying efficiencyFood scienceAllium fistulosumBroad beans

The invention provides a hotpot condiment and a preparation method thereof. The raw materials needed by the invention include: 800-1200 parts of butter, 150-250 parts of vegetable oil, 600-1000 partsof chili, 70-120 parts of broad bean paste, 7-12 parts of edible salt, 150-230 parts of Chinese prickly ash, 20-40 parts of old ginger, 30-50 parts of garlic, 15-25 parts of fermented soya beans, 15-25 parts of chicken essence, 2-5 parts of rock sugar, 15-25 parts of cooking wine, 20-40 parts of pea, 15-25 parts of turmeric, 20-40 parts of Alpinia tonkinensis Gagnep, and 70-120 parts of allium fistulosum stalk. The preparation method provided by the invention has a high degree of automation, utilizes the cooperation of a stir-frying device, a cooling device, a capping machine, a first electromagnetic valve and a second electromagnetic valve to realize automatic production and packaging of the stir-frying process, the stirring and frying efficiency is high, the labor intensity of the stir-frying workers is greatly eased while the quality of the hotpot condiment is guaranteed.

Owner:辜海钦

Electromagnetic melon seed roasting machine capable of ensuring uniform stir-frying effects

InactiveCN108541976AStir fry evenlyImprove frying efficiencyFood treatmentThermal insulationDrive shaft

The invention discloses an electromagnetic melon seed roasting machine capable of ensuring uniform stir-frying effects. The electromagnetic melon seed roasting machine capable of ensuring uniform stir-frying effects comprises a frame body, a thermal insulation cylinder, a stir-frying drum, an electromagnetic heating block, rotating wheels, a rotating shaft, a motor A, a stirring shaft, a motor B,a transmission shaft sleeve, a bearing, a stirring shaft shaped like the Chinese character 'ao', a motor C and a feeding apparatus; the thermal insulation cylinder is arranged on the frame body; the stir-frying drum is arranged in the thermal insulation cylinder; the electromagnetic heating block is arranged in the thermal insulation cylinder; the rotating wheels are arranged on an inner side wallof the thermal insulation cylinder; the rotating shaft is arranged outside the rotating wheels, and is connected with the motor A; the stirring shaft is arranged in the stir-frying drum, and is connected with the motor B; the transmission shaft sleeve sleeves on the rotating shafts; the transmission shaft sleeve penetrates through inner walls of the thermal insulation cylinder and the stir-fryingdrum via the bearing, and stretches into the interior of the stir-frying drum; the stirring shaft shaped like the Chinese character 'ao' is arranged, in the stir-frying drum, on the transmission shaft sleeve; an outer end of the transmission shaft sleeve is connected with the motor C; and the feeding apparatus is arranged above the thermal insulation cylinder. In general, the electromagnetic melon seed roasting machine has the advantages of being capable of ensuring uniform stir-frying effects, feasible to perform integrated drying, multi-functional, and high in stir-frying efficiency and quality.

Owner:许昌智工机械制造有限公司

Raw material stir-frying machine for dried food processing based on swing baffle plate material blocking

The present invention discloses a raw material stir-frying machine for dried food processing based on swing baffle plate material blocking. The raw material stir-frying machine comprises a base seat,a left support frame, a right support frame, a motor, a material feeding hopper and a roller; idler wheels are arranged at a lower side of the base seat, an output shaft of the motor is coaxially andfixedly connected with a horizontal rotating shaft, and the roller is fixedly connected with the rotating shaft via a plurality of fixedly arranged support rods; and a heating cover is arranged on anoutside frame of the roller, a plurality of pin shafts are evenly distributed on an inner wall of the roller, fixing rods are fixedly welded on the pin shafts, swing baffle plates are fixed on the fixing rods, and the rotating shaft has a hollow structure. The swing baffle plates enable internal raw materials to slowly fall, extends the raw materials and prevents the raw materials from stacking together to affect internal ventilation. The stir-frying machine instantly discharges water vapor generated in drying and improves drying efficiency, at the same time, hot air is ventilated in a center,and the stir-frying machine improves internal heating areas, enables the raw materials to be dried more rapidly, is easy to move and flexible in use, and improves stir-frying efficiency.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

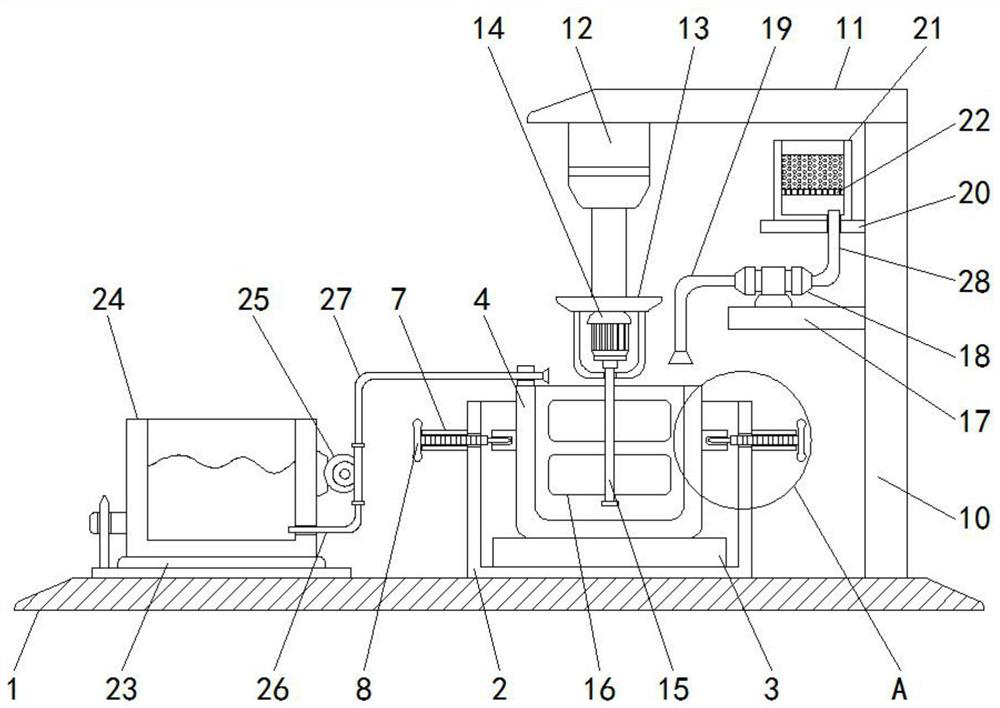

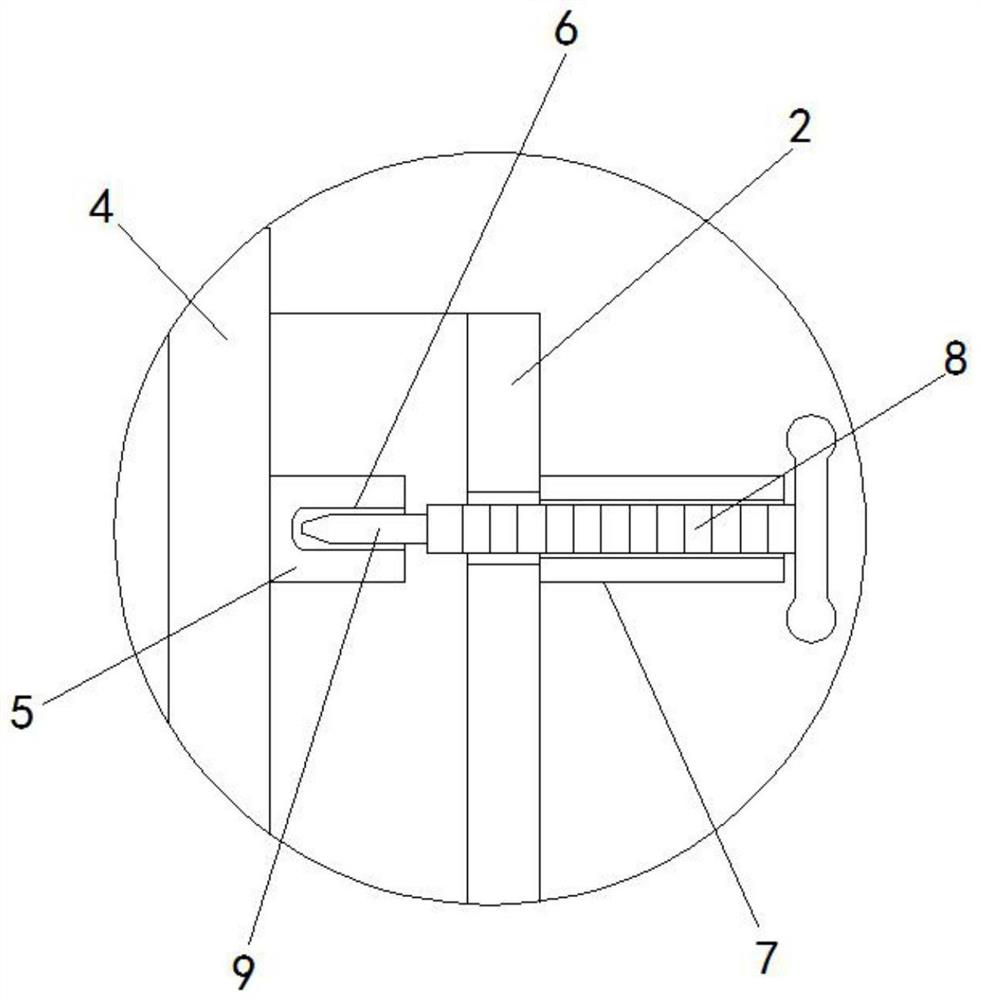

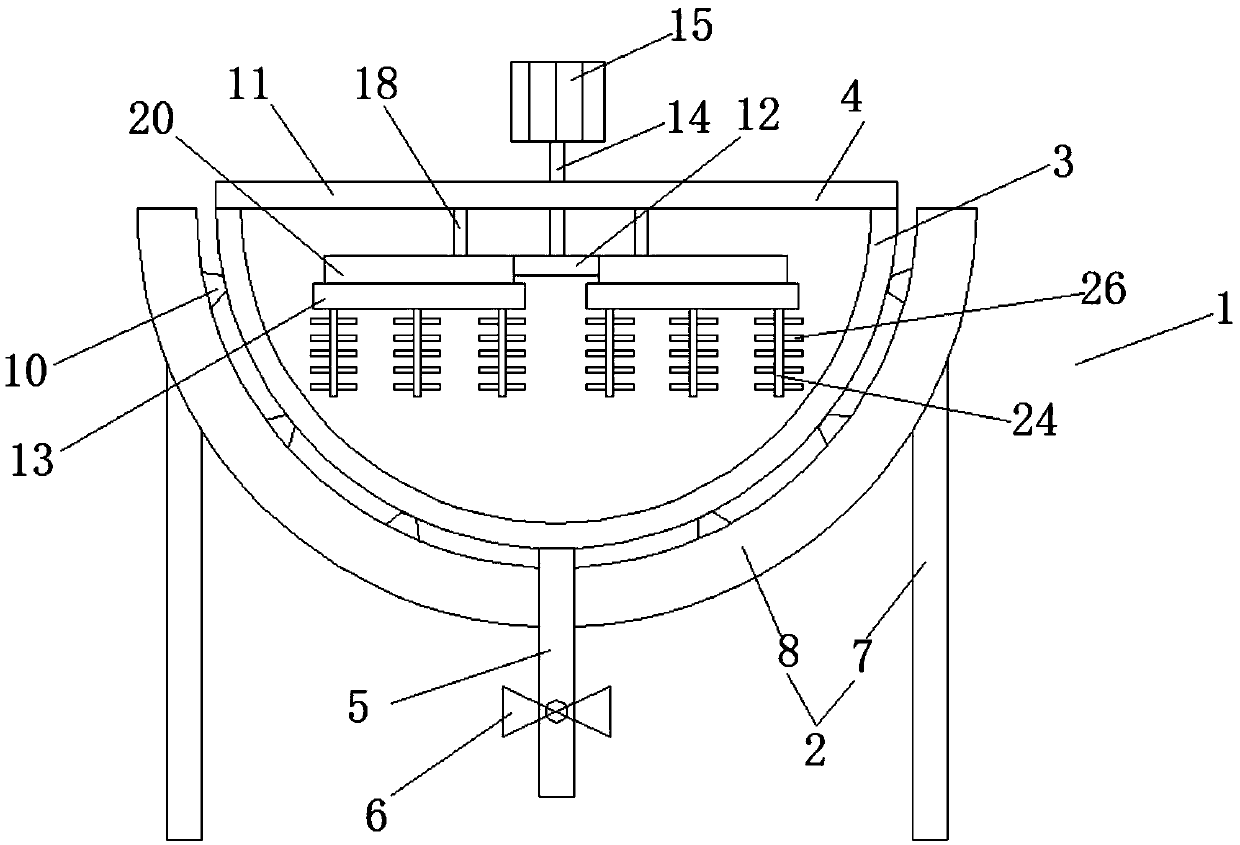

Sunflower seed oil pressing, steaming and stir-frying processing system

InactiveCN111793520APrevent scorching and fryingEven heating inside and outsideFatty-oils/fats productionMechanical engineeringMaterials science

The invention relates to the technical field of agricultural processing equipment, particularly to a sunflower seed oil pressing, steaming and stir-frying processing system, which comprises a stir-frying furnace and a mounting cover covering the stir-frying furnace, wherein the stir-frying furnace and the mounting cover are matched to form a heating cavity for heating sunflower seeds, the bottom of the stir-frying furnace is in a downward concave arc shape, a rotary stirring device and a driving device are arranged in the stir-frying furnace, the rotary stirring device is propped against the bottom of the stir-frying furnace in a sliding manner so as to stir the sunflower seeds at the bottom of the stir-frying furnace, the driving device is arranged on the stir-frying furnace and is positioned at the furnace mouth of the stir-frying furnace to drive the rotary stirring device to operate, and an internal and external exchange device is arranged between the rotary stirring device and thedriving device and is driven by the driving device. According to the invention the sunflower seed oil pressing, steaming and stir-frying processing system has the effects that the sunflower seed stir-frying process is convenient and fast, and the sunflower seed stir-frying efficiency is improved.

Owner:苏静雯

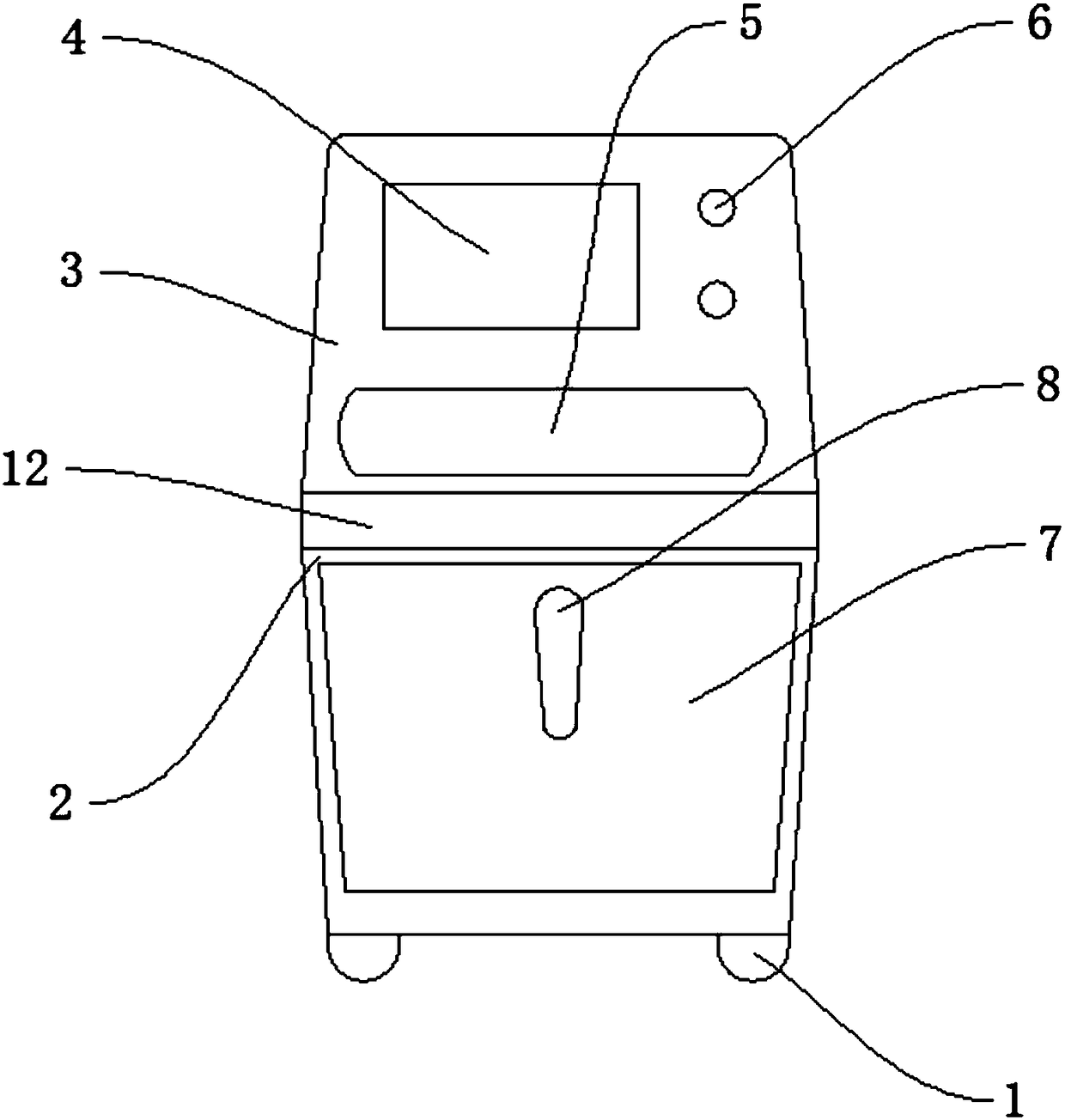

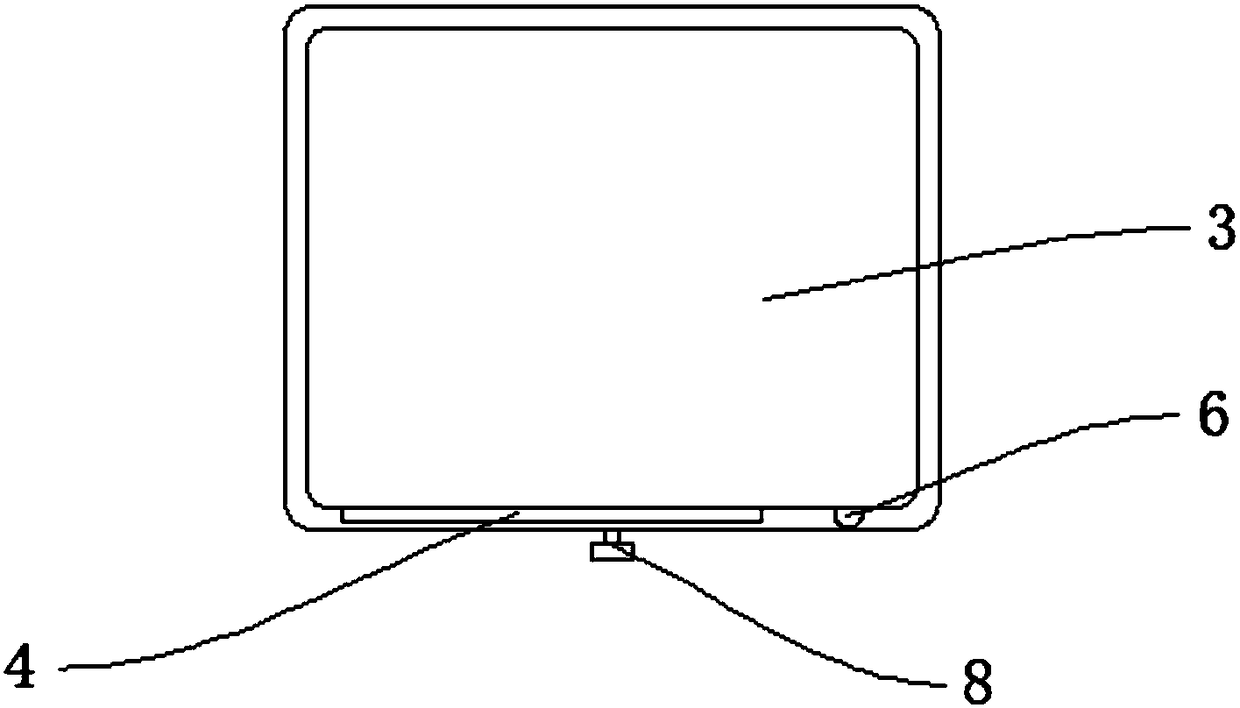

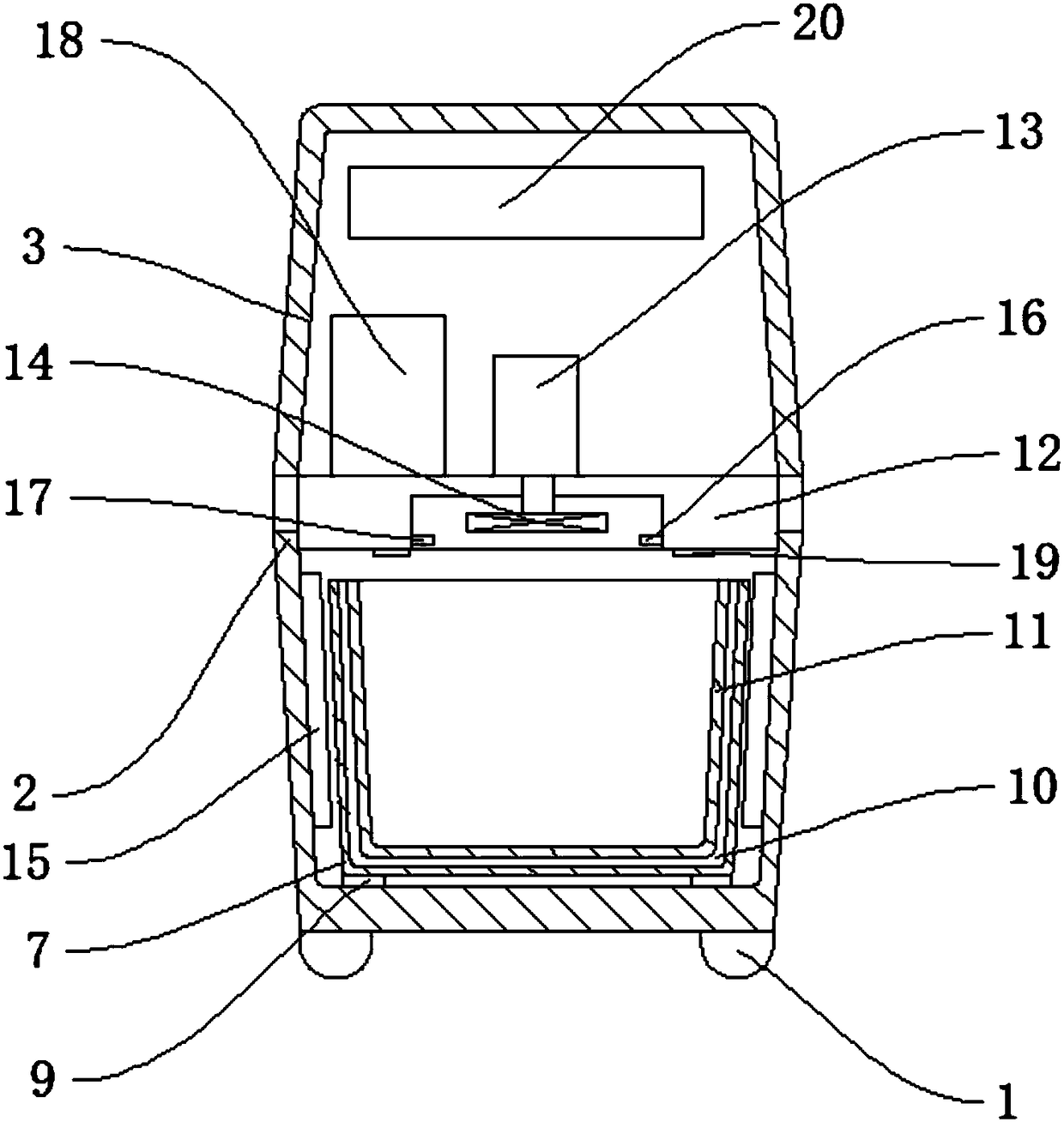

Full-automatic sea sedge frying device

InactiveCN105165933AScientific and reasonable structureEasy to useOil/fat bakingAutomatic controlFixed frame

The invention discloses a full-automatic sea sedge frying device. The device comprises a control box, a fryer, an oil-water separator, universal self-locking wheels, a fixing frame, automatic lifting platform columns and heat dissipating holes, wherein both the control box and the fixing frame are arranged on the upper surface of a safeguarding box body; a liquid crystal touch display screen is arranged at the top of the control box; a frying oil control disc is placed at the top of the safeguarding box body through the fixing frame; the fryer is mounted inside the safeguarding box body; an electric valve is arranged at the bottom of the fryer; the automatic lifting platform columns are mounted at the bottom of the fryer; the oil-water separator is mounted at the bottom of the safeguarding box body; the universal self-locking wheels are mounted at the bottom of the safeguarding box body. According to the device, the control box, a temperature detector and the liquid crystal touch display screen closely cooperate with one another, full-automatic control on the sea sedge frying process and temperature is realized, the condition that the taste is affected due to excessive frying of sea sedge is avoided fundamentally, and the frying efficiency is improved.

Owner:TAIXIANG GRP TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com