Nut stir-frying machine

A frying machine and nut technology, which is applied in the field of frying machine, can solve the problems of continuous frying process, time-consuming and labor-intensive work efficiency, etc., and achieve the effect of saving time and effort in frying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

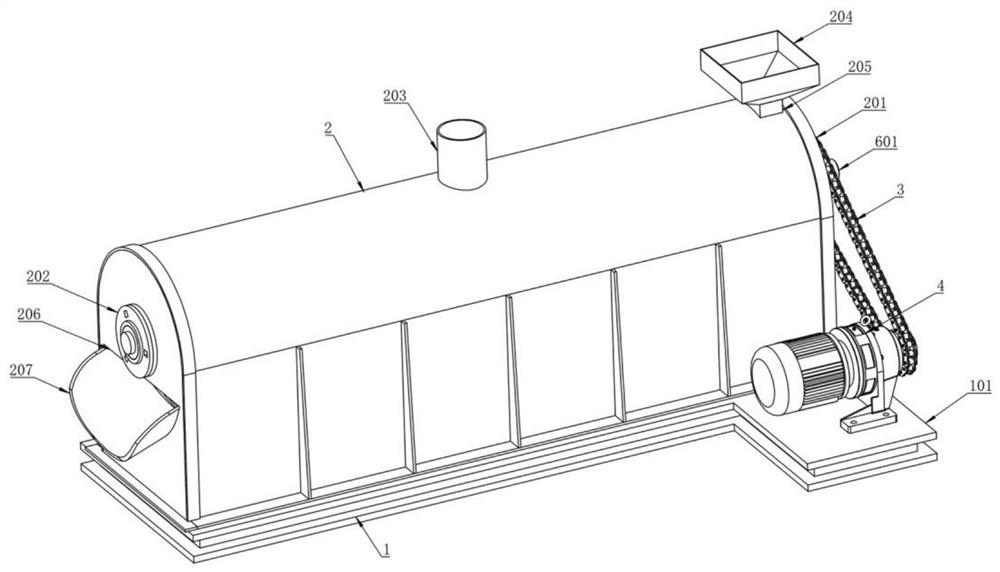

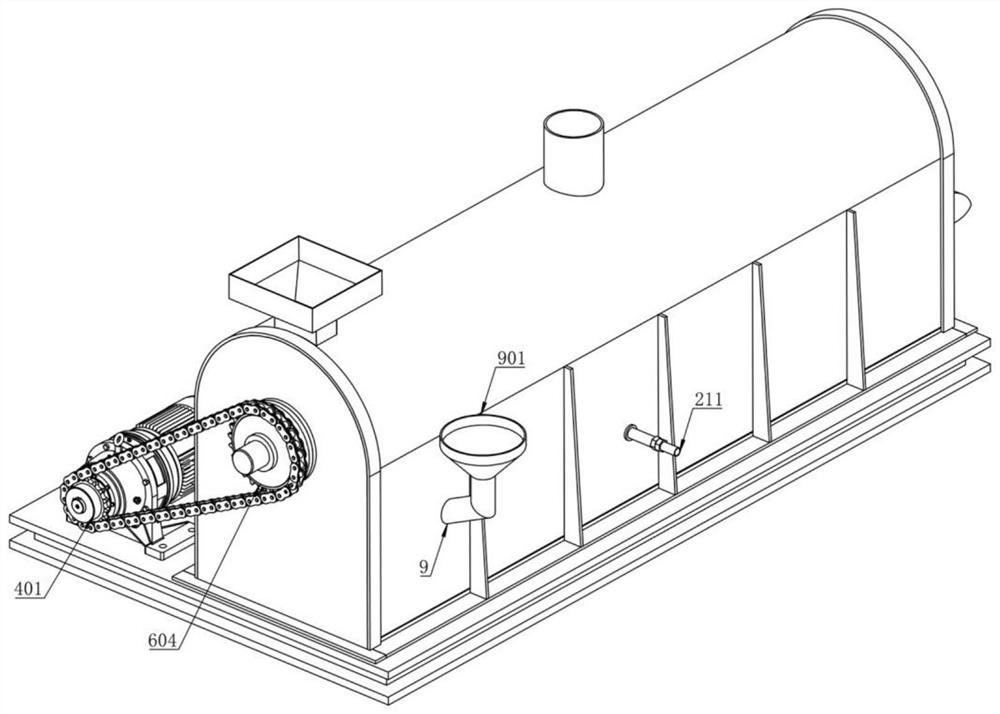

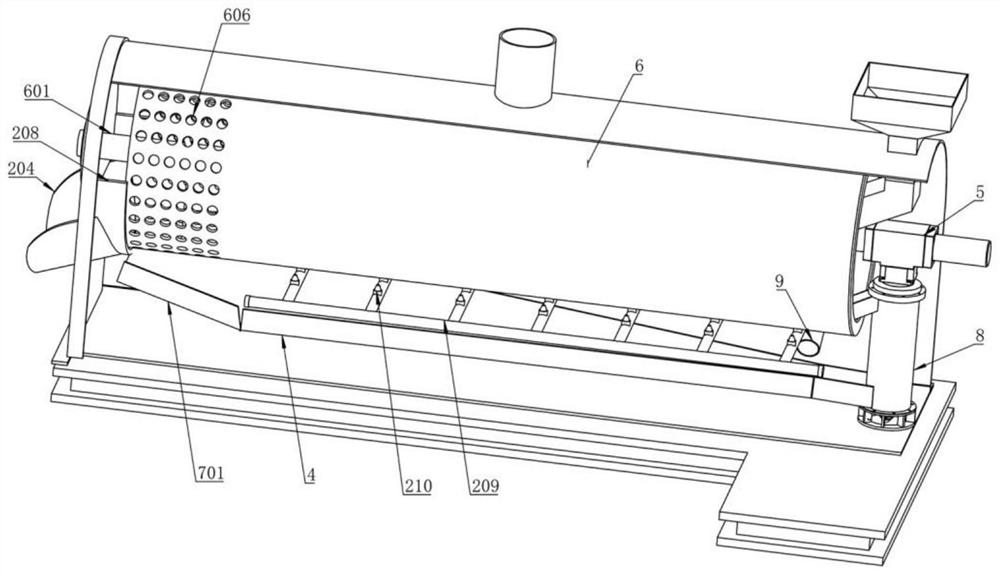

[0029] Specific implementation mode one: combine Figure 1-7 As shown, a nut frying machine is characterized in that it includes a base 1, a shell 2, a chain 3, a gear motor 4, a gearbox 5 and a frying drum 6; the right end of the base 1 is provided with a fixing seat 101; The deceleration motor 4 is fixedly arranged on the fixed seat 101; the outer shell 2 is fixedly arranged on the top of the base 1; the outer two parts of the outer shell are provided with thermal insulation layers; the left and right ends of the outer shell 2 are fixedly arranged with side walls 201 The middle part of the side wall 201 is fixedly equipped with a bearing 202 with a seat; the middle part of the frying drum 6 is provided with a main shaft 601; a plurality of connecting rods 602 are arranged between the main shaft 601 and the frying drum 6; The main shaft 601 is arranged above the inside of the frying drum 6 through the bearing 202; the inside of the frying drum 6 is fixedly provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com