Raw material stir-frying machine for dried food processing based on swing baffle plate material blocking

A frying machine and dry goods technology, applied in applications, food processing, food science, etc., can solve the problems of low frying efficiency and affecting processing efficiency, and achieve the effects of flexible use, convenient equipment movement, and improved drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

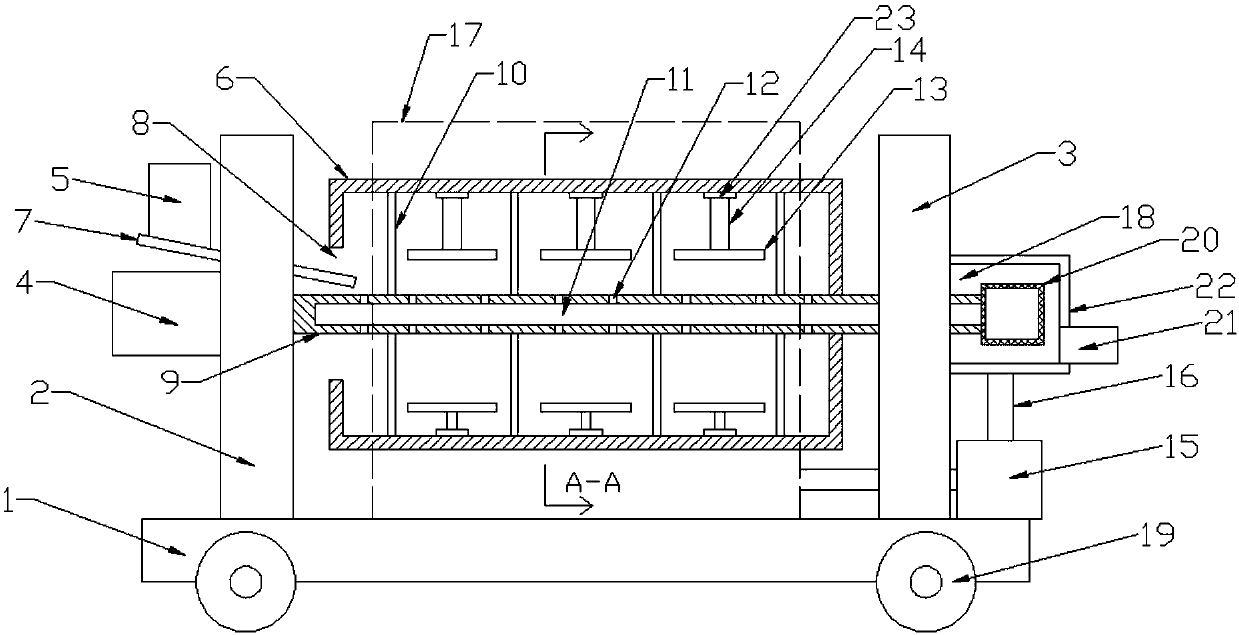

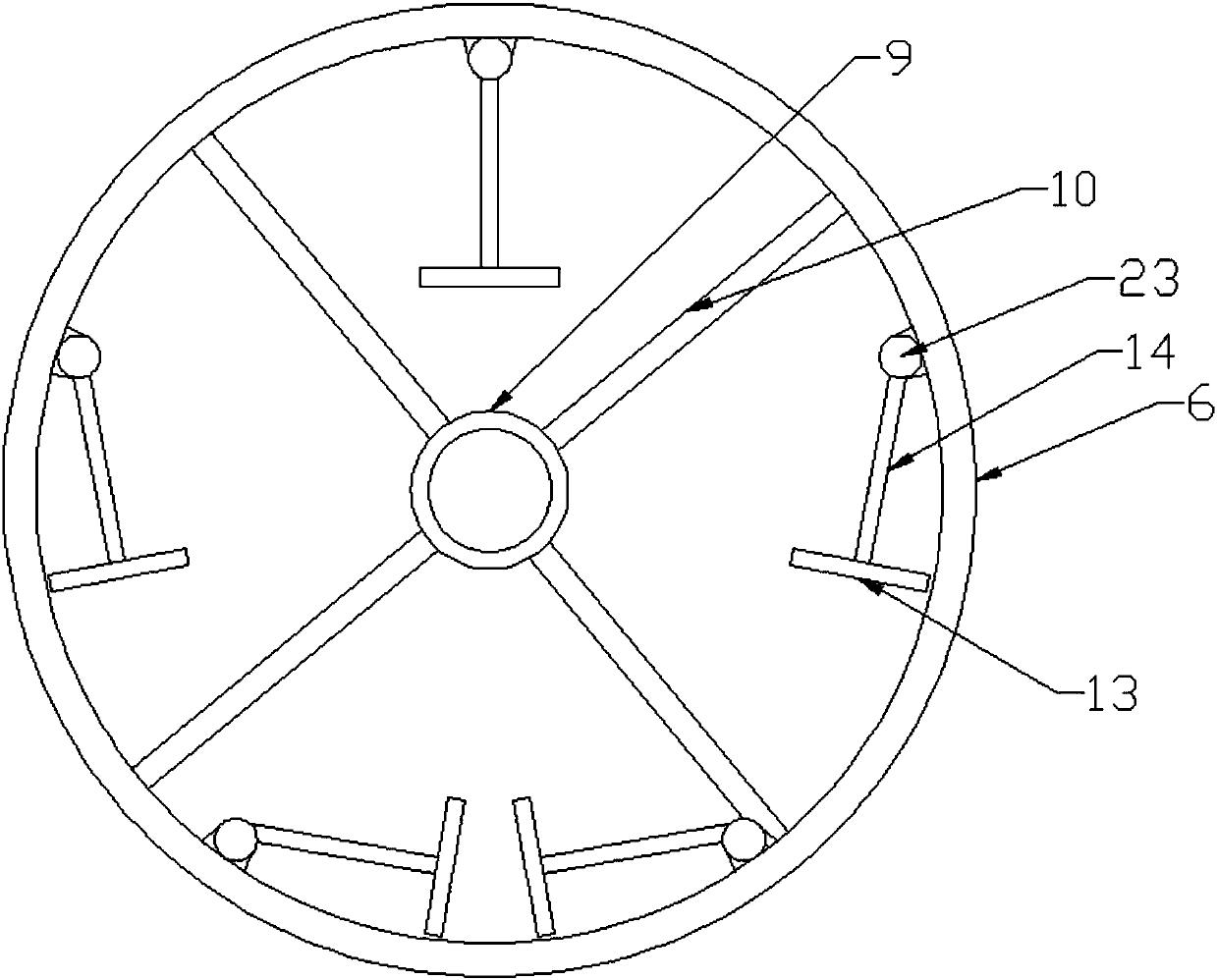

[0014] Please refer to the figure, in the embodiment of the present invention, a raw material frying machine for dry goods processing based on a swing baffle retaining material, including a base 1, a left support frame 2, a right support frame 3, a motor 4, a feed hopper 5 and a drum 6; Rollers 19 are installed on the underside of the base 1 to make the frying machine move conveniently; vertical left support frame 2 and right support frame 3 are respectively fixedly installed on the left and right ends of the upper surface of the base 1, and the left support frame 2 has the same structure as the right support frame 3, the motor 4 is horizontally and fixedly installed on the left support frame 2, the output shaft of the motor 4 is coaxially fixedly connected with a horizontal rotating shaft 9, and the other end of the rotating shaft 9 passes through the right supporting frame 3 , the fixed sleeve on the rotating shaft 9 is provided with a bearing 18, the outer side of the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com