Sunflower seed oil pressing, steaming and stir-frying processing system

A processing system and technology of sunflower seeds, applied in the field of edible oil, can solve the problems of low efficiency of frying sunflower seeds, cumbersome frying process, low efficiency of sunflower seeds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

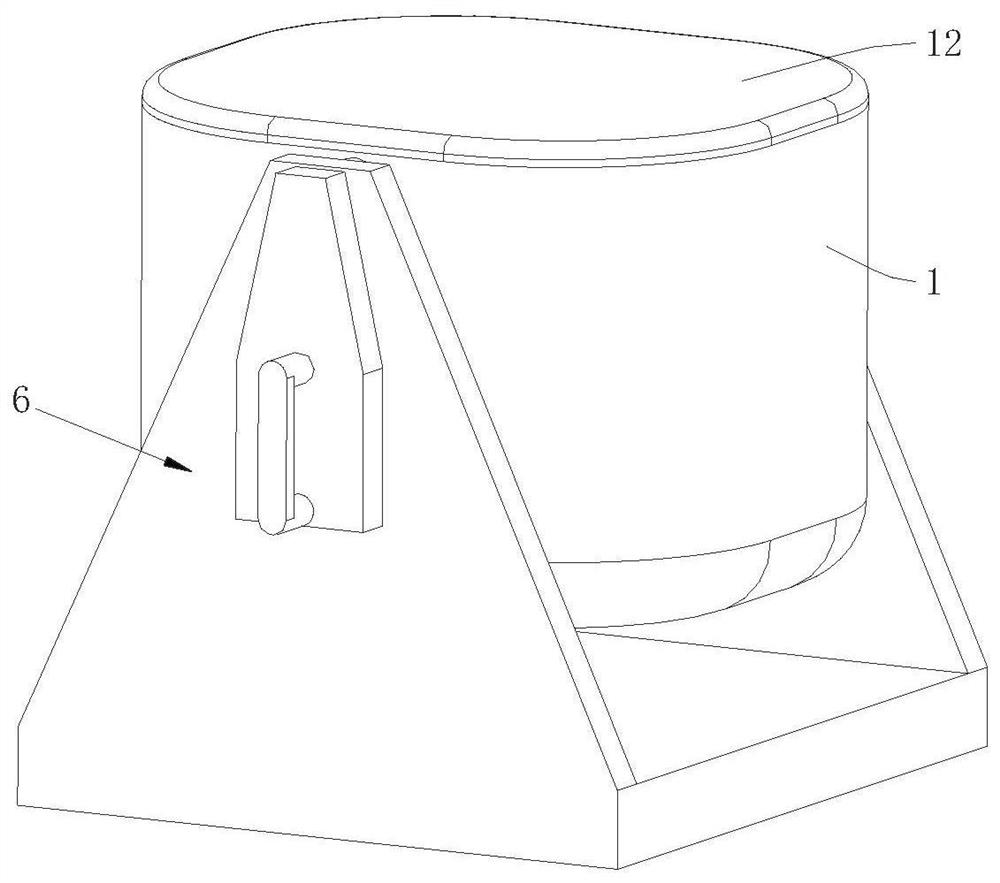

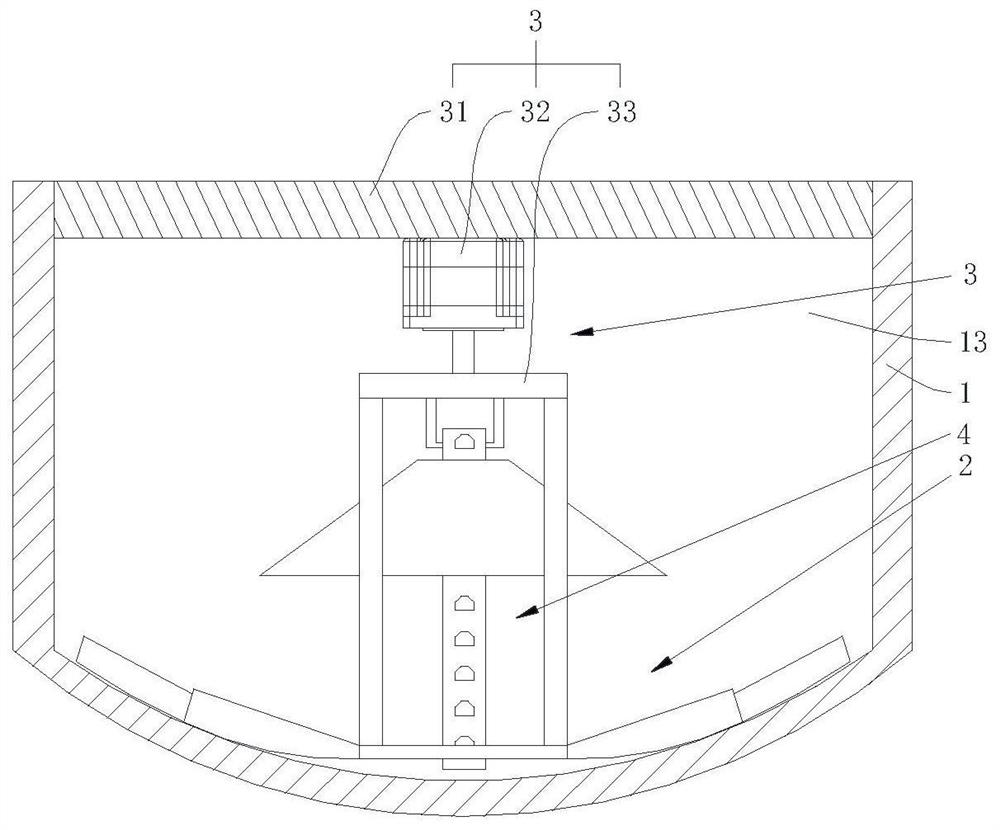

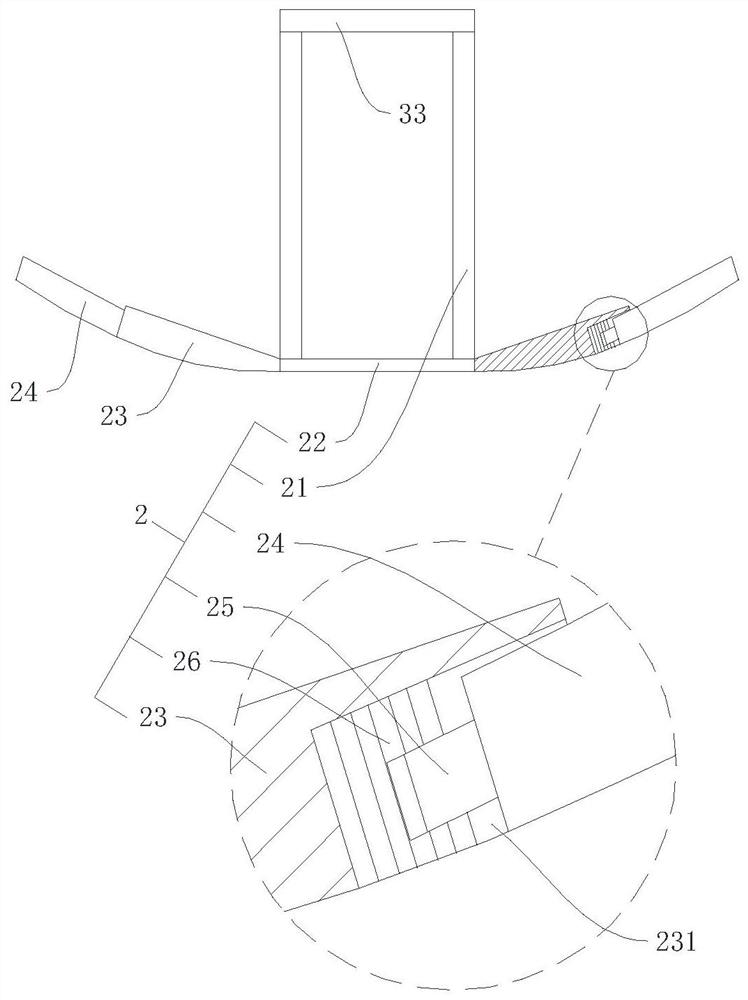

[0030] refer to figure 1 , figure 2 As shown, it is a sunflower seed oil-pressing, steaming and frying processing system disclosed in the present invention, which includes a frying furnace 1 and an installation cover 12 that covers the frying furnace 1. The frying furnace 1 and the installation cover 12 cooperate to form a The heating cavity 13 for heating the seeds, wherein, the bottom of the frying furnace 1 is set in a downwardly recessed arc, and the frying furnace 1 only needs to be powered on to heat and fry the sunflower seeds in the process of actual use; In order to be able to move the sunflower seeds in the frying furnace 1 to prevent the sunflower seeds from being fried, the frying furnace 1 is provided with a rotating stirring device 2 and a driving device 3, and the rotating stirring device 2 and the furnace bottom of the frying furnace 1 slip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com