Frequency doubling crystal heating device and method thereof

A frequency-doubling crystal and heating device technology, which is applied to laser components, electrical components, laser components, etc., can solve problems affecting optical path transmission and heating, and achieve improved efficiency, uniform internal and external heating, and controllable time and temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

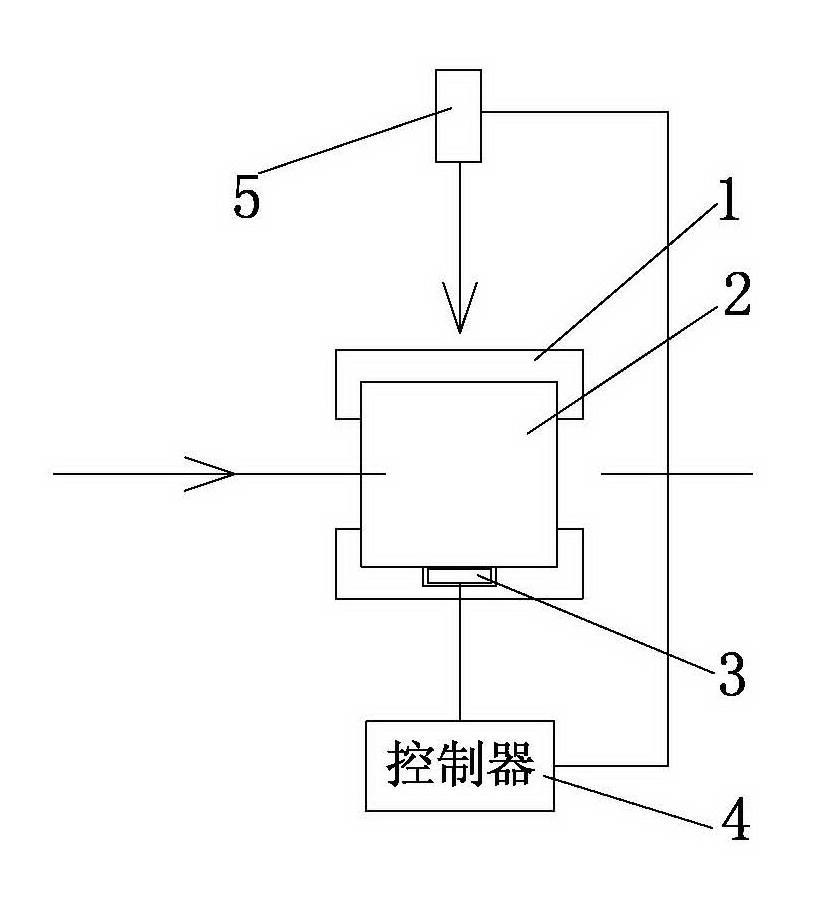

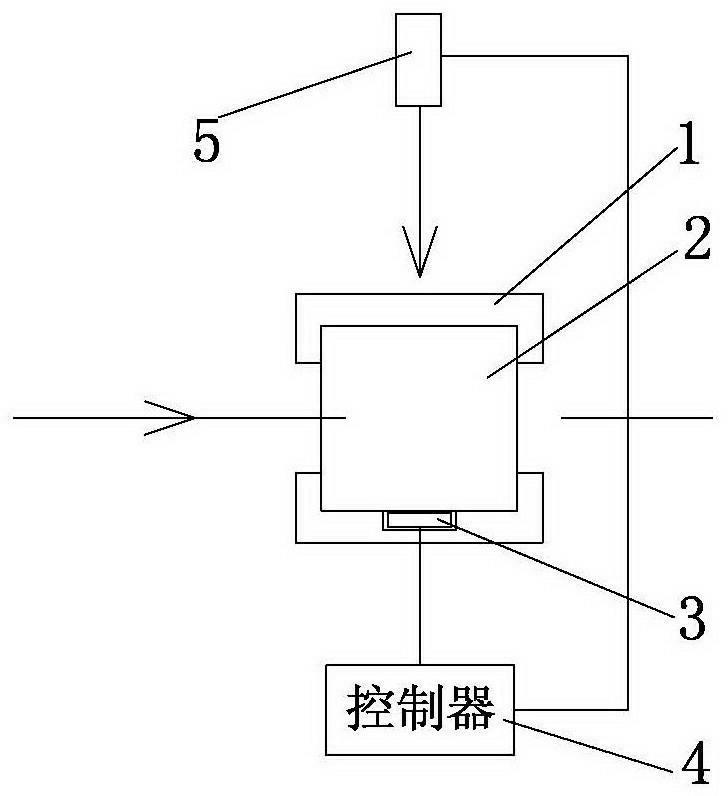

[0014] figure 1 A frequency doubling crystal heating device is shown, the frequency doubling crystal 2 is fixed on the heat insulating frame 1, and a temperature sensor 3 is arranged on the surface of the frequency doubling crystal 2 between the heat insulating frame 1 and the frequency doubling crystal 2, The heating device is provided with a pulse light generator 5 and a controller 4, and the controller 4 monitors the temperature of the frequency doubling crystal 2 detected by the temperature sensor 3 in real time, and controls the pulse light generator 5 to heat Pulsed light, the heating pulsed light emitted by the pulsed light generator 5 penetrates the frequency doubling crystal 2 .

[0015] The frequency doubling crystal heating method of the above-mentioned heating device is as follows:

[0016] The pulsed light emitted by the pulsed light generator 5 penetrates the frequency doubling crystal 2 and heats the frequency doubling crystal 2. The temperature sensor 3 detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com