Patents

Literature

50results about How to "Even heating inside and outside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

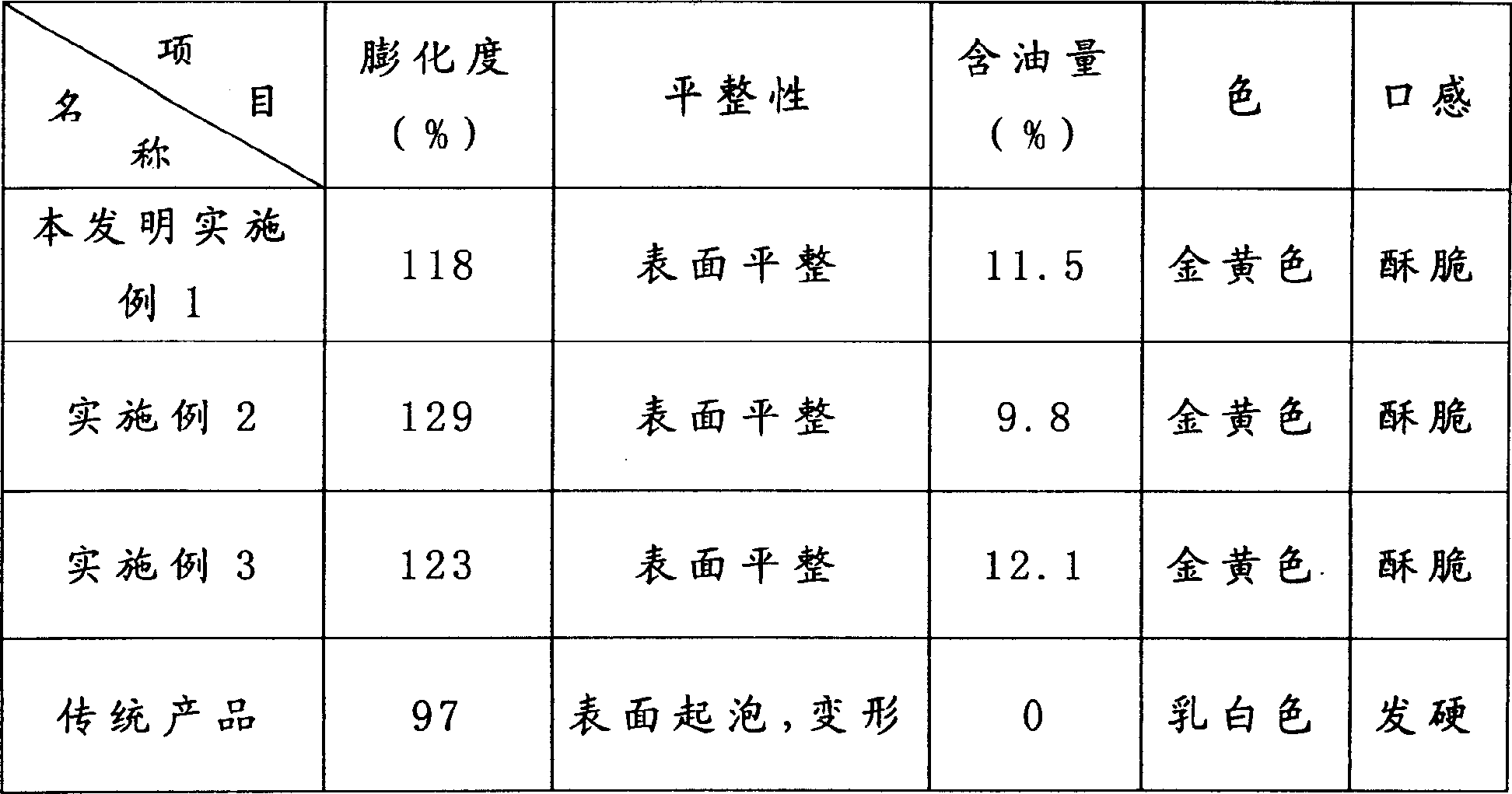

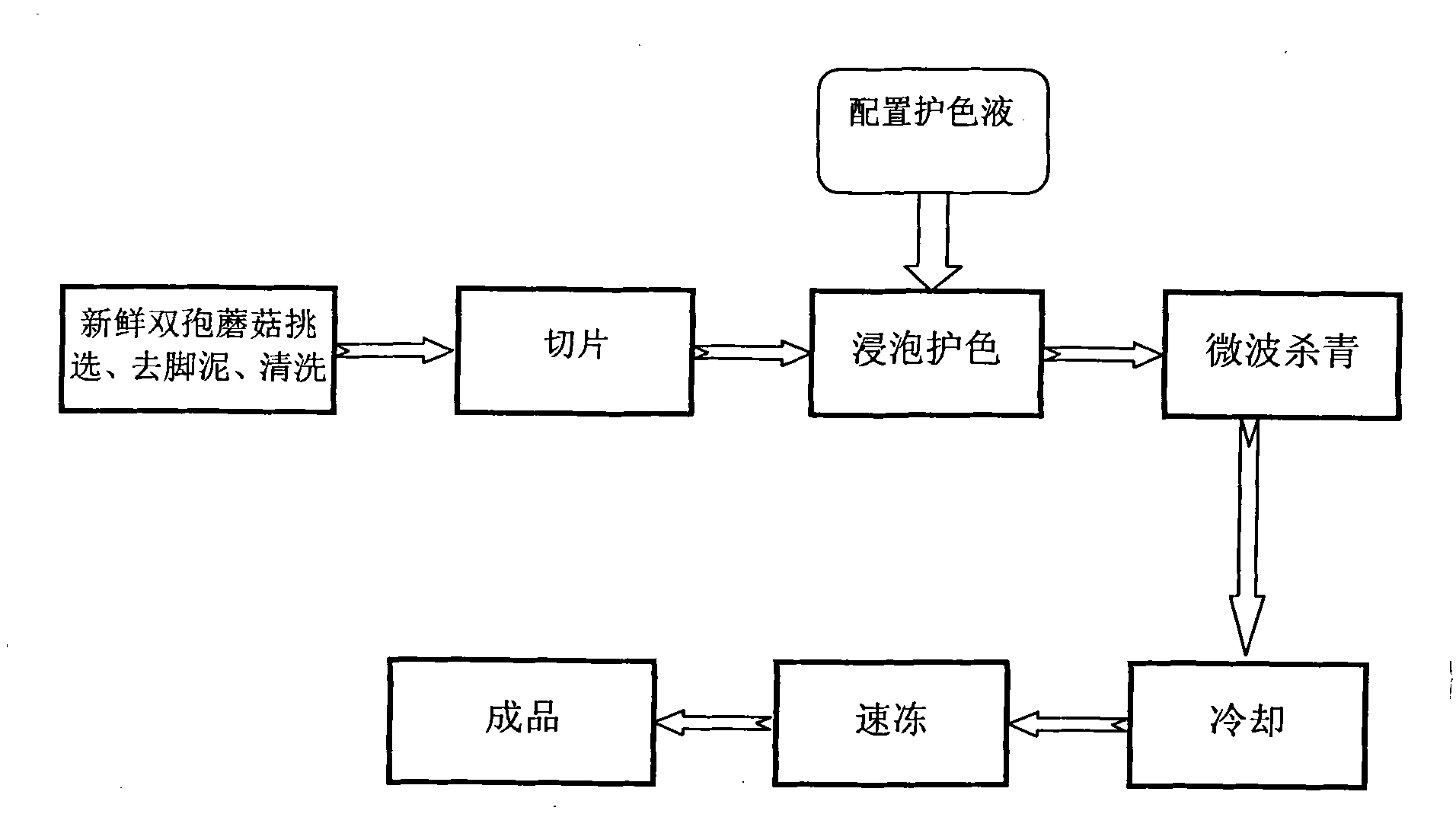

Method for preparing white mushroom slices

InactiveCN101961045AReduce churnLess nutrient lossFruits/vegetable preservation by heatingMicrowaveMoisture

The invention belongs to the technical field of edible fungus processing and relates to a preparation method of white mushroom slices. In the method, fresh white mushroom is used as a raw material; and the white mushroom slices are prepared by pretreatment, slicing, soaking, preserving color, killing green in microwaves, cooling, quickly freezing and refrigerating. The white mushroom slice products prepared by the method have natural color, full structure, less moisture loss, less nutrient loss, cooking effect similar to that of fresh white mushroom.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

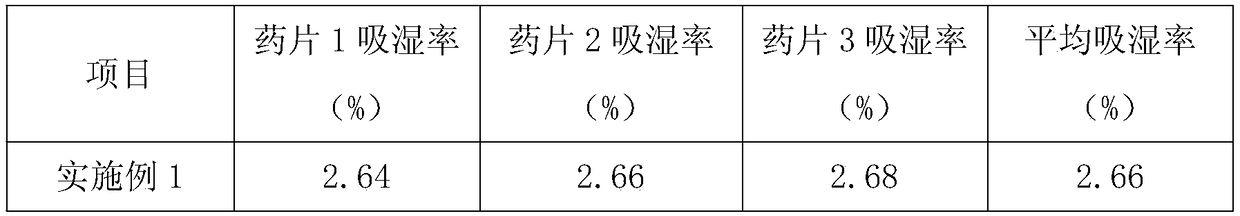

Drug moisture-proof agent and preparation method and application thereof

ActiveCN108635586ALow moisture absorptionImprove moisture resistanceInorganic non-active ingredientsMoisture absorptionSilica gel

The invention discloses a drug moisture-proof agent and a preparation method and application thereof,and belongs to the field of moisture-proof technologies of traditional Chinese medicine preparations. The drug moisture-proof agent comprises zein,soluble starch,calcium hydrophosphate,lactose,magnesium stearate,microcrystalline cellulose,hydroxypropyl cellulose,povidone,cane sugar,micro-powder silica gel,hydrophobic nano silicon dioxide and maltodextrin. The drug moisture-proof agent is prepared in the steps of dissolving,modifying,mixing,stirring and the like. A reinforcing system composed ofthe micro-powder silica gel,the hydrophobic nano silicon dioxide and the maltodextrin is applied to the drug moisture-proof agent,the viscosity and moisture absorption rate of the drug moisture-proofagent are further reduced,and the drug stability is improved.

Owner:湖南药圣堂中药科技有限公司

Quick-frozen mushroom-pig-meat pie and making method thereof

InactiveCN101015370ASoft tasteEasy to digest and absorbDough treatmentPre-baking dough treatmentShiitake mushroomsChemistry

Disclosed is a quick-frozen mushroom and pork pie and process for preparation, wherein the problem of long time re-processing and inability of microwave heating existed in the current quick-frozen pies is solved. The pie comprises (by weight portions) flour 90-110 parts, water 55-65 parts, yeast powder 0.7-1.3 parts, sugar 1.2-1.8 parts, salt 1.5-2.5 parts, mushroom 35-45 parts, cabbage 8-12 parts, fresh pork 45-55 parts, soy sauce 0.7-1.3 parts, gourmet powder 0.4-0.6 part, salad oil 4-6 parts and sesame oil 1.5-2.5 parts. The process for preparing the pie comprises the steps of making pie covers, making pie stuffing, wrapping the stuffing and compacting, frying the roasting the two sides, and quick freezing.

Owner:刘平

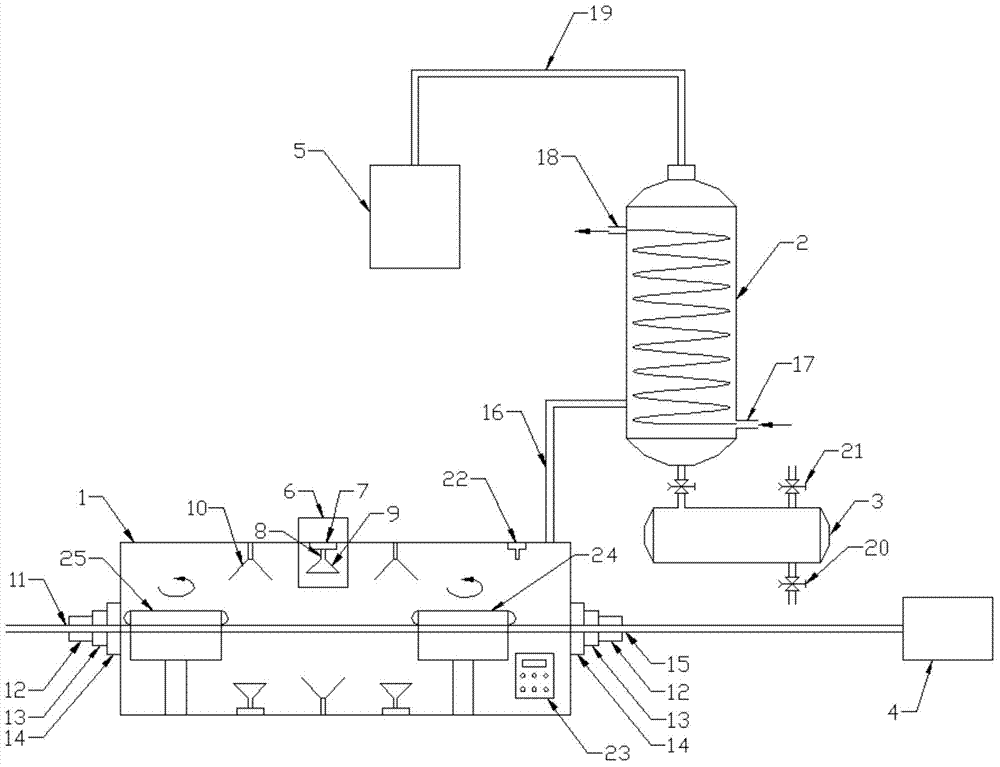

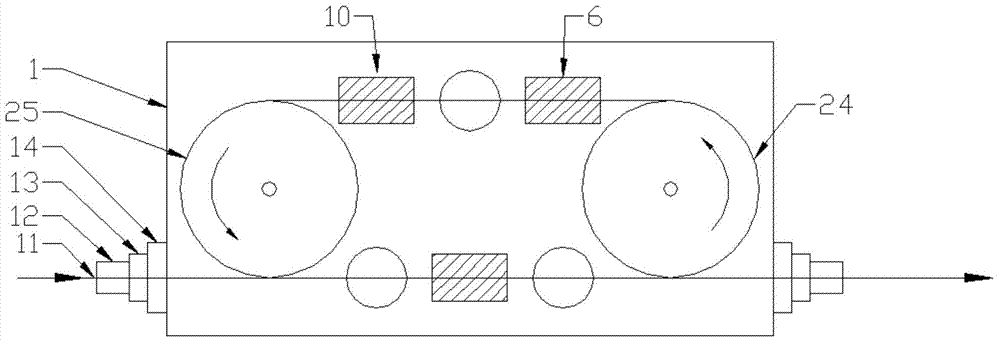

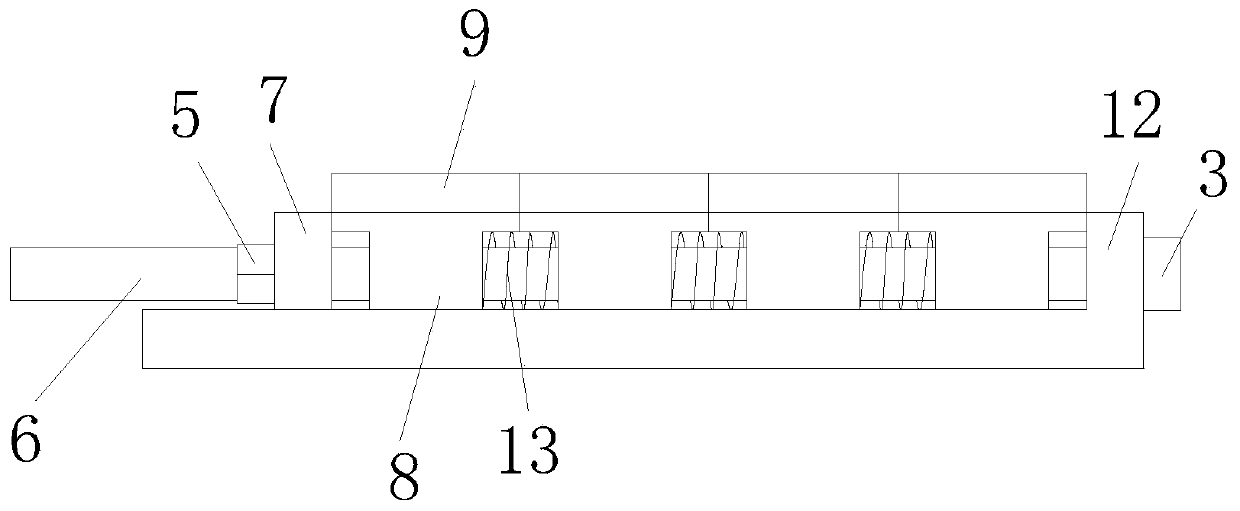

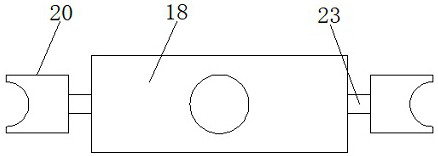

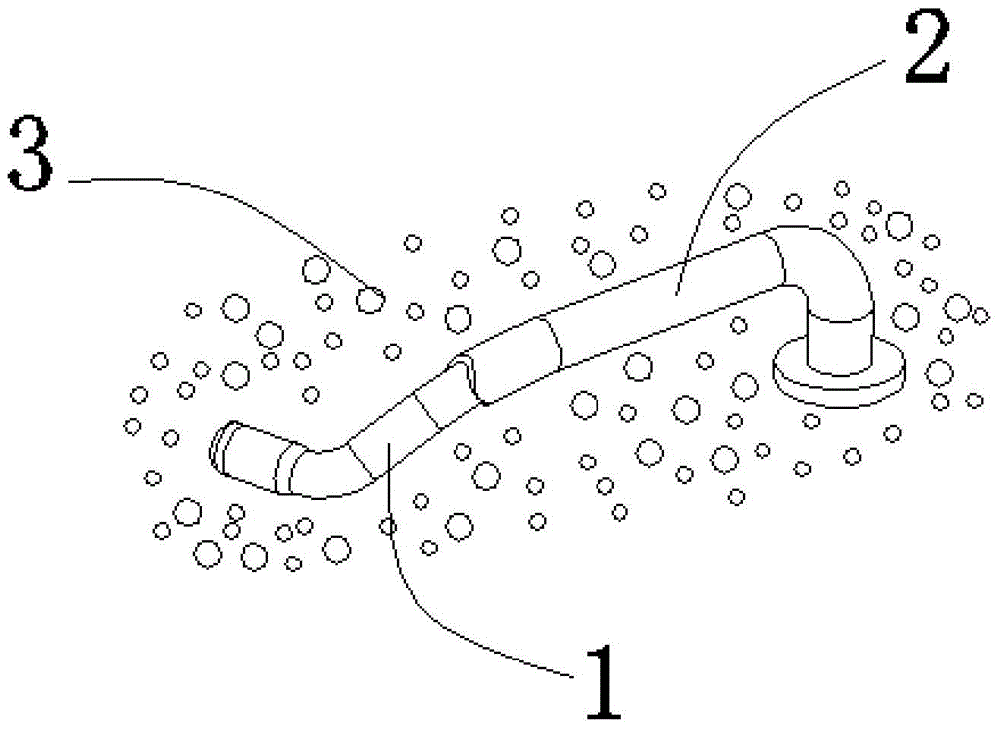

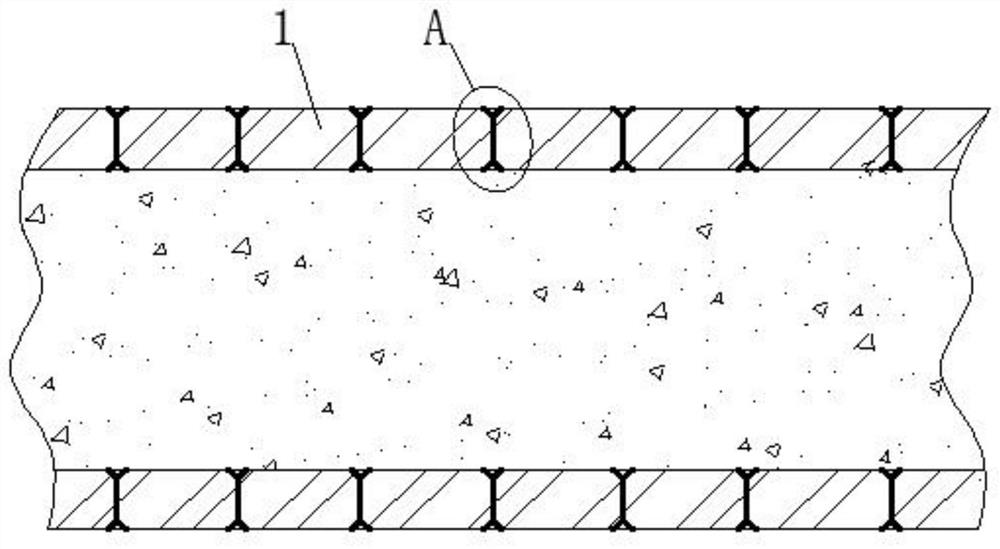

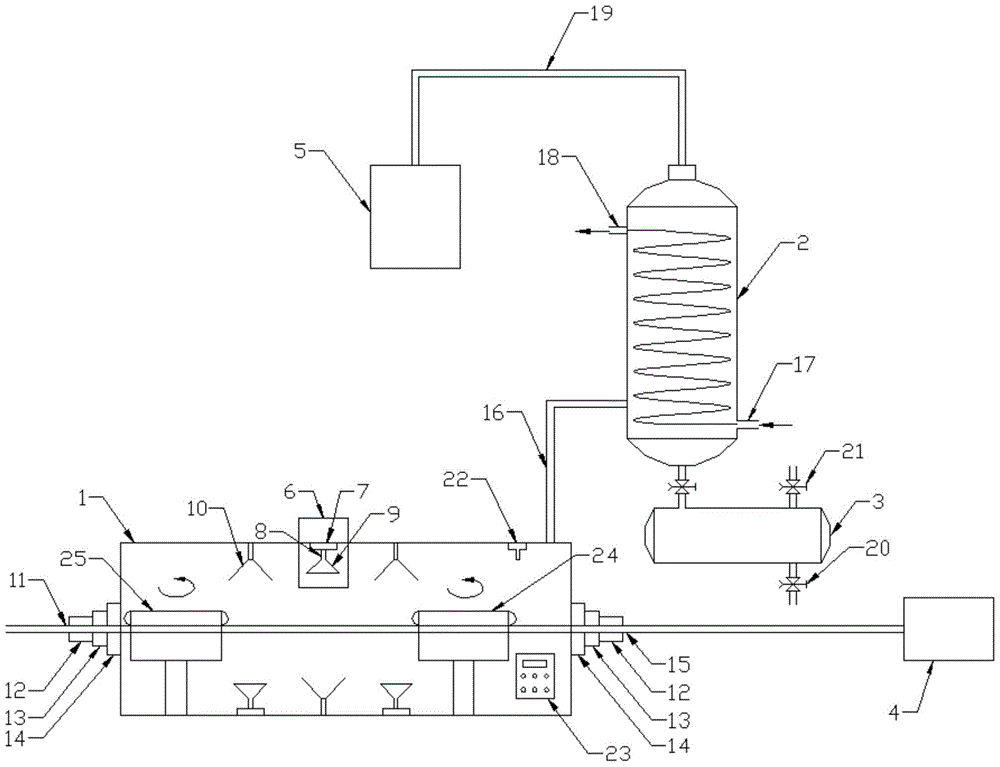

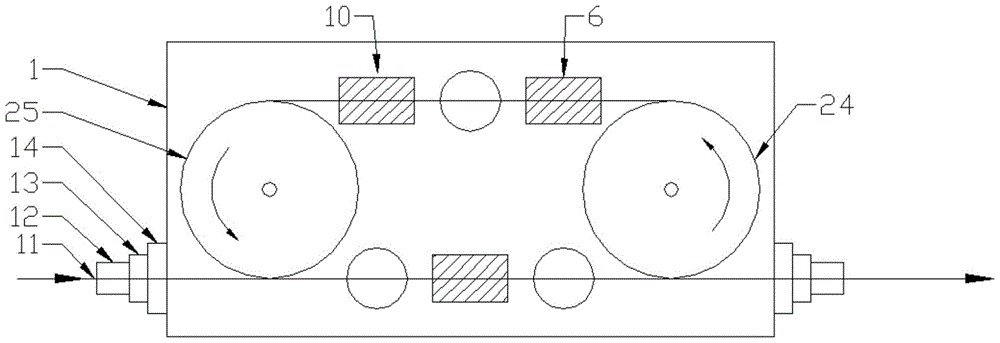

Vacuum microwave drying method and drying recycling treater of high temperature-resistant communication cable insulation process

ActiveCN104332257ASimple processReduce manufacturing costCable/conductor manufactureElectronic waste recyclingLow-k dielectricResonant cavity

The invention provides a vacuum microwave drying recycling treater of a high temperature-resistant communication cable insulation process. The vacuum microwave drying recycling treater is characterized by comprising a microwave dryer (1), a coil heat exchanger (2), a vacuum pump (5), an auxiliary recovery storage tank (3), an infrared temperature detector (22) and a feedback and control system (23), wherein the microwave dryer (1) comprises a microwave emission device (6), and a cable transmitting and microwave heating cavity; the coil heat exchanger (2) is connected with the vacuum pump (5) by use of a vacuum pipe (19); the microwave emission device (6) is composed of a microwave emitter (7), a waveguide tube (8) and a resonant cavity (9). The vacuum microwave drying recycling treater has the advantages of high drying efficiency, and evener and more thorough volatilization of auxiliaries, and more dispersive and evener pores formed in an insulating layer, and therefore, the low dielectric constant and the good quality of the insulating layer are guaranteed; in addition, the auxiliaries can be recycled after vacuum condensation and reflux, and therefore, the production cost can be reduced and the economic benefit can be improved.

Owner:JIANGSU TRIGIANT TECH

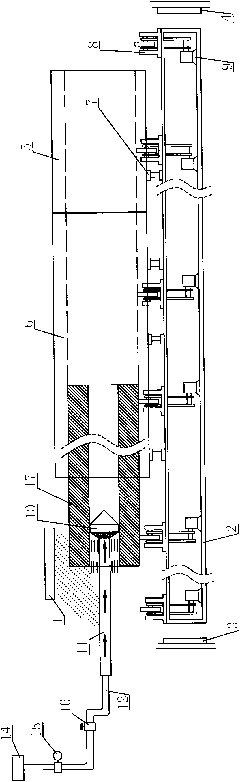

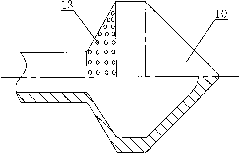

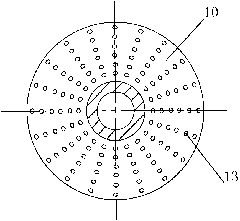

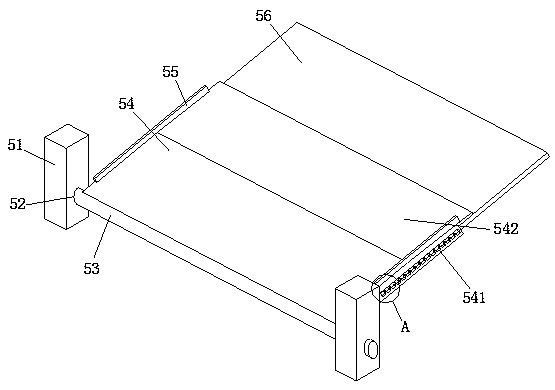

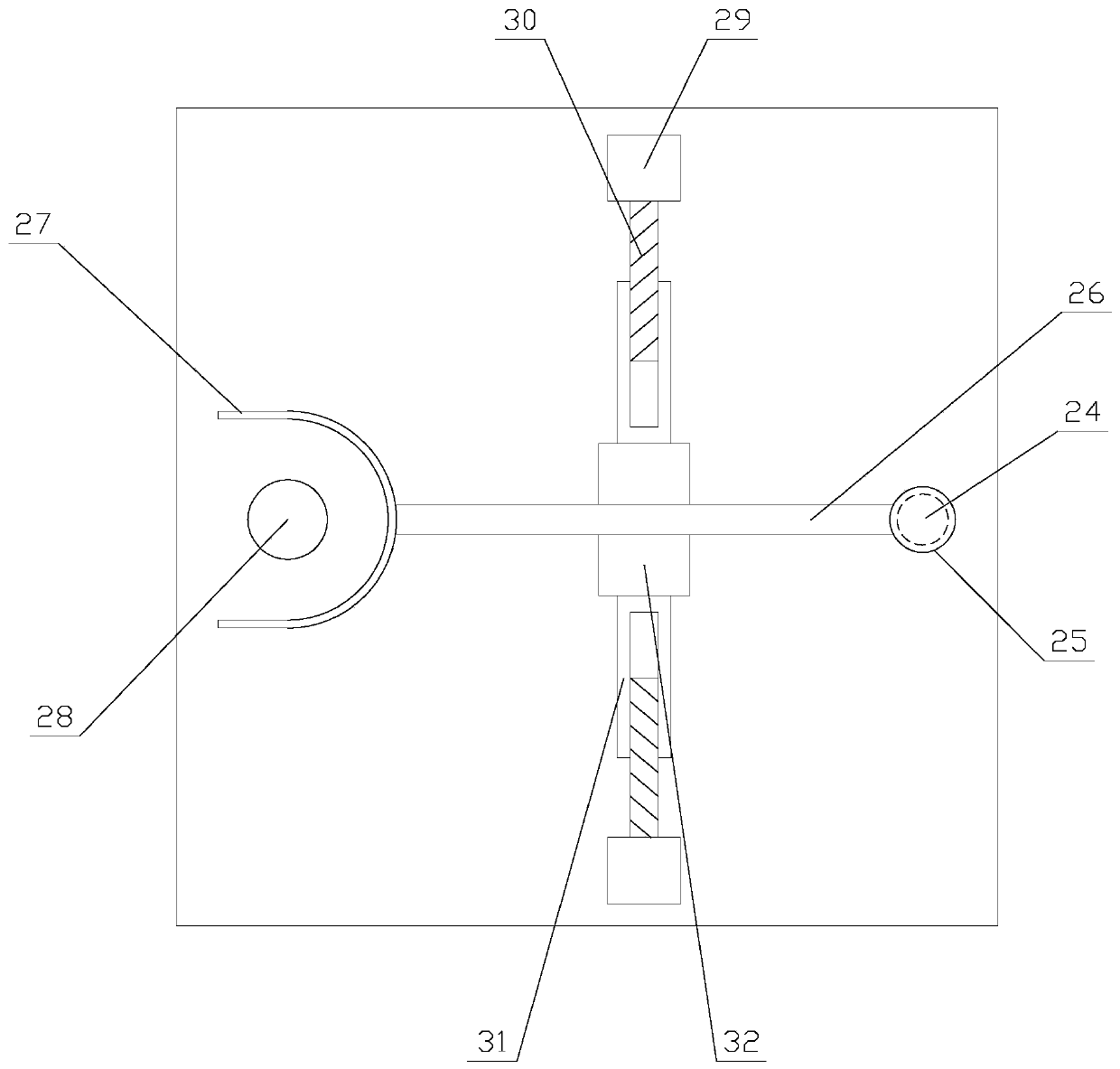

Medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials

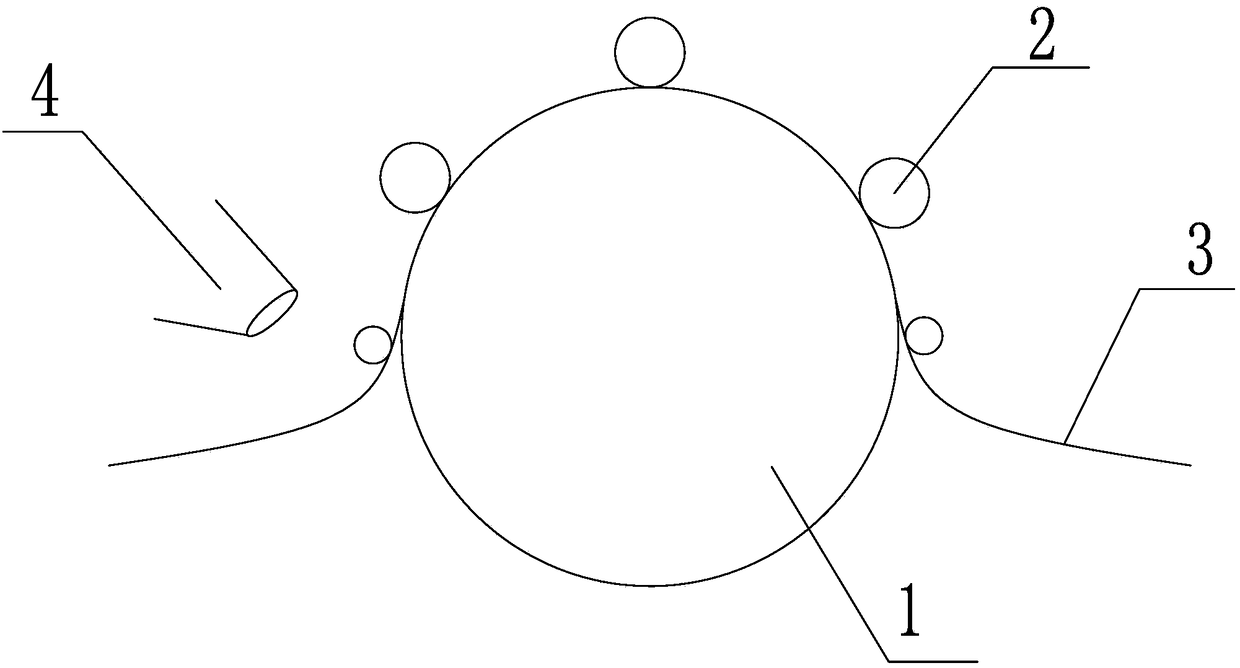

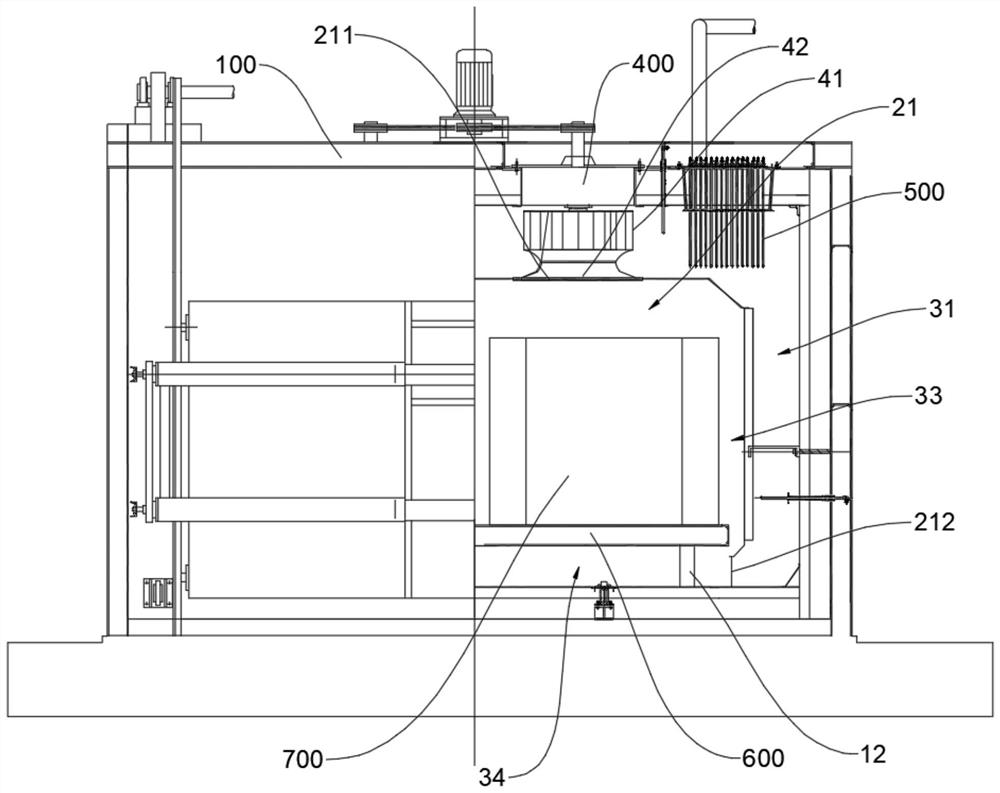

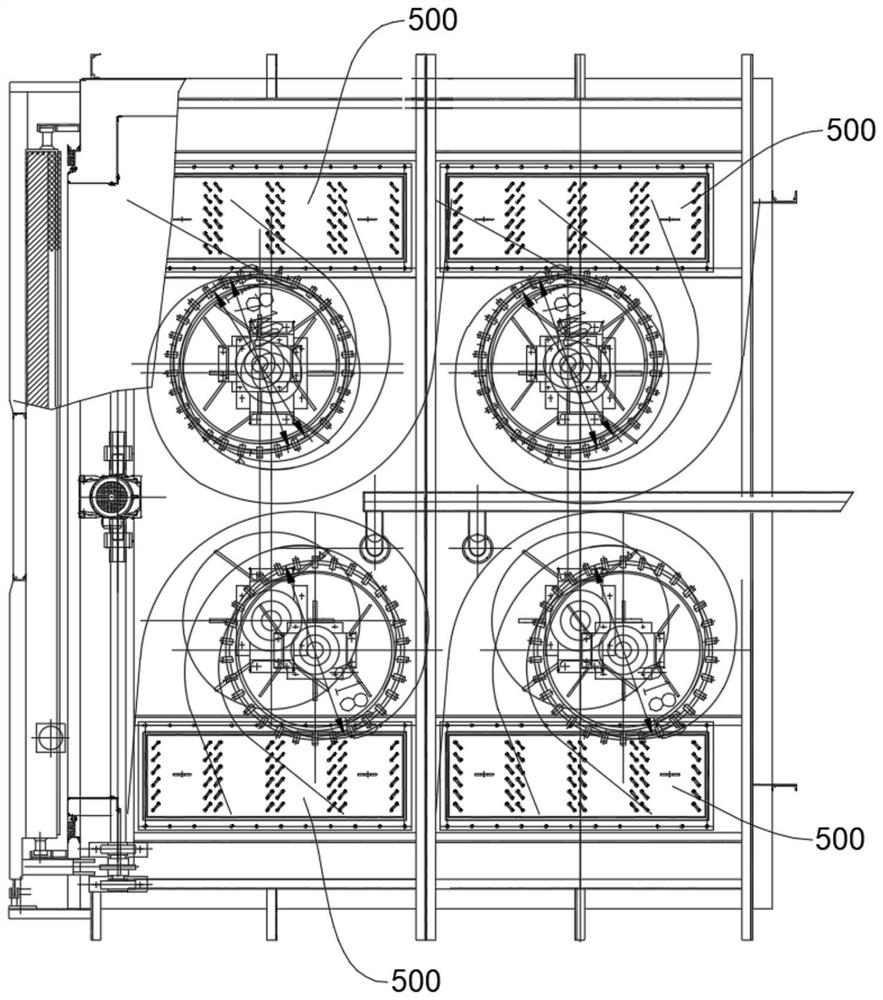

ActiveCN101824526AEven heating inside and outsideCompact structureFurnace typesIncreasing energy efficiencyThermodynamicsSprayer

The invention discloses a medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials. The heat treatment system comprises a medium-frequency heater, a discharge rack, a feed rack, a sprayer and a circulating air cooler, wherein the discharge rack and the feed rack are respectively arranged at the left end and the right end of the medium-frequency heater; the sprayer is arranged above the middle part of the medium-frequency heater; and the circulating air cooler cooperates with the sprayer for use. The heat treatment process comprises the following steps: (1) cleaning the petroleum tool irregular materials; (2) heating the petroleum tool irregular materials, soaking, and water-cooling and air-cooling at the same time; (3) heating the petroleum tool irregular materials, soaking, and air-cooling; and (4) inspecting before warehousing. The invention has the advantages of simple process steps, favorable process parameters, reasonable system structure, high heat treatment efficiency and simple control operation. The invention can effectively avoid the phenomena of cracking and laminating at the end of the petroleum tool irregular material, prevent cooling water from entering the inner bores and ensure that the inside and the outside thereof are uniformly heated. The whole treatment process does not have oxidation or decarbonization, thereby having no pollution.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司 +1

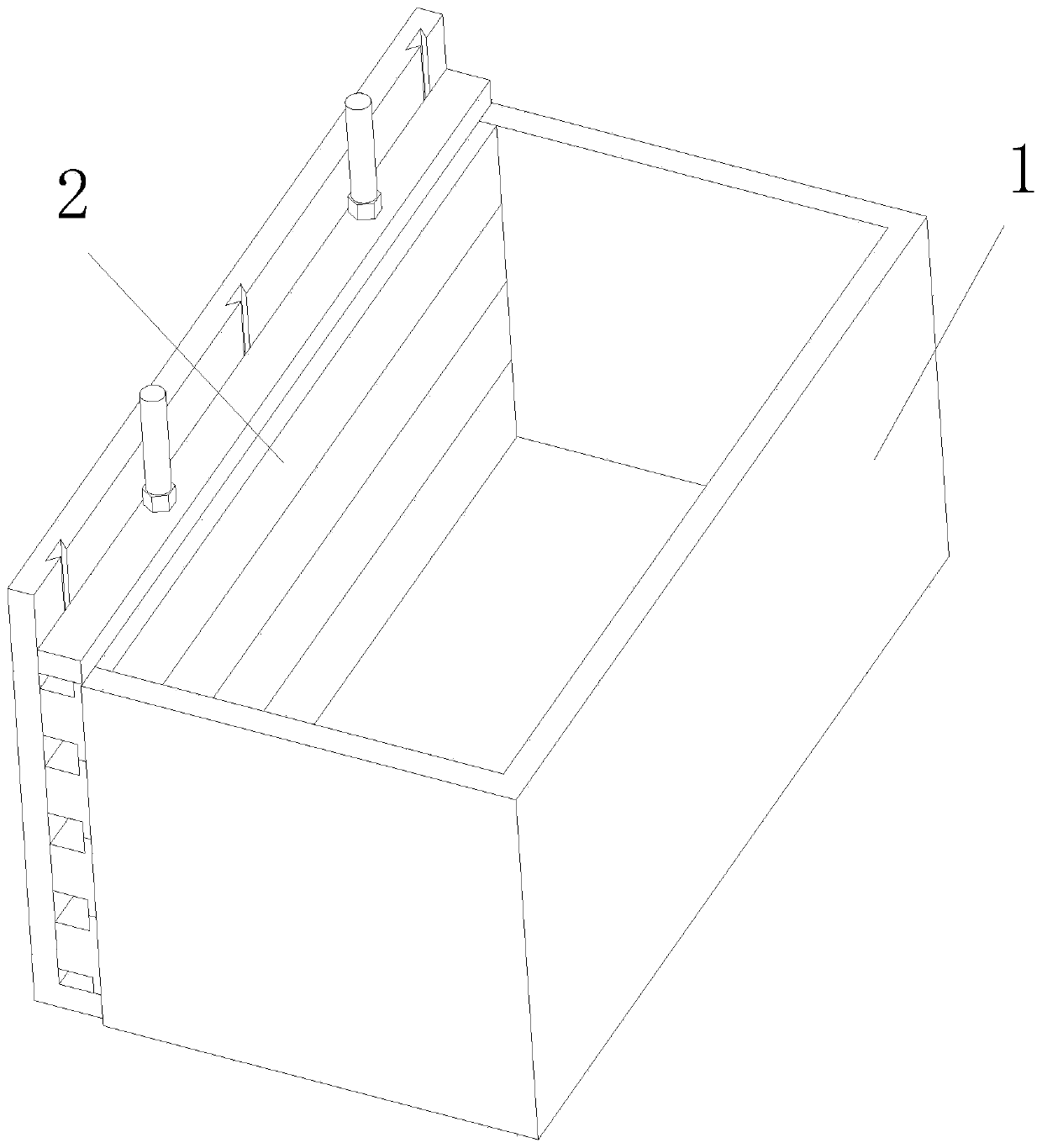

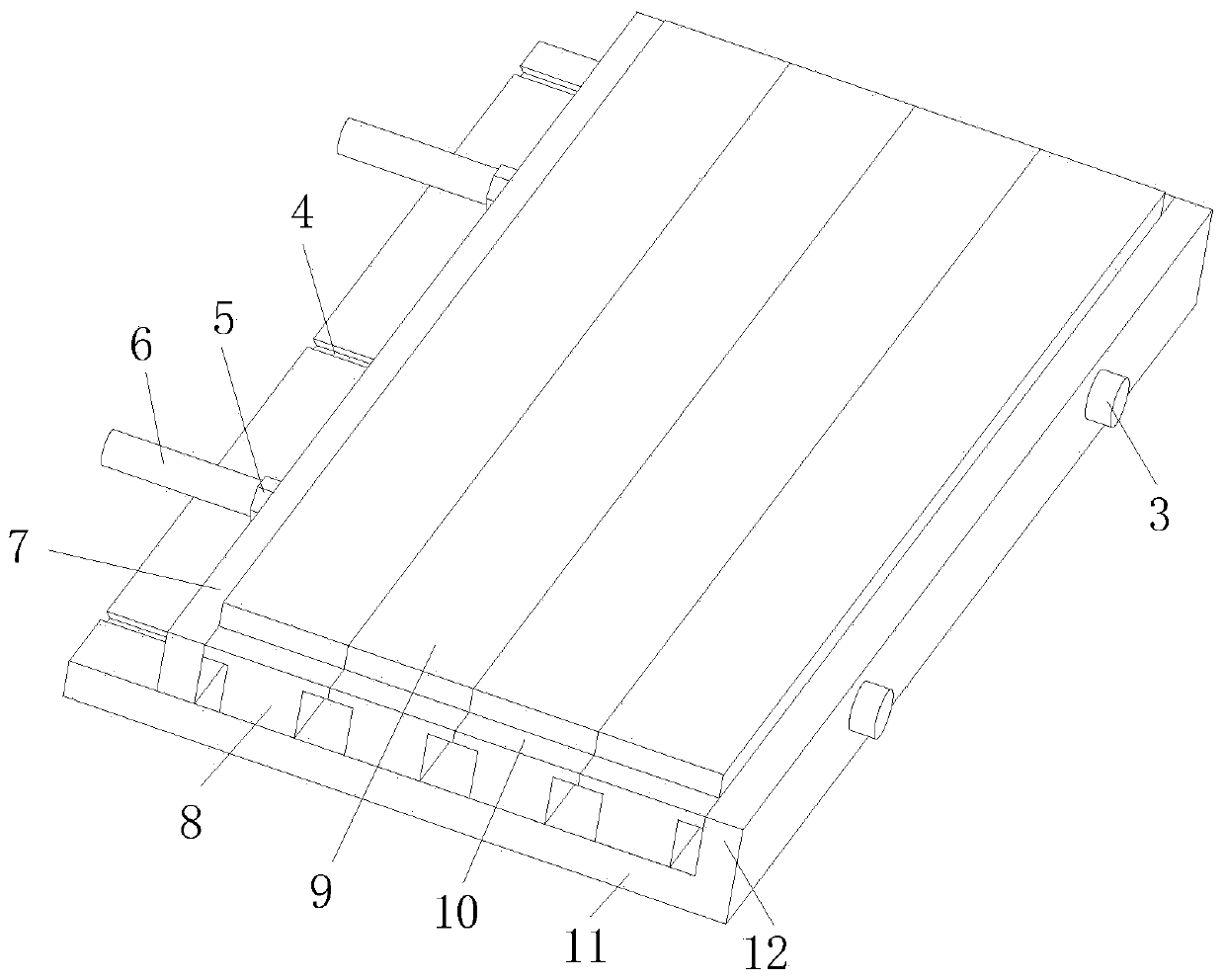

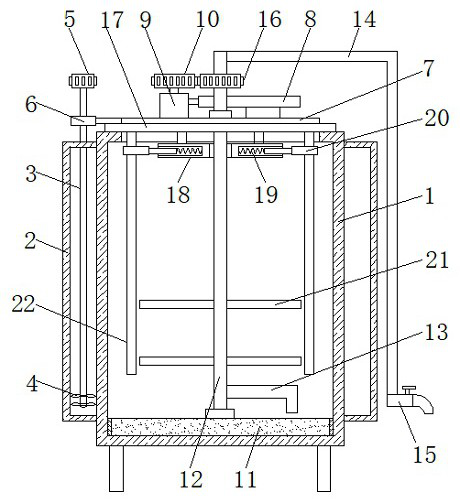

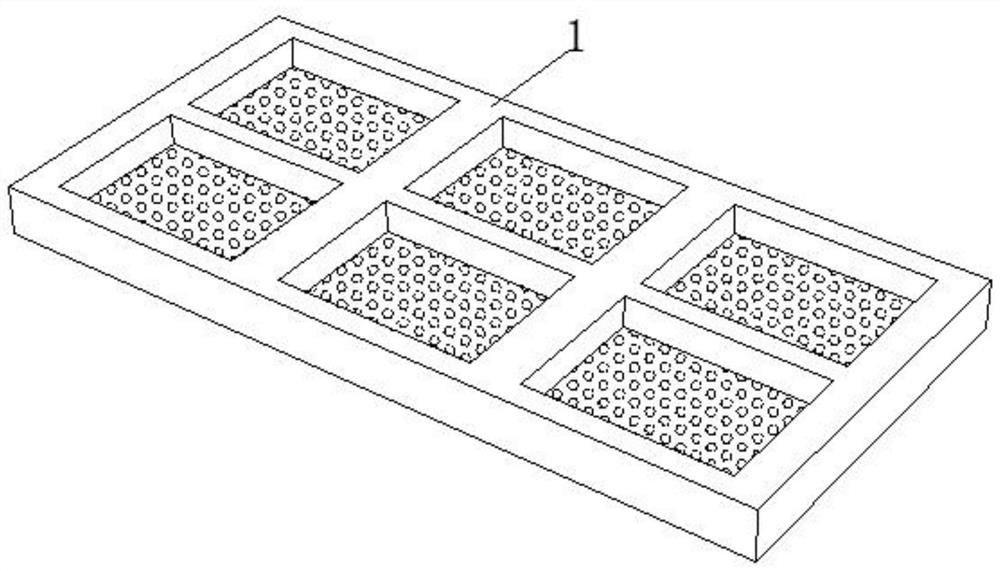

Separable concrete block curing device

InactiveCN110524702AQuality improvementEven heating inside and outsideCeramic shaping apparatusRear quarterEngineering

The invention relates to the technical field of concrete block curing equipment, in particular to a separable concrete block curing device. The device comprises a coaming; the top and one side surfaceof the coaming are open; each side plate comprises a bottom plate; a limiting plate is integrally formed at the bottom end of the bottom plate; three slideways are formed in one end, far away from the limiting plate, of the bottom plate; supporting plates are integrally formed on the face, close to the bottom plate, of the panel. At least two guide rods are arranged between the push plate and thelimiting plate, limiting blocks are integrally formed at the bottom ends of the guide rods, the guide rods sequentially penetrate through the limiting plate, the supporting plates and the push platefrom bottom to top, a compression spring is arranged between every two supporting plates, and the guide rods are sleeved with the compression springs. According to the device, a certain distance is reserved between every two adjacent cut building blocks, then the building blocks are fed into the steam-curing kettle to be cured, due to the fact that the distance between the building blocks is increased, internal and external heating is more uniform, and the building block quality is improved.

Owner:ANHUI LYUFENG ENVIRONMENTAL PROTECTION & ENERGY SAVING MATERIAL CO LTD

Aquilaria sinensis flower tea drink and preparation technology thereof

ActiveCN104206581AGive full play to natural performanceSoup color goldenTea substituesBiotechnologyAquilaria sinensis

The invention relates to the technical field of tea drink, and concretely relates to aquilaria sinensis flower tea drink and a preparation technology thereof. The aquilaria sinensis flower tea drink comprises the following raw materials in parts by weight: 0.1-3 parts of aquilaria sinensis flower tea, 0.5-10 parts of a sweetener, 0.01-1 part of a stabilizing agent, and 100 parts of water. The aquilaria sinensis flower tea is prepared by performing acquisition and winnowing on aquilaria sinensis flower, combined deactivating of enzymes, spreading and cooling, first baking and secondary baking. The aquilaria sinensis flower tea drink is prepared from the above raw materials by performing raw material preparation, crushing, extraction, blending, homogenizing, sterilization and canning. The aquilaria sinensis flower tea drink has no compositions for compatibility, has the unique flavor of the aquilaria sinensis flower tea, also contains abundant trace elements and flavonoids, has both nutrition efficacy and health-care efficacy, and is good in mouthfeel. The preparation technology is capable of improving the mouthfeel of the drink and fully giving play to the unique effects of the aquilaria sinensis flower tea, and is simple and low in cost.

Owner:东莞市莞香园艺科技有限公司

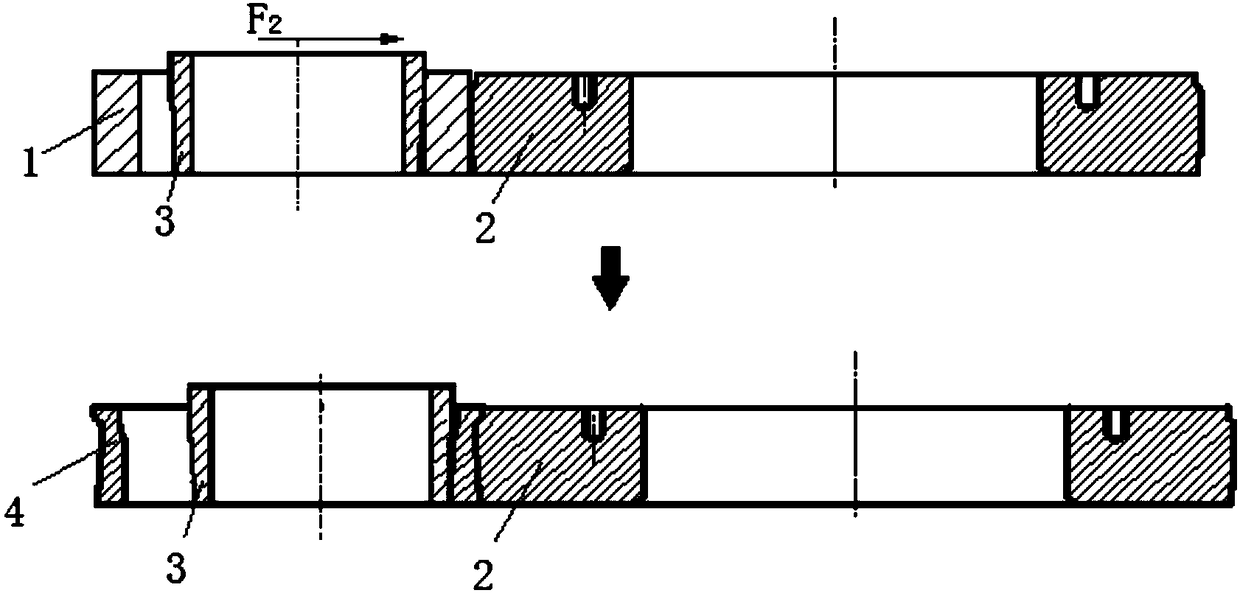

Nb-containing Cr-Ni carburizing steel for cold forming and cold forming method of part

ActiveCN113373382ALow costControl hardnessSolid state diffusion coatingFurnace typesCold formedCrazing

The invention discloses a Nb-containing Cr-Ni carburizing steel for cold forming and a cold forming method of a part. The content of C is reduced and the content of spherical pearlite obtained after spheroidizing annealing is reduced, so that the hardness of a blank is effectively controlled; high-content Ni is added, so that plasticity and toughness of ferrite in the blank are improved, and deformation micro-cracks are not prone to occurring in the interior and on the surface of the part during cold forming; by means of the solid solution characteristic of Nb, N and C in steel, part of Nb, N and C are separated out at an austenitizing temperature of 1100-1250 DEG C, and steel grains can be prevented from being coarsened at a forging temperature; and nbN / NbC is completely separated out, so that the grain size is guaranteed to be smaller than 7 grades, and intermediate cooling treatment is not needed. Pre-oxidation adopts sectional control, the surface of a workpiece is activated, the inside and outside temperature difference is reduced, the inside and outside heating is more uniform, and the internal structure of the part starts repeated crystallization, so that the internal and external structures are more uniform, and thermal treatment deformation aggravation caused by rapid temperature rise is avoided; and residual austenite on the surface of a Ni-containing steel quenching part is reduced, so that the surface hardness is improved to be not smaller than HRC61.

Owner:DONGFENG COMML VEHICLE CO LTD

Preparation method of woven carpet without gumming process

ActiveCN108411460AEnhanced shape retention and dimensional stabilityOmit the adhesive processHeating/cooling textile fabricsWoven fabricsCopolyesterWeft yarn

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber-formed filament or a staple fibre yarn, a first coating layer is apolyester fiber filament or a staple fibre yarn, the second coating layer accounts for 20%-50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass ofthe composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt copolyester fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt copolyester fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, the pile and weft yarns as well as the weftyarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpet are enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

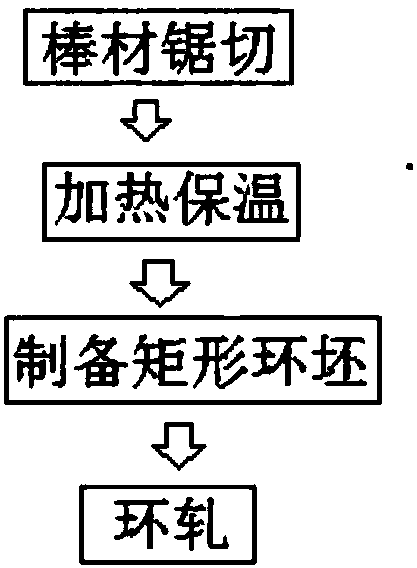

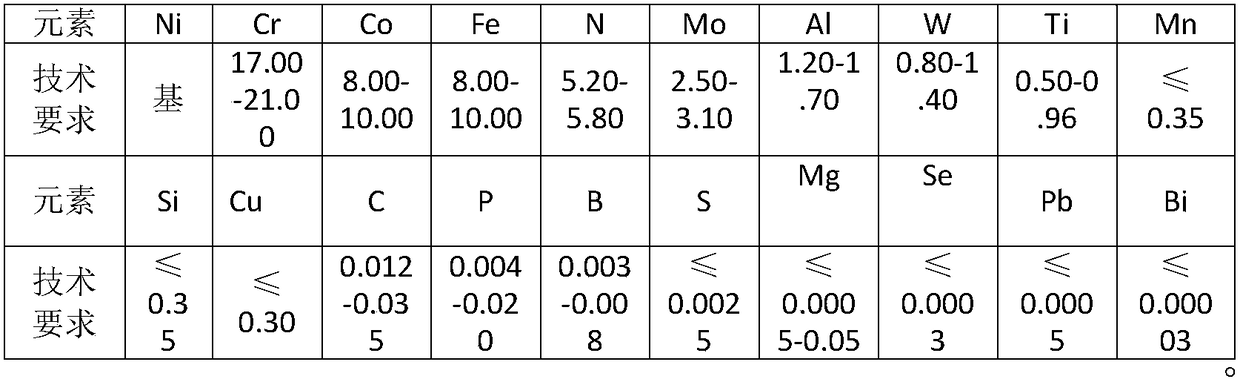

Manufacturing method of 718plus special-shaped cartridge receiver forging

InactiveCN108213844AEven heating inside and outsideReduce manufacturing costAircraft componentsFiberManufacturing technology

The invention relates to the technical field of forging manufacturing, in particular to a manufacturing method of a 718plus special-shaped cartridge receiver forging. Binding of ceramic fibers is carried out, and the heat preservation time is determined according to the effective thickness of materials, so that the interiors and the exteriors of the materials are evenly heated, the temperature drop generated in the transfer process is reduced, the temperature in the machining process can effectively meet machining requirements, the defect that cracks are generated on the surfaces of the materials during machining due to the too low temperature is avoided, meanwhile, the defect that in order to meet the requirement that no crack is generated on the surfaces of the materials during machining, when the materials are heated to reach high temperature, the grain size is large, and the structure property is poor can be avoided, the energy consumption is reduced, the percent of pass of products is increased, and the manufacturing cost of the forging is reduced.

Owner:GUIZHOU AVIATION TECHN DEV

Production process of pumpkin powder

InactiveCN102366061AIncrease aromaEven heating inside and outsideFood shapingFood preparationPumpkin seedMicrowave sterilization

The invention discloses a production process of pumpkin powder. The production process comprises the following steps: selecting a mature old pumpkin; soaking the old pumpkin in clear water for 3-4 hours; peeling, washing, removing seeds, and cutting the pumpkin into slices; putting the pumpkin slices in a dryer for drying at the temperature of 70-80 DEG C for 10-12 hours; crushing the dried pumpkin slices into 100-120 mesh size; carrying out microwave sterilization (10-12kw) for 3-5 minutes; and vacuum-packaging to finally obtain the pumpkin powder. The pumpkin powder obtained by the production process has the advantages of rich nutrition and simple production flow.

Owner:兴义市东泰天然果蔬开发有限公司

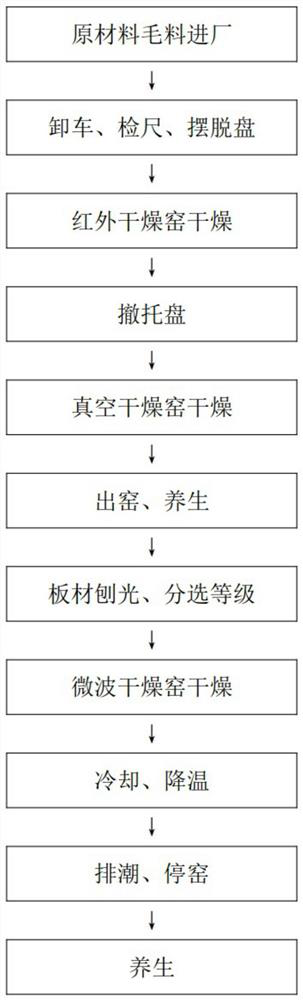

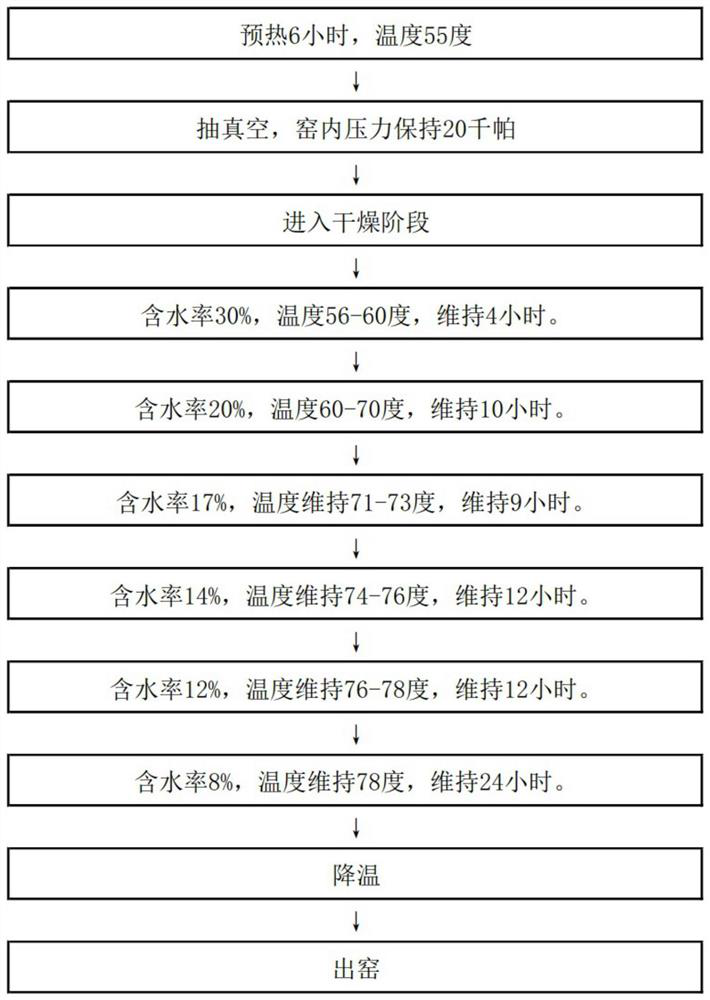

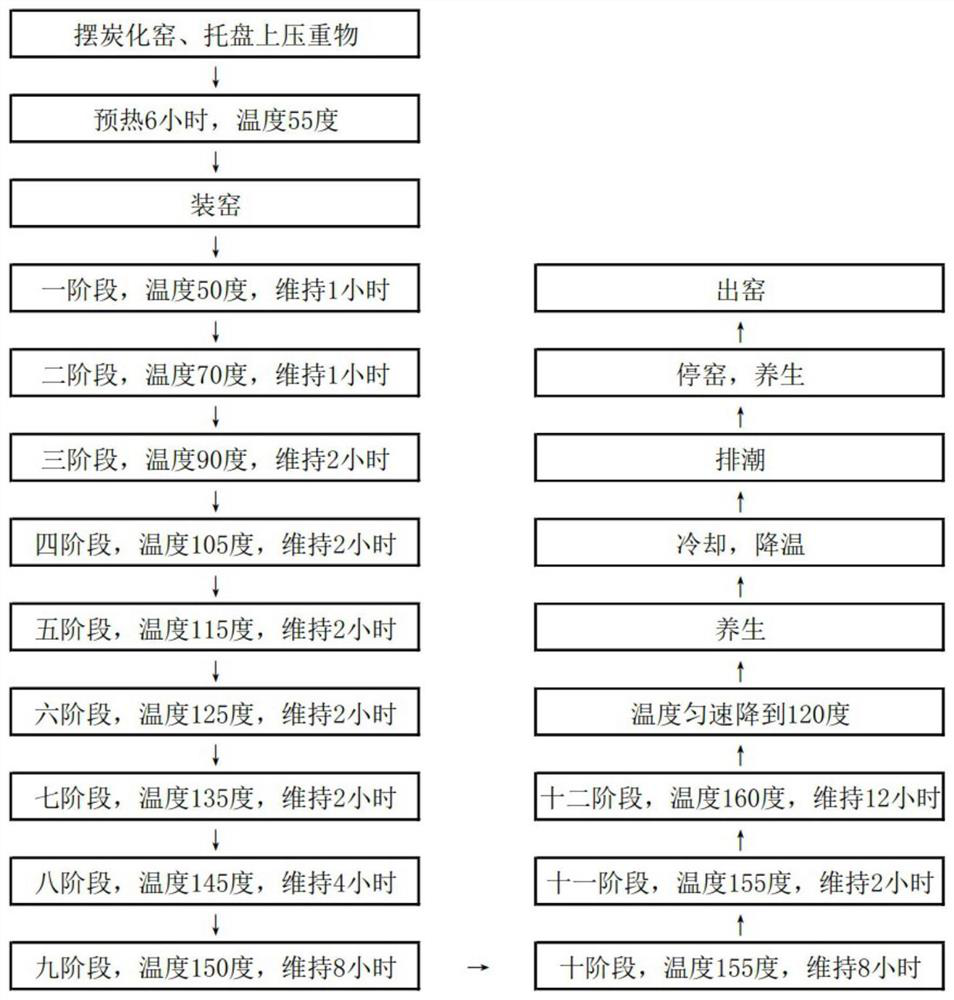

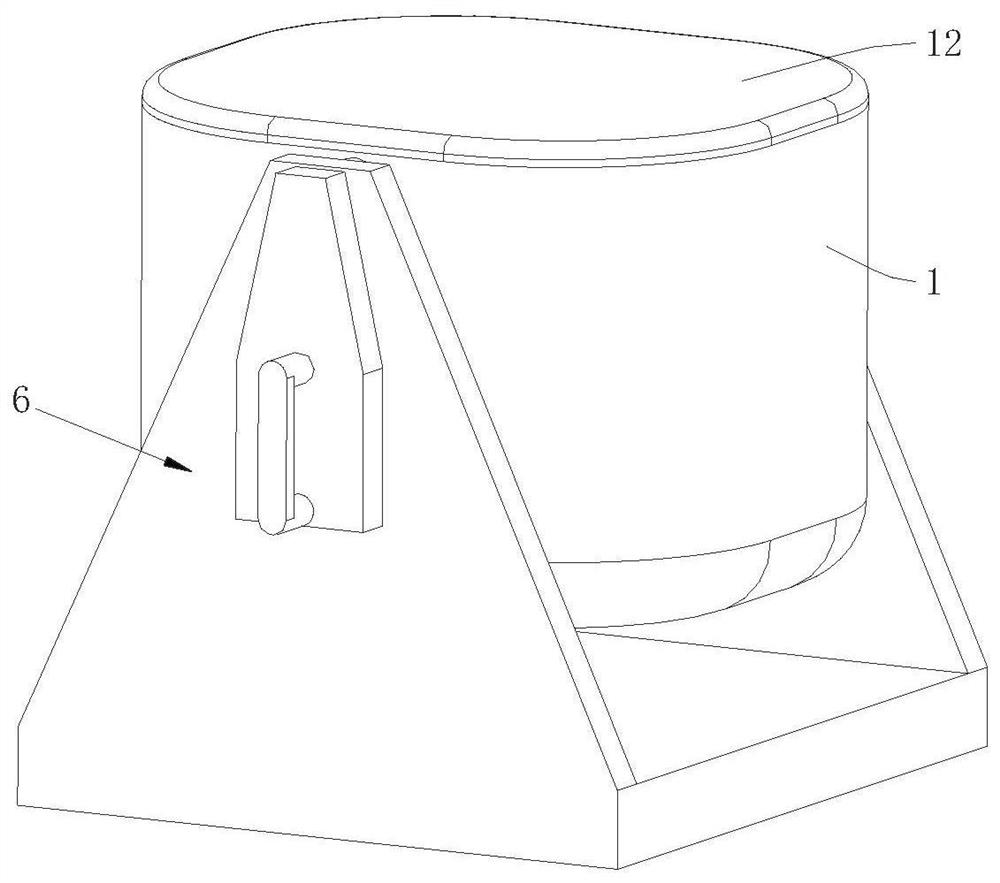

Medium-temperature heat treatment method for floor wood

InactiveCN112856939AKeep naturalSolve the cracking problemDrying solid materials with heatDrying solid materials without heatPulp and paper industryMoisture absorption

The invention discloses a medium-temperature heat treatment method for floor wood, and belongs to the field of drying of wood boards and wood. According to the method, a vacuum and microwave drying kiln is adopted for medium-temperature heat treatment, so that the water content of the treated wood is between the water content of carbonized wood and the water content of common wood; and according to the wood treated through the method provided by the invention, the high moisture absorption rate of the common wood can be restrained, and the problem that carbonized wood is prone to cracking and inelastic after being extremely dried can be solved. The wood treated by the method is purely natural, purely green and pollution-free. In the whole treated process, the wood only makes contact with water vapor and hot air, and no chemical reagent is added, so that the natural essence of the wood is kept. Meanwhile, the wood has good environmental stability and corrosion resistance and is not easily influenced by the surrounding environment.

Owner:DALIAN SHENGYU TECH DEV CO LTD

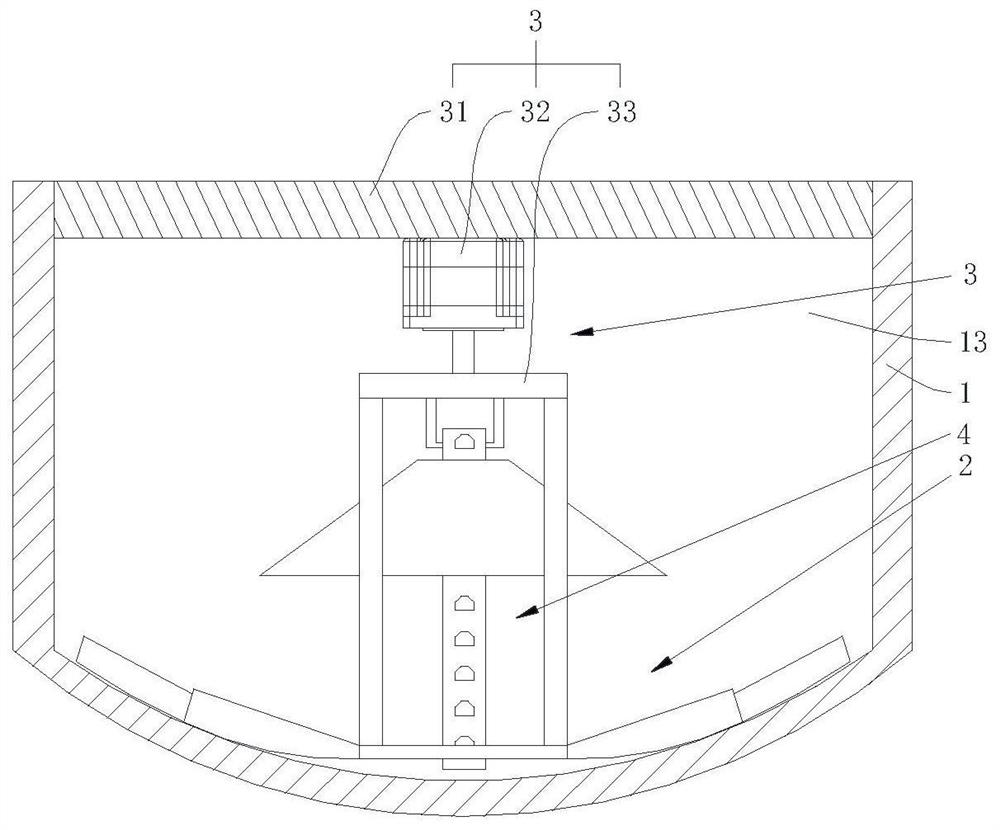

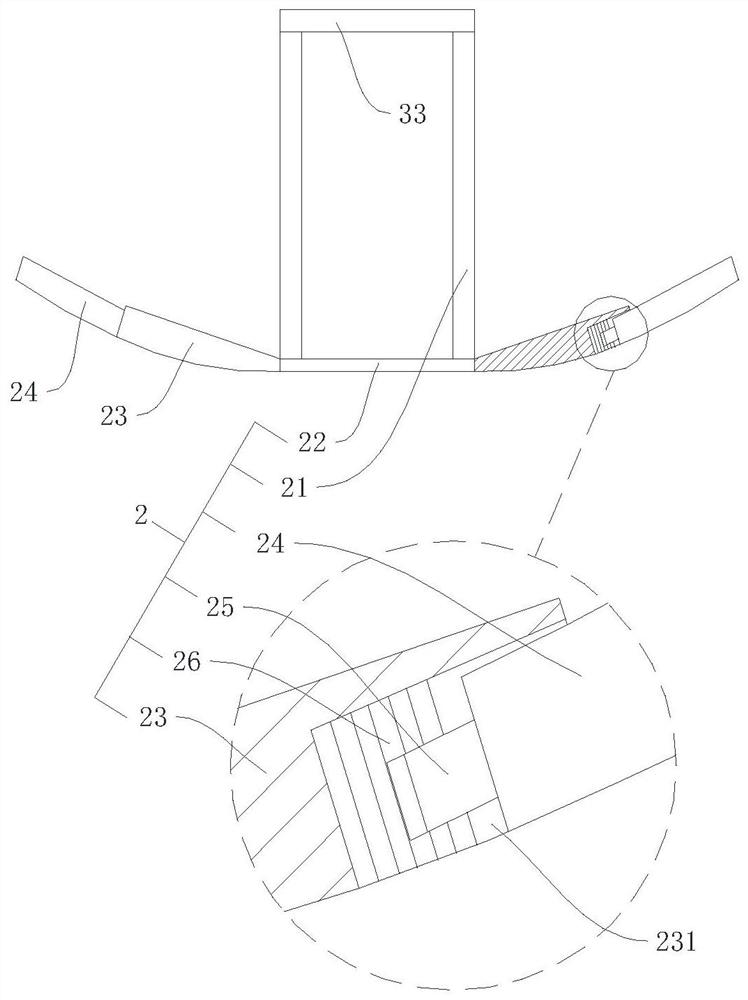

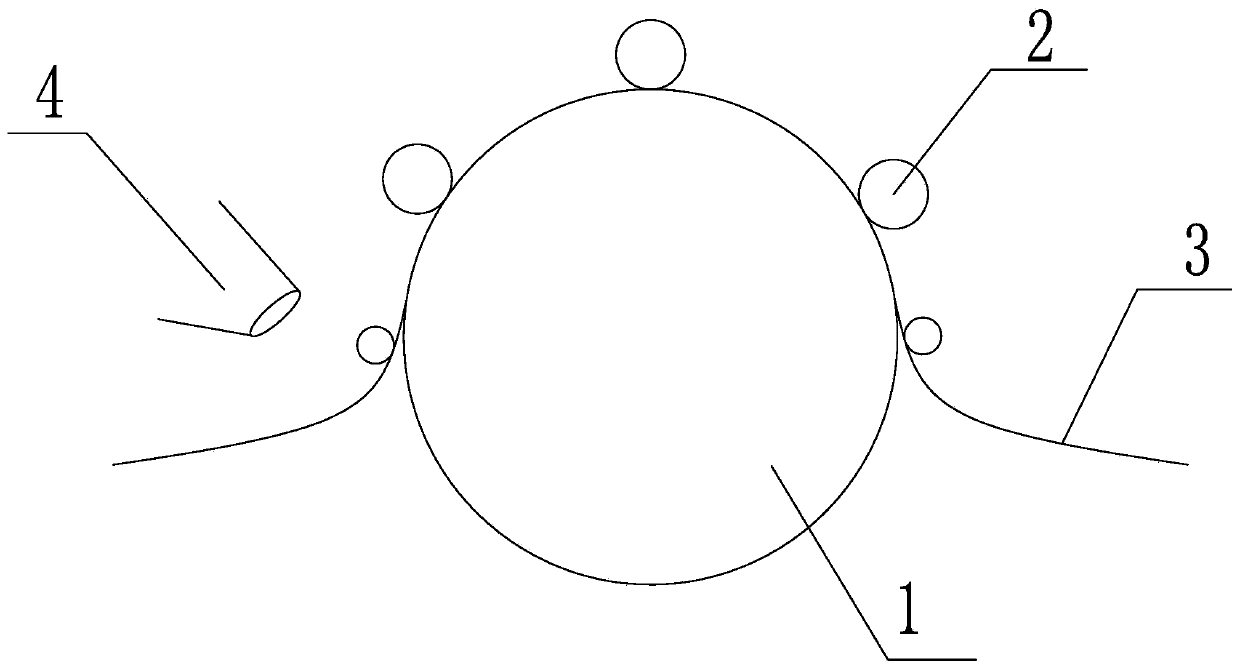

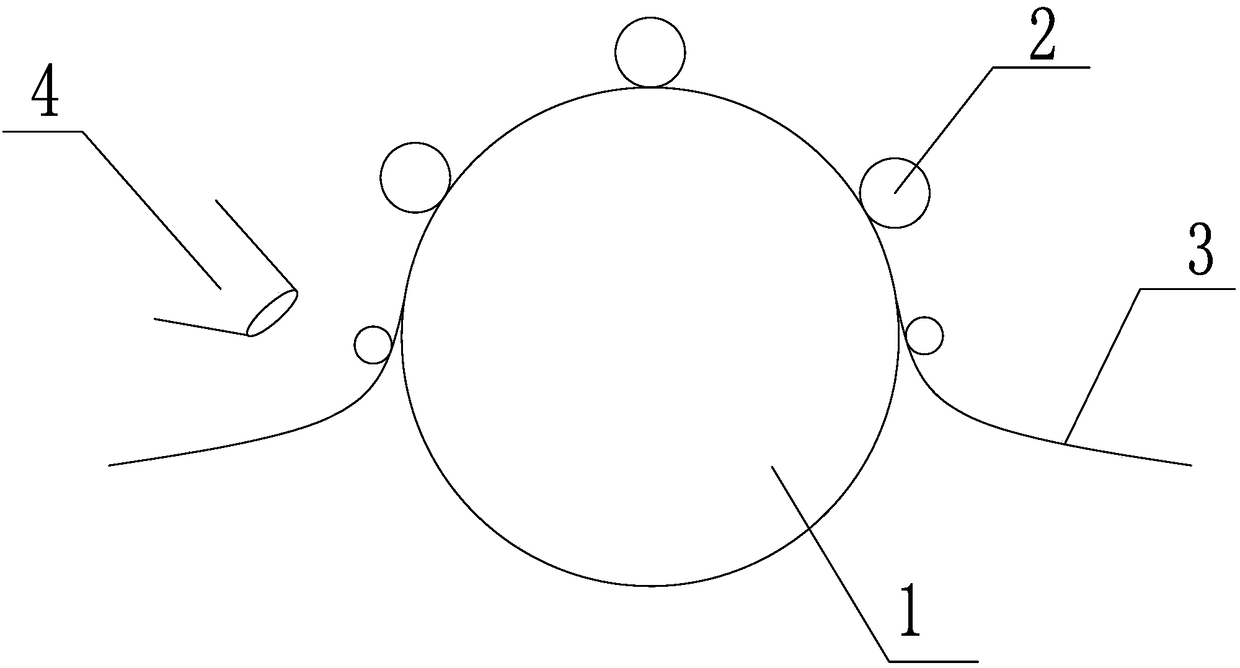

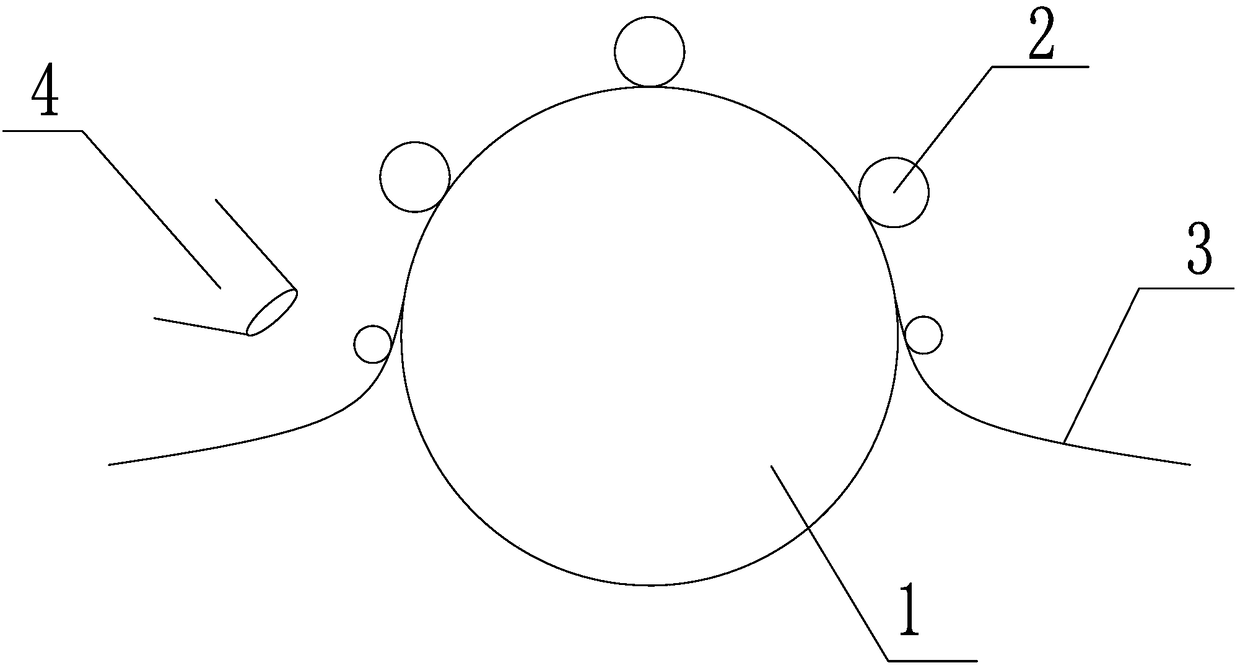

Sunflower seed oil pressing, steaming and stir-frying processing system

InactiveCN111793520APrevent scorching and fryingEven heating inside and outsideFatty-oils/fats productionMechanical engineeringMaterials science

The invention relates to the technical field of agricultural processing equipment, particularly to a sunflower seed oil pressing, steaming and stir-frying processing system, which comprises a stir-frying furnace and a mounting cover covering the stir-frying furnace, wherein the stir-frying furnace and the mounting cover are matched to form a heating cavity for heating sunflower seeds, the bottom of the stir-frying furnace is in a downward concave arc shape, a rotary stirring device and a driving device are arranged in the stir-frying furnace, the rotary stirring device is propped against the bottom of the stir-frying furnace in a sliding manner so as to stir the sunflower seeds at the bottom of the stir-frying furnace, the driving device is arranged on the stir-frying furnace and is positioned at the furnace mouth of the stir-frying furnace to drive the rotary stirring device to operate, and an internal and external exchange device is arranged between the rotary stirring device and thedriving device and is driven by the driving device. According to the invention the sunflower seed oil pressing, steaming and stir-frying processing system has the effects that the sunflower seed stir-frying process is convenient and fast, and the sunflower seed stir-frying efficiency is improved.

Owner:苏静雯

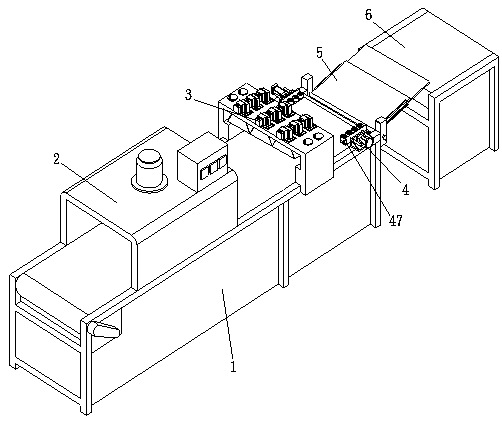

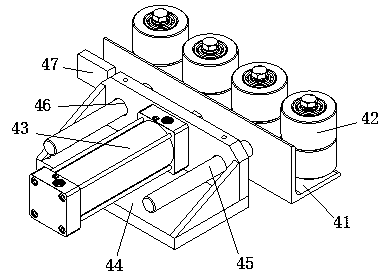

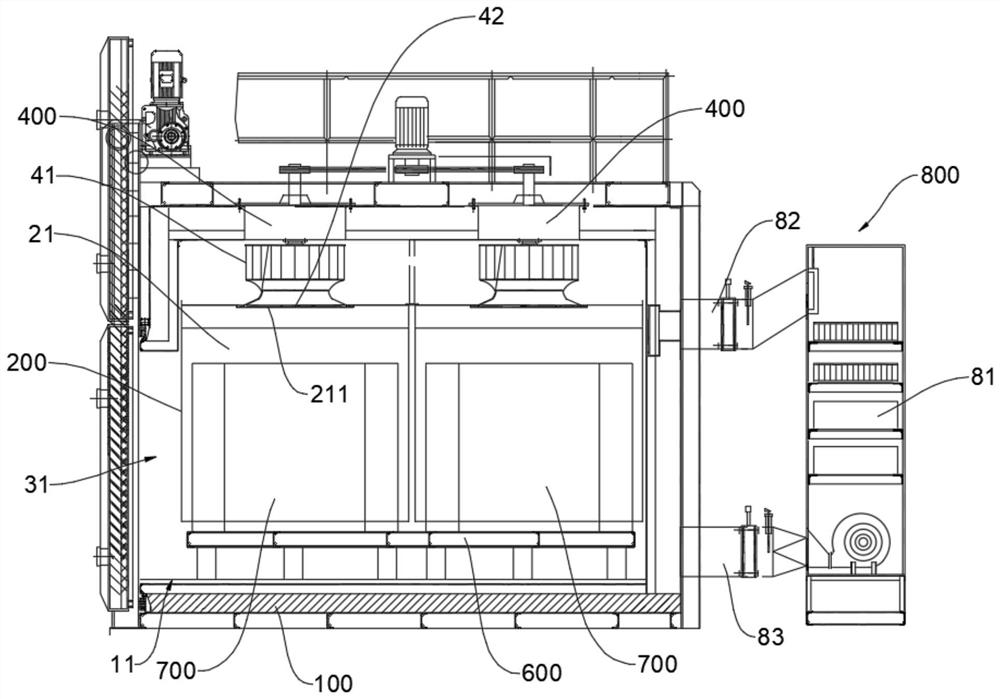

Device for heating cakes and breads by microwave energy and use method of device

ActiveCN110623013AEven heating inside and outsideGreat tasteBaking ovenFood processingMicrowaveEngineering

The invention relates to the field of cake and bread heating treatment devices, in particular to a device for heating cakes and breads by microwave energy and a use method of the device. Compared witha traditional bread heating treatment device, the device adopts two-stage heating, at the first stage, cakes and breads are baked on an assembly line, at the second stage, the cakes are heated by a microwave device, the cakes and breads are heated and baked at two stages, and the cakes can be heated uniformly inside and outside, have better taste and longer shelf life; under the action of mutualcooperation of a transfer plate and a connecting plate, a conveyor and a processing table can be connected well, so that the cakes and breads can be directly pushed onto the processing table after being baked, manual carrying of trays is avoided, following processing time is shortened, and the space occupied by the conveyer can be reduced; and under the action of a rotating shaft, the transfer plate and the connecting plate swing to adapt processing tables at different heights, and the device is more practical.

Owner:福建省然利食品集团有限公司

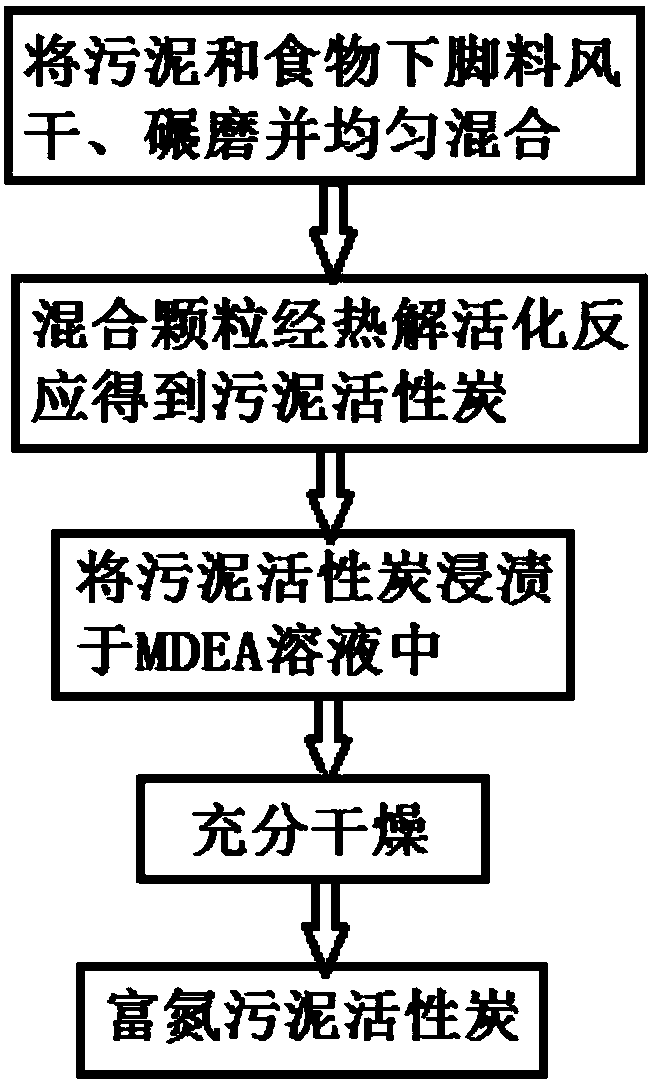

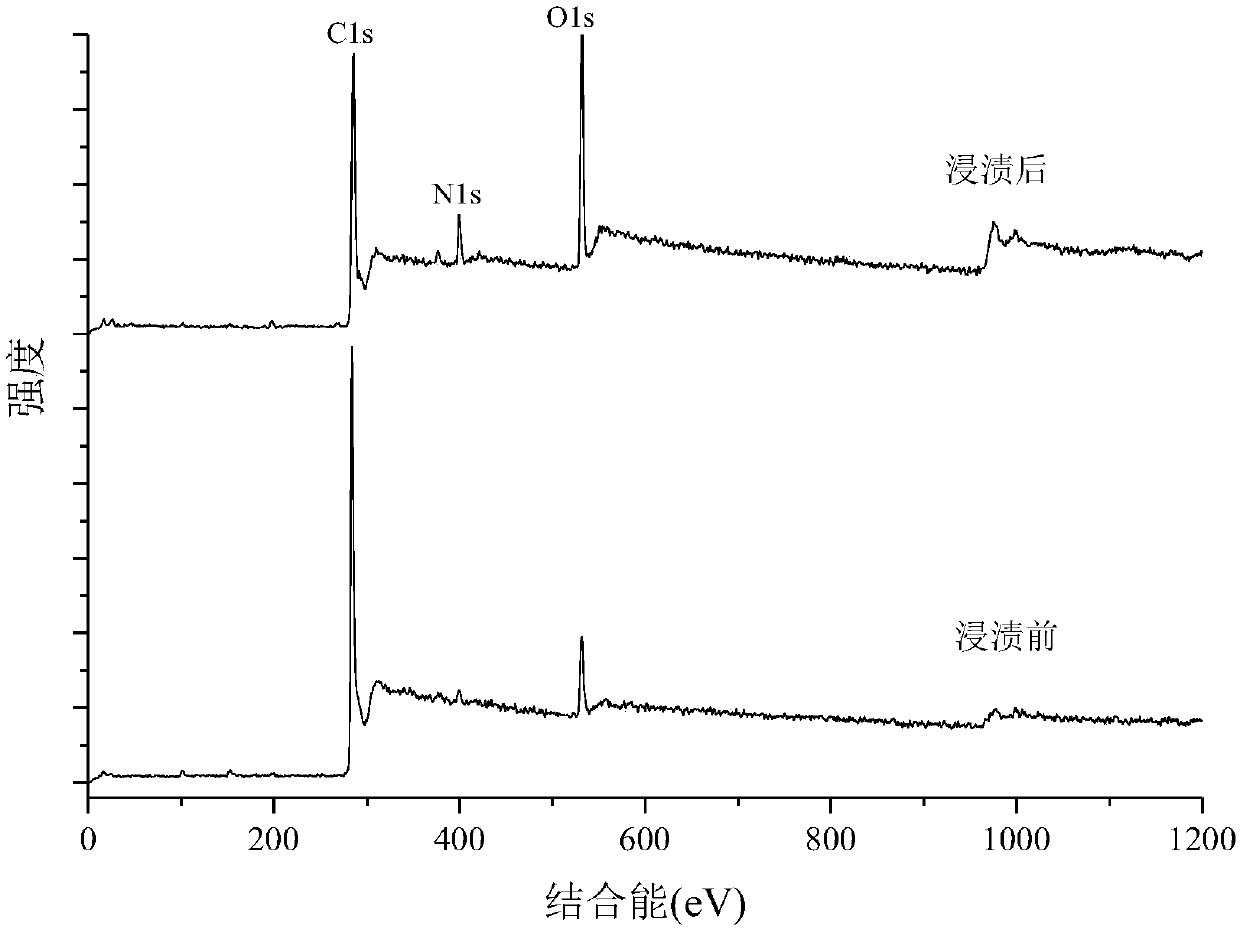

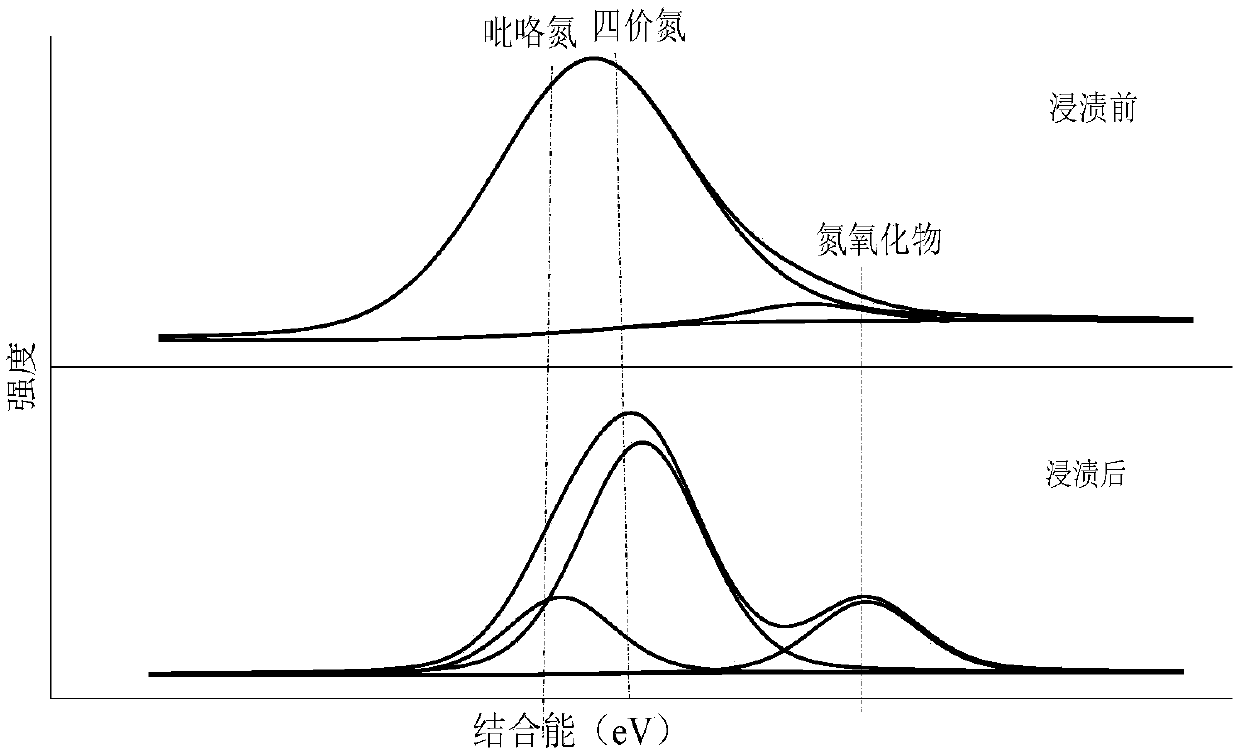

Preparation method of nitrogen-rich sludge activated carbon doped with food leftover

InactiveCN107628619AImprove the effect of desulfurization and denitrificationMeet the use requirementsCarbon compoundsDispersed particle separationActivated carbonPorosity

Belonging to the field of sludge treatment, the invention particularly relates to a preparation method of nitrogen-rich sludge activated carbon doped with food leftover. The method specifically includes the steps of: S1 subjecting sludge and food leftover to air drying respectively and performing milling, and mixing the sludge granules and food leftover granules obtained by milling evenly; S2 subjecting the prepared mixed particles to pyrolysis activation reaction to obtain sludge activated carbon doped with food leftover; S3 impregnating the sludge activated carbon in an MDEA impregnation solution, and stirring the substances fully; and S4 fully drying the sludge activated carbon to obtain the nitrogen-rich sludge activated carbon. The preparation method provided by the invention can improve the carbon content and nitrogen content of activated carbon, and generates sludge activated carbon with high porosity and good adsorption properties, also the whole process does not cause secondary pollution to the environment, and has the advantages of high efficiency, high quality, low cost, no toxicity, convenient control and the like, thereby being especially suitable for mass production application occasions.

Owner:SHENZHEN WATER GRP CO LTD +1

Brewing device for tea wine production

InactiveCN112175771AEven insulationAvoid accumulationAlcoholic beverage preparationWater flowProcess engineering

The invention discloses a brewing device for tea wine production, and relates to the technical field of tea wine brewing. In order to solve the problems that in the prior art, when tea wine is brewed,that internal liquid is heated uniformly cannot be guaranteed, and the outside lacks heat preservation measures, the following scheme is provided. The brewing device comprises a fermentation barrel,wherein the fermentation barrel is fixedly sleeved with a heat preservation water storage cover, the heat preservation water storage cover is internally and movably sleeved with a water flow circulating mechanism, the fermentation barrel is internally and movably sleeved with a piston, the top of the piston is rotationally connected with a fixed pipe, one side of the bottom of the fixed pipe is fixedly connected with a water suction pipe, the top of the fermentation barrel is fixedly connected with a sealing cover, the bottom of the fermentation barrel is fixedly connected with a positioning mechanism, and a movable plate is arranged at the top of the sealing cover. The inside and outside of the fermentation barrel are heated uniformly, high-quality and efficient fermentation is facilitated, the discharging direction can be adjusted, sediment in the barrel can be conveniently removed, and the device is rapid and saves labor.

Owner:湖南茶酒有道酒业有限公司

Wire rod coiled material annealing furnace

PendingCN114561518ASpeed up the cycleImprove uniformityFurnace typesHeat treatment furnacesWire rodEngineering

The invention discloses a wire rod coiled material annealing furnace, which comprises a furnace body, a furnace cover, a wire rod and a wire rod, the flow guide device is contained in the hearth, and a first flow guide channel and a containing cavity communicated with the first flow guide channel are formed in the flow guide device; the circulating fan comprises a first air outlet connected with the first flow guide channel and an air return opening connected with the containing cavity. The heating device is accommodated in the first flow guide channel; wherein the containing cavity is internally provided with a material disc for bearing the coiled material, the material disc comprises a guide sleeve, the coiled material is concentrically arranged on the periphery of the guide sleeve in a sleeving mode, an inner ring airflow channel is formed between the inner ring of the coiled material and the guide sleeve, an outer ring airflow channel is formed between the outer ring of the coiled material and the fluid director, and the outer ring airflow channel is communicated with the inner ring airflow channel. The air flow flowing into the containing cavity flows back to the air return opening along the outer ring air flow channel and the inner ring air flow channel at the same time. The coiled material heating device can realize rapid and uniform heating of coiled materials.

Owner:SUZHOU LONGRAY THERMAL TECH

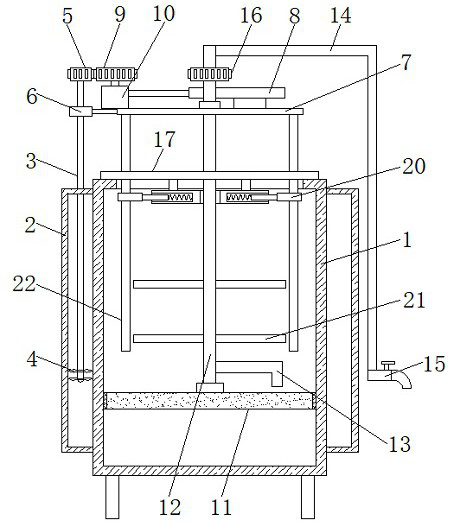

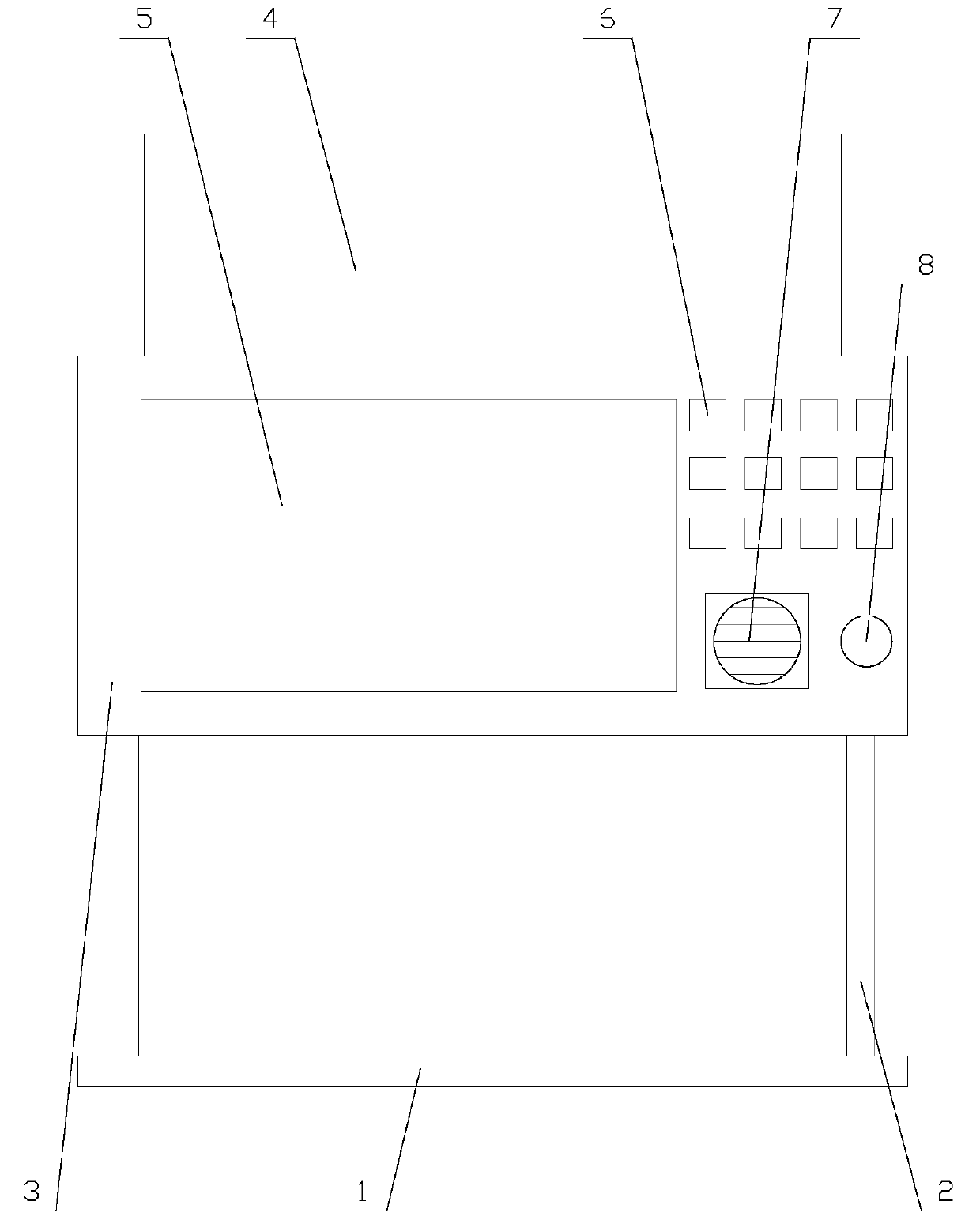

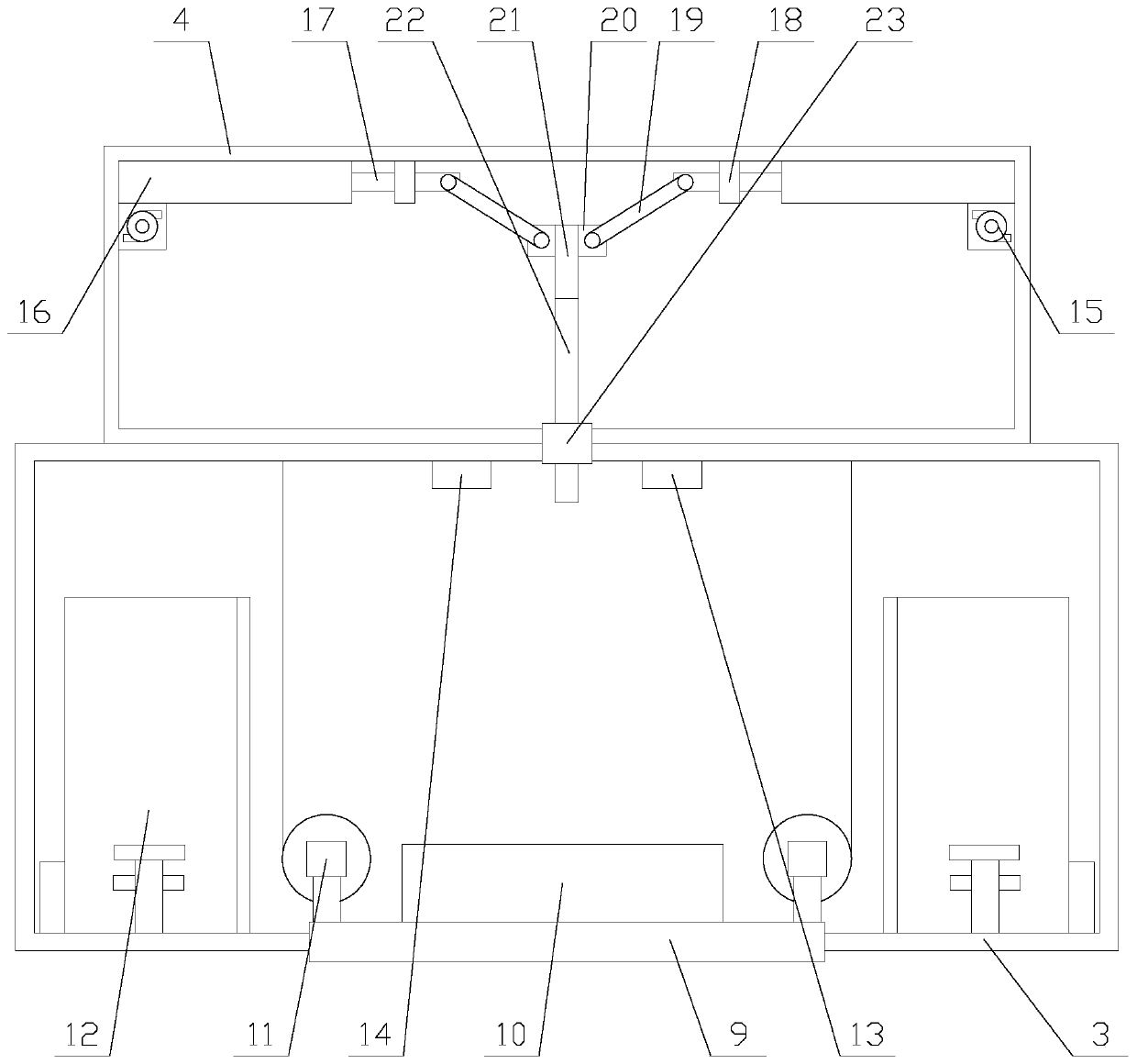

An evenly heated infrared drying oven based on the Internet of Things

ActiveCN107367133BEven heating inside and outsideEvenly heatedDrying solid materials with heatDrying machines with local agitationInfrared lampThe Internet

The invention relates to a uniform heating energy-saving type infrared ray drying box based on the Internet of Things. The infrared ray drying box comprises a bottom plate, a heating box, a heat supplementing box and two supporting columns. A heat supplementing mechanism is arranged in the heat supplementing box. The heat supplementing mechanism comprises a lifting rod, a first infrared lamp, a lantern ring and two drive units. A supporting plate and two direction adjusting mechanisms are arranged in the heating box. Each direction adjusting mechanism comprises a fixing rod, a sleeve, a vertical plate, a reflection cover, a second infrared lamp and two telescopic units. A locating mechanism and two lifting mechanisms are arranged above the supporting plate. According to the uniform heating energy-saving type infrared ray drying box based on the Internet of Things, the two direction adjusting mechanisms drive angles of the two infrared lamps to change correspondingly, while articles are dried from the different directions, the number of the infrared lamps is reduced, thus, the loss of electric energy is reduced, and the purpose of energy saving is achieved. Moreover, by means of the heat supplementing mechanism, the first infrared lamp extends into a cavity of each article, the articles are heated and dried internally, and thus it is ensured that the articles are uniformly heated internally and externally in the drying process.

Owner:江苏中聚检测服务有限公司

Manufacture method of herba dendrobii moon cakes

InactiveCN106172668APromote peristalsisPromote digestionDough treatmentBakery productsSmall intestineDigestion

The present invention belongs to the technical filed of food processing and particularly relates to a manufacture method of herba dendrobii moon cakes. The manufacture method is characterized by comprising the following steps: (1) moon cake bases are manufactured; and (2) the moon cakes are baked. Herba dendrobii powder is added into the produced herba dendrobii moon cakes, accelerates the pushing function of small intestines and the emptying function of stomach, promotes the peristalsis and digestion of the stomach, can greatly reduce the greasy taste of the moon cakes, enables the moon cakes to have health-care functions of strengthening stomach and spleen, and solves the problem that the greasiness of the moon cakes is easy to aggravate the burdens of the intestines and stomach. In the manufacture processes of the moon cakes, Manuka honey and compound starch films are also added, which can kill bacteria of the moon cake fillings, extends the shelf life of the moon cakes, and thus solves the problem that the moon cakes are easy to grow molds and denature.

Owner:GUANGXI RONGXIAN COUNTY TIANSHUN DENDROBIUM CO LTD

Method for preparing lemon jam by fermentation of spent edible fungus substrate

InactiveCN107822039AMaintain qualityMaintain nutrientsFood ingredient as taste affecting agentFood ingredient as flavour affecting agentBiotechnologyCyclodextrin

The invention discloses a method for preparing lemon jam by fermentation of spent edible fungus substrate and belongs to the field of food. A nontoxic and natural organic sweetener is extracted from stevia rebaudiana leaf. The sweetener doesn't participate in metabolism in human body or provide heat; and lemon itself promotes digestion. Thus, jam is especially suitable for people with poor gastrointestinal functions as well as diabetic patients and middle-aged and aged people. The jam has a wide range of customers and has efficacy of clearing heat, promoting dieresis and regulating gastric acid. Then, health efficacy of the jam is also enhanced. In addition, sour flavour of lemon can be covered with sweetness of the sweetener, and beta-cyclodextrin has an embedding effect on bitter substances. Therefore, mouthfeel of the jam is further improved. Existing jams are mostly prepared from pulp and pericarp is thrown away as house refuse such that the environment is polluted and resources are wasted. In addition, white sugar is used as a sweetener, thus limiting the range of customers. The above problems are solved by the method of the invention.

Owner:李炫颖

Process method for rubber tube vulcanization

InactiveCN105619668AEven heating inside and outsideReduce air bubbles or crackingTubular articlesThermal conductivityEngineering

The invention discloses a process method for rubber tube vulcanization and relates to the field of process methods for rubber tube vulcanization. The process method for rubber tube vulcanization comprises the specific steps that a mold sleeving stage is conducted, specifically, a preforming rubber tube blank and an aluminum mandril mold are prepared, and the aluminum mandril mold is made to be sleeved with the preforming rubber tube blank from the non-ring opening end; and a vulcanization stage is conducted, specifically, the mold-sleeving tube blank is hung on a vulcanization vehicle, the vulcanization vehicle is pushed into a vulcanization tank, an air inlet valve is opened and is filled with high-temperature steam, the air inlet valve is closed, an air exhausting valve is opened, and the mold-sleeving tube blank is taken out for demolding. According to the process method, the good thermal conductivity of an aluminum mandril is used, so that in the mold sleeving stage, the aluminum mandril is cooled naturally, and automatic vulcanization due to the fact that the rubber tube blank is heated excessively is effectively avoided; in the vulcanization stage, the temperature of the aluminum mandril can be quickly kept the same as that of the high-temperature steam in the vulcanization tank, so that the inside and the outside of the rubber tube blank are heated evenly, and the defects of bubbles or cracks generated due to partial uneven heating of a rubber tube are effectively overcome.

Owner:ANHUI ZHONGDING HOSE PROD

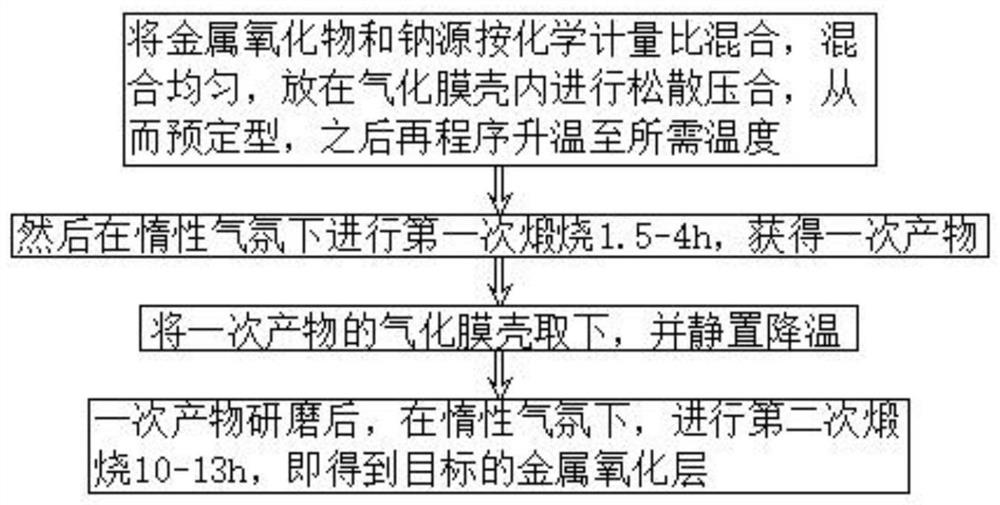

A kind of preparation method of metal oxide layer on the electrolyte surface of sodium battery

ActiveCN110416601BGuaranteed clearanceCalcined evenlySecondary cellsElectrical batteryPhysical chemistry

Owner:钠悦新能源(上海)有限公司

A kind of preparation method of latex-free machine-woven carpet

ActiveCN108396397BGuaranteed pull-out forceReduce dosageCarpetsWoven fabricsPolymer scienceLatex rubber

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is filament or spun yarn formed of hot-melt fibers, and the first coating layer is fiber long yarn formed of nylon 6 or nylon 66. Silk or spun yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn. Pile weft. When hot-melt copolyamide fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of nylon or wool fibers, when the hot-melt copolyamide fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the carpet pile and The shape retention and dimensional stability of the carpet, thereby omitting the back glue process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

A kind of preparation method of machine-woven carpet without back glue process

ActiveCN108411460BGuaranteed pull-out forceReduce dosageHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention discloses a preparation method of a machine-woven carpet without adhesive backing process. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the pile and the carpet Excellent shape retention and dimensional stability, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

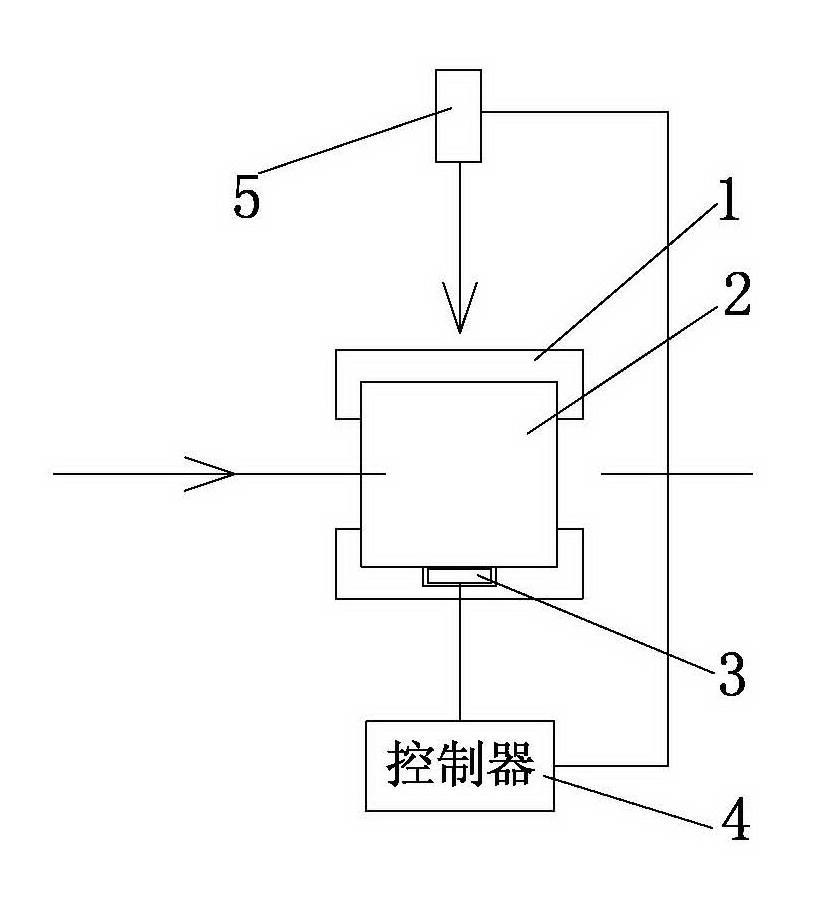

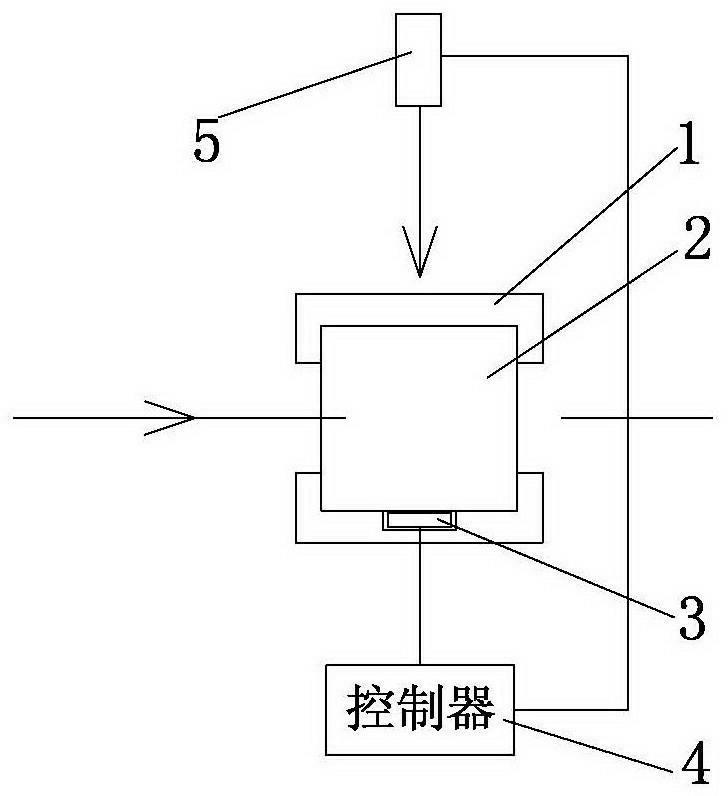

Frequency doubling crystal heating device and method thereof

InactiveCN102694336AImprove efficiencyDoes not affect delivery routesLaser constructional detailsHeating timeEngineering

The invention discloses a frequency doubling crystal heating device and a method thereof. A frequency doubling crystal is fixed on a heat insulation rack; a temperature sensor is arranged between the heat insulation rack and the frequency doubling crystal; the heating device is provided with a pulsed light generator and a controller; the controller real-timely monitors the temperature of the frequency doubling crystal detected by the temperature sensor and controls the pulsed light generator to produce heating pulsed light; and the heating pulsed light emitted by the pulsed light generator penetrates the frequency doubling crystal. When the temperature of the frequency doubling crystal is higher than the set value, the pulsed light generator stops producing pulsed light; and when the temperature of the frequency doubling crystal is lower than the set value, the pulsed light generator produces pulsed light to heat the frequency doubling crystal, so that operating laser can pass through the frequency doubling crystal in the set temperature. The heating device and method adopt non-contact heating, thereby achieving cleanness, zero contamination and uniform and stable internal and external heating; and the light pulse heating time and temperature are controllable, the light transmission route can not be influenced and the efficiency of the frequency doubling crystal is effectively improved.

Owner:上海奥通激光技术有限公司

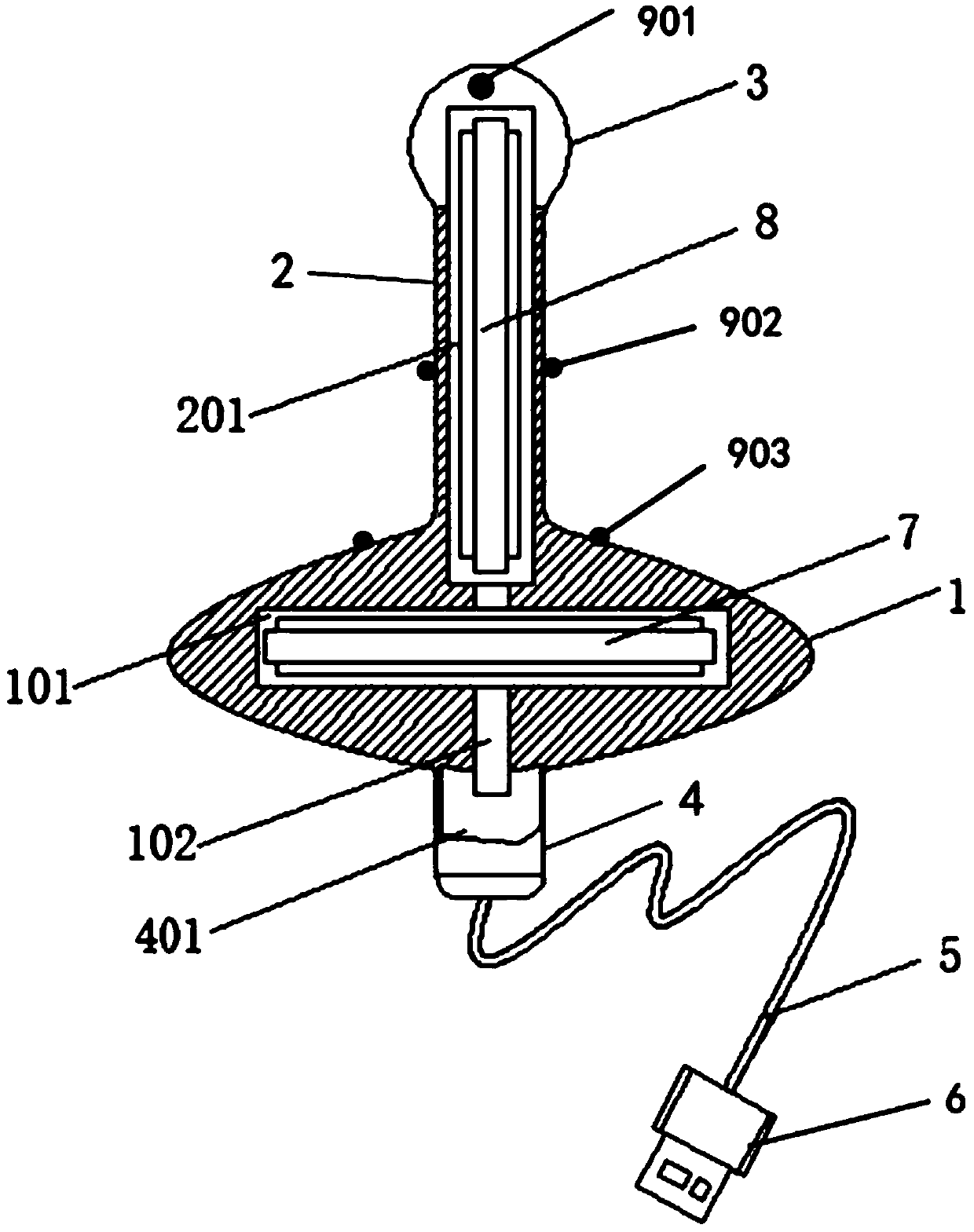

Constant-temperature treatment device for conducting moxibustion on anus and perineum

PendingCN109620710ASimple structureEasy to operateDevices for heating/cooling reflex pointsTherapeutic coolingPerineumAnus

The invention discloses a constant-temperature treatment device for conducting moxibustion on the anus and perineum. The constant-temperature treatment device comprises a cooling base, a cooling pipe,a positioning head, a connecting base, a wire, a plug, a controller and multiple temperature probes. Through the cooling base and the cooling pipe, the perineum part and the anal tube are effectivelyheated, blood circulation of peripheral tissue and organs of the anal tube are promoted to remove blood stases, local blood circulation and lymph smoothing are improved, and the constant-temperaturetreatment device is suitable for auxiliary treatment for multiple anal tube and perineum diseases. The cooling pipe and the positioning head composed of imitative ceramic materials are smooth in surface, free of toxic and side effects and easy to arranged in the anus, and damage to the anal tube is avoided; through the controller and the temperature probes, PTC heating pieces of the constant-temperature treatment device can be matched with a power adapter to control the temperature of the outer surface of the positioning head, the outer surface of the cooling pipe and the surface of the upperportion of the cooling base to be 39-42 DEG C, and the effect of heating physical therapy is ensured.

Owner:侯德胜 +1

Production method of woven carpet with no latex

InactiveCN108396441AGood shape retentionGood dimensional stabilityCarpetsWoven fabricsLow-density polyethyleneViscous flow

The invention discloses a production method of a woven carpet with no latex. A second covering layer is made with hot-melt fiber filaments or staple yarns; a first covering layer is made with high-density polyethylene fiber filaments or staple yarns; the second covering layer accounts for 20-50% of total mass of composite yarn; the first covering layer accounts for 10-15% of the total mass of thecomposite yarn; the balance is core yarns; pile wefts are therefore produced. During the production of a no-gum carpet with hot-melt low-density polyethylene fiber as an adhesive material, pile yarnsare made in conjunction with nylon fiber or wool; the hot-melt low-density polyethylene fiber melts down when heated to above its melting point in a hot pressing step, and fiber macromolecular chain conformation varies; segmer transition allows the whole macromolecular chain to slide, a viscous flow occurs, piles, wefts and warps are effectively fixed after solidifying, pull-out strength of the piles is enhanced, and shape-maintaining property and dimensional stability are enhanced for the carpet; therefore, the gumming step in the carpet production process is omitted, so that the carpet produced is more environmentally friendly.

Owner:QINGDAO UNIV

Preparation method of latex-free woven carpet

InactiveCN108411459ASolve the problem of impermeabilityOmit the adhesive processCarpetsWoven fabricsViscous flowEngineering

The invention discloses a preparation method of a latex-free woven carpet. A second wrapping layer is made of filaments or short fiber yarn formed by hot melt fiber, and a first wrapping layer is madeof polyester fiber filaments or short fiber yarn. Composite yarn comprises, by mass, 20-25% of second wrapping layer, 10-15% of first wrapping layer and the balance pile weft prepared from core yarn.When the latex-free carpet is produced from hot-melt copolyester fiber serving as an adhesive material and pile yarn prepared from nylon fiber or wool, the hot-melt copolyester fiber is melted when heated to be higher than the melting point in the hot pressing procedure, and a fiber macromolecular chain conformation changes; through transition of a chain segment, the whole macromolecular chain slides, viscous flow is generated, cured piles and the weft are effectively solidified, and the weft and warp are effectively solidified, so that the drawing strength of the piles and the shape preservation and size stability of the carpet are enhanced, then the gumming procedure in the carpet preparation process is omitted, and the prepared carpet is more environmentally friendly.

Owner:QINGDAO UNIV

A vacuum microwave drying method for high temperature resistant communication cable insulation process and its drying recovery and reuse treatment device

ActiveCN104332257BImprove performanceEnsure safetyCable/conductor manufactureElectronic waste recyclingRefluxResonant cavity

Owner:JIANGSU TRIGIANT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com