Medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials

A heat treatment system and intermediate frequency technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as affecting the heat treatment quality of long and short materials, uneven heating of long and short materials, and reducing material utilization, so as to avoid cracks and delamination. , The use effect is good, the use effect is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

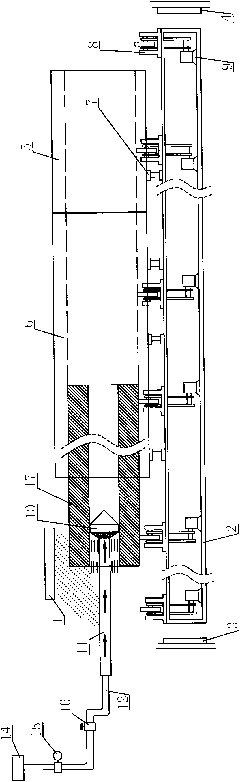

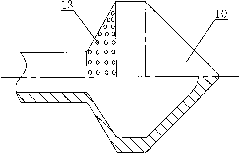

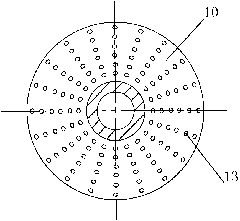

[0039] like figure 1 , 2 An intermediate frequency heat treatment system for long and short materials of petroleum tools as described in and 3, comprising an intermediate frequency heating device and a discharge frame 3 and a feeding frame 4 respectively arranged at the left end and the right end of the intermediate frequency heating device, and the middle part of the intermediate frequency heating device is provided with The spraying device 1, the intermediate frequency heating device includes the main frame 2 and the heating inductor and the uniform heat constant temperature sensor uniformly arranged on the upper right part of the main frame 2, and the uniform heat constant temperature sensor is located on the left side of the heating sensor. The heating inductors and the uniform temperature inductors are all fixed on the main frame 2 through the adjustment rod 7, the number of the heating inductors is 6 and connected to each other to form a heating zone 5, and the number of...

Embodiment 2

[0055] In this embodiment, the intermediate frequency heat treatment system for long and short oil tool materials according to the present invention is the same as that in Embodiment 1.

[0056] In this embodiment, the heat treatment process using the intermediate frequency heat treatment system for long and short materials of petroleum tools is different from the first embodiment: the heating temperature in 201 is 685°C, and the direct current during heating is 1200A. The DC voltage is 450V, the intermediate frequency voltage is 600V, the intermediate frequency power is 500KW, the intermediate frequency frequency is 240Hz, the walking frequency is 9.5Hz, and the walking speed is 240mm / min; The current is 550A, the DC voltage is 500V, the intermediate frequency voltage is 720V, the intermediate frequency power is 300KW, the intermediate frequency frequency is 320Hz, the walking frequency is 9.5Hz, and the walking speed is 240mm / min; after the water cooling and air cooling menti...

Embodiment 3

[0058] In this embodiment, the intermediate frequency heat treatment system for long and short oil tool materials according to the present invention is the same as that in Embodiment 1.

[0059] In this embodiment, the heat treatment process using the intermediate frequency heat treatment system for long and short materials of petroleum tools is different from the first embodiment: the heating temperature in 201 is 675°C, and the direct current during heating is 1150A. The DC voltage is 400V, the intermediate frequency voltage is 550V, the intermediate frequency power is 450KW, the intermediate frequency frequency is 190Hz, the walking frequency is 9Hz, and the walking speed is 230mm / min. 450A, DC voltage 400V, IF voltage 670V, IF power 200KW, IF frequency 270Hz, walking frequency 9Hz, walking speed 230mm / min; water-cooling and air-cooling as mentioned in 203, residence time 3.5min and then quenching At the end, the air cooling pressure is 0.6MPa. The heating temperature ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com