Patents

Literature

65results about How to "Even insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

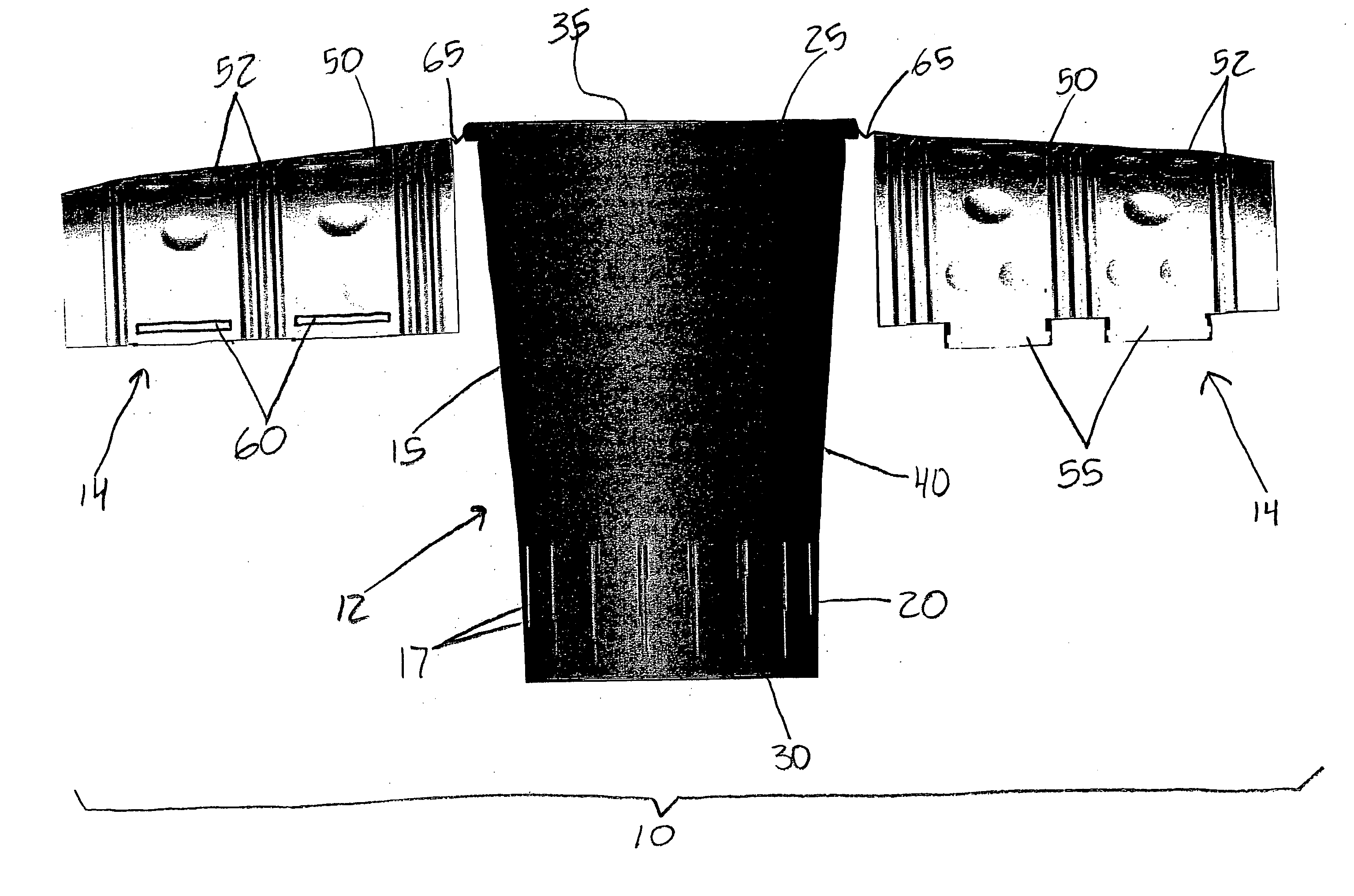

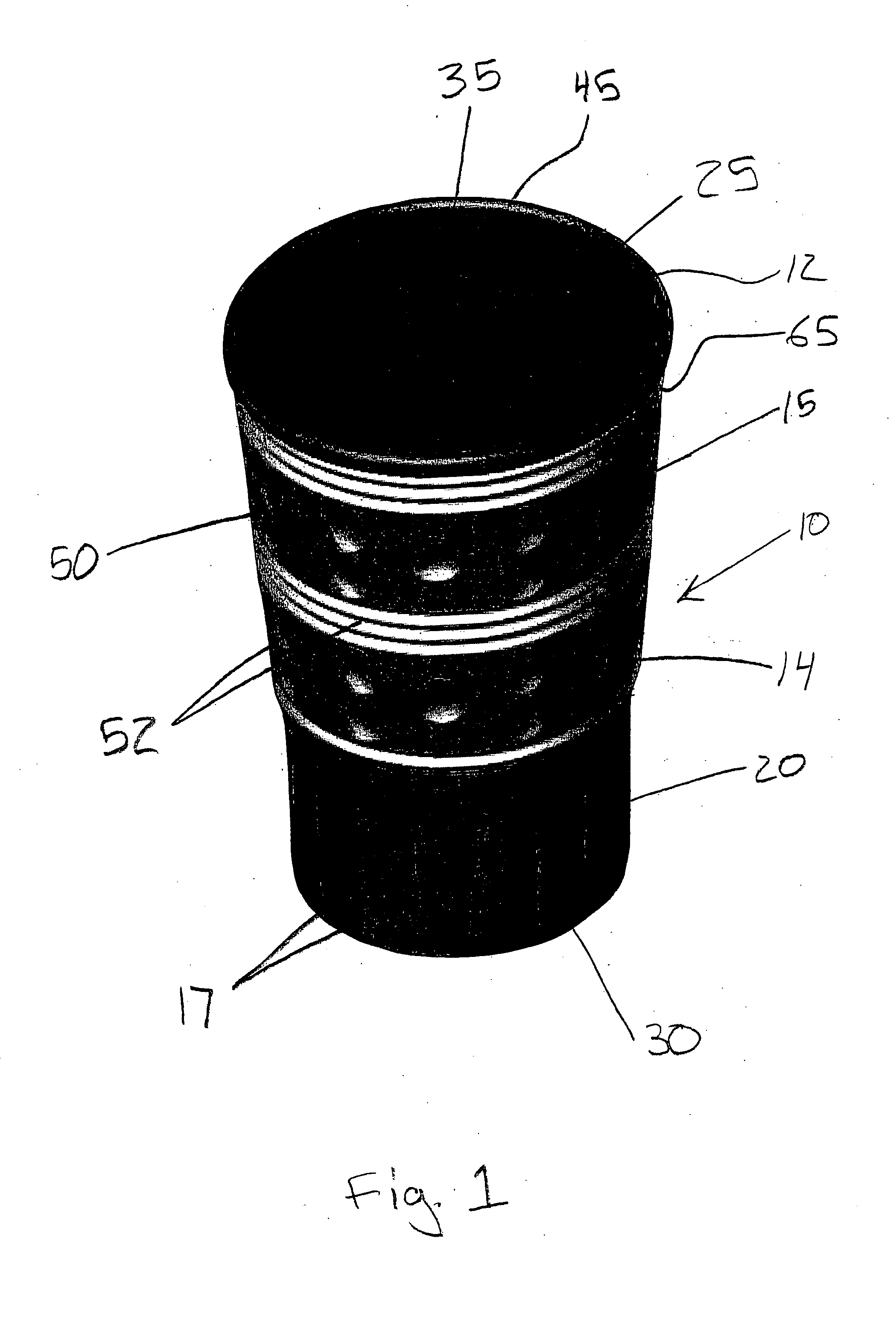

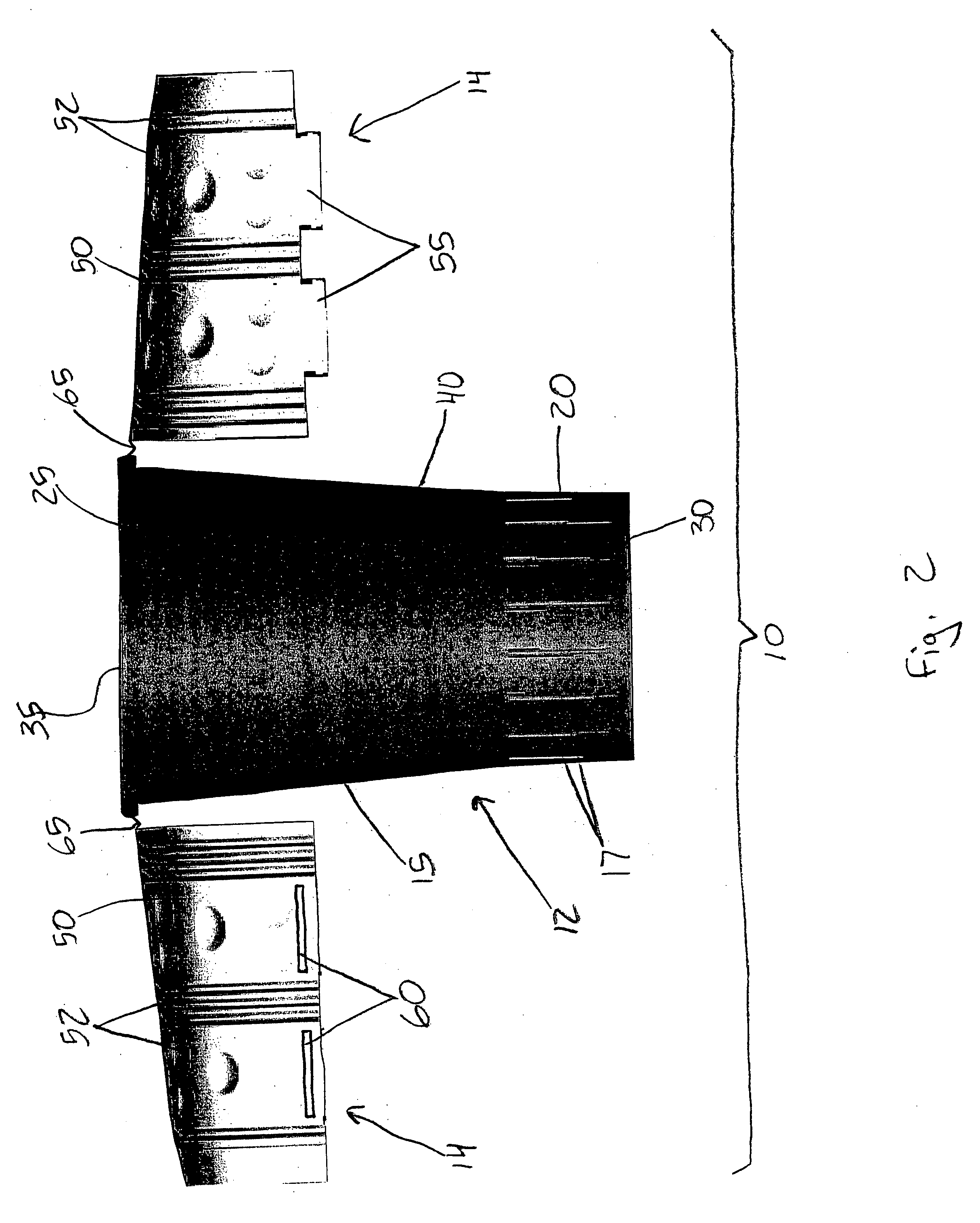

Unitary double walled container and method for making

InactiveUS20050040218A1SturdyEven insulationDomestic cooling apparatusLighting and heating apparatusDouble walledBuilding construction

A single-piece seamless construction container formed from a thermoformable material, the container including a vessel, at least one wing, and at least one hinge coupling the wing to the vessel. The wings comprise a patterned surface, although only the vessel, or the wings and the vessel may also be configured to include a patterned surface. The wings are configured to wrap about the container with the patterned surface serving to trap air between an outer surface of the vessel and an inner surface of the wing. The trapped air and the wing forms an insulative air gap between a surface of the container and the wing. The container may be nestably stacked in a wing open or wing closed position.

Owner:HINCHEY TIMOTHY J +1

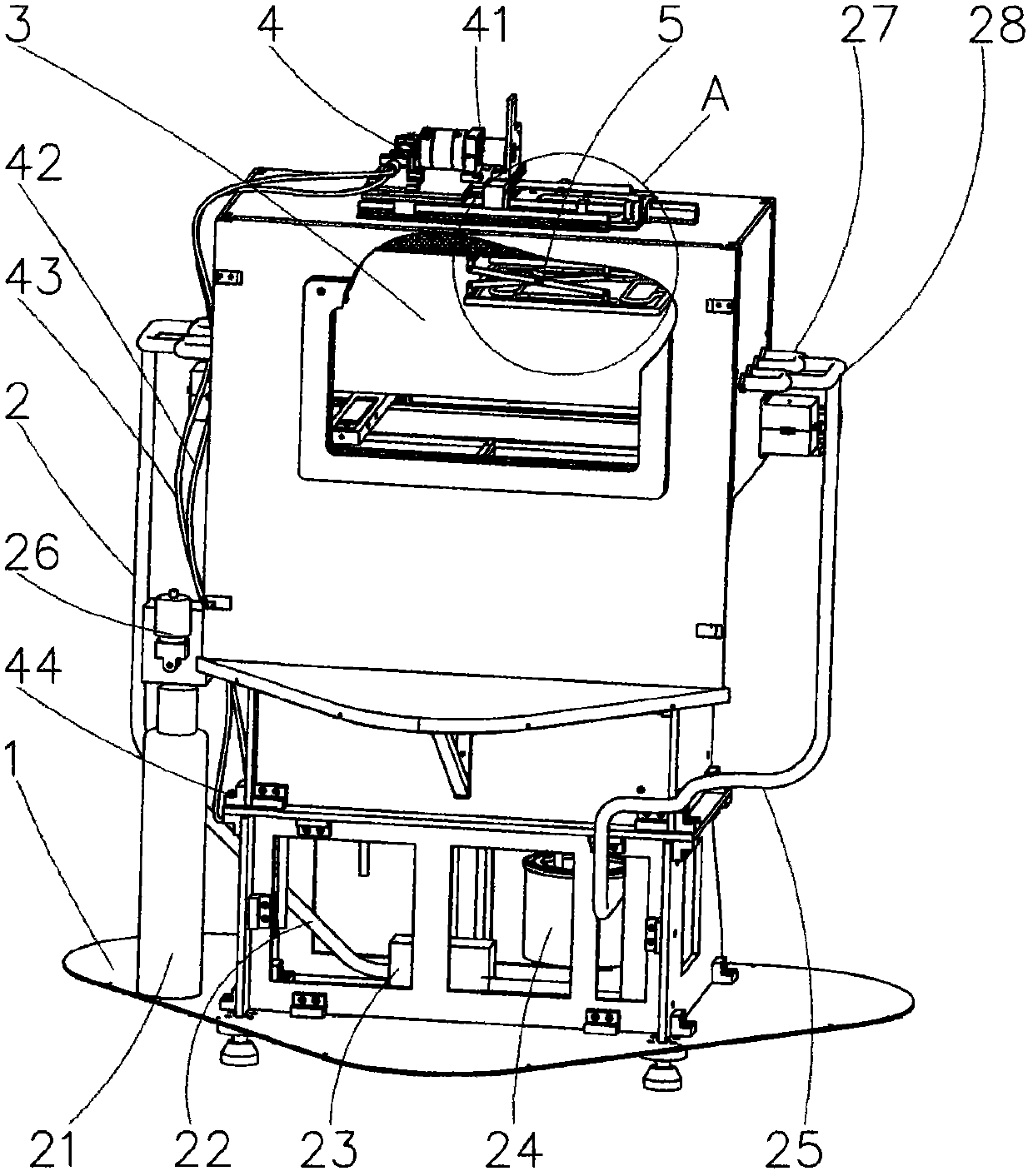

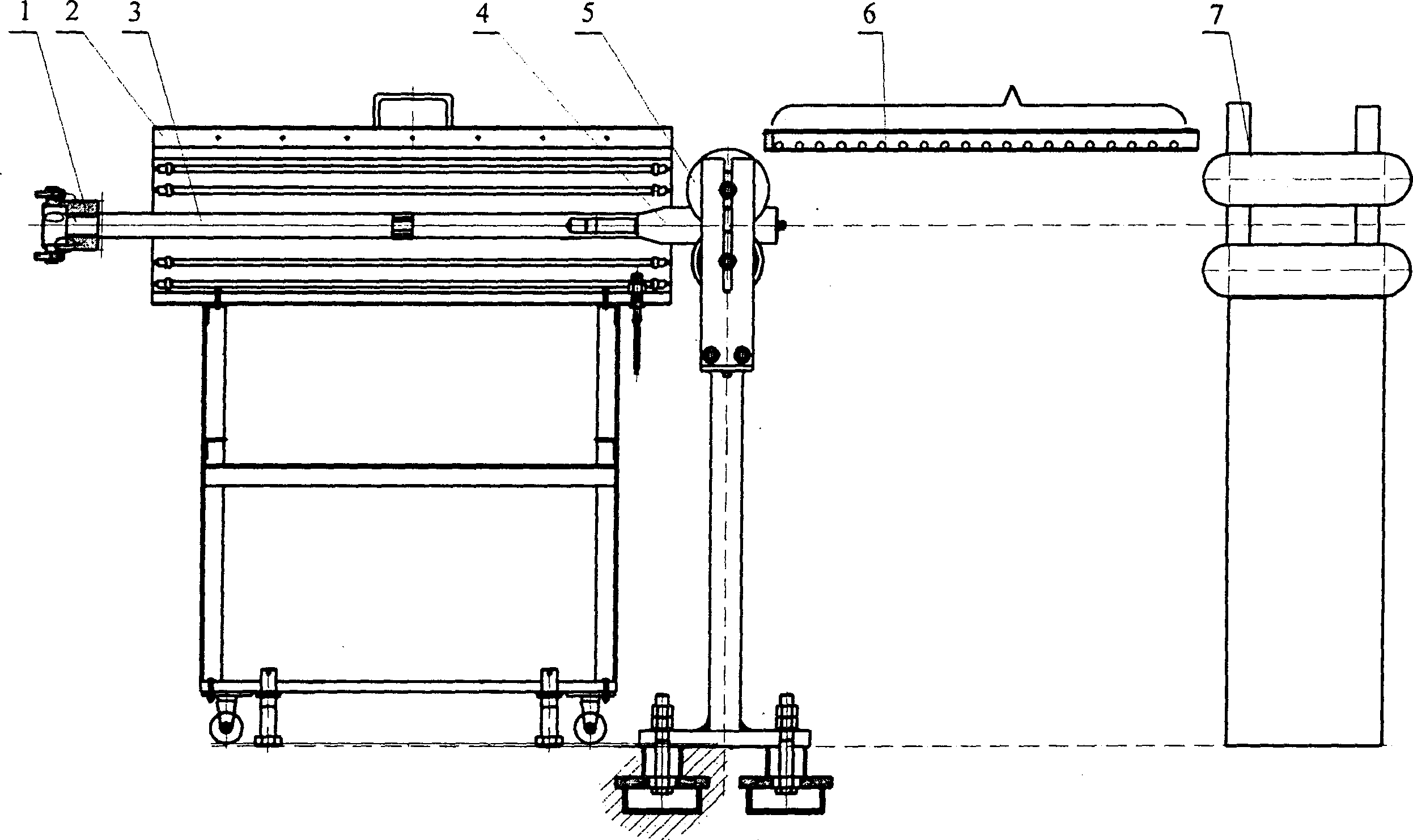

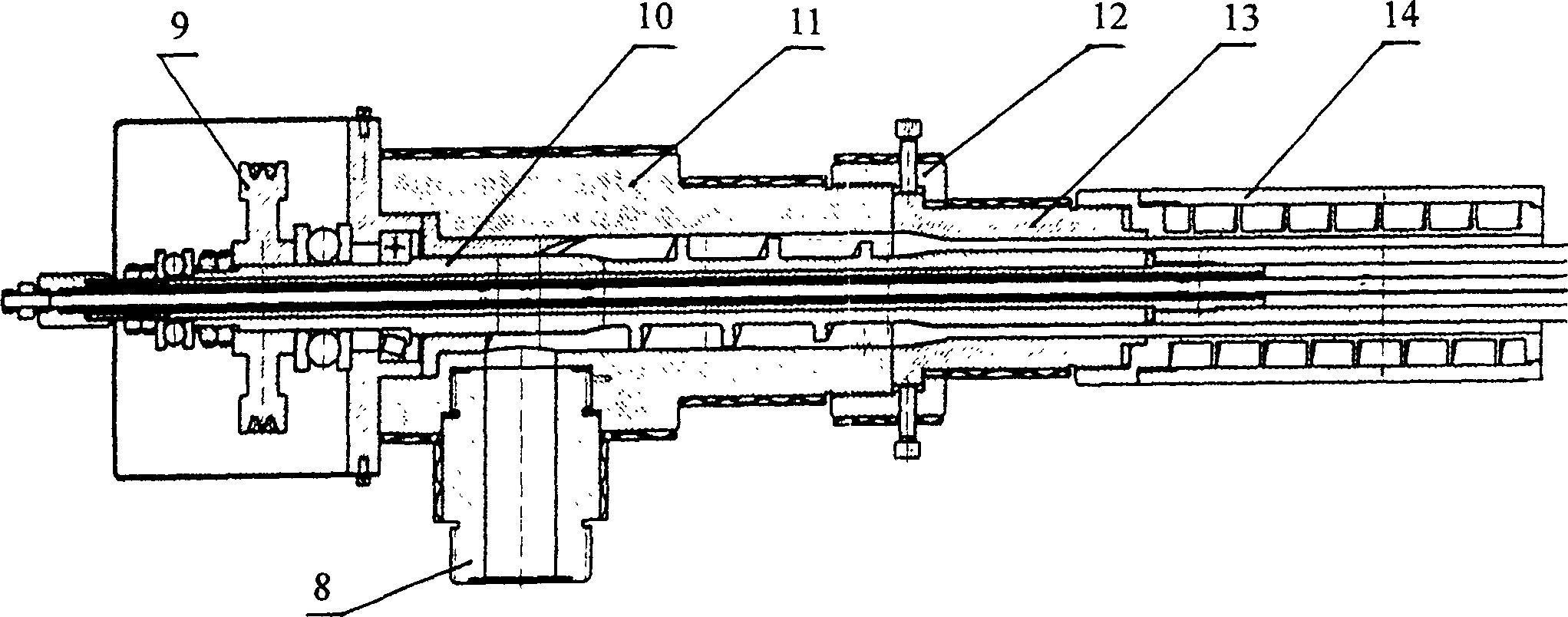

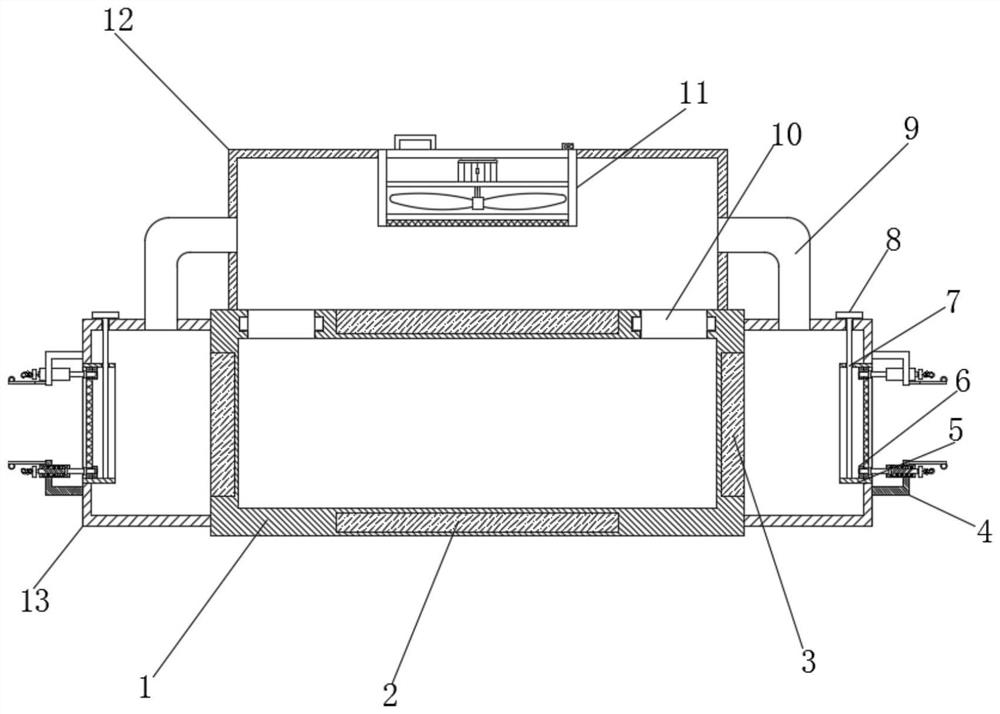

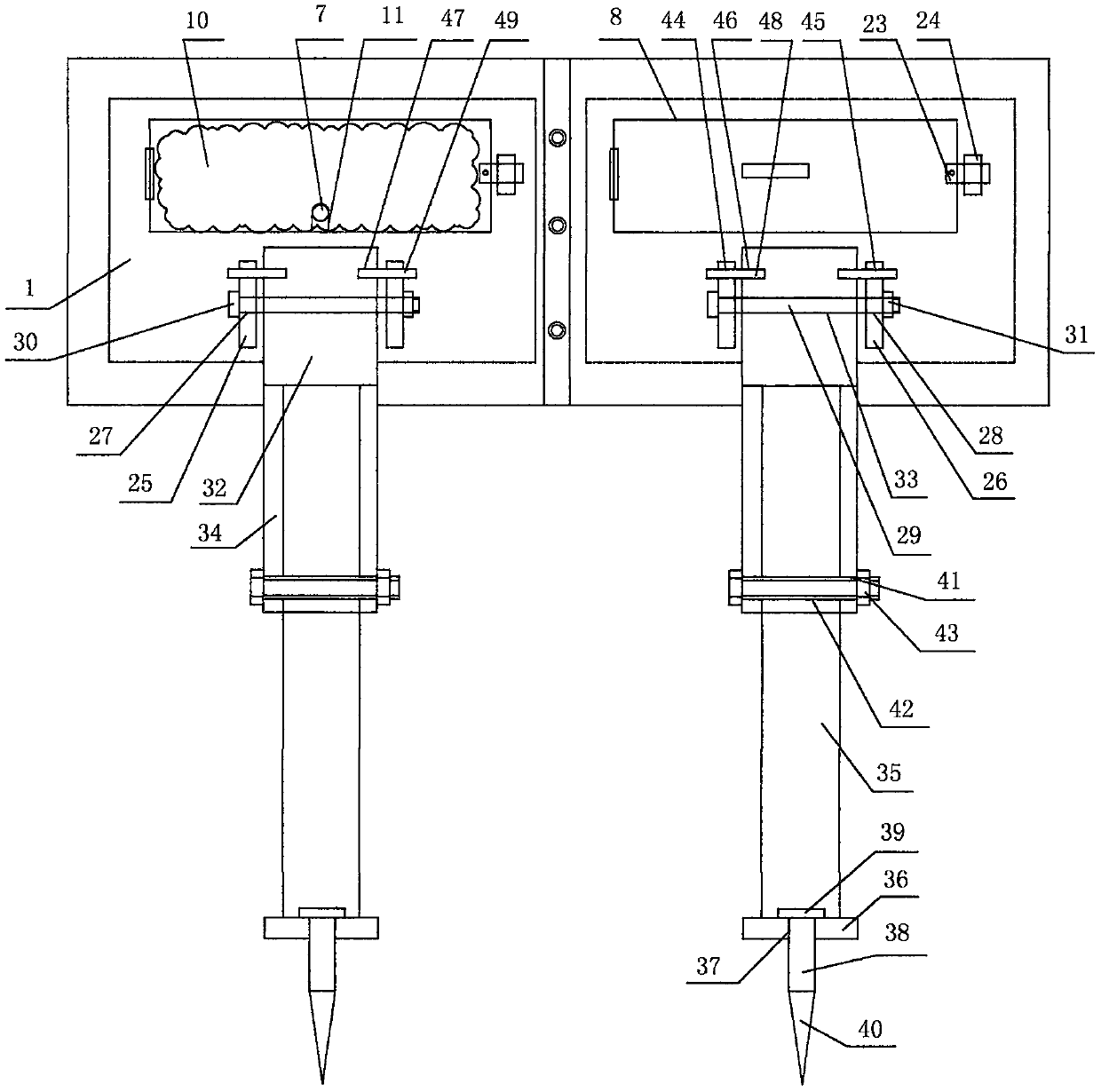

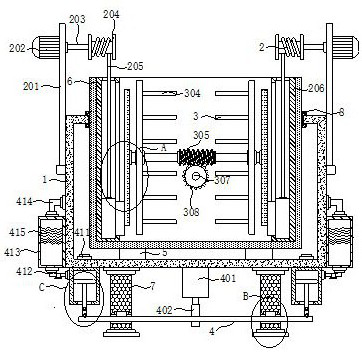

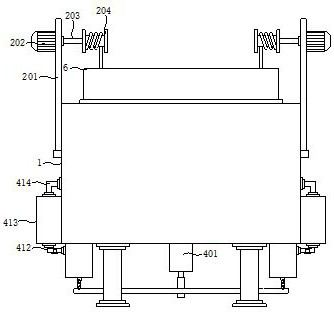

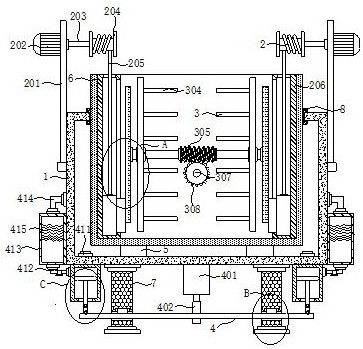

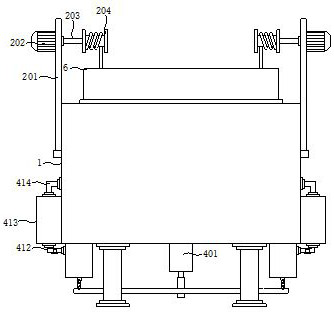

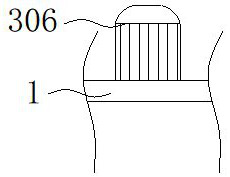

Manufacturing equipment of laser additive

ActiveCN103737933AReduce in quantityReduce lossesIncreasing energy efficiencyEngineeringProtection system

The invention provides manufacturing equipment of a laser additive. The manufacturing equipment comprises a frame, a work cavity, a laser system, an atmosphere protection system and a preheating system, wherein the work cavity is a sealed cavity defined by a heat insulation sandwich panel; a scanning galvanometer of a laser system is arranged at the top of the external part of the work cavity; the preheating system is a three-dimensional flexible heating system, and has a plurality of radiation heating layers with adjustable interlayer spaces arranged at the top inside the work cavity; an air feed pipe and an air return pipe of the atmosphere protection system are divided into a plurality of passages to be respectively connected with two sides of the work cavity through U-shaped tee joints, so that the circulation of inactive gas inside the work cavity is achieved. By adopting the manufacturing equipment of the laser additive, the space can be effectively saved, the heat loss is reduced, the heating efficiency is improved, the energy consumption is reduced, the temperature inside the work cavity is relatively even in distribution, the protective effect on the processing process caused by an internal atmosphere is obvious, different types of materials (metal, macromolecule and the like) can be molded, the processing deformation is reduced, and the excellent quality of molded spare parts is ensured.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

Method for making double-axial hard polyvinyl chloride tubular material

The production method of biaxial oriented hard polyvinyl chloride pipe material includes: using 100 portions of polyvinyl chloride, 2-6 portions of stabilizing agent, 1-12 portions of toughening agent, 0.1-1.5 portions of lubricating agent, 5-15 portions of filling material and proper quantity of colouring matter and adding them into a high-speed mixing machine, mixing them at 100-120 deg.C for 20-40 min., discharging, sieving, removing block and viscous melt material to obtain hard polyvinyl chloride premixed powder material, adding said mixture material into extrude single screw or extruder twin screw to make continuous forming at 100-180 deg.C, then making the obtained material undergo the processes of extruding pipe blank, stretching orientation, heating to 100-120 deg.C to implement radial expansion, forming, cooling, drawing and cutting.

Owner:SICHUAN UNIV +1

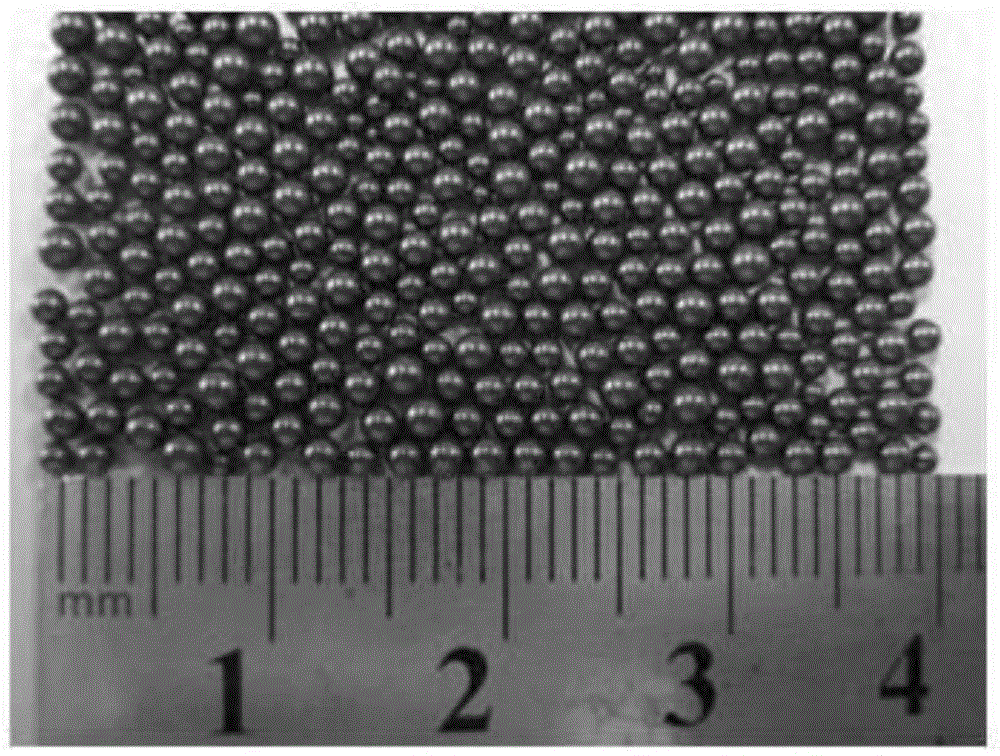

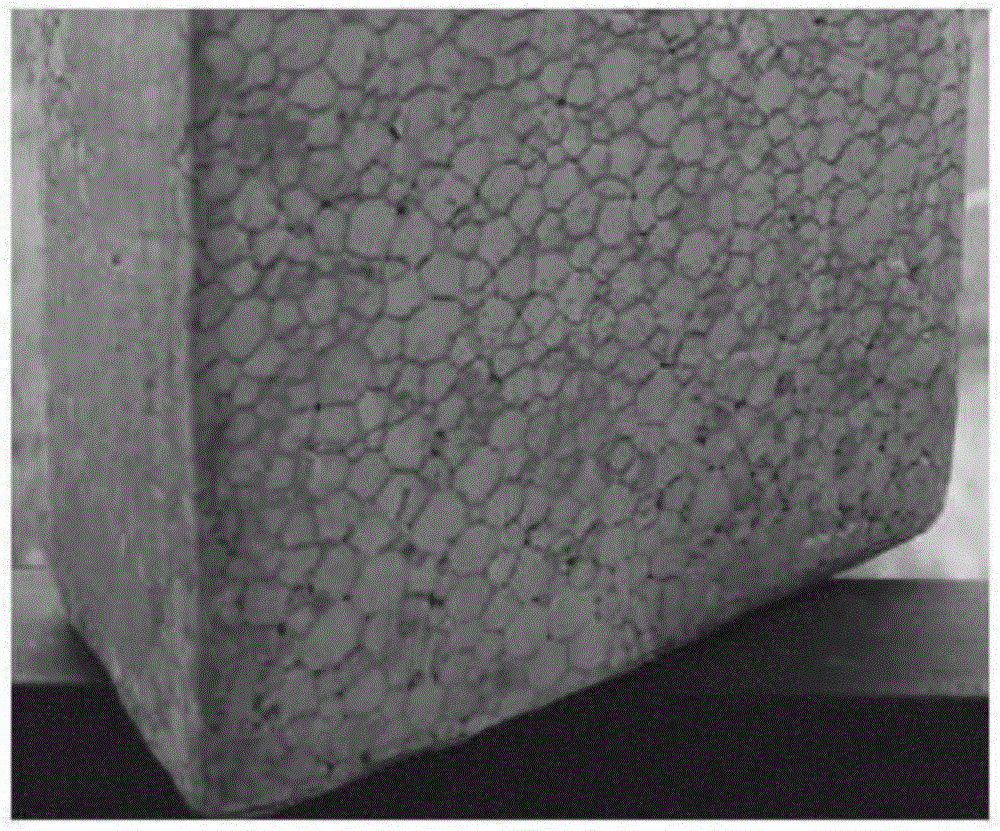

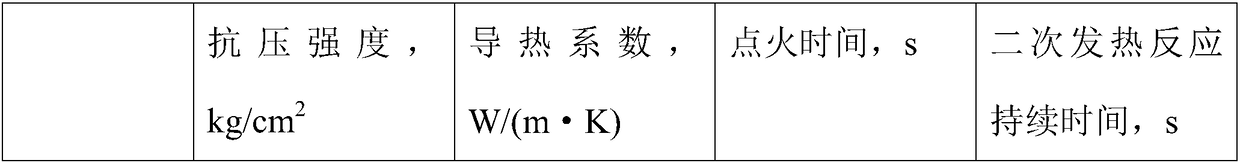

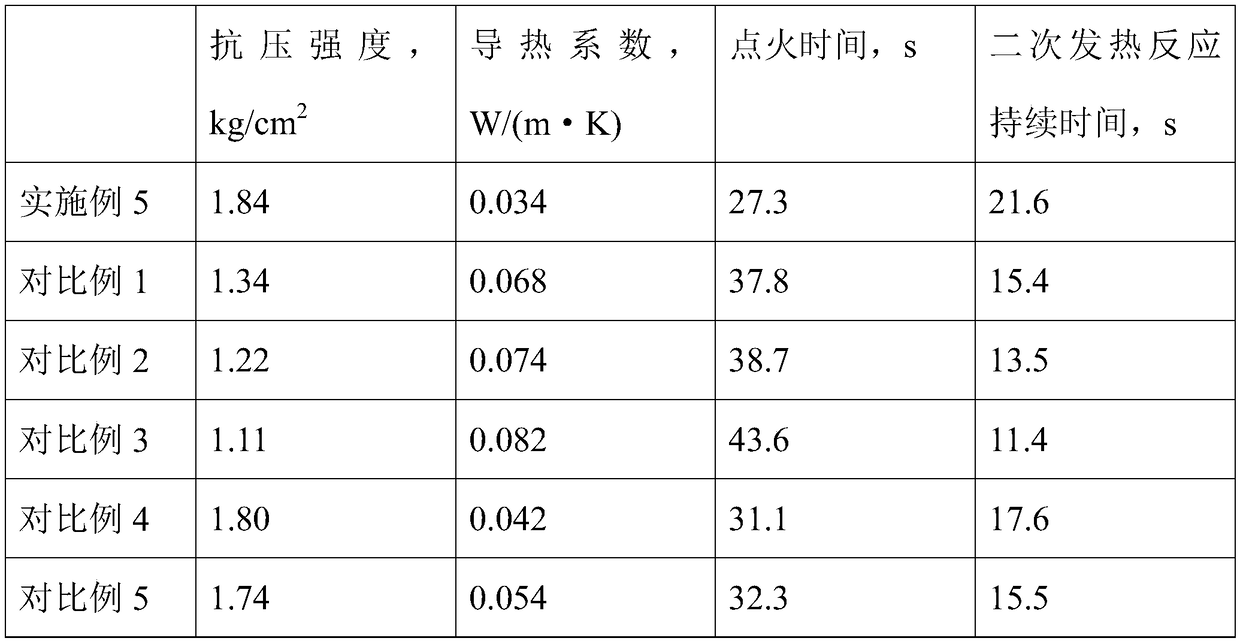

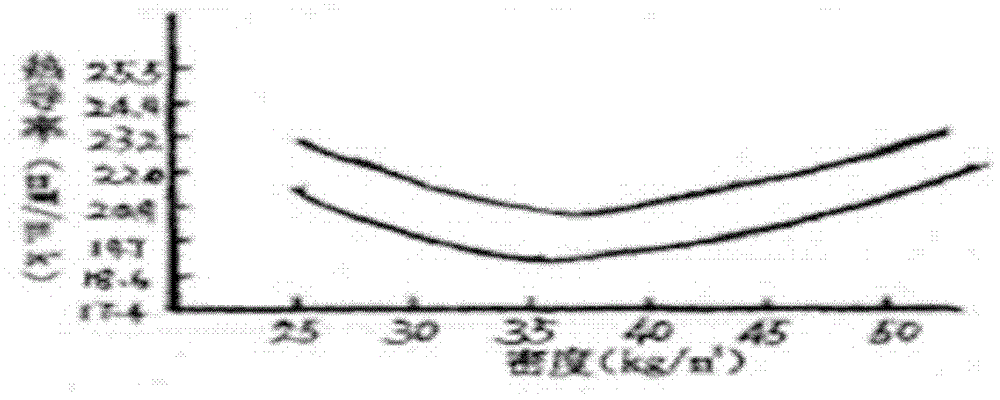

Water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on basis of waste polystyrene materials and products of water-phase suspension granulation method

ActiveCN105566670AExcellent reflective infrared characteristicsRealize resource utilizationPolystyrene beadOil phase

The invention belongs to the field of high-value recycling of waste polystyrene foam materials, and particularly relates to a water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on the basis of waste polystyrene materials and products of the water-phase suspension granulation method. The water-phase suspension granulation method includes forming oil phases by inorganic-organic gradient cooperative flame-retardant heat-insulation systems, organic solvents and the waste polystyrene materials; forming water-phase dispersion media by surfactants, inorganic-organic synergistic suspension agents and deionized water; stably suspending and dispersing oil-phase liquid drop in the water-phase media under the actions of mechanical stirring by means of water-phase suspension granulation; heating and steaming out the organic solvents to cure gradient flame-retardant polystyrene beads; acquiring gradient flame-retardant polystyrene heat-insulation plates by means of pentane filling and foaming molding. The waster-phase suspension granulation method and the products have the advantages that waste polystyrene is used as a raw material, is recycled by the aid of physical processes and is used for preparing the gradient flame-retardant foamable polystyrene beads, accordingly, waste can be utilized, and the gradient flame-retardant performance and heat-insulation effects of the gradient flame-retardant foamable polystyrene beads can be improved; the organic solvents can be recycled, accordingly, the water-phase suspension granulation method and the products are environmental friendly, and industrial production can be facilitated.

Owner:WUHAN POLYTECHNIC UNIVERSITY

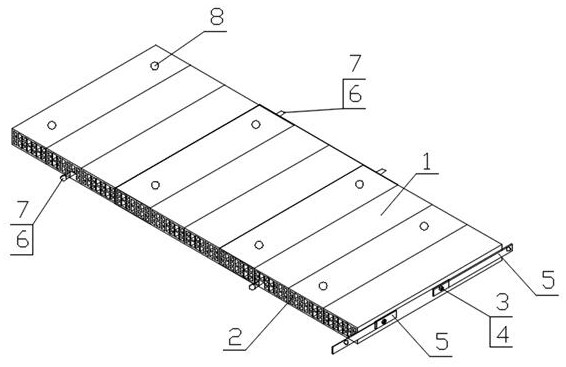

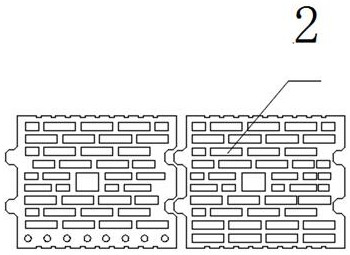

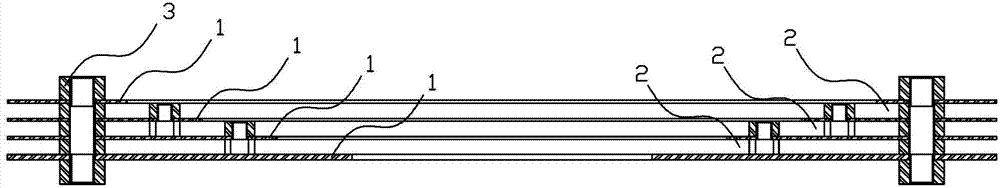

Manufacturing method of shale sintered composite plate for prefabricated building

InactiveCN111663710AImprove construction efficiencyShorten the construction periodWallsHeat proofingBrickThermal insulation

The invention discloses a manufacturing method of a shale sintered composite plate for a prefabricated building. A plurality of thermal insulation holes are formed in a hollow brick body. One or morepenetrating reinforcing steel bar holes for reinforcing steel bars to penetrate through are formed in the direction perpendicular to the direction of the thermal insulation holes. A viscose for connection is sprayed or painted quantitatively between ends of every two adjacent hollow brick bodies, and a reinforcing steel bar penetrates into each overall reinforcing steel bar hole; the viscose fulfills gaps between every two adjacent hollow brick bodies under extrusion; and the ends of the hollow brick bodies are provided with connecting blocks correspondingly, each connecting block is at leastprovided with two connecting holes, one connecting hole is connected with one end of the corresponding reinforcing steel bar, other holes serve as bolt connecting holes for fixing bolts, and the sintered composite plate is formed. Platy wall board structures of various areas are prefabricated in a factory and then transported to a construction site to be overall installed on site, so that construction efficiency is greatly improved, operators for on-site bricklaying construction are greatly reduced, a construction period is shortened, and construction cost is reduced.

Owner:重庆金彧新型环保建材有限公司

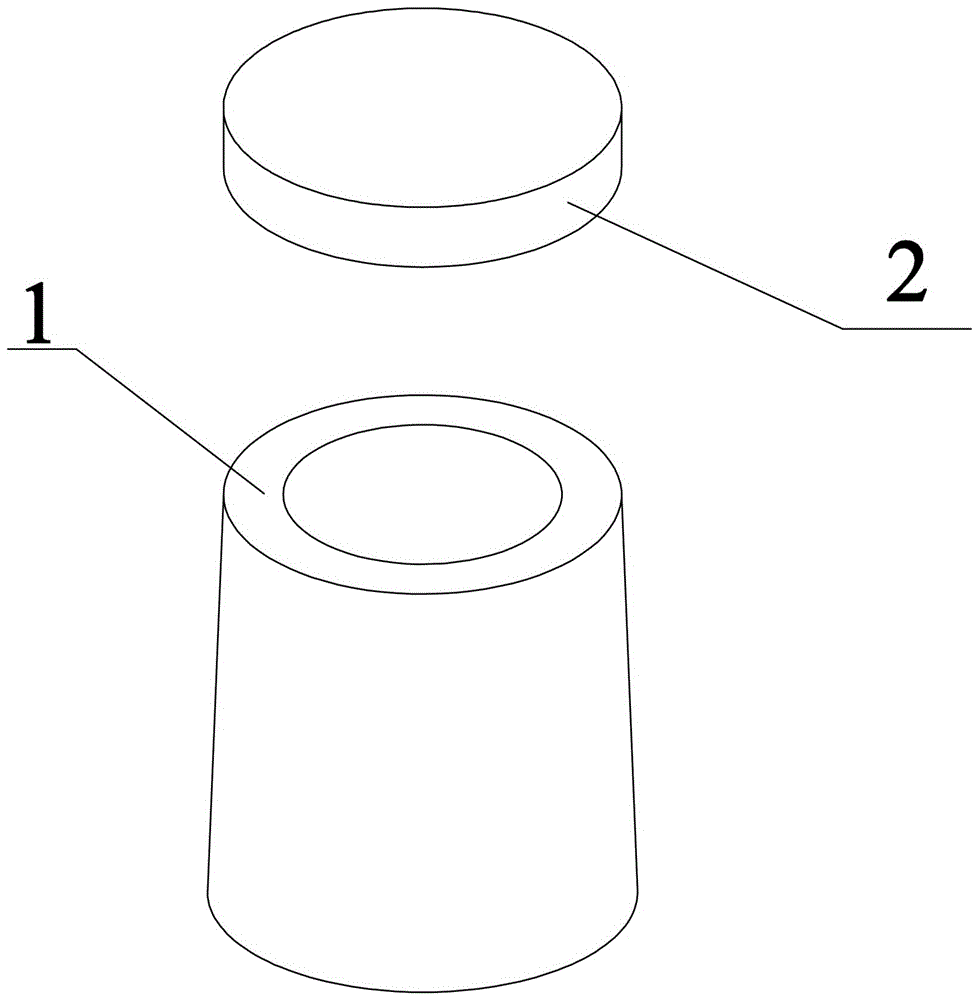

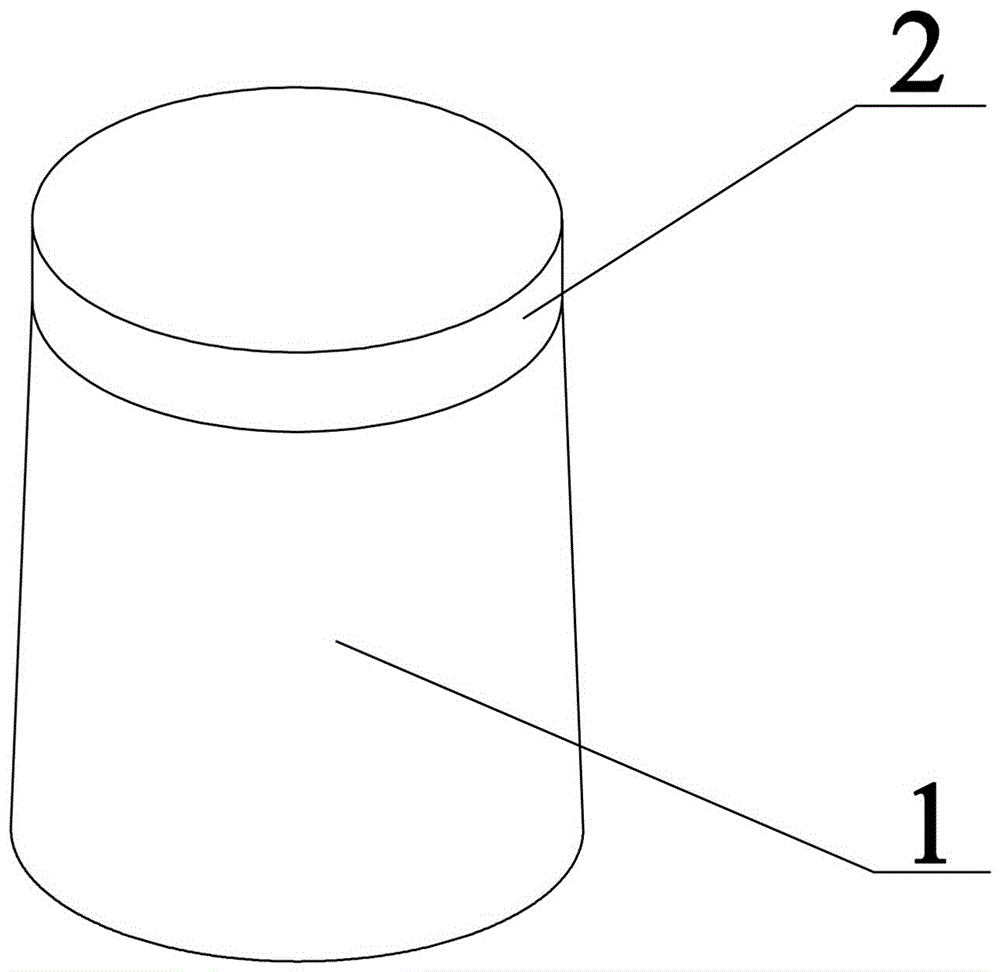

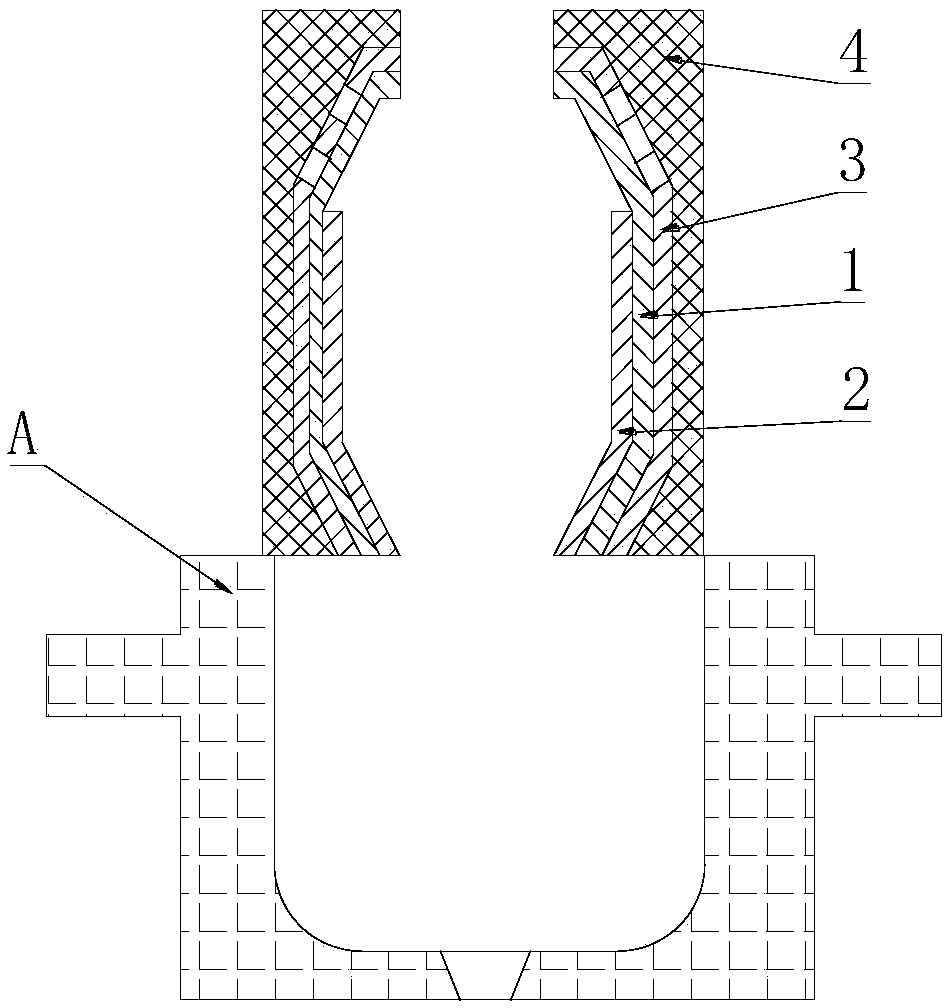

Cast steel exothermic riser sleeve

The invention relates to a casting riser sleeve, in particular to a cast steel exothermic riser sleeve. The two ends of the exothermic riser sleeve are opened. A top cover is arranged at the top end of the exothermic riser sleeve. The top cover is made of precoated sand. The exothermic riser sleeve is adopted for replacing a sand mold overflow riser in the prior art, the setting time is prolonged, heat supply is uniform, and the interior of an exothermic riser is free of defects, deformation and expansion; and the surface of a casting is bright and clean, the appearance is tidy, the technology yield is increased by 4.6%, and the production cost is reduced.

Owner:西峡飞龙特种铸造有限公司

Heating and heat insulating feeder sleeve

PendingCN108465778AReduce volume sizeIncrease temperatureFoundry mouldsFoundry coresCarbon fibersPhosphoric acid

The invention discloses a heating and heat insulating feeder sleeve. The heating and heat insulating feeder sleeve is used for feeding in a casting mold. The heating and heat insulating feeder sleevecomprises a matrix, a heating layer, a heat insulating layer and a protecting layer. A feeding cavity is formed in the matrix and communicated with the interior of the casting mold, the heating layeris arranged on the inner wall of the feeding cavity, the matrix is coated with the heat insulating layer, and the heat insulating layer is coated with the protecting layer. The heat insulating layer is prepared from a polystyrene composite. The polystyrene composite is prepared from, by weight, 50-80 parts of expandable polystyrene, 40-60 parts of polyurethane plastic, 40-50 parts of nitrile silicone rubber, 1-2 parts of physical foaming agent, 1.5-2.5 parts of sodium lignosulphonate, 2-4 parts of disproportionated rosin, 10-20 parts of heat insulating vermiculite, 2-4 parts of polyacrylonitrile-based carbon fibers, 10-18 parts of diatomite, 2-4 parts of insulating glass beads, 8-16 parts of sepiolite powder, 1.5-2.5 parts of p-methylsulfonic acid, 2-4 parts of phosphoric acid and 40-60 parts of water.

Owner:霍山县东胜铸造材料有限公司

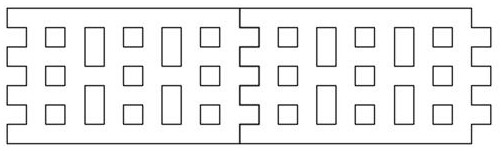

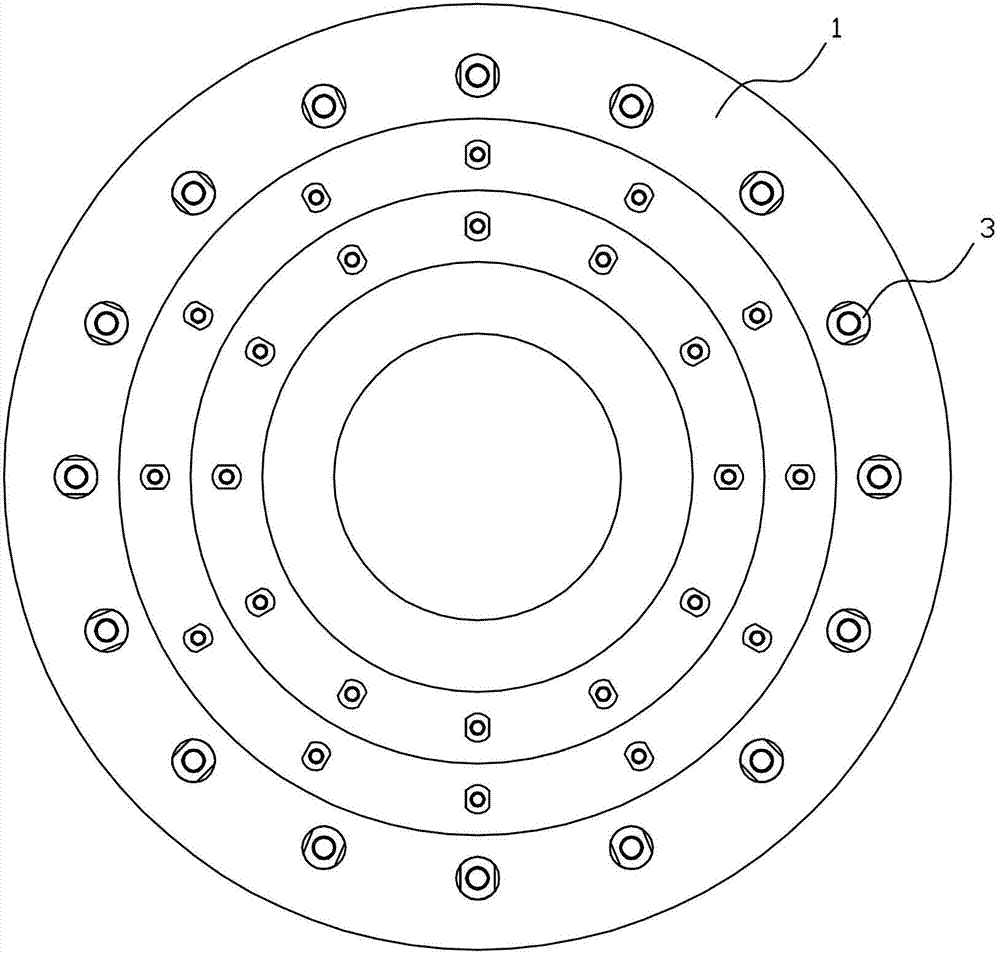

Cold crucible cover for top seed crystal temperature gradient method

InactiveCN103484931AEven insulationHigh melting pointPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

The invention relates to the field of sapphire crystal growth, and particularly relates to a cold crucible cover for a top seed crystal temperature gradient method. The cold crucible cover comprises at least two ring tungsten plates, wherein the ring tungsten plates are same in outer diameter and different in inner diameter, and the ring tungsten plates are sequentially arranged from top to bottom and from small to large based on inner diameters; a gap is reserved between the ring tungsten plates; the temperature gradient of stable crystal growth is acquired when seed crystals inside a crucible are heated by utilizing the top seed crystal temperature gradient method. The cold crucible cover disclosed by the invention has the advantages of good balance, good stability, flexibility in structural design and good consistency.

Owner:FUJIAN XINJING PRECISION CORUNDUM TECH CO LTD

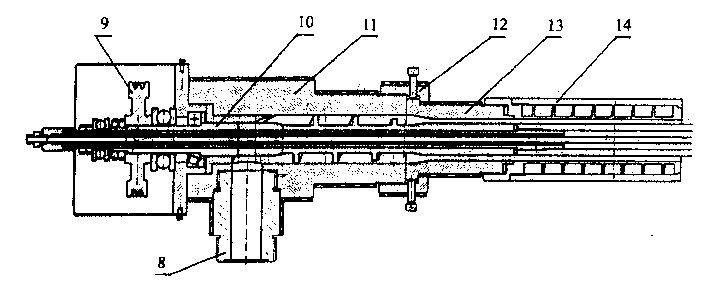

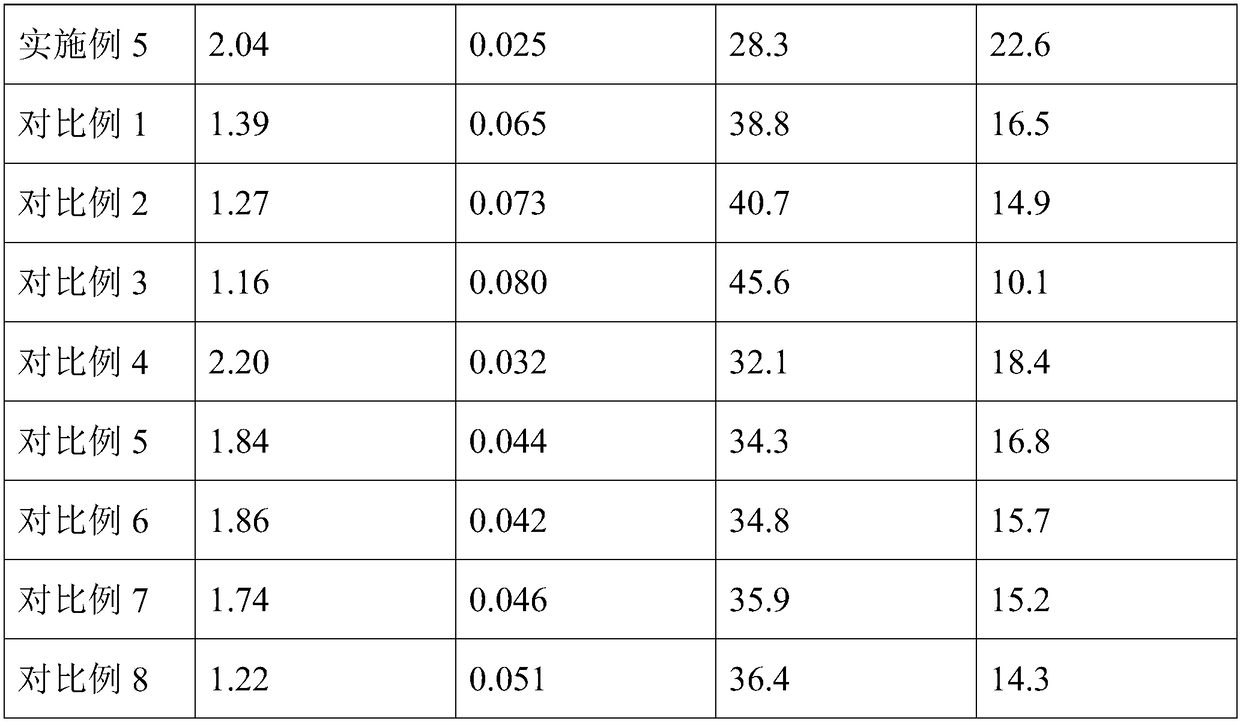

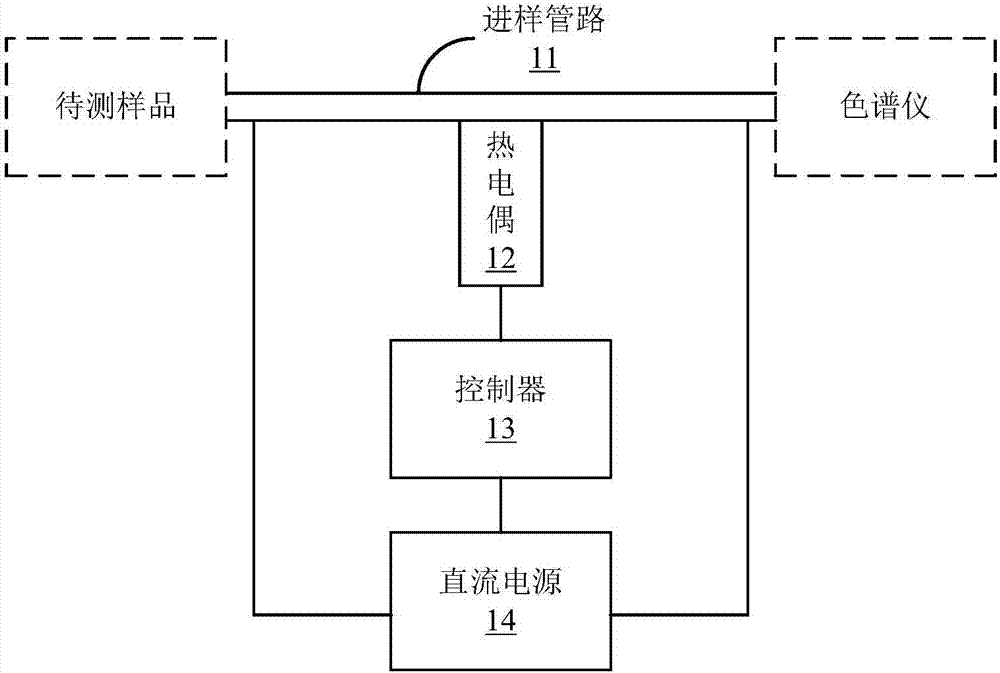

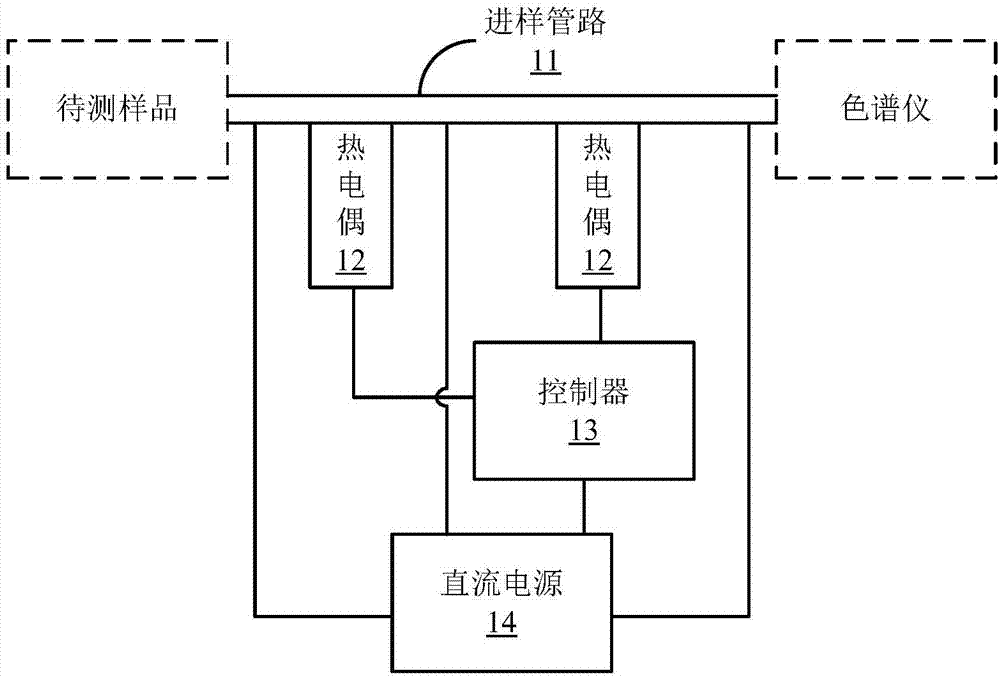

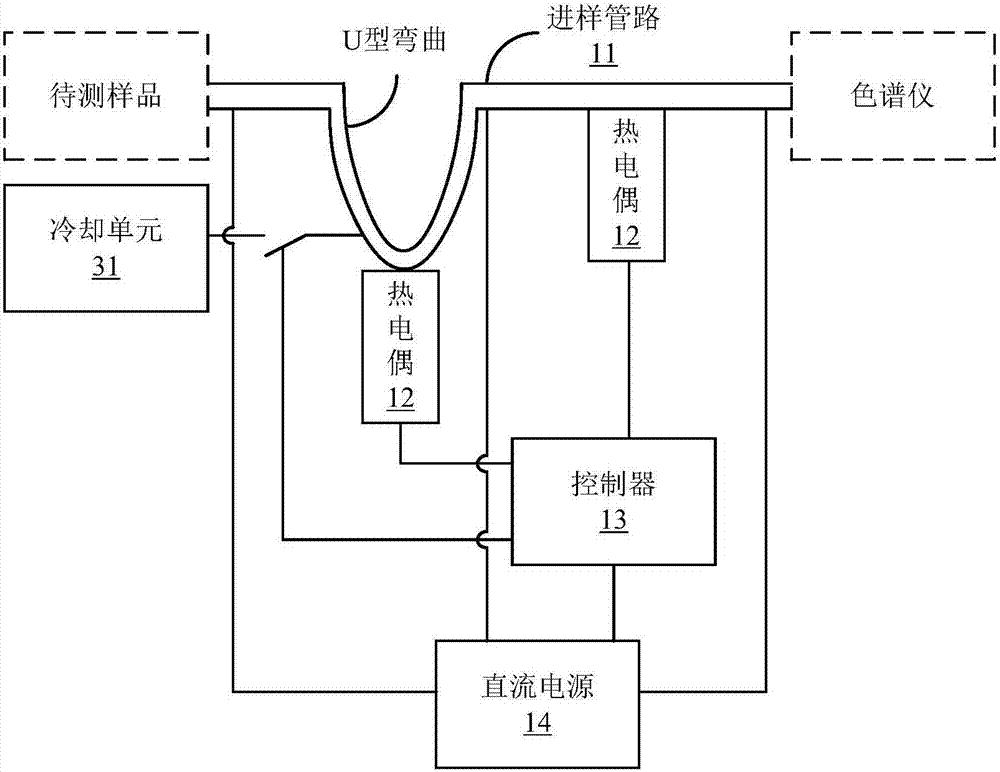

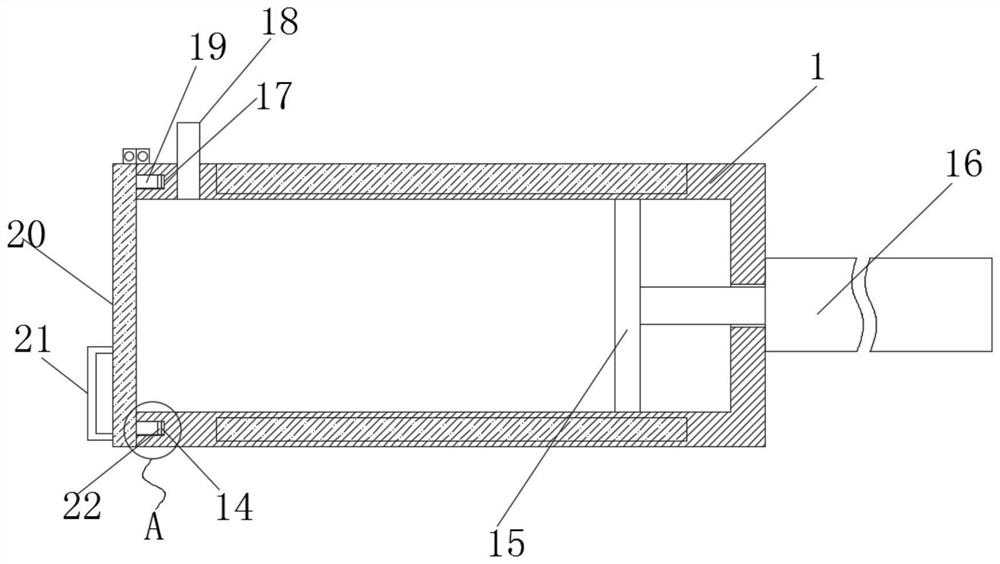

Sample injection device of chromatographic online analysis system and method of using same to process sample

The invention discloses a sampling device of a chromatographic on-line analysis system and a method for processing samples by using the same. The device includes a sampling pipeline, a tubular passage connecting the sample to be tested and a chromatograph, and the device is used during the process of transporting the sample to be tested. It is directly heated and / or cooled to realize the processing of the sample to be tested; the thermocouple is connected with the sampling pipeline and the controller, and is used to measure the temperature of the sampling pipeline; the controller, according to the substance of the sample to be tested The transmission requirement and the measured temperature value of the sample injection pipeline control the temperature adjustment of the sample injection pipeline. The device ensures the enrichment and rapid release of substances with different molecular weights, and at the same time, the heat preservation of the pipeline is uniform, which avoids the residue of the substance to be tested before entering the chromatograph, and improves the detection accuracy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermal-insulation adhesive for die-forging of forge pieces and preparation method thereof

The invention discloses a thermal-insulation adhesive for die-forging of forge pieces, which is used for forming die forging pieces and especially suitable for thermal-insulation forming of high-temperature alloy, titanium alloy and aluminum alloy die-forging pieces. The adhesive for thermal-insulation materials can form a continuous, uniform and compact film for thermal insulation and lubrication on the surface of a forge piece. The adhesive disclosed by the invention is prepared from the following components in percentage by weight: 20-40% of organosilicon heat-resistant resin or organic titanium epoxy resin, 20-40% of glass powder, 0-5% of trisodium phosphate, 2-6% of anhydrous borax, 0-5% of graphite, 1-3% of leafing aluminum paste, 1-5% of magnesium aluminum silicate suspending agent and 10-40% of xylene. The invention can accurately control the forging temperature, reduce the number of times of blank returning, prolong the forgeable time each time, lower the cost of the used coating materials, widen the optional range of the thermal-insulation coating materials, and the like. Meanwhile, the invention also provides a preparation method of the thermal-insulation adhesive.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +1

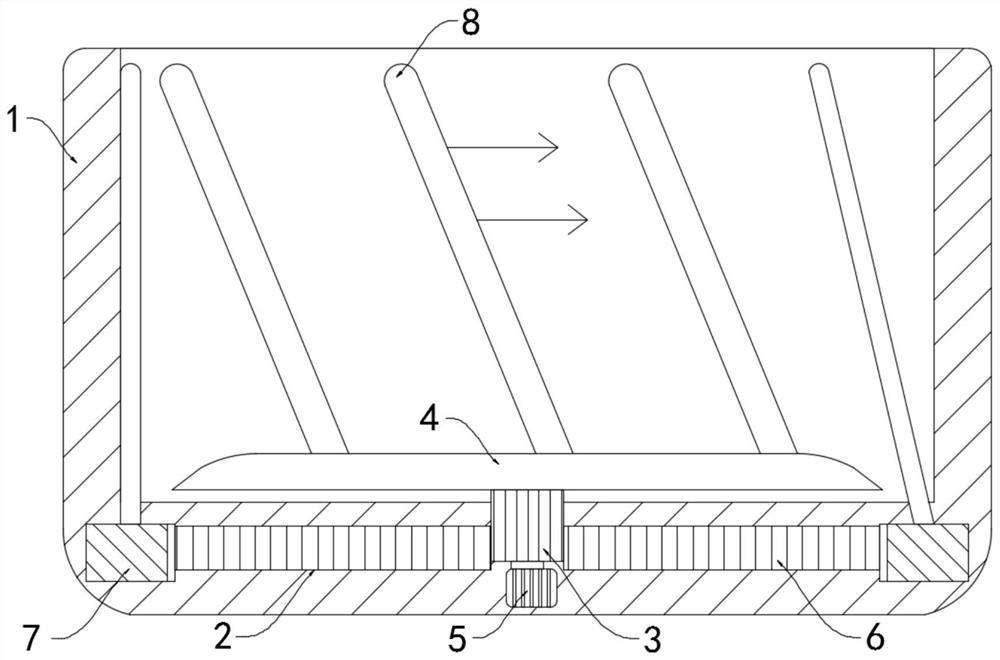

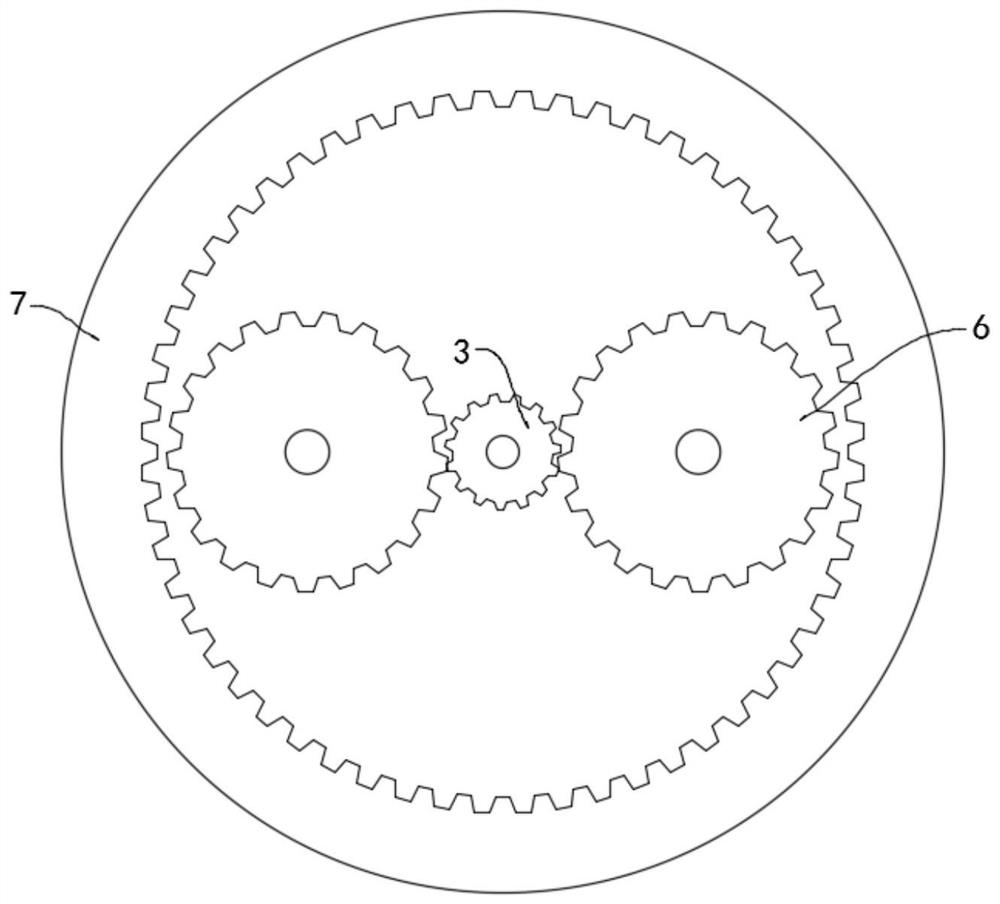

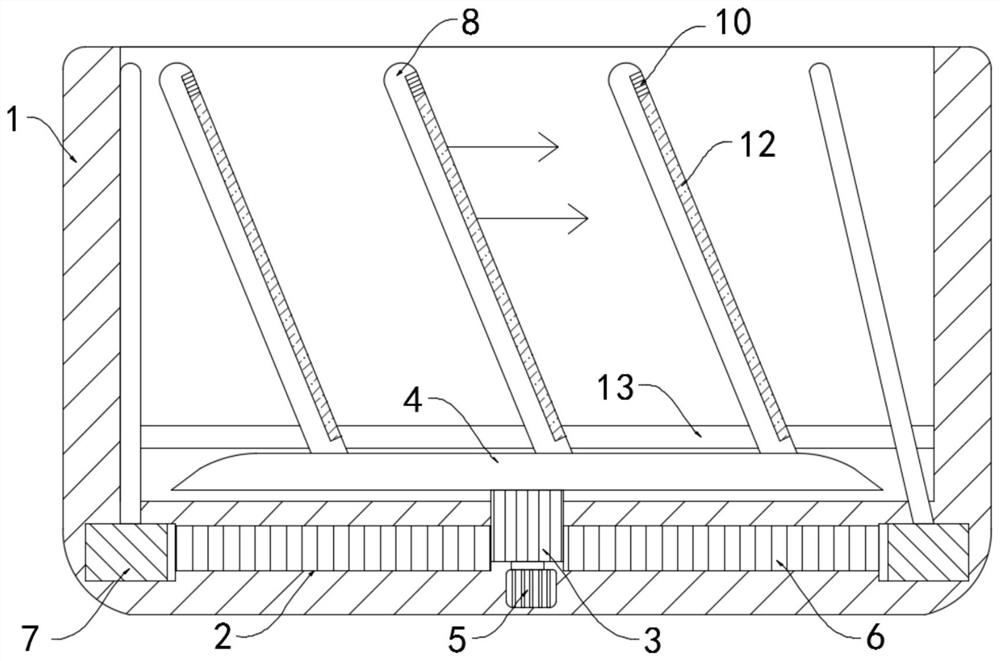

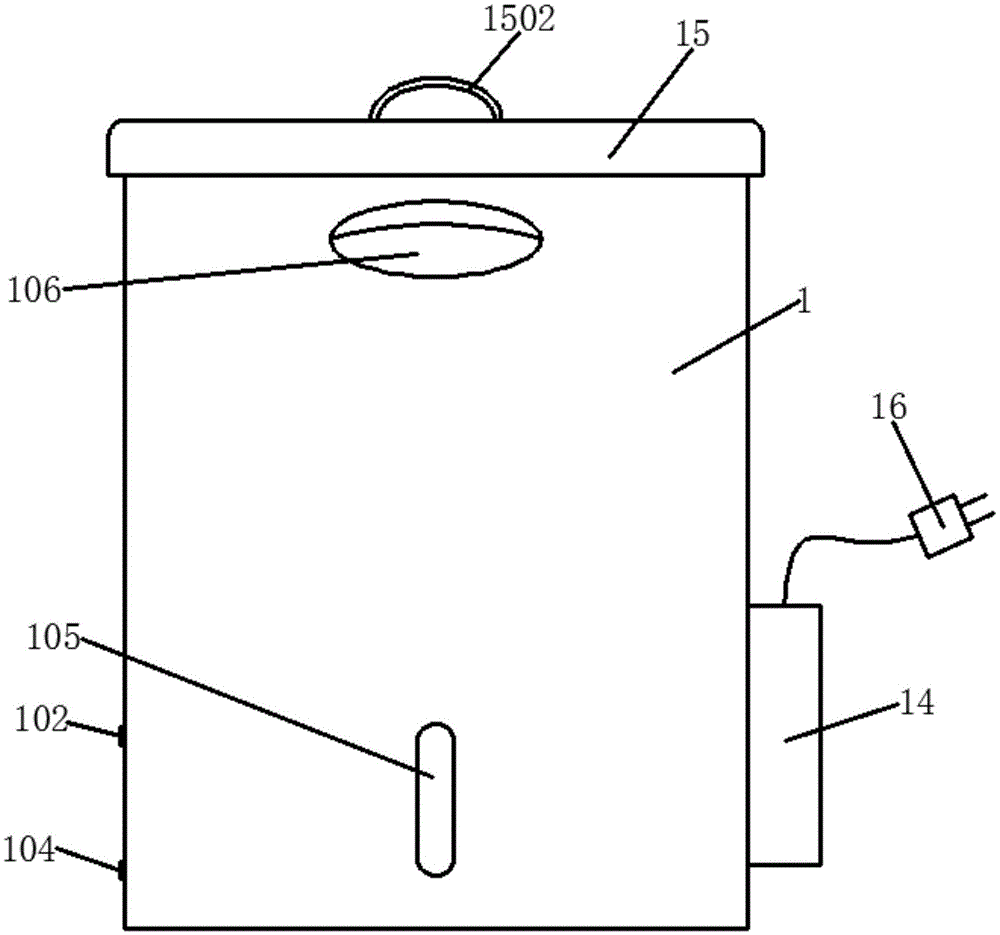

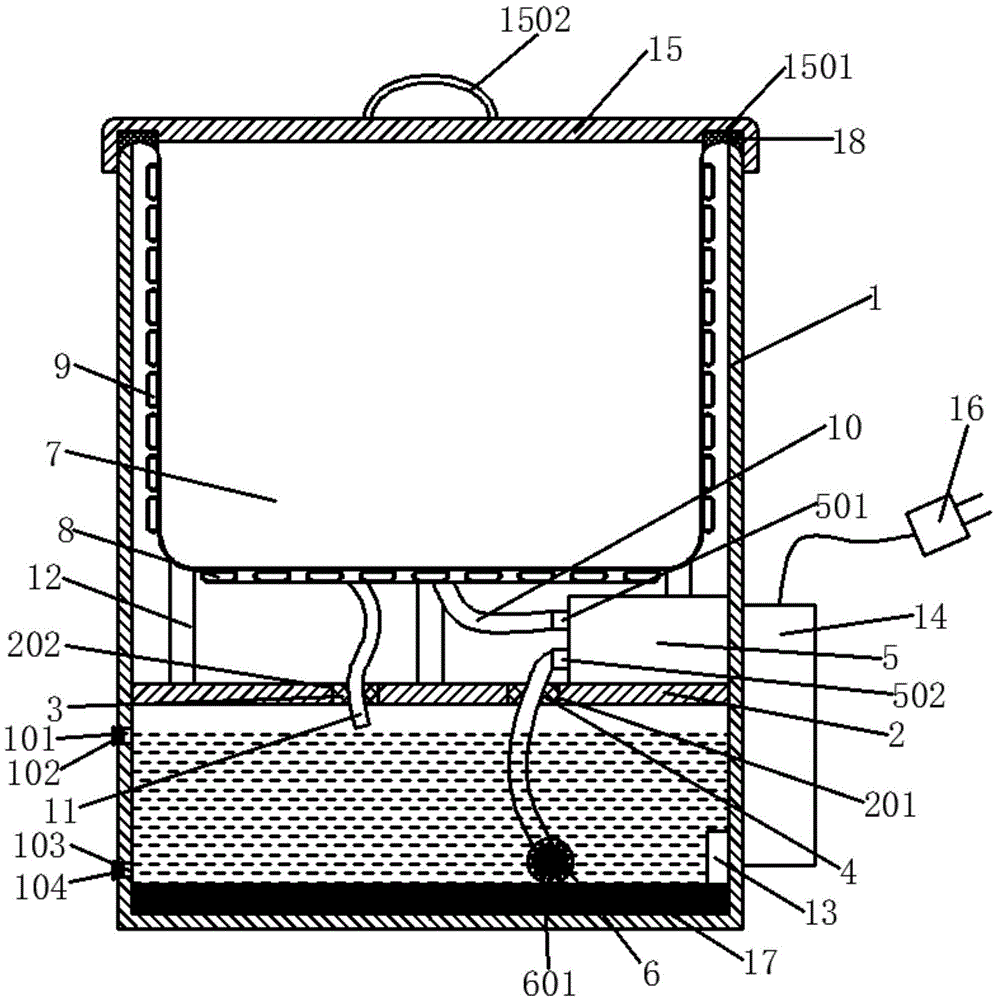

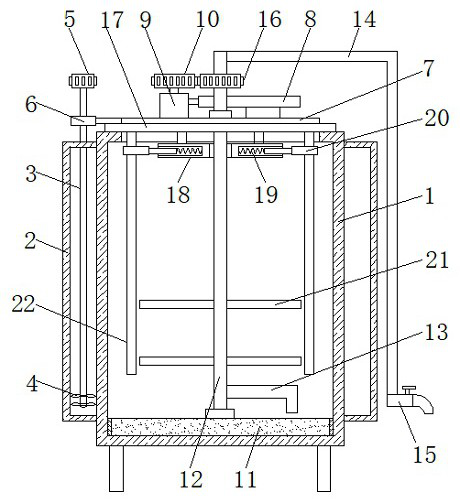

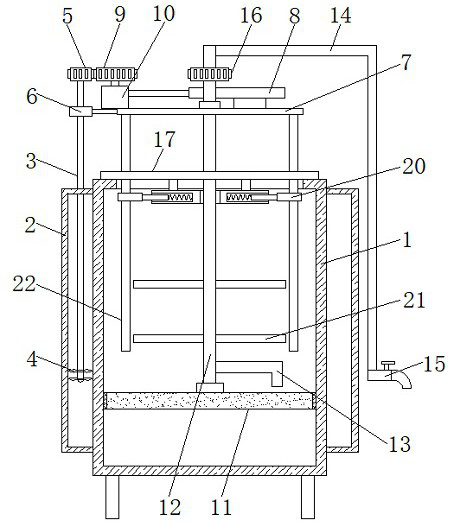

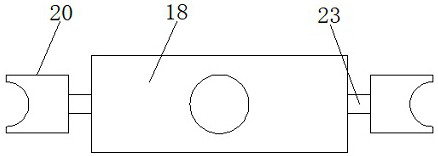

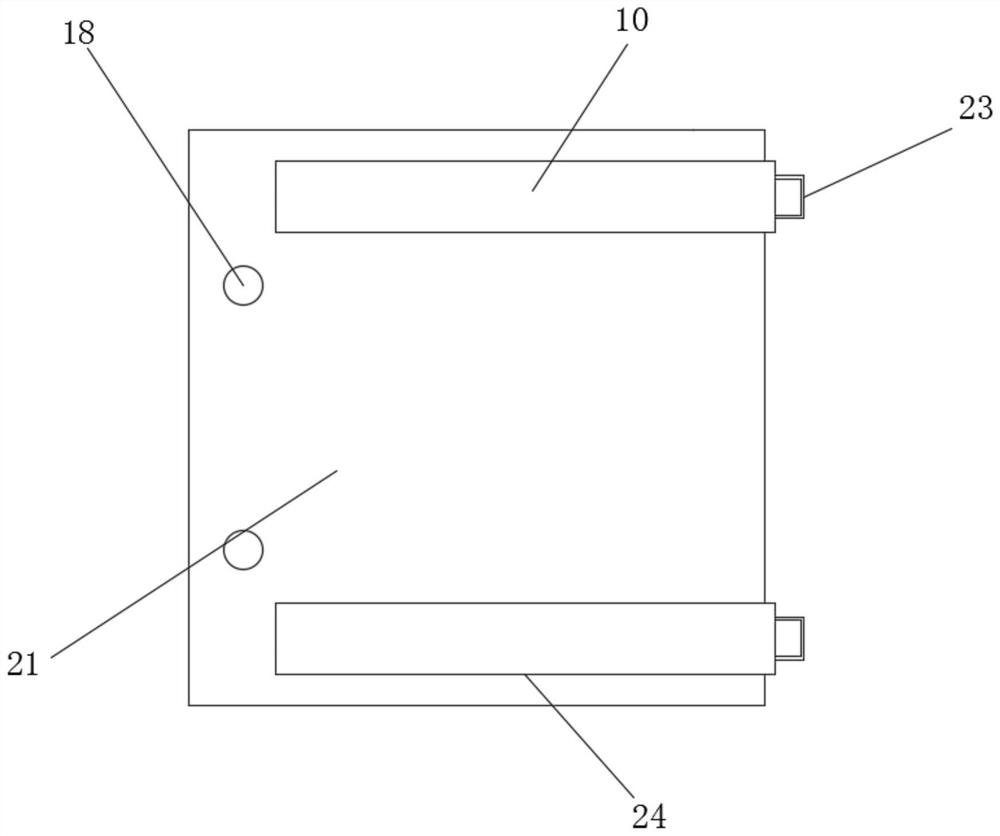

Incubator capable of automatically removing condensed water

ActiveCN112111377AEvenly distributedEven insulationBioreactor/fermenter combinationsBiological substance pretreatmentsGear wheelElectric machinery

The invention belongs to the field of biological culture, and particularly relates to an incubator capable of automatically removing condensed water. The incubator comprises a horizontally arranged incubator body, a transmission cavity is arranged in the lower side wall of the incubator body, the center of the transmission cavity is rotatably connected with a central gear, the upper end of the central gear extends into the incubator body and is fixedly connected with a bearing disc, a motor is fixedly installed at the lower end of the transmission cavity, the output end of the motor is coaxially and fixedly connected with the lower side wall of the central gear, planetary gears are connected to the two sides of the central gear in an engaged mode and rotationally connected with the transmission cavity, an inner gear ring is rotationally connected into the transmission cavity, and the two planetary gears are sleeved with the inner gear ring, and the inner gear ring is in engaged connection with the two planetary gears. When an incubator cover of the incubator is opened, an elastic corrugated pipe can be filled with gas, a push block is extruded downwards to extrude water on a waterabsorption strip, the elastic corrugated pipe can shrink when the incubator cover is closed, and the extruded water absorption strip can be unfolded at the moment to continue to absorb condensate water on the side wall of the incubator body.

Owner:江苏保捷舒药研医药销售有限公司

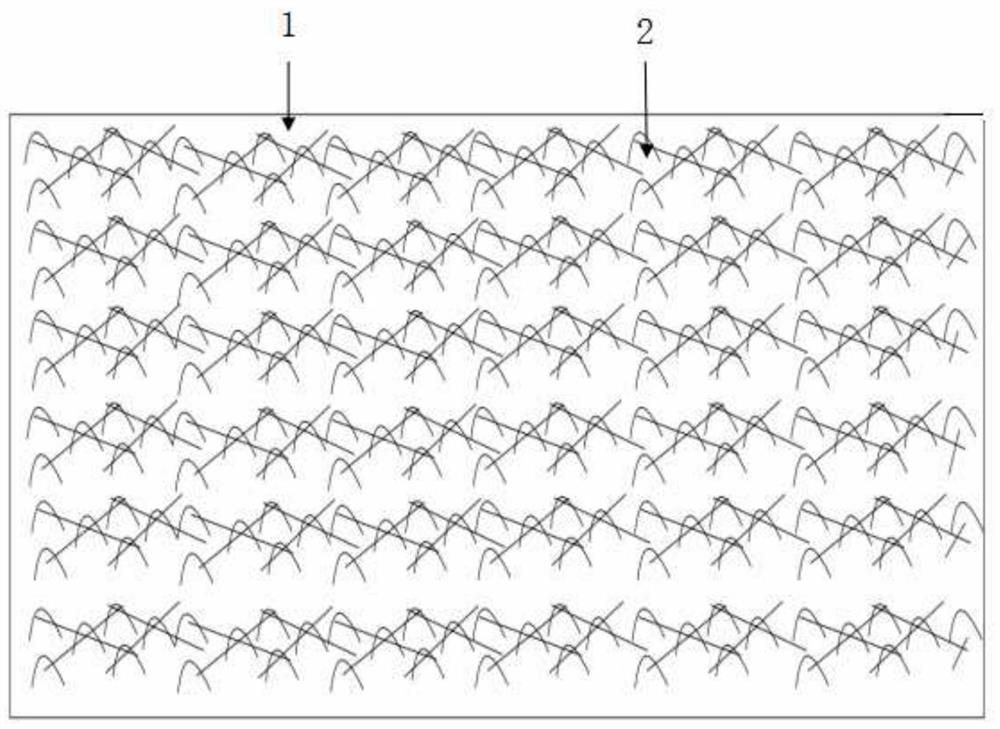

Carbon fiber thermal insulation material and preparation method thereof

PendingCN112481817ASimple componentsLow costHeating/cooling textile fabricsNon-woven fabricsThermal insulationPhenol formaldehyde resin

The invention belongs to the technical field of composite thermal insulation materials, and particularly relates to a carbon fiber thermal insulation material and a preparation method thereof. The carbon fiber thermal insulation material is formed by uniformly distributing carbon fibers and phenolic resin fibers, wherein the carbon fibers and the phenolic resin fibers are connected through a graphitization process after being subjected to spinning, pressurizing, curing and forming. The technical problems that an existing carbon fiber thermal insulation material is complex in component, poor inthermal insulation effect, tedious in production process and serious in process pollution are solved. The carbon fiber thermal insulation material provided by the invention is simple in component, lower in cost, better in heat preservation effect, higher in compression strength, controllable in shrinkage, simplified in technological process and stable in structure, and a felt body formed by blending and spinning the fiber carbon fibers and the phenolic fibers is formed at a time.

Owner:中宝(西安)科技集团有限公司

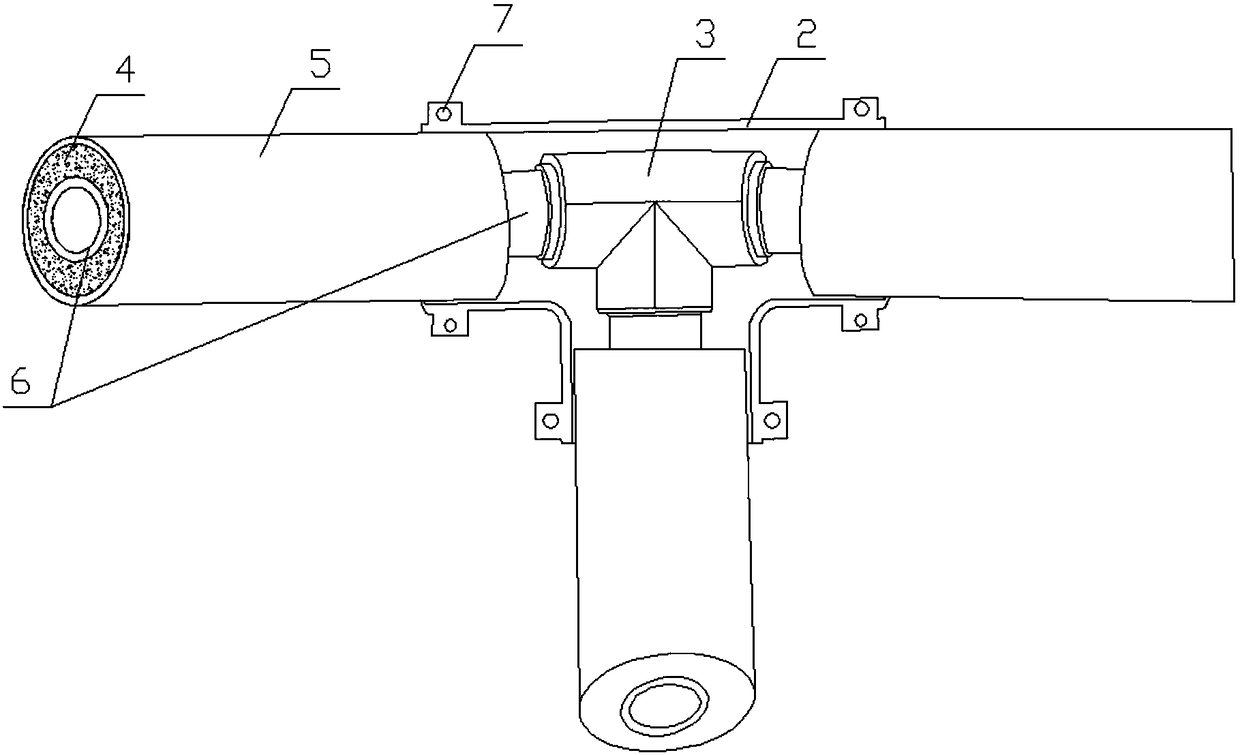

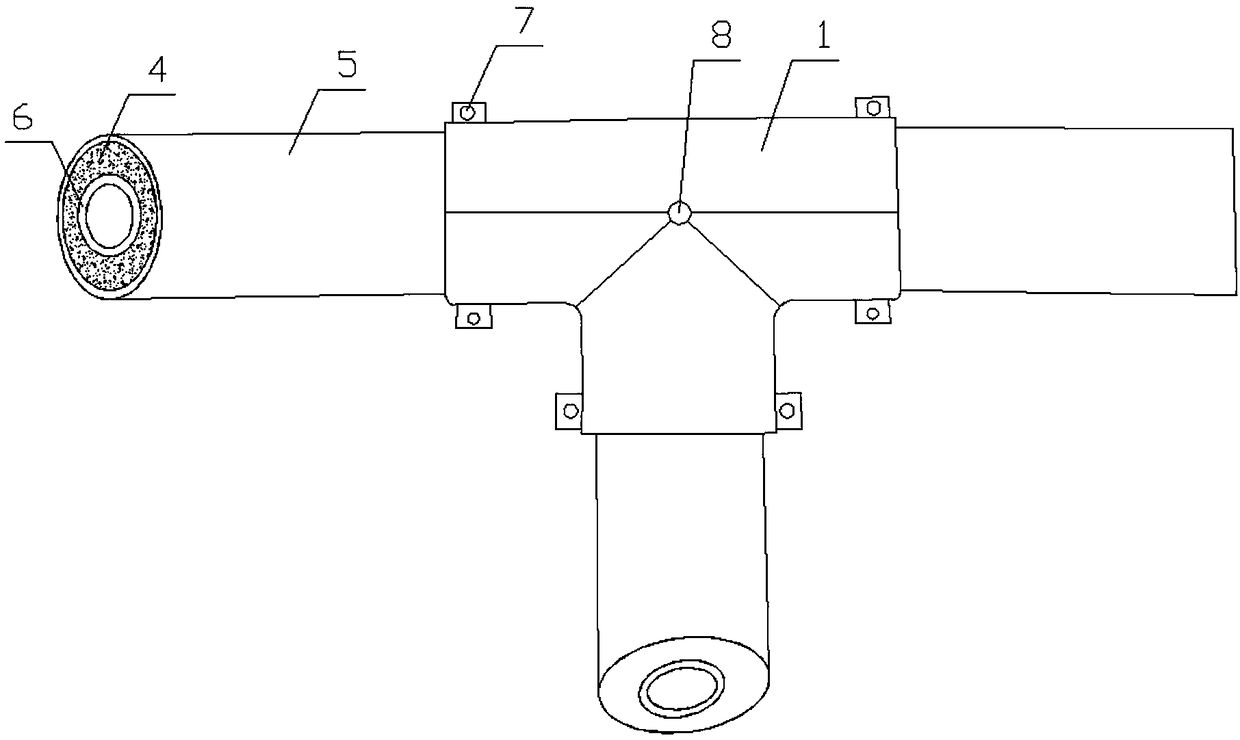

Two-section type tee joint heat-preserving bend accessory

InactiveCN108548051ASpeed up the flowImprove insulation effectThermal insulationPipe protection by thermal insulationChinese charactersFoaming agent

The invention discloses a two-section type tee joint heat-preserving bend accessory. The two-section type tee joint heat-preserving bend accessory is used for being connected among three to-be-connected heat-preserving pipes, and comprises an upper tee joint pipe shell, a lower tee joint pipe shell, an inner tee joint pipe and a foaming agent. Outer pipes and the foaming agent are removed throughthe connecting ends of the three to-be-connected heat-preserving pipes, inner pipes are exposed, the inner tee joint pipe is arranged on the three inner pipes in a communicated manner, connecting bases shaped like a Chinese character 'hui' are symmetrically arranged at the positions of three-end connection ports of the upper tee joint pipe shell and the lower tee joint pipe shell, the lower tee joint pipe shell and the upper tee joint pipe shell are cooperatively connected and arranged on the outer pipes, an injection hole is formed in the middle position of the upper tee joint pipe shell, theupper tee joint pipe shell and the lower tee joint pipe shell are connected together in the manner that screws penetrate through the connecting bases shaped like the Chinese character 'hui', and theportions among the inner straight pipes, the upper tee joint pipe shell and the lower tee joint pipe shell are filled with the foaming agent through the injection hole. The structure is simple, and the two-section type tee joint heat-preserving bend accessory can be used for connection among the heat-preserving pipes, and can protect water pipes at the turning joints just like the heat-preservingpipes.

Owner:WUHU JUNRU THERMAL INSULATION MATERIAL CO LTD

Novel insulation barrel

ActiveCN105480584APrevent spoilageEven and reliable heatingContainers preventing decayShock-sensitive articlesThermal insulationEngineering

The invention discloses a novel insulation barrel, comprising an outer shell, an insulation barrel body, a water inlet pipe, a water outlet pipe, a controller, a cover plate and a heating plate; a water suction pump is arranged on an upper end face of a supporting plate inside the outer shell; the insulation barrel body is arranged over the supporting plate and a supporting rod is connected between a bottom surface of the insulation barrel body and the supporting plate; a bottom surface hot water pipe is arranged on the bottom surface of the insulation barrel body; a cylindrical hot water pipe is arranged on an outer cylindrical surface of the insulation barrel body; the water inlet pipe is connected with a drain pipe, while the water outlet pipe is arranged in an inner hole of a second sealing ring; the heating plate is arranged on a bottom surface of the outer shell; a temperature sensor is arranged on an inner sidewall of the outer shell; the controller is arranged on an outer sidewall of the outer shell; and the cover plate is arranged on an upper side of the outer shell; according to the novel insulation barrel, the bottom surface hot water pipe and the cylindrical hot water pipe are arranged on the bottom surface and the side surface of the insulation barrel, respectively, to implement uniform heating to articles in the barrel; further, the novel insulation barrel is simple in structure, good in thermal insulation effect, and convenient to operate, and can be widely popularized and applied.

Owner:徐州茱萸谷生态旅游度假有限公司

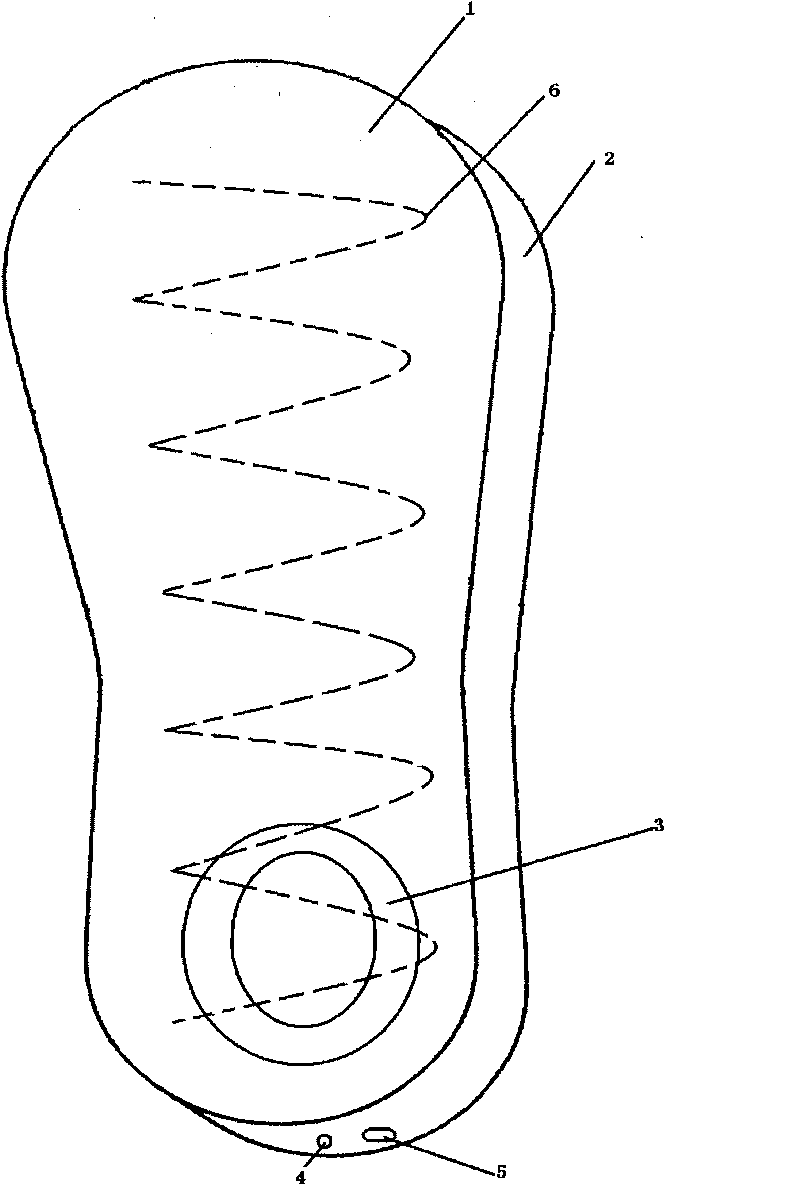

Novel slippers

The invention discloses novel slippers. The novel slippers consist of vamps, soles and welts, wherein the soles are made of a material with good heat transfer effect; heels of the soles are provided with attaching plug holes and temperature control devices; and resistance wires are laid in the middles of the soles. The novel slippers have the advantages of uniform heat-preserving effect and long-time heat preservation.

Owner:沈晶

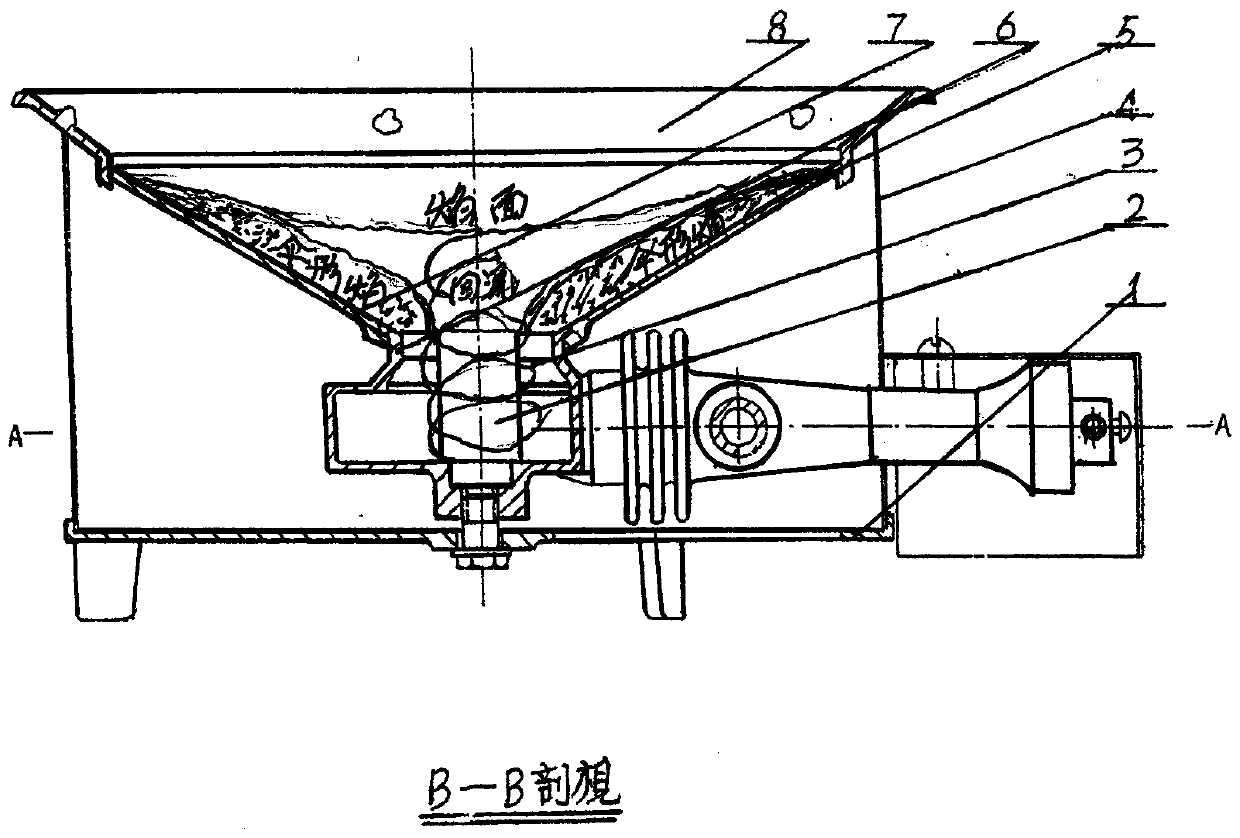

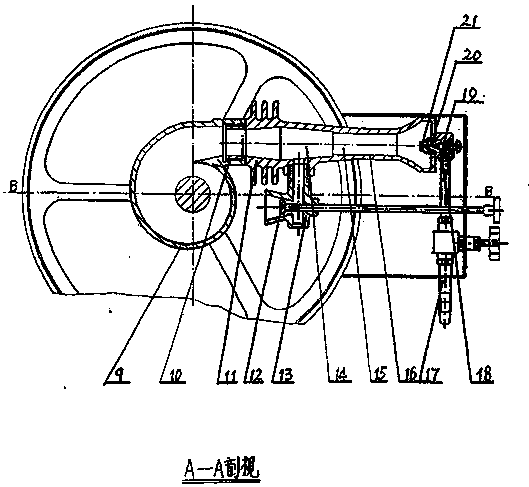

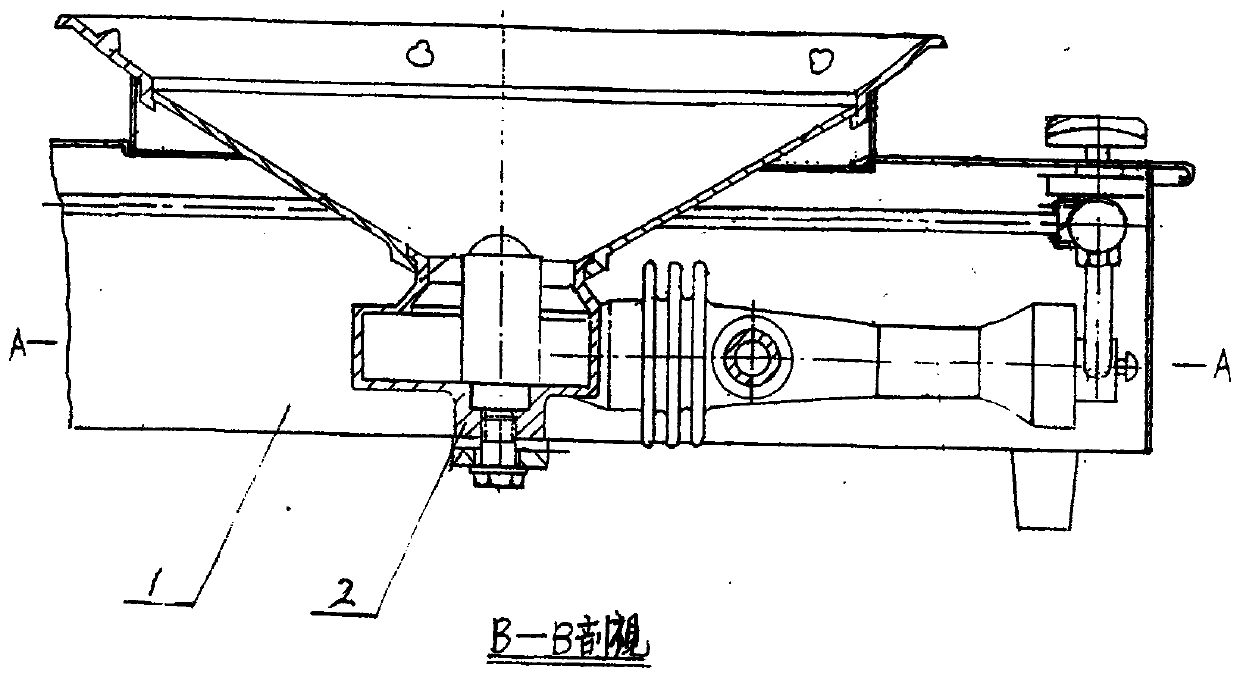

Supercharged spiral umbrella flame stepless regulation energy-saving combustor

InactiveCN107816719AGeneralizationTo achieve the purpose of high efficiency and energy savingGaseous fuel burnerCycloneFurnace temperature

The invention discloses a supercharged spiral umbrella flame stepless regulation energy-saving combustor. The combustor is provided with an environment-friendly type energy-saving combustion structurewhere gas stepless regulation, overload supercharging, radiation combustion and ultrahigh furnace temperatures are achieved. The combustor is composed of a nozzle shell, a nozzle, an ejector, a cyclone, a supercharger, an expansion gradually-shrinking cover, an expansion flame path cover and a cooking bench. A needle valve is arranged in the shell. A valve body can rotate or be adjusted in the shell. A gas pipe communicating with a gas system is manufactured at the middle section of the shell. One end of the gas pipe is connected with the ejector, and a mixing pipe and a diffuser pipe are manufactured at the middle section of the ejector. The middle section of the diffuser pipe communicates with a diffuser, and a spraying head is manufactured at an outlet of the diffuser pipe. An output of the spraying head is connected with the cyclone, the expansion gradually-shrinking cover and the expansion flame path cover are manufactured on the cyclone, and a spiral shaft is manufactured in thecenter of the cyclone. Energy of gas enters the cyclone to generate high-speed rotation airflow through mixing and purifying of the ejector. Different heat loads can be achieved by adjusting the spray hole flow, and therefore the combustor can have multiple purposes, the high efficiency and energy conservation effects are achieved, and the combustor is widely used for industrial furnaces and catering industry cookers.

Owner:湖北满天星节能环保科技有限公司

Vegetable greenhouse

InactiveCN107047137AReduce labor intensityEven insulationClimate change adaptationSaving energy measuresGreenhouseAgricultural engineering

The invention belongs to the technical field of mulching films, and particularly discloses a vegetable greenhouse. According to the main technical scheme, the vegetable greenhouse is composed of a shed frame for heat preservation lighting and a shed frame rear wall, wherein the shed frame comprises a dual-layer light transmitting diaphragm plate with a hollow cavity in the middle, an inner layer and an outer layer, and the cavity can be filled with heat preservation materials or evacuated through a logistic pump. According to the vegetable greenhouse of the structure, the labor intensity of a vegetable grower can be relieved in the using process, the good heat preservation performance is achieved, and the land utilization efficiency is effectively improved.

Owner:吕兴军

Box type heat preservation annealing method for fused zircon corundum brick

The invention relates to a box type heat preservation annealing method for a fused zircon corundum brick, and belongs to the technical field of refractory materials. The method comprises the following steps of: placing a casting mold in a heat preservation box before casting; filling the bottom and the surrounding part of the heat preservation box with aluminum silicon hollow balls; and directly and continuously covering the aluminum silicon hollow balls on the top of the casting mold to perform heat preservation annealing after the casting. The method has the advantages of guaranteeing product quality and improving product yield, along with low labor intensity, good working environment and uniform heat preservation and is easy and convenient to operate.

Owner:淄博艾杰旭刚玉材料有限公司

Brewing device for tea wine production

InactiveCN112175771AEven insulationAvoid accumulationAlcoholic beverage preparationWater flowProcess engineering

The invention discloses a brewing device for tea wine production, and relates to the technical field of tea wine brewing. In order to solve the problems that in the prior art, when tea wine is brewed,that internal liquid is heated uniformly cannot be guaranteed, and the outside lacks heat preservation measures, the following scheme is provided. The brewing device comprises a fermentation barrel,wherein the fermentation barrel is fixedly sleeved with a heat preservation water storage cover, the heat preservation water storage cover is internally and movably sleeved with a water flow circulating mechanism, the fermentation barrel is internally and movably sleeved with a piston, the top of the piston is rotationally connected with a fixed pipe, one side of the bottom of the fixed pipe is fixedly connected with a water suction pipe, the top of the fermentation barrel is fixedly connected with a sealing cover, the bottom of the fermentation barrel is fixedly connected with a positioning mechanism, and a movable plate is arranged at the top of the sealing cover. The inside and outside of the fermentation barrel are heated uniformly, high-quality and efficient fermentation is facilitated, the discharging direction can be adjusted, sediment in the barrel can be conveniently removed, and the device is rapid and saves labor.

Owner:湖南茶酒有道酒业有限公司

Plastic plate extrusion die

PendingCN114670417AHeating evenlyImprove the heating effectDispersed particle filtrationTransportation and packagingCooling effectEngineering

The invention discloses a plastic plate extrusion die, and belongs to the technical field of plastic plate dies, the plastic plate extrusion die comprises a die body, first heating plates are arranged in the upper wall and the lower wall of the die body, and second heating plates are arranged on the two side walls of the die body; a plastic solution in the mold body is directly heated through the first heating plate and the second heating plate, meanwhile, heat formed by the second heating plate is dissipated into the second shell and can also be transmitted into the first shell through the air pipe, and the heating and heat preservation effects of the mold are improved; a plastic plate in the mold body is heated more uniformly through multi-face heating, the heating efficiency is improved, during cooling, a sliding plate is opened, a sealing plate and a first sealing cover are opened for cooling, an exhaust fan is started for air exhaust, air flow passes through an air pipe from the interior of a second shell and then goes out from a second frame plate, the air flow flows from the second shell, and the cooling efficiency is improved. And the periphery of the mold body is cooled, and the cooling effect is improved.

Owner:CHENGDU TECH UNIV

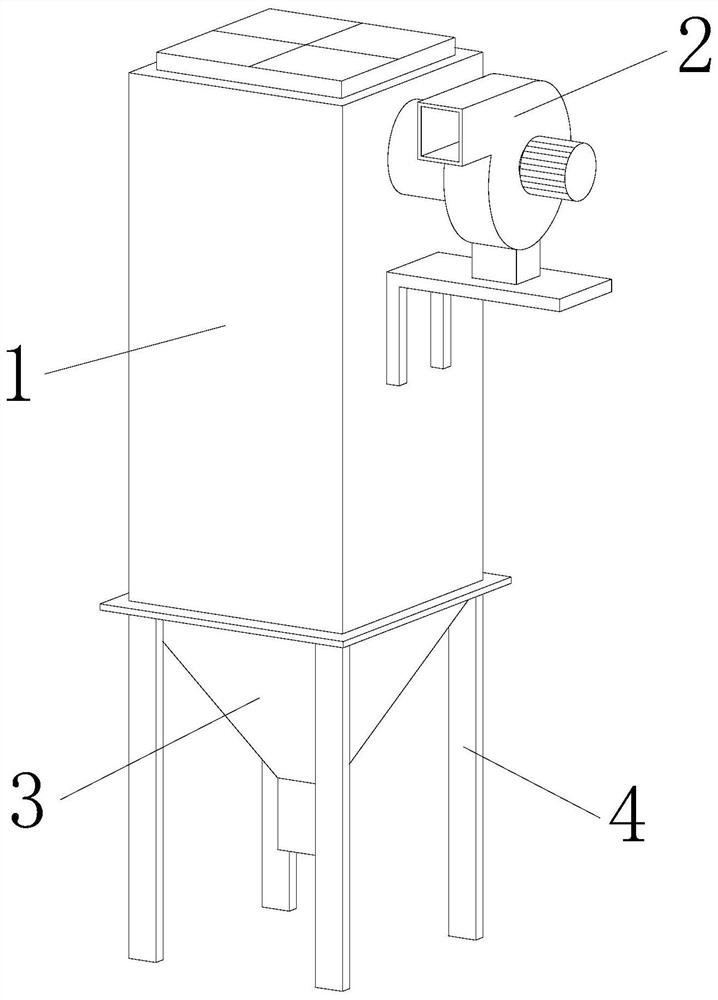

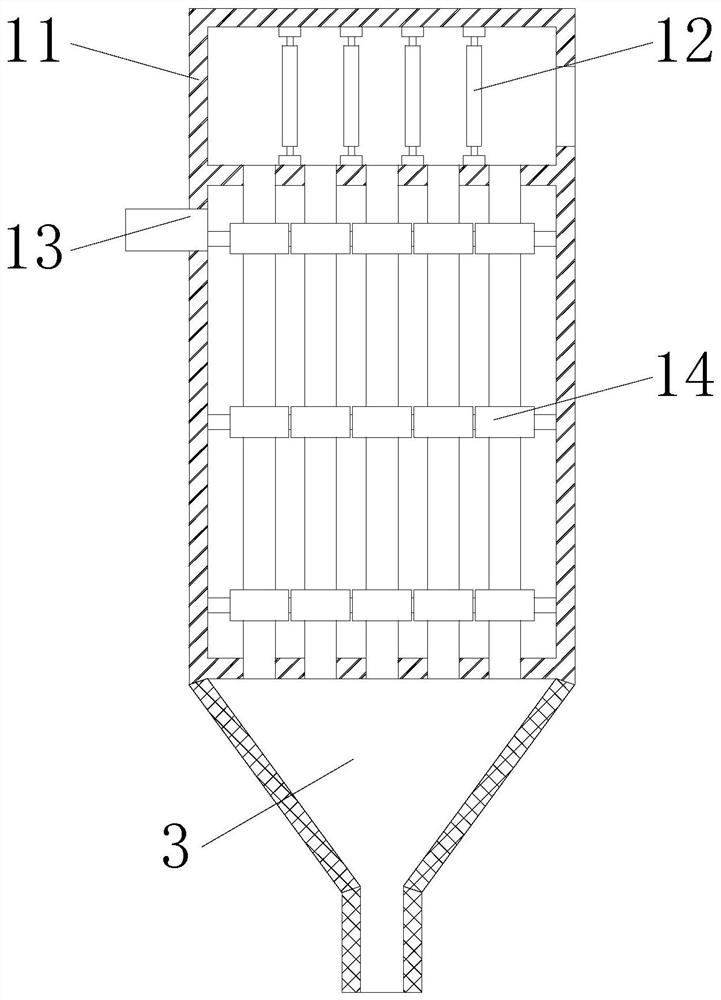

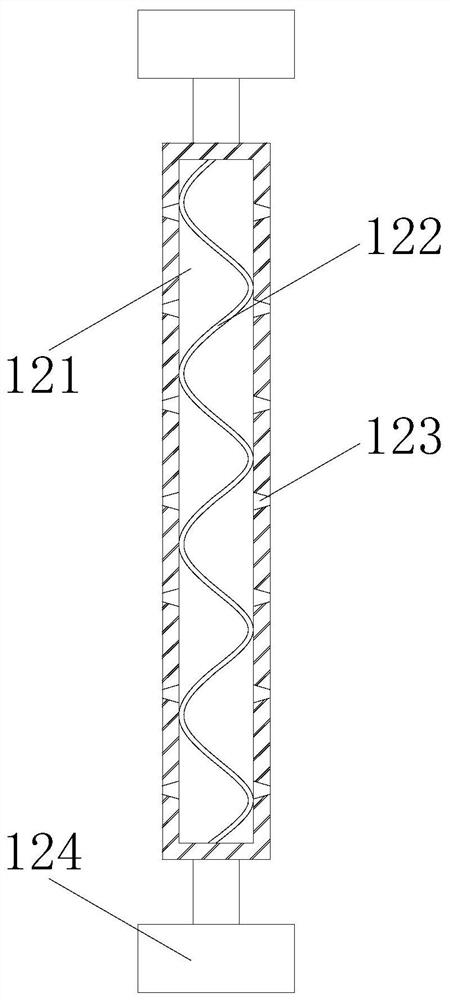

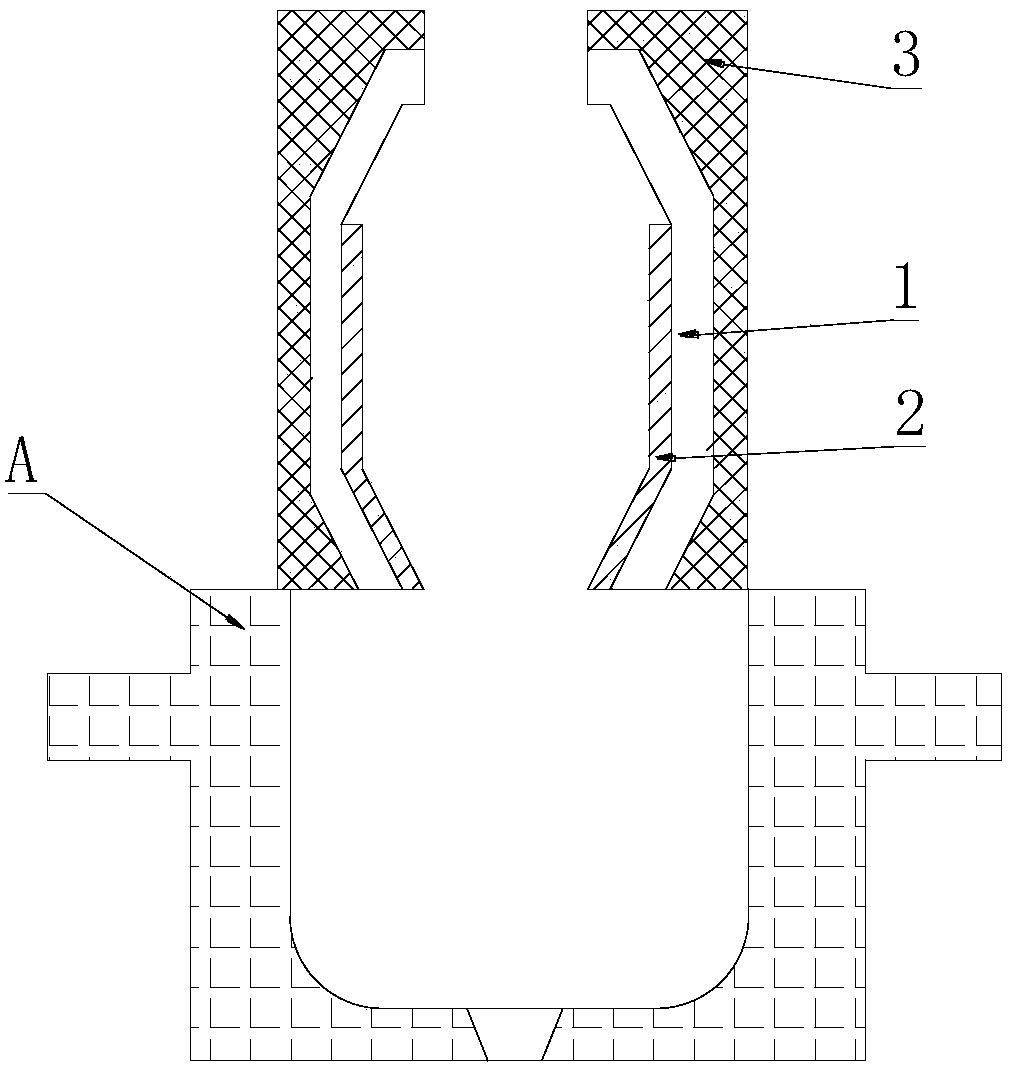

Mine plant dust removal purifier for environmental protection equipment

InactiveCN112827267AEven insulationReduce the temperatureHuman health protectionDispersed particle filtrationEnvironmental engineeringWaste gas

A disclosed mine plant dust removal purifier for environmental protection equipment structurally comprises a dust removal main machine, a draught fan, a dust discharging opening and supporting legs, the draught fan is fixedly installed at the upper right end of the dust removal main machine in an embedded mode and communicates with the dust removal main machine, waste gas at the lower end enters an air inlet to blow a rotating piece to rotate, and a protective shell rotates stably. An electric heating wire in a connecting rod rotates to heat, and hot air is rotatably discharged through the air holes, so that the whole dust at the upper end in the box body is more uniformly insulated, and the dust in the waste gas is prevented from staying in a filter bag due to too low dust temperature and too large moisture in the waste gas. During filtering, waste gas blows a sliding block to slide in a fixed block, so that the filter bag shakes, meanwhile, the waste gas is discharged into a fixed ring through a gas inlet hole, the sliding block is blown to annularly rotate on a guide rod, a pressing block rotates and extrudes the outer side of the filter bag, and dust condensed and adhered to the inner surface of the filter bag is prevented from falling off.

Owner:黄彩英

Heat-insulating riser bush for casting

The invention discloses a heat-insulating riser bush for casting. The heat-insulating riser bush for casting is used for feeding in a casting mold. The heat-insulating riser bush for casting comprisesa base body, a heating layer and a protective layer. A feeding cavity is formed in the base body. A feeding outlet is formed in the bottom of the base body. The feeding cavity communicates with the interior of the casting mold through the feeding outlet. The radial sectional area of the end, away from the feeding cavity, of the feeding outlet is smaller than the radial sectional area of the end,close to the feeding cavity, of the feeding outlet. The heating layer is arranged on the inner wall of the feeding cavity. The base body is wrapped with the protective layer. The base body is made from a heat-insulating material. The heat-insulating material comprises, by weight, 40-50 parts of heat-insulating vermiculite, 10-20 parts of expanded perlite, 20-30 parts of hollow micro-beads, 8-16 parts of silica powder, 20-30 parts of graphite powder, 10-18 parts of boraxes, 10-18 parts of steel slag powder, 8-16 parts of tailing sand, and 10-20 parts of bentonite.

Owner:霍山县东胜铸造材料有限公司

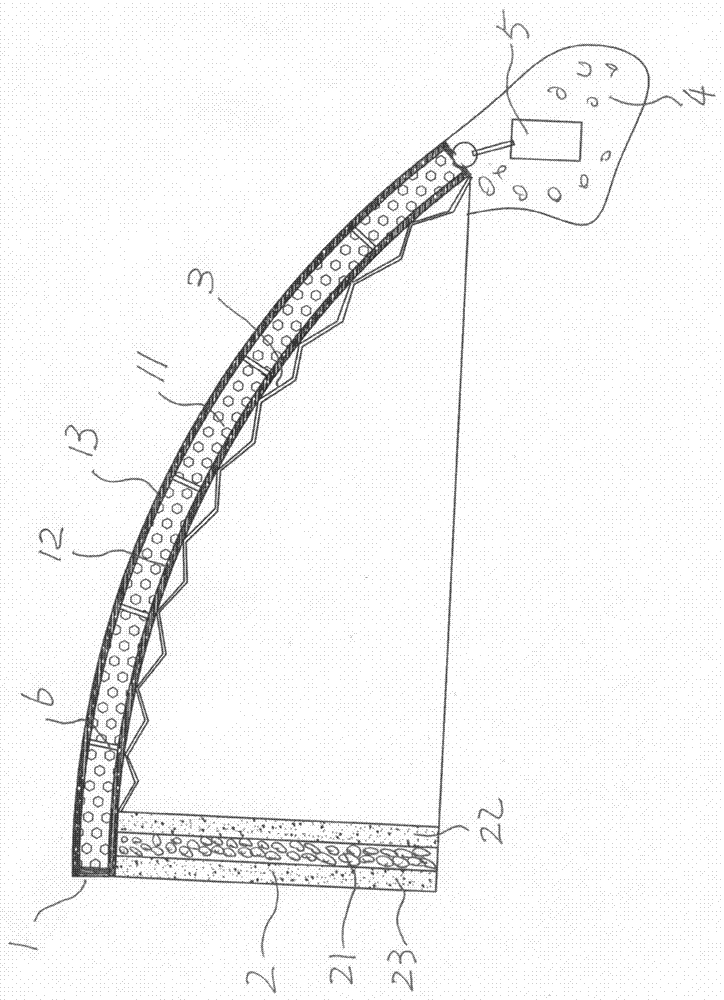

Heat preservation heating device used in culvert low-temperature environment and using method

InactiveCN110080805AEasy to solidifyQuality assuranceMining devicesUnderground chambersEngineeringInverted u

The invention discloses a heat preservation heating device used in a culvert low-temperature environment and a using method. The product comprises the following components: an inner arc board, the inner arc board is sequentially connected with a left wall board, an upper wall board, a right wall board and a lower wall board, the left wall board, the upper wall board, the right wall board and the lower wall board are connected through steel meshes. The steel mesh is fixedly connected with a group of supporting rods, the supporting rods are transversely arranged and then vertically arranged, theinner arc board is provided with a group of charging ports, the charging ports are transversely arranged and then vertically arranged, a hot paste is arranged between the inner arc board and the steel mesh, the hot paste is bonded with a hard strip board, an inverted U-shaped bayonet is formed in the bottom of the hard strip board, and the supporting rods are clamped into the inverted U-shaped bayonet to be fixed. The heat preservation heating device is used for heat preservation heating in the culvert low-temperature environment.

Owner:HEILONGJIANG COLLEGE OF CONSTR

A grinding wheel heat preservation rack with good heat preservation effect

ActiveCN112875044BEasy to replaceShorten the timeContainers for annular articlesExternal framesThermal insulationElectric machine

The invention discloses a grinding wheel heat preservation rack with good heat preservation effect, and relates to the technical field of grinding wheel production. The heat preservation rack for grinding wheels with good heat preservation effect includes a heat preservation box. The inside of the heat preservation box is provided with a lifting mechanism and a rotating mechanism. A heating mechanism is provided below the heat preservation box. The tops of the two groups of support columns are fixedly equipped with a placement box, the placement box is provided with an opening, and the bottom of the incubator is fixedly equipped with two groups of support legs. The heat preservation rack for the grinding wheel with good thermal insulation effect controls the rotation of the placed grinding wheel through the cooperation of the fixed plate, the rotating shaft, the rotating disc, the placing sleeve rod, the worm, the second motor, the rotating rod and the turbine, so that the heat received by the grinding wheel Uniformity, uniform heat preservation effect, multiple grinding wheels can be placed at the same time, greatly increasing the efficiency of the device, and good air permeability, large contact area between the grinding wheel and hot air, increasing the plasticity of the device.

Owner:重庆市腾龙磨料磨具有限公司

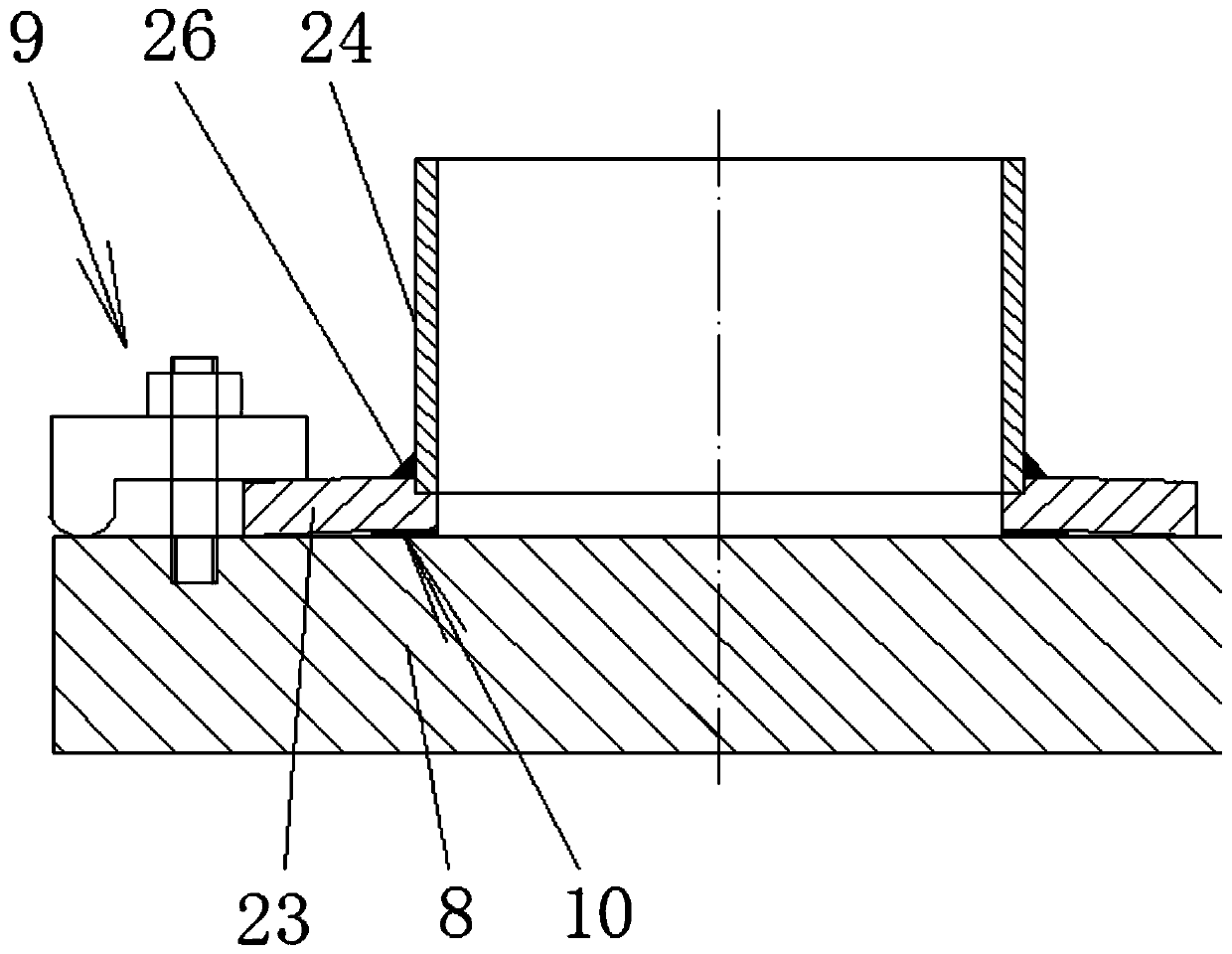

Injection molding equipment and injection molding method for water heater insulation layer

Owner:HAIER GRP CORP +1

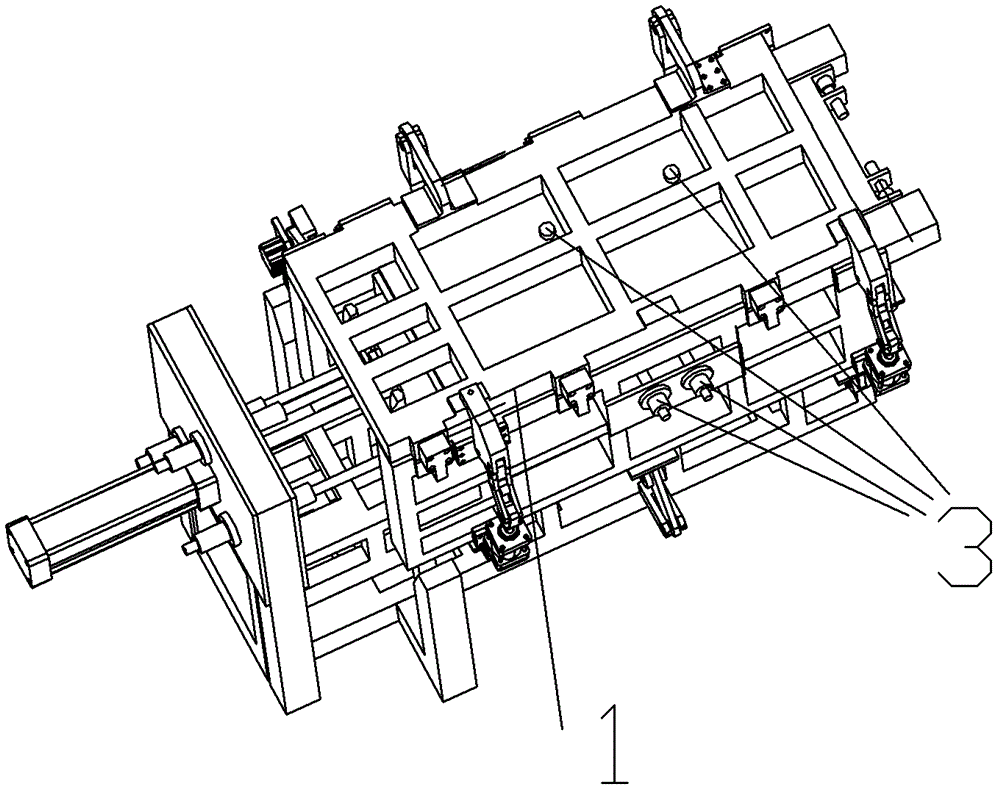

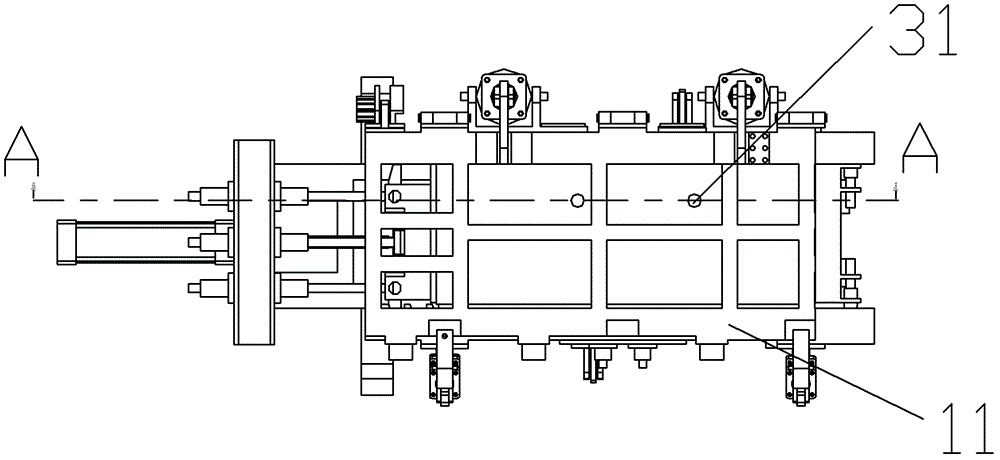

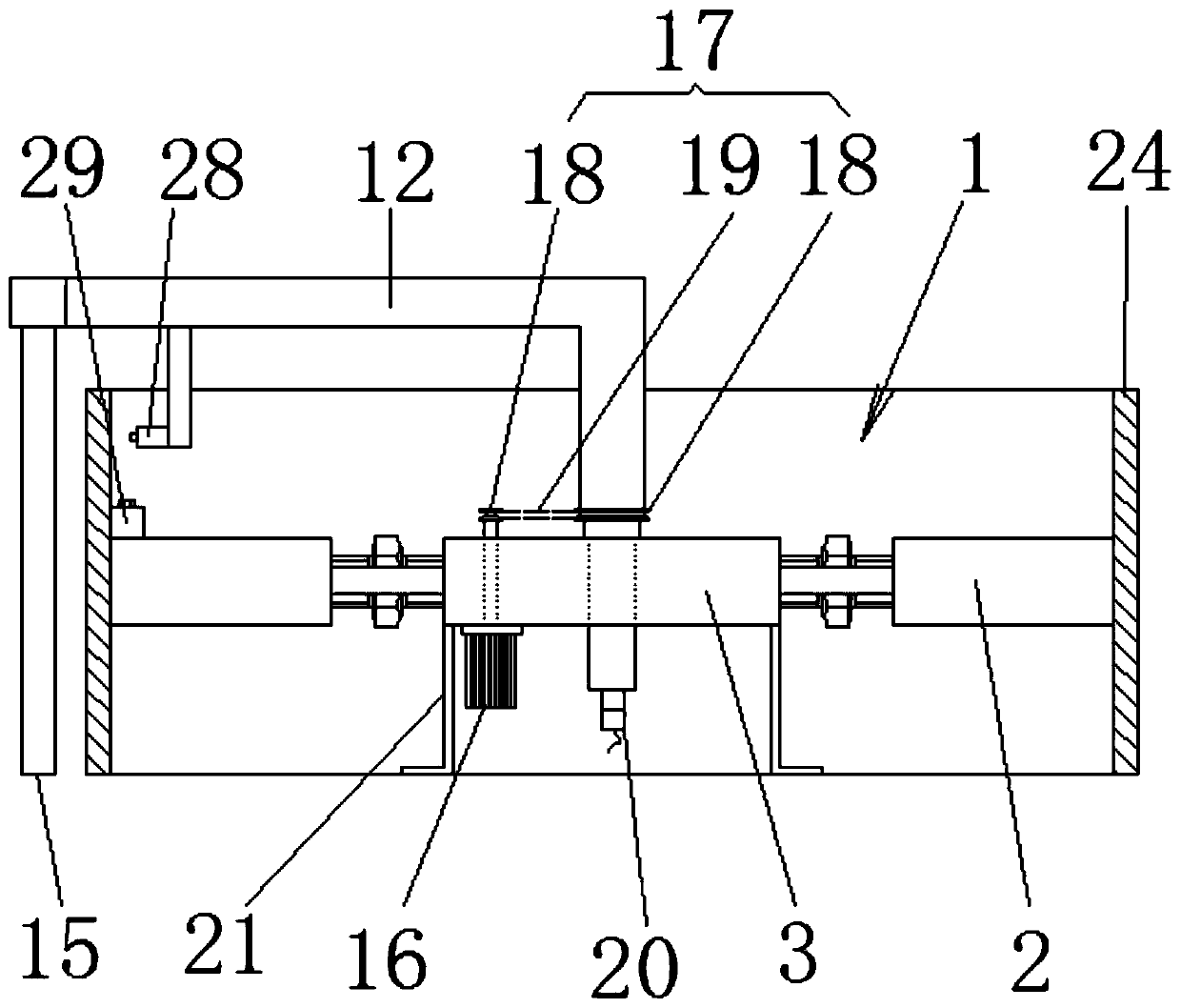

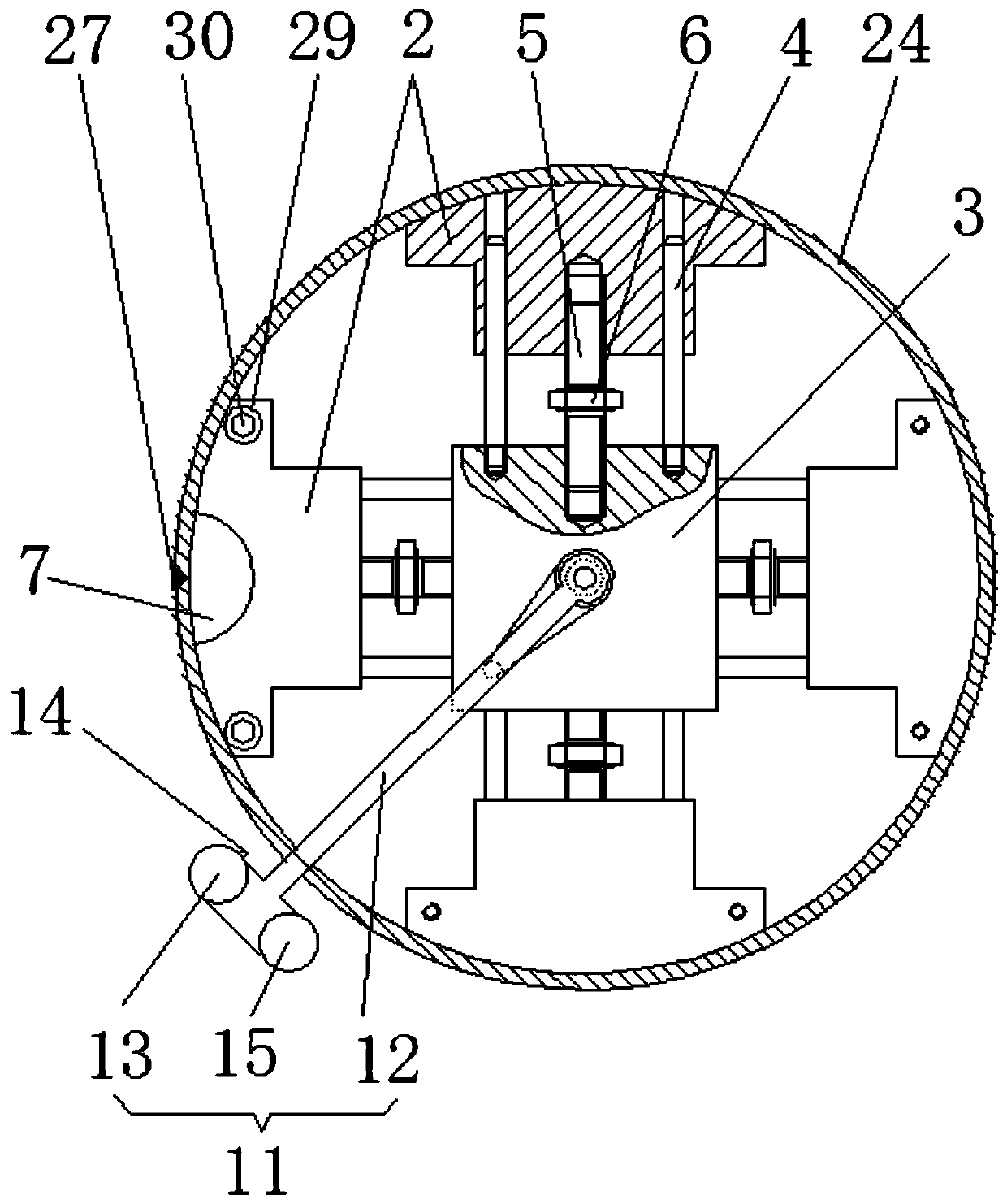

A manufacturing process of manhole well welded parts

The invention relates to the field of welding technologies, and discloses a manufacturing technology for a manhole well welding part. The manufacturing technology for the manhole well welding part comprises the technological steps of steel plate blanking, steel plate rolling, cylinder inner wall reinforcing by adopting an anti-deformation positioning tool, cylinder welding, anti-deformation positioning tool disassembling, flange machining, assembling, total welding and the like, wherein the anti-deformation positioning tool comprises four arc-shaped positioning blocks which jack the inner wallof a cylinder through helical jacking mechanisms and are evenly distributed in the circumferential direction of the inner wall of the cylinder, and the arc-shaped faces of the four arc-shaped positioning blocks make contact with the inner wall of the cylinder. According to the manufacturing technology for the manhole well welding part, welding deformation of the manhole well welding part is reduced, and the manufacturing precision of the manhole well welding part is improved.

Owner:JIANGYIN FUREN HIGH TECH

Grinding wheel heat preservation placing frame with good heat preservation effect

ActiveCN112875044AEasy to replaceShorten the timeContainers for annular articlesExternal framesElectric machineryEngineering

The invention discloses a grinding wheel heat preservation placing frame with a good heat preservation effect, and relates to the technical field of grinding wheel production. The grinding wheel heat preservation placing frame with the good heat preservation effect comprises a heat preservation box, wherein a lifting mechanism and a rotating mechanism are arranged in the heat preservation box; a heating mechanism is arranged below the heat preservation box; two sets of supporting columns are fixedly installed at the bottom of the inner side of the heat preservation box; a placing box is fixedly installed at the tops of the two sets of supporting columns and is provided with an opening; and two sets of supporting legs are fixedly installed at the bottom of the heat preservation box. According to the grinding wheel heat preservation placing frame with the good heat preservation effect, a fixed plate, a rotating shaft, a rotating disc, a placing sleeve rod, a worm, a second motor, a rotating rod and a turbine are used in cooperation, and a placed grinding wheel is controlled to rotate, so that heat borne by the grinding wheel is uniform, and the heat preservation effect is uniform; meanwhile, multiple grinding wheels can be placed, so that the efficiency of the device is greatly improved; and air permeability is good, so that the contact area between the grinding wheel and hot air is large, and the plasticity of the device is improved.

Owner:重庆市腾龙磨料磨具有限公司

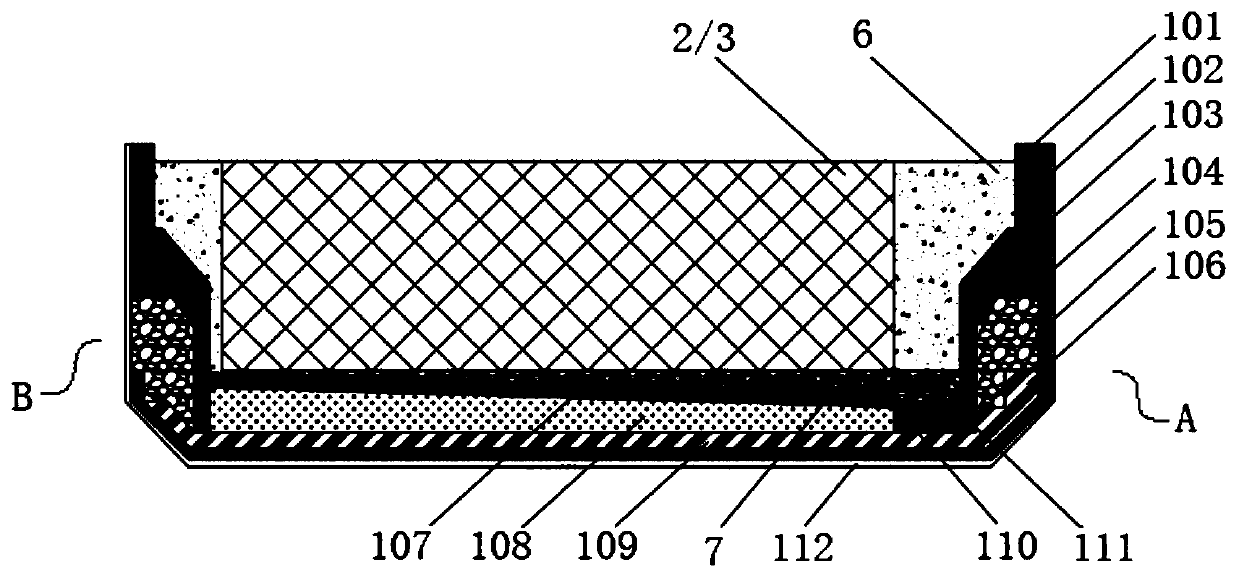

Liner structure, and aluminum electrolysis bath with liner structure

The invention discloses a liner structure, and an aluminum electrolysis bath with the liner structure. The liner structure is arranged on the inner wall of a bath shell of the aluminum electrolysis bath and comprises a bath chamber side part and a bath chamber bottom part, wherein the bottom surface of the bath chamber bottom part is inclined toward one side; an aluminum collecting ditch sunken relative to the bath chamber bottom surface is arranged on one lower side; the bath chamber side part is formed by splicing side part inner side carbon blocks and side part special-shaped carbon blockswhich are constructed and fixed through high-alumina bricks and high-strength castables; the side part inner side carbon blocks are located on the upper part; the side part special-shaped carbon blocks are located on the lower part and cover a melt area of the aluminum electrolysis bath side part in the perpendicular direction; and heat insulation boar layers are arranged on the bath chamber bottom part and the bath chamber side part close to an electricity feeding side of the aluminum electrolysis bath. The liner structure is particularly applied to a continuously running multi-chamber aluminum electrolysis bath, an inclined bottom hearth structure is arranged according to a molten aluminum flowing rule in the bath, and meanwhile, non-uniform heat insulation structures are built on the electricity feeding side and an electricity discharging side at the same time, so that the maximum heat insulation and the temperature field distribution uniformity of the electrolysis bath, and the automatic collection of molten aluminum are realized.

Owner:CENT SOUTH UNIV

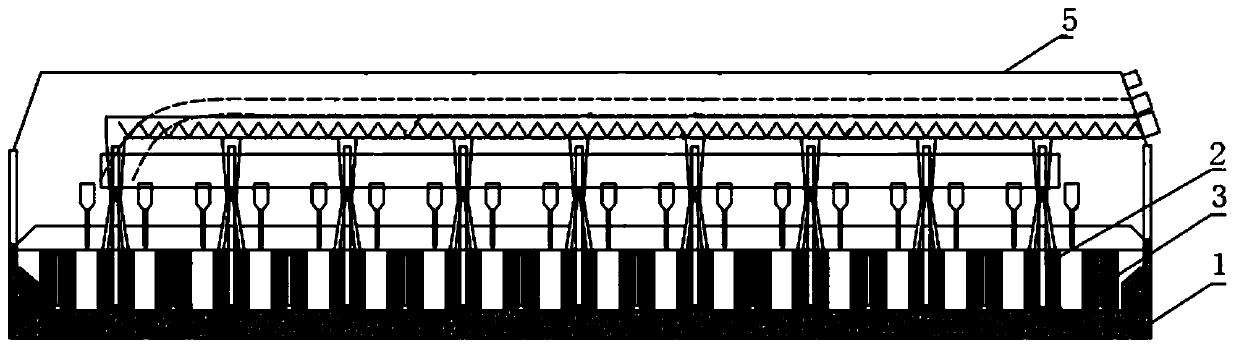

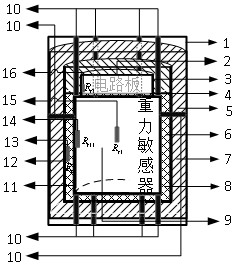

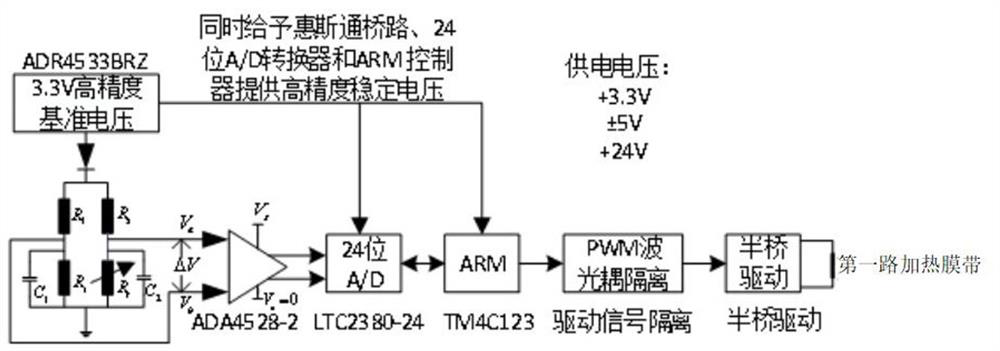

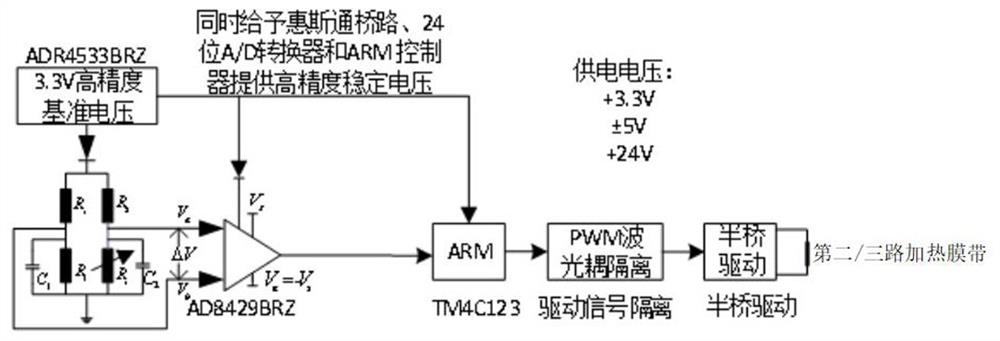

Constant temperature system of portable relative gravimeter

ActiveCN114779847APlay the role of constant temperature protectionReduce lossTemperature control using electric meansGravitational wave measurementInsulation layerThermal break

The invention relates to a constant-temperature system of a portable relative gravimeter. The constant-temperature system is characterized in that a first-path constant-temperature structure comprises a gravity sensor shell, a first-path heating film belt, a first-path aerogel heat insulation layer and two first thermistors, wherein the first-path heating film belt is tightly adhered to the outside of the shell, and the first-path aerogel heat insulation layer tightly wraps the periphery of the first-path heating film belt; the third constant temperature structure comprises a third heating film belt tightly attached to the periphery of the circuit board mounting shell, a third aerogel heat insulation layer tightly wrapping the periphery of the third heating film belt and a third thermistor; the second constant-temperature structure comprises an aluminum shielding cylindrical thin barrel tightly attached to the first aerogel heat insulation layer and the second aerogel heat insulation layer, a second heating film belt tightly attached to the periphery of the aluminum shielding cylindrical thin barrel, a second aerogel heat insulation layer tightly wrapping the periphery of the second heating film belt and a second thermistor; the upper end, the lower end and the periphery of the outer side of the gravity sensor shell are connected with the gravimeter outer frame through light shock absorbers. The system has the advantages of low power consumption and good constant temperature effect.

Owner:TIANJIN NAVIGATION INSTR RES INST

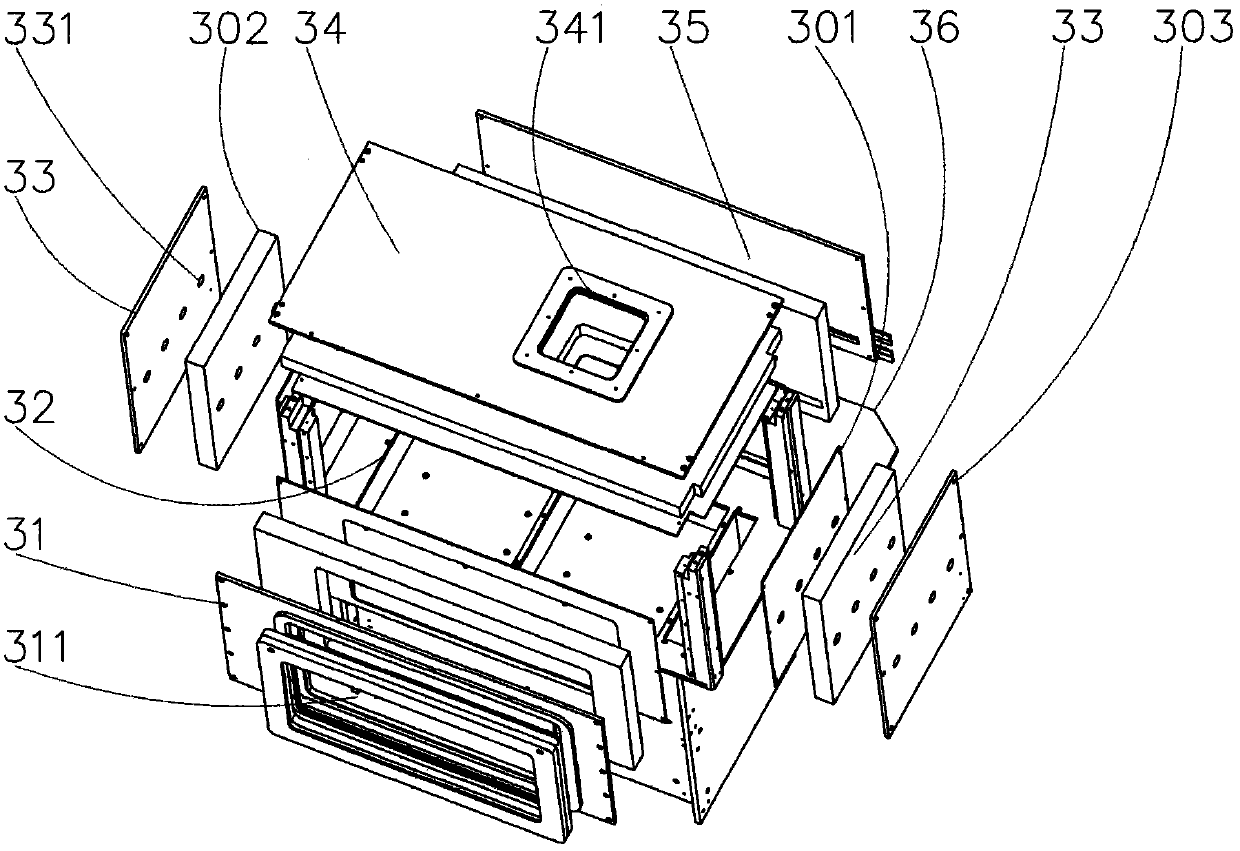

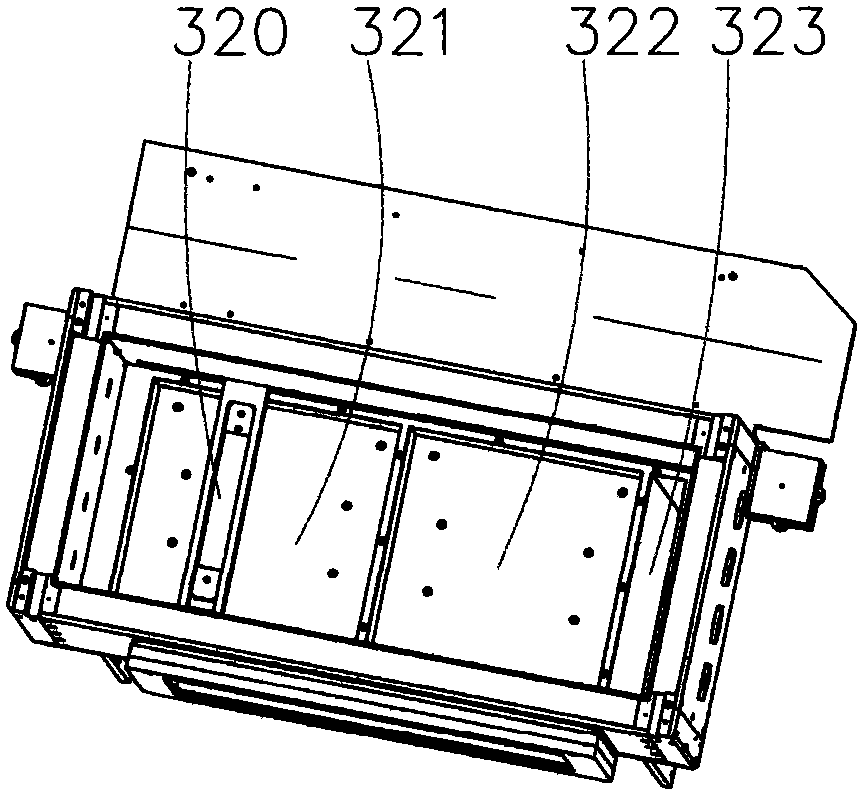

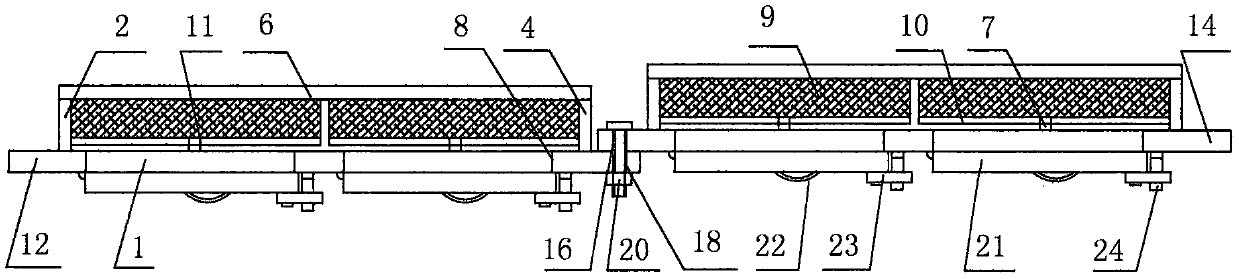

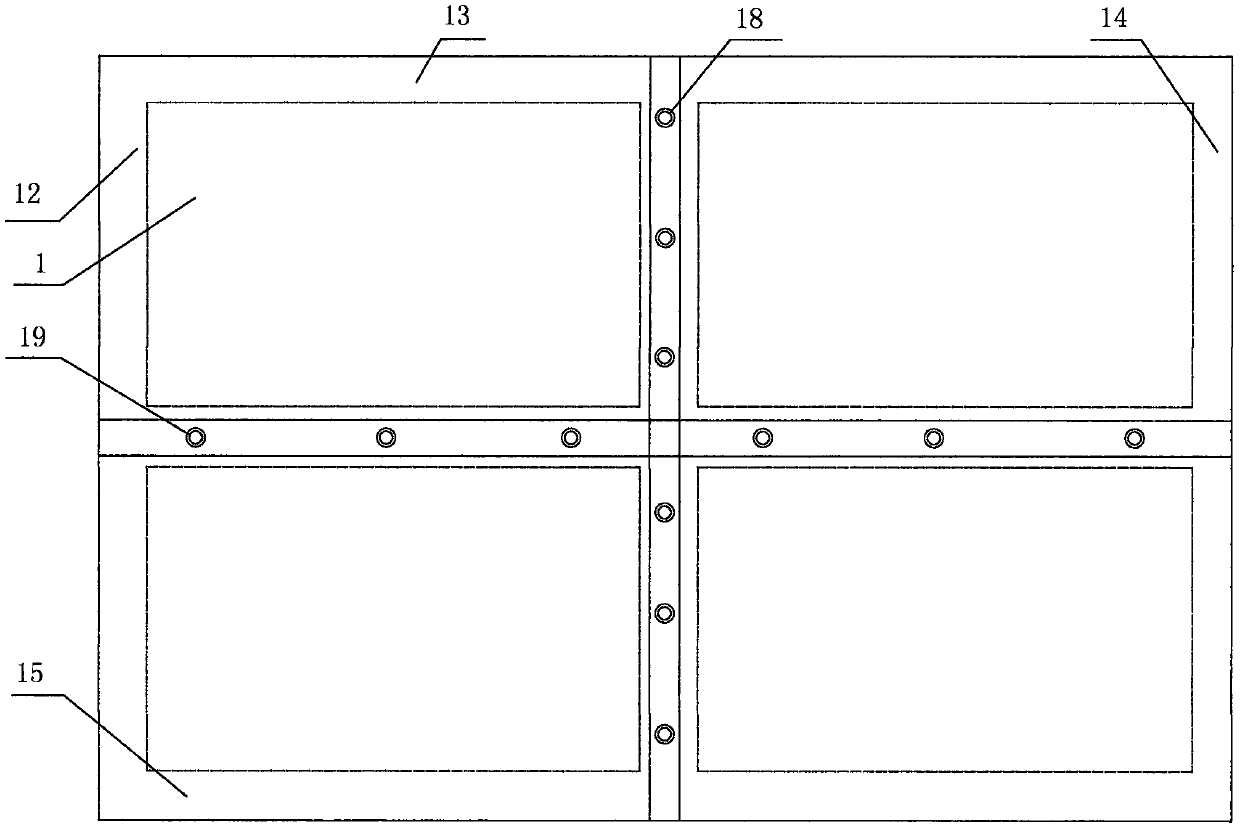

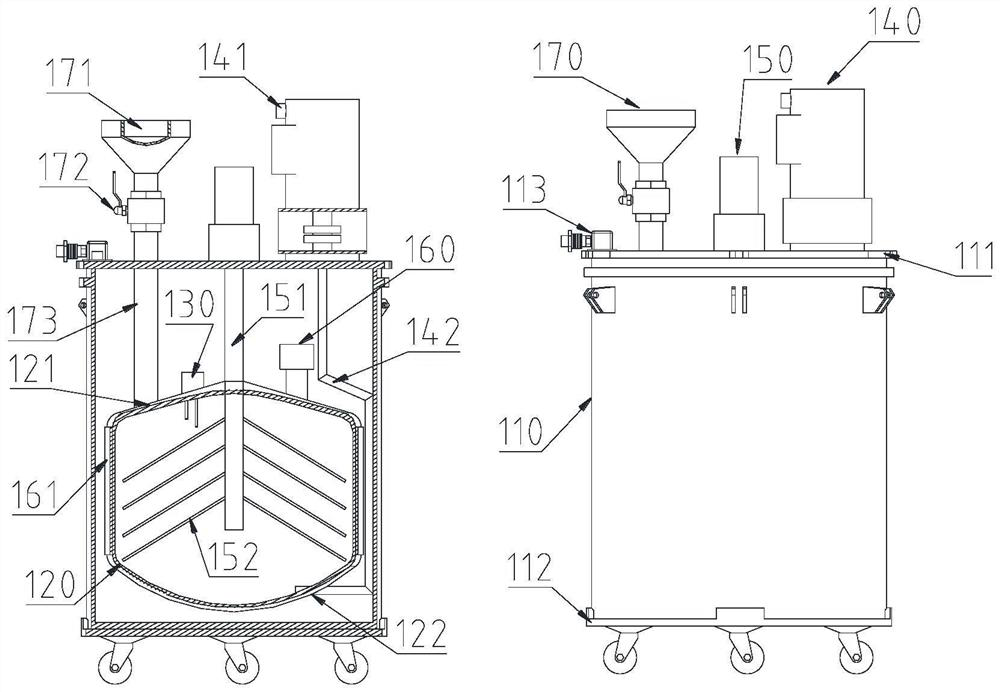

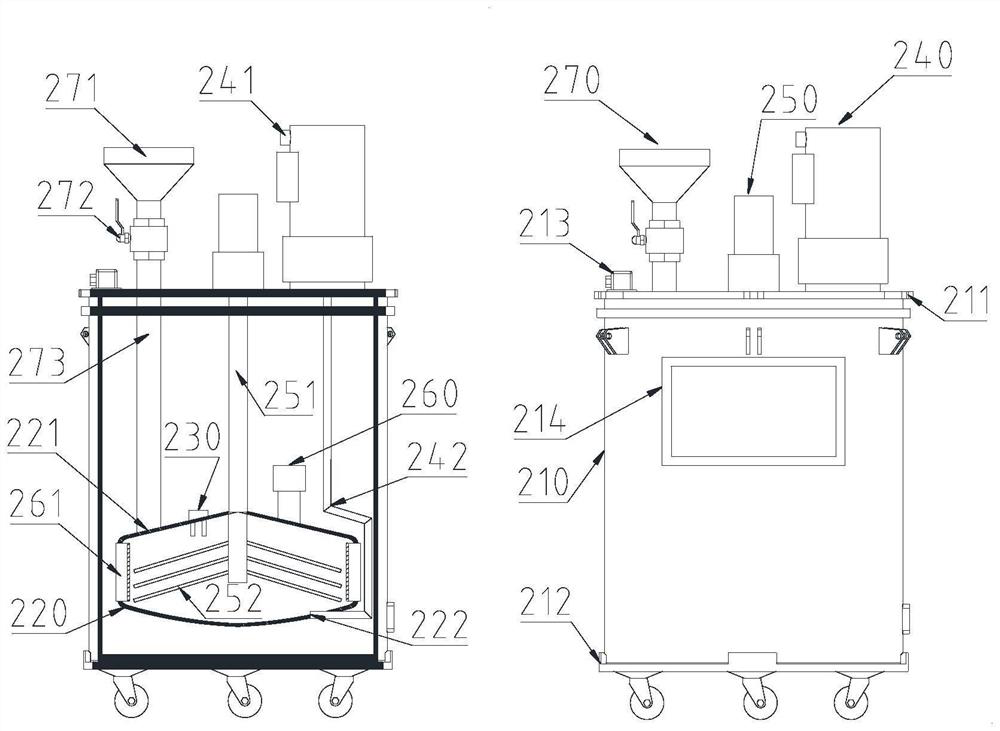

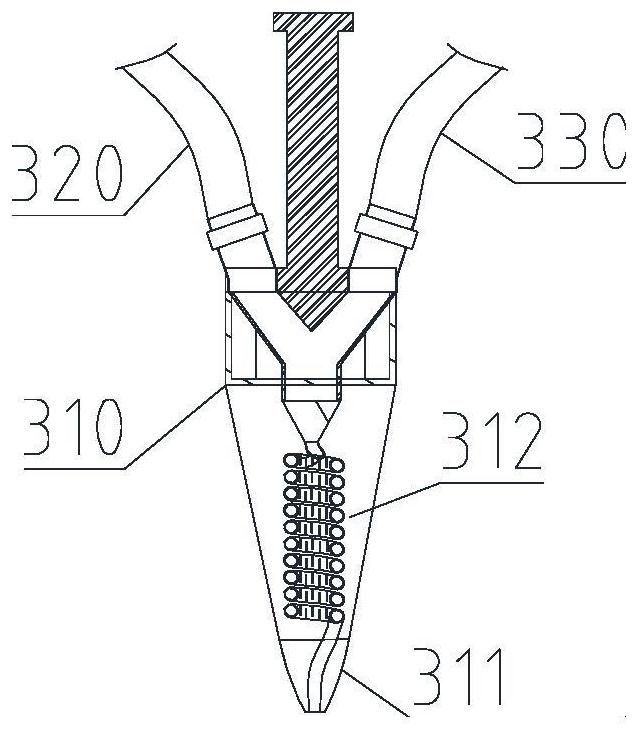

Modular vacuum casting machine

PendingCN114393761AOvercome the problem that the large volume cannot pass through the narrow area inside the hullReduce volumeEpoxyVacuum casting

The invention provides a modular vacuum casting machine. The modular vacuum casting machine comprises a main material module, an auxiliary material module and a casting module, the main material module is used for containing and pretreating epoxy resin; the auxiliary material module is used for containing and pretreating auxiliary materials; the pouring module is connected with the main material module and the auxiliary material module, and epoxy resin and auxiliary materials are instantly mixed in the pouring module. The modular vacuum casting machine has the characteristics that the size of each module is small, the modules can pass through narrow entrances and exits in a ship body, and the modules are convenient to connect and can be mixed instantly.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com