Plastic plate extrusion die

A technology for extruding molds and plastic sheets, applied in separation methods, transportation and packaging, separation of dispersed particles, etc., can solve the problems of uneven heating on the surface of plastic sheets, low heating efficiency and cooling efficiency, and poor sheet processing effects, and achieves installation. Easy and quick disassembly, improved heating efficiency, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

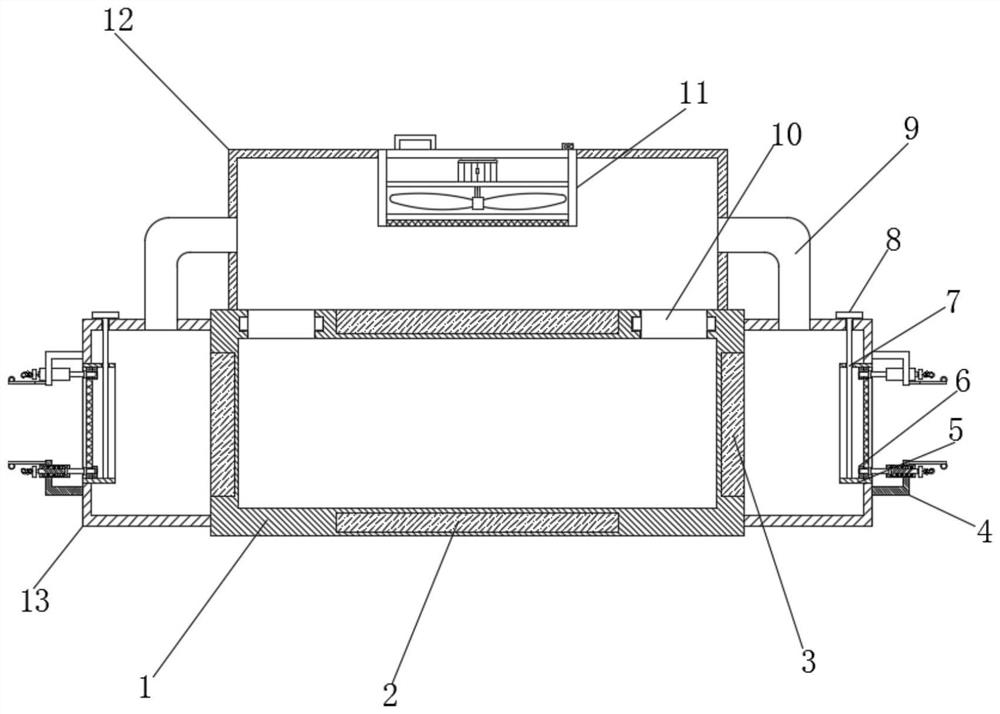

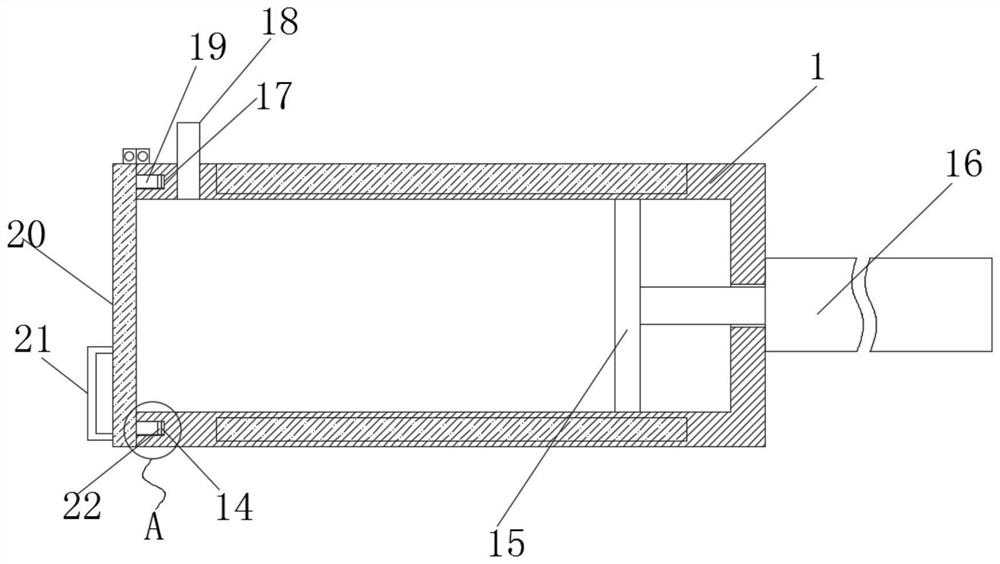

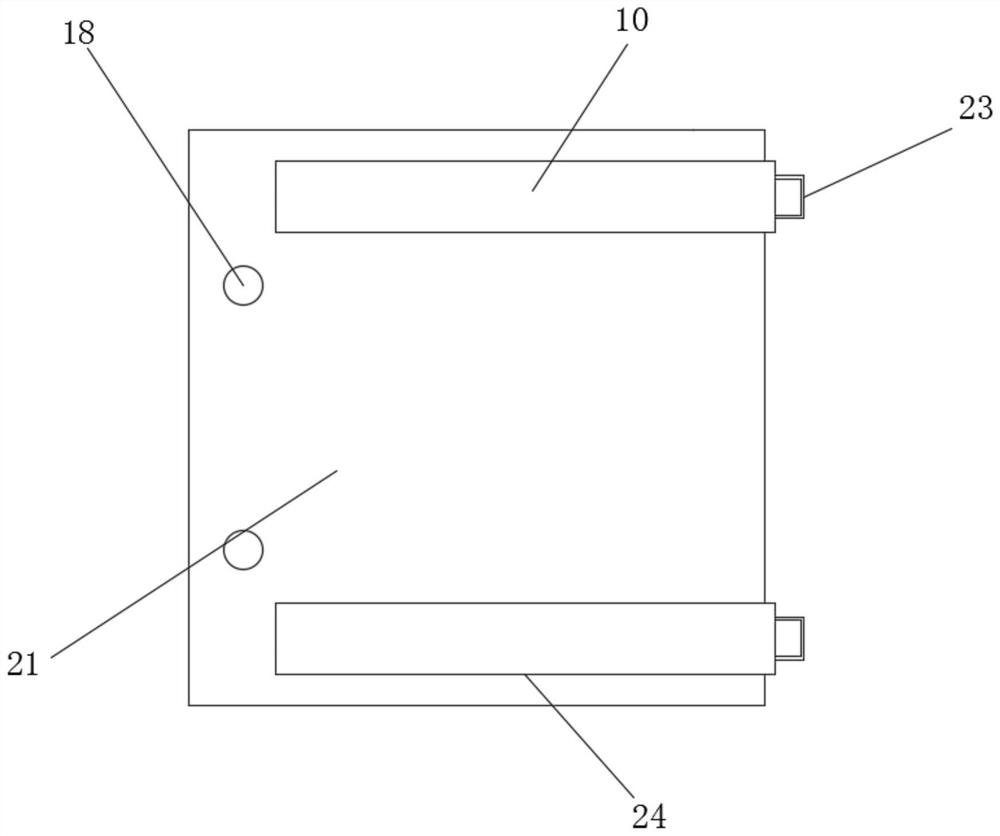

[0028] A plastic sheet extrusion die, comprising a die body 1, the upper and lower walls of the die body 1 are provided with a first heating plate 2, both side walls of the die body 1 are provided with a second heating plate 3, the second heating plate 3 The outer side of the mold body 1 is provided outside the mold body 1, the left side of the second heating plate 3 is provided with a second shell 13, the upper end of the mold body 1 is provided with a first shell 12, the first shell 12 and the second shell 13 The air pipes 9 communicate with each other. The upper surface of the mold body 1 is provided with two sets of chute 24. The inside of the chute 24 is provided with a sliding plate 10. The outer side of the sliding plate 10 is provided with a third pull handle 23. There is a pouring tube 18 , which is arranged outside the first housing 12 .

[0029] In this embodiment, in order to rapidly cool and improve its cooling efficiency, the upper end of the first casing 12 is p...

Embodiment 2

[0034] As an optional situation, a plastic sheet extrusion die, the interior of the first frame plate 5 is provided with a filter assembly 4;

[0035] The filter assembly 4 includes a fixing frame 410 fixed on the side wall of the second housing 13, a sleeve 48 is arranged inside the fixing frame 410, a movable column 43 is arranged inside the sleeve 48, and a spring 49 is arranged outside the movable column 43, The movable column 43 is provided with a pull plate 47 through the outer end of the sleeve 48, the other end of the movable column 43 is provided with a movable block 42, one end of the movable block 42 is provided with an insertion rod 41, and the outside of the insertion rod 41 is provided with a fixing hole 25, A limit block 6 is arranged outside the fixing hole 25 , the limit block 6 is fixed inside the first frame plate 5 , a filter screen 412 is arranged on the outside of the limit block 6 , and the insertion rod 41 penetrates through the sleeve 48 and the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com