Method for making double-axial hard polyvinyl chloride tubular material

A rigid polyvinyl chloride, biaxially oriented technology is applied in the field of manufacturing biaxially oriented rigid polyvinyl chloride pipes to achieve the effects of accurate size, good quality and high drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

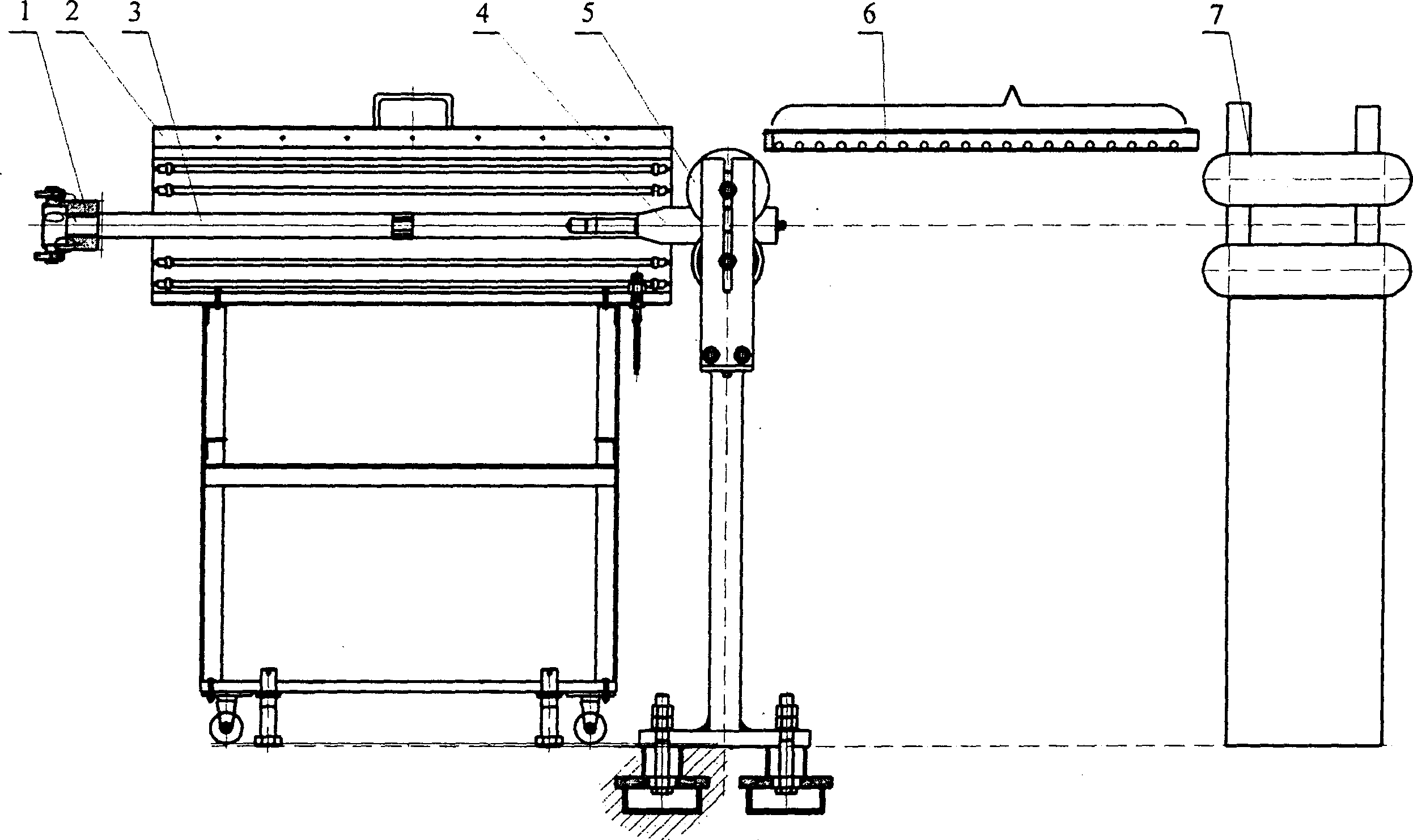

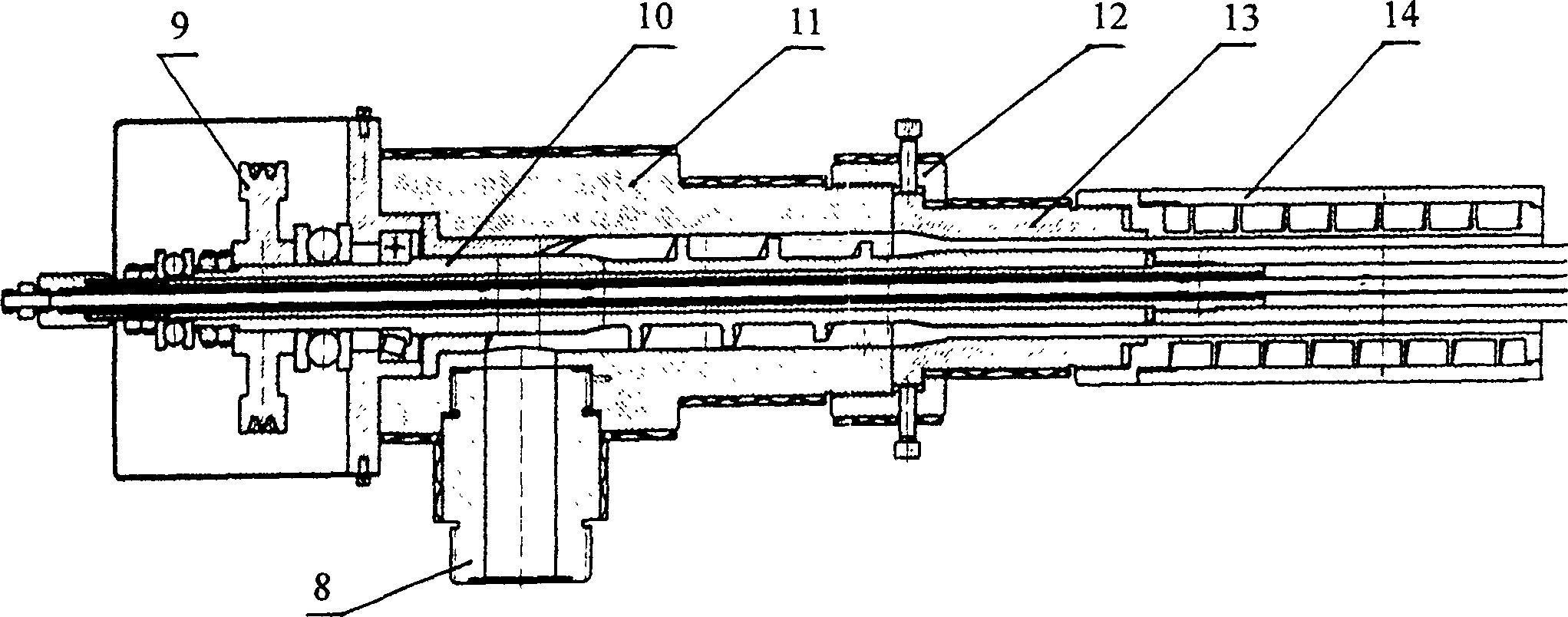

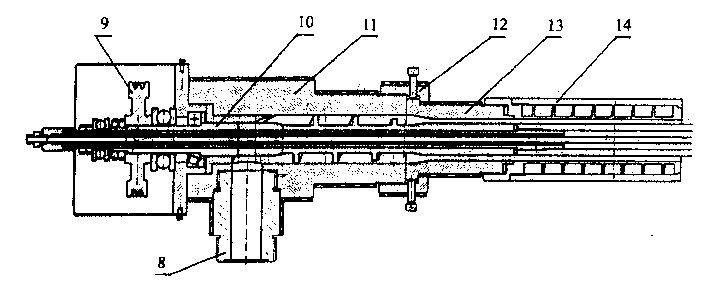

[0028] Add 100 kg of polyvinyl chloride, 3 kg of tribasic lead sulfate, 1.6 kg of acrylate, 0.8 kg of paraffin, 6 kg of light calcium carbonate and 0.3 kg of pigment, and put them into a high-speed mixer, and mix at a temperature of 110 ° C for 25 minutes, discharge, input into the cold mixer, cool to below 40℃ while mixing, discharge, sieve, remove agglomerates and sticky melts, and obtain rigid PVC powder. The above-mentioned mixture of rigid polyvinyl chloride is added to the gradient single-screw extruder for continuous molding, and the molding temperature is: the barrel temperature of the feeding section is 120 ° C, the temperature of the barrel of the melting section is 175 ° C, and the temperature of the barrel of the metering section is 165 ° C. Then, the tube blank is extruded through the die and subjected to the action of the traction device to achieve axial stretching orientation, and then enters the setting auxiliary machine, and then is heated by the heating box. ...

Embodiment 2

[0030] 100 kg of polyvinyl chloride, 3 kg of dibasic lead stearate, 1.5 kg of chlorinated polyethylene, 0.8 kg of polyethylene wax, 8 kg of heavy calcium carbonate and 0.3 kg of pigment were added into a high-speed mixer, and the mixture was heated to a temperature of 120°C, kneading for 25 minutes, discharging, inputting into a cold mixer, cooling to a temperature below 40°C while mixing, discharging, sieving, removing agglomerates and sticky melts to obtain rigid polyvinyl chloride powder. Then the mixture of the above-mentioned rigid polyvinyl chloride is added to the parallel and counter-rotating twin-screw extruder for continuous molding. ℃, then the tube blank is extruded through the die and subjected to the action of the traction device to realize the axial stretching orientation, and then enters the setting auxiliary machine, and then is heated by the infrared rays of the heating box. Radial expansion, and then through conventional treatments such as pressing rollers, ...

Embodiment 3

[0032] 100 kg of polyvinyl chloride, 0.5 kg of lead stearate, 2.5 kg of acrylic acid-butadiene-styrene copolymer, 3 kg of organic tin, 8 kg of talc and 0.3 kg of pigment were added into a high-speed mixer, and the mixture was heated to 100 ~120℃, knead for 30 minutes, discharge, input into cold mixer, cool to below 40℃ while mixing, discharge, sieve, remove agglomerates and sticky melts to obtain rigid polyvinyl chloride powder. Then, the mixture of the above-mentioned rigid polyvinyl chloride is added to the conical counter-rotating twin-screw extruder for continuous molding. 175℃, then the tube blank is extruded through the die and subjected to the action of the traction device to achieve axial stretching orientation, and then enters the setting auxiliary machine, and then is heated by the infrared rays of the heating box. The radial expansion is realized, and then the biaxially oriented rigid PVC pipe products are obtained by conventional treatments such as pressing roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com