Patents

Literature

70results about How to "Improve stretching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making double-axial hard polyvinyl chloride tubular material

The production method of biaxial oriented hard polyvinyl chloride pipe material includes: using 100 portions of polyvinyl chloride, 2-6 portions of stabilizing agent, 1-12 portions of toughening agent, 0.1-1.5 portions of lubricating agent, 5-15 portions of filling material and proper quantity of colouring matter and adding them into a high-speed mixing machine, mixing them at 100-120 deg.C for 20-40 min., discharging, sieving, removing block and viscous melt material to obtain hard polyvinyl chloride premixed powder material, adding said mixture material into extrude single screw or extruder twin screw to make continuous forming at 100-180 deg.C, then making the obtained material undergo the processes of extruding pipe blank, stretching orientation, heating to 100-120 deg.C to implement radial expansion, forming, cooling, drawing and cutting.

Owner:SICHUAN UNIV +1

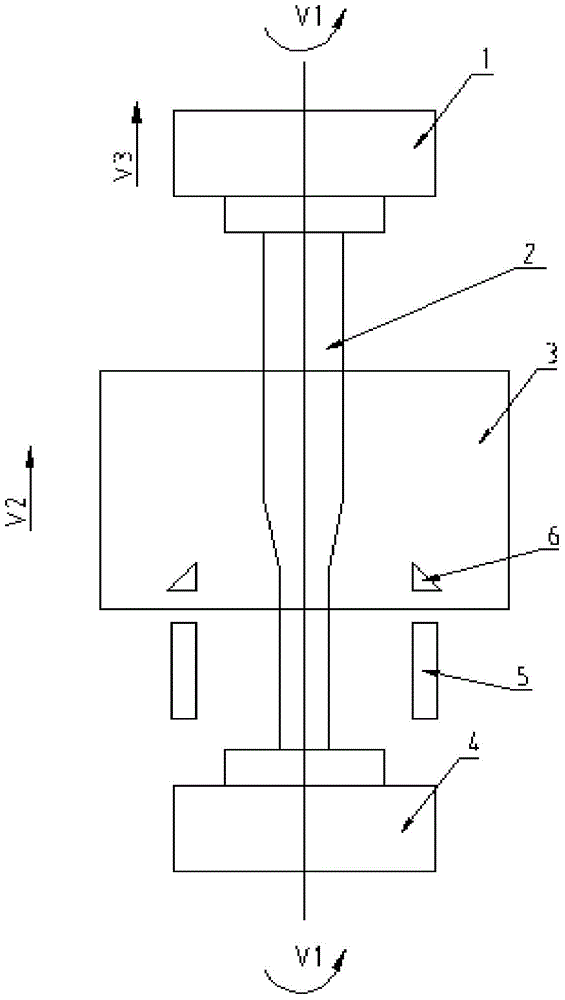

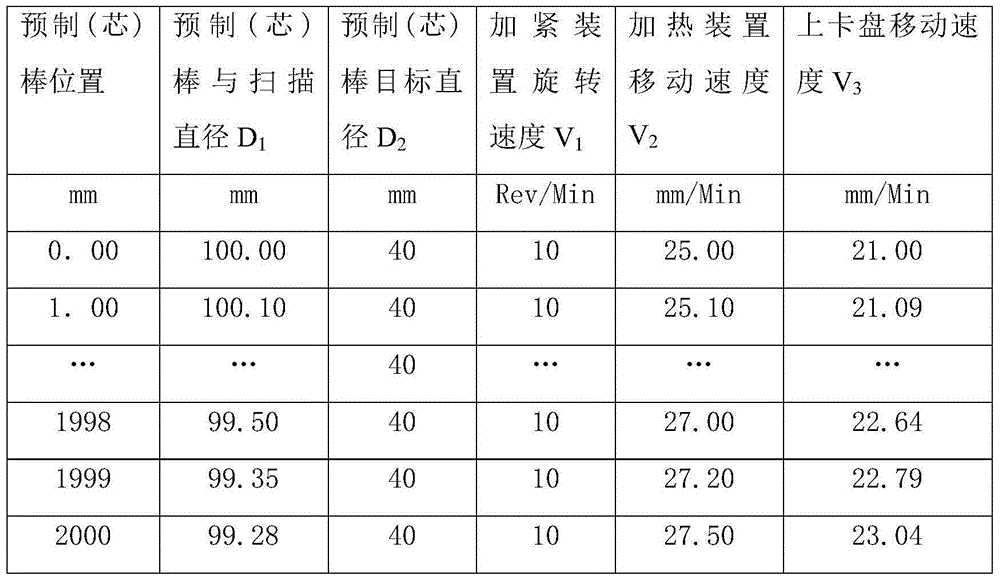

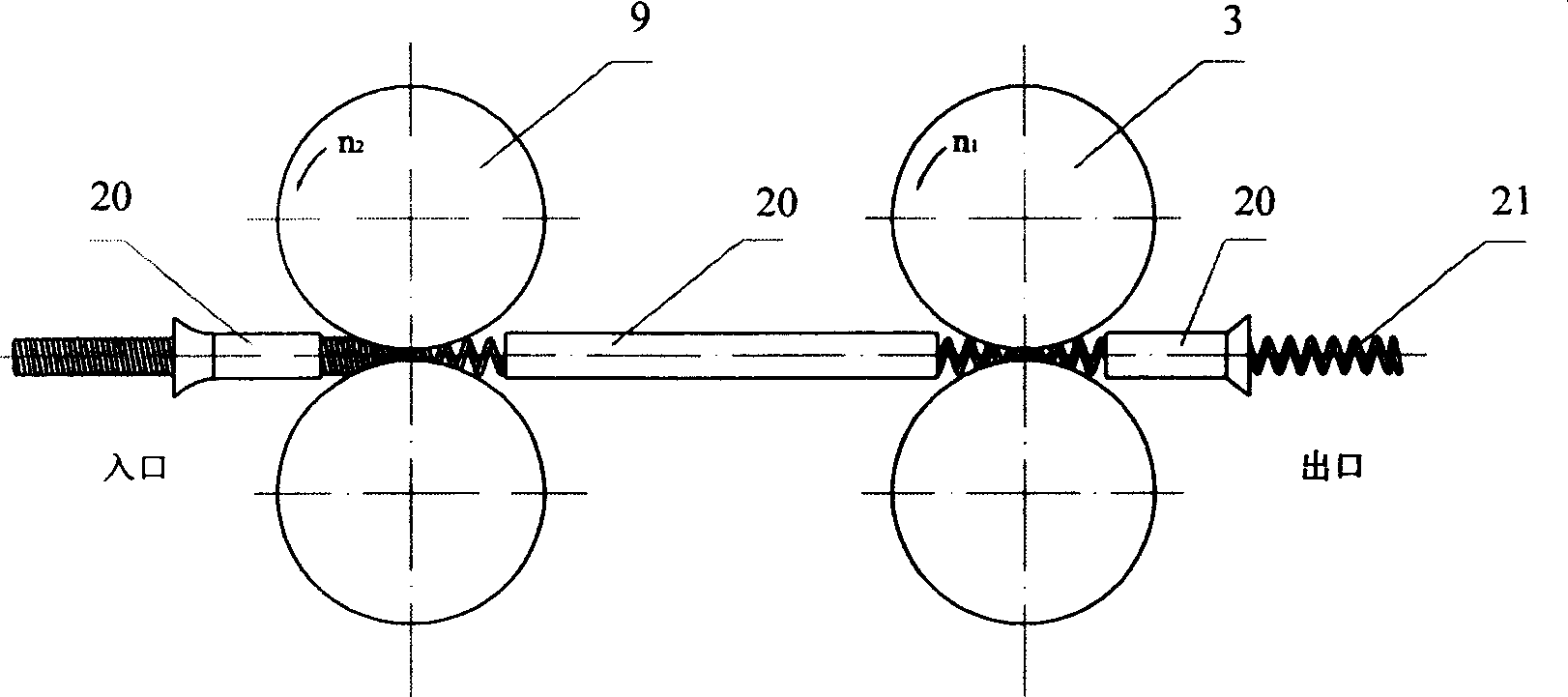

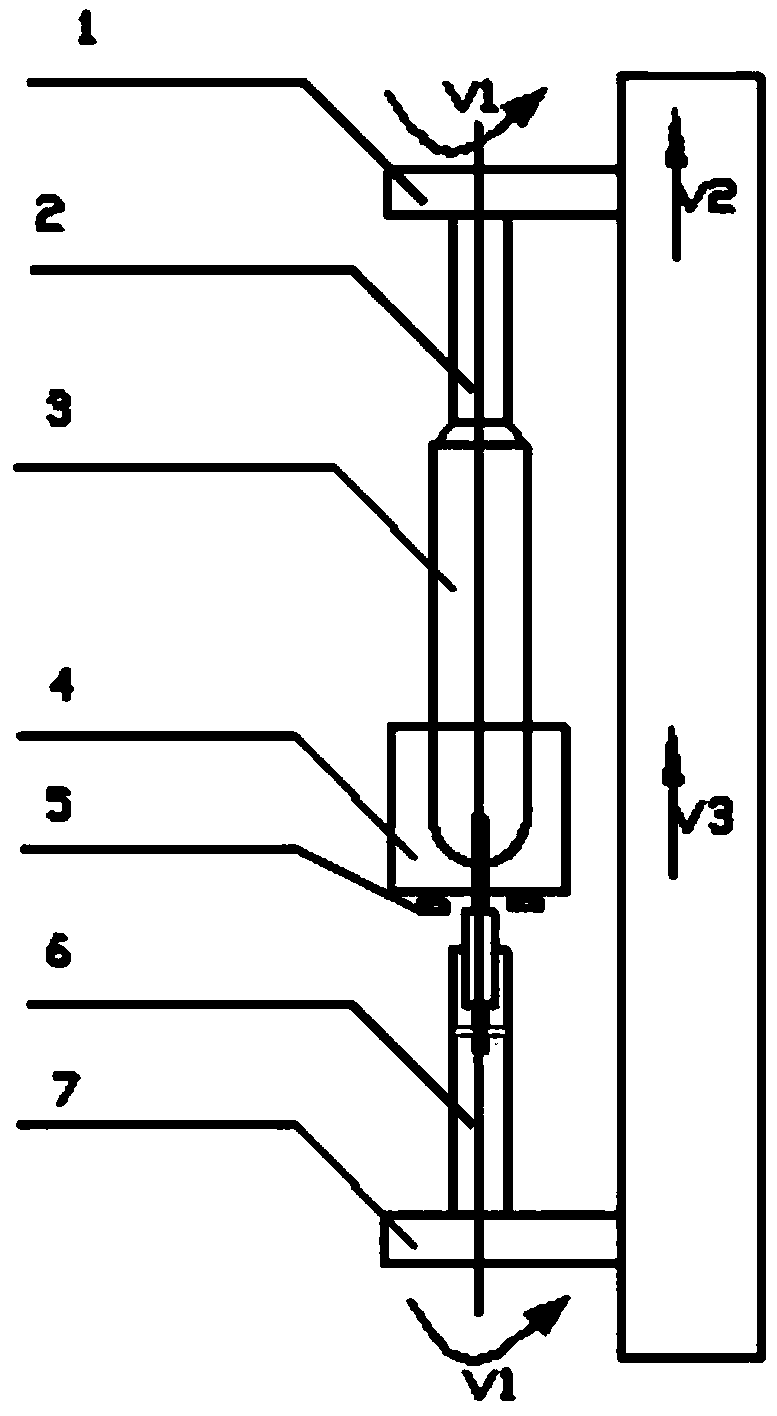

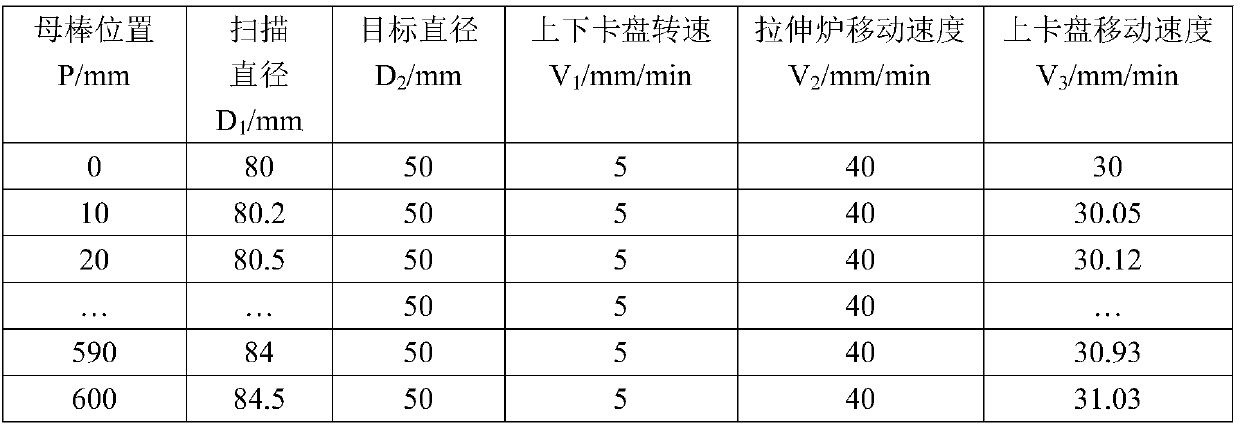

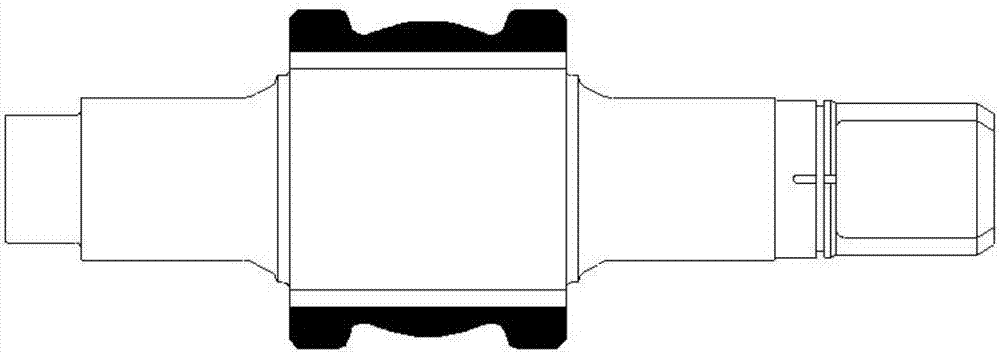

Perpendicular stretching method and equipment for optical fiber perform

ActiveCN105217951AAvoid large hysteresisReduce the impactGlass making apparatusMolten stateEngineering

The invention discloses a perpendicular stretching method and equipment for an optical fiber perform. The method comprises the steps that a large-diameter optical fiber perform is clamped, pretreatment starts to be performed on the optical fiber perform, and key parameter values in the stretching process are obtained in advance; then, an upper clamping device and a lower clamping device are controlled to synchronously rotate, the large-diameter optical fiber perform is heated to a semi-molten state through a heating device, an upward moving velocity V<3> is applied to the large-diameter optical fiber perform in the perpendicular direction through the upper clamping device, meanwhile, the heating device moves at an upward velocity V<2>, and the outer diameters obtained before and after stretching meet the relation V<3>*the square of D<1>=V<2>*(the square of D<1>-the square of D<2>). By means of the perpendicular stretching method and equipment for the optical fiber perform, the hysteretic nature in a common real-time feedback adjusting mode can be effectively avoided, the influence of the geometric dimension of the large-diameter optical fiber perform on a stretching result can be reduced to the maximum degree, the stretching control precision is improved, and the machining efficiency is further improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

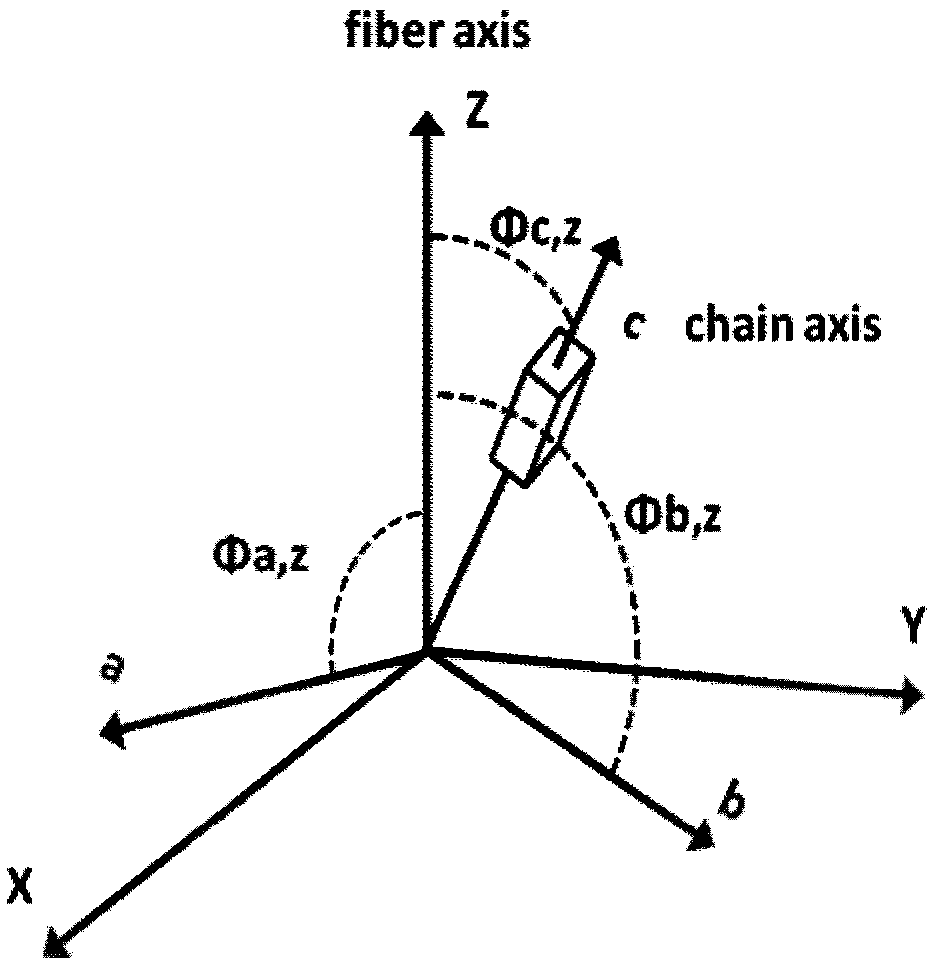

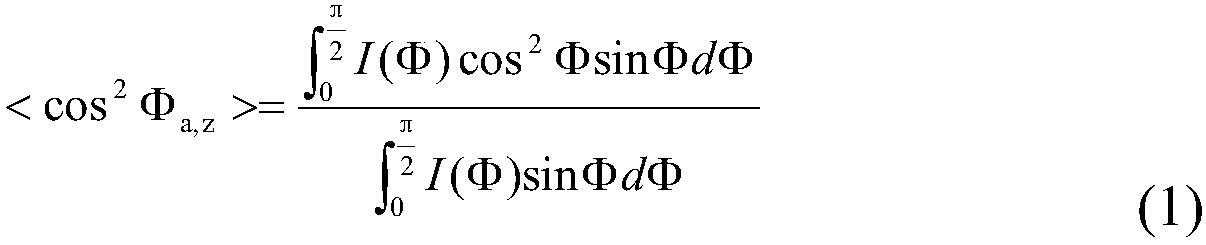

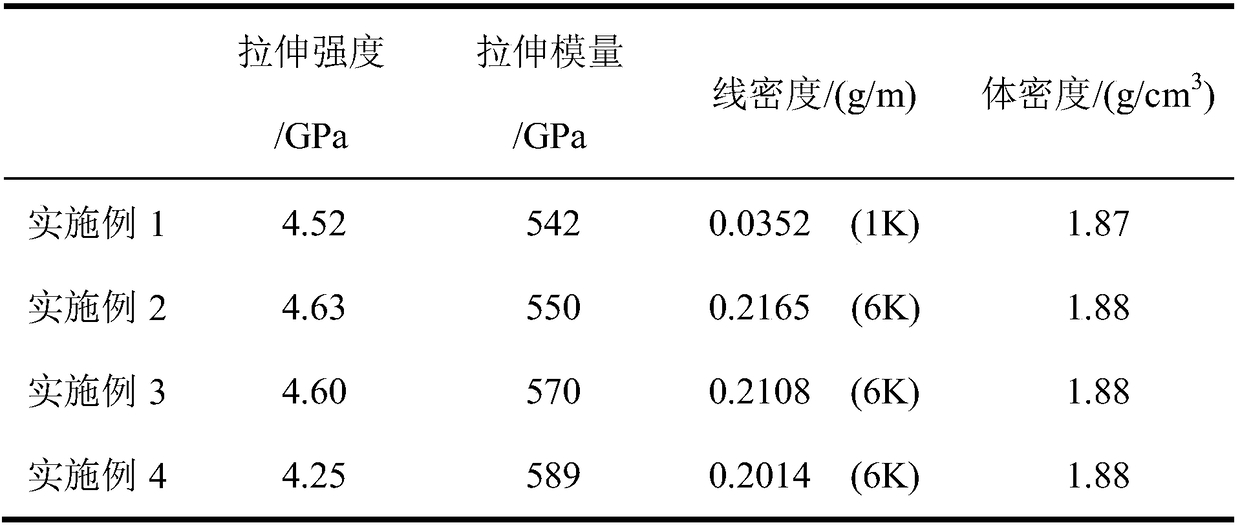

Preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers

ActiveCN108286090AImprove stretching efficiencyLow processing temperatureFibre chemical featuresCarbonizationPolyacrylonitrile

The invention relates to a preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers. After polyacrylonitrile (PAN) precursors are subjected to conventional pre-oxidationand low-temperature carbonization, the carbon crystalline orientation can be effectively controlled by increasing the high-temperature carbonization temperature and matching a certain stretching, or increasing the high-temperature carbonization stretching ratio to obtain high-temperature carbonized fibers with an orientation angle of being not greater than 17.5 degrees, and high-temperature graphitization hot drawing treatment is conducted at a relatively low temperature to obtain the high-strength high-modulus carbon fibers with tensile strength of 3.8-5.0 GPa and tensile modulus of 500-600 GPa. The preparation method reduces the requirements on equipment for high-temperature graphitization, which is beneficial to energy saving and cost reduction, and the operation is simple and easy.

Owner:BEIJING UNIV OF CHEM TECH

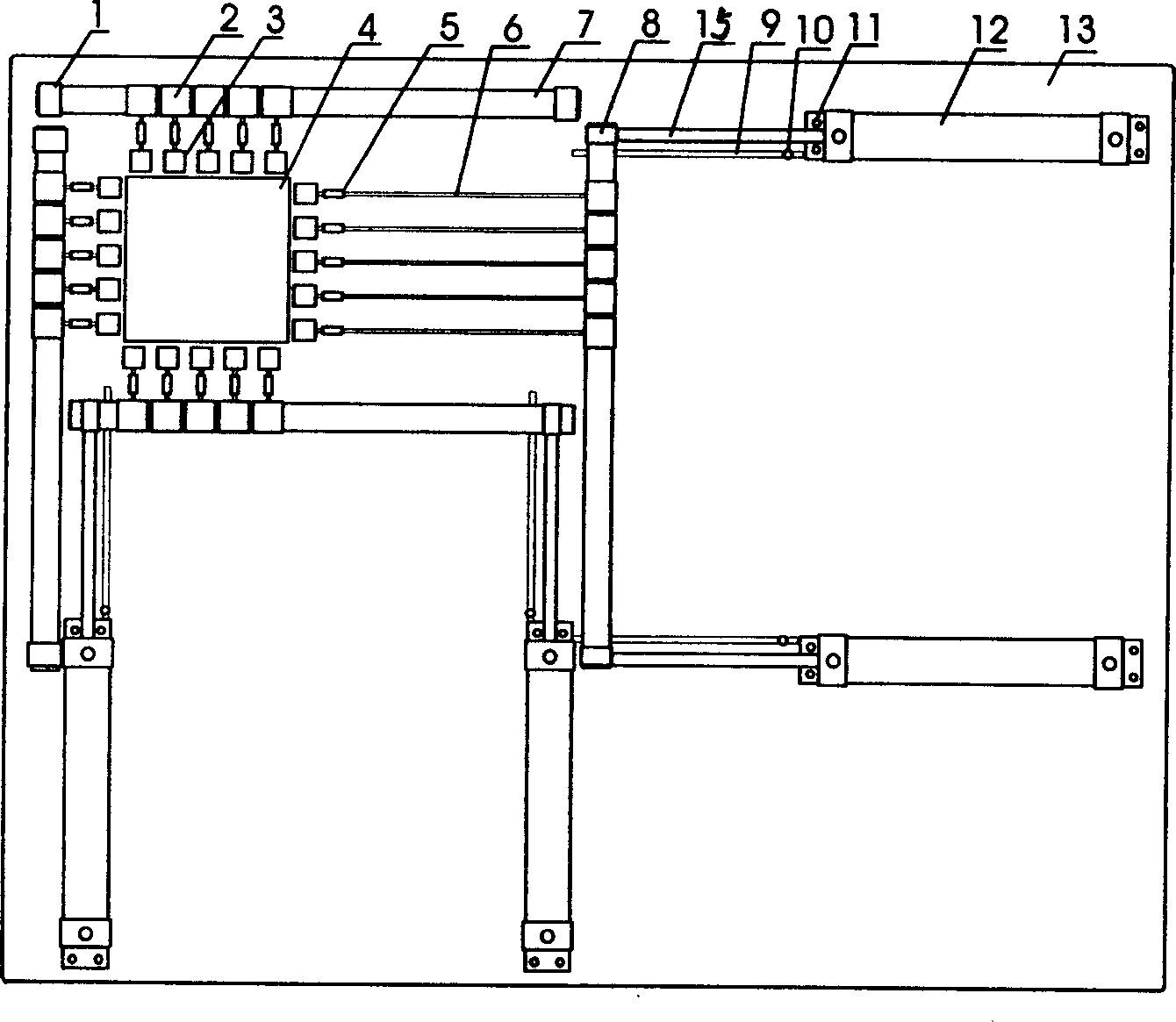

Stretching device for flexible flat plate

A stretching apparatus for flexible flat board is composed of a bottom plate, 4 guide tracks arranged on said bottom plate in rectangular mode, and cylinders. The adjacent two guide tracks are fixed onto bottom plate. One of another two guide tracks equipped with cylinders is linked to the flexible flat board clampers via slide block, connecting rod and length regulator. The final guide track is linked to the flexible flat board clampers via slide block and length regulator.

Owner:潘建强

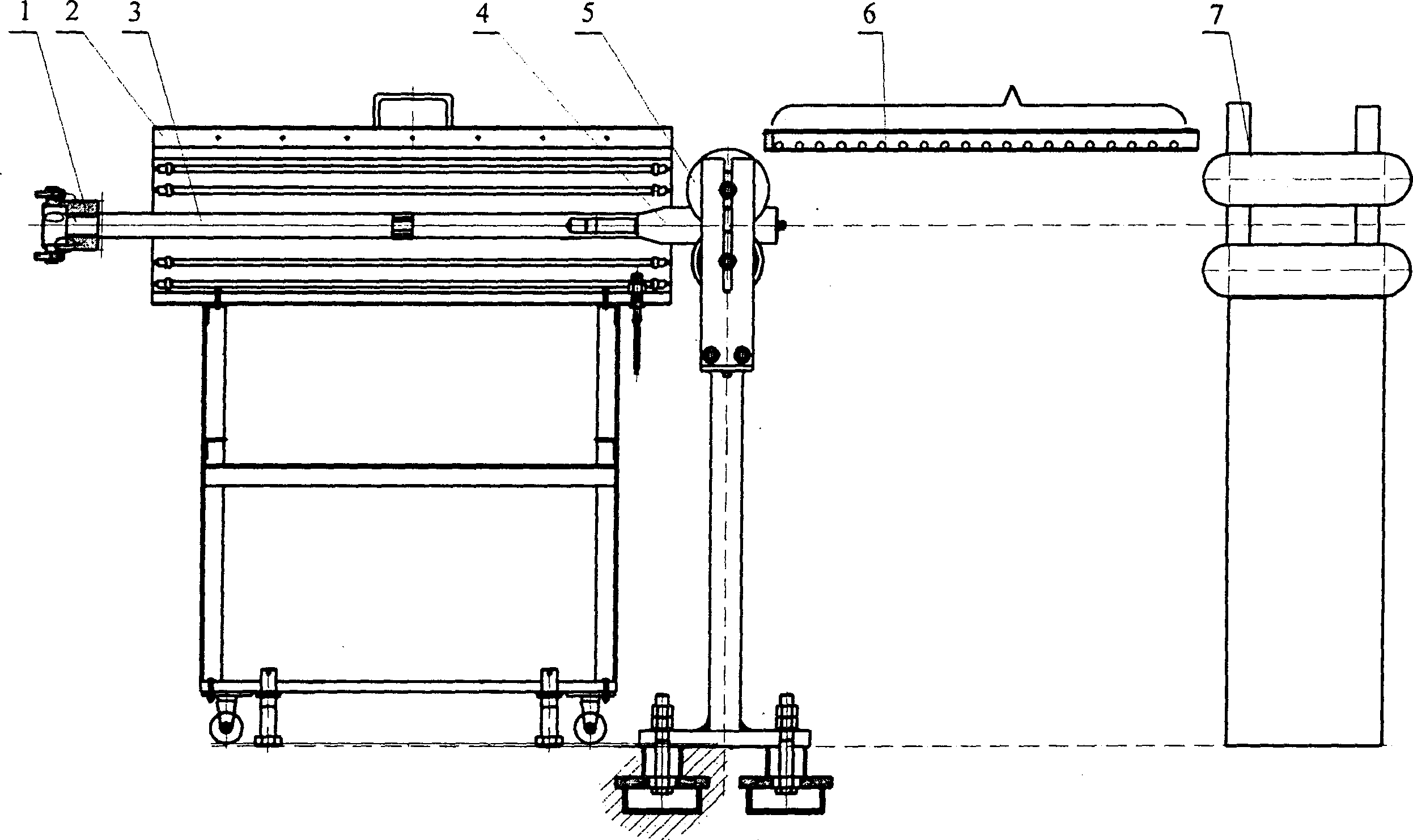

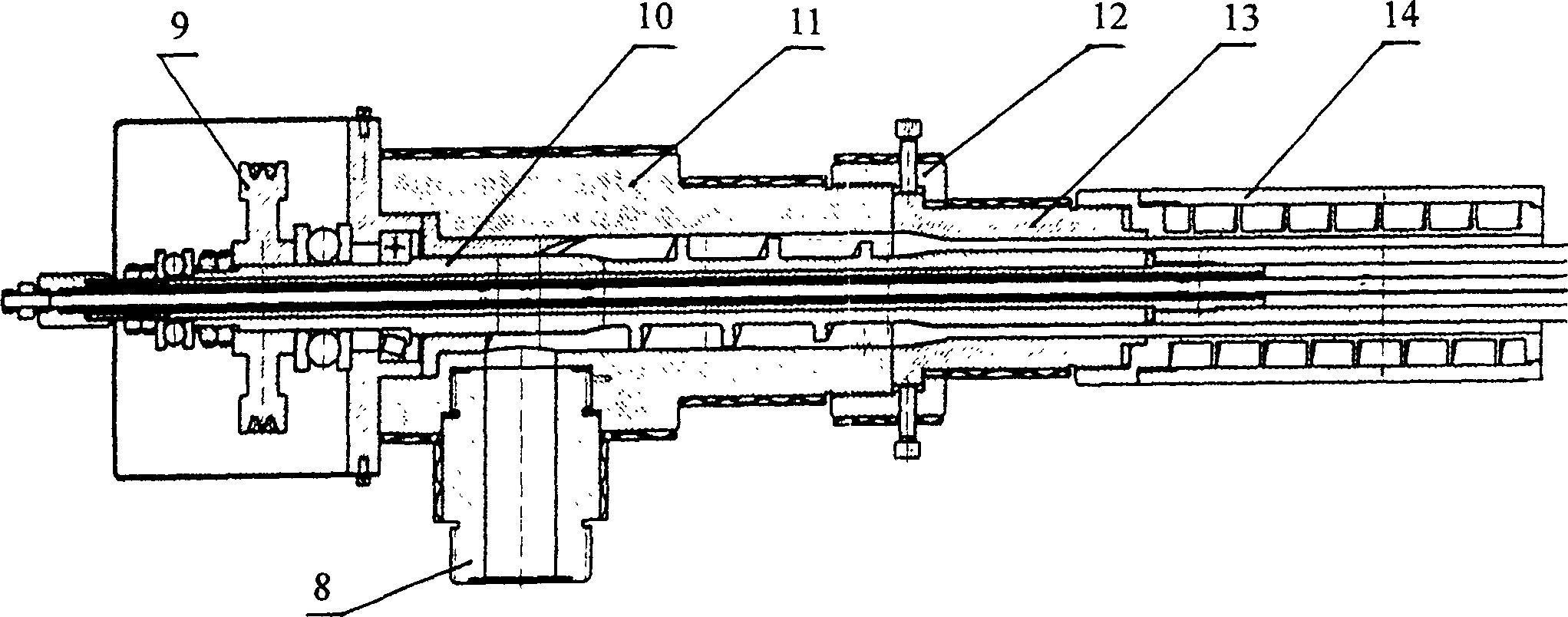

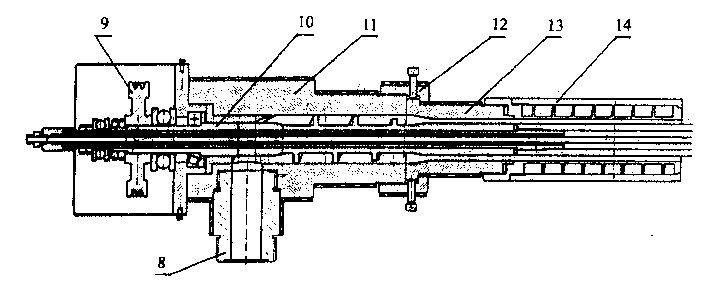

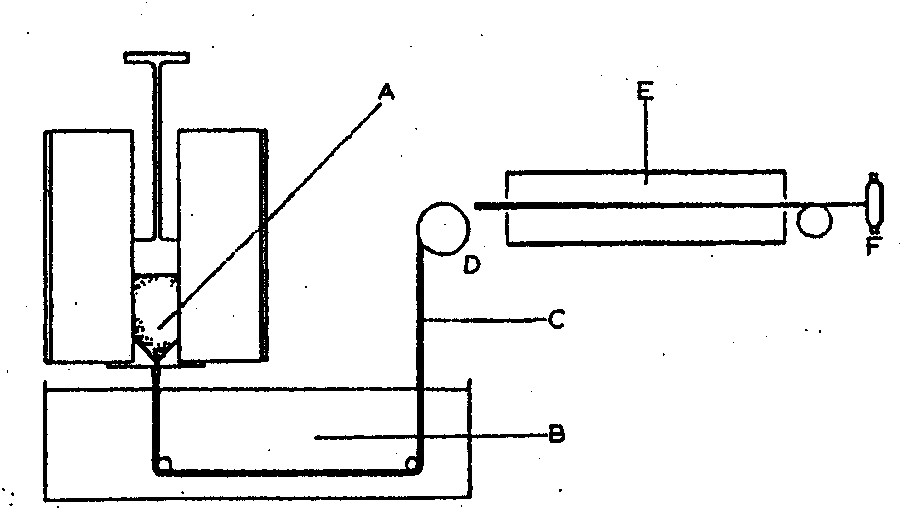

Screw roll fixed pitch stretching device

The screw roll fixed-pitch stretching equipment consists of motor, high-speed belt drive stage, low-speed belt wrive stage, driving rubber roller, differential rubber roller, driving conic roller, driven conic roller, speed-regulating screw, shaft and bearings. The motor drives the small belt pulley of high-speed belt drive stage; the driving conic roller, the large belt pulley of high-speed belt drive stage and the driving rubber roller are on the drive shaft; the driven conic roller and the small belt pulley of low-speed belt drive stage are on the middle shaft; the large belt pulley of low-speed belt drive stage and the differential rubber roller are on the driven shaft; there is speed regulating screw with control handle installed between the driving conic roller and the driven conic roller; and the bearings are mounted on the box.

Owner:HARBIN INST OF TECH

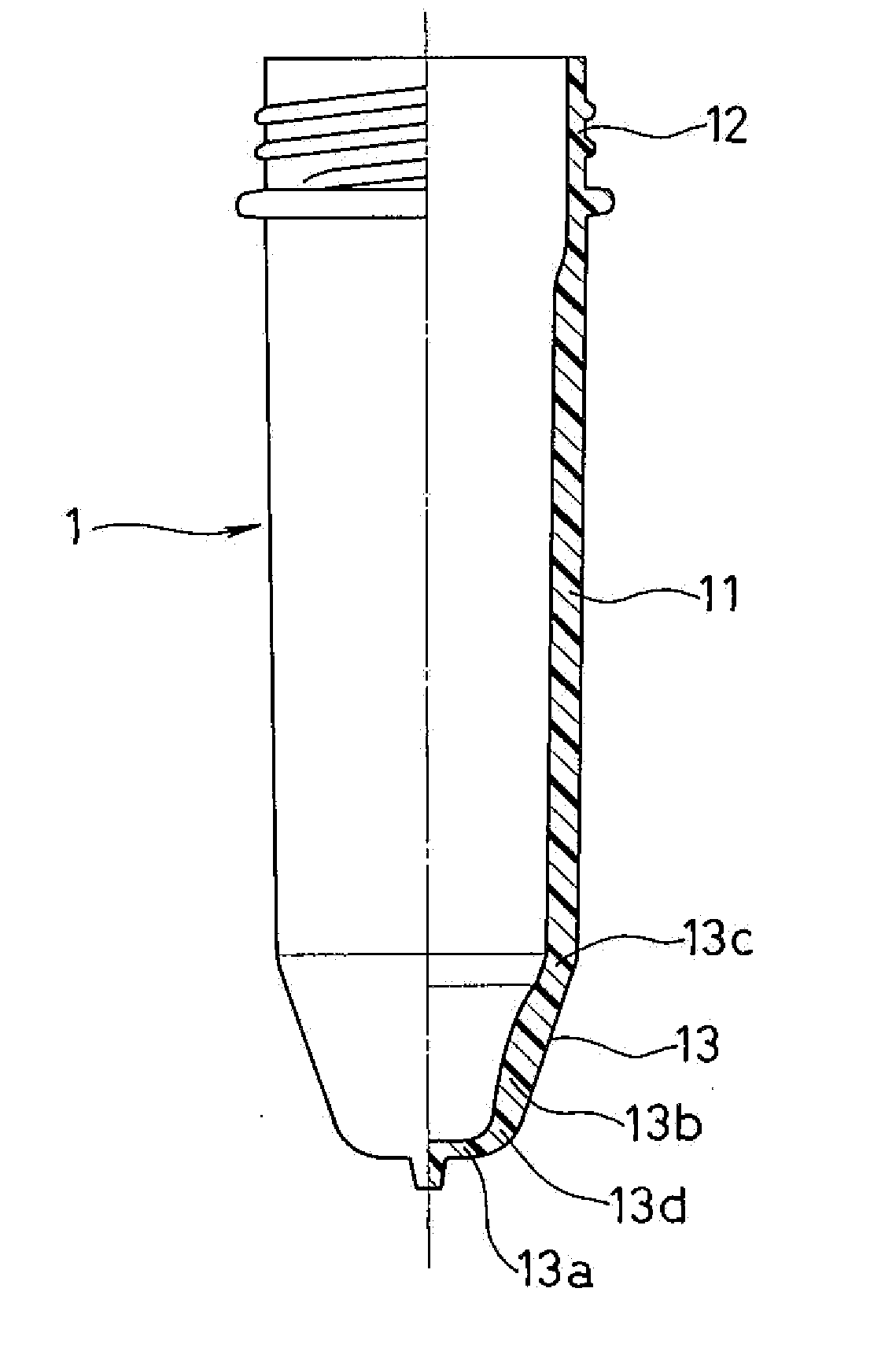

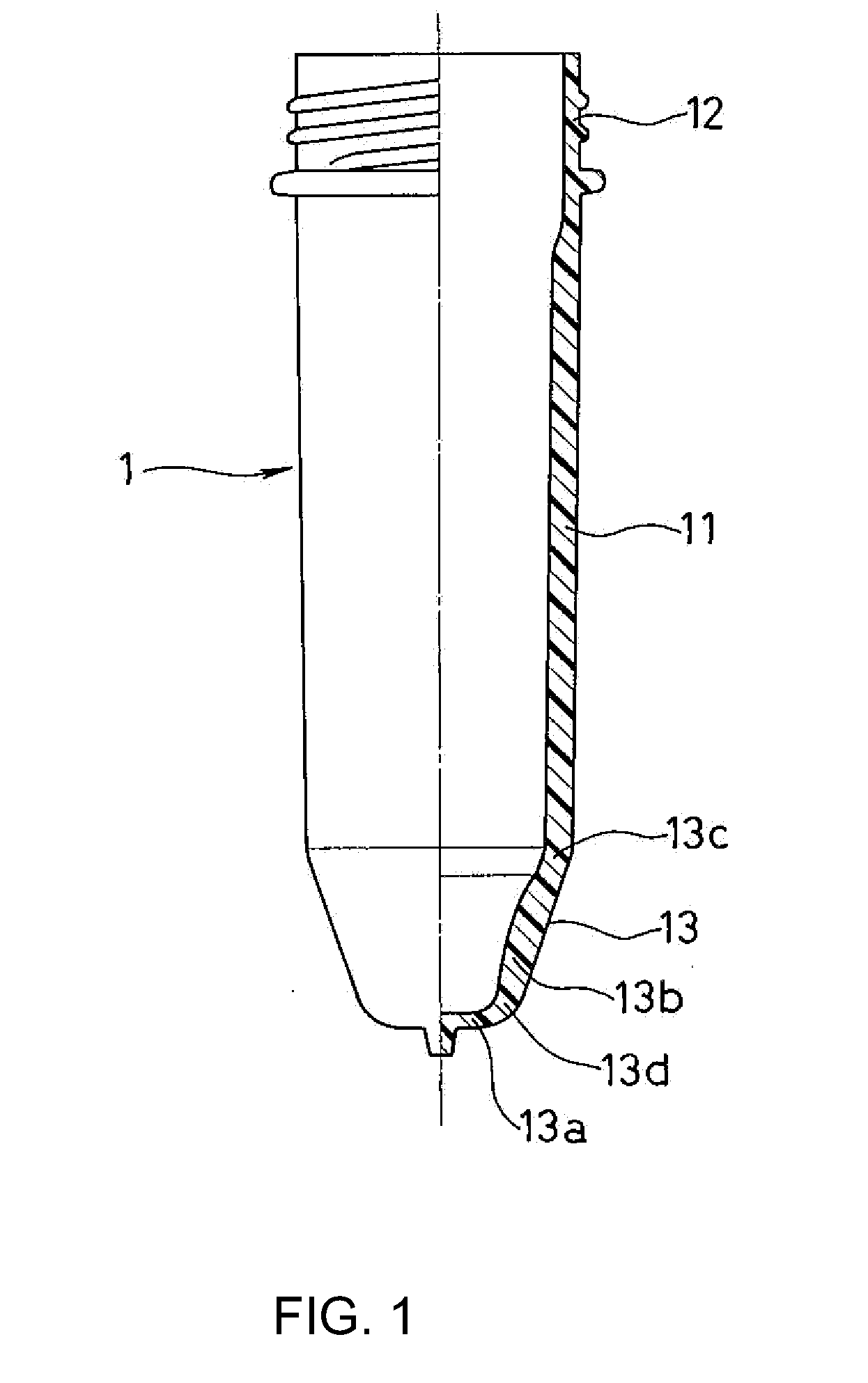

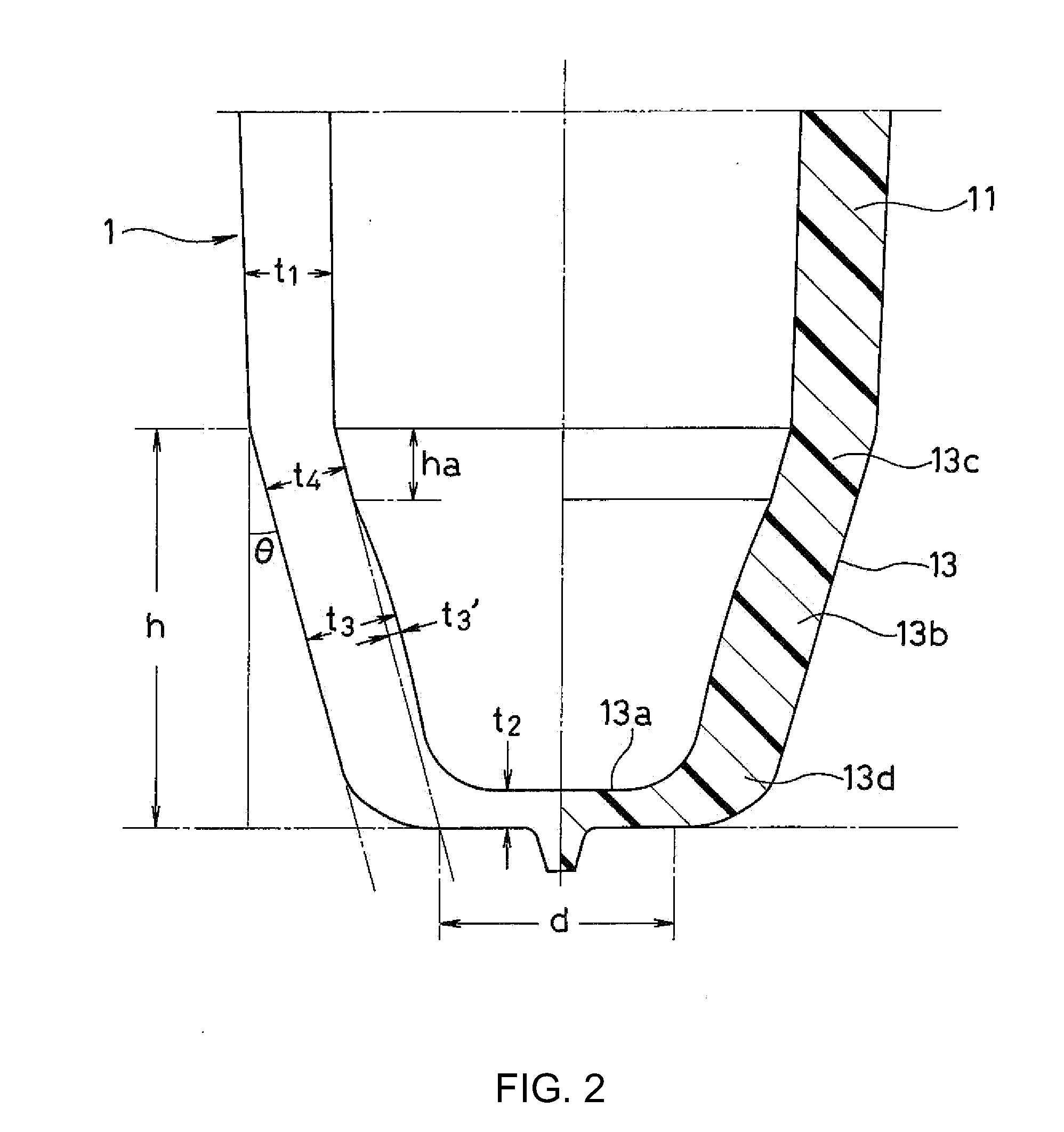

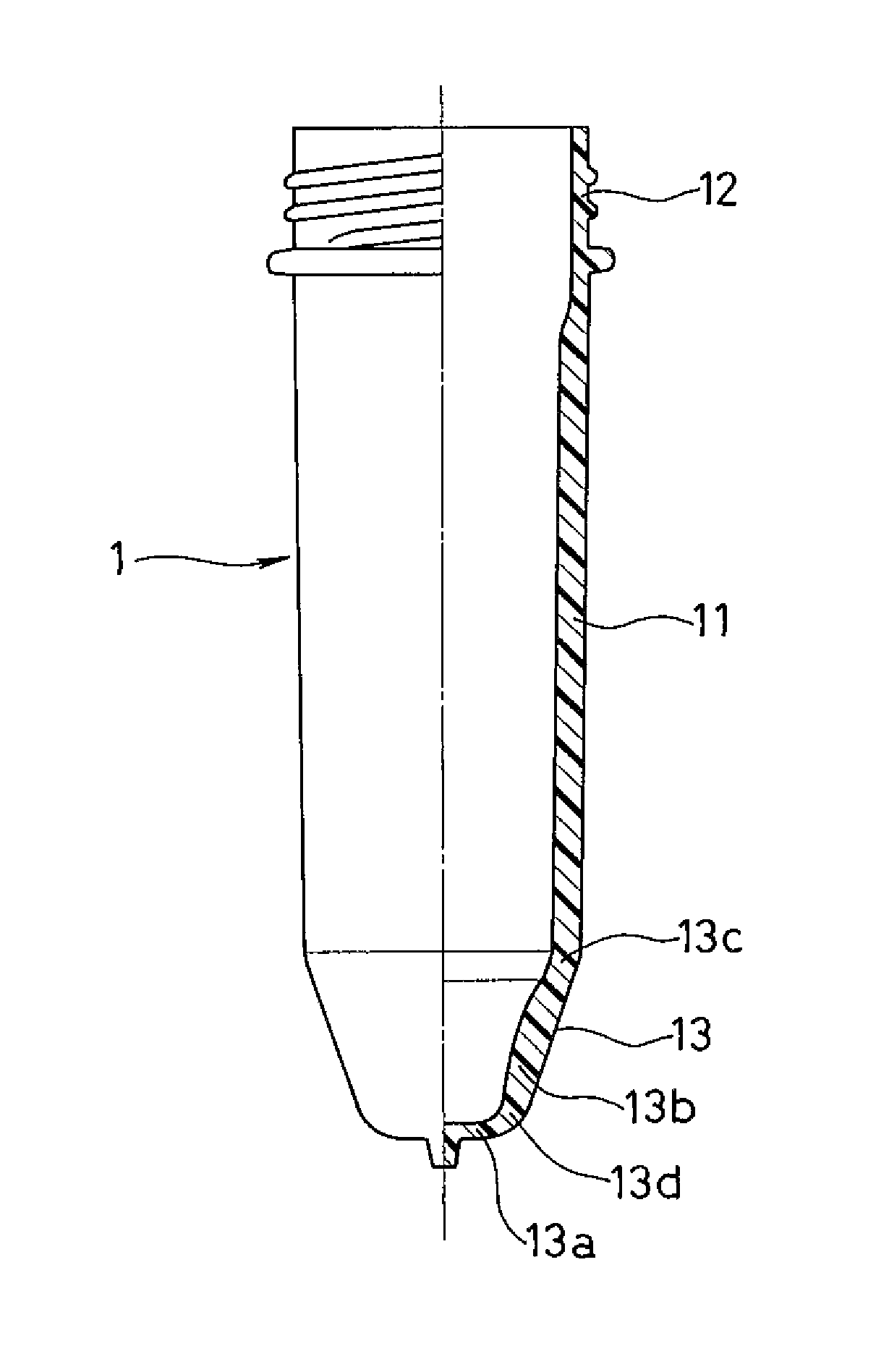

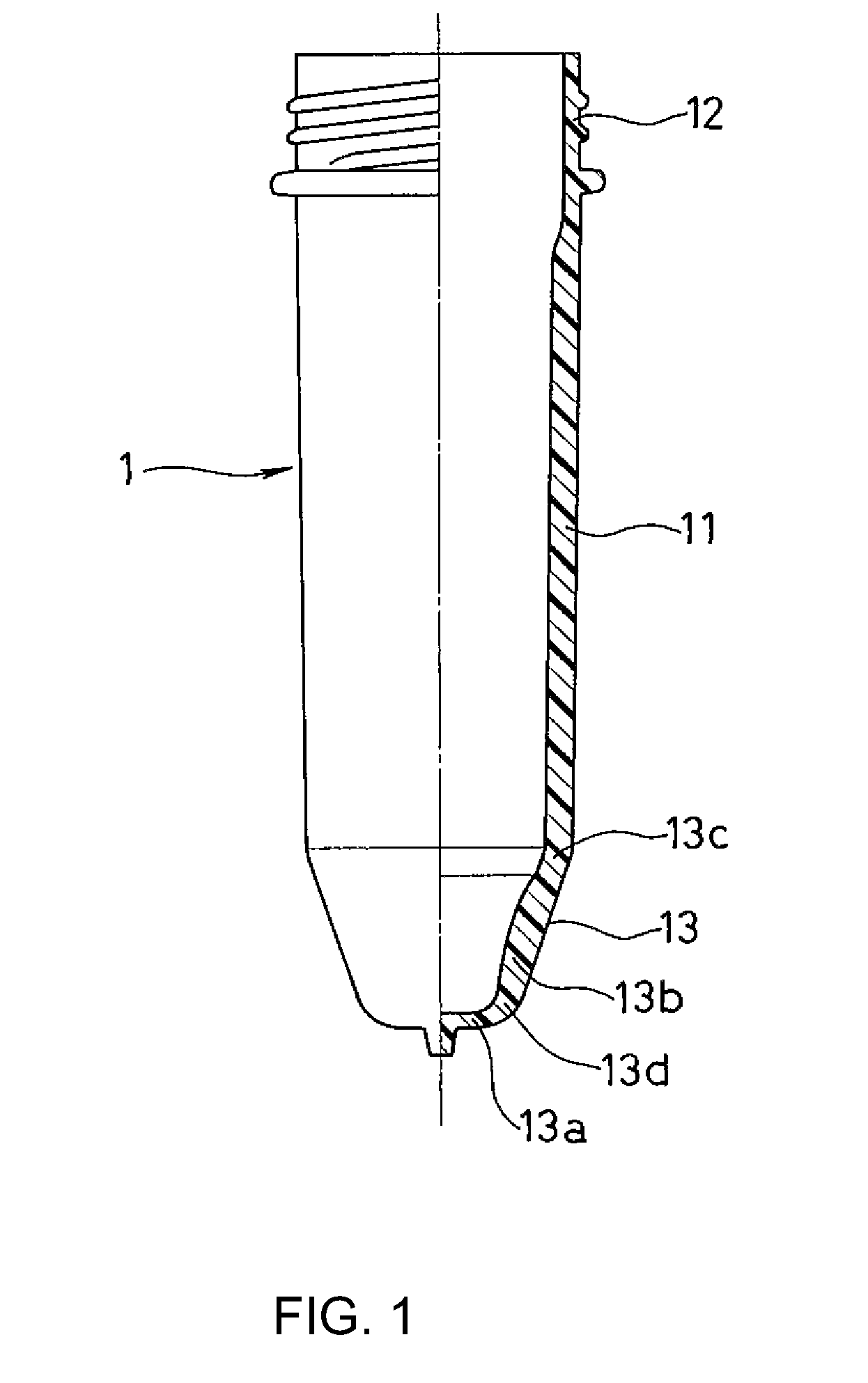

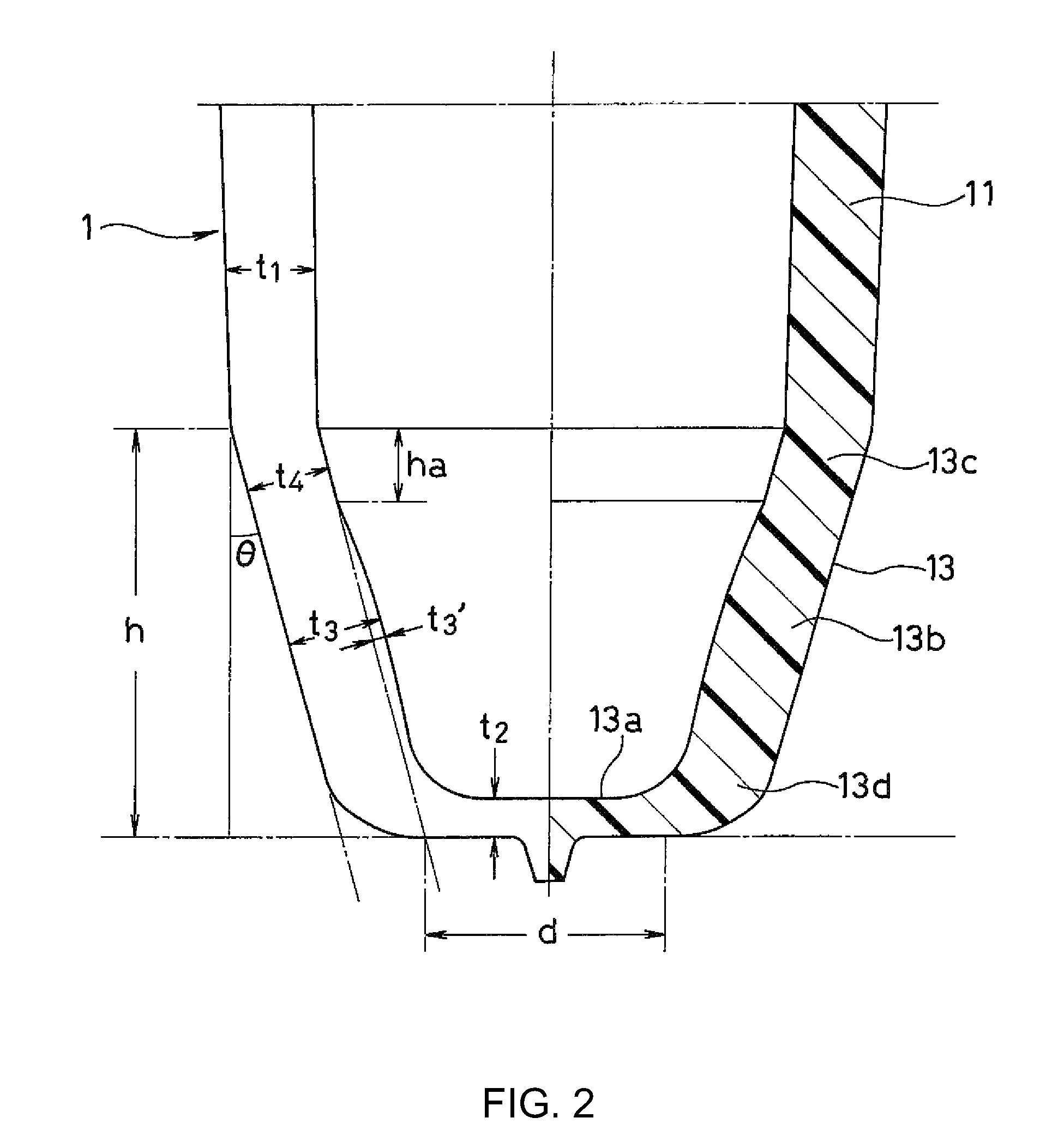

Preform for stretch blow-molded bottle

ActiveUS20100323136A1Increasing the thicknessReduce weightSynthetic resin layered productsDomestic articlesEngineeringBottle

A preform having an inverted truncated conical bottom section is used. The inclined inner surface of a bottle bottom surface-forming portion of the bottom section is formed into a gently curved convex surface that extends from the lower portion of a bottle bottom edge-forming portion of the bottom section to a curved portion in the lower portion of the bottom section so that the thickness of the bottle bottom surface-forming portion is greater than the thickness of the barrel section of the preform and the thickness of the bottle bottom edge-forming portion. The increase in thickness of the bottom section improves the efficiency of stretching the bottom section, and the circumferential wall of the bottom section can thereby be efficiently stretched. This allows a reduction in weight (thickness) of the bottom surface section of a stretch blow molded bottle, and a reduction in weight of the bottle is thereby achieved.

Owner:A K TECH LAB INC

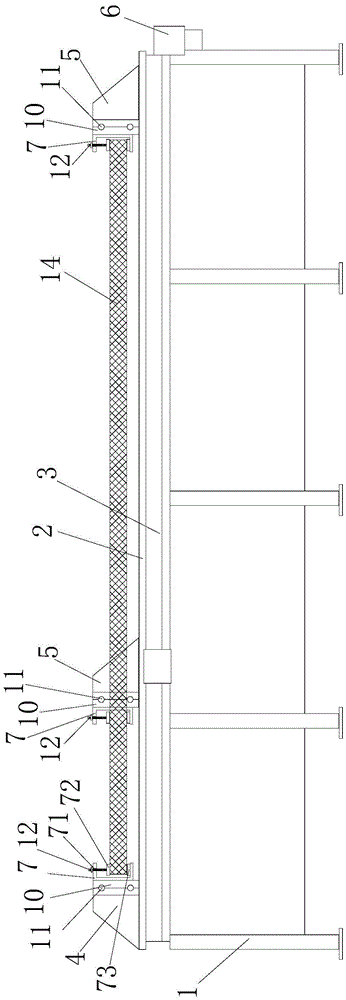

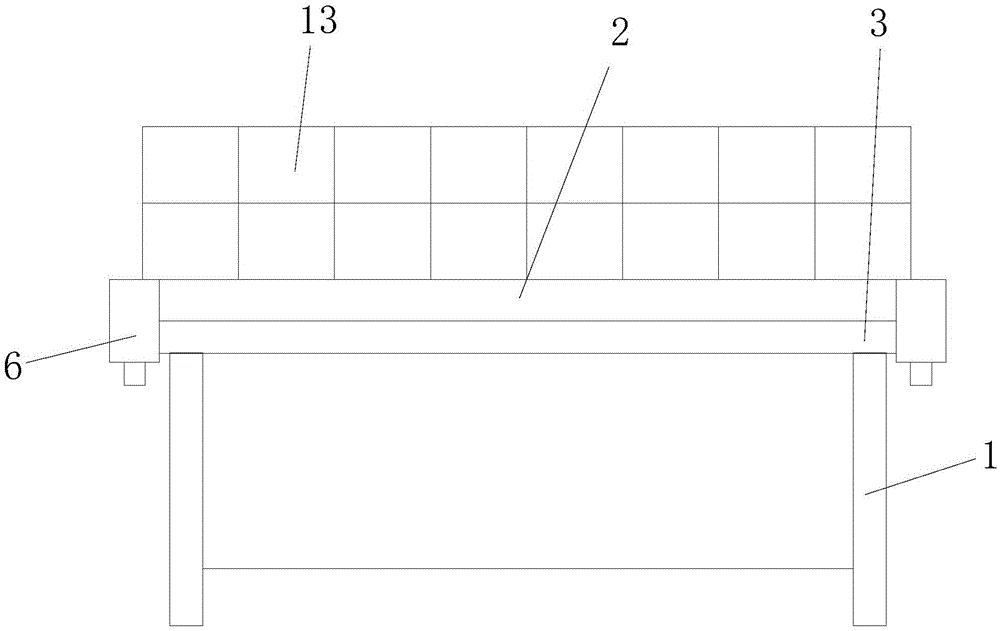

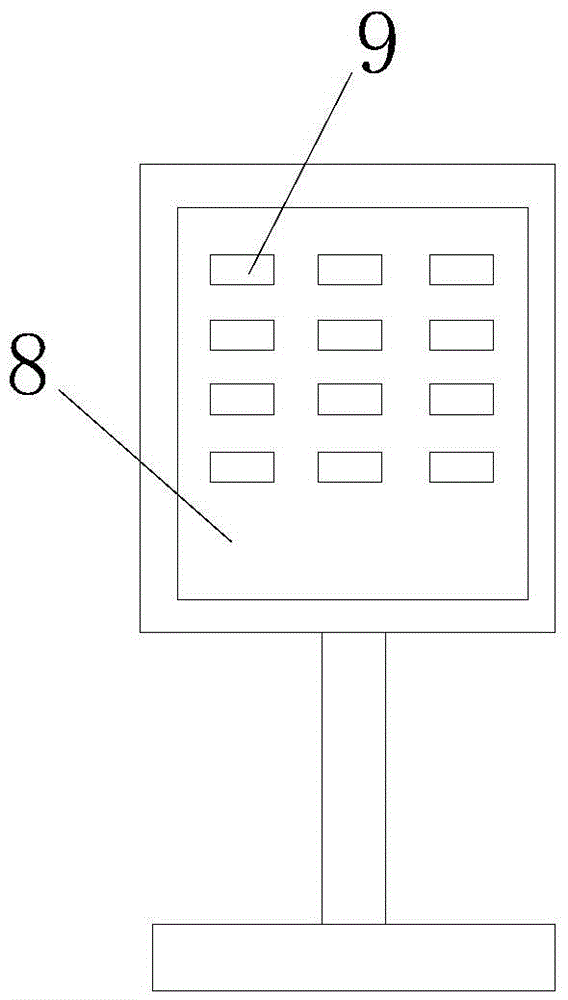

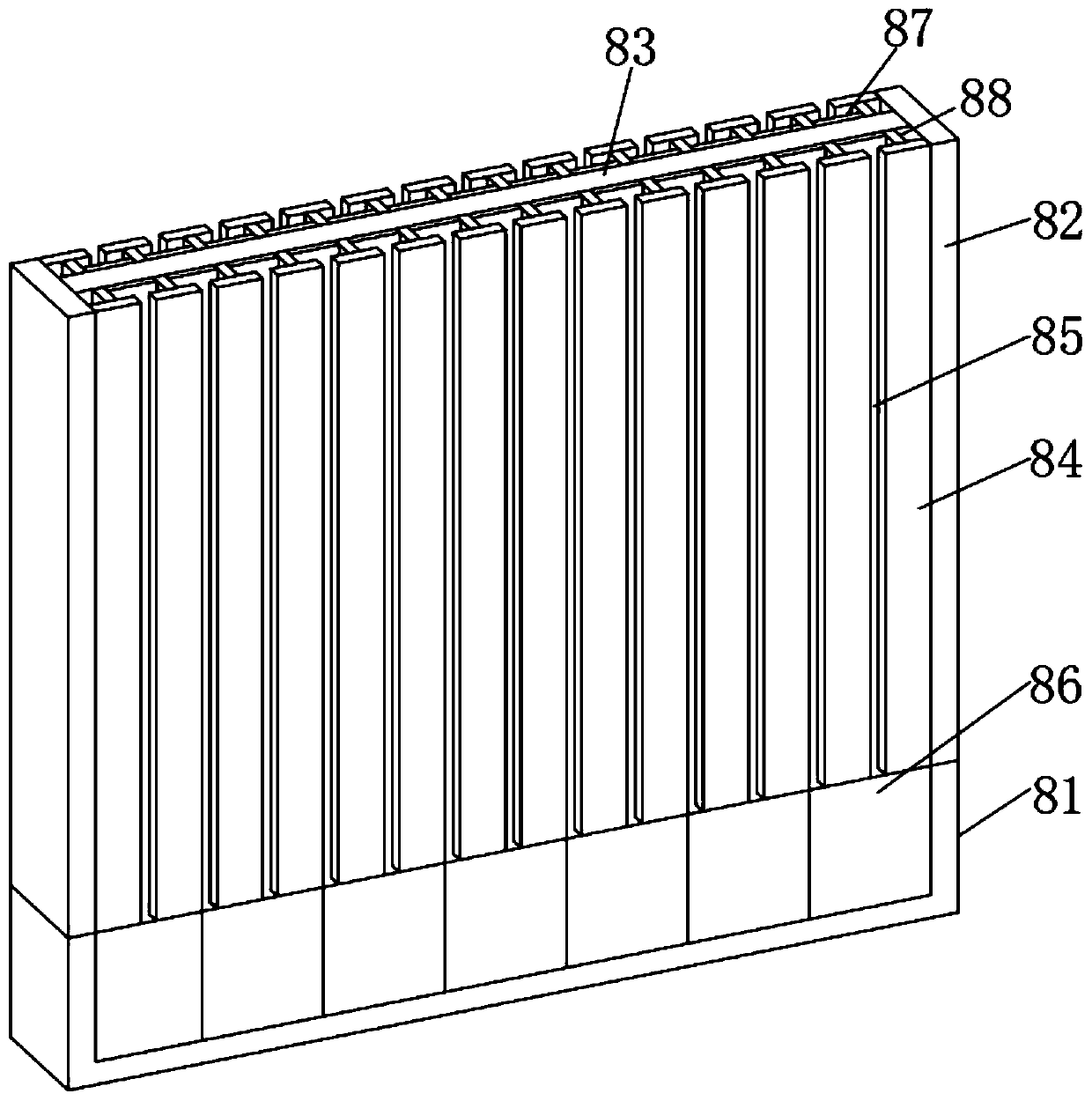

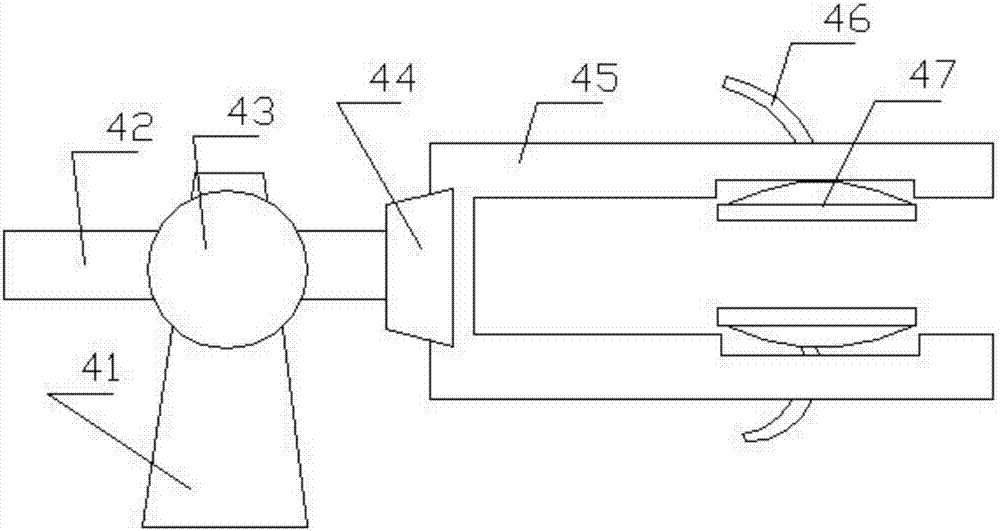

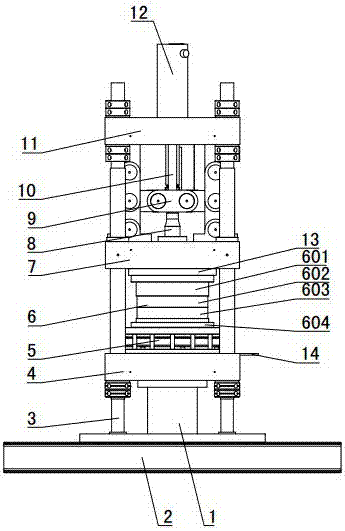

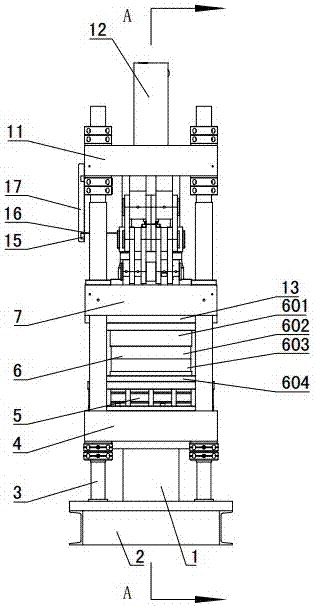

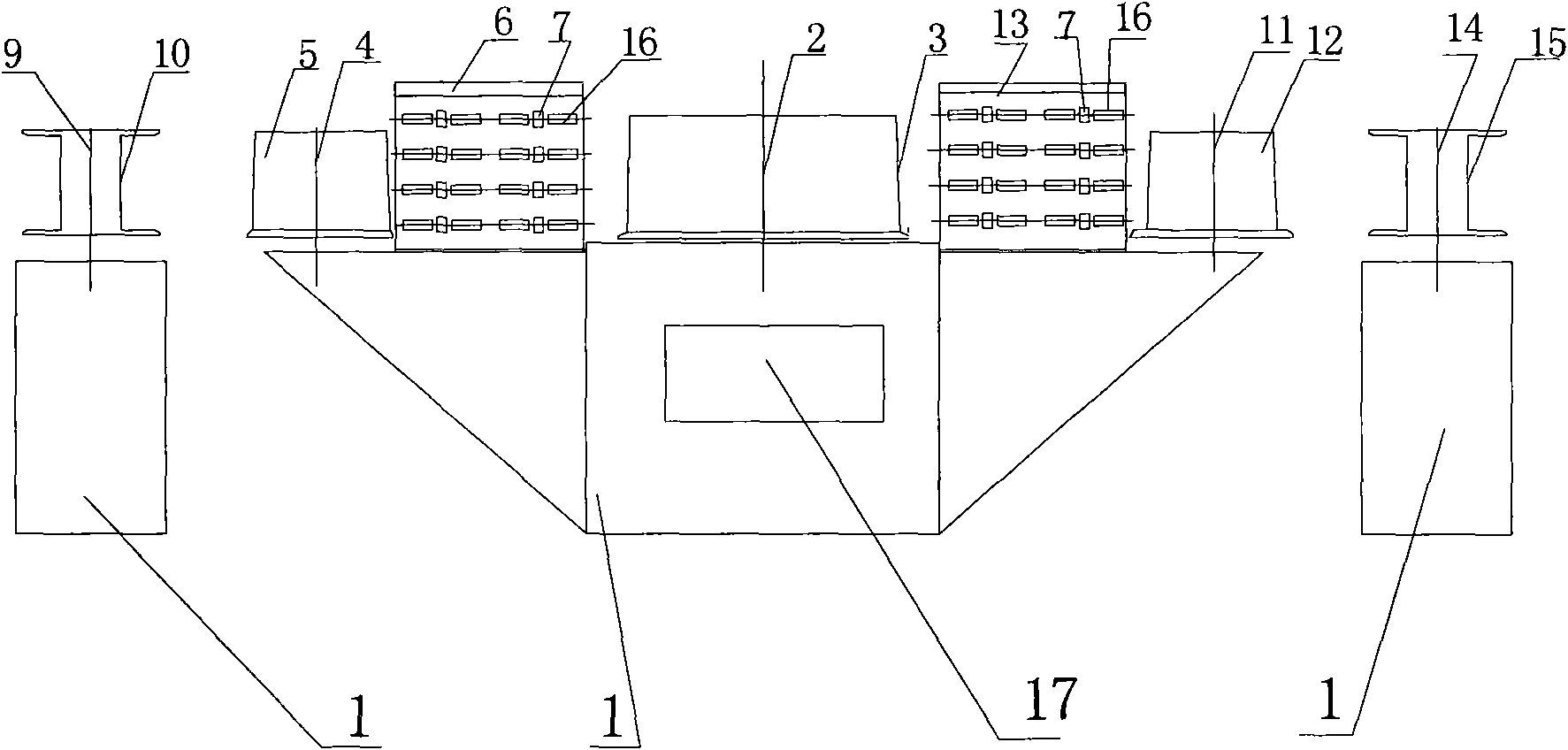

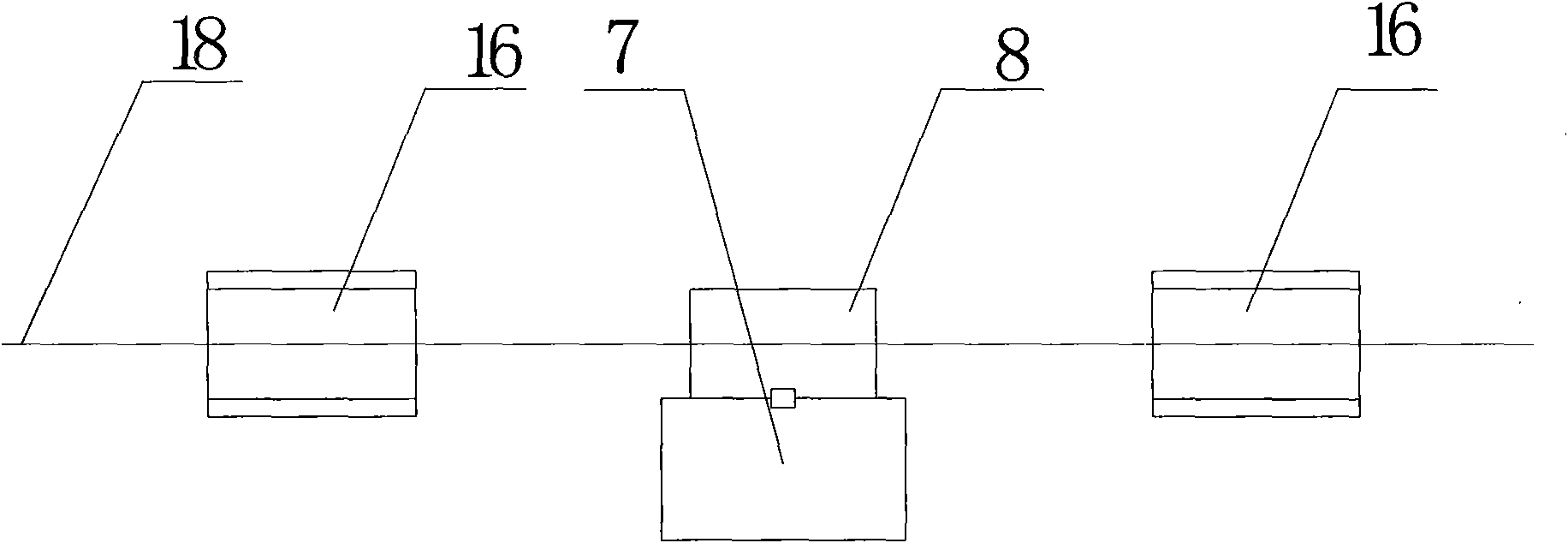

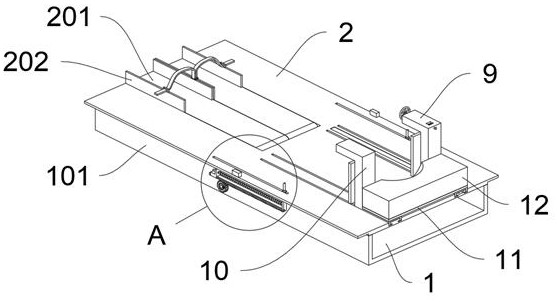

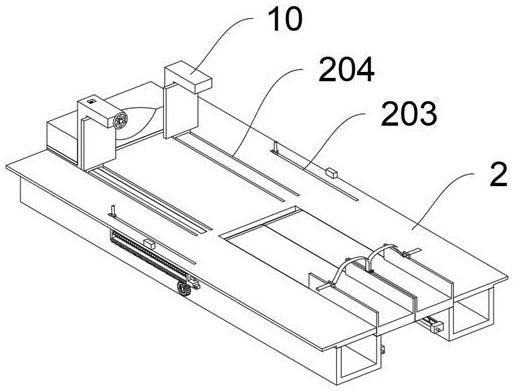

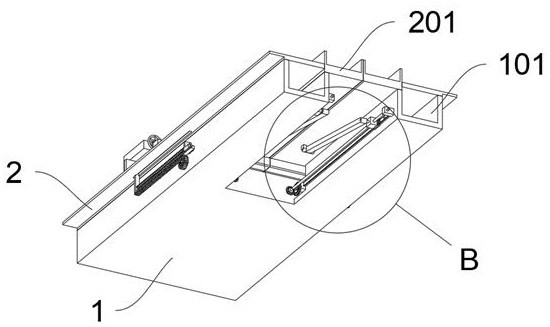

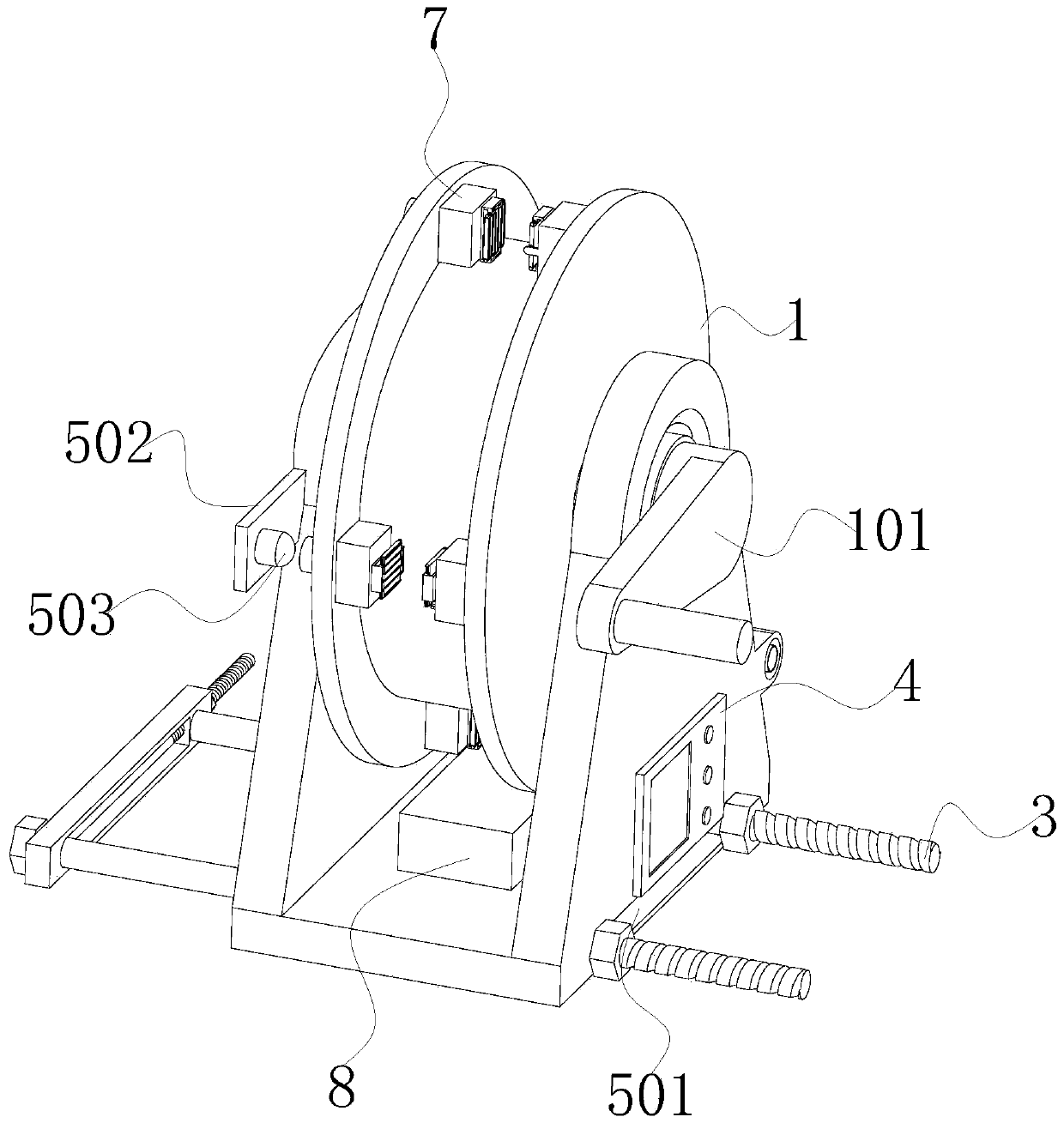

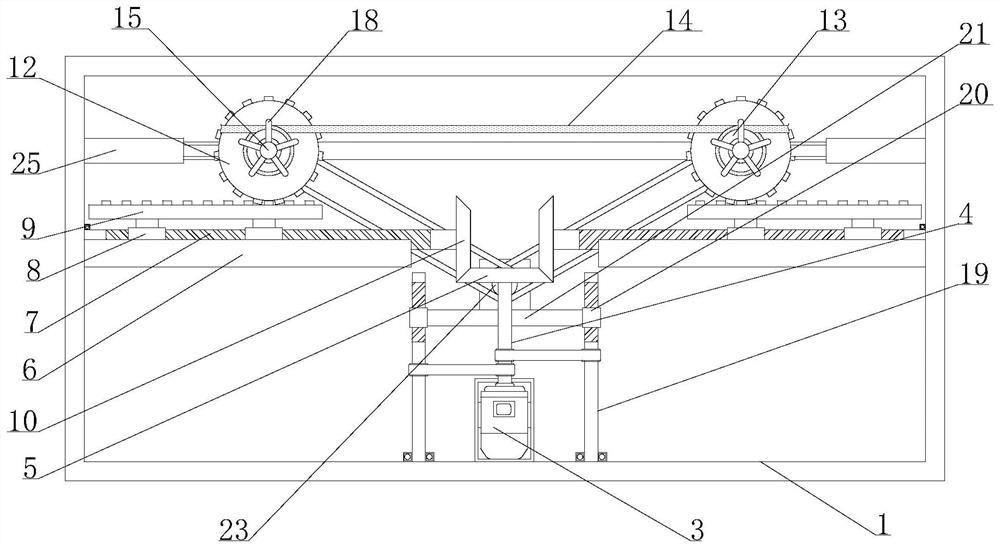

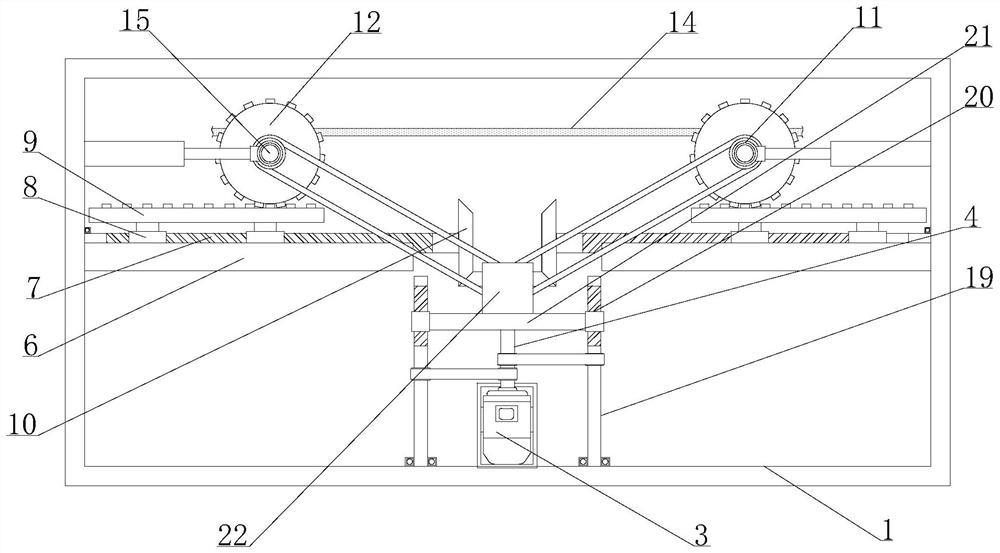

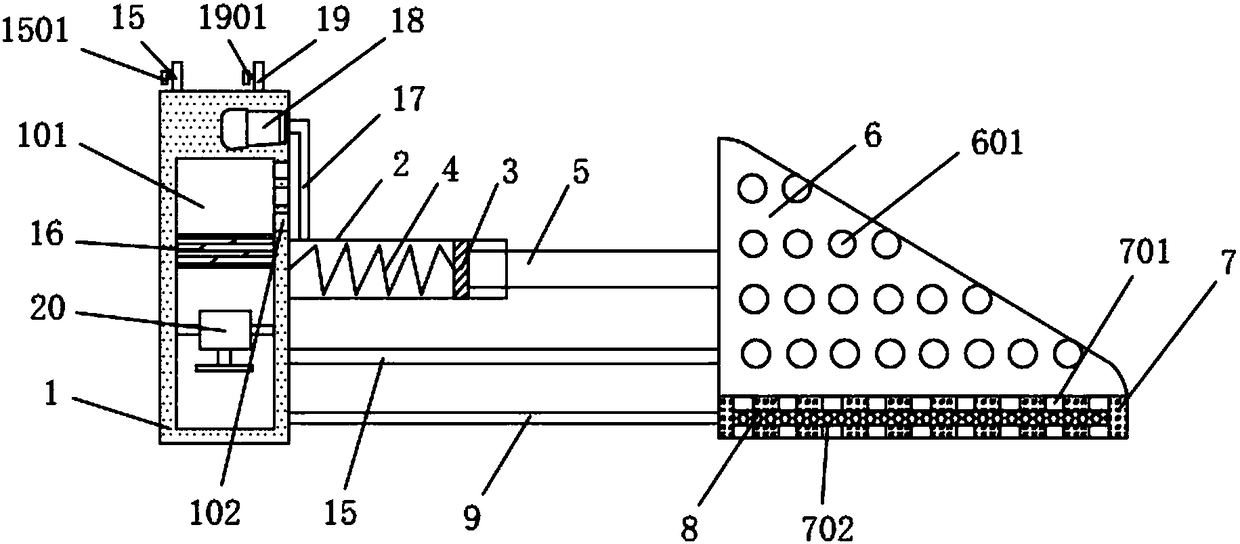

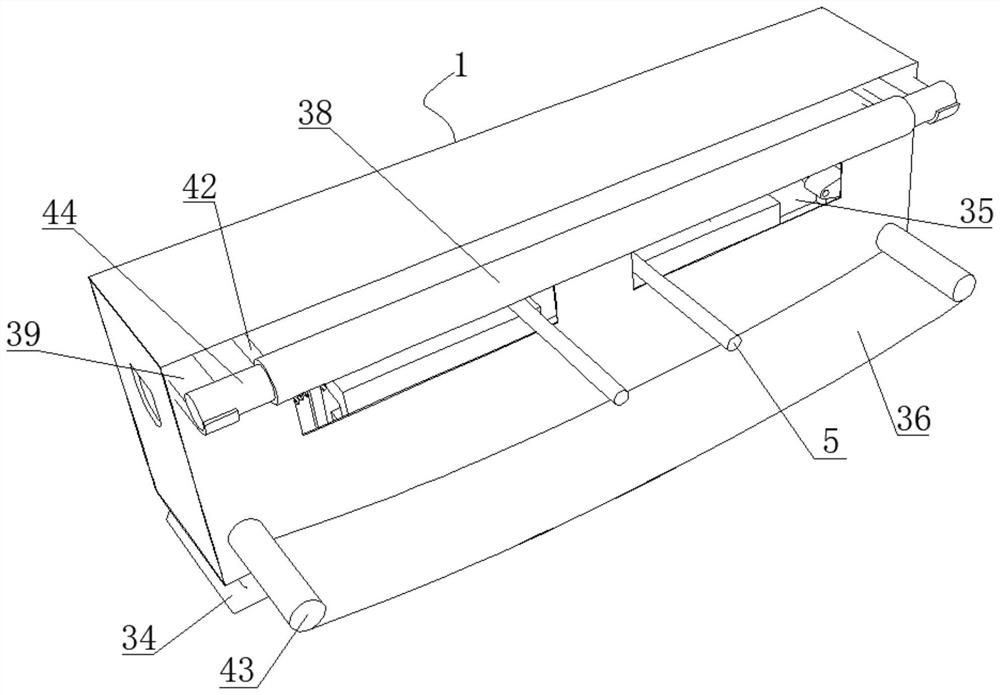

Drawing forming device for honeycomb material

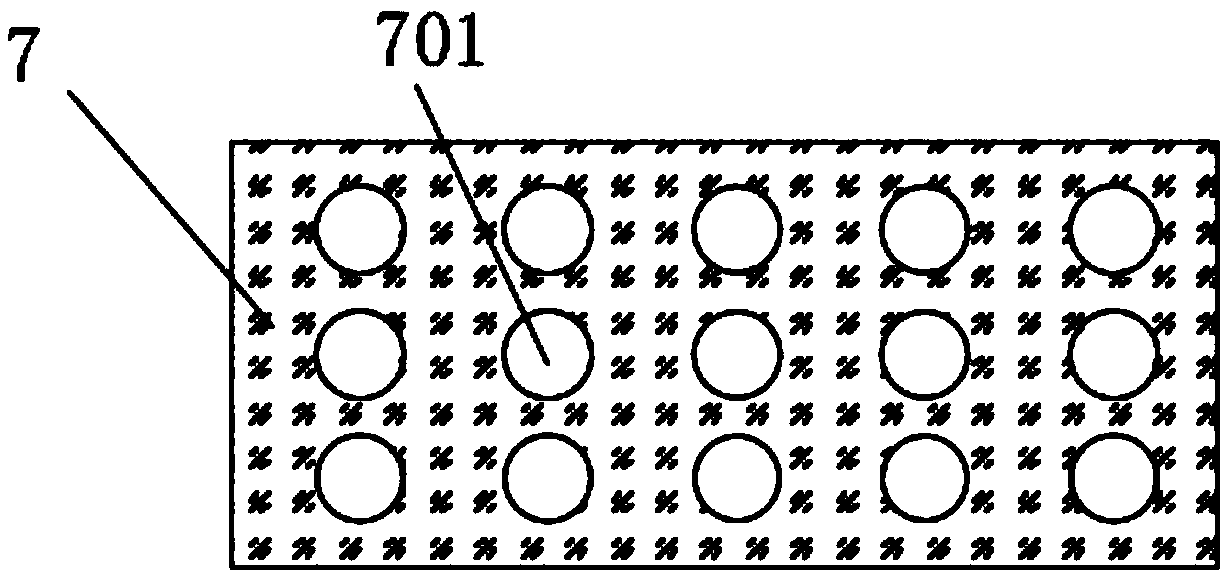

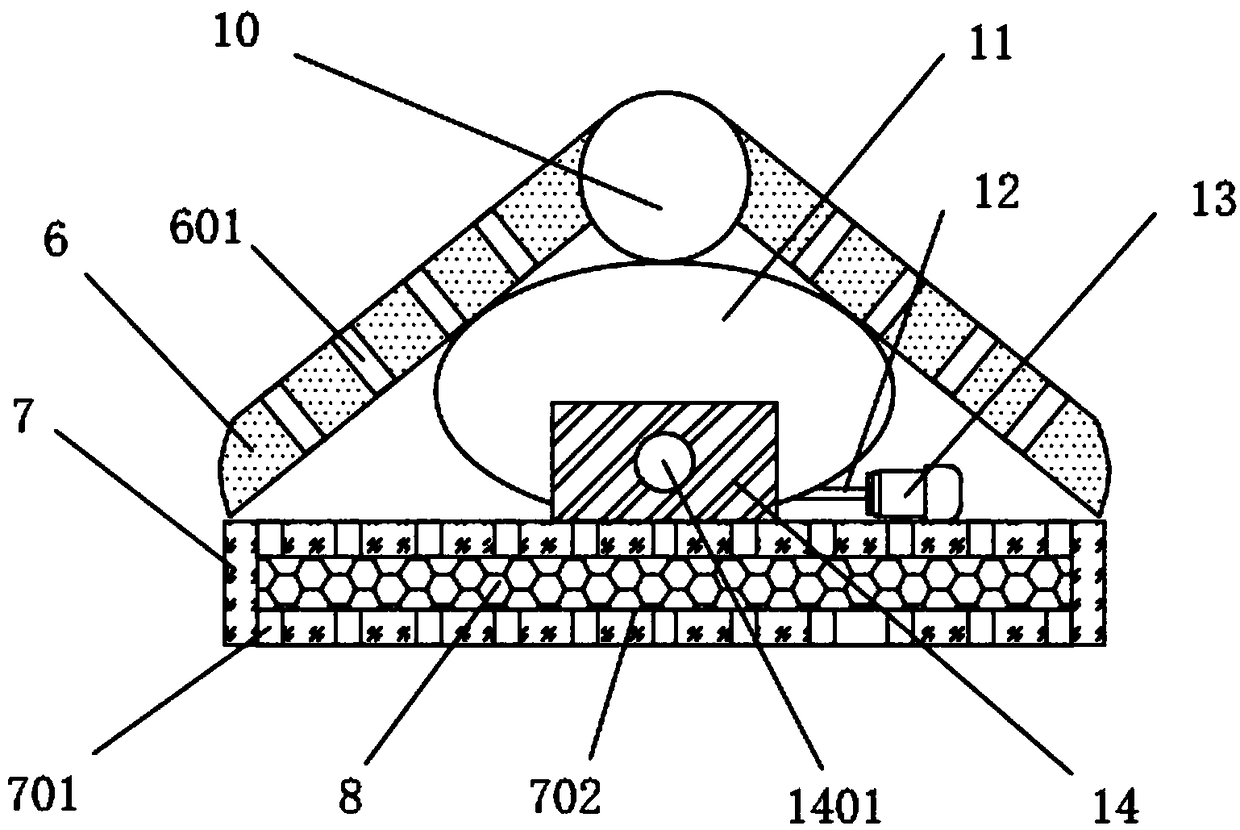

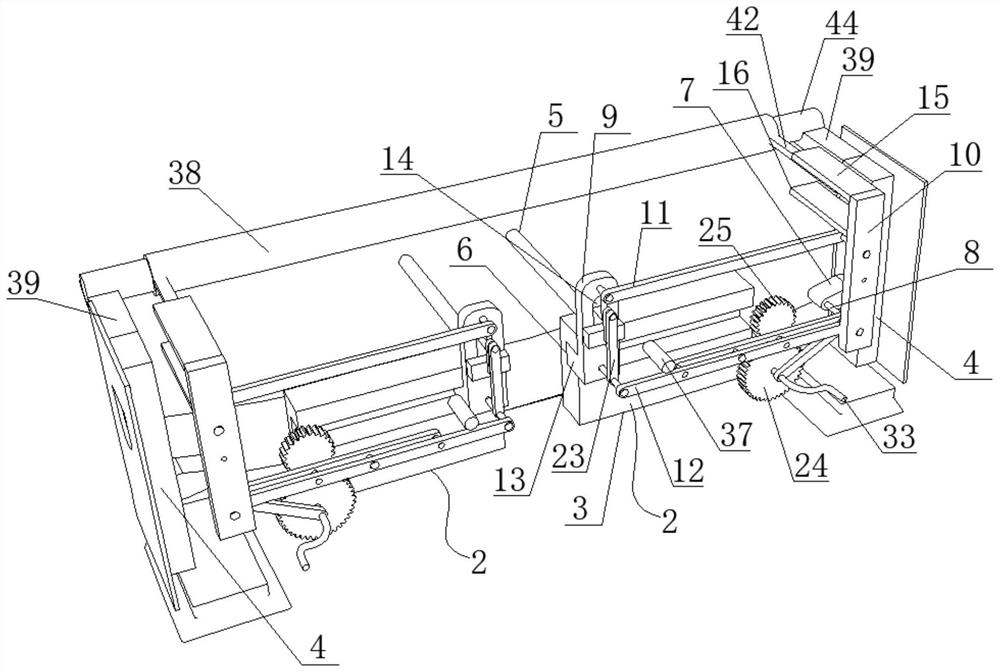

InactiveCN105479723AImprove quality and efficiencyImprove stretching efficiencyControl systemHoneycomb

A drawing forming device for a honeycomb material comprises a rack and a control system, wherein a drawing platform, a driving mechanism, two guide rails, a fixed seat and a sliding seat are arranged on the rack; the fixed seat and the sliding seat are arranged on the two guide rails which are arranged on the drawing platform parallelly in a spaced manner; the fixed seat is fixedly arranged at one ends of the guide rails; the sliding seat is arranged on the guide rails in a sliding manner; the driving mechanism comprises a motor and a screw-nut pair, the motor is arranged on the rack on the side where the fixed seat is located, and the screw-nut pair is in driving connection with the motor; the driving mechanism is oppositely connected with the sliding seat so as to drive the sliding seat to slide back and forth along the guide rails; clamping structures are arranged on opposite side surfaces of the fixed seat and the sliding seat respectively. According to the technical scheme, the sliding seat is driven by the driving mechanism to be lowered and draw a honeycomb stacked block along the guide rails, the structure is impact and light, the operation is convenient, and the running is reliable. The honeycomb drawing quality and drawing efficiency are improved greatly.

Owner:ARAMICORE COMPOSITE

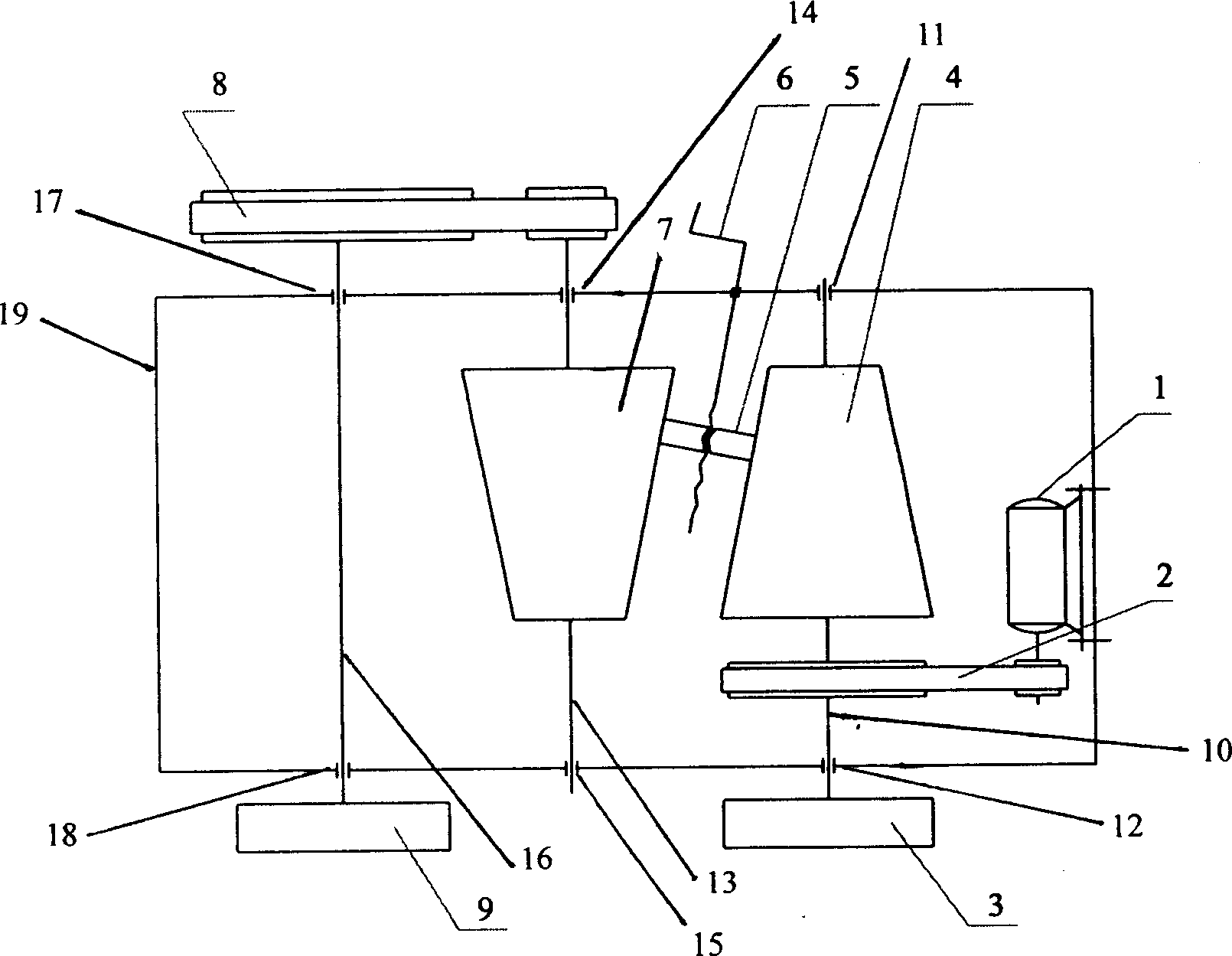

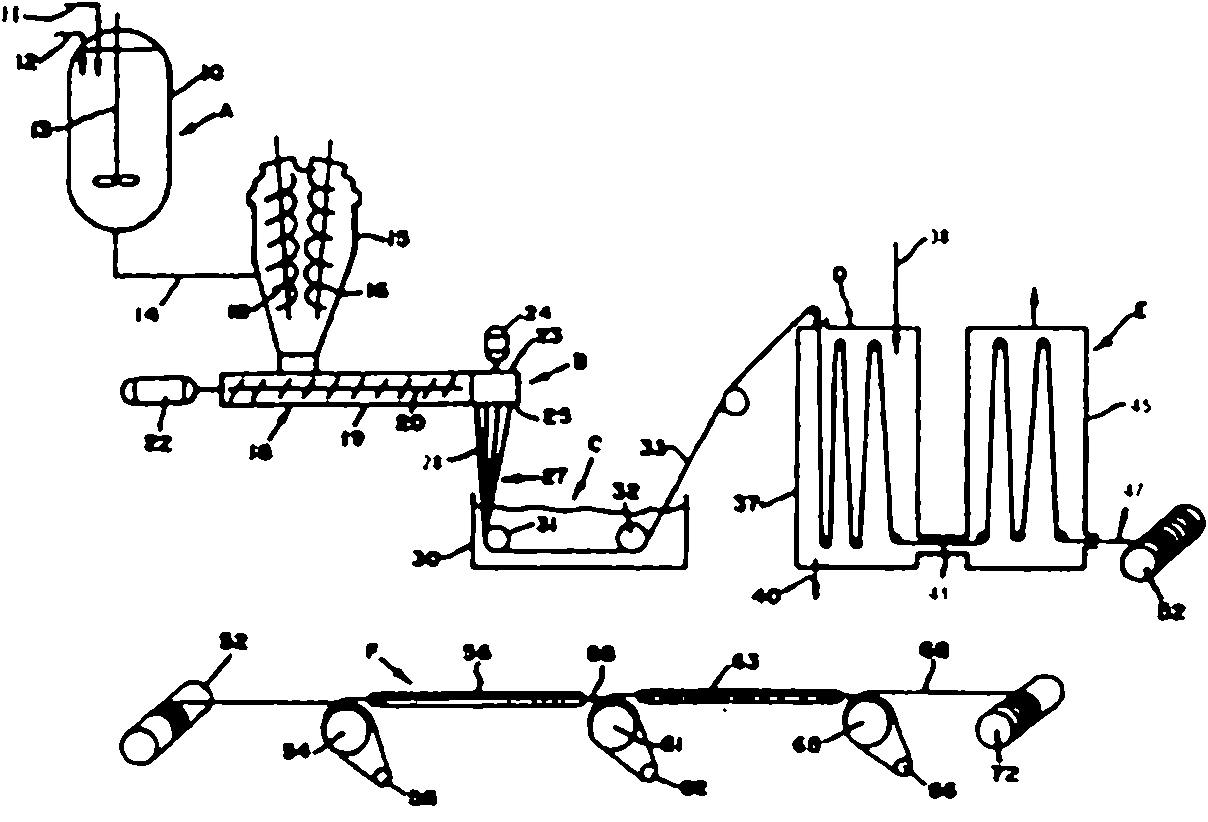

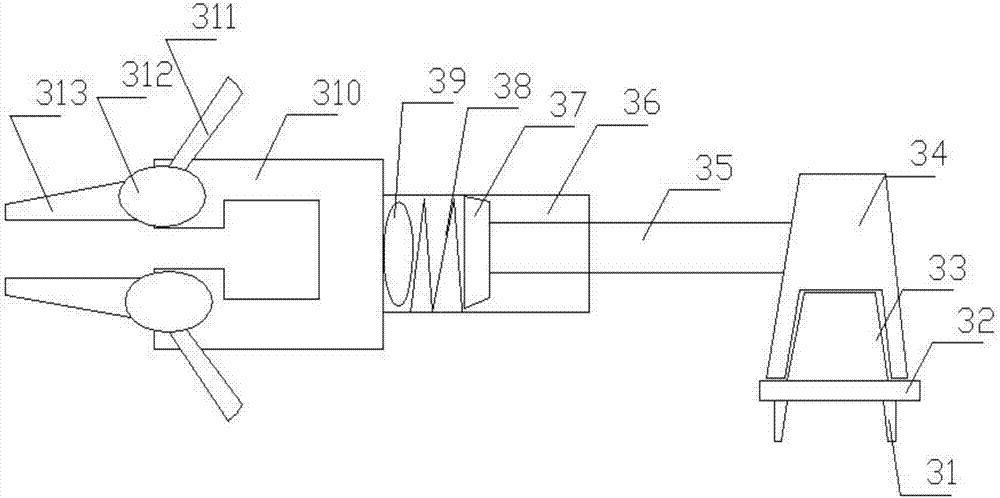

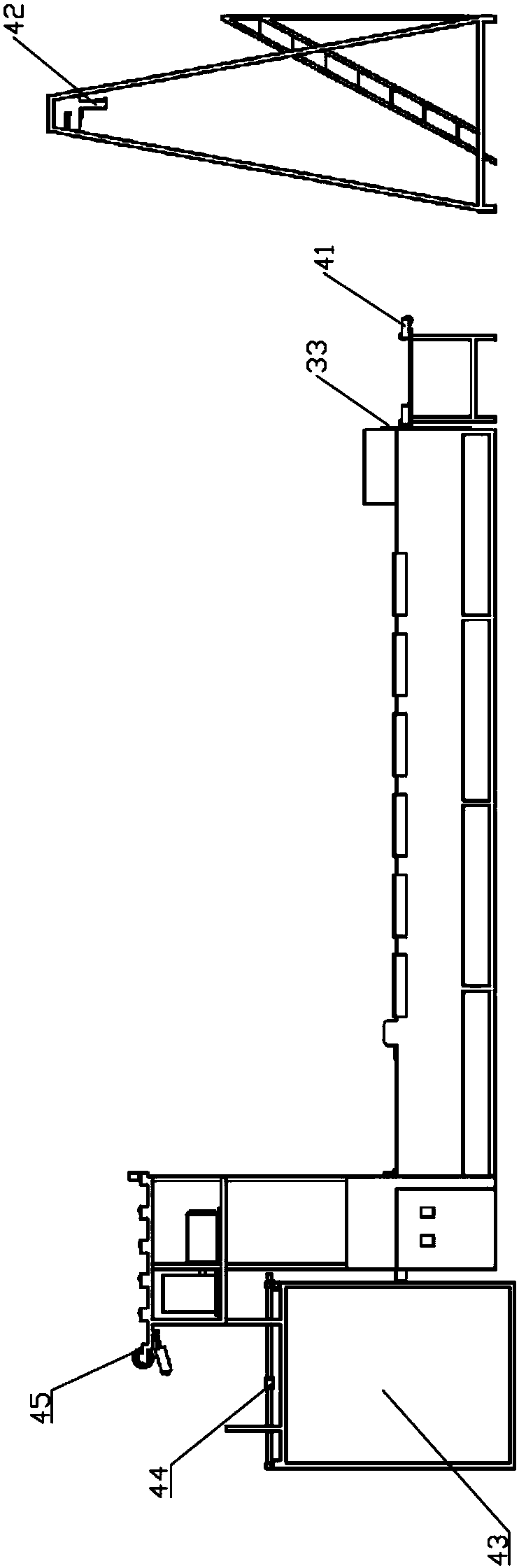

Environment-friendly and energy-saving multi-stage combination type high-performance fiber hyperploid heat drawing device

InactiveCN101775667AEmission reductionImprove stretching efficiencyArtificial thread manufacturing machinesStretch-spinning methodsFiberYarn

The invention relates to an environment-friendly and energy-saving multi-stage combination type high-performance fiber hyperploid heat drawing device, which is characterized in that pre-drawing drying ovens and a plurality of drawing heat drying ovens are independently arranged in a closed heat preservation box; the upper parts of all the pre-drawing drying ovens and the drawing heat drying ovens which are arranged independently are all provided wit air exhaust devices; a pre-drawing machine is arranged in each pre-drawing drying oven; and a drawing machine is arranged in each drawing heat drying oven. The invention has the advantages of environmental protection, energy saving and high drawing efficiency and can reduce pernicious and hazardous gas emission by 95%, save the energy by 50%-75%, and improve the yield by 150%-300%; in addition, the fiber property intensity of the same primary raw silk can be improved greatly by the drawing means. The invention also has the advantages of low drawing multiple per stage, rare yarn break, less waste, low equipment manufacture cost, reliable performance as well as convenient maintenance and use.

Owner:上海博迪纺织新材料有限公司 +1

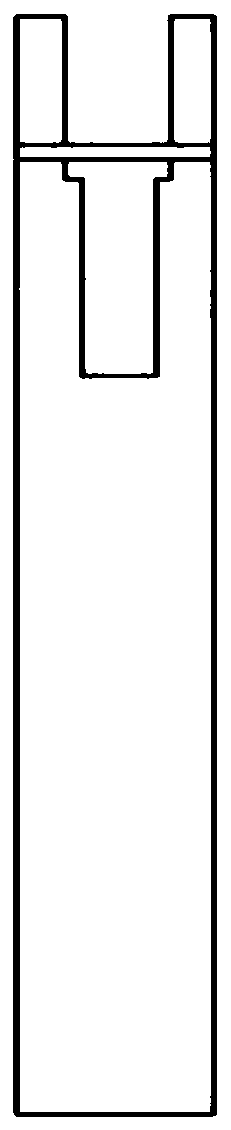

Stretching device and stretching method for VAD sintered optical fiber prefabricated base bar

The invention relates to a stretching device and a stretching method for a VAD sintered optical fiber prefabricated base bar. The stretching device comprises an upper chuck, a stretching furnace and alower chuck which are successively arranged along a vertical direction. The stretching method comprises the following steps: measuring and collecting diameter of the optical fiber prefabricated basebar on each position; calculating an upward moving rate of the upper chuck and confirming the upward moving rate of the upper chuck according to the required diameter of stretched core rod, the upwardmoving rate of the stretching furnace and the diameter of the stretched optical fiber prefabricated base bar; synchronously rotating the upper chuck and the lower chuck at a same rotation rate beforeheating and stretching, and then starting to heat the lower end of the optical fiber prefabricated base bar by starting the stretching furnace; controlling the upper chuck to calculate the upward moving rate and stretching the optical fiber prefabricated base bar, thereby forming a core rod. According to the invention, stretching quality and efficiency of optical fiber prefabricated base bar canbe guaranteed, dosage of guiding rod can be reduced and welding times of guiding rod can be reduced.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

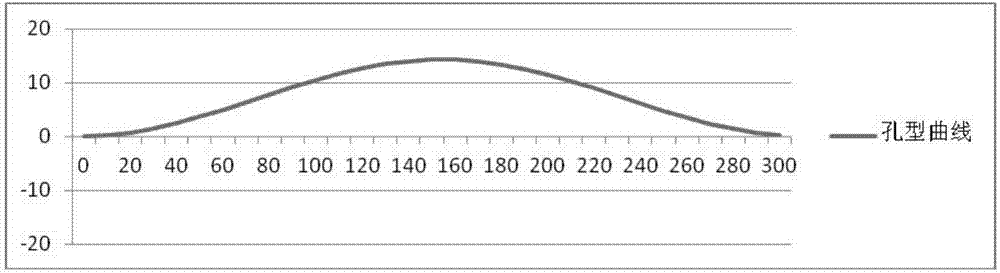

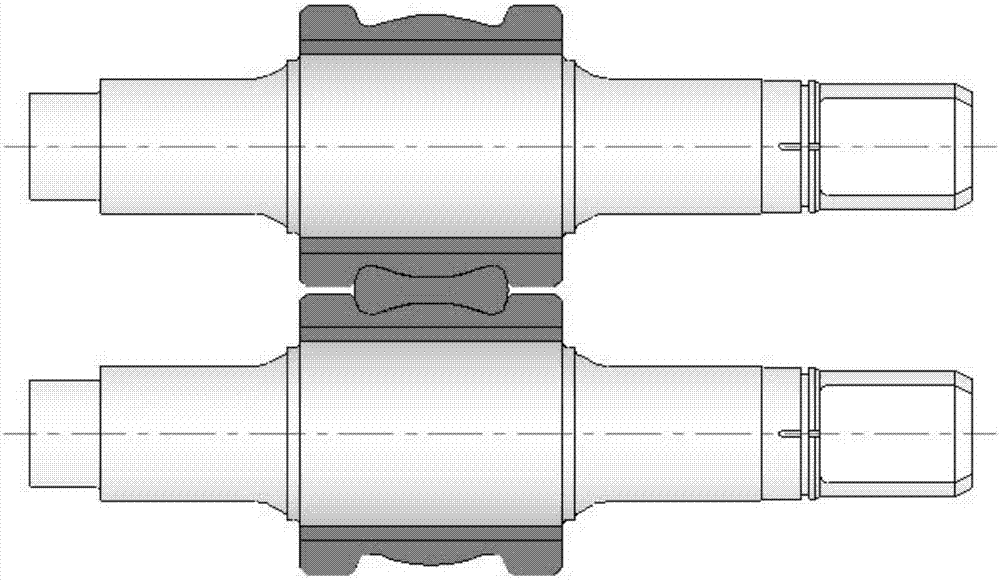

Wear-resistant type strong-widening roller for strip steel

ActiveCN107511398AHigh anti-wear propertiesSolve the problem of not easy to bite steelRollsMetal rolling arrangementsWear resistantStrip steel

The invention discloses a wear-resistant type strong-widening roller for strip steel and belongs to the field of narrow strip steel production equipment. A roller work layer adopts a high-chrome-molybdenum-vanadium-series alloy material which comprises 2.0-3.0% of C, 0.4-1.0% of Si, 0.6-1.0% of Mn, 8-32% of Cr, 0.8-1.8% of Ni, 0.8-2.0% of Mo and 0.2-1.2% of V; and the roller shape adopts a sine curve. The roller is used for a narrow strip steel rough rolling rack and has the effects of being high in strip steel blank forced widening efficiency and capable of eliminating loosening of steel blank centers and improving the plate quality; the roller has super-strong wear resistance, and thus the online time is 2-3 times that of a traditional NiCrMo roller; the roller has good characteristics of the hot cracking resistance and the fatigue weight losing resistance, the dismounted reconditioning restoration quantity of the roller is reduced by 40% compared with a traditional NiCrMo roller, and the plate face quality is obviously improved; and the comprehensive service life is prolonged to be three times or more that of the traditional roller, and the comprehensive ton-of-steel cost is reduced by 30%.

Owner:SANXIN HEAVY IND MACHINERY

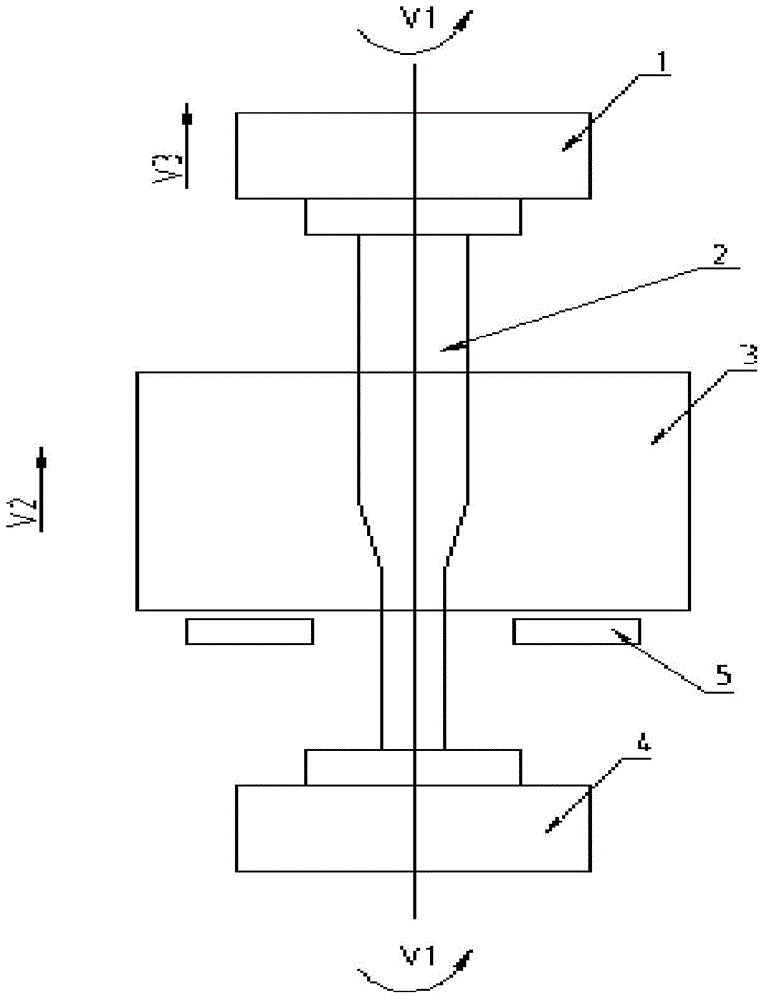

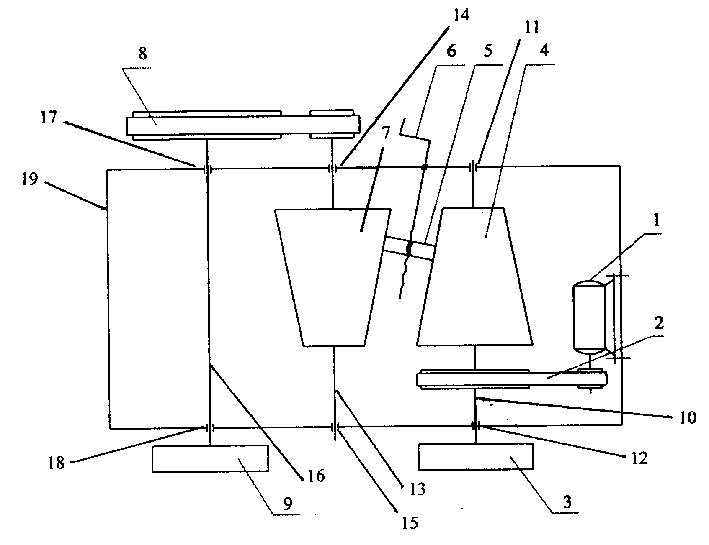

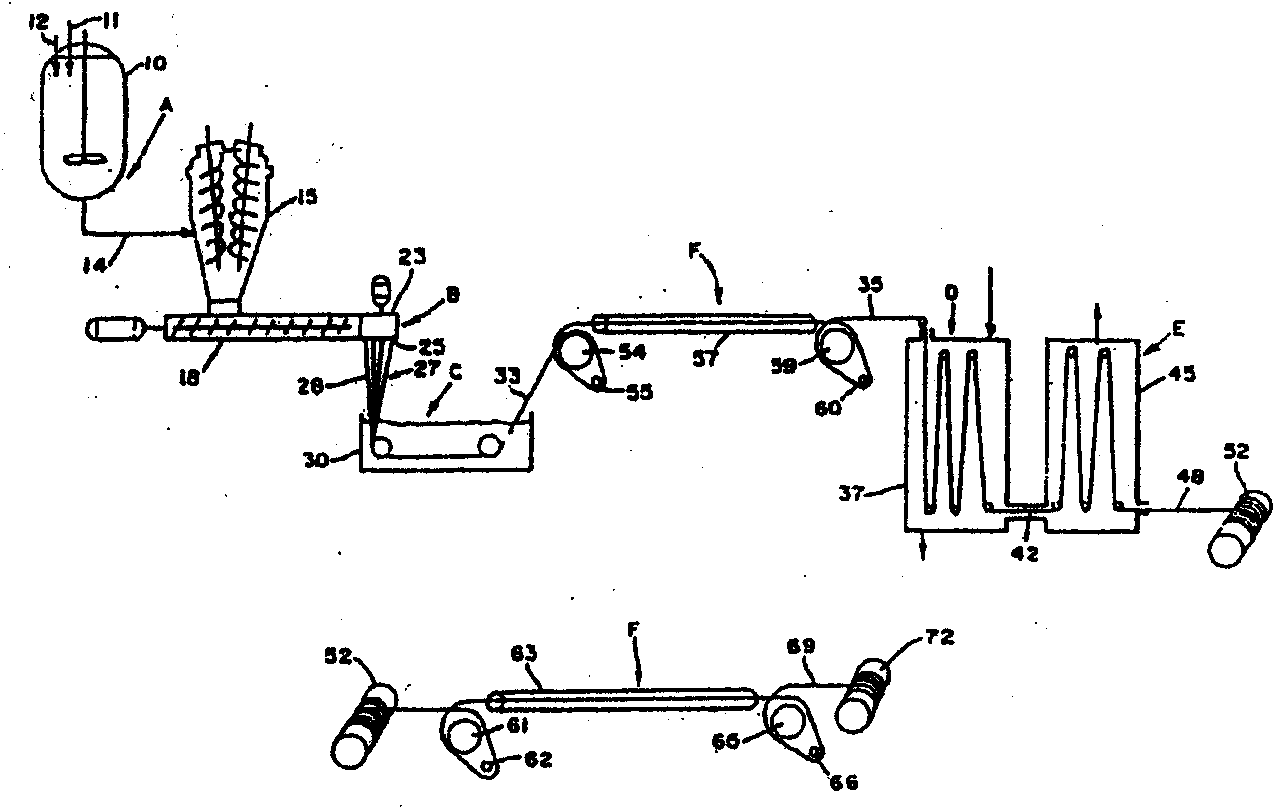

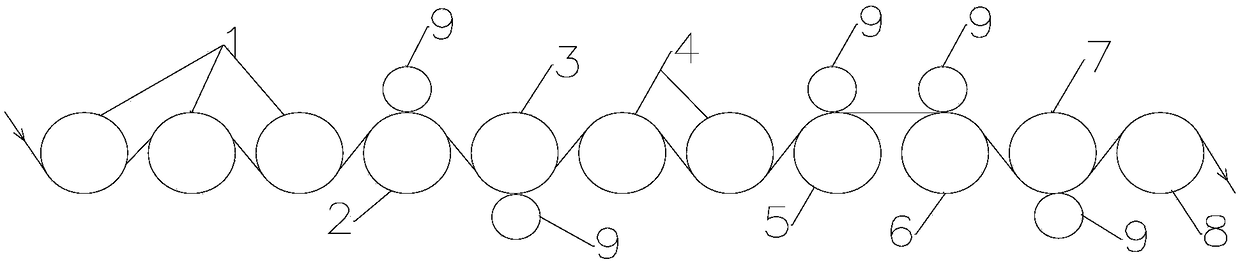

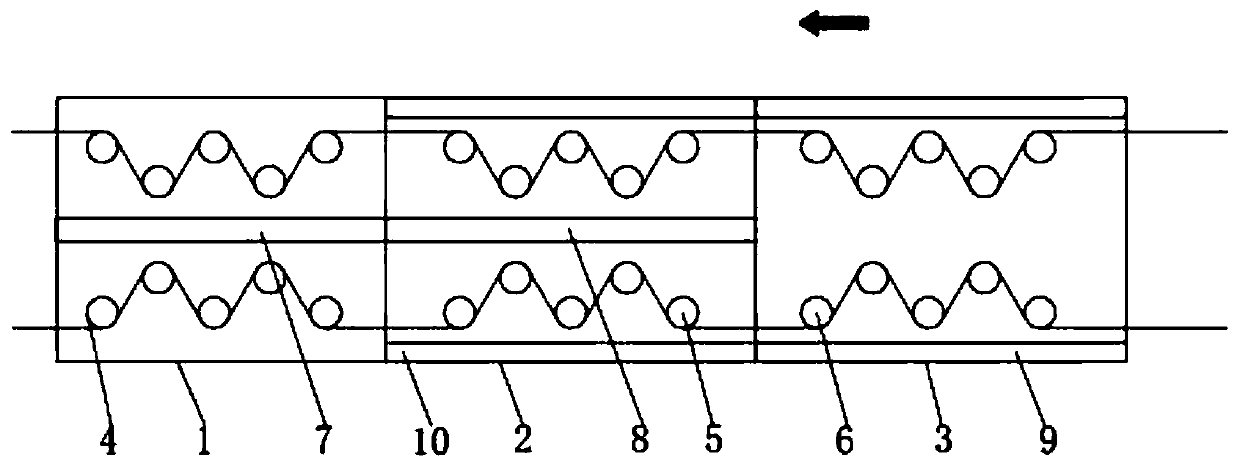

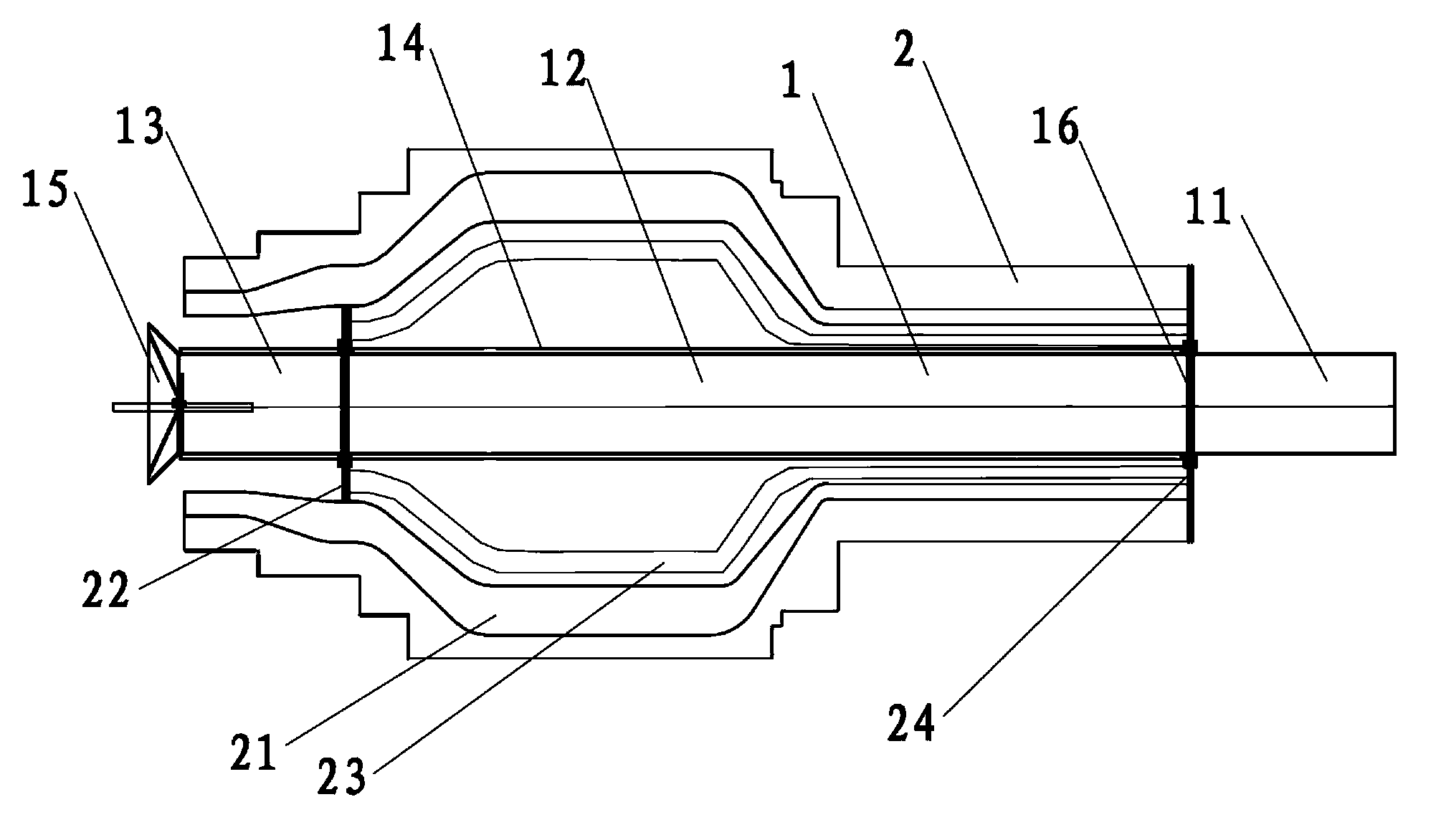

Longitudinal drawing method and device of two-directional drawn polyester film

InactiveCN108115923AImprove thickness uniformityImprove stretching efficiencyFlat articlesPolyesterEngineering

The invention provides a longitudinal drawing method of a two-directional drawn polyester film. The method comprises the following step: carrying out primary pre-heating, longitudinal drawing of a first section, primary cooling, secondary pre-heating, longitudinal drawing of a second section, longitudinal drawing of a third section and secondary cooling successively on an unextended sheet on a longitudinal drawing device, wherein the primary pre-heating temperature is 98-102 DEG C; the secondary pre-heating temperature is 108-112 DEG C; the primary cooling temperature is 28-32 DEG C; the secondary cooling temperature is 18-22 DEG C; the draw ratio of longitudinal drawing of the first section is 1.5-2.0 times and the drawing temperature is 115-120 DEG C, the draw ratio of longitudinal drawing of the second section is 1.5-1.8 times and the drawing temperature is 120-125 DEG C, and the draw ratio of longitudinal drawing of the third section is 1.5-2.0 times and the drawing temperature is125-130 DEG C. The invention also provides a longitudinal drawing device suitable for the method. The method has the advantage that the produced two-directional drawn polyester films are relatively good in thickness uniformity.

Owner:爱思开迈克沃尖端塑料(江苏)有限公司

Optical pulse series spectral stretcher based on high nonlinear optic fibre

InactiveCN1645771AWidening is effectiveImprove stretching efficiencyFibre transmissionFiberPulse sequence

The invention contains two different lengths of highly nonlinear fibers. A standard single-mode fiber is welded between them and is taken as wide- band coherent source of pulse repetition frequency of WDM 40 GHz.

Owner:HUAZHONG UNIV OF SCI & TECH

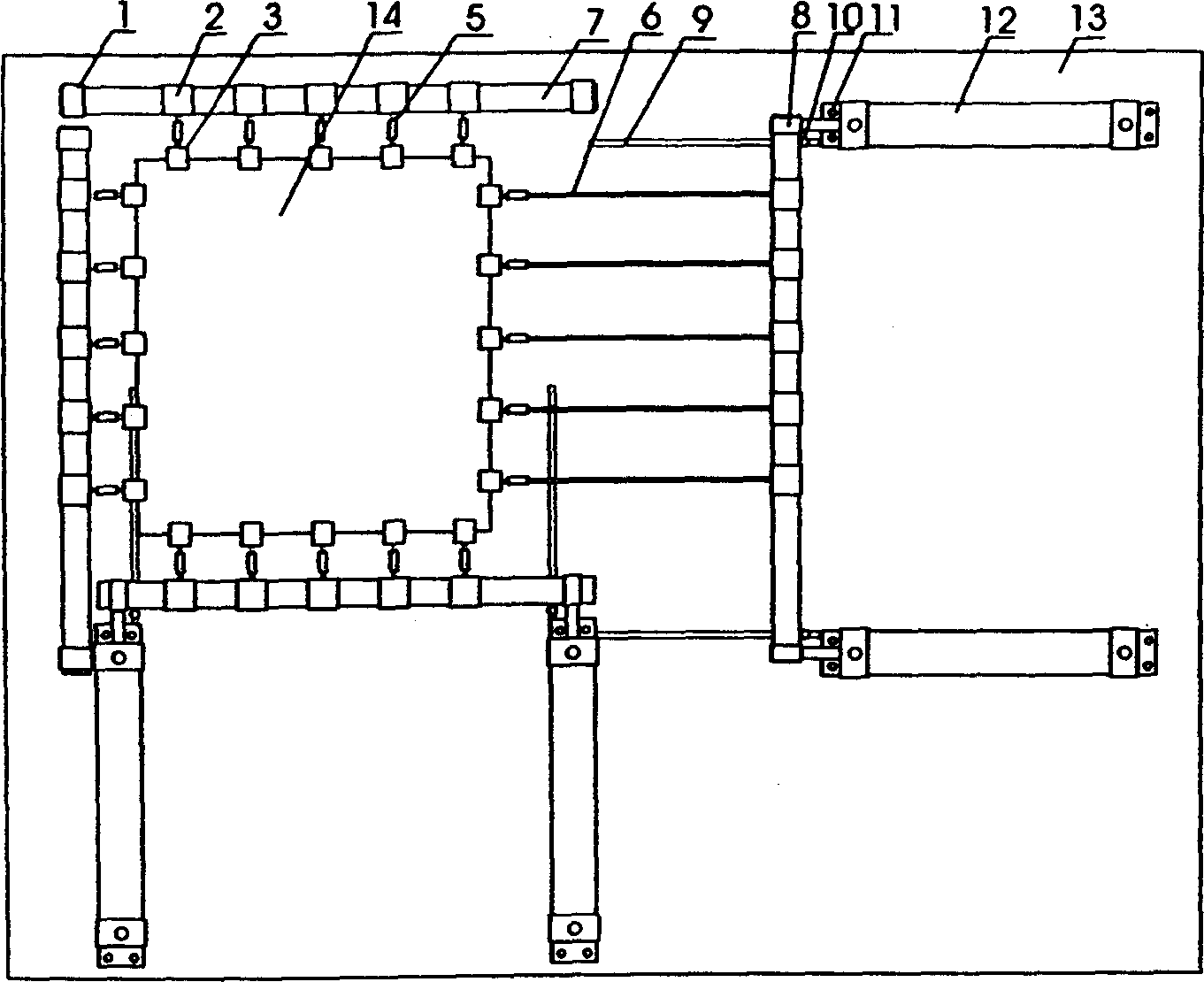

Transverse stretching mechanism for polyimide film

The invention discloses a transverse stretching mechanism for a polyimide film. The transverse stretching mechanism for the polyimide film comprises an imidization device, a stretching device and a preheating device. The imidization device and the preheating device are fixedly connected to the left side and the right side of the stretching device correspondingly. The imidization device, the stretching device and the preheating device are internally and correspondingly provided with two first film winding devices, two second film winding devices and two third film winding devices correspondingly. An infrared heating device is perpendicularly arranged at the bottom of the inner wall of the imidization device. The bottom of the inner wall of the stretching device is fixedly connected with a hot air heating device. The front side and the back side of the stretching device are both fixedly connected with heat preservation boards. The transverse stretching mechanism for the polyimide film has the advantages that two polyimide films are conveyed in the stretching device, during conveyance, heat on the front side and the back side of the stretching device can communicate with each other, so that heat loss can be reduced, and heat can be well utilized; and compared with original equipment, the stretching efficiency is improved by one time, and the stretching efficiency is improved.

Owner:合肥中汇睿能能源科技有限公司

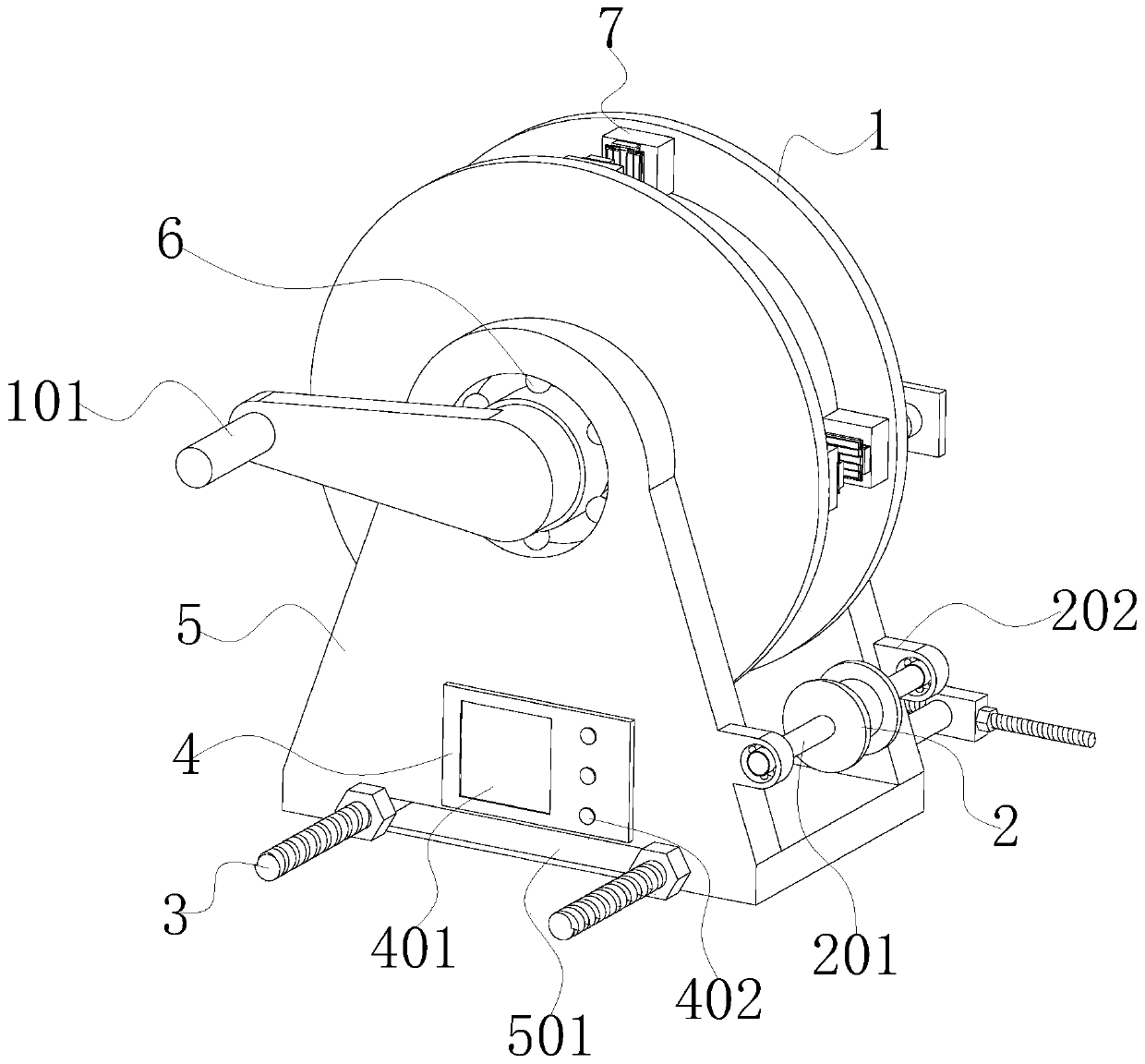

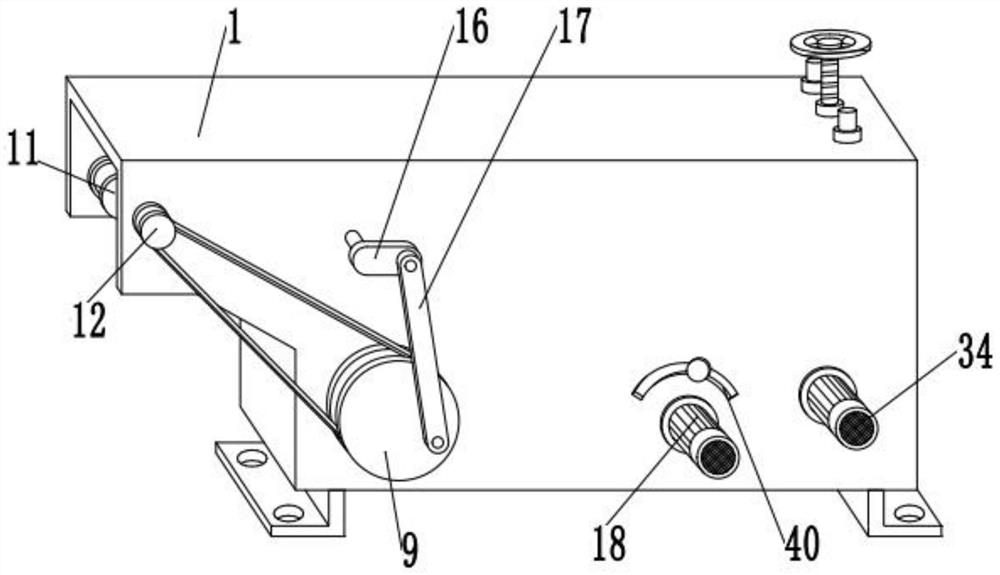

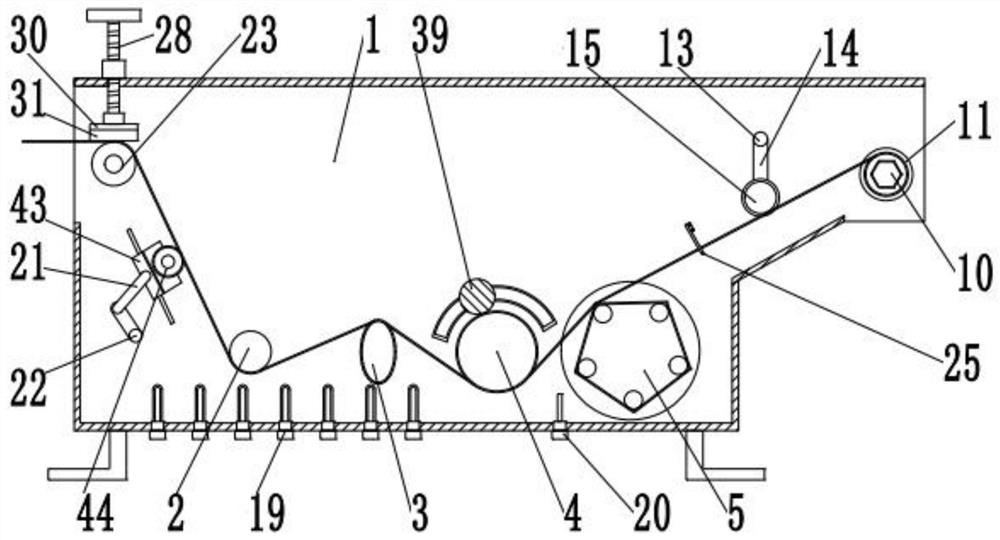

Leather stretching equipment

InactiveCN107142339AEasy to operateEasy to adjustLeather stretching/tensioningSkins/hides/leather/fur manufacturing apparatusEngineeringScrew thread

The invention relates to the technical field of leather stretching, in particular to leather stretching equipment. The leather stretching equipment comprises a base and further comprises an operation base in screw joint to one end of the upper side of the base through a thread, a first stretching component, and a second stretching component clamped and connected to the other end of the upper side of the base. The first stretching component comprises an outer fixing cover, an inner clamping and connecting head clamped and connected to the lower portion of the outer fixing cover, a clamping and connecting disc, clamping and connecting feet clamped and connected to the lower side of the clamping and connecting disc, a push rod, a guiding barrel arranged on the push rod in a sleeving manner in the axial direction of the push rod, an outer clamping frame in screw joint to the end portion of the guiding barrel through a thread, an extrusion piece, a buffering piece, a first spring, a first screw joint head, a clamping head and an adjusting rod, wherein the first spring is pressed between the buffering piece and the extrusion piece, and the adjusting rod is screwed on the first screw joint head in the radial direction of the first screw joint head. The leather stretching equipment is convenient to adjust, and the stretching quality is good.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

Preform for stretch blow-molded bottle

ActiveUS8389085B2Increasing the thicknessReduce weightEnvelopes/bags making machinerySynthetic resin layered productsEngineeringBottle

A preform having an inverted truncated conical bottom section is used. The inclined inner surface of a bottle bottom surface-forming portion of the bottom section is formed into a gently curved convex surface that extends from the lower portion of a bottle bottom edge-forming portion of the bottom section to a curved portion in the lower portion of the bottom section so that the thickness of the bottle bottom surface-forming portion is greater than the thickness of the barrel section of the preform and the thickness of the bottle bottom edge-forming portion. The increase in thickness of the bottom section improves the efficiency of stretching the bottom section, and the circumferential wall of the bottom section can thereby be efficiently stretched. This allows a reduction in weight (thickness) of the bottom surface section of a stretch blow molded bottle, and a reduction in weight of the bottle is thereby achieved.

Owner:A K TECH LAB INC

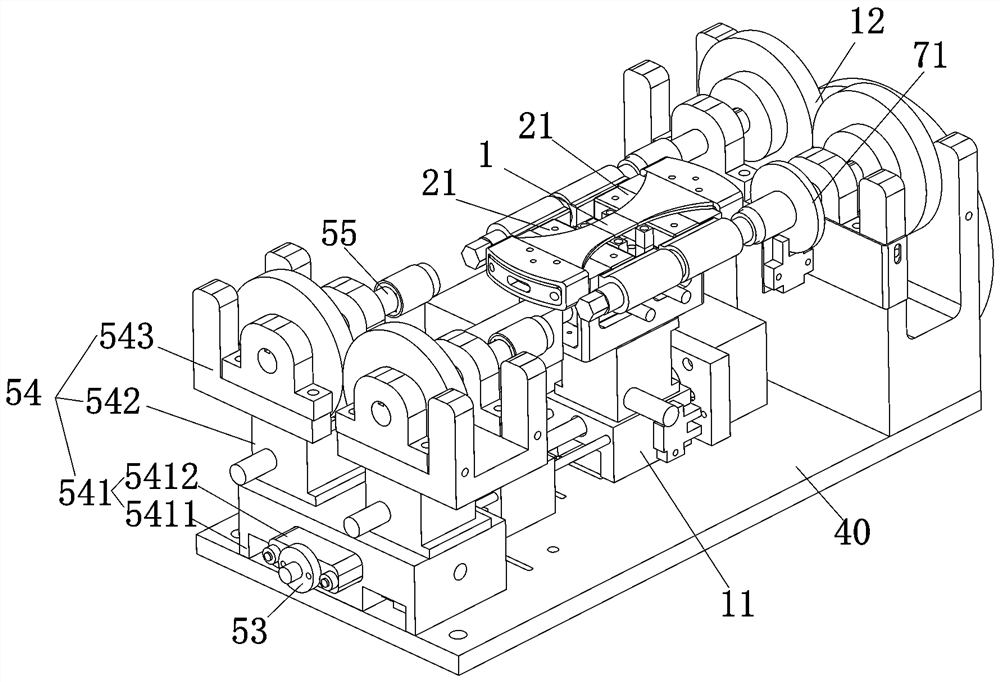

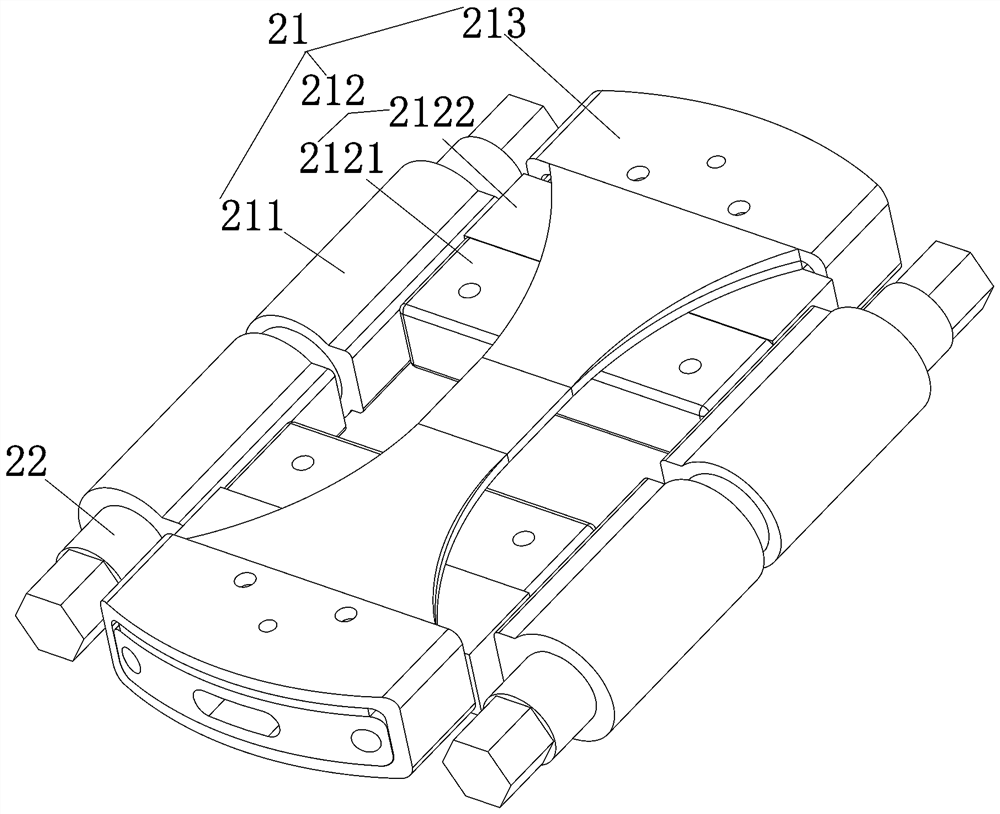

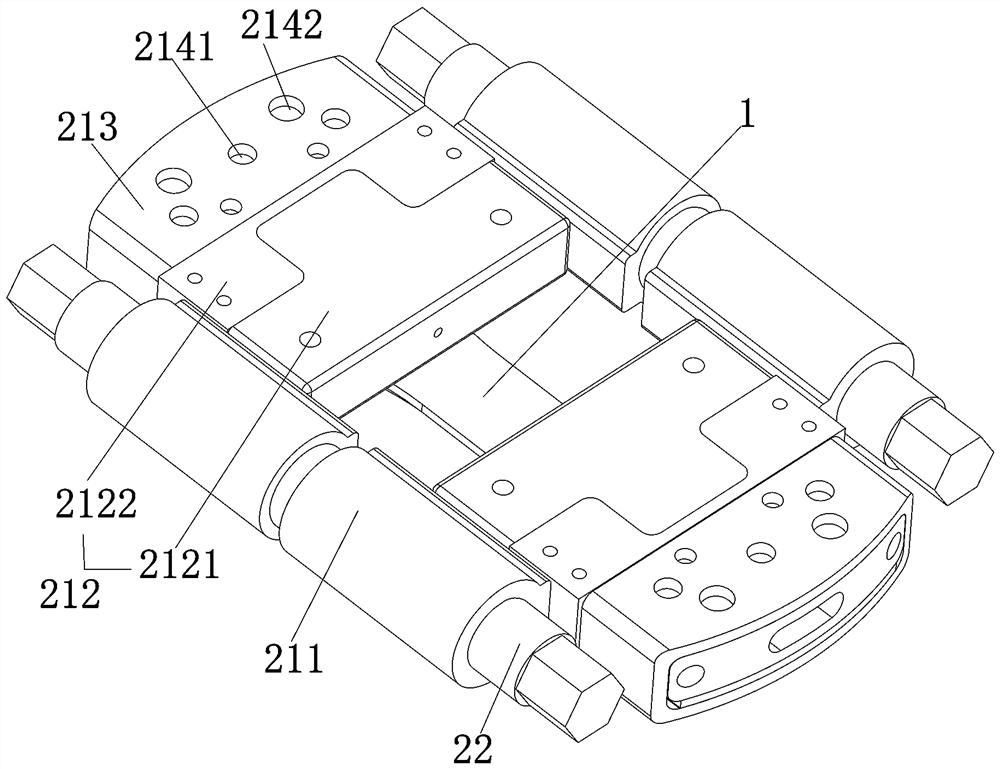

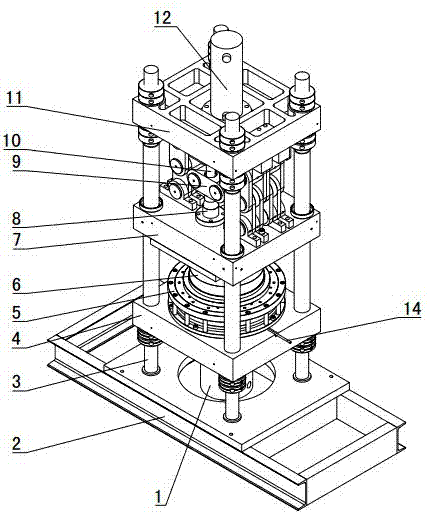

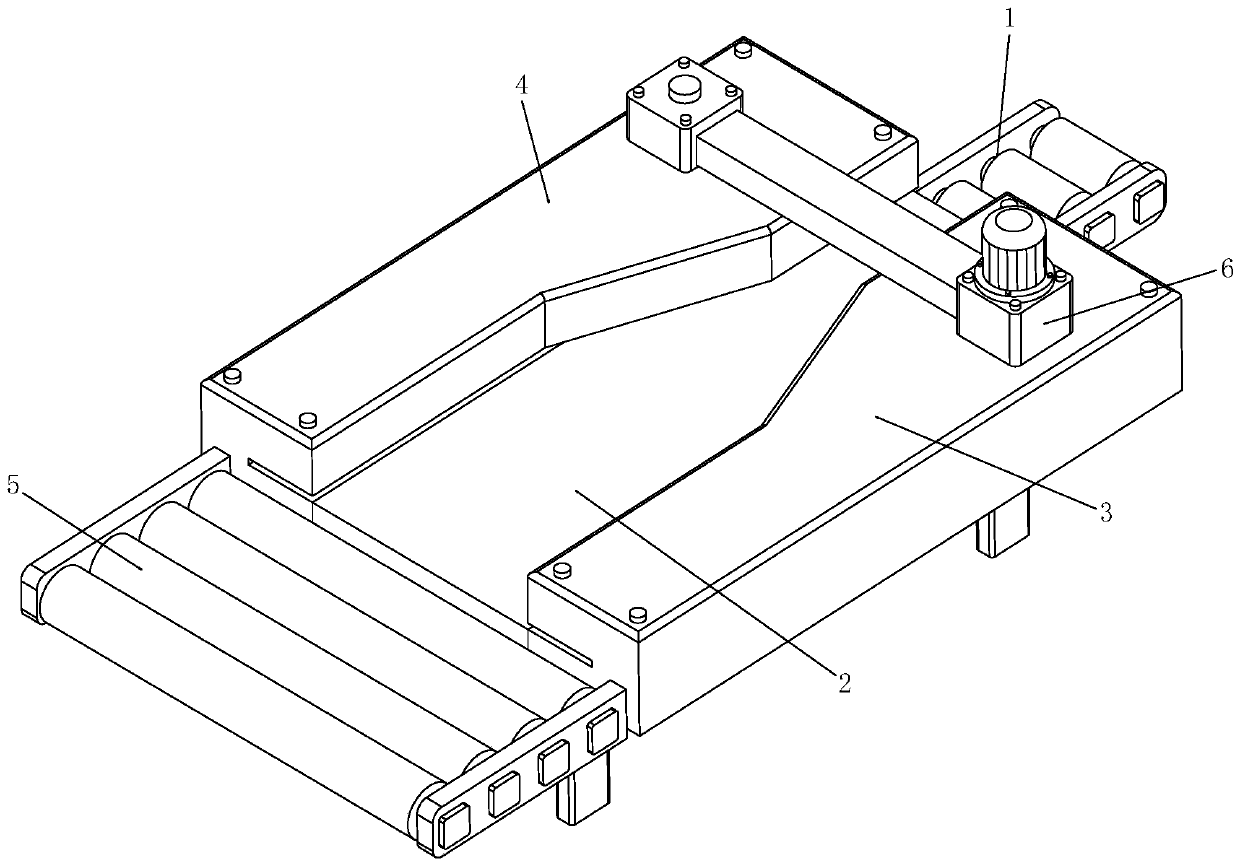

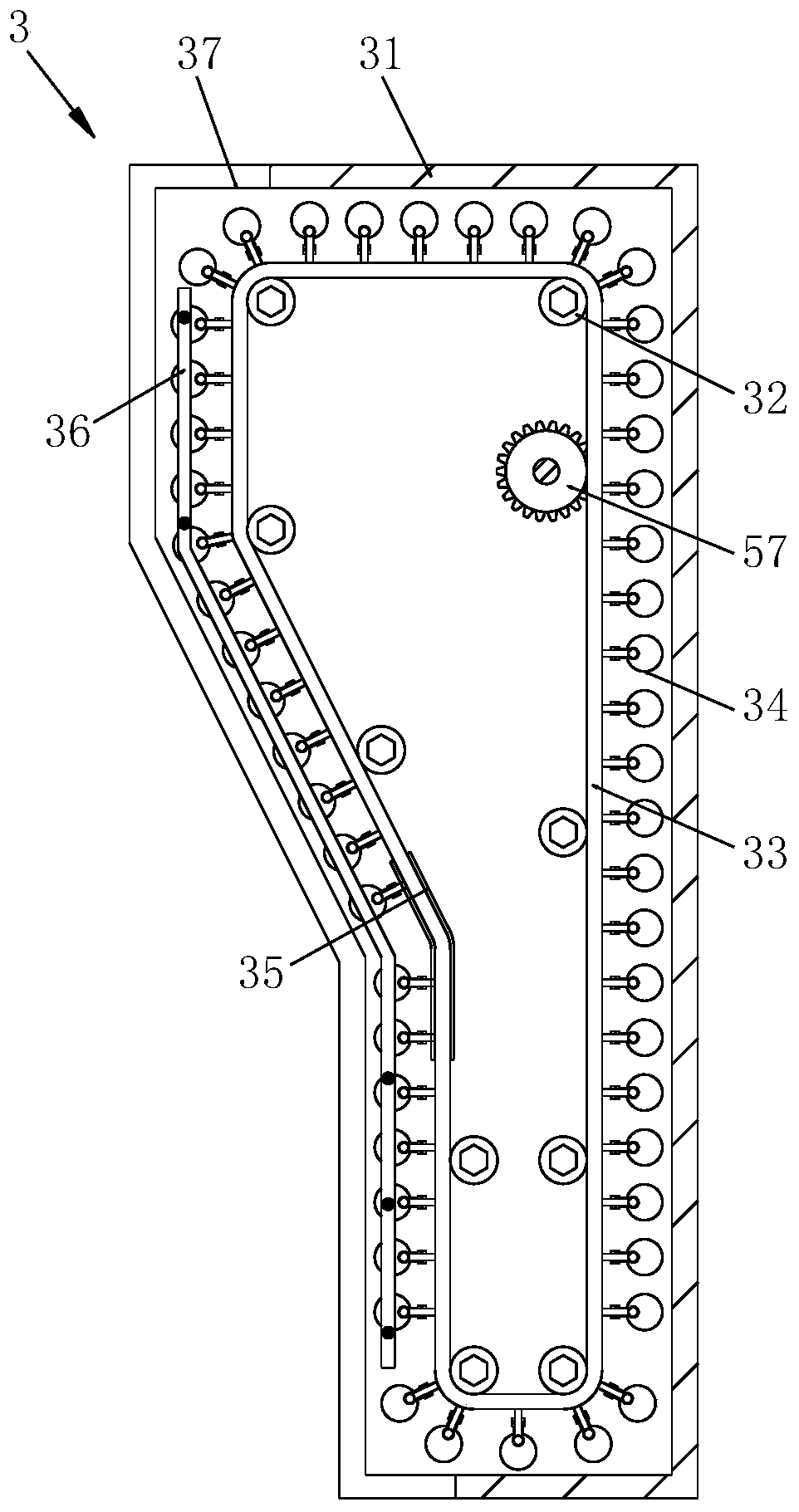

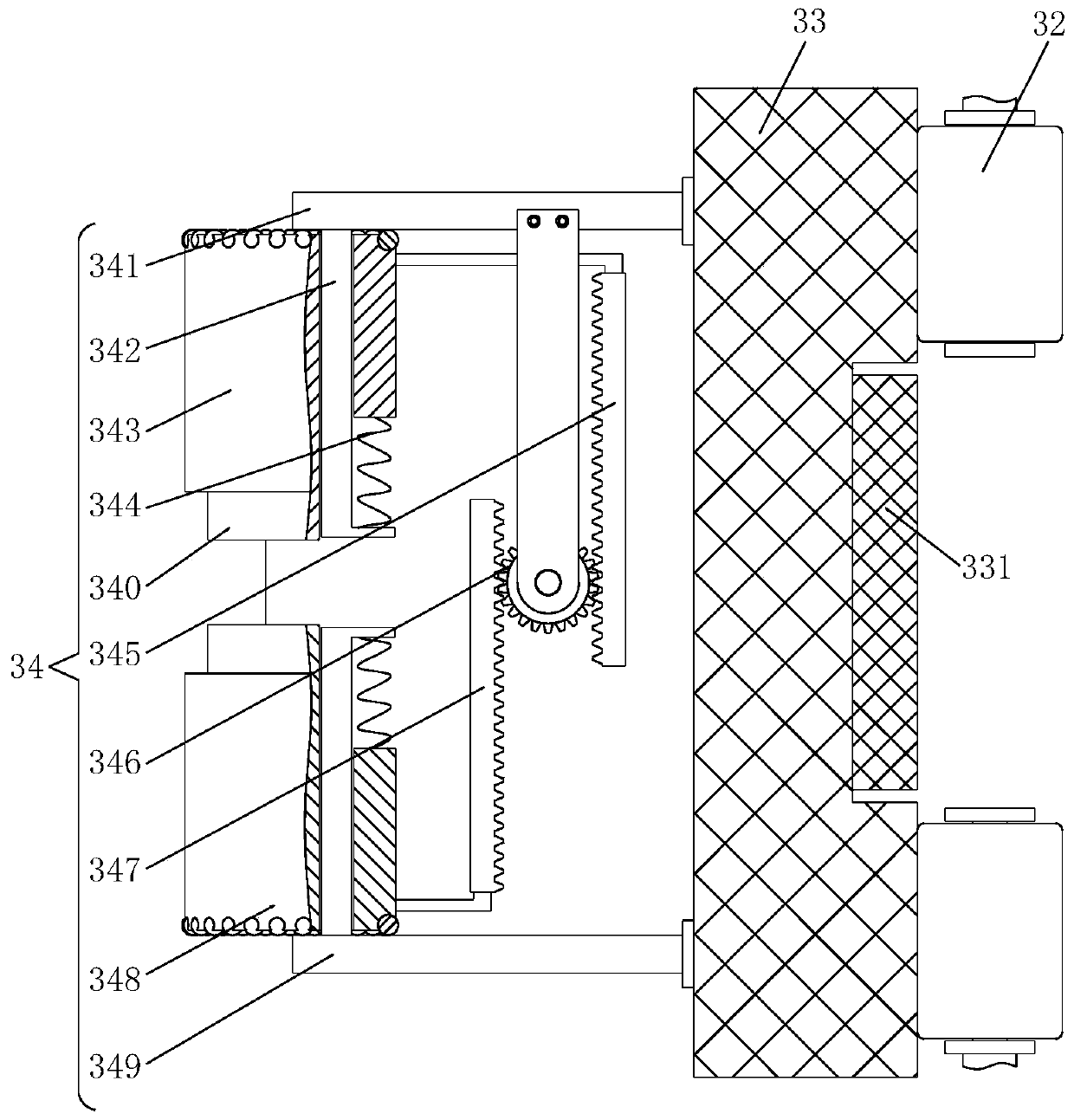

Off-line in-situ stretching device for X-ray diffraction experiment

ActiveCN113390720AMeet testing needsImprove adaptabilityMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesMechanical engineeringRay

The invention provides an off-line in-situ stretching device for an X-ray diffraction experiment. The device comprises a loading assembly which comprises a support and a stretching drive assembly, and a stretching assembly, wherein the stretching assembly is detachably arranged on the support, the stretching assembly comprises two stretching modules which are symmetrically arranged in the length direction, the two stretching modules are used for stretching a test piece, the test piece is fixed to the surfaces of the two stretching modules, and the stretching driving assembly is in driving connection with the two stretching modules; therefore, the two stretching modules synchronously move in the same direction or in the opposite directions. According to the device, a technical problem of in-situ stretching in the X-ray diffraction experiment can be solved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

A pot body stretching machine

Owner:山东多星电器有限公司

Stretcher

The invention relates to a wire rod stretching manufacturing device, specifically to a stretcher for stretching wire rods such as metal profile shapes, capillary and mechanical tubes. The stretcher provided by the invention comprises a machine body, a driving shaft and driven shafts arranged on the machine body, and is characterized in that the driving shaft is electrically connected with a motor; a driving disc is installed on the driving shaft; driven discs are disposed on the driven shafts; the driven shaft is one or more driven shafts; die racks are installed between the driven discs and the driving disc on the machine body; one layer or parallelly arranged multiple layers of die holders are horizontally disposed on the die racks; and stretching dies are disposed on the die holders. According to the stretcher, mangy dies are arranged on one die holder and many die holders are disposed on one stretcher, thus greatly saving space, minimizing energy consumption needed by the active driving disc, reducing cost, raising the production efficiency and improving the product precision.

Owner:湖北省麻城市镡鑫科技有限公司

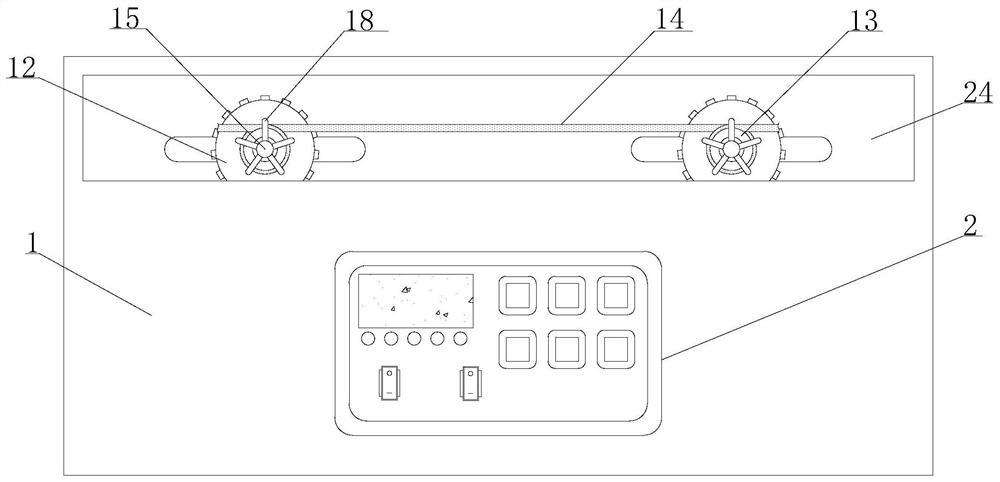

Polyurethane plastic film two-way stretching processing system

InactiveCN111391286ASame degree of stretch in both directionsAchieve two-way stretch workPolymer scienceBoPET

The invention relates to a polyurethane plastic film two-way stretching processing system. The polyurethane plastic film two-way stretching processing system comprises a feeding roller, a placing platform, a first stretching mechanism, a second stretching mechanism, a discharging roller and a driving mechanism, wherein the first stretching mechanism and the second stretching mechanism are respectively mounted on two sides of the placing platform, and are fixed to the placing platform through bolts; the first stretching mechanism and the second stretching mechanism are two components of which the structures are completely the same; the driving mechanism is arranged on the top of the first stretching mechanism; the feeding roller is mounted at one end of the placing platform; the dischargingroller is mounted at the other end of the placing platform; a first protective shell and a second protective shell are respectively and correspondingly mounted on the upper end surface of the secondstretching mechanism and the upper end surface of the first stretching mechanism through bolts; and a driving motor is mounted on the top of the second protective shell. By the polyurethane plastic film two-way stretching processing system, continuous two-way stretching work on a coiled thick film can be carried out, the stretching efficiency is high, and the stretching effect is good.

Owner:仇芳

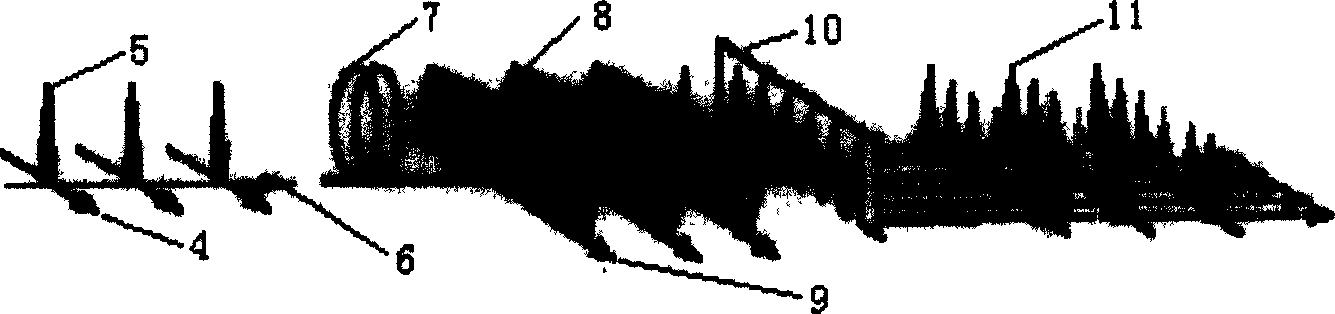

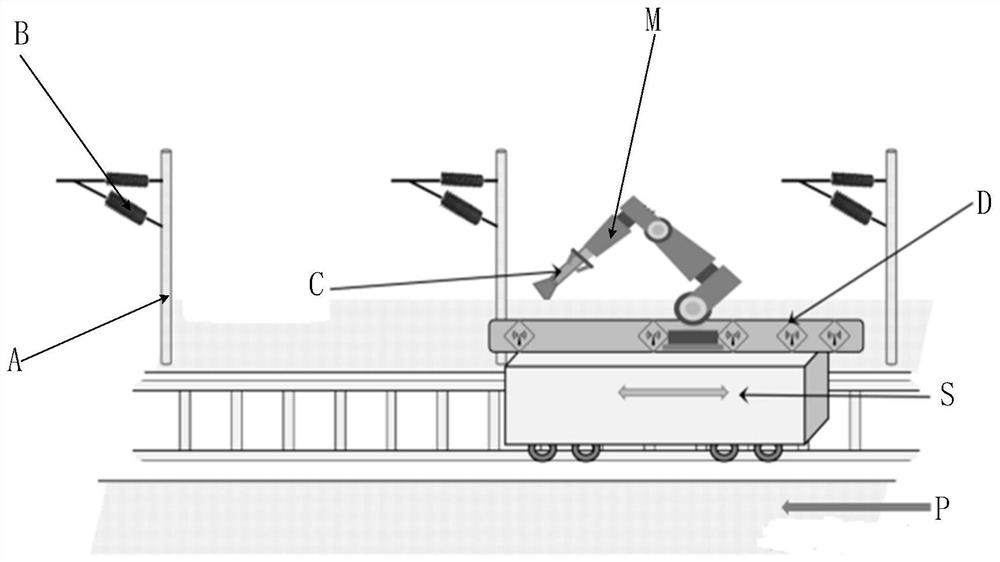

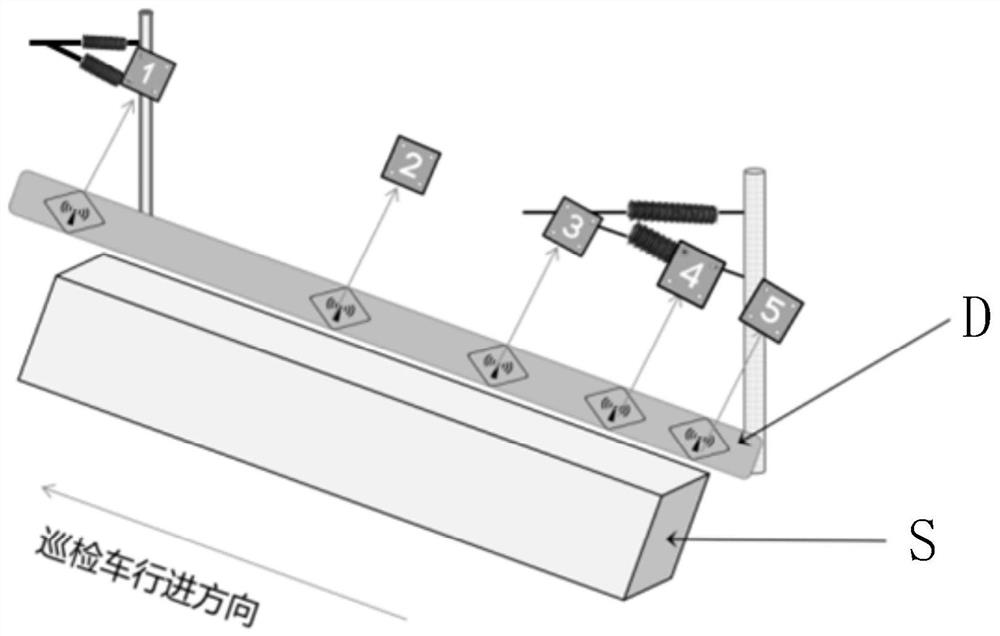

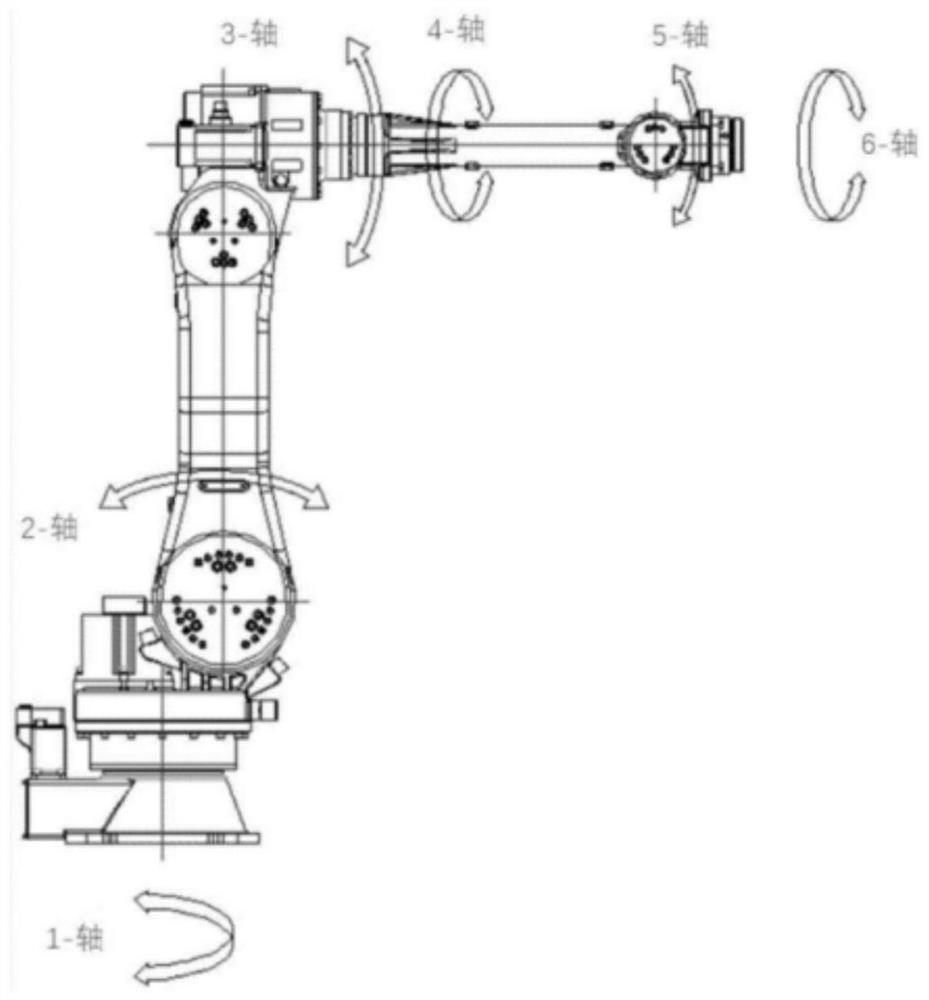

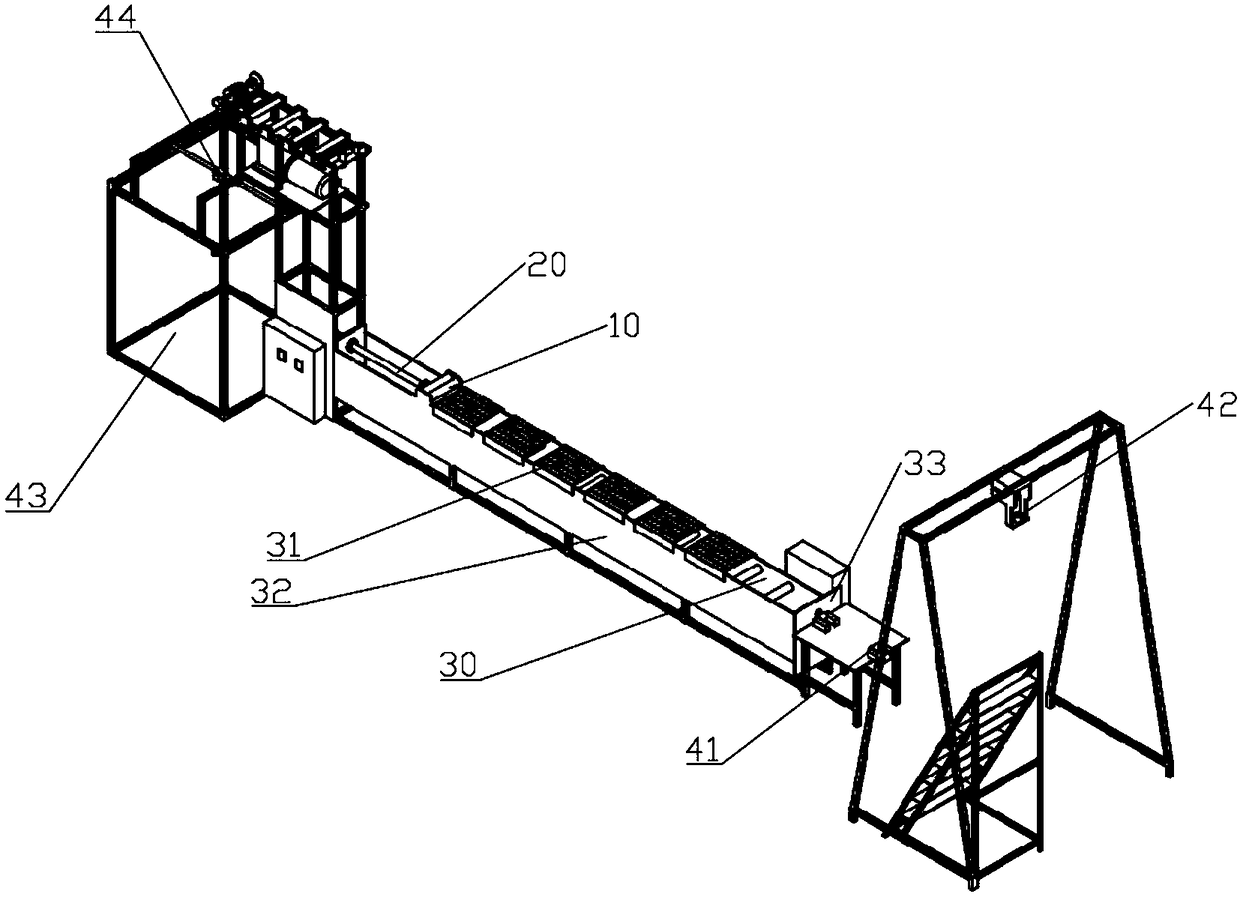

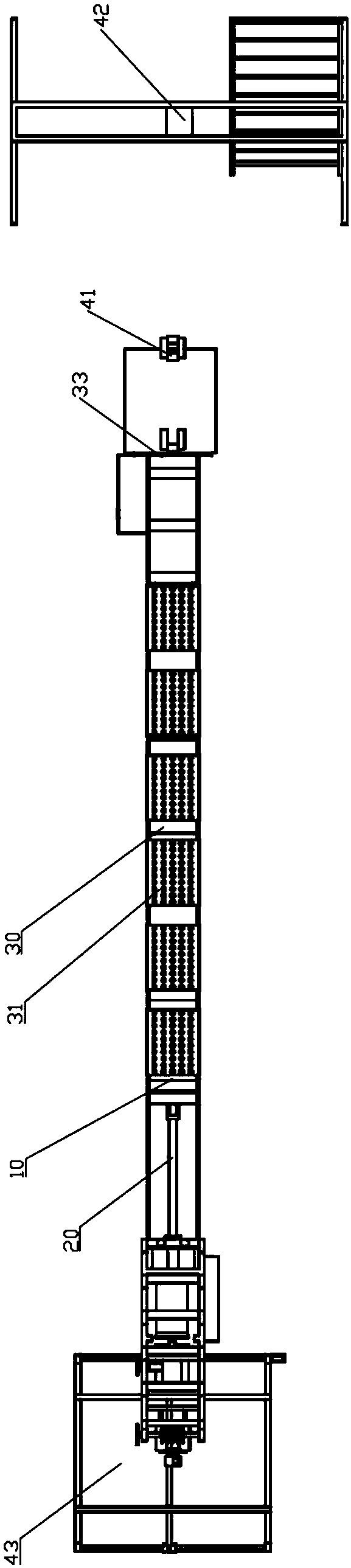

Cleaning system for railway insulator, and cleaning method

InactiveCN113369221AImprove cleaning efficiencyImprove stretching efficiencyCleaning using liquidsElectromagnetic wave reradiationLaser rangingMechanical engineering

The invention provides a cleaning system for a railway insulator, and a cleaning method. The cleaning system comprises a controller, a multi-axis robot installed on a railway inspection vehicle, a cleaning spray gun installed on the multi-axis robot, and a laser ranging array installed beside the railway inspection vehicle and located on the same side with an insulator supporting rod, wherein the laser ranging array comprises multiple ranging units arranged side by side; the multiple ranging units are used for respectively collecting ranging data between the railway inspection vehicle and the insulator supporting rod when the railway inspection vehicle moves, and sending the ranging data to the controller; and the controller is used for determining whether the railway inspection vehicle arrives at a target position which is a preset distance away from the insulator supporting rod or not according to the ranging data collected by the multiple ranging units, so that when the railway inspection vehicle is determined to arrive at the target position, the controller is used for controlling the cleaning spray gun on the multi-axis robot to spray and clean the corresponding insulator. According to the cleaning system for the railway insulator, and the cleaning method provided by the invention, the cleaning efficiency of the railway insulator can be improved.

Owner:深圳市中安维科技有限公司

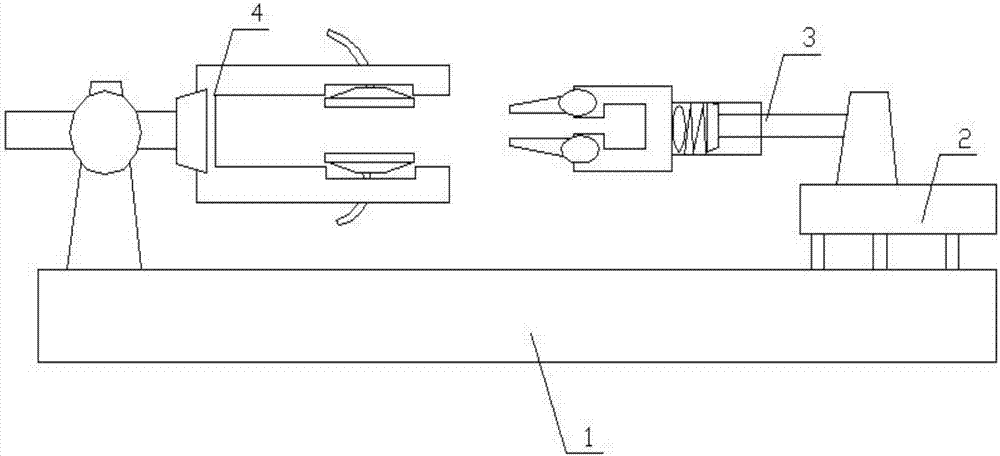

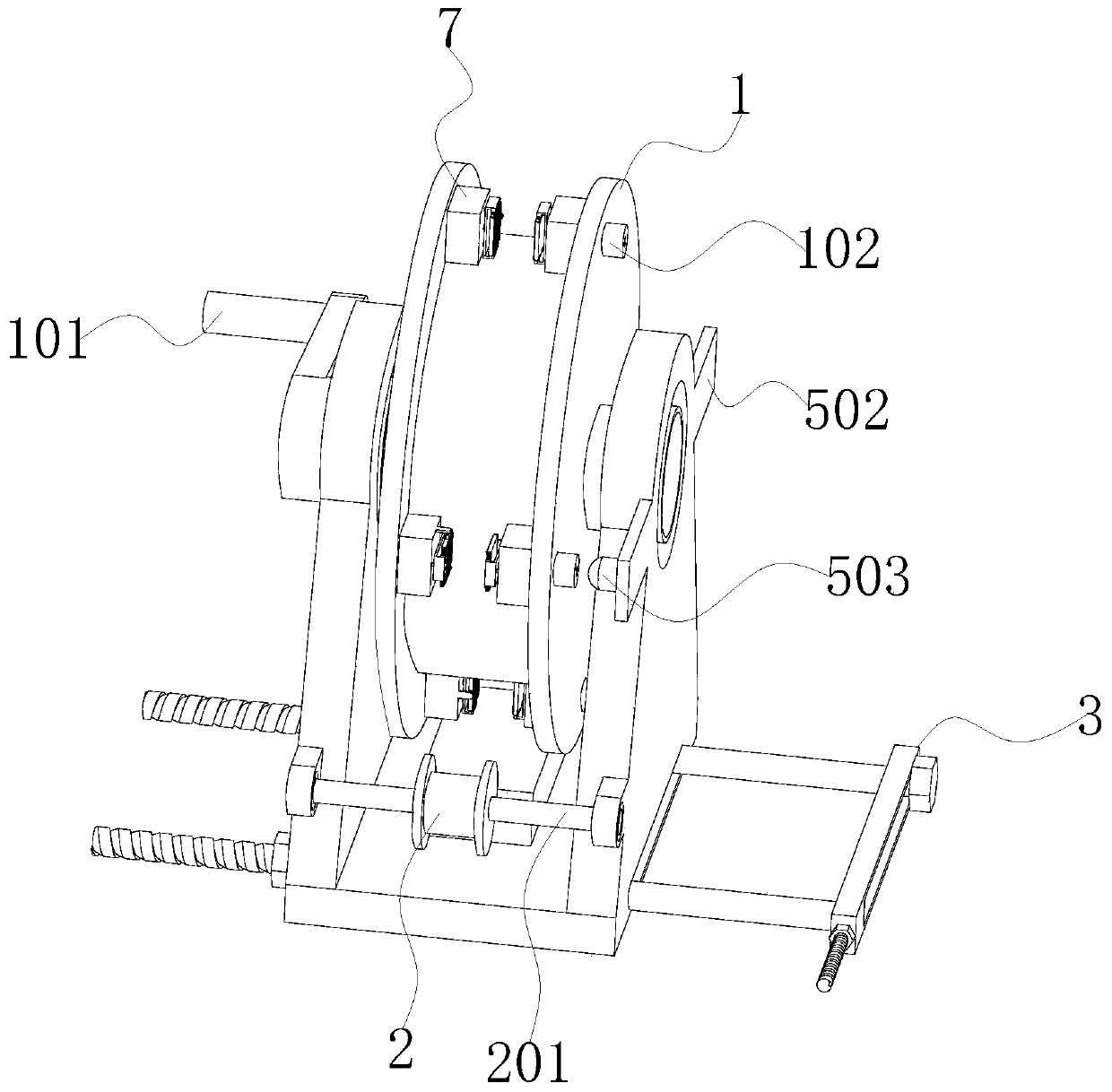

Iron chain breaking strength detection device

PendingCN108444829AImprove stretching efficiencySolve operational safety issuesMaterial strength using tensile/compressive forcesBreaking strengthEngineering

The invention discloses an iron chain breaking strength detection device which comprises two opposite fixing seats, wherein two opposite clamping plates are fixedly connected between the two fixing seats; certain space is reserved between the two clamping plates; a chain ring of a compensation chain is clamped in the gap between the two clamping plates for fixing, and then the compensation chain is stretched so as to detect whether the stretched compensation chain has pseudo soldering or solder skips; after the stretching, the chain ring is taken out of the gap between the two clamping plates,without needing other fixing structures; therefore, the stretching efficiency of the compensation chain is improved, and the problems of pseudo soldering and solder skips of the compensation chain and consequent influence on the elevator running safety can be solved.

Owner:南通中力科技有限公司

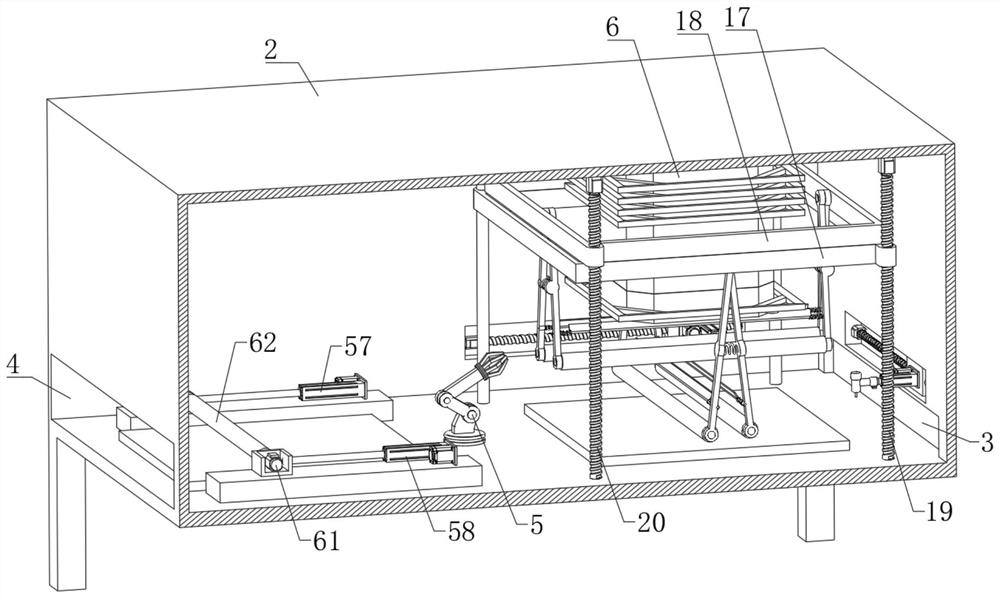

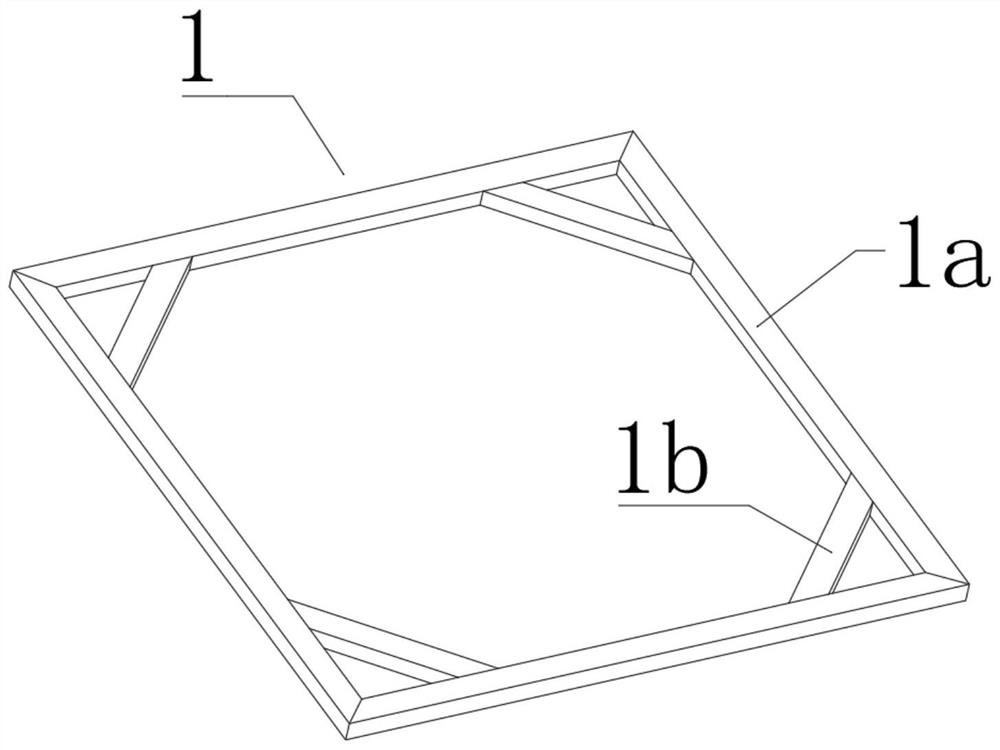

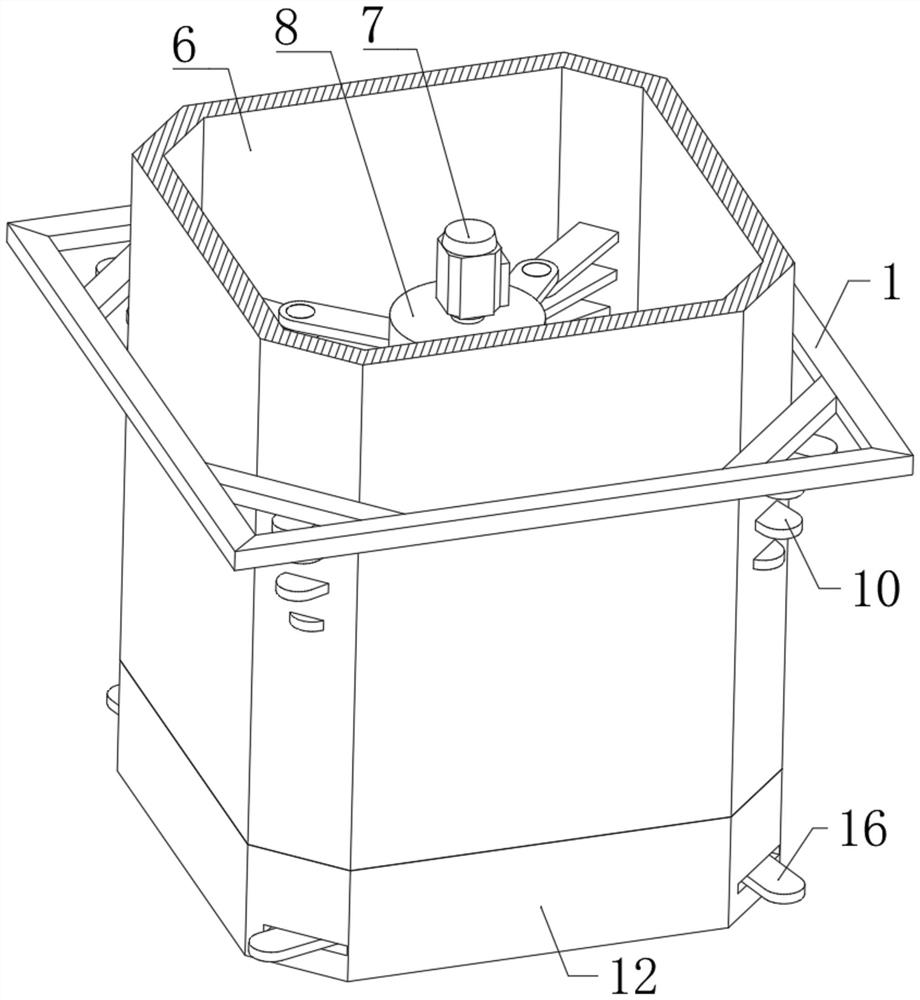

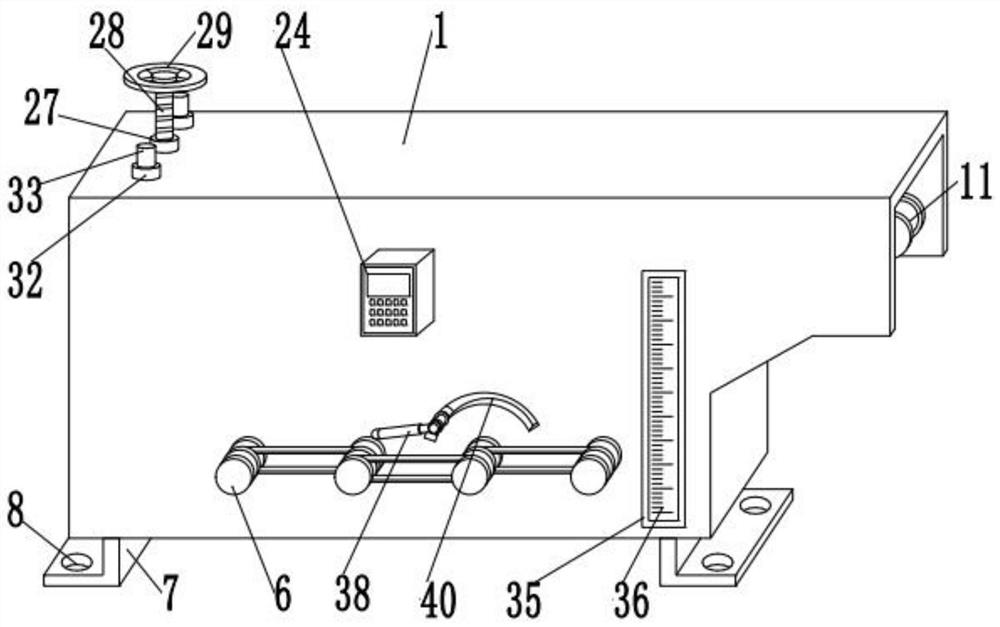

Cloth tightening device of oil painting frame

ActiveCN113829792AQuality assuranceConvenient teaching workSpecial ornamental structuresPolishingEngineering

A cloth tightening device of an oil painting frame comprises a box body, the side, provided with a feeding port, of the side wall of the box body is the front side, the other side, provided with a discharging port, of the side wall of the box body is the rear side, and a cloth tightening unit used for tightening canvas on the painting frame and a polishing unit used for polishing the canvas are arranged in the box body from front to back. A clamping hand for transferring the painting between the cloth tightening unit and the polishing unit is also arranged between the cloth tightening unit and the polishing unit. The cloth tightening device can quickly complete cloth tightening work of the oil painting frame, is simple in structure, can improve the cloth tightening efficiency, reduce labor intensity and guarantee cloth tightening quality, is smooth in warp and weft, and facilitates teaching work of art teachers.

Owner:CHONGQING TECH & BUSINESS UNIV

Ligament traction device for track and field training

ActiveCN113426070ARealize the stretch functionStretch slowGymnastic exercisingRatchetPhysical medicine and rehabilitation

The invention discloses a ligament traction device for track and field training, relates to the technical field of track and field training, and solves the problems that a ligament traction device used at present is mainly used for fixing a leg through a leg fixing structure and then unfolding the leg, the stress is mainly applied to the leg, the bearing force is large, and a ligament pulling structure facilitating whole body stretching does not exist. The ligament traction device for track and field training comprises a base. Two sets of leg seats are integrally arranged on the two sides of the rear end of the base, and lead screws are rotationally arranged on the adjacent sides of the two sets of leg seats; a top plate is fixedly arranged at the tops of the base and the leg seats; two sets of pre-moving motors are fixedly arranged in the base, and inner ratchet gears A are fixedly arranged at the shaft ends of the pre-moving motors. According to the invention, convenience is provided for ligament traction by arranging side plates, the legs can be rapidly lifted to the ligament stress position to be further slowly stretched through two stress modes, and the whole body can be conveniently stretched; the stretching efficiency is improved, and a single leg can be quickly stretched.

Owner:兰溪市网奥运动器材有限公司

Cable straightening device for communication engineering

InactiveCN111468645AEasy to useSolve the problem that the large size cannot be used for straightening during cable installationApparatus for laying cablesStructural engineeringMechanical engineering

The invention discloses a cable straightening device for communication engineering, and relates to the technical field of communication engineering. The cable straightening device comprises a rotatingroller, a base and clamping mechanisms, wherein the rotating roller is arranged at the upper end position of the inner side of the base, the four sets of clamping mechanisms are uniformly distributedon the two opposite inner sides of the rotating roller in the circumferential direction, and each set of clamping mechanisms is composed of two opposite clamping mechanisms; a through limiting grooveis formed in a bottom plate of the base; mounting plates are symmetrically arranged at the two ends of the outer wall of one side of the base, and an infrared emitter is fixedly mounted on the outerwall of one side, close to the rotating roller, of each mounting plate; and the outer surface of one side, close to the infrared emitters, of the rotating roller is provided with four infrared receivers which correspond to the clamping mechanisms in a one-to-one mode in the circumferential direction. According to the cable straightening device, a cable is straightened in the cable installation process, so that the straightening efficiency is high; and according to the device, the cable stretching degree can be monitored in real time, so that excessive straightening is avoided.

Owner:合肥智瑞工程科技有限公司

Stretching device for producing welding wire

The invention relates to the technical field of welding wire production, in particular to a stretching device for producing a welding wire. The stretching device comprises a shell, wherein a conical roller connected between the inner walls of the two sides of the shell through bearings, an elliptical roller is connected between the inner walls of the two sides of the shell through bearings, a second stretching roller is connected between the inner walls of the two sides of the shell through bearings, and an embossing roller is connected between the inner walls of the two sides of the shell through bearings; one end of the conical roller, one end of the elliptical roller, one end of the second stretching roller and one end of the embossing roller extend out of the shell to be connected with transmission wheels through flat keys; every two adjacent transmission wheels are in transmission connection through a belt; and the outer wall of one side of the shell is connected with a first motor through a bolt. The welding wire is wound on the elliptical roller, the second stretching roller and the embossing roller, so that the linear speeds generated when a first stretching roller, the second stretching roller and the embossing roller rotate are different, the effect that the welding wire is gradually stressed and stretched is achieved, the stress is uniform, and the welding wire is not prone to being snapped.

Owner:贵溪广信新能源科技有限公司

Coaxial cable tension test method

PendingCN113624598ATo achieve the purpose of stretchingTensile test is convenient and quickMaterial strength using tensile/compressive forcesCoaxial cablePull force

The invention discloses a coaxial cable tension test method. The two ends of a to-be-detected cable body are wound on the surfaces of mounting shafts on the two sides respectively; and a first sliding nut on the surface of the first rotating screw rod drives an adjusting rod to move relatively, so that the upper side of the adjusting rod drives adjusting gears to move oppositely, the distance between the adjusting gears is changed, and the purpose of stretching the cable body is achieved. A second driving motor is started, a second transmission rod rotates through a crawler belt and a first mounting rod, so that the first mounting rod drives a cable body to move through a mounting shaft, the position needing to be stretched is changed, the stretching part of the cable body can be adjusted according to requirements during testing, time and labor are saved, and therefore, the stretching efficiency of the cable body is improved during the test.

Owner:SHENYU COMM TECH

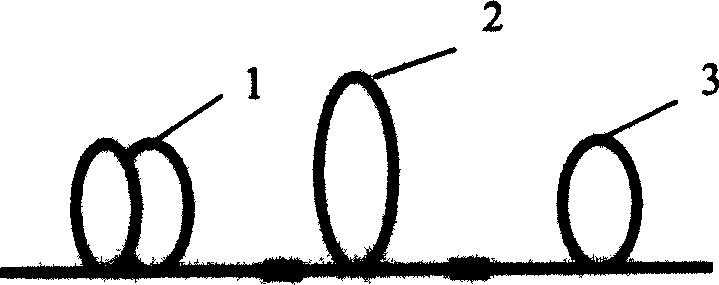

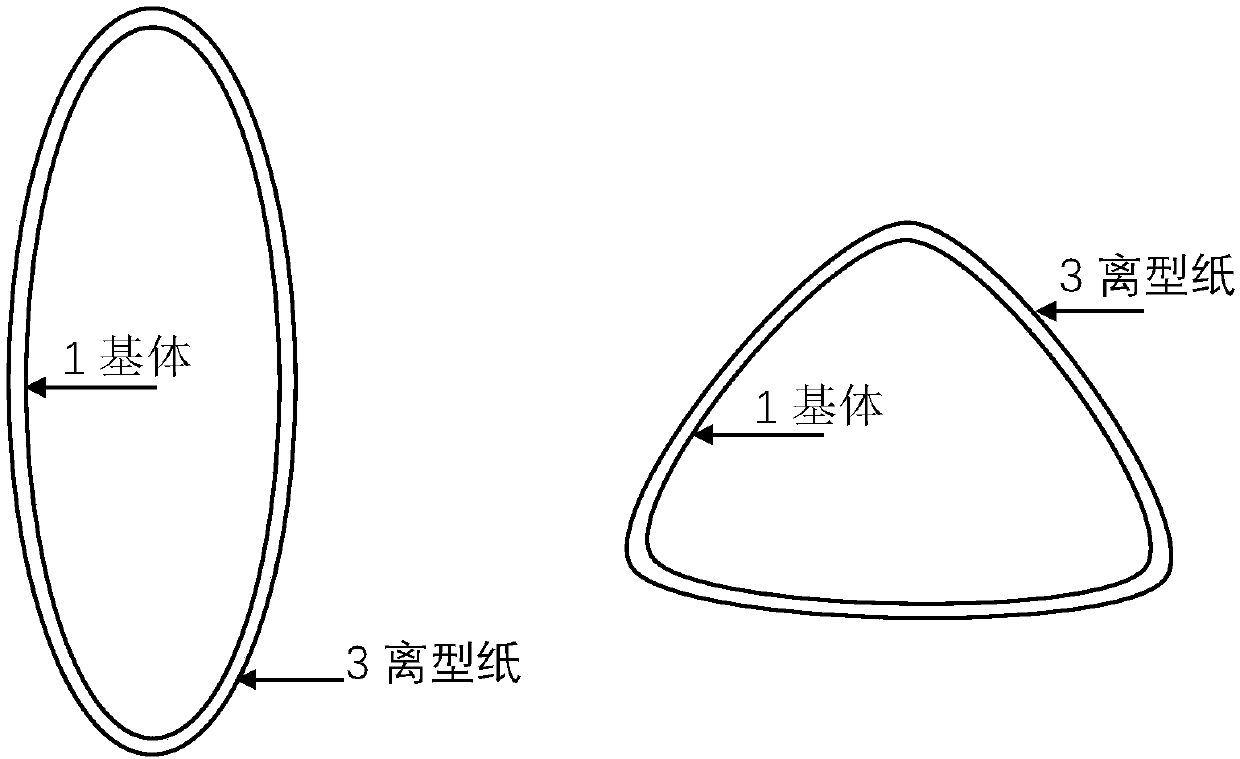

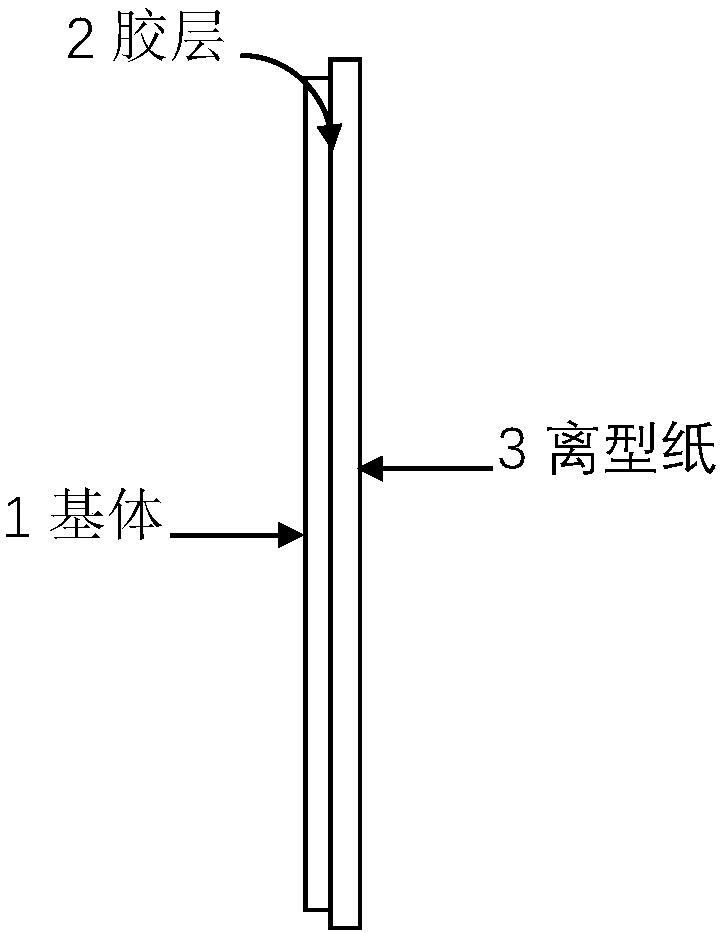

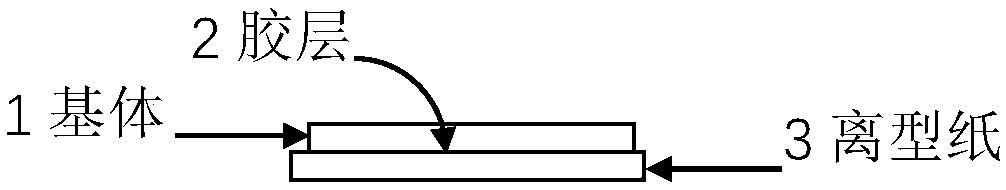

Kinesiology tape having nonlinear gradient biological mechanical characteristics

A kinesiology tape having nonlinear gradient biological mechanical characteristics is disclosed. The kinesiology tape includes a substrate having nonlinear gradient material performance, a two-dimensional wave-shaped glue layer and common release paper. The kinesiology tape is spindle-shaped or triangle as shown in attached drawings 1-3. By utilizing a fact that the nonlinear gradient material performance can reduce the wrinkle rate and enhance biological breathable effects during movement processes, a series of mechanical protection can be achieved, such as increase in muscle eccentric contraction force generation, exercise fatigue time prolonging, and movement impact damage reducing. In addition, a muscle-like shape design effectively improves the traction efficiency for muscles, and thetwo-dimensional wave-shaped glue layer can relieve tissue edema to a certain degree.

Owner:BEIHANG UNIV

Novel in-shoe expanding device

The invention discloses a novel in-shoe expanding device. The novel in-shoe expanding device comprises a back supporting block, an inner cavity, air exhaust holes, a sleeve, a sliding block, a spring,a supporting column, front supporting blocks, through holes, an active carbon bottom plate, ventilation holes, a cavity, a sponge block, a connecting pipe, a connecting shaft, an air sac, a first airfeeding pipe, a first micro air pump, a fixing plate, a supporting-column threaded hole, a first air exhaust pipe, a first air exhaust valve, an electrical heating wire net, a second air feeding pipe, a second micro air pump, a second air exhaust pipe, a second air exhaust valve and an air exhaust fan. The novel in-shoe expanding device is simple in structure and novel in design, the novel in-shoe expanding device is conveniently put inside a shoe, the application range is wide, the novel in-shoe expanding device is suitable for expanding shoes with different types, and original shoe types ofthe shoes are guaranteed; meanwhile, next wearing of users is convenient, using of the shoes is protected, the service life of the shoes is prolonged, and when the novel in-shoe expanding device is used, residual bad smells in the shoes are conveniently filtered and adsorbed.

Owner:柏宗翰 +5

Core cooling system of pipe extruding mould

InactiveCN103538242AImprove cooling effectIncrease extrusion speedTubular articlesCold airInsulation layer

The invention provides a core cooling system of a pipe extruding mould. The core cooling system comprises a core mould arranged inside the extruding mould, wherein an extruding channel and a center cavity which are mutually independent are arranged on the core mould, a cold air pipe is arranged in the center cavity in a penetrating manner and comprises an inlet ventilator, a middle ventilator and an outlet ventilator, the inlet ventilator extends out of the outer part of the core mould, a heat insulation layer is arranged on the outer wall of the middle ventilator, a cooling channel is arranged at a position, close to the extruding channel, inside the core mould, one end of the cooling channel is connected with an external air inlet device, the other end of the cooling channel is connected with a hot air outlet, and the outlet ventilator is connected with the external air inlet device. By using the core cooling system of the pipe extruding mould, provided by the invention, the extruding speed and quality of a pipe are improved, the heat radiation condition of the mould is also improved, the environmental friendliness and low energy consumption are achieved, the cost is low, and the energy can be recycled.

Owner:NINGBO KANGRUN MACHINERY TECH

Auxiliary processing device for food

InactiveCN111802420AGood for fallingAvoid stickingDough shapingDough processingStructural engineeringMechanical engineering

The invention provides an auxiliary processing device for food. A guide sliding groove is formed in each inner support plate; each outer support plate is fixedly connected with a connection base provided with a cross rod A; the upper end of the front part of each outer support plate is fixedly connected with a cross rod B; a guide sliding block in one guide sliding groove is arranged at the lowerend of each strip-shaped vertical plate A and a strip-shaped hole A is formed in the upper part of each strip-shaped vertical plate A; the inner ends of each upper strip-shaped transverse plate and one corresponding lower strip-shaped transverse plate are hinged with the upper end and the lower end of one corresponding strip-shaped vertical plate A through one corresponding connecting rod A and one corresponding connecting rod B separately; the outer ends of each upper strip-shaped transverse plate and one corresponding lower strip-shaped transverse plate are hinged with the upper end and thelower end of one corresponding strip-shaped vertical plate B through one corresponding connecting rod C and one corresponding connecting rod D separately; the rear end of each dough pulling rod passesthrough one strip-shaped hole A and then is fixedly connected with one corresponding limiting block; one connecting rod X and one connecting rod Y which are hinged are connected with one corresponding limiting block and one corresponding connecting rod B separately; a rotating shaft A and a rotating shaft B at the centers of each fixed gear and one corresponding movable gear are hinged with two ends of one corresponding rocking bar A separately; one end of each rocking bar B is connected with one corresponding cross rod A and the middle part of each rocking bar B is connected with an eccentric rotating shaft C of one movable gear and hinged with one corresponding lower strip-shaped transverse plate through one corresponding connecting rod E; and two ends of each fixed connecting rod are connected with one cross rod A and the rear end of one corresponding rotating shaft A separately. The auxiliary processing device can assist operating personnel in making hand-pulled noodles.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com