Cleaning system for railway insulator, and cleaning method

A cleaning system and technology for insulators, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as insecurity and low cleaning efficiency of railway insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

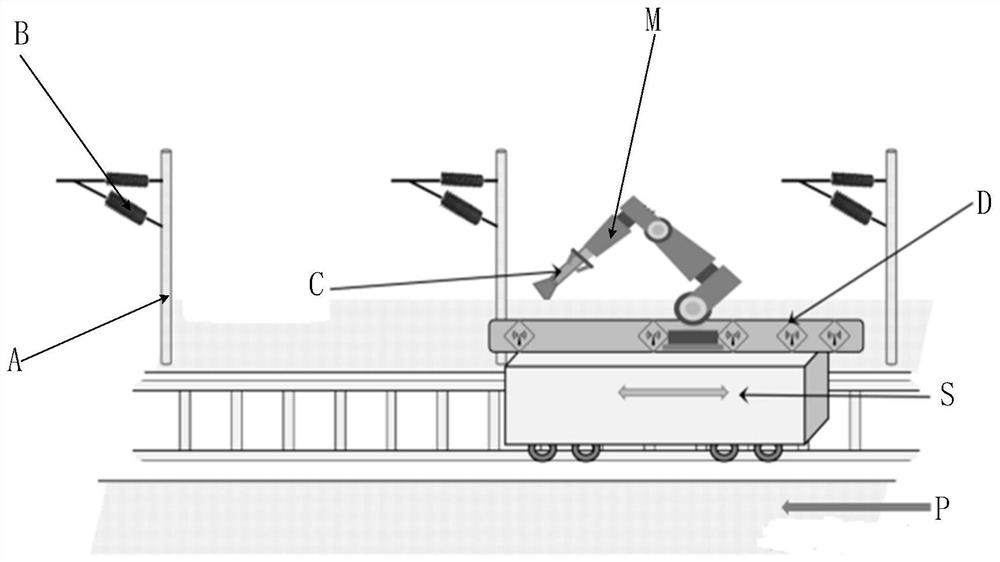

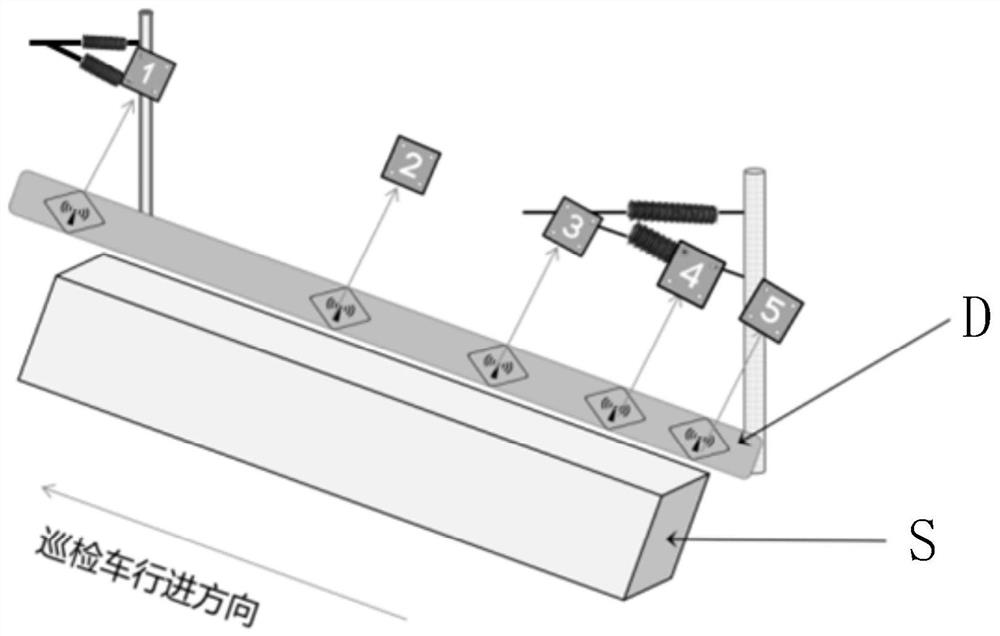

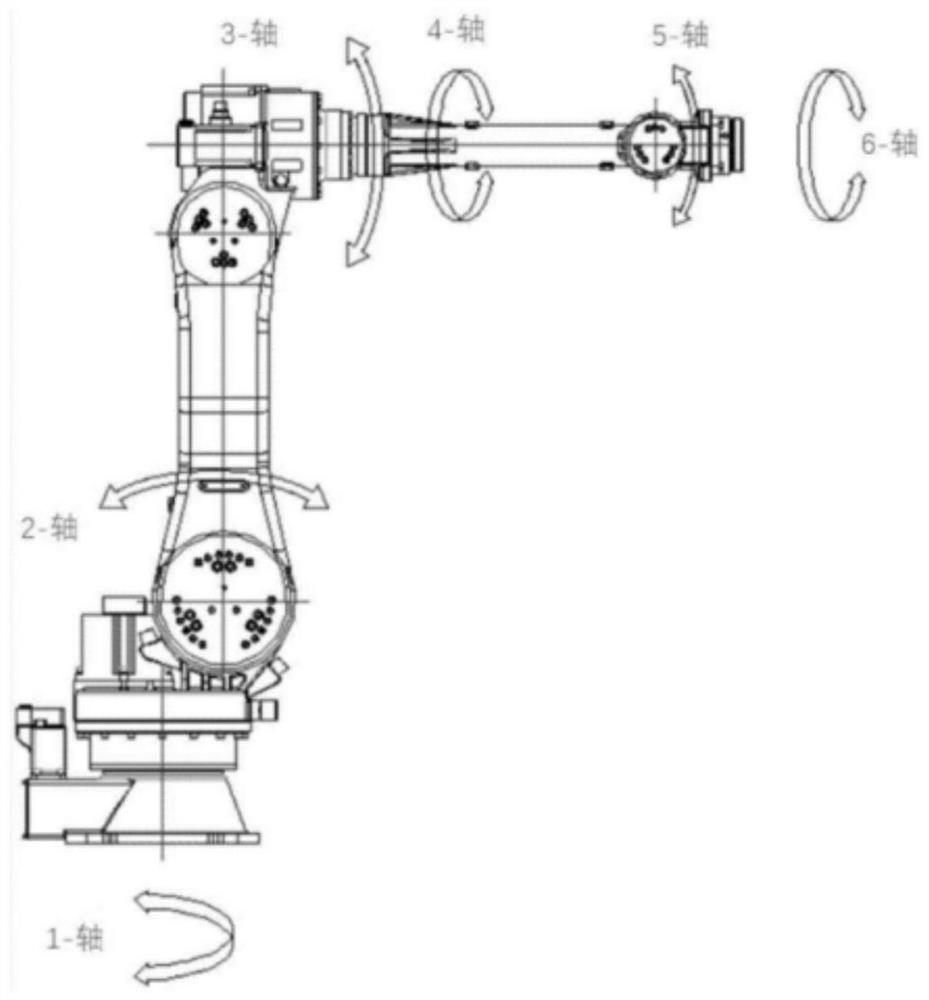

[0045] A first aspect of the present invention provides a cleaning system for railway insulators B, such as figure 1 and figure 2 As shown, the cleaning system includes a controller (not shown in the figure), wherein the controller can be understood as an MCU (Microcontroller Unit) micro-control unit, and the MCU micro-control unit can be a single-chip microcomputer, or a 16-bit micro-control unit , or a 32-bit micro-control unit (such as an STM32 chip), etc.; the multi-axis robot M installed on the railway inspection car S, the multi-axis robot M can be a 5-axis robot or a 6-axis robot, etc.; The cleaning spray gun C on the multi-axis robot M, and the laser ranging array D installed next to the railway inspection vehicle S and on the same side as the insulator support rod A.

[0046] Specifically, the laser ranging array D includes a plurality of ranging units arranged side by side, that is, the plurality of ranging units are arranged side by side next to the railway inspec...

Embodiment 2

[0069] The second aspect of the present invention provides a cleaning method, which can be applied to the cleaning system of any embodiment in the above-mentioned embodiment 1. In one embodiment, such as Figure 4 As shown, cleaning methods include:

[0070] S10: The controller acquires ranging data respectively collected by a plurality of ranging units.

[0071] The laser ranging array based on the cleaning system includes multiple ranging units, and each ranging unit is used to collect the ranging data between the railway inspection vehicle and the insulator support rod. Each ranging unit will correspond to the collected measurement data. After the distance data is sent to the controller, the controller can obtain the distance measurement data respectively collected by the plurality of distance measurement units.

[0072] S20: The controller determines whether the railway inspection vehicle has reached a target position at a predetermined distance from the insulator support...

Embodiment 3

[0083] In one embodiment, the third aspect of the present invention provides a cleaning device, and the functions realized by the cleaning device correspond to the steps of the cleaning method in the above embodiments one by one. Specifically, the cleaning device may include an acquisition module 10 , a determination module 20 and a control module 30 . Among them, the detailed description of each functional module is as follows:

[0084] The acquiring module 10 is configured to acquire ranging data respectively collected by a plurality of ranging units.

[0085] The determination module 20 is configured to determine whether the railway inspection vehicle has reached a target position that is a predetermined distance away from the insulator support rod according to the plurality of distance measurement data.

[0086] The control module 30 is configured to control the cleaning spray gun on the multi-axis robot to spray and clean the corresponding insulators when it is determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com