Wear-resistant type strong-widening roller for strip steel

A roll and strip steel technology, which is applied in the field of narrow strip steel production equipment, can solve the problems that the original looseness in the center of the billet cannot be eliminated in the optimal temperature range, poor roll shape retention ability, frequent meat loss in the pass shape, etc., to avoid roll neck Performance deterioration, solving the effects of short online time and high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

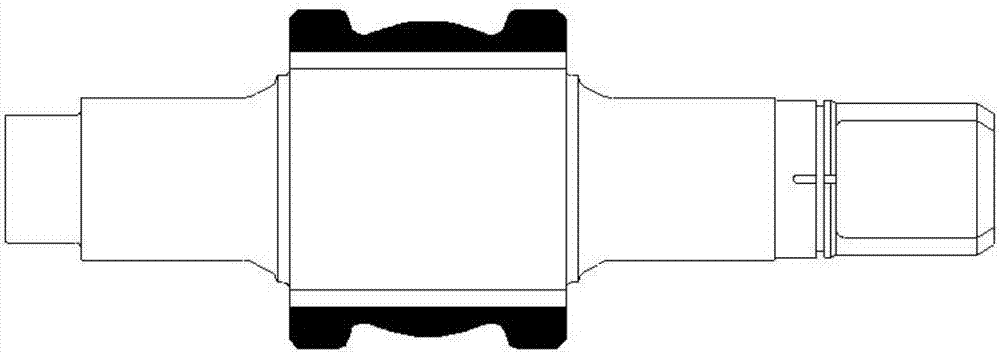

[0032] Embodiment 1: A kind of manufacturing method of high anti-abrasion strength spread roll (1)

[0033] see Image 6 The pouring schematic diagram shown, the casting process is as follows:

[0034] 1) The chemical composition of the outer CrMoV wear-resistant alloy is composed by mass fraction (%): C2.0-3.0, Si0.4-1.0, Mn0.6-1.0, Cr8-32, Ni0.8-1.8, Mo0.8- 2.0, V0.2-1.2 requirements, prepare the charge;

[0035] 2) Use intermediate frequency furnace for smelting, adjust the chemical composition according to the upper limit of the implementation process requirements;

[0036] 3) Control the temperature T of the outer high CrMoV alloy molten metal 出 =1520-1580°C;

[0037] 4) Outer layer high-CrMoV alloy molten metal out of furnace modification treatment: during the out of furnace process, along with the metal flow, 0.2-0.5% vanadium alloy (containing 50-80% of vanadium mass fraction) of the metal liquid weight is poured into 0.3-2mm particles of modifier, fully stir;

...

Embodiment 2

[0045] Embodiment 2: A kind of manufacturing method of high anti-abrasion strength spread roll (two)

[0046] 11) The casting roll blanks of high wear-resistant stretch rolls are cleaned to remove flashes, burrs, and casting sticky sand, etc.;

[0047] 12) After the roll blank is naturally cooled to room temperature, the as-cast roll retains the machining allowance for heat treatment, and performs rough machining of the blank, and at the same time rough-cuts the hole pattern;

[0048] 13) The heat treatment process of the high wear-resistant and strong stretching roll. The rough machining roll protects the upper and lower roll necks of the roll with ceramic fibers; heats from room temperature to 650 °C at a heating rate of ≤15 °C / h, and keeps the temperature for 3-6 hours. 30-50°C / h heating rate, rapid heating to 950-1000°C for austenitization, holding temperature for 5-8 hours to make Cr, Mo, V alloy fully dissolve into austenite to form supersaturated austenite, then turn on...

Embodiment 3

[0053] Embodiment 3: A kind of manufacturing method of high anti-abrasion strength spread roll (three)

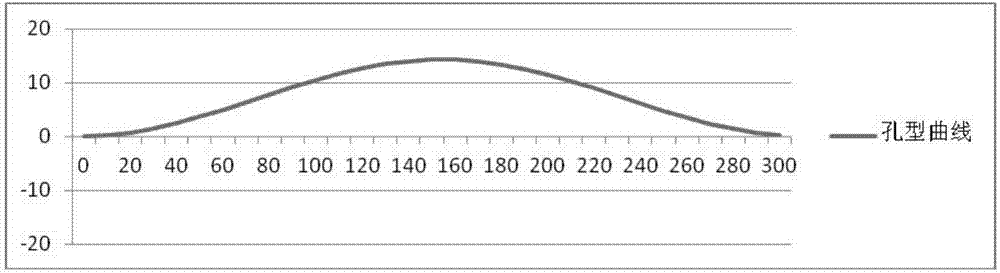

[0054] 17) After special heat treatment to adjust the structure, hardness and stress, and meet the control requirements of the process index, the roll is subjected to the finishing process, and the roll pass curve conforms to y=a×[sin(x×b-c)+d] sinusoidal curve, a, b, c, d are constants, x is the variable of the axial length of the pass, and the maximum value range of x can be adjusted from 190 to 350 according to the width specification of the specific rolled product; y is the change of the pass with the length x Sinusoidal function.

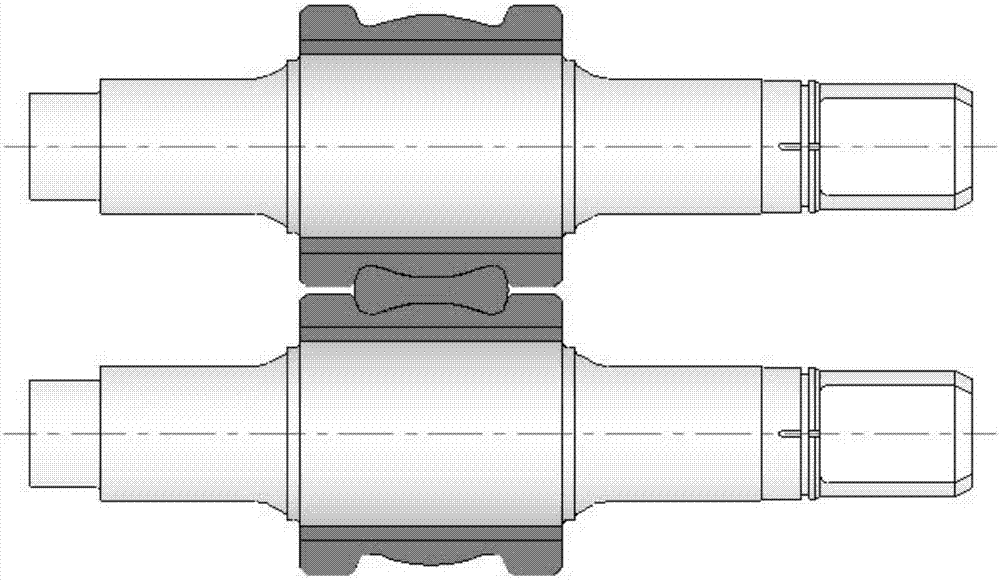

[0055] Taking the expanded plate width B=300mm as an example, the raised height in the middle of the roll pass is 14.27mm, x=0-300mm, a=7.15, b=0.02, c=45.5, d=1. That is, y=7.15×[sin(x×0.02-45.5)+1], the sinusoidal curve is as figure 2 As shown, the structure of the resulting high wear-resistant and strong spreader roll is as follows fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com