Nano tyre for keeping use with flat tyre

A run-flat tire technology, which is applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., to achieve high anti-wear characteristics, long service life, and the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

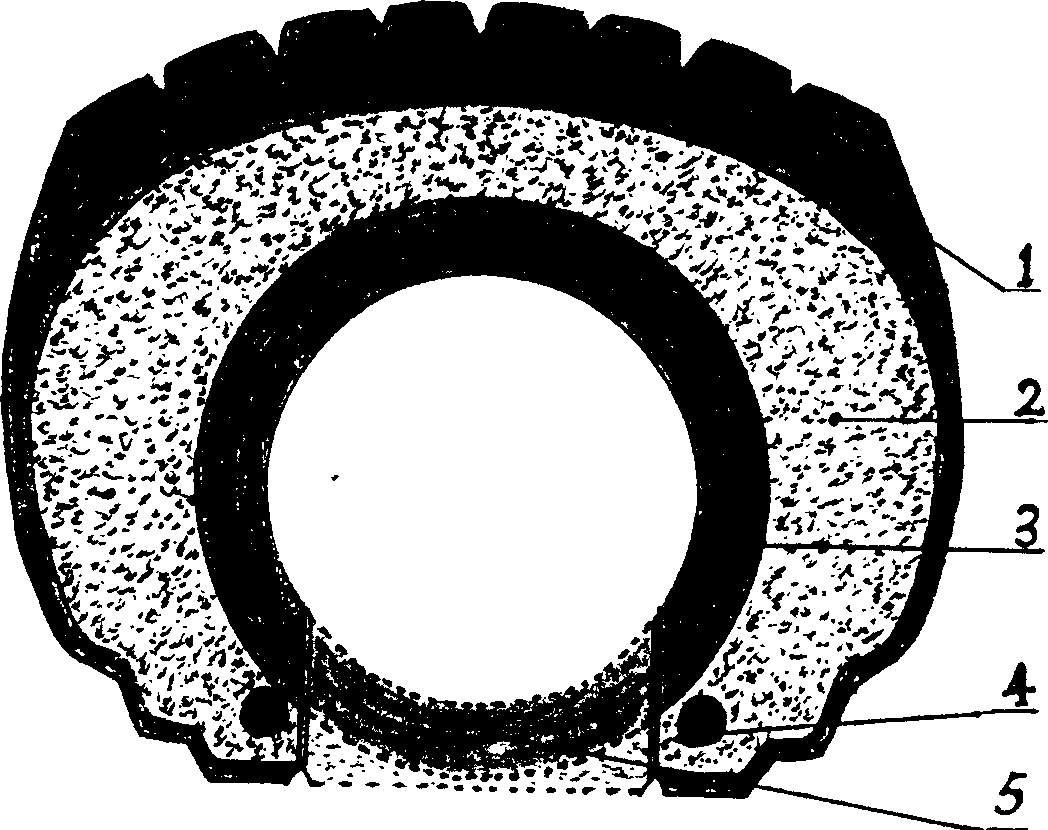

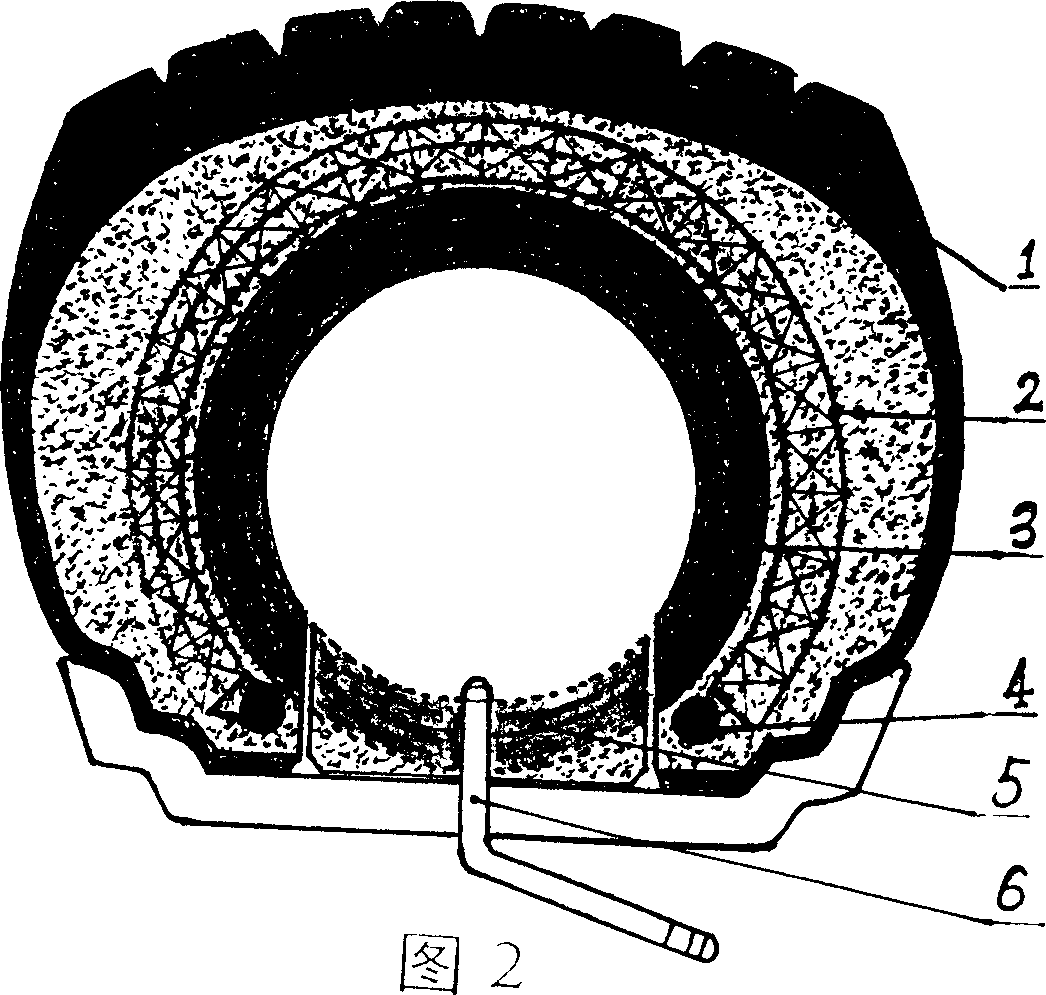

[0018] like figure 1 As shown in Fig. 2, the run-flat nano tire of the present invention has a tire tread (1) with a tire tread (1) which is mixed uniformly with the polyurethane liquid raw material by high wear resistance and good thermal stability, and then poured and centrifugally formed. No foaming agent is added to the raw materials, so that the finished tread has the characteristics of high density, low modulus, high wear resistance, high toughness, and good thermal stability. The thickness of the tread can be adjusted by controlling the injection amount of raw materials Carcass (2) is poured and centrifugally molded by mixing evenly with polyurethane liquid raw materials and can also be made by pouring other rubber materials by nano-materials with low internal heat generation and good heat resistance, and an appropriate amount of foaming agent can be added in its raw materials to The made carcass has the characteristics of low density, high modulus, high elasticity, sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com