Hydrophilic oil special for centrifugal pump in outdoor and humid areas and preparation method of hydrophilic oil

A hydrophilic, centrifugal pump technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of not meeting the special requirements of centrifugal pumps, easily destroying the lubricating film, equipment lubrication failure, etc., and achieve excellent anti-oxidation performance, use The effect of long cycle time and best low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: A special oil for centrifugal pumps in a hydrophilic outdoor and humid area, prepare 800 kg of polyether No. 50, 120 kg of polyester No. 30, 80 kg of ethylene glycol, 8 kg of mixed ammonium salt of aryl phosphate, and alkoxylated fat Alcohol 30kg, ALOX 2290AS 4kg, No. 4 high water resistance compound antifoaming agent 1kg, benzotriazole 3kg.

[0027] Production method: (1) Put 800kg of polyether No. 50, 120kg of No. 30 polyester, and 80kg of ethylene glycol into the reactor, heat up to 45-65°C, and stir for 8-10 minutes;

[0028] (2) Add 8kg of aryl phosphate mixed ammonium salt, 30kg of alkoxylated fatty alcohol, 4kg of ALOX 2290AS, 1kg of No. 4 high water resistance composite antifoaming agent, 3kg of benzotriazole, and keep the temperature at 60℃~70℃ ℃, stirred for 60 minutes, and filtered through a 1μm filter bag to become a finished product.

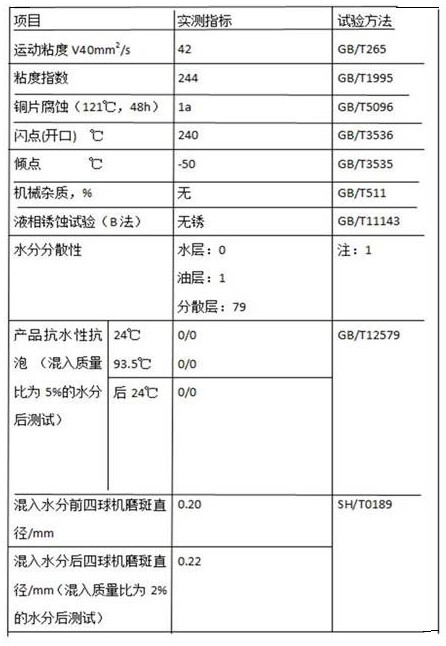

[0029] (3) Quality indicators

[0030]

[0031] Note 1: Water dispersibility test: a mixture of 40ml water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com