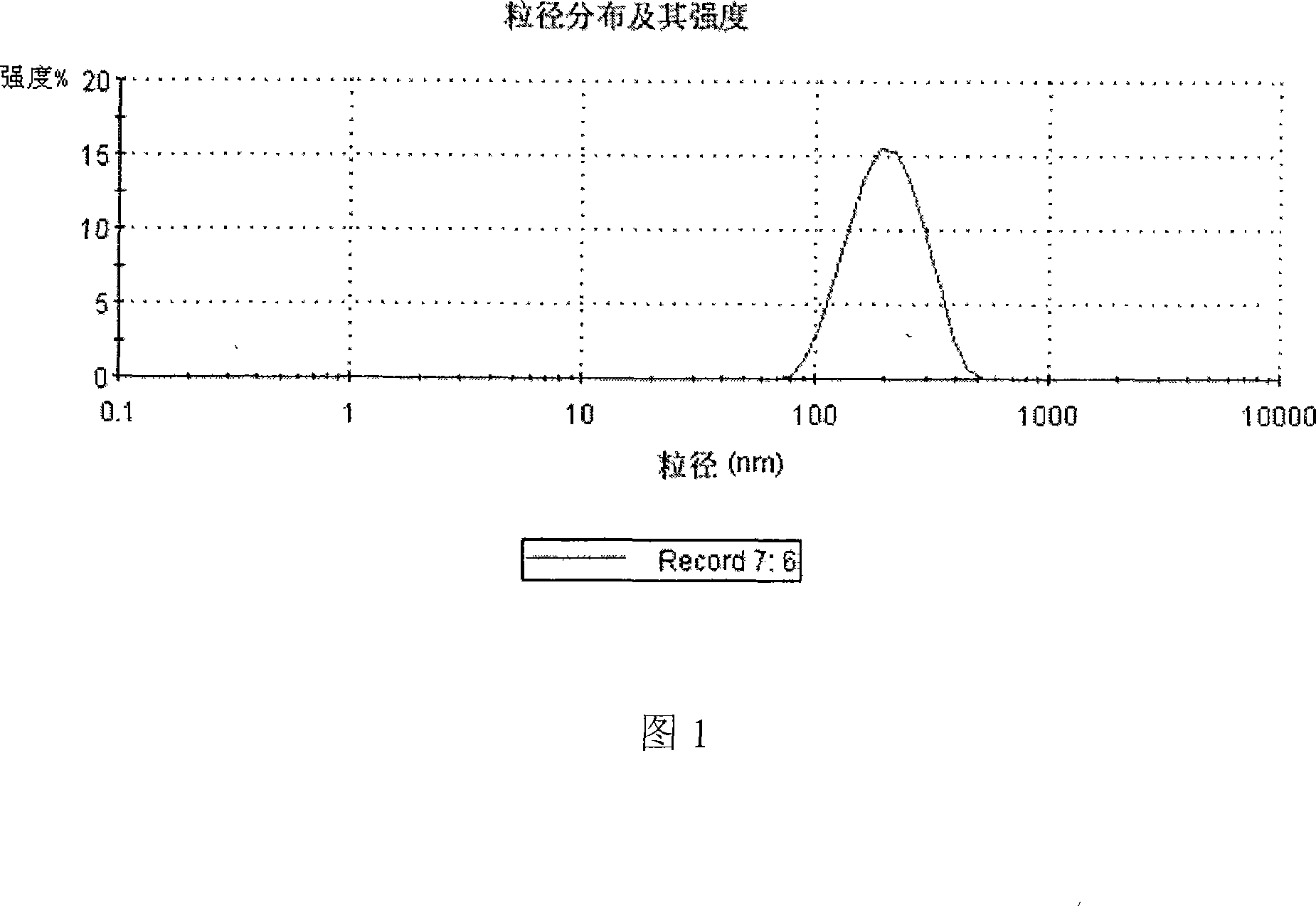

Product of Nano disperseion of water-soluble lycopene

A nano-dispersion and lycopene technology, which is applied in the field of natural pigment application, can solve the problems of insufficient particle crushing, impact on biological value, large particle size, etc., and achieve the effect of solving the problem of dissolution and increasing biological value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of lycopene organic solution (organic phase): take lycopene oleoresin with lycopene content of 1% (W / W), use acetone as solvent, prepare lycopene content as 0.01% (W / V) The solution is called the organic phase.

[0015] Aqueous solution of emulsifier (water phase): Tween 20 is selected as an emulsifier, and formulated into an aqueous solution of emulsifier at a dose of 0.5% (W / V), which is called the aqueous phase.

[0016] Mixing of organic phase and water phase: under low-speed stirring (100r / min), slowly pour the organic phase into the water phase, the ratio of the organic phase to the water phase is controlled at 1:9 (V / V), and continue at a high speed (800r / min). / min) and stirred for 10 minutes to make the mixture uniform.

[0017] High-speed emulsification: the obtained mixed solution was emulsified for 20 min at a rotational speed of 8000 r / min to obtain a coarse emulsion.

[0018] Nano treatment: homogenize the coarse emulsion under a pressure of ...

Embodiment 2

[0021] The preparation of lycopene organic solution (organic phase): take the purified lycopene with lycopene content of 20% (W / W), use sherwood oil as solvent, prepare lycopene content as 0.5% (W / W) The solution of V) is called the organic phase.

[0022] The aqueous solution (water phase) of emulsifying agent: choose Tween 60 and 1: 1 (W / W) of molecularly distilled monoglyceride as emulsifying agent, press the dosage of 0.5% (W / V), be mixed with the aqueous solution of emulsifying agent, called the aqueous phase.

[0023] Mixing of organic phase and water phase: under low-speed stirring (150r / min), slowly pour the organic phase into the water phase, the ratio of the organic phase to the water phase is controlled at 2:8 (V / V), continue to high-speed (900r / min) / min) and stirred for 20min to make the mixture uniform.

[0024] High-speed emulsification: the obtained mixed solution was emulsified for 10 min at a rotational speed of 10000 r / min to obtain a coarse emulsion.

[...

Embodiment 3

[0028] The preparation of lycopene organic solution (organic phase): take the purified lycopene with lycopene content of 90% (W / W), use chloroform as solvent, prepare lycopene content as 1% (W / V) ) is called the organic phase.

[0029] Aqueous solution of emulsifier (water phase): Span 20 is selected as an emulsifier, and formulated into an aqueous solution of emulsifier at a dosage of 0.5% (W / V), which is called the aqueous phase.

[0030] Mixing of organic phase and water phase: under low-speed stirring (200r / min), slowly pour the organic phase into the water phase, the ratio of the organic phase to the water phase is controlled at 3:7 (V / V), continue to high speed (1000r / min) / min) and stirred for 30min to make the mixture uniform.

[0031] High-speed emulsification: the obtained mixed solution was emulsified for 2 min at a rotational speed of 15000 r / min to obtain a coarse emulsion.

[0032] Nano treatment: the coarse emulsion is treated under 22KHz ultrasonic conditions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com